Page 1

TORO GTS 200 OVERHEAD VALVE ENGINE SERVICE MANUAL

Table of Contents – Page 1 of 2

SPECIFICATIONS

GENERAL INFORMATION

OIL

GASOLINE

COOLING SYSTEM

AIR CLEANER – GENERAL

AIR CLEANER SERVICE

TUNE-UP PROCEDURE

OVERHAUL PROCEDURE

CHECK-UP

EQUIPMENT AFFECTING ENGINE OPERATION

IGNITION

CHECK IGNITION

SPARK PLUG

REMOVE FLYWHEEL

INSPECT FLYWHEEL KEY, KEYWAYS, FLYWHEEL, AND CRANKSHAFT

INSTALL FLYWHEEL

SPECIFICATIONS

CARBURETION

CARBURETOR IDENTIFICATION

SERVICE CARBURETOR WALBRO LMS

GOVERNOR CONTROLS, CARBURETOR LINKAGE, AND FLYWHEEL BRAKE

REMOTE GOVERNOR CONTROLS

FLYWHEEL BRAKE

GOVERNOR ADJUSTMENTS

GOVERNOR AND CARBURETOR LINKAGES

GOVERNOR

GENERAL INFORMATION

GOVERNED RPM LIMITS

MECHANICAL GOVERNOR

COMPRESSION

TEST COMPRESSION

REMOVE CYLINDER HEAD

VALVE SERVICE

ASSEMBLE CYLINDER HEAD

SPECIFICATION TABLES

REWIND STARTER

GENERAL INFORMATION

REMOVE BLOWER HOUSING AND STARTER

Page 2

TORO GTS 200 OVERHEAD VALVE ENGINE SERVICE MANUAL

Table of Contents – Page 2 of 2

DISASSEMBLE REWIND STARTER

ASSEMBLE REWIND STARTER

ELECTRIC STARTER

GENERAL INFORMATION

TROUBLESHOOTING 12 VOLT STARTING SYSTEM

TEST EQUIPMENT

BATTERY

STARTER

ALTERNATOR

ALTERNATOR SPECIFICATIONS

EQUIPMENT TO TEST ALTERNATORS

1/2 AMP ALTERNATOR

LUBRICATION

EXTENDED OIL FILL AND DIPSTICK

BREATHER

REMOVE BREATHER

INSTALL BREATHER VALVE

REMOVE OIL PUMP

INSPECT OIL PUMP

INSTALL OIL PUMP

INSTALL PUMP COVER

INSTALL OIL FILTER ADAPTER

PISTONS, RINGS, AND RODS

PISTON AND CONNECTING ROD

SPECIFICATION TABLES

CRANKSHAFT AND CAMSHAFT

REMOVE CRANKSHAFT AND CAMSHAFT

INSTALL CRANKSHAFT AND CAMSHAFT

SPECIFICATION TABLES

CYLINDER AND BEARINGS

CYLINDER

PLAIN OR DUTM BEARINGS

CRANKCASE SUMP

SPECIFICATION TABLES

MUFFLER

REMOVE EXHAUST SYSTEM

INSPECT EXHAUST SYSTEM

INSTALL MUFFLER

INSTALL MUFFLER GUARD

Page 3

About This Manual

This manual was written expressly for the Toro GTS 200 Overhead Valve

Engine. The Toro Company has made every effort to make the information in

this manual complete and correct.

This manual was written with the service technician in mind. We hope that you

find this manual a valuable addition to your service shop. If you have questions

or comments regarding this manual, please contact us at the following address:

The Toro Company

Consumer Service Department

8111 Lyndale Avenue South

Bloomington, MN 55420–1196

The Toro Company reserves the right to change product specifications or this

manual without notice.

The Toro Company gratefully acknowledges the assistance of the Briggs &

Stratton Corporation in the production of this manual.

COPYRIGHT – ALL RIGHTS RESER

The Toro Company – 1999

Bloomington, MN 55420 – U.S.A

VED

1

Page 4

Contents

Specifications 4.

General Information5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Specifications5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Oil Level5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change Oil5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Approximate Crankcase Oil Capacity (Dry)

Specifications 6

Gasoline 7

Cooling System7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Cleaner – General8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Cleaner Service8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T

une-Up Procedure9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overhaul Procedure10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check-Up 12

Check Compression12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Ignition (Using Engine Starter)12. . . . . . . . . . . .

Check Carburetion12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Af

Hard Starting, or W

Vibration 13

Power Loss13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Noise 13

Ignition 14

Check Ignition14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check For Spark Miss14. . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug Maintenance15. . . . . . . . . . . . . . . . . . . . . . .

Remove Ignition Armature15. . . . . . . . . . . . . . . . . . . . .

Remove Flywheel15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspect Flywheel Key

and Crankshaft16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Flywheel16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Flywheel16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Ignition Armature16. . . . . . . . . . . . . . . . . . . . . . .

Adjust Ignition Armature Air Gap17. . . . . . . . . . . . . . .

Specifications 17

Carburetion 18

Carburetor Identification18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Carburetor W

Remove Air Cleaner18. . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Carburetor19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassemble Carburetor19. . . . . . . . . . . . . . . . . . . . . . .

Carburetor Cleaning Recommendations20. . . . . . . . . . .

Assemble Carburetor20. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change Oil—Drain Plug Method6. . . . . . . . . . . .

Change Oil—Oil Fill T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

fecting Engine Operation12. . . . . . . . . . . . . . .

ill Not Start13. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

, Keyways, Flywheel,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

albro LMS18. . . . . . . . . . . . . . . . . . . . .

Install W

Install Throttle Shaft20. . . . . . . . . . . . . . . . . . . . . .

Install Inlet Needle Seat20. . . . . . . . . . . . . . . . . . .

elch Plug20. . . . . . . . . . . . . . . . . . . . . . . .

ube Method6. . . . . . . . . .

Install Inlet Needle and Float20. . . . . . . . . . . . . . .

High Altitude Compensation21. . . . . . . . . . . . . . .

Install Carburetor21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Air Cleaner21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Governor Contr

and Flywheel Brake22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Governor Controls22. . . . . . . . . . . . . . . . . . . . . . . . .

Remote Control W

Speed Regulation22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust Remote Controls22. . . . . . . . . . . . . . . . . . . . . . .

Flywheel Brake22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 22

Remove Flywheel Brake23. . . . . . . . . . . . . . . . . . . . . . .

Assemble Flywheel Brake23. . . . . . . . . . . . . . . . . . . . . .

Brake Adjustment24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Governor Adjustments24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Governor and Carburetor Linkages24. . . . . . . . . . . . . . . . . . .

Governor 25

General Information25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Governed RPM Limits25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Governor25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassemble 25

Inspect Governor26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assemble Governor Crank26. . . . . . . . . . . . . . . . . . . . .

Install Crankcase Cover or Sump26. . . . . . . . . . . . . . . .

Adjust T

Seal Protectors26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compression 27

T

est Compression27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Cylinder Head28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prepare Cylinder Head for Removal28. . . . . . . . . . . . . .

Remove Rocker Cover28. . . . . . . . . . . . . . . . . . . . . . . .

Remove Cylinder Head28. . . . . . . . . . . . . . . . . . . . . . . .

Remove V

Inspect V

V

alve Service29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reface V

Assemble Cylinder Head29. . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Cylinder Head Plate and Rocker Arm Studs29. .

Install V

Install V

Install Cylinder Head30. . . . . . . . . . . . . . . . . . . . . . . . .

Install Rocker Arms—Current Style30. . . . . . . . . . . . . .

Install Rocker Arms—Early Style31. . . . . . . . . . . . . . .

Adjust V

Adjust V

Install V

Specification T

Rewind Starter33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Blower Housing and Starter33. . . . . . . . . . . . . . . . .

Disassemble Rewind Starter34. . . . . . . . . . . . . . . . . . . . . . . .

ols, Carbur

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

op No Load RPM26. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

alves 29

alve Guides29. . . . . . . . . . . . . . . . . . . . . . . . . .

alves and Seats29. . . . . . . . . . . . . . . . . . . . . . .

alves 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

alve Springs and Retainers30. . . . . . . . . . . . . . .

alve Clearance—Current Style31. . . . . . . . . . .

alve Clearance—Early Style31. . . . . . . . . . . . .

alve Cover32. . . . . . . . . . . . . . . . . . . . . . . . . . .

ables 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

etor Linkage,

ire Travel 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

Contents

2

GTS 200

Page 5

Remove Rope34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspect Rope34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Pulley And Spring

Inspect Spring, Starter Housing and Pulley35. . . . . . . .

Assemble Rewind Starter36. . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Pulley and Spring36. . . . . . . . . . . . . . . . . . . . . . .

Install Pawls and Retainer Assembly36. . . . . . . . . . . . .

W

ind Spring and Install Rope36. . . . . . . . . . . . . . . . . . .

Install Rewind Starter on Blower Housing37. . . . . . . . .

Install Blower Housing and Rewind Starter37. . . . . . . .

Install Fuel T

Electric Starter38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T

roubleshooting 12 V

T

est Equipment39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Multimeter39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Shunt39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tachometer 39

Starter T

Other Equipment39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery 40

Starter 41

Alternator 45

Alternator Specifications45. . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment to T

1/2 Amp Alternator45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication 47

Extended Oil Fill and Dipstick47. . . . . . . . . . . . . . . . . . . . . .

Breather 47

Remove Breather47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Breather V

Remove Oil Pump47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspect Oil Pump48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handling Instructions40. . . . . . . . . . . . . . . . . . . . . . . . .

First Aid40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Battery40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replace Battery T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Starter Motor Drive and Clutch

W

iring Diagrams41. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check 12 V

Starter Motor Specifications41. . . . . . . . . . . . . . . . . . . .

T

roubleshoot Starter Motor41. . . . . . . . . . . . . . . . . . . . .

Check Brake Switch42. . . . . . . . . . . . . . . . . . . . . . . . . .

Check Brake Switch W

Disassemble Starter Motor42. . . . . . . . . . . . . . . . . . . . .

Clean and Inspect Starter43. . . . . . . . . . . . . . . . . . . . . . .

Assemble Starter Motor43. . . . . . . . . . . . . . . . . . . . . . .

Install Starter44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Multimeter45. . . . . . . . . . . . . . . . . . . . . . . . . . . .

T

est Alternator Output45. . . . . . . . . . . . . . . . . . . . . . . . .

Install Stator Studs46. . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust Stator Air Gap46. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ank 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

olt Starting System38. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

est Bracket39. . . . . . . . . . . . . . . . . . . . . . . . . . .

erminal 40

olt Starter Motor41. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

est Alternators45. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

alve 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

iring 42

. . . . . . . . . . . . . . . . . . . .

35

41

Install Oil Pump48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Pump Cover48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Oil Filter Adapter48. . . . . . . . . . . . . . . . . . . . . . . . . . .

Pistons, Rings, and Rods49. . . . . . . . . . . . . . . . . . . . . . . . . .

Piston and Connecting Rod49. . . . . . . . . . . . . . . . . . . . . . . . .

Remove Piston and Connecting Rod49. . . . . . . . . . . . . .

Remove Piston Rings49. . . . . . . . . . . . . . . . . . . . . . . . .

Check Piston Ring Groove W

Check Piston Ring End Gap50. . . . . . . . . . . . . . . . . . . .

Check Connecting Rod50. . . . . . . . . . . . . . . . . . . . . . . .

Check Piston Pin and Piston Pin Bore50. . . . . . . . . . . .

Assemble Piston and Connecting Rod50. . . . . . . . . . . .

Install Piston Rings On Piston51. . . . . . . . . . . . . . . . . . .

Compress Rings51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Connecting Rod and Piston51. . . . . . . . . . . . . . .

Specification T

Crankshaft and Camshaft53. . . . . . . . . . . . . . . . . . . . . . . . .

Remove Crankshaft and Camshaft53. . . . . . . . . . . . . . . . . . . .

Remove Crankshaft53. . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspect Crankshaft53. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspect Camshaft54. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Compression Release54. . . . . . . . . . . . . . . . . . . .

Install Crankshaft and Camshaft54. . . . . . . . . . . . . . . . . . . . .

Install Crankshaft54. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Camshaft54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Crankcase Sump54. . . . . . . . . . . . . . . . . . . . . . . .

Adjust Crankshaft End Play

Specification T

Cylinder and Bearings56. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder 56

Inspection 56

Cylinder Finish (Cross Hatch)56. . . . . . . . . . . . . . . . . . .

