Page 1

Consumer Products

Power Max™

Snowthrower

Service Manual

Page 2

THIS PAGE INTENTIONALLY LEFT BLANK

Page 3

ABOUT THIS MANUAL

This service manual was written expressly for Toro service technicians. The Toro Company has made every effort to

make the information in this manual complete and correct.

Basic shop safety knowledge and mechanical/electrical skills are assumed. The Table of Contents lists the systems

and the related topics covered in this manual.

For information specifi c to the engines used on this unit, refer to the engine chapter of this book.

Power Max model years 2004 - 2005 are covered in this manual. The manual may also be specifi ed for use on later

model products.

We are hopeful that you will fi nd this manual a valuable addition to your service shop. If you have questions or

comments regarding this manual, please contact us at the following address:

The Toro Company

Consumer Service Department

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

The Toro Company reserves the right to change product specifi cations or this manual without notice.

Copyright© All Rights Reserved

©2005 The Toro Company

Page 4

TABLE OF CONTENTS

SAFETY INFORMATION

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifi cations . . . . . . . . . . . . . . . . . . . . . . .

ENGINE

Service Information . . . . . . . . . . . . . . . . . . . . . . . .

Servicing the R tek Engine . . . . . . . . . . . . . . . . . . . . .

Primer Button . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tank, Fuel Line, Fuel Filter . . . . . . . . . . . . . . . . . .

Prime Line Routing . . . . . . . . . . . . . . . . . . . . . . . .

Engine Shroud Assembly . . . . . . . . . . . . . . . . . . . . .

1 - 1

2 - 1

2 - 3

3 - 1

3 - 1

3 - 2

3 - 2

3 - 3

3 - 3

3 - 3

CONTROLS

Quick Stick . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation . . . . . . . . . . . . . . . . . . . . . . . . .

Removal . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly . . . . . . . . . . . . . . . . . . . . . . .

Reassembly . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . .

Control Interlock . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Operation, Replacement & Adjustment . . . . . . . . . .

Defl ector Cable

Defl ector Cable Adjustment

Shift Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shift Rod Adjustment . . . . . . . . . . . . . . . . . . .

Auger Control . . . . . . . . . . . . . . . . . . . . . . .

Auger Cable Adjustment . . . . . . . . . . . . . . . . .

Auger Brake Adjustment . . . . . . . . . . . . . . . . .

Traction Control . . . . . . . . . . . . . . . . . . . . . .

Traction Cable Adjustment . . . . . . . . . . . . . . . .

Replace & Adjust Wheel Clutch Cables . . . . . . . . . . . . . .

4 - 1

4 - 1

4 - 1

4 - 3

4 - 4

4 - 5

4 - 5

4 - 7

4 - 7

4 - 8

4 - 8

4 - 8

4 - 9

4 - 9

4 - 10

4 - 10

4 - 11

4 - 11

ii Power Max Service Manual

Page 5

TABLE OF CONTENTS

TABLE OF CONTENTS

BELT REPLACEMENT

Auger Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Traction Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AUGER HOUSING

Auger Housing Components . . . . . . . . . . . . . . . . . . . .

Skids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scraper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fixed Scraper . . . . . . . . . . . . . . . . . . . . . . .

Scraper Replacement . . . . . . . . . . . . . . . . . .

Adjusting the Skids and Scraper - Fixed . . . . . . . . .

Pivoting Scraper . . . . . . . . . . . . . . . . . . . . .

Scraper Replacement & Adjustment . . . . . . . . . . .

Adjusting the Skids and Scraper - Pivoting . . . . . . . .

5 - 1

5 - 2

6 - 1

6 - 1

6 - 1

6 - 1

6 - 1

6 - 2

6 - 2

6 - 2

6 - 3

AUGER GEARBOX

Auger Gearbox Removal Primary Method . . . . . . . . . . . . .

Separating the Auger & Traction Assemblies

Secondary Method . . . . . . . . . . . . . . . . . . . .

Gearbox Installation . . . . . . . . . . . . . . . . . . . . . . . .

Auger Gearbox Repair . . . . . . . . . . . . . . . . . . . . . . .

Lubrication . . . . . . . . . . . . . . . . . . . . . . . .

Gearbox Disassembly & Repair . . . . . . . . . . . . .

Failure Analysis . . . . . . . . . . . . . . . . . . . . . .

Gearbox Assembly . . . . . . . . . . . . . . . . . . . .

NON-WHEEL CLUTCH TRACTION DRIVE SYSTEM

General Description . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WHEEL CLUTCH TRACTION DRIVE SYSTEM

General Description . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive System Reassembly . . . . . . . . . . . . . . . . . . . . .

