Page 1

Specifications:

• Controls up to 200 stations for the

Stand-Alone model

• Input power supply

100 VAC, 50/60Hz

120 VAC, 50/60Hz

240 VAC, 50/60Hz

• TDC output voltage: 40 VAC max.

• TDC output power: 98VA max.

• Storage temperature: -30C–60C

• Operating temperature: 0–60C

• Cabinet Type: Non-corrosive, lockable wall mount,

indoor/outdoor installation

• Six 25.4mm conduit openings and one 38mm conduit opening

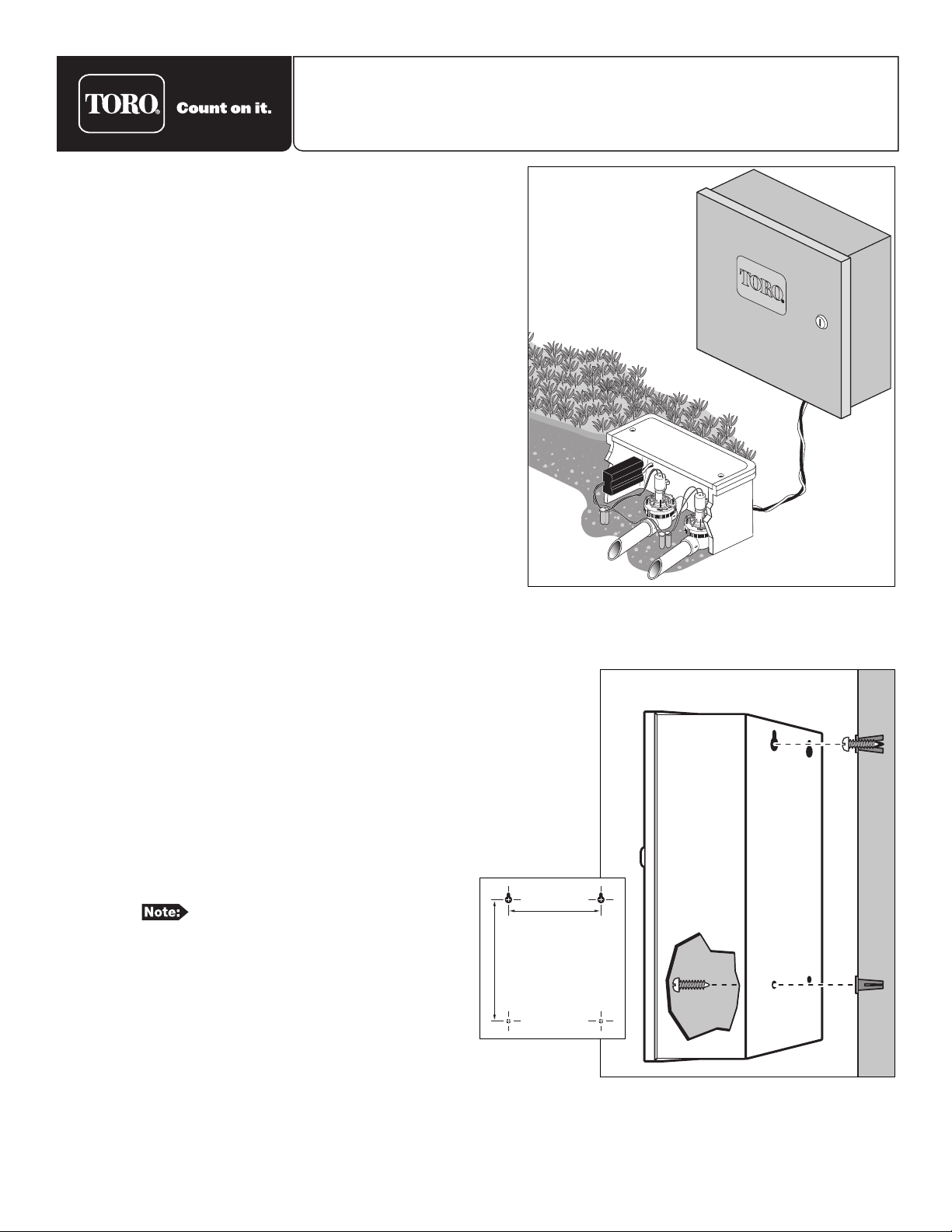

Cabinet Installation

Selecting the proper installation site for the 2-wire decoder is essential to safe

and reliable operation. The 2-wire decoder features a weather resistant cabinet designed for indoor or outdoor installation.