Cylinder Cleaning56. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Plain or DU Bearings57. . . . . . . . . . . . . . . . . .

Check Camshaft Bearings57. . . . . . . . . . . . . . . . . . . . . .

Plain or DU Bearings57. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair W

Remove DU Magneto Bearing57. . . . . . . . . . . . . . . . .

Install Magneto DU Bushing57. . . . . . . . . . . . . . . . . .

Oil Seals58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankcase Sump58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install 58

Specification T

Muffler 59

Remove Exhaust System59. . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspect Exhaust System59. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Muf

Install Muf

ables 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ables 55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

orn Aluminum Bearings57. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ables 58

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

fler 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

fler Guard60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ear 50

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

55

GTS 200

3

Contents

Page 6

Specifications

Basic

model series

. . . . . . . . . . . . . . . .

123600.

Oil capacity

Armature air gap

Torque specifications

Flywheel nut

Cylinder head

Connecting

Crankcase

Valve

clearance

Intake

Exhaust .004/.008

Crankshaft

Stroke 2.040

.

. . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . .

rod

.

. . . . . . . . . . . . . . . .

cover or sump

.

. . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . .

22 fl. oz. (.65 Liter)

26

fl. oz. (.78 Liter) with oil filter

.006/.014 in.

0.15/0.36mm

60 ft. lb.

81.0Nm

210 in. lb.

24.0Nm

100 in. lb.

11.0Nm

1

10 in. lb.

12Nm

.004/.008 in.

0.10/0.20mm

in.

0.10/0.20mm

in.

51.81mm

Standard

Journal

End play

Engine RPM (no load)

Spark plug

Type

Gap

crankpin journal

reject sizes

Magneto

Crankpin 1.097

PTO 1.065

.

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . .

.

. . . . . .

.

. . . . . . . . . . . . .

1.0983/1.0991 in.

27.897/27.917mm

.878 in.

22.30mm

in.

27.86mm

in.

27.05mm

.002/.033 in.

0.05/0.84mm

3,000 RPM 150

Champion RC12YC

0.020 in.

0.51mm

Specifications

4

GTS 200

Page 7

General

Information

Contents

Oil 5.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Specifications5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Oil Level5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change Oil5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change Oil—Drain Plug Method6. . . . . . . . . . . .

Change Oil—Oil Fill T

Approximate Crankcase Oil Capacity (Dry)

Specifications 6

Gasoline 7

Cooling System7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Cleaner – General

Air Cleaner Service8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T

une-Up Procedure9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overhaul Procedure10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check-Up 12

Equipment Af

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Compression12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Ignition (Using Engine Starter)12. . . . . . . . . . . .

Check Carburetion12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

fecting Engine Operation12. . . . . . . . . . . . . . .

Hard Starting, or W

Vibration 13

Power Loss13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Noise 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ill Not Start13. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ube Method6. . . . . . . . . .

Check Oil Level

Fill

crankcase with SAE 30 oil until oil level reaches FULL

mark on dipstick as shown in Figure 1. The maximum

crankcase capacity is 22 ounces (0.65 Liter). On models

equipped with an oil filter

26 ounces (0.78 Liter). Use any high quality detergent oil

having the American Petroleum Institute (API) “service

classification”—SF

Before each use or every five hours, ensure oil level is

between ADD and FULL marks on dipstick (Fig. 1). Add oil if

8

level is low

1.

Position mower on level surface and clean around oil

dipstick.

2.

Remove dipstick by rotating cap counterclockwise 1/4 turn

(Fig. 1).

3. W

clockwise 1/4 turn. Then remove dipstick and check level

of oil (Fig. 1). If level is low

level to FULL mark on dipstick.

FULL MARK BECAUSE ENGINE COULD BE

DAMAGED WHEN STARTED. POUR OIL SLOWL

4.

Insert dipstick into oil fill tube and rotate cap clockwise

1/4 turn to lock (Fig. 1).

.

ipe dipstick and insert it into oil fill tube. Rotate cap

, the maximum crankcase capacity is

, SG SH, or SJ.

, add only enough oil to raise

DO NOT FILL ABOVE

4

3

Y.

Oil

Oil Specifications

Service classification .

V

iscosity grade. . . . . . . .

Oil capacity. . . . . . . . . . . . 22 fl. oz. (.65 Liter)

Check oil. . . . . . . . . . . . . .

Change oil .

Change filter .

. . . . . . . . . . . .

. . . . . . . . . . on models so equipped,

. .

SF,

SG, SH, or SI

SAE

30

26 fl. oz. (.78 Liter) with filter

before

each use or every five

hours.

after

the first five hours;

thereafter

hours or every season.

every 100 operating hours or

yearly

, every 50 operating

, whichever occurs first.

2

1

m–3845

Fig. 1

– Checking Oil Level

1. Oil

fill tube

2. Dipstick

ADD mark

3.

4.

FULL mark

Change Oil

Change

change the oil every 50 operating hours or every season. More

frequent oil changes are required when operating engine under

a heavy load, or when used in dusty

Replace the oil filter (on models so equipped) every 100 hours

or yearly

There are two methods of changing engine oil, the drain plug

method and the oil fill tube method. Both work equally well.

the oil after the first 5 operating hours. Thereafter

, dirty

, or hot conditions.

, whichever occurs first.

,

GTS 200

5

General

Information

Page 8

Change Oil—Drain Plug Method

1. Run

engine at least 5 minutes to warm the oil. W

drains more easily and more of the contaminants are

removed.

2.

Remove oil drain plug (Fig. 2). Drain oil into a pan.

arm oil

5. If

replacing the oil filter (on models so equipped), do so at

this time.

6.

When oil is drained, return mower to upright position and

add fresh oil to engine. Refer to Oil in this section.

Approximate Crankcase Oil Capacity (Dry)

Specifications

1

Fig. 2

– Drain Plug Location

1. Oil

drain plug

3. If

replacing the oil filter (on models so equipped), do so at

this time.

4.

Install drain plug snugly

5.

Remove dipstick and refill slowly with new oil of proper

.

service classification and viscosity grade.

6.

Start and run engine at idle. Check for oil leaks.

7.

Stop engine. Recheck oil level and add oil if required.

Change

1. Stop

2.

Oil—Oil Fill T

ube Method

engine and wait for all moving parts to stop. Pull wire

of

f spark plug.

Remove grass bag. Drain gasoline from fuel tank.

Without

With oil filter

oil filter

.

. . . . . . .

.

. . . .

22 oz.

.65

Liter

26 oz.

.78

Liter

Change Oil Filter

(on models so equipped)

Change

lightly oil filter gasket with fresh clean engine oil. Screw filter

clockwise by hand until gasket contacts filter adapter

1/2 to 3/4 turn farther

engine at idle for 30 seconds and stop engine. Recheck oil

level and add oil if required. Restart engine and check for oil

leaks, Fig. 4.

1. Install 2. Remove

filter every 100 hours. Before installing new filter

. Tighten

. Add fresh oil. Then, start and run

1

Fig. 4

– Remove and Install Oil Filter

2

,

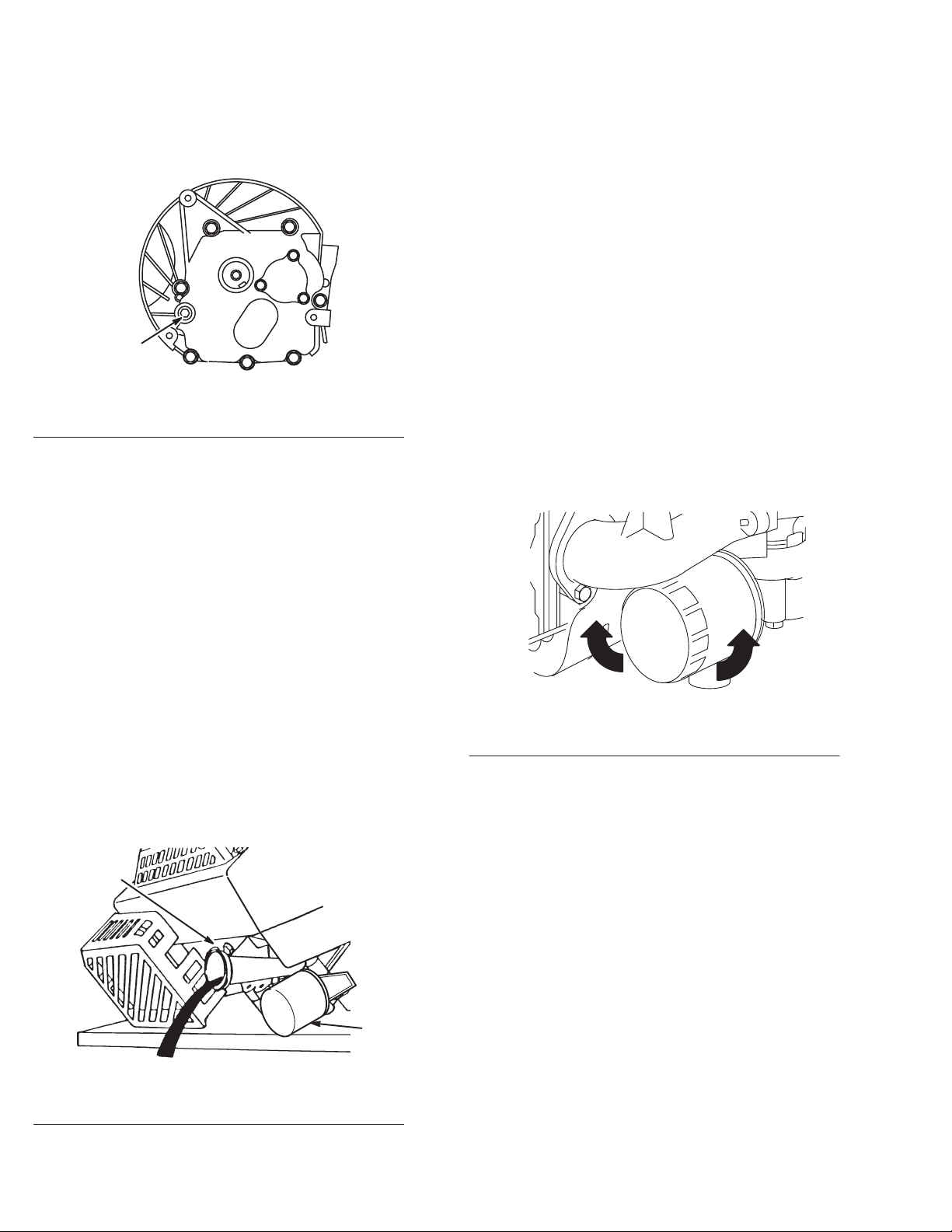

3.

Remove dipstick from oil fill tube and place a drain pan

next to left side of mower

4. T

ip mower on its left side, allowing oil to drain into drain

.

pan (Fig. 3).

1

Fig. 3

1. Oil

fill tube

General

Information

2.

Oil filter

2

m–3848

6

GTS 200

Page 9

Gasoline

Use

clean, fresh, lead-free gasoline (including

reformulated

o ensure freshness, purchase only the quantity of gasoline

T

that can be used in 30 days. Using unleaded gasoline results in

fewer combustion chamber deposits and longer spark plug

life.

Engines certified to comply with California and U.S. EP

emission r

operate on regular unleaded gasoline, include EM and TWC

(if so equipped) emission control systems, and do not include

any user adjustable features.

IMPORTANT

methanol, gasohol containing more than 10% ethanol,

pr

emium gasoline, or white gas. Using these fuels can

damage the engine’

gasoline) with an octane rating of 87 or higher

egulations for ULGE engines

: Do not use methanol, gasoline containing

s fuel system.

DANGER

POTENTIAL HAZARD

•

In certain conditions gasoline is extr

flammable and highly explosive.

WHA

T CAN HAPPEN

•

A fir

e or explosion fr

others, and cause pr

HOW T

•

•

•

• Stor

•

O AVOID THE HAZARD

Use a funnel and fill the fuel tank outdoors, in

an open ar

any gasoline that spills.

Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the level is 1/4” to

1/2” (6 mm to 13 mm) below the bottom of the

filler neck. This empty space in the tank allows

gasoline to expand.

Never smoke when handling gasoline, and stay

away fr

fumes may be ignited by a spark.

keep it out of the r

Never buy mor

gasoline.

ea, when the engine is cold. W

om an open flame or wher

e gasoline in an appr

om gasoline can burn you,

operty damage.

oved container and

each of childr

e than a 30-day supply of

oxygenated or

.