7 - 1

7 - 4

7 - 5

7 - 6

7 - 6

7 - 6

7 - 7

7 - 8

8 - 1

8 - 1

8 - 6

9 - 1

9 - 1

9 - 9

iiiPower Max Service Manual

Page 6

TABLE OF CONTENTS

TABLE OF CONTENTS

WHEEL CLUTCH TRACTION DRIVE SYSTEM (cont.)

Wheel Clutch Disassembly . . . . . . . . . . . . . . . . . . . .

Wheel Clutch Reassembly . . . . . . . . . . . . . . . . . . . . .

DISCHARGE CHUTE

Chute & Auger Cover Removal . . . . . . . . . . . . . . . . . .

Chute Gears . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly . . . . . . . . . . . . . . . . . . . . . . .

Assembly . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL

Electric Start System . . . . . . . . . . . . . . . . . . . . . . . .

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 - 17

9 - 20

10 - 1

10 - 4

10 - 4

10 - 4

10 - 6

11 - 1

11 - 1

11 - 1

WHEELS and TIRES

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 - 1

12 - 1

iv Power Max Service Manual

Page 7

General Information

SAFETY INFORMATION

This symbol means WARNING or

PERSONAL SAFETY INSTRUCTION read the instruction because it has to do

with your safety. Failure to comply with

the instruction may result in personal

injury or even death.

This manual is intended as a service and repair manual

only. The safety instructions provided herein are for

troubleshooting, service, and repair of the Power Max™

snowthrower. The Power Max™ snowthrower operator’s

Think Safety First

Avoid unexpected starting of engine...

Always turn off the engine and disconnect the spark

plug wire(s) before cleaning, adjusting, or repair.

Avoid lacerations and amputations...

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as if they were

moving whenever the engine is running or has the

potential to start.

manual contains safety information and operating tips for

safe operating practices. Operator’s manuals are available through your parts source or:

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Avoid asphyxiation...

Never operate an engine in a confined area without

proper ventilation.

Avoid injury due to inferior parts...

Use only original equipment parts to ensure that

important safety criteria are met.

Avoid injury to bystanders...

Avoid burns...

Do not touch the engine, muffler, or other components

which may increase in temperature during operation,

while the unit is running or shortly after it has been

running.

Avoid fires and explosions...

Avoid spilling fuel and never smoke while working with

any type of fuel or lubricant. Wipe up any spilled fuel or

oil immediately. Never remove the fuel cap or add fuel

when the engine is running. Always use approved,

labeled containers for storing or transporting fuel and

lubricants.

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due to projectiles...

Always clear the area of sticks, rocks, or any other

debris that could be picked up and thrown by the

powered equipment.

Avoid modifications...

Never alter or modify any part unless it is a factory

approved procedure.