The TDC should be installed on a vertical wall or other sturdy structure near

a grounded power source. Select a location that shades the controller during the

hottest hours of the day and provides as much protection from direct sunlight,

rain, wind and snow as possible. DO NOT mount the controller where it is

exposed to direct spray from the irrigation system.

For easy operation and better view of the display (Stand-alone model),

install the TDC so that the display is at or slightly below eye level.

Step 1 – Drill two pilot holes 15.25cm apart for the top keyholes of the

controller cabinet.

Step 2 – Install the top screws leaving approximately 5–6mm of exposed

screw to accommodate

the cabinet.

If mounting the cabinet on dry wall or

masonry, install the appropriate type of screw

anchors or fasteners to ensure secure installation.

Step 3 – Hang the cabinet using the top keyhole slots.

See Figure 1.

Step 4 – Open the cabinet door and install the bottom two

screws to

secure the cabinet.

TDC 100/200 Stand-Alone Model

Installation Instructions

Figure 1

15.25cm

23.175cm

Page 2

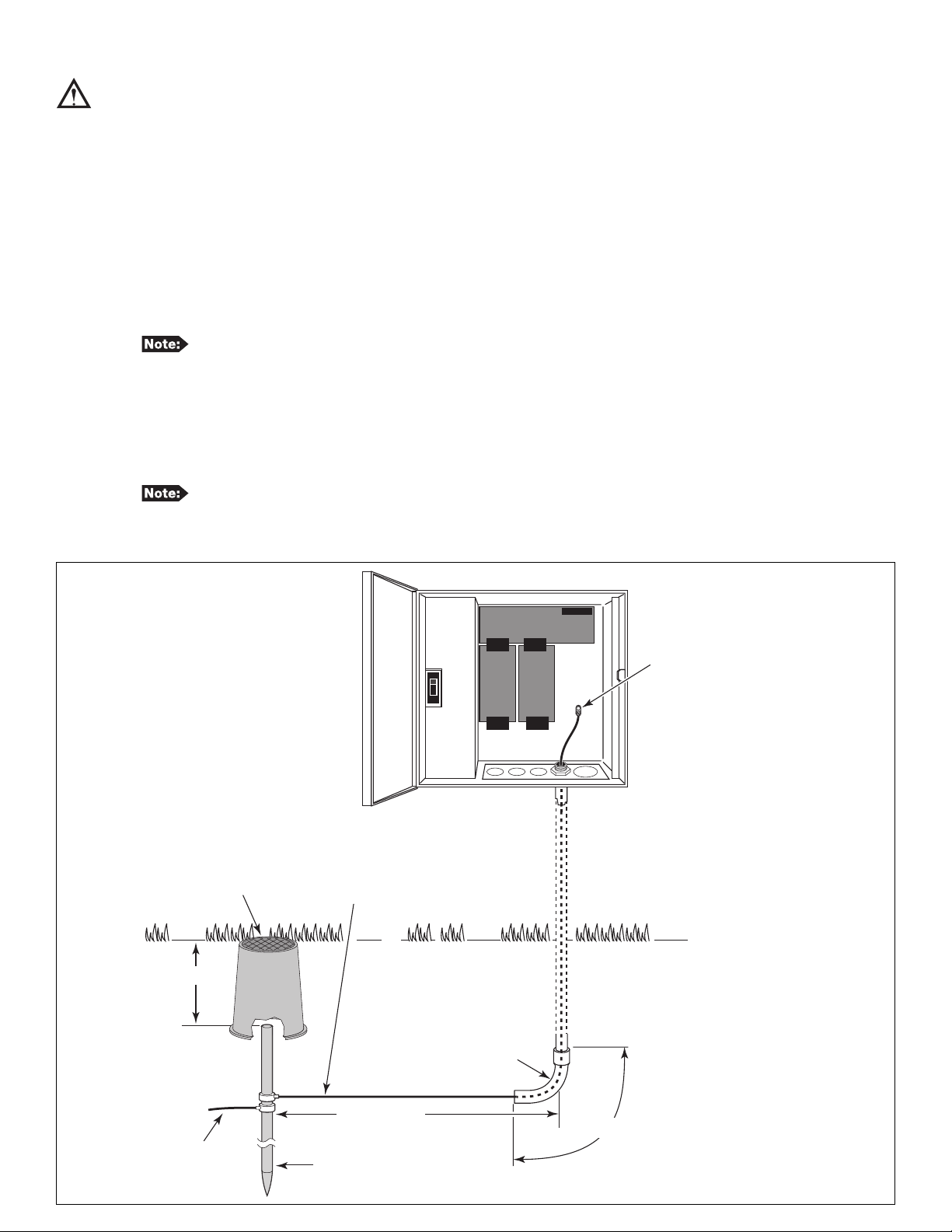

Earth Ground Installation

IMPORTANT! The TDC surge protection components cannot properly function unless an efficient pathway to earth

ground is provided. The ground path must be as direct as possible, without sharp bends and must not exceed 30 Ohm

resistance (when measured with an earth ground resistance device). All electrical components throughout the irrigation system

should be grounded similarly to provide the same ground potential.

The following instructions depict one of several acceptable earth grounding methods. Due to variables in soil composition and

terrain, the method shown may not be suitable for your installation site. Contact your local Toro distributor for assistance and