A

are certified to

emely

ipe up

e gasoline

en.

DANGER

POTENTIAL HAZARD

•

When fueling, under certain cir

static charge can develop, igniting the gasoline.

WHA

T CAN HAPPEN

•

A fir

e or explosion fr

and others and cause pr

HOW T

•

•

•

•

•

Use a fuel stabilizer/conditioner regularly during operation

and storage. A stabilizer/conditioner cleans the engine during

operation and prevents gum–like varnish deposits from

forming in the engine during storage.

IMPORTANT

stabilizer/conditioner

alcohol base such as ethanol, methanol, or isopr

1.

2.

3.

IMPORTANT

filler neck. This space is for expansion of fuel. Do not fill

the tank completely full.

O AVOID THE HAZARD

Always place gasoline containers on the gr

away from your vehicle befor

Do not fill gasoline containers inside a vehicle

or on a truck or trailer bed because interior

carpets or plastic truck bed liners may insulate

the container and slow the loss of any static

charge.

When practical, r

equipment fr

the equipment with its wheels on the gr

If this is not possible, then refuel such

equipment on a truck or trailer from a portable

container

dispenser nozzle.

If a gasoline dispenser nozzle must be used,

keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until

fueling is complete.

Clean the area around the fuel tank cap.

Remove the cap from the fuel tank.

Using unleaded, regular gasoline, fill the tank to within 1/4

to 1/2 in. (6 to 13mm) from the top of the tank.

om the truck or trailer and r

, rather than fr

: Do not use fuel additives other than a fuel

: Do not fill the tank with gasoline into the

om gasoline can burn you

operty damage.

emove gas–power

om a gasoline

. Do not use fuel stabilizers with an

cumstances, a

ound

e filling.

ed

efuel

ound.

opanol.

GTS 200

4.

Install the fuel tank cap.

5. W

ipe up any spilled gasoline.

Cooling

Grass

particles, chaf

especially after prolonged service in very dusty conditions or

when cutting dry grass. Continued operation with a clogged

cooling system can cause severe overheating and possible

engine damage. Figures 5 and 6 show the areas to be cleaned.

7

System

f, or dirt can clog the air cooling system,

General Information

Page 10

This

should be a regular maintenance operation, performed

yearly or every 100 hours, whichever comes first and more

often when dust or when airborne debris is present.

1

Fig. 5

– Static Screen

1. Static

screen

1 2

1 2

Fig. 7

– Remove Spark Plug W

1. Primer 2. Spark

ire Prior to Service

m–3662

plug wire

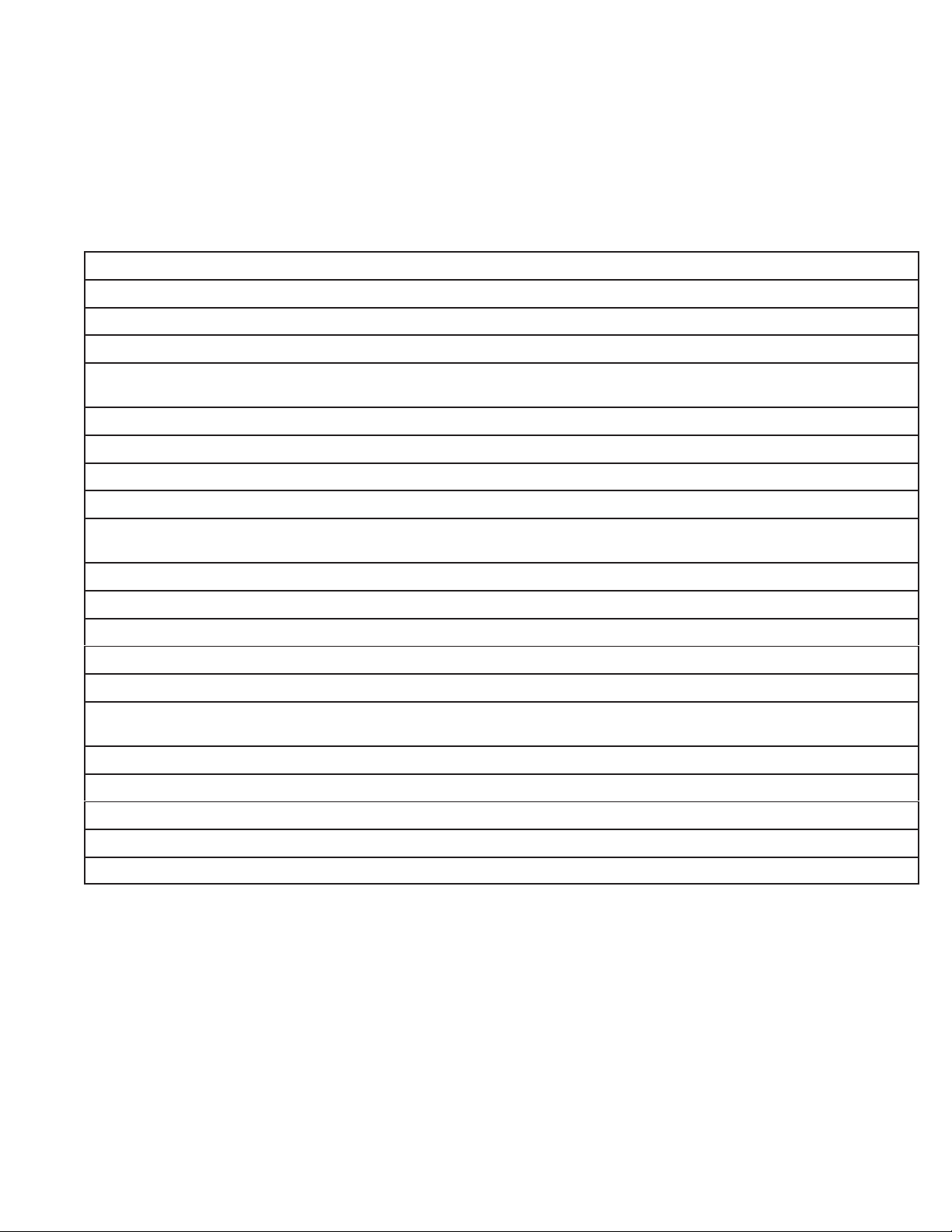

Fig. 6 – Cylinder Fins and Ducting

1. Ducting 2. Cylinder

Air

Cleaner – General

A

properly serviced air cleaner protects internal parts of the

engine from dust particles in the air

. If air cleaner instructions

fins

are not carefully followed, dirt and dust which should be

collected in the air cleaner will be drawn into the engine and

become a part of the oil film, which is very detrimental to

engine life; dirt in the oil forms an abrasive mixture which

wears moving parts instead of protecting them.

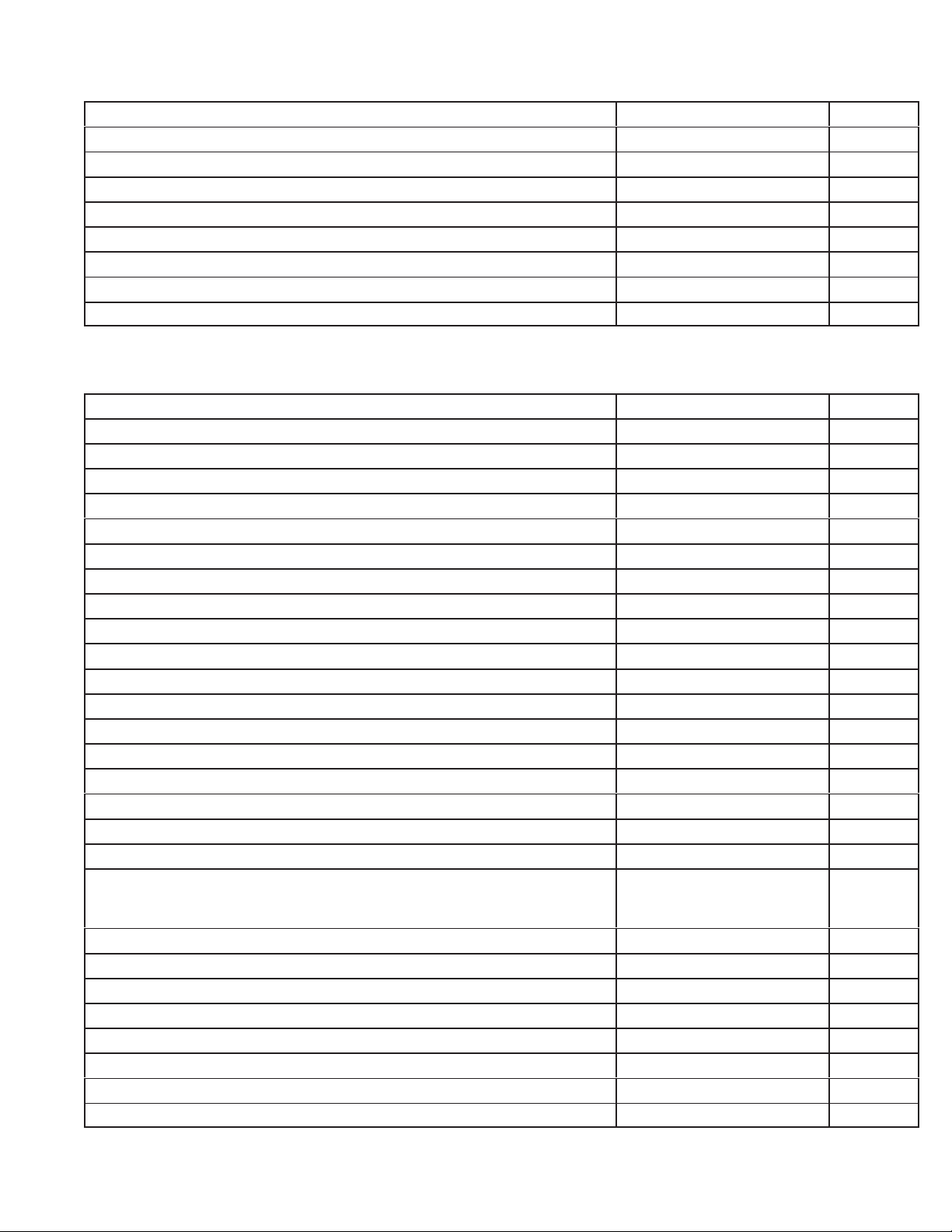

2. Loosen

(Fig. 8).

3

1. Knob

2. Cover

two (2) knobs securing air cleaner cover to engine

1

2

4

m–3664

Fig. 8

– Air Cleaner Service

3. Foam

4.

pre–cleaner

Paper cartridge

Air

Cleaner Service

Normally,

clean the air cleaner pre–cleaner after every

25 operating hours or every season. Clean or replace the paper

cartridge after every 100 hours or every season. More frequent

cleaning is required when mower is operated in dusty or dirty

conditions. Replace air cleaner parts, if very dirty

IMPORTANT

elements; extr

Note: T

: Do not operate engine without air filter

eme engine wear or damage will occur

ipping mower on wrong side to service underside of

.

.

mower may cause damage to air filters.

1.

Stop engine and pull wire of

General

Information

f spark plug (Fig. 7).

3. Lift

cover of

Carefully remove pre–cleaner

4.

f. Clean cover thoroughly

. If pre–cleaner is dirty

.

carefully wash it in a solution of liquid soap and warm

water

. Rinse in clear water

. Allow to dry thoroughly before

using.

5.

If paper cartridge is dirty

it

gently

on a flat surface. If very dirty

IMPORTANT

Do not use pr

6.

Reinstall pre–cleaner over paper cartridge. Reinstall air

: Do not oil pr

essurized air to clean paper cartridge.

, clean the paper filter by tapping

, replace cartridge.

e–cleaner or paper cartridge.

cleaner cover and tighten securely in place with two (2)

knobs.

8

,

GTS 200

Page 11

Tune-Up

By

performing the following steps you will either be sure that the engine is functioning properly or will know what repairs should

be made.

These steps are also covered in the Overhaul Procedure and will normally be performed as a part of complete overhaul.

Carbon deposits in combustion chamber should be removed every 100 to 300 hours of use (more often when run at steady loads),

or whenever cylinder head is removed.

Procedure

Step No.

1. Remove

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

Check oil level and drain oil.

Remove blower housing, inspect rewind assembly

Clean cooling fins and entire engine.

Remove carburetor

necessary and assemble. Set initial adjustment.