1-1Power Max Service Manual

Page 8

THIS PAGE INTENTIONALLY LEFT BLANK

1-2 Power Max Service Manual

Page 9

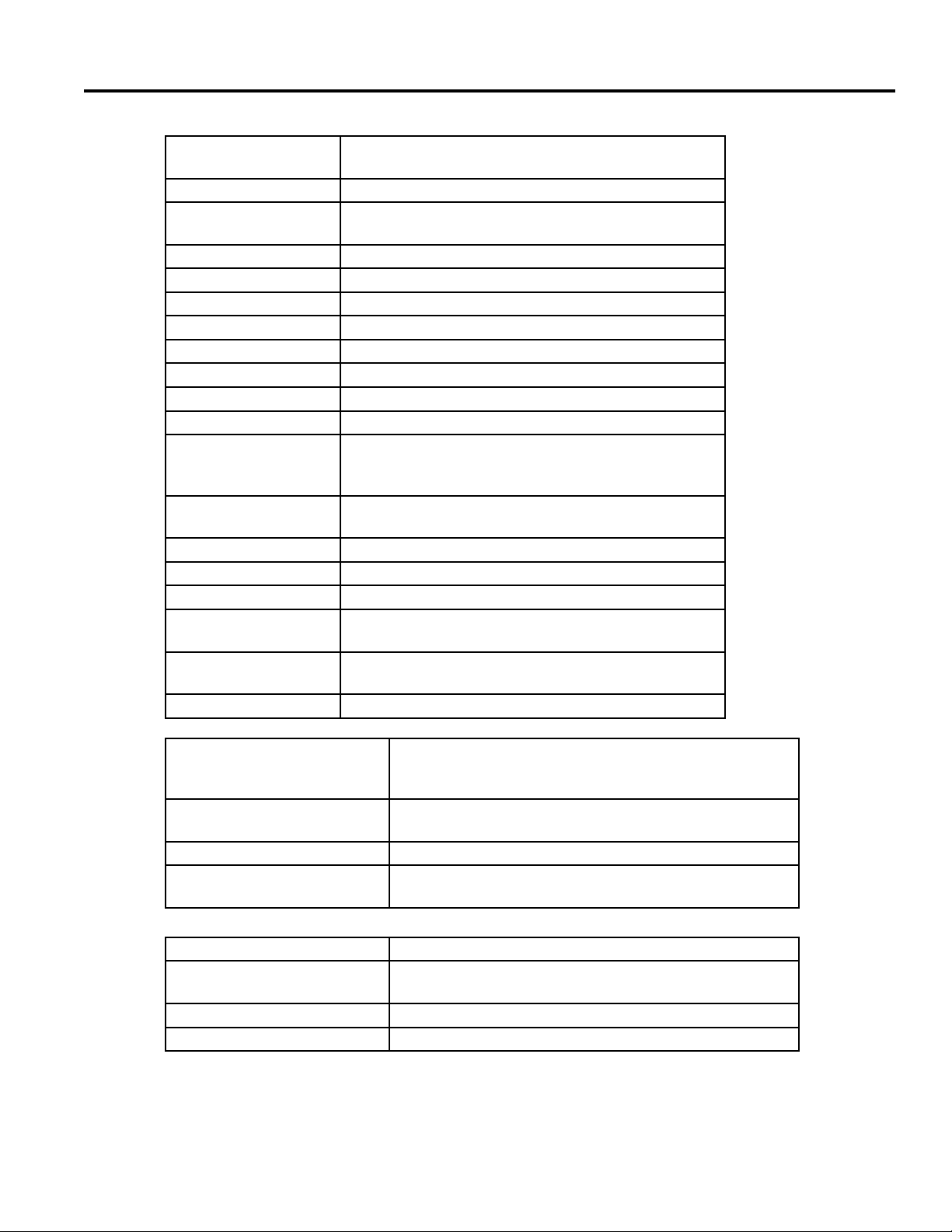

SPECIFICATIONS

Engine RPM

2-cycle 4,000 +250 -250 RPM

4-cycle 3,300 +150 -150 RPM

Auger

26” 26” (66cm) Wide & 21.5” (54.6cm) High

28” 28” (71cm) Wide & 21.5” (54.6cm) High

Auger Speed 123 RPM @ engine RPM listed above

Impeller 12” Dia. (30.5cm)

Impeller Speed 1228 RPM @ engine RPM listed above

Chute Rotation 200 degrees

Defl ector tilt angle 70 degrees

Tires Semi pneumatic 15x500x6

Pressure 17-20 psi ( 116-137kPa)

Ground speeds

Forward 0.7, 1.1, 1.5, 1.9, 2.3, 2.7 mph

(1.1, 1.8, 2.4, 3.0, 3.7, 4.3 kph)

Reverse 1.0 & 1.6 mph

(1.6 & 2.5 kph)

Height 44.5” (113cm) Approx.

Overall Width 27.5” (69.8cm) and 29.5” (74.9cm)

Length 62” (157cm)

Weight 724= 210 lbs (462kg) 826= 238 lbs (526kg)

828 & 1028= 245 lbs (539kg) 1128= 253 lbs (556kg)

Fuel Capacity

2 cycle engine 1.46 US qts (1.38l)

4 cycle engine 4 US qts (3.8l)

Fuel/oil

2-cycle Fuel Unleaded regular grade gasoline mixed at a ratio of 50:1

2.6 oz. (80ml) oil / 1 US gallon (3.8l) gasoline.

2-cycle Required oil Toro 2 cycle oil or any 2-cycle oil that is NMMA TCW3

(ISO E GD) certifi ed as an acceptable substitute.

4-cycle Fuel Unleaded regular grade gasoline (do not mix with oil).

4-cycle Oil automotive detergent oil with a service classifi cation of

SH or higher Maximum capacity 26 oz. (770ml)

The recommended weight varies with the outside temperature

For Temps Above 32

For Temps Between 00 F and

320 F ( -180 C to 00 C)

For Temps Below 00 F (-180 C) use SAE 0W30

Auger Gearbox lubricant* SAE 90 gear oil with a rating of GL5 or higher

*A multi weight may be used such as 85-120 as long as it meets the GL rating. Place the

unit on level ground and fi ll to the fi ll/check plug. Maximum capacity 4 oz (118ml).

0

F (00 C) use SAE 30W

use SAE 5W30 or SAE 10W

2-1Power Max Service Manual

Page 10

SPECIFICATIONS

The following parts should be lightly coated with an anti-seize

compound when assembling after making repairs.