availability of the required earth ground resistance test instrument.

Step 1 – Drive a 5/8" x 8' (17mm x 2.5m) copper-clad steel rod into well moistened soil not less than 8' (2.5m) or not more

than 12' (3.7m) from the controller cabinet. The top of the ground rod should be 12" (30.5cm) below grade level.

See Figure 2.

Step 2 – Using a 5/8" (17mm) clamp or “Cad weld” fastener, attach an 8 AWG (8mm

2

) solid copper wire near the top of the

ground rod. Avoiding wire bends of less than 8" (20.3cm) radius and more than 90

o

, route the wire through conduit

and into the cabinet. Secure the wire to the copper ground lug.

Make sure the soil surrounding the ground rod(s) remains well moistened at all times. The addition of

some form of irrigation may be required if the cabinet is installed in a non-irrigated location.

Step 3 – Measure the ground resistance per the instructions provided with the ground test instrument. A reading of

0.0 Ohm is optimum, up to 10 Ohm is good and 11–30 Ohm is acceptable in most cases. If the resistance exceeds

the acceptable limit, additional ground rod(s) can be installed at a distance equal to twice the buried depth of the

first rod; i.e., 16' (4.9m). Interconnect the ground rods using 8 AWG (8mm

2

) solid copper wire and test again. If the

measured ground resistance continues to read above the acceptable limit, contact your local Toro distributor for

further assistance and recommendations.

Installing a round valve box over the ground rod enables the ground rod to be easily located as well as

providing access to the ground wire connection(s).

Figure 2

Ground Lug

Valve Box

8 AWG (8mm2)

Solid Copper Ground Wire

Copper Clad

Ground Rod

Ground Wire To

Additional Rod(s)

(Optional)

12" (30.5cm)

8'–12'

(2.4m – 3.7m)

8" (20.3cm)