Inspect intake elbow or carburetor spacer for damaged gaskets.

Check governor, linkage, and springs for damage, wear

Clean fuel tank and lines.

Remove flywheel. Check for oil seal leakage, both flywheel and PT

Check armature coil. Inspect all wires for breaks and/or damaged insulation. Be sure lead wires do not touch

flywheel. Check stop switch and lead(s).

Remove oil, debris, and nicks from flywheel and crankshaft tapers.

Install flywheel and set air gap. Check for spark with Briggs & Stratton T

Remove spark plug and cylinder head.

Inspect valves for seating.

Clean carbon from cylinder head and piston.

Replace gaskets and install cylinder head. Tighten to specified torque. Adjust valve clearance. Set spark plug

gap or replace plug if necessary

air cleaner

, check for proper servicing. Replace if damaged or dirty

.

, disassemble, and inspect for wear or damage. W

, also check adjustment.

.

ash in solvent. Replace parts as

O sides. Check flywheel key

ool #19051 or #19368 ignition tester

.

.

.

17.

18.

19.

20.

21.

GTS 200

Replace gaskets and install carburetor

Adjust remote control linkage and cable, if used, for correct operation.

Check muf

Replace oil and fuel.

Run engine and adjust carburetor mixture and engine T

fler for restrictions or damage.

op No Load RPM.

9

General

Information

Page 12

Overhaul

The

Overhaul Procedure which follows is intended to help you become accustomed to a systematic method of repairing T

GTS 200

operations are performed in the same sequence every time.

The Overhaul Procedure can also be used as an index. For information on how to perform most operations listed, refer to the

section number or operation.

Disassemble

Check

OHV engines. Naturally these steps could be rearranged in dif

compression

Procedure

ferent order but ef

Section

Compression 27

oro

ficiency is obtained when the repair

Beginning

Page

Drain oil – Remove oil filter (when equipped)

Air cleaner

Fuel line, tank assembly and brackets, carburetor and linkage, carburetor

intake manifold or spacer

Exhaust manifold, muf

Disassemble carburetor

Electric starter (12 V) Blower housing

Breather and valve cover

V

alves and springs, rocker arms, push rods, cylinder head and shields,

valve guides and seats

Rewind starter

Flywheel Ignition 14

Check crankshaft end play

Remove burrs from crankshaft extension

Crankcase cover or sump

Mechanical governor parts

Cam gear and tappets

Connecting rod and piston

fler Muffler 59

Lubrication 47

General Information

Carburetion 18

Carburetion 18

Electric Starter

Lubrication 47

Compression 27

Rewind Starter

Crankshaft and Camshaft

Crankshaft and Camshaft

Crankshaft and Camshaft

Governor 25

Crankshaft and Camshaft

Pistons, Rings, and Rods

38

33

53

53

53

53

49

5

Crankshaft

Inspection Section

Inspect carburetor choke, throttle shaft, and bushings for wear and

freedom of movement

Inspect and test ignition coil

Crankshaft – inspect and check

Oil pump – inspect and check, if so equipped

Cylinder – check bore, main bearing

Check piston, rings, connecting rod, and piston pin

General Information

10

Crankshaft and Camshaft

Carburetion 18

Ignition 14

Crankshaft and Camshaft

Lubrication 47

Cylinder and Bearings

Pistons, Rings, and Rods

53

Beginning

Page

53

56

49

GTS 200

Page 13

Beginning

Repairs Section

Clean/replace parts as required

Replace block or short block if cylinder is over allowable dimension Cylinder and Bearings

Replace valve guides – intake or exhaust, if required

Reface valves and seats and lap, if required

Replace ignition armature, if required

Replace throttle shaft bushings, if required

Repair carburetor

Replace rewind starter spring and rope (if so equipped)

Replace main bearings and seals, if required

Reassemble Section

Crankshaft

Piston, piston pin, connecting rod, and rings

T

appets, cam gear

Oil pump, if so equipped

Mechanical governor

Crankcase cover or sump

Breather Lubrication 47

Flywheel, starter cup, and fan

Ignition armature assembly

Adjust ignition armature to flywheel air gap

Check spark

Electric starter (12 V)

V

alves, valve stem seals, springs, retainers, rocker arms

Cylinder head and push rods

Adjust valve clearance

V

alve cover

Spark plug – adjust gap to .020”

Exhaust manifold, muf

Intake manifold

Carburetor and linkage and governor controls Governor Controls,

Check and adjust mechanical governor

Blower housing and rewind starter

Fuel filter

Clean/replace and assemble air cleaner

Fill crankcase with oil, fill with gas, start engine

Adjust carburetor

Set governor to obtain correct engine speed (remote controls)

Spray paint engine parts and apply decals

, tank, and line

flers Muffler 59

Compression 27

Compression 27

Ignition 14

Carburetion 18

Carburetion 18

Rewind Starter

Cylinder and Bearings

Crankshaft and Camshaft

Pistons, Rings, and Rods

Crankshaft and Camshaft

Lubrication 47

Governor 25

Crankshaft and Camshaft

Ignition 14

Ignition 14

Ignition 14

Ignition 14

Electric Starter

Compression 27

Compression 27

Compression 27

Compression 27

Ignition 14

Carburetion 18

Carburetor Linkage, and

Flywheel Brake

Governor 25

Ignition 14

Carburetion 18

General Information

General Information

Carburetion 18

Governor 25

Page

56

33

56

Beginning

Page

53

49

53

53

38

22

5

5

GTS 200

11

General Information

Page 14

Check-Up

Most

complaints concerning engine operation can be

classified as one or a combination of the following:

1. W

ill not start

2.

Hard starting

3.

Lack of power

4. Vibration

5. Overheating

6.

High oil consumption

Whe

n the c

aus

e o

f m

alfunctio

chec

k o

f th

e c

ompression

, p

check-up

i

n a m

atter o

determinin

possibl

e c

time. Th

models

subjec

e b

, w

t h

erforme

g the c

aus

asi

hil

eading.

f m

inutes. I

aus

e o

f futur

c c

heck-u

e any v

d i

n a s

e o

ariation

Check Compression

See

the section Compression for proper procedure.

If compression is poor

1.

Loose spark plug

2.

Loose cylinder head bolts

3.

Blown head gasket

4.

Burned valves, valve seats

5. Insuf

6. W

7. W

8. W

9.

ficient valve clearance

arped cylinder head or warped valve cover

arped or worn valve stems and guides

orn bore and/or rings

Broken connecting rod

Check Ignition (Using Engine Starter)

WARNING

n i

, i

gnition

ystemati

t i

s the q

f failure. Thi

e f

ailures

, w

p p

rocedur

, b

y m

, look for –

s n

ot readil

, and c

c m

uickes

hic

e i

odel

y a

arburetio

anner

, can u

t and s

s c

heck-u

h can b

s the same for all e

, will b

pparent

ures

t m

p will p

e c

orrecte

e s

how

n s

suall

n u

, p

erfor

m a

ystems. This

y b

e d

one

etho

d o

f

oin

t o

ut

d a

t t

he

ngine

nder the

If spark does not occur

1.

Shorted stop switch wire

2.

Shorted stop switch

3.

Ignition armature failure

4.

Improperly operating interlock system

Note:

If engine runs but misses during operation, a quick

check to determine if ignition is or is not at fault can be made

by inserting the spark tester between the ignition cable and the

spark plug. A spark miss will be readily seen. See the Ignition

section.

, look for –

Check Carburetion

Before

making a carburetion check, be sure the fuel tank has

an ample supply of fresh, clean gasoline. Be sure that the

shut-of

f valve is open and fuel flows freely through fuel line

and filter before starting engine. Inspect and adjust the needle

valve. Check to see that the choke closes completely

will not start, remove and inspect the spark plug.

If plug is wet, look for –

1.

Over choking

2.

Excessively rich fuel mixture

3. W

ater in fuel

4.

Inlet needle stuck open

5.

Clogged air cleaner

6.

Fouled spark plug

If plug is dry

1.

Leaking carburetor mounting gaskets

2.

Gummy or dirty carburetor

valve or fuel tank

3.

Inlet needle stuck shut

4.

Inoperative fuel pump (if so equipped)

A simple check to determine if the fuel is getting to the

combustion chamber through the carburetor is to remove the

spark plug and pour a small quantity of gasoline through the

spark plug hole. Replace the plug. If the engine fires a few

times and then stops, look for the same conditions as for a dry

plug.

, look for -

, fuel filter

, fuel lines, shut-of

. If engine

f

BE

SURE ther

which might be ignited by the spark and cause a

fir

e or explosion.

Attach a spark tester to spark plug wire and ground the other

end of the tester to the engine block. W

spark plug. Spin the flywheel with the engine starter

jumps the

ignition system is performing satisfactorily

Ignition for additional information.

General Information

e is no fuel or fuel vapor pr

.166”

(4.20mm)

tester gap, you can assume the

esent,

arning: Do not remove

. If spark

. See the section

Equipment

Affecting Engine

Operation

What

appears to be a problem with engine operation, such as

hard starting, vibration, etc., may be the fault of the mower

rather than the engine itself. Listed are the most common

ef

fects of equipment problems and what to look for as the

most common cause.

12

GTS 200

Page 15

Hard Starting, or Will Not Start

Power Loss

1. Check

2. Chec

remote control assembly for proper adjustment.

k i

gnitio

n s

ystem.

Vibration

1.

Cutter blade bent – Remove and replace.

2.

Cutter blade out of balance – Remove and balance.

3.

Crankshaft bent – Replace.

4. W

orn blade coupling – Replace if coupling allows blade to

shift, causing unbalance.

5.

Mounting bolts loose – T

6.

Mounting deck or plate cracked – Repair or replace.

7.

Damaged belts or pulleys.

ighten.

1. Grass

2.

3.

4.

cuttings build-up under deck.

No lubrication in transmission or gear box.

Dull blade.

Excessive drive belt tension may cause excess bearing

wear or seizure.

Noise

1.

BBC system problems (if so equipped).

2.

No lubricant in transmission or gear box.

3. W

orn drive belts.

4. W

orn bearings.

GTS 200

13

General

Information

Page 16

Ignition

Contents

Check Ignition14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check For Spark Miss14. . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug Maintenance15. . . . . . . . . . . . . . . . . . . . . . .

Remove Ignition Armature15. . . . . . . . . . . . . . . . . . . . .

Remove Flywheel15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspect Flywheel Key

and Crankshaft16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Flywheel

Install Flywheel16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Ignition Armature16. . . . . . . . . . . . . . . . . . . . . . .

Adjust Ignition Armature Air Gap17. . . . . . . . . . . . . . .

Specifications 17

, Keyways, Flywheel,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

1

Fig. 9

– Checking for Spark

1. Spark

plug wire

Check For Spark Miss

2.

Spark tester

Stratton T

#19368

2

, Briggs &

ool #19051 or

WARNING

T

O PREVENT accidental starting, the spark plug

wir

e must be r

gr

ounded, failur

injury.

emoved fr

e to do so can cause personal

om spark plug and

WARNING

DO NOT r

ignition. A fir

emove spark plug when checking

e or explosion may occur

.

WARNING

FL

YWHEEL KICKBACK can occur if the

flywheel key is shear

occur.

Check

1. Connect

2.

Operate starter and observe spark gap in tester

jumps tester gap, ignition is good.

Ignition

spark plug wire to Spark T

ed and bodily injury may

ester

, Fig. 9.

. If spark

1. Install

1. Spark

2.

2. Start

3.

Briggs & Stratton T

Tester

, in series with spark plug lead and spark plug,

Fig. 10.

1

Fig. 10 – Running Check

plug lead

Spark tester

Stratton T

#19368

If spark jumps tester gap regularly

problem is spark plug, compression, or fuel system.

, Briggs &

ool #19051 or

and run engine.

ool #19051 or #19368, Spark

2

3.

Spark plug

, but miss continues,

3

Note:

Note:

Ignition

Flywheel must rotate at 350 RPM, minimum.

Spark will be observed.

14

GTS 200

Page 17

Spark

The

Plug

recommended spark plug is:

Spark Plug Type Brand

Resistor Long Plug

Note:

In some areas, local law requires the use of a resistor

Champion

RC12YC

spark plug to suppress ignition signals. If an engine was

originally equipped with a resistor spark plug, be sure to use

the same type of spark plug for replacement.

Spark Plug Maintenance

Set

gap at .020” (0.51mm), Fig. 11. If electrodes are burned

away

, or porcelain is cracked or fouled, replace with a new

plug.