1. The impeller shaft, before installing the impeller pulley.

2. The engine crankshaft before installing the engine pulley.

3. The full length of the auger shaft before installing the augers.

4. The outer 5” (12.7cm) of the axle before installing the wheels.

Accessories

• Drift Breaker

• Tire Chains

• Snow Cab

• Weight Kit (Required with Cab)

2-2 Power Max Service Manual

Page 11

SPECIFICATIONS

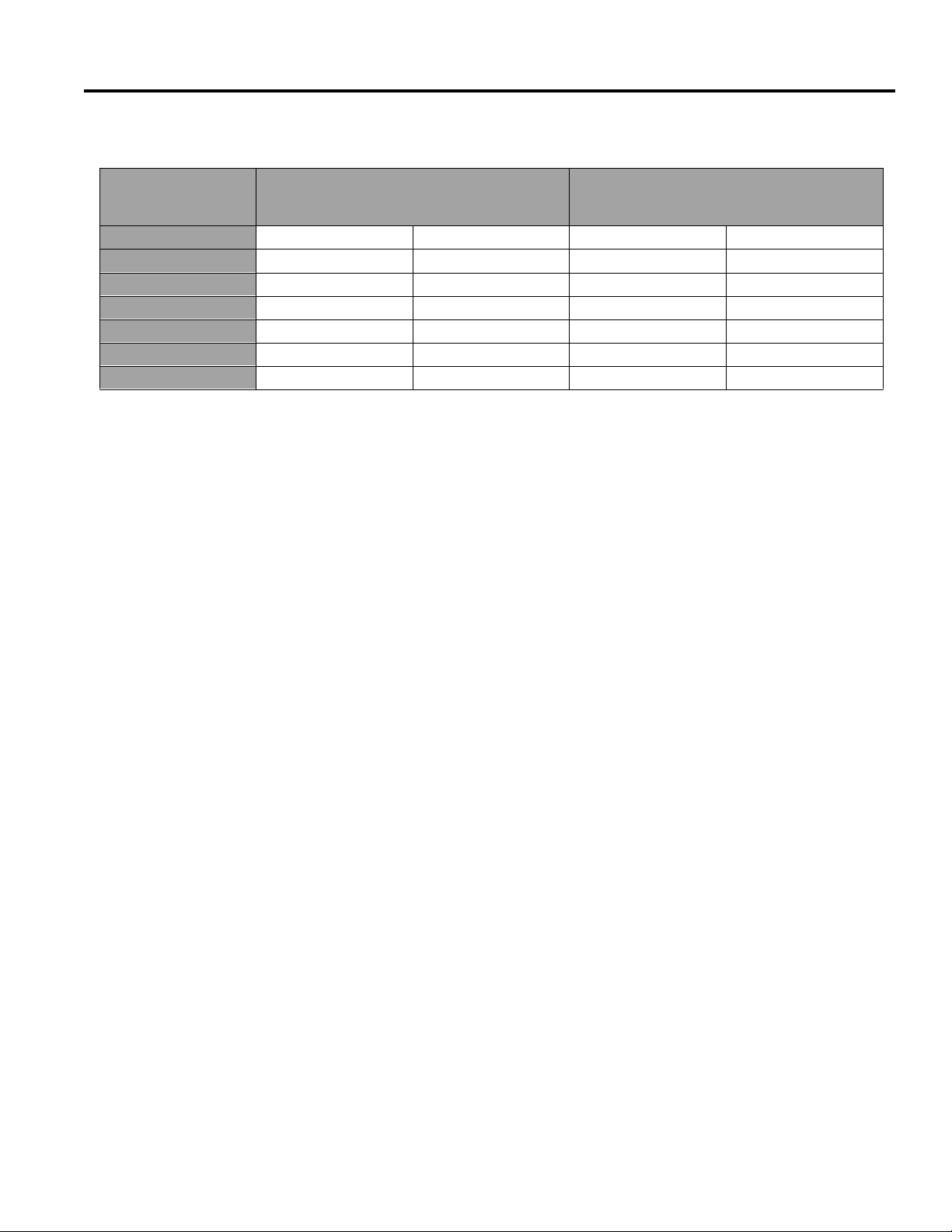

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as

determined by Toro, either the recommended torque or

a torque that is unique to the application is clearly

identified and specified in the service manual.

These torque specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in the

service manual. The following factors shall be

considered when applying torque: cleanliness of the

fastener, use of a thread sealant (Loctite), degree of

lubrication on the fastener, presence of a prevailing

torque feature, hardness of the surface underneath of

the fastener’s head, or similar condition which affects

the installation.