Minimum Radius

90oMinimum Angle

Page 3

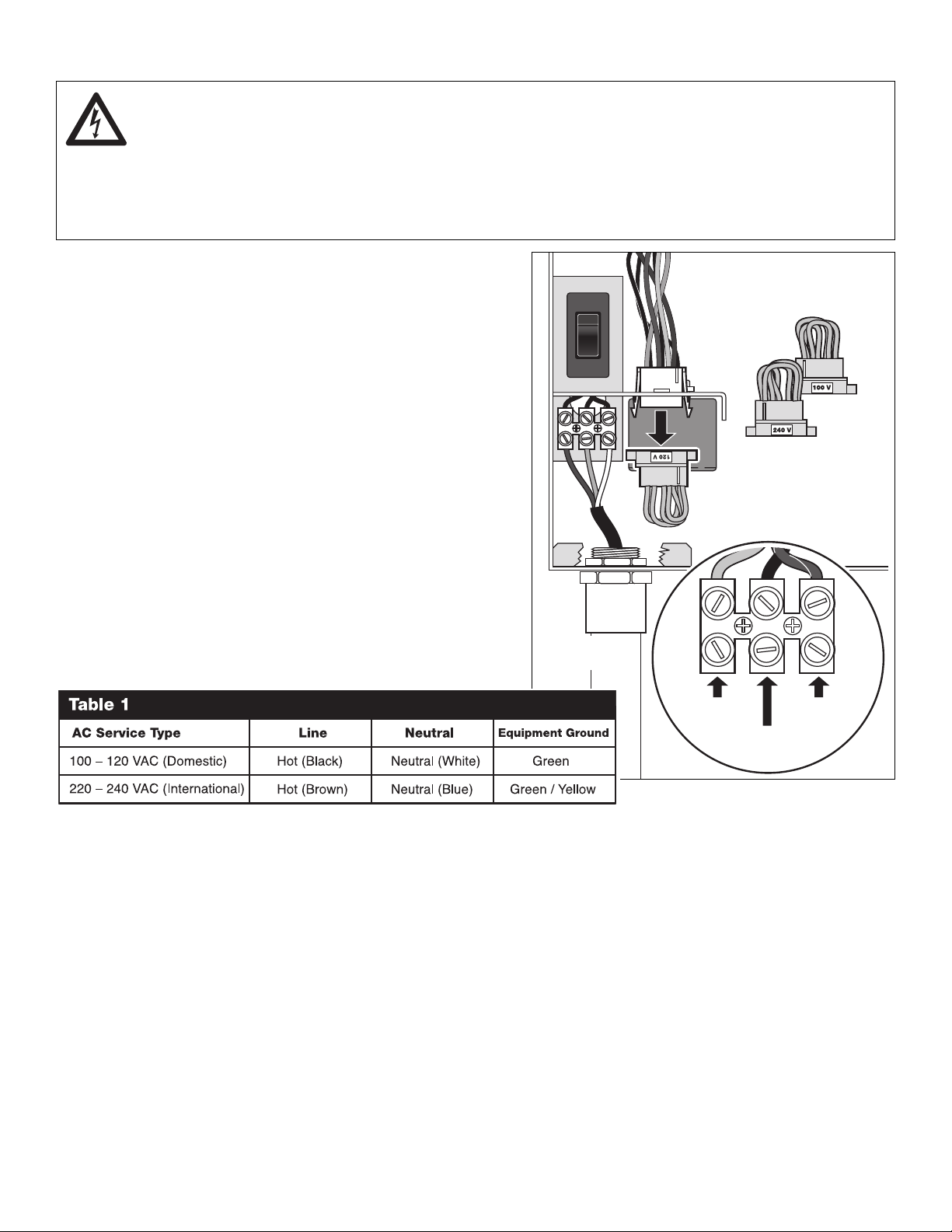

Power Source Installation

Step 1 – Turn off the power at the power source location and

place the controller’s power switch to OFF. Connect and

route the appropriate size 3-conductor cable (10 AWG

[2.5mm

2

] maximum) from the power source to the

controller cabinet.

The provided power cable access hole can

accommodate a 1" (25mm) conduit fitting. If conduit is

required, install a section of flexible 1" (25mm) electrical

conduit from the power source conduit box to the

cabinet’s access hole.

Step 2 – Open the cabinet door and remove the two retaining

screws from the power supply cover.

Step 3 – Locate the voltage cable assembly and note the voltage

on the label. The TDC is equipped with 120V cable

assembly from the factory. Replace the voltage cable

assembly with the proper rating as necessary. See

Figure 3.

Step 4 – Strip the power cables and secure them to the terminal

block. Reference Table 1 for the appropriate type of

power connection.

Step 5 – Reinstall the power supply cover.

Step 6 – Apply power to the controller.

WARNING! AC POWER WIRING MUST BE INSTALLED AND CONNECTED BY QUALIFIED

PERSONNEL ONLY.

ALL ELECTRICAL COMPONENTS AND INSTALLATION PROCEDURES MUST COMPLY WITH ALL

APPLICABLE LOCAL AND NATIONAL ELECTRICAL CODES. SOME CODES MAY REQUIRE A MEANS OF

DISCONNECTION FROM THE AC POWER SOURCE, INSTALLED IN THE FIXED WIRING, HAVING A CONTACT

SEPARATION OF AT LEAST 3mm IN THE LINE AND NEUTRAL POLES.