Note:

Do not use abrasive cleaning machines.

Remove

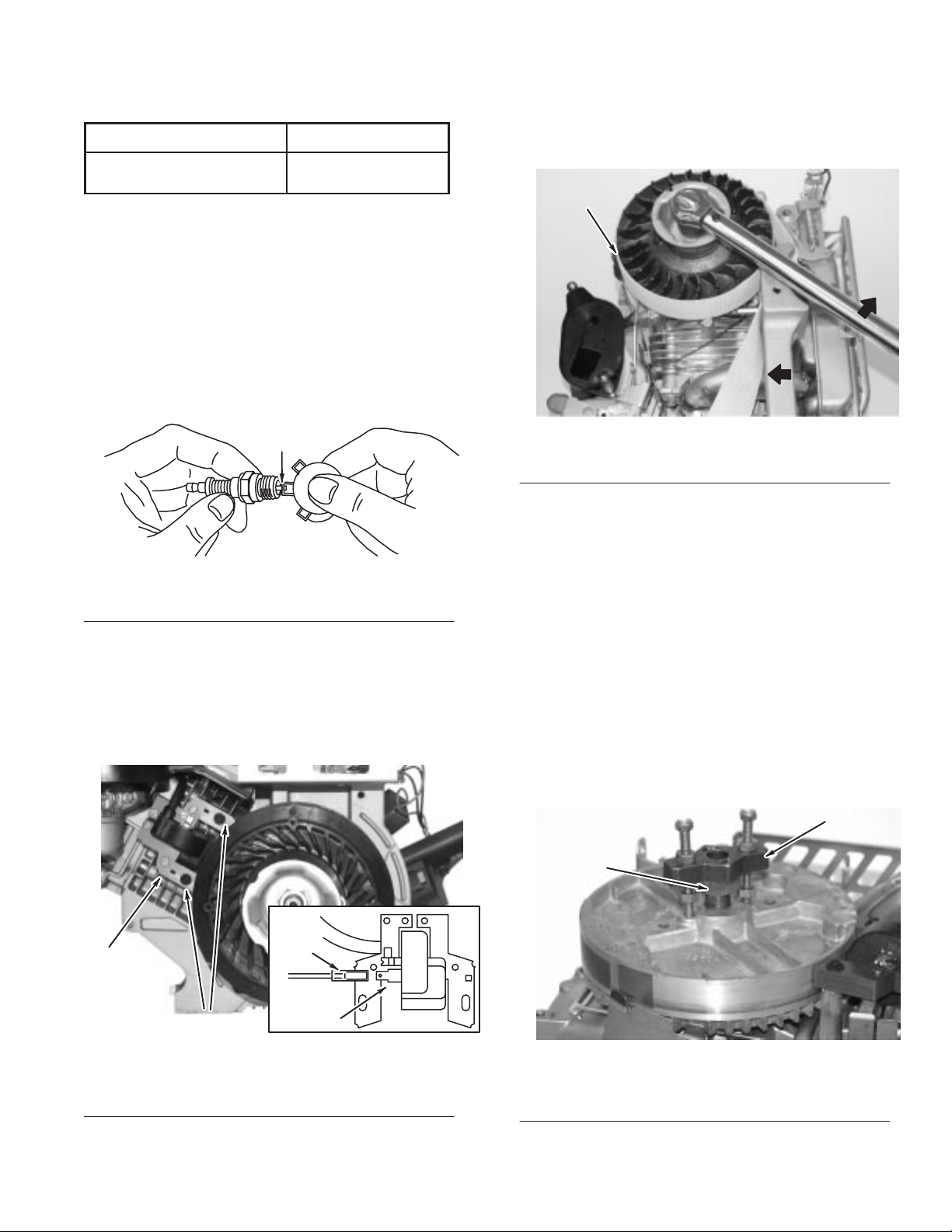

1. Remove

2.

Use flywheel holder to hold flywheel from turning,

Flywheel

blower housing.

Fig. 13.

1

1

1. .020”

Fig. 11

(0.51mm) wire gauge

– Adjusting Spark Plug Gap

Remove Ignition Armature

1. Remove

2.

Remove armature screws, disconnect stop wire, and lift of

armature, Fig. 12.

blower housing.

Fig. 13

1. Flywheel

3. Use

socket and breaker bar to remove flywheel nut.

Note:

Remove ignition armature before removing

– Removing Flywheel Nut

holder Briggs & Stratton T

ool #19372

flywheel.

4.

Thread flywheel nut onto crankshaft until top of nut is

flush with crankshaft threads or slightly 1.5mm (1/16”)

above end of threads.

5.

Attach flywheel puller

6. T

urn puller screws into flywheel puller holes until screws

.

bottom.

7. T

f

urn lower nuts down until flywheel puller body rests

firmly on flywheel nut.

8.

Then turn upper nuts down onto puller body

. T

urn both

nuts equally until flywheel pops loose, Fig. 14.

2

1

1

Fig. 12

1. Ignition

2. Screws

GTS 200

3

2

– Removing Ignition Armature

armature

Stop switch wire

3.

4. Terminal

4

1. Flywheel

15

Fig. 14

nut

– Removing Flywheel

2.

Briggs & Stratton T

#19069 flywheel puller

ool

Ignition

Page 18

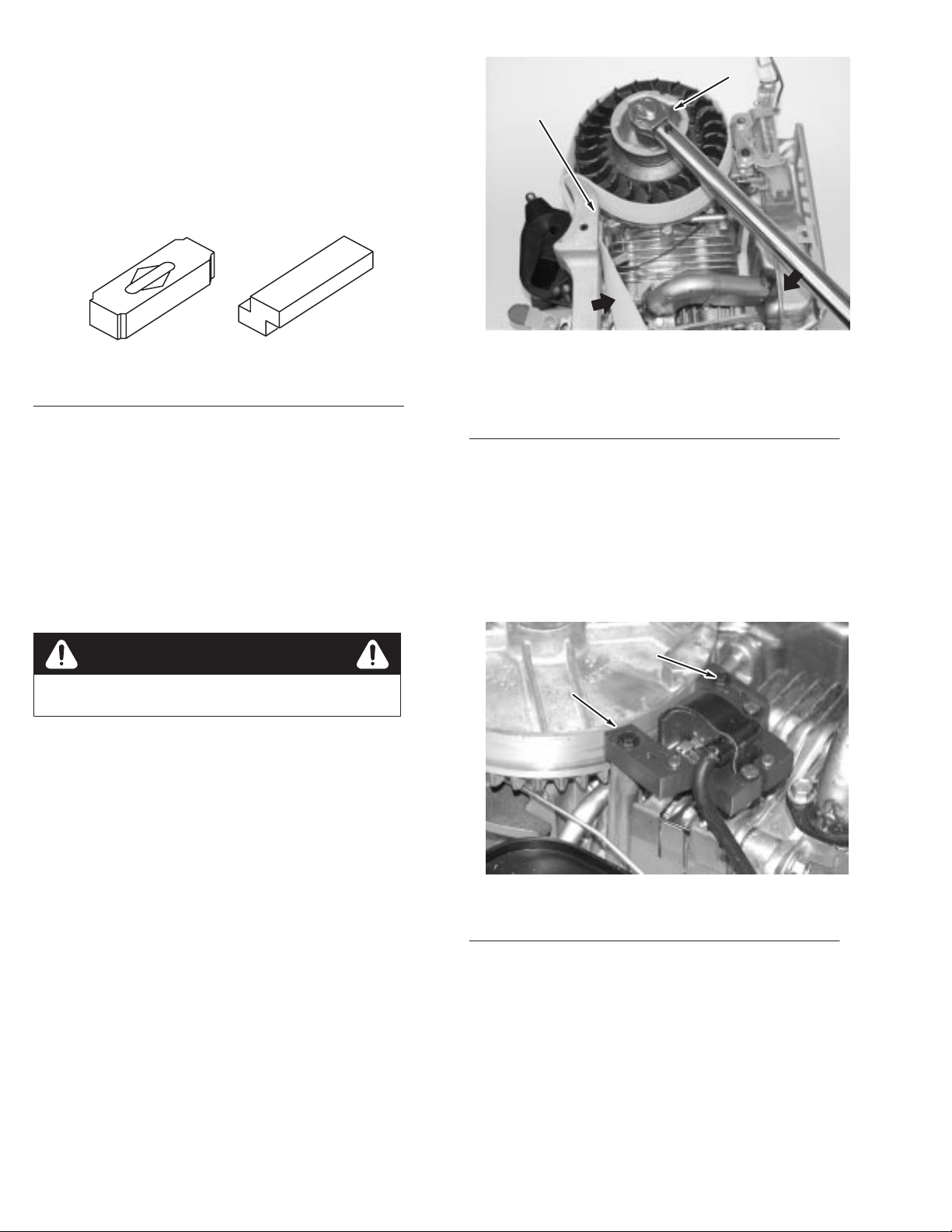

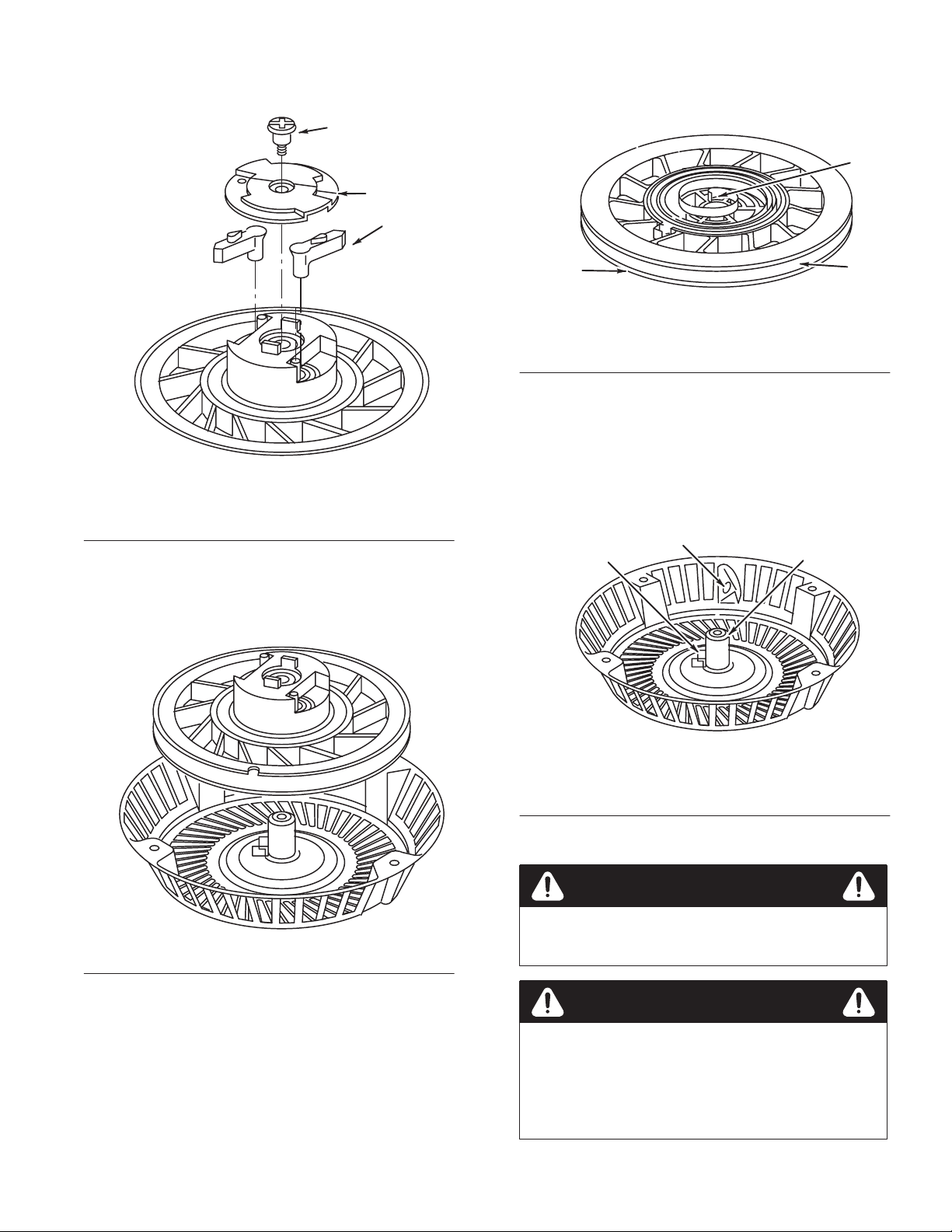

Inspect

Flywheel Key

, Keyways,

Flywheel, and Crankshaft

Inspect

flywheel key for partial or complete shearing. If

sheared, replace, Fig. 15. Flywheel should be inspected for

cracks, burrs on taper or keyway, and distortion of keyway

Check taper of crankshaft for burrs, rust, oil, or other damage.