As noted in the following tables, torque values should

be reduced by 25% for lubricated fasteners to

achieve the similar stress as a dry fastener. Torque

values may also have to be reduced when the fastener

is threaded into aluminum or brass. The specific

torque value should be determined based on the

aluminum or brass material strength, fastener size,

length of thread engagement, etc.

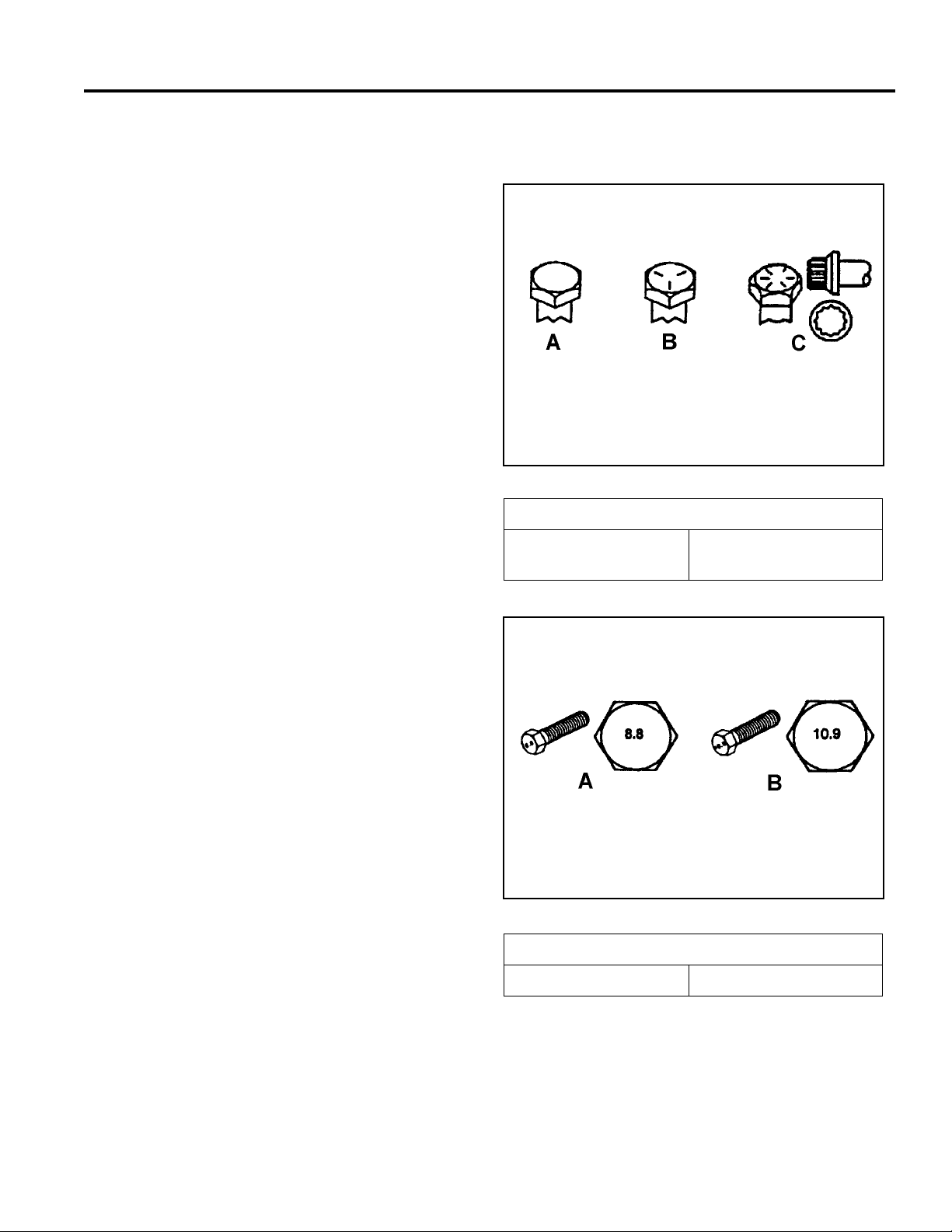

Fastener Identification

Inch Series Bolts and Screws

(A) Grade 1

(B) Grade 5

Figure 1

(C) Grade 8

The standard method of verifying torque shall be

performed by marking a line on the fastener (head or

nut) and mating part, then back off fastener 1/4 of a

turn. Measure the torque required to tighten the

fastener until the lines match up.