ENSURE THE AC POWER SOURCE IS OFF PRIOR TO SERVICING. FAILURE TO COMPLY MAY RESULT IN SERIOUS

INJURY DUE TO ELECTRICAL SHOCK HAZARD.

Figure 3

Line

Neutral

Voltage Cable

Assembly

Flexible Conduit

(Optional)

Equipment

Ground

Page 4

Station Decoder Installation

The station decoder module is available in 1-station, 2-station or 4-station configuration. The decoder modules are installed into

the TDC output board terminals.

The stand-alone TDC model can handle up to 100 stations per output board. These stations can be connected to the output

board terminals in any configuration (25 stations connected to each of the four terminal pairs or 100 stations connected to one

terminal pair, etc.). The decoder modules can be connected in parallel anywhere on the two-wire communication line connected

to the station terminals. Each station can activate up to two solenoids.

It is recommended that the decoder modules are installed in an approved valve box to provide easy access to the wiring. Use

high-voltage waterproofing to all the wire connections.

Recommended Controller-to-Decoder cable: 14 AWG (2.5mm

2

), solid copper, jacketed 2-conductor, direct burial. The

preferred wire make and model is the Paige Irrigation Wire, Spec P7350D.

Recommended Decoder-to-Solenoid cable: 14 AWG (2.5mm

2

), solid copper, 2-conductor, direct burial. The preferred wire

make and model is the Paige Irrigation Wire, Spec P7351D.

IMPORTANT!

Cable Splices: In order for the wire connections to comply with the 2005 edition of the National Electric Code®

Article 300.5 (Underground Installations) and 110.14 (Electrical Connections), in wet or damp locations, the connector

must be listed under specification “UL 486D” if installed in a valve box. It must be listed under specification “UL 486DDirect Burial” if buried in dirt. This requirement applies to all electrical connections in wet or damp locations,

regardless of voltage. The 3M DBY-6 and DBR-6 are listed as “UL 486D-Direct Burial” and meet these requirements for

all underground installations.

Cable Burial Depth: The TDC decoder operate at voltages between 30–40 volts. The 2005 edition of the National

Electrical Code®, Article 300-5, requires that wires and cables subjected to voltages higher than 30 volts are to have a

minimum cover of 24" (60.96 cm).

• Use only wire approved for direct burial if installing the wires underground without conduit.

• All field wiring splices must be accessible to facilitate troubleshooting and/or service.

Step 1 – Route communication cable from the controller to the station decoder module installation location.

The maximum wire length between the controller and the decoder module is 15,000' (4500m).

Step 2 – Secure the communication wires to terminal 1 of the TDC output board. White wire onto the 1st terminal and black

wire onto the second terminal. See Figure 4.

Step 3 – Install the decoder module in a valve box. Record the decoder module’s address number found on the side label.

This address number identifies the station(s) that the decoder module control.

Step 4 – Secure the communication wires to the decoder module’s black and white wires. Connect the black communication

wire to the black decoder module wire. Connect the remaining communication wire (red or white) to the white

decoder module wire. Use proper water proofing method for all wire connections.

Step 5 – Route output wires from the decoder module to the solenoid.

The maximum wire length between the decoder module and the solenoid is 410' (125m).

Step 6 – Connect the solenoid wires to the decoder module’s station wires. The station wires are color coded for easy

identification. Connect the solid colored (red, green, orange or blue) station wire to the red/white solenoid wire.

Connect the similar color station wire with black stripe to the black solenoid wire. Waterproof all wire connections.

Step 7 – Connect an additional solenoid to the station wire as necessary.

Each station has a maximum load of two solenoids.

Step 8 – Repeat Steps 3–8 for additional decoder modules.

Page 5

Paths – 1

234

Valve Box

Maximum communication wire length

between the controller and the farthest

decoder is 15,000ft (4500m).

Recommended Cable for Controller-to-Decoder is the Paige

®

P7350D, 14 AWG, Solid Copper, Jacketed 2-Conductor,

Direct Burial cable.

White

Black

White

Black

White

Black

White

Black

The maximum communication wire length

between the decoder module and the

solenoid is 410ft (125m).