Check cooling fan or flywheel for broken fins. If parts are

damaged, replace with new parts.

1 2

.

2

1

Fig. 15 – Inspect Flywheel Key

1. OK 2. Replace

Install

Flywheel

Install Flywheel

1. Clean

2.

flywheel taper and crankshaft taper of all grease, oil

and dirt.

Slide flywheel onto crankshaft and line up both keyways.

Insert flywheel key into both keyways.

Note:

DO NOT use a steel key under any circumstances.

WARNING

DO NOT use impact wr

3.

Install starter cup, cooling fan, and flywheel nut or screw

4.

Use flywheel holder to hold flywheel from turning,

Fig. 16.

enches to install flywheel.

Fig. 16 – Torquing Flywheel

1. Briggs

& Stratton T

#19321,

flywheel holder or

Tool

# 19372 flywheel

strap wrench

ool

2. Cup

Install Ignition Armature

1. Install

2. T

3.

.

stop switch wire on armature, Fig. 12, Page 15.

urn flywheel so magnet is away from armature.

Install armature and mounting screws, Fig. 17.

Note:

Mounting holes in armature are slotted.

2

1

5.

Install flywheel nut or screw

Use socket and torque wrench to tighten flywheel nut or

6.

screw.

7. T

orque as listed in T

Ignition

able No. 1, Page 17.

.

16

Fig. 17

1. Ignition

4. Push

armature

armature away from flywheel as far as possible and

tighten one screw to hold armature in place.

– Installing Armature

2. T

ighten one screw

GTS 200

Page 19

Adjust Ignition Armature Air Gap

1. Rotate

2.

flywheel until magnet is under armature

laminations.

Place thickness gauge, T

able No. 1, Page 17, between

magnet and armature laminations, Fig. 18.

1

2

3

5

3. See T

able No. 1, Page 17 for armature air gap. Loosen

mounting screw so magnet will pull armature down against

thickness gauge.

4. T

orque both mounting screws to 25 in. lbs.

(3.0Nm)

Rotate

flywheel to remove thickness gauge.

5.

Install outer blower housing and screws and torque screws

to 85 in. lbs., (10.0Nm),Fig. 19.

1

4

1

Fig. 18

1. Magnet

2. Turn

magnet away from

armature

Armature down; gauge

3.

stock in place

– Adjusting Armature Air Gap

Specifications

Armature

.006” – .012”

(0.15 – 0.30mm)

Air Gap

4. Turn

5.

Roll out gauge

Flywheel Puller

Briggs & Stratton T

19069 19372

ool #

Fig. 19

1. Torque

Table No. 1

Flywheel Holder

Briggs & Stratton T

– Installing Outer Blower Housing

screws to 85 in. lbs.

ool #

Flywheel Nut Torque

60 ft. lbs.

(81.0Nm)

GTS 200

17

Ignition

Page 20

Carburetion

Contents

Service

These carburetor

non-adjustabl

Carburetor W

e idle m

s have a f

ixture

ixe

d high s

, Fig.

21.

albro LMS

pee

d main jet w

ith

Carburetor

Service Carburetor W

Carburetor

Identification18. . . . . . . . . . . . . . . . . . . . . . . . . . .

albro LMS18. . . . . . . . . . . . . . . . . . . . .

Remove Air Cleaner18. . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Carburetor19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassemble Carburetor19. . . . . . . . . . . . . . . . . . . . . . .

Carburetor Cleaning Recommendations20. . . . . . . . . . .

Assemble Carburetor20. . . . . . . . . . . . . . . . . . . . . . . . . .

Install W

Install Throttle Shaft20. . . . . . . . . . . . . . . . . . . . . .

Install Inlet Needle Seat20. . . . . . . . . . . . . . . . . . .

Install Inlet Needle and Float20. . . . . . . . . . . . . . .

High Altitude Compensation21. . . . . . . . . . . . . . .

Install Carburetor21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Air Cleaner21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

elch Plug20. . . . . . . . . . . . . . . . . . . . . . . .

Identification

3

2

111

1. Float

2.

Choke plate

3.

Choke lever

Fig. 21

bowl

– Fixed Main Jet Carburetor

Remove Air Cleaner

1. Remove

air cleaner element, Fig. 22.

air cleaner screws and air cleaner cover

4.

Throttle lever

5.

Idle speed screw

6.

I.D. number

4

5

6

. Remove

Fig. 20

– Primer Carburetor

WARNING

NEVER STAR

removed, fir

T o

e can r

r o

esult.

perat

e e

ngin

e with air c

leaner

CAUTION

T

O PREVENT accidental starting when servicing

engine or equipment, always remove spark plug

wir

e from spark plug and pr

contacting spark plug.

event wir

e fr

om

2. Then remov

o

n c

arburetor

3

5

Fig. 22

1. 2 screws

2. Cover

3. Pre-cleaner

e t

wo (2

) s

crew

s h

oldin

g air c

, Fig.

22.

– Removing Air Cleaner

4. Cartridge

5. Base

leaner/primer base

1

2

4

m–3664

Carburetion

18

GTS 200

Page 21

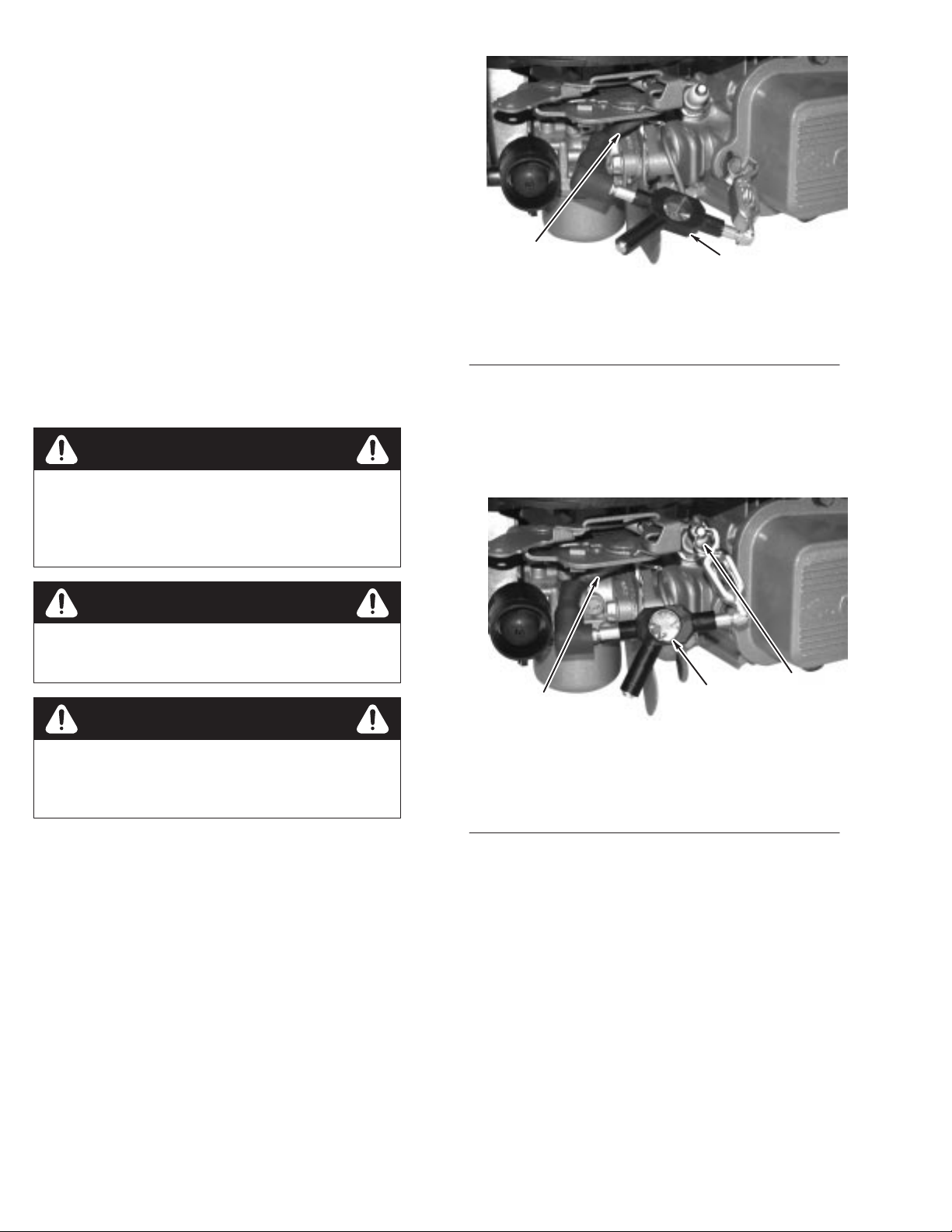

Remove Carburetor

1. Move

fuel line clamp and disconnect fuel line from

carburetor.

1

2

WARNING

CLOSE FUEL valve or plug fuel line to pr

fuel spillage. Do not use a scr

ew to plug fuel line

as this damages interior of hose.

2.

Remove carburetor and rotate carburetor until governor

link is free.

3.

On current production engines, the control bracket is held

on with three (3) screws, of which two (2) were removed

to remove the carburetor

, Fig. 23. On early production

engines, only two (2) screws held both carburetor and

control bracket. Reinstall both screws to retain control

bracket until carburetor is reinstalled.

Note:

Replace air cleaner gaskets and mounting gaskets

whenever carburetor is removed for service.

56

1

event

3

3

Fig. 24

– Removing Main Jet, Float Hinge Pin

and Inlet Needle

1. Float

2. Float

4. Remove

5.

6.

7.

8.

hinge pin

idle speed screw with spring, when used.

Rotate throttle shaft to closed position and remove throttle

plate screw

.

Remove throttle plate and throttle shaft with foam seal.

Grasp choke plate and remove from choke shaft.

Remove choke shaft and felt or foam washer

3.

Inlet needle

, when used.

2

1

Fig. 23

1. Mounting screw

2. Carburetor

Carburetor control bracket

3.

4. Gasket

4. Remove

two (2) carburetor mounting screws.

– Removing Carburetor

5.

6.

1

Current style, mounting

hole

Early style

Disassemble Carburetor

1. Remove

2.

Remove float bowl and bowl gasket from carburetor

Remove float hinge pin, float and inlet needle, Fig. 24.

3.

bowl nut (with fixed main jet) and fiber washer

9. W

ith a modified 5/16 inch (3.9mm) pin punch, remove

welch plug(s) from carburetor body

Note:

A convenient way to remove inlet needle seat is with a

, Fig. 25.

#5 crochet hook.

4

1

2

3

4

5

6

.

.

1. Choke

2.

Idle speed screw

3.

Throttle shaft

Fig. 25

plate and shaft

– Removing W

4. W

5.

6.

elch Plug

elch plug

5/32” punch

Throttle plate screw

GTS 200

19

Carburetion

Page 22

Carburetor Cleaning Recommendations

1. Disassemble

Remove all old gaskets, seals and sealing material.

2.

3.

Use commercial carburetor cleaning solvents to clean

carburetor parts and body

4.

When cleaning non-metallic parts (plastic, nylon,

Minlon

cleaner bath more than 15 minutes.

Note:

Parts containing rubber

pump diaphragms should never be placed in commercial

carburetor cleaner bath.

5.

Use only compressed air (blowing in both directions) to

clean out all openings and passages.

Note:

Do not

metering holes or passages.

carburetor

.

.

, etc.), do not leave in commercial carburetor

, such as seals, “O” rings or

use wires, drills or any other devices to clean out

3.

Lay throttle plate on shaft with numbers facing out and

install screw

, Fig. 27. Use a new patchlock screw

Loctite to secure screw in place.

2

1

3

Fig. 27 – Installing Throttle Shaft

1. Numbers

2. Throttle

shaft

3.

Foam washer

, or use

Assemble Carburetor

Install Welch Plug

1. Install

1. Welch

2. Press

3.

Install Throttle Shaft

1. Install

2. T

welch plug(s) with pin punch slightly smaller than

outside diameter of plug, Fig. 26.