Figure 2

Metric Bolts and Screws

(A) Class 8.8 (B) Class 10.9

2-3Power Max Service Manual

Page 12

SPECIFICATIONS

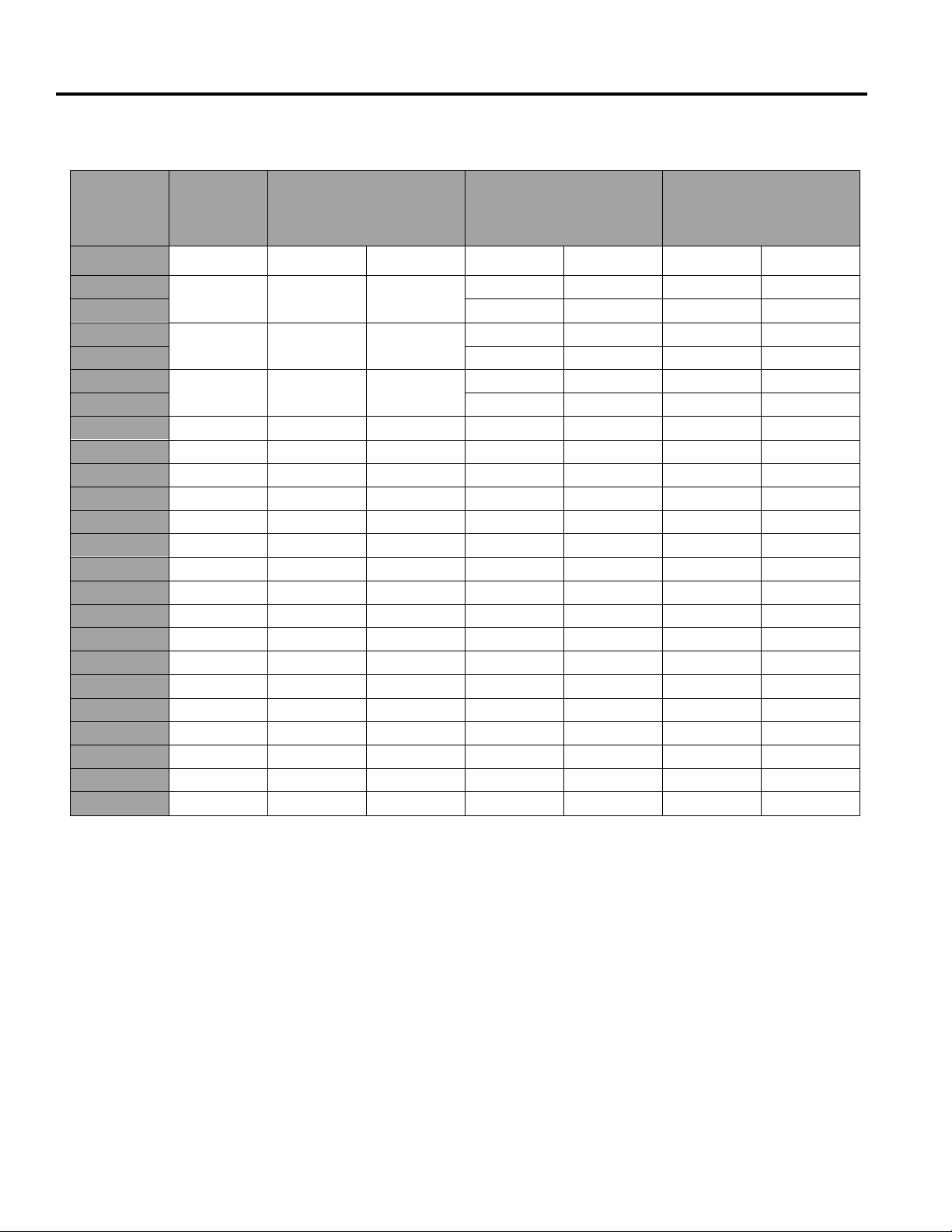

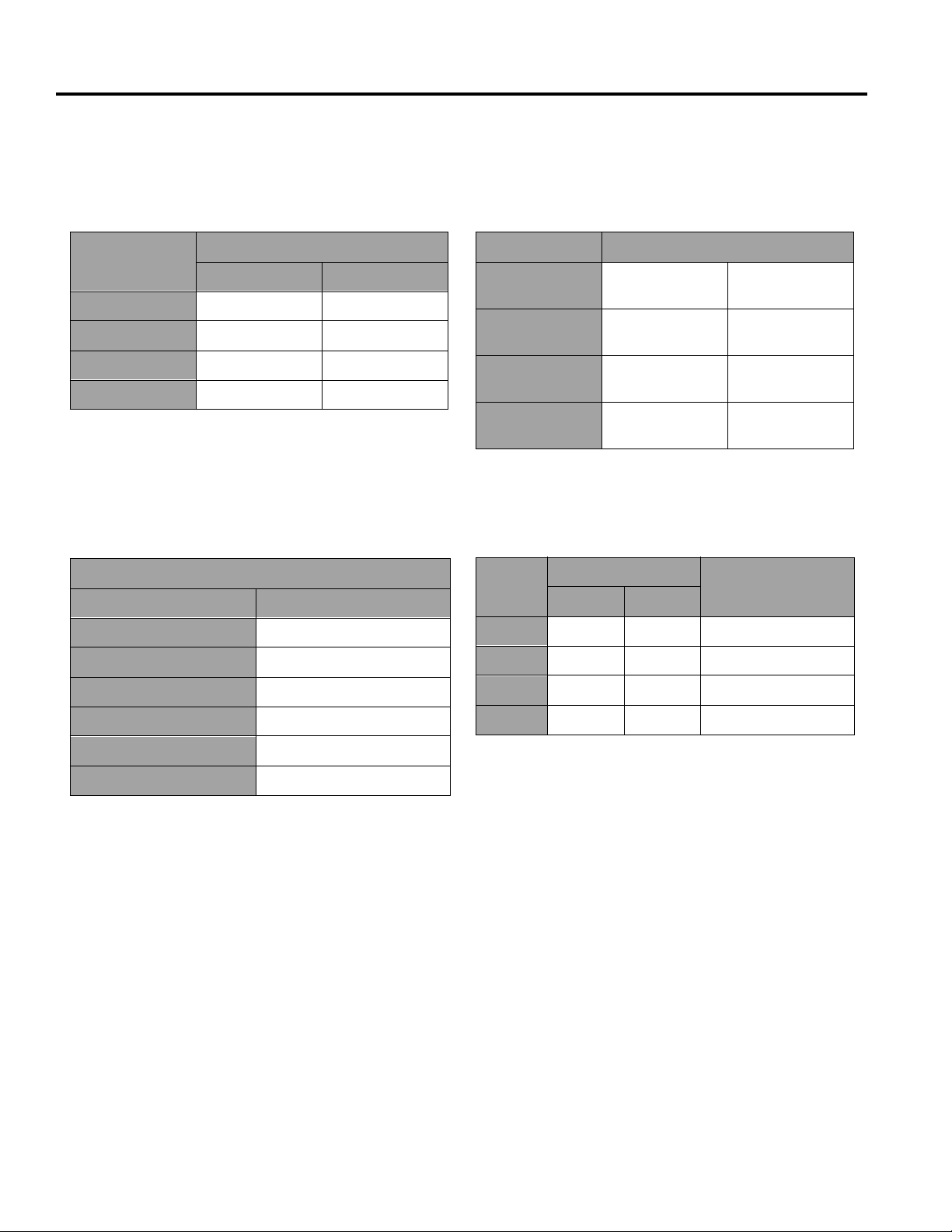

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

Grade 1, 5, &

Thread Size

# 6 - 32 UNC

# 6 - 40 UNF 17 ± 2 190 ± 20 25 ± 2 280 ± 20

# 8 - 32 UNC

# 8 - 36 UNF 31 ± 3 350 ± 30 43 ± 4 31 ± 3

# 10 - 24 UNC

#10 - 32 UNF 48 ± 4 540 ± 45 68 ± 6 765 ± 70

1/4 - 20 UNC 48 ± 7 53 ± 7 599 ± 79 100 ± 10 1125 ± 100 140 ± 15 1580 ± 170

1/4 - 28 UNF 53 ± 7 65 ± 10 734 ± 113 115 ± 10 1300 ± 100 160 ± 15 1800 ± 170

5/16 - 18 UNC 115 ± 15 105 ± 17 1186 ± 169 200 ± 25 2250 ± 280 300 ± 30 3390 ± 340

5/16 - 24 UNF 138 ± 17 128 ± 17 1446 ± 192 225 ± 25 2540 ± 280 325 ± 30 3670 ± 340

3/8 - 16 UNC 16 ± 2 16 ± 2 22 ± 3 30 ± 3 41 ± 4 43 ± 4 58 ± 5

3/8 - 24 UNF 17 ± 2 18 ± 2 24 ± 3 35 ± 3 47 ± 4 50 ± 4 68 ± 5

7/16 - 14 UNC 27 ± 3 27 ± 3 37 ± 4 50 ± 5 68 ± 7 70 ± 7 68 ± 9

7/16 - 20 UNF 29 ± 3 29 ± 3 39 ± 4 55 ± 5 75 ± 7 77 ± 7 104 ± 9

1/2 - 13 UNC 30 ± 3 48 ± 7 65 ± 9 75 ± 8 102 ± 11 105 ± 10 142 ± 14

1/2 - 20 UNF 32 ± 3 53 ± 7 72 ± 9 85 ± 8 115 ± 11 120 ± 10 163 ± 14

5/8 - 11 UNC 65 ± 10 88 ± 12 119 ± 16 150 ± 15 203 ± 20 210 ± 20 285 ± 27

5/8 - 18 UNF 75 ± 10 95 ± 15 129 ± 20 170 ± 15 230 ± 20 240 ± 20 325 ± 27

3/4 - 10 UNC 93 ± 12 140 ± 20 190 ± 27 265 ± 25 359 ± 34 374 ± 35 508 ± 47