Recommended Cable for Decoder-to-Solenoid

is the Paige

®

P7351D, 14 AWG, Solid Copper,

2-Conductor, Direct Burial cable.

To easily identify stations for

troubleshooting, install wires with the same

color code as the station wires.

Output Board

White Power/Communication Wire

Black Power/Communication Wire

Station 1

Solid Red Station Wire - Connect to the Red/White solenoid wire

Red with Black Stripe

Station Wire - Connect to the Black solenoid wire

Station 2

Solid Green Station Wire - Connect to the Red/White solenoid wire

Green with Black Stripe

Station Wire - Connect to the Black solenoid wire

Station 3

Solid Orange Station Wire - Connect to the Red/White solenoid wire

Orange with Black Stripe

Station Wire - Connect to the Black solenoid wire

Station 4

Solid Blue Station Wire - Connect to the Red/White solenoid wire

Blue with Black Stripe

Station Wire - Connect to the Black solenoid wire

Figure 4

Each station can activate up

to two DC Latching Solenoids.

Out to additional

decoder modules

Station Wires

The Stand-Alone TDC output board

can accommodate up to 100 stations.

The decoder modules can be

connected in any configuration using

the four station terminals.

1-Station

Decoder

Module

When possible, install the decoder

module in a valve box for ease of service.

DC Latching

Solenoid

Red

Black

Page 6

Grounding Communication Cable

IMPORTANT!

Cable Splices: In order for the wire connections to comply with the 2005 edition of the National Electric Code®

Article 300.5 (Underground Installations) and 110.14 (Electrical Connections), in wet or damp locations, the connector

must be listed under specification “UL 486D” if installed in a valve box. It must be listed under specification “UL 486DDirect Burial” if buried in dirt. This requirement applies to all electrical connections in wet or damp locations,

regardless of voltage. The 3M DBY-6 and DBR-6 are listed as “UL 486D-Direct Burial” and meet these requirements for

all underground installations.

Cable Burial Depth: The TDC decoder operate at voltages between 30–40 volts. The 2005 edition of the National

Electrical Code®, Article 300-5, requires that wires and cables subjected to voltages higher than 30 volts are to have a

minimum cover of 24" (60.96 cm).

The optional lightning arrester (Toro P/N DEC-SG-LINE) is available to protect the decoder module in lightning prone areas.

Without lightning arrester, the decoder are vulnerable to lightning damage. In order for these arrester to discharge lightning

energy efficiently, they must be properly grounded. Figure 5 illustrates the proper grounding and wiring of the arrester.

Step 1 – Locate decoder’s power/communication wires (black and white wires). Disconnect the wire connectors that joins it

to the controller-to-decoder cable.

Step 2 – Strip the insulation from lightning arrester’s white wire and connect it to the white wires from the decoder and

controller-to-decoder cable. Secure the splices with a water proofed wire connector. (See Figure 5.)

Step 3 – Strip the insulation from lightning arrester’s black wire and connect it to the black wires from the decoder and

controller-to-decoder cable. Secure the splices with a water proofed wire connector. (See Figure 5.)

Step 4 – Connect the lightning arrester’s ground wire to the ground plate’s wire. If the ground plate is not pre-wired, use a

10 AWG bare copper wire. (See Figure 5.)

IMPORTANT! Verify that the wire length between the lightning arrester and the ground plate is no less than

3' (91.44 cm). Longer lengths will decrease the lightning arrester’s effectiveness.

Step 5 – Bury the Ground plate next to the valve box or decoder’s location. Set it at the maximum depth that the ground

wire would allow. Surround the ground plate with 50 lbs (2.68 Kg) of Earth contact material such as PowerSet

®

(Paige Electric, part number 1820058).

Step 6 – Check the system for proper operation.

Figure 5

3' (91.4 cm)

Minimum Distance

Between the Arrester

and the Ground Plate

Lightning Arrester

Toro P/N DEC-SG-LINE

4'' x 36'' (10.16 cm x 91.44 cm)

Ground Plate - Surrounded by

50 lbs (2.68 Kg) of PowerSet

®

Toro Decoder Module

Paige P7350D

Controller-to-Decoder

Communication Cable

Use Paige P7351D for

Decoder-to-Solenoid

Communication Wiring

Page 7

Master Valve / Pump Relay Installation

TDC provide switch terminals to control a master valve or a pump relay if the system requires it.