1

Fig. 26 – Installing W

plug

elch Plug

2.

Pin punch

in until plug is flat. Do not cave in plug.

After plug is installed, seal outside edge of plug with

fingernail polish or non-hardening sealant.

throttle shaft and foam washer

.

urn shaft until flat is facing out.

Install

Inlet Needle Seat

Install

inlet needle seat with groove down using Briggs &

Stratton T

ool #19057, Bushing Driver

, until seated, Fig. 28.

1

2

2

Fig. 28 – Installing Inlet Needle Seat

1. Bushing

#19057

driver tool

2. Groove

Install Inlet Needle and Float

1. Install

2.

inlet needle on float and install assembly on

carburetor body

.

Insert float hinge pin and center pin between float pin

bosses. Float height is non-adjustable.

3.

Install rubber gasket on carburetor and lay float bowl on

body.

Carburetion

20

GTS 200

Page 23

4.

Place fiber washer over main jet and install main jet.

T

orque nut to 50 in. lbs. (6.0Nm), Fig. 29.

2

1

3

Fig. 29 – Installing Float, Hinge Pin and

Inlet Needle

1. Float

2. Hinge

pin

3.

Inlet needle

High Altitude Compensation

Note:

If engine is operated at high altitudes, performance may

decrease. If poor performance is experienced refer to the

proper T

oro parts manual for replacement high altitude main

jet.

56

1

Fig. 31

1. Mounting screw

2. Carburetor

3.

Carburetor control bracket

4. Gasket

– Installing Carburetor

Install Air Cleaner

1. Install breather tub

bas

e with new g

2.

Install air c

carburetor.

e on air c

aske

leaner primer bas

2

leaner primer bas

t o

n c

arbureto

3

1

4

1

Current style, mounting

5.

hole

6.

Early style

e and p

osition

r m

ountin

g s

urface.

e with two (2) screws into

Install Carburetor

1. Hook

2. Place

3.

4.

governor link into grommet on throttle lever from

the top, Fig. 30.

Fig. 30

– Install Carburetor

new intake gasket on throttle side of carburetor

Fig. 31.

Using carburetor mounting screws to align parts, place

carburetor on control bracket, Fig. 31.

Install carburetor assembly with two (2) mounting screws

torquing screws to 80 in. lbs. (10.0Nm), Fig. 31.

orque two (2) carburetor mounting screws to 30 in. lbs.

3. T

(3.0Nm), Fig. 32.

1

2

4

3

5

m–3664

Fig. 32

1. 2 screws

,

2. Cover

3. Pre-cleaner

4. Install

5.

Install air cleaner cover and two (2) screws, tighten screw

– Installing Intake Elbow Assembly

4. Cartridge

5. Base

air cleaner cartridge and pre-cleaner, Fig. 32.

farthest from spark plug first.

GTS 200

21

Carburetion

Page 24

Governor

Controls,

Carburetor Linkage,

and Flywheel Brake

Contents

3

2

1

Remote

Flywheel Brake22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Governor Adjustments24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Governor and Carburetor Linkages24. . . . . . . . . . . . . . . . . . .

Remote

Governor Controls22. . . . . . . . . . . . . . . . . . . . . . . . .

Remote Control W

Speed Regulation22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust Remote Controls22. . . . . . . . . . . . . . . . . . . . . . .

Operation 22

Remove Flywheel Brake23. . . . . . . . . . . . . . . . . . . . . . .

Assemble Flywheel Brake23. . . . . . . . . . . . . . . . . . . . . .

Brake Adjustment24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ire Travel 22

. . . . . . . . . . . . . . . . . . . .

Governor Controls

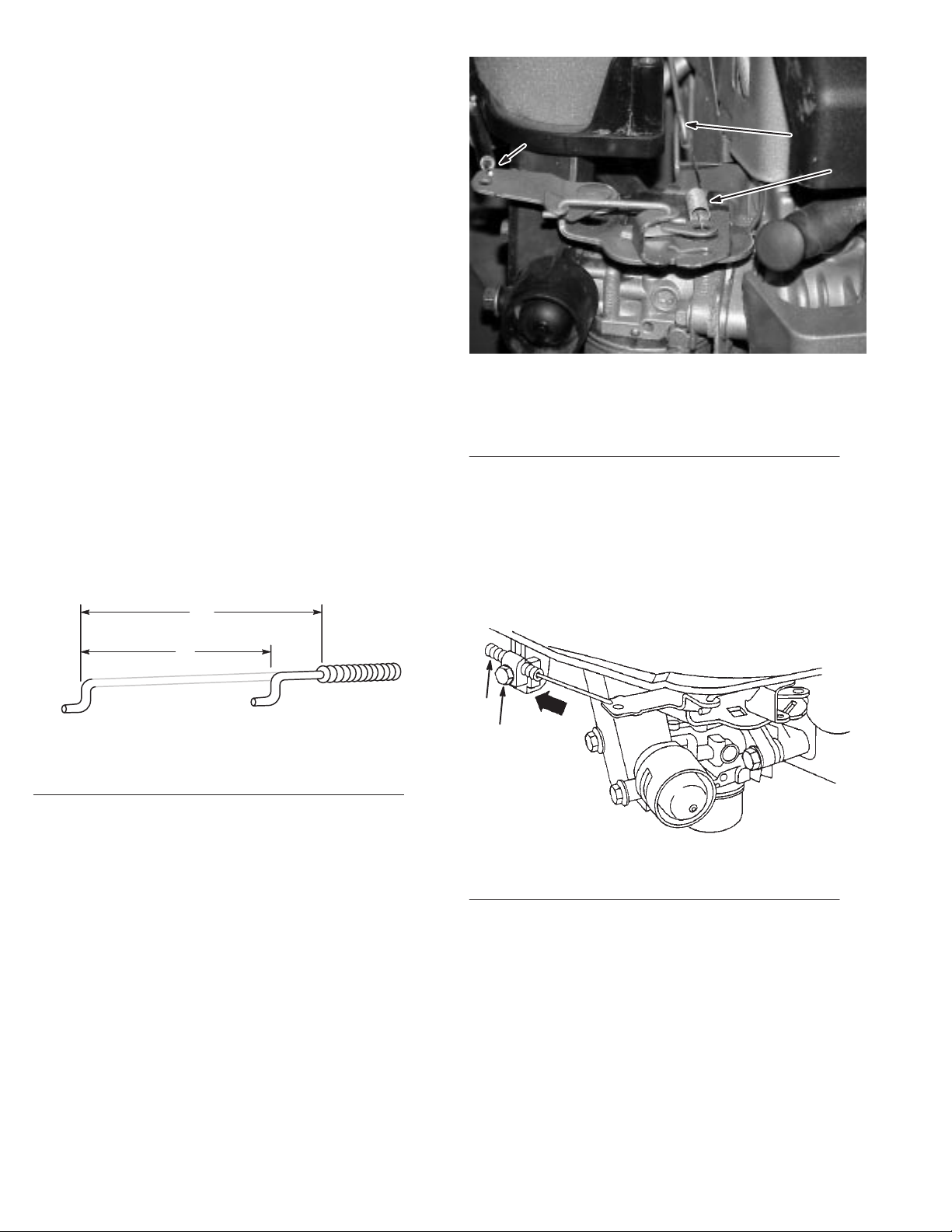

Remote Control Wire Travel

In

order to make proper remote control adjustments, the travel

of the remote control wire must be not less than 1–3/8”

(35mm) with controls mounted in equipment, Fig. 33.

1

2

Fig. 34 – Speed Regulation

(air cleaner removed for clarity)

1. Governor

2.

Governor link

spring

3.

Remote control cable

Adjust Remote Controls

1. Loosen

2.

3.

casing clamp screw

Move equipment throttle lever to fast position.

Move casing in direction of arrow (Fig. 35) until casing

stops moving.

.

Fig. 33

1. 2–1/8”

Remote

or decreasing tension on governor spring to obtain desired

engine speed. Remote controls will provide governor control

at all positions.

(54mm) minimum

governor controls change engine speed by increasing

– Control W

ire T

ravel

2.

1–3/8” (35mm) minimum

travel

Speed Regulation

When

remote control is moved toward FAST position,

governor control rotates and increases tension of governor

spring on governor lever

and valve on carburetor toward wide open position, Fig. 34.

. Governor link moves throttle lever

2

1

Fig. 35

1. Casing

4. Tighten

– Adjusting Remote Controls

clamp screw

casing clamp screw

2. Casing

.

Flywheel Brake

Operation

The

flywheel brake is part of the safety control system

required for this engine. The flywheel brake

engine within three seconds, while running at

position, when the operator releases the equipment safety

control.