3/4 - 16 UNF 115 ± 15 165 ± 25 224 ± 34 300 ± 25 407 ± 34 420 ± 35 569 ± 47

7/8 - 9 UNC 140 ± 20 225 ± 25 305 ± 34 430 ± 45 583 ± 61 600 ± 60 813 ± 81

7/8 - 14 UNF 155 ± 25 260 ± 30 353 ± 41 475 ± 45 644 ± 61 660 ± 60 895 ± 81

8 with Thin

Height Nuts

In-lb In-lb N-cm In-lb N-cm In-lb N-cm

10 ± 2 13 ± 2 147 ± 23

13 ± 2 25 ± 5 282 ± 30

18 ± 2 30 ± 5 339 ± 56

ft-lb ft-lb N-m ft-lb N-m ft-lb N-m

SAE Grade 1 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

15 ± 2 170 ± 20 23 ± 2 260 ± 20

29 ± 3 330 ± 30 41 ± 4 460 ± 45

42 ± 4 475 ± 45 60 ± 6 674 ± 70

SAE Grade 8 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the

minimum proof load specified in SAE J429. The

tolerance is approximately

value. Thin height nuts include jam nuts.

± 10% of the nominal torque

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

2-4 Power Max Service Manual

Page 13

SPECIFICATIONS

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws, and Studs with

Thread Size

M5 X 0.8 57 ± 5 in-lb 640 ± 60 N-cm 78 ± 7 in-lb 885 ± 80 N-cm

M6 X 1.0 96 ± 9 in-lb 1018 ± 100 N-cm 133 ± 13 in-lb 1500 ± 150 N-cm

M8 X 1.25 19 ± 2 ft-lb 26 ± 3 N-m 27 ± 2 ft-lb 36 ± 3 N-m

M10 X 1.5 38 ± 4 ft-lb 52 ± 5 N-m 53 ± 5 ft-lb 72 ± 7 N-m

M12 X 1.75 66 ± 7 ft-lb 90 ± 10 N-m 92 ± 9 ft-lb 125 ± 12 N-m

M16 X 2.0 166 ± 15 ft-lb 225 ± 20 N-m 229 ± 22 ft-lb 310 ± 30 N-m