Step 1 – Place the controller’s power switch to OFF.

Step 2 – Connect the Positive/Hot wire of the power source that controls the master valve or the pump relay to the Master

valve/Pump relay switch terminal. See Figure 6.

Step 3 – Route another wire from the Master Valve / Pump terminal and connect it to the master valve solenoid or pump

relay.

Step 4 – Connect the Negative/Equipment ground wire of the power source to the master valve solenoid or pump relay.

Step 5 – Place the controller’s switch to ON.

Pressure Sensor Installation

The TDC 100/200 controller is designed to accept both normally-open and normally-closed pressure sensor. Set the pressure

sensor model in TDC controller preference menu.

Step 1 – Place the controller’s power switch to OFF.

Step 2 – Route the pressure sensor’s cable into the controller.

Step 3 – Connect the cable wires to the Pressure Sensor Terminals (See Figure 6).

Step 4 – Place the controller’s switch to ON.

Rain Sensor Installation

The TDC 100/200 controller is designed to accept both normally-open and normally-closed rain switch. Set the rain switch

model in TDC controller preference menu.

Step 1 – Place the controller’s power switch to OFF.

Step 2 – Route the rain sensor’s cable into the controller.

Step 3 – Connect the cable wires to the Rain Sensor Terminals (See Figure 6).

Step 4 – Place the controller’s switch to ON.

Toro Maintenance Remote (TMR) Receiver Plug Installation

The TDC 100/200 controller is fully ccompatible with the TMR remote.

See TMR’s User’s Guide for operating and mounting instructions.

Step 1 – Place the controller’s power switch to OFF.

Step 2 – Route the TMR’s receiver plug cable into the controller.

Step 3 – Connect the RJ45 plug into the socket shown in Figure 6.

Step 4 – Connect the power wires into the 28 VAC terminals labeled A in Figure 6.

Step 5 – Place the controller’s switch to ON.

Figure 6

Master Valve / Pump Relay

Switch Terminals

Rain Sensor

Terminals

Pressure Sensor

Terminals

Rain Sensor

Master valve

or

Pump Relay

Pressure Sensor

24-Volts Transformer

(Voltage Source must

not exceed 3 Amps

Max, 28 Volts Max)

Toro

Maintenance

Remote (TMR)

Receiver Plug

The 28VAC (Label A) can

also be used to power the

Toro Wireless Rain Sensor

(TWRS/TWRFS) receiver.

A

A

Page 8

Lithium Battery Replacement

A 3.9V Lithium battery (P/N 363-2200) is installed in the timing mechanism to sustain the controller’s clock time and date for

approximately 10-years with no additional power applied.

Step 1 – Place the controller’s power switch to OFF.

Step 2 – Remove the ribbon cable from the rear of the timing mechanism.

Step 3 – Remove timing mechanism’s circuit board by pushing the retaining clip downward while carefully pulling the PCB

board. See Figure 6.

Step 4 – Secure the Lithium battery into the battery socket. See Figure 7.

Step 5 – Reattach the circuit board to the timing mechanism.

Step 6 – Secure the ribbon cable back to the timing mechanism socket.

Step 8 – Place the controller’s switch to ON.

Electromagnetic Compatibility

Domestic: This equipment has been tested and found to comply with the limits for a FCC Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. The equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual, may cause harmful interference to the radio

communications. Operation in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

International: This is a CISPR 22 Class A product. In a domestic environment, this product may cause radio interference, in

which case the user may be required to take adequate measures.Each stations can activate up to two solenoids.

© 2008 The Toro Company, Irrigation Division • An ISO-9000-Certified Facility Form Number 373-0399 Rev. C

WARNING! DANGER OF EXPLOSION IF BATTERY IS INSTALLED INCORRECTLY. REPLACE ONLY WITH THE

SAME OR EQUIVALENT TYPE OF BATTERY. ALWAYS DISPOSE OF USED BATTERIES ACCORDING TO THE

MANUFACTURER’S INSTRUCTIONS.

Push Retaining Clip

to Release the PCB

Disconnect the

Ribbon Cable

Figure 6 Figure 7

Loading...

Loading...