MUST

FAST

stop the

speed

m–3638

Governor

and Flywheel Brake

Controls, Carburetor Linkage,

22

GTS 200

Page 25

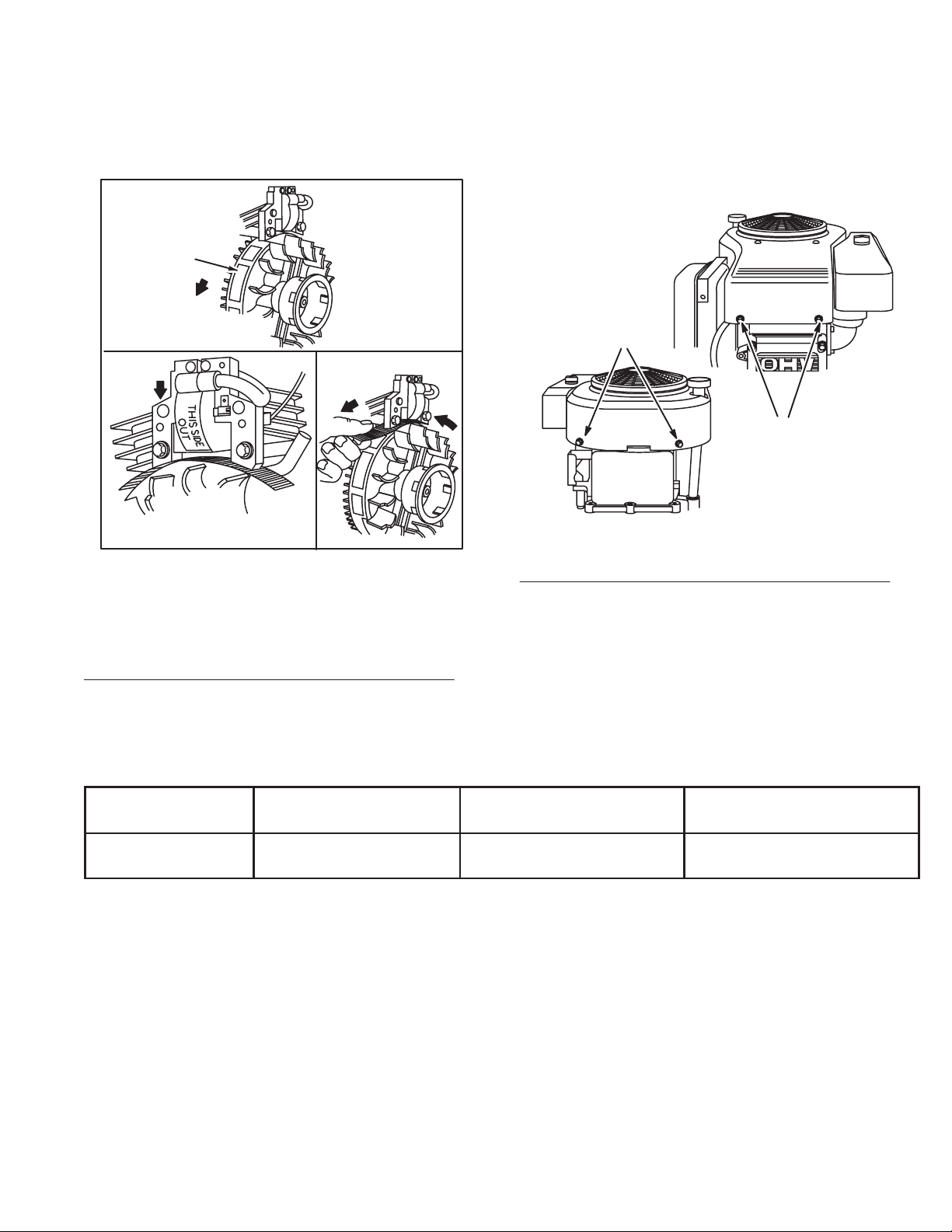

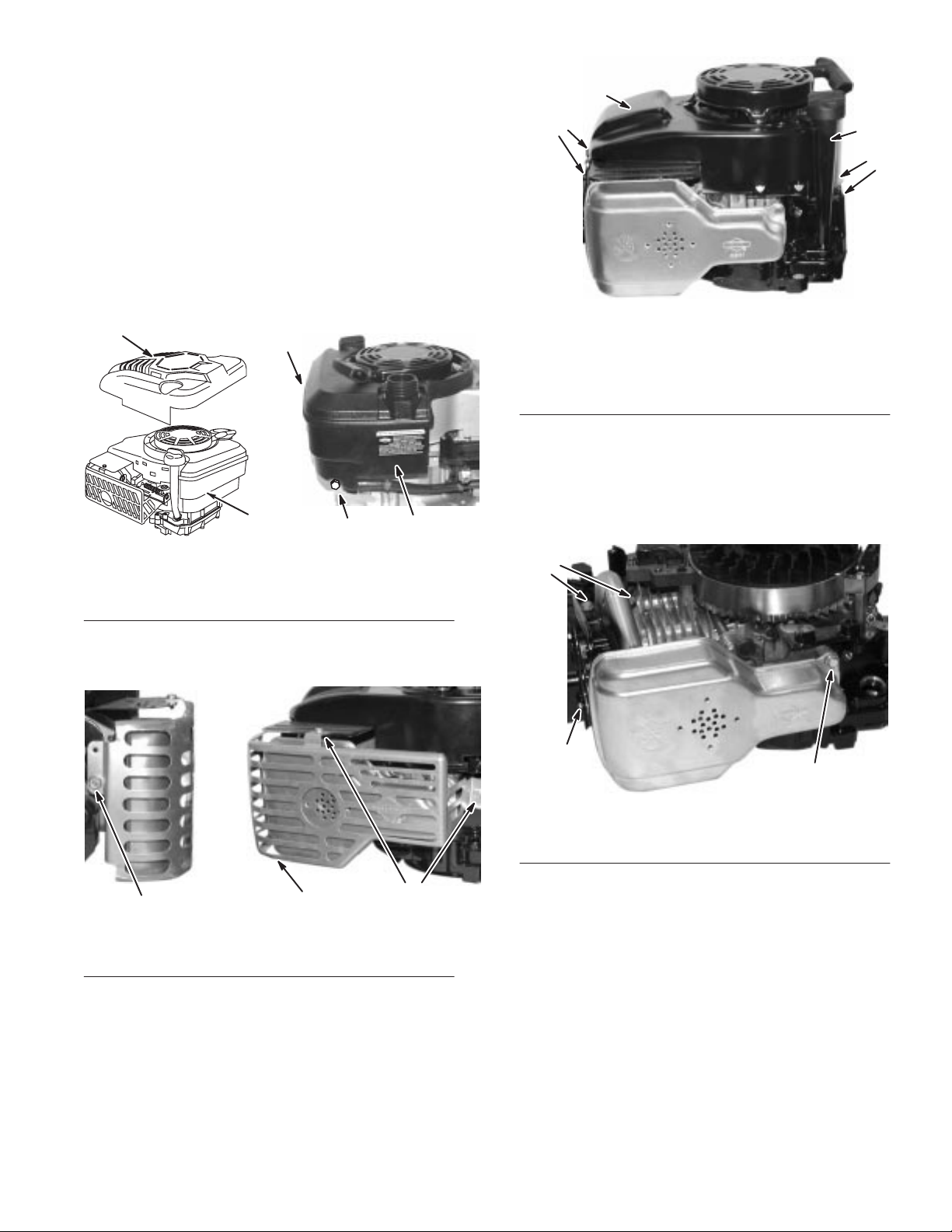

Remove Flywheel Brake

1. Disconnect

2.

Remove static guard and fuel tank, Fig. 36.

1

spark plug lead from spark plug.

7.

Remove two screws from brake bracket and remove

bracket, Fig. 38.

1

8

2

3

2

Fig. 36

1. Static

2.

3. Remove

4.

– Removing Static Guard and Fuel T

guard

Fuel tank

3. Screw

dipstick and oil fill tube, Fig. 37.

Remove blower housing and rewind starter

3

2

1

3

2

ank

, Fig. 37.

1

6

7

5

1. Stop

2. Screw

3. Anchor

4.

switch wire

Brake bracket

Fig. 38

– Removing Brake Bracket

5.

Starter interlock switch

wires

Brake spring

6.

7.

Brake lever

8.

Brake pad

Inspect Flywheel Brake and Switches

1. Inspect

2. T

brake lining on brake lever

. Replace brake

assembly if lining is less than .090” (2.28mm) thick.

est stop switch as described in the section General

Information, stop switch – remote control.

3

4

4

Fig. 37

– Removing Dipstick and Oil Fill T

ube,

Blower Housing and Rewind Starter

1. Screw

2. Blower

5. Disconnect

6.

housing and

rewind starter

spring from brake anchor

Disconnect stop switch wire from stop switch. If engine is

3. Dipstick screw

4.

Dipstick and oil fill tube

.

equipped with electric starter, disconnect both wires from

starter interlock switch.

3. T

est electric starter interlock switch as described in the

section Electric Starter

, Check Interlock Switch.

Assemble Flywheel Brake

1. Install

2.

3.

4.

5.

brake assembly on crankcase and torque mounting

screws to 40 in. lbs. (5.0Nm) Fig. 38.

Install stop switch wire and bend end of wire 90°. Install

interlock switch wires on interlock switch, if used, Fig. 38.

Install blower housing as described on page 37, “Install

Blower Housing and Rewind Starter

.”

Install dipstick tube and dipstick.

Install fuel tank and static guard.

GTS 200

23

Governor

Controls, Carburetor Linkage,

and Flywheel Brake

Page 26

Brake Adjustment

WARNING

TO

PREVENT accidental starting, the spark plug

wir

e must be r

gr

ounded, after r

can cause personal injury

1.

Using a torque wrench and socket to fit flywheel nut, turn

flywheel clockwise with brake engaged. While turning at a

steady rate, torque reading should be 30 in. lbs. (3.0Nm) or

higher.

2.

If reading is low

brake lever and pad if pad thickness is less than .090”

(2.28mm).

3.

If brake pad thickness is acceptable, adjust control cable

casing anchor to position pad closer to flywheel when

handle control bail is in RUN position.

4.

Replace brake assembly if correct adjustment cannot be

made.

emoved fr

emoving boot. Failur

, check thickness of brake pad. Replace

om spark plug and

e to do so

.

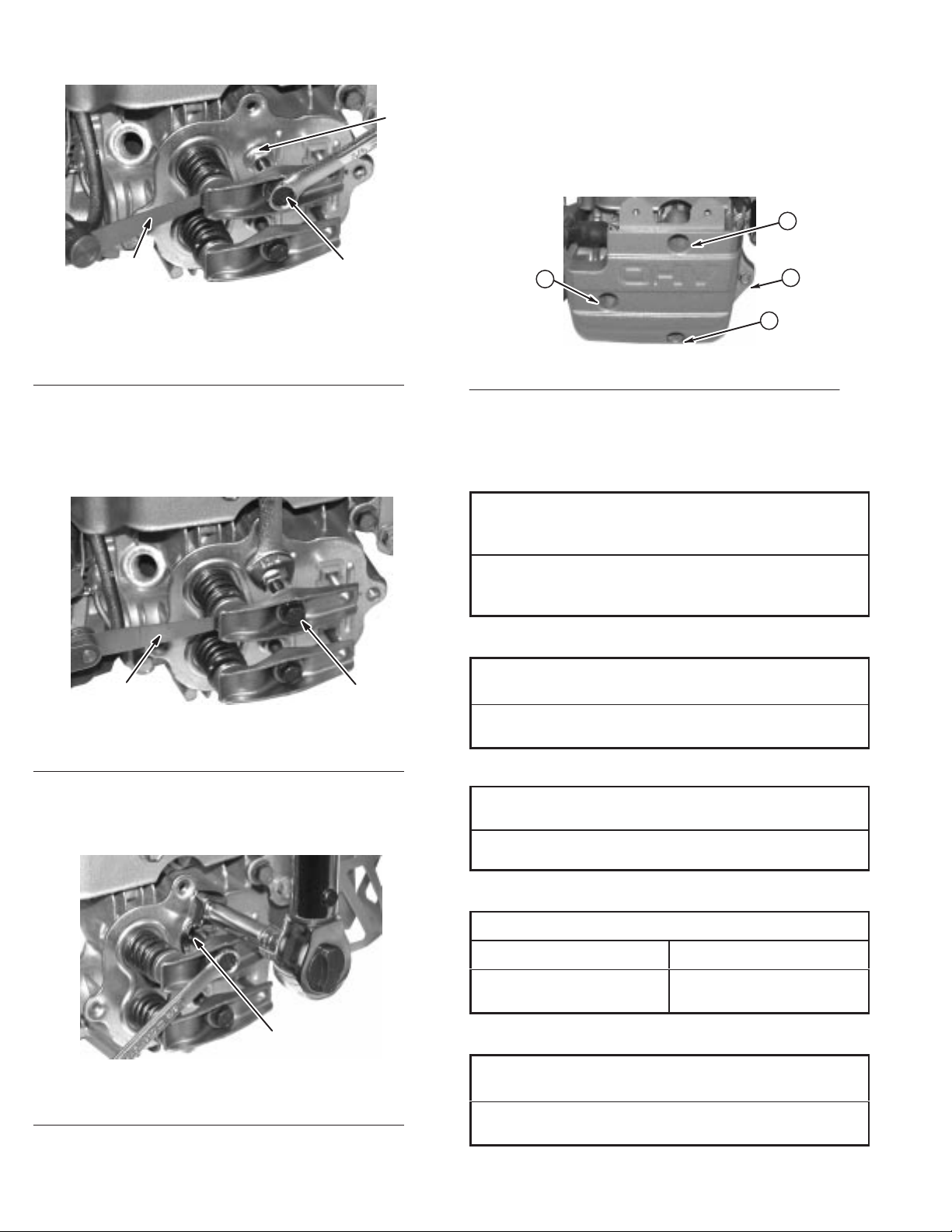

Governor

and Carburetor

Linkages

Figures 40 and 41 show governor and carburetor linkages.

1

Fig. 40 – Linkages

1. Governor

link

Governor

To

remove slack from the governor linkage:

1.

Slightly loosen the governor nut, Fig. 39.

Fig. 39 – Adjusting Governor Linkage

1. Governor

2.

Governor lever

2. Turn

the governor crank to the right (clockwise) until it

stops.

Adjustments

1

lever nut

3

3.

Governor crank

2

2

Fig. 41 – Linkages

(air cleaner removed for clarity)

1. Governor

spring

2.

Remote control cable

1

Rotate the governor lever to the right until it stops. Hold

3.

and tighten the governor lever nut.

T

o adjust top no load RPM, see page 26.

Refer to page 26 for specific procedures for governor

adjustments.

Governor

and Flywheel Brake

Controls, Carburetor Linkage,

24

GTS 200

Page 27

Governor

Contents

General

Governed RPM Limits25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Governor25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General

The

of the counterweights, which are operated by centrifugal

force, tends to close the throttle. The engine speed at which

these two forces balance is called the governed speed. The

governed speed can be varied by changing governor spring

tension or governor spring, Fig. 42.

Information25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassemble 25

Inspect Governor26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assemble Governor Crank26. . . . . . . . . . . . . . . . . . . . .

Install Crankcase Cover or Sump26. . . . . . . . . . . . . . . .

Adjust T

Seal Protectors26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

op No Load RPM26. . . . . . . . . . . . . . . . . . . . .

Information

governor spring tends to pull the throttle open. The force

completely assembled machine. The RPM should be measured

with the mower on a hard surface to eliminate cutting load on

the blade.

If a governor spring must be replaced, consult the appropriate

T

oro Illustrated Parts List.

CAUTION

AFTER A new governor spring is installed, check

engine top no load speed.

Run engine at half throttle to allow the engine to reach normal

operating temperature before measuring speed with a

tachometer.

oro rotary mowers should be set to run at 3,000 RPM 150,

T

which will produce blade tip speeds of 19,000 feet per minute.

If a service replacement engine is used, check the top no load

speed with the engine operating on a completely assembled

mower

. If necessary

top no load speed limit device, so the engine will not exceed

the recommended speed. See page 26 for adjustment

procedure for mechanical governor