M20 X 2.5 325 ± 33 ft-lb 440 ± 45 N-m 450 ± 37 ft-lb 610 ± 50 N-m

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Strong Nuts)

Note: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately

the nominal torque value. Thin height nuts include jam nuts.

Class 10.9 Bolts, Screws, and Studs with

Regular Height Nuts (

Class 10 or Strong Nuts)

± 10% of

2-5Power Max Service Manual

Page 14

SPECIFICATIONS

Other Torque Specifications

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 - 20 UNC 140 ± 20 in-lb 73 ± 12 in-lb

5/16 - 18 UNC 215 ± 35 in-lb 145 ± 20 in-lb

3/8 - 16 UNC 35 ± 10 ft-lb 18 ± 3 ft-lb

1/2 - 13 UNC 75 ± 15 ft-lb 50 ± 10 ft-lb

Thread Cutting Screws

(Zinc Plated Steel)

Typ e 1 , Ty pe 23, or Type F

Thread Size Baseline Torque*

No. 6 - 32 UNC 20 ± 5 in-lb

Wheel Bolts and Lug Nuts

Thread Size Recommended Torque**

7/16 - 20 UNF

Grade 5

1/2 - 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

65 ± 10 ft-lb 88 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

** For steel wheels and non-lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 ± 5 in-lb

Threads per Inch

Baseline Torque*

Type A Typ e B

No. 8 - 32 UNC 30 ± 5 in-lb

No.10 - 24 UNC 38 ± 7 in-lb

1/4 - 20 UNC 85 ± 15 in-lb

5/16 - 18 UNC 110 ± 20 in-lb

3/8 - 16 UNC 200 ± 100 in-lb

Conversion Factors

in-lb X 11.2985 - N-cm

ft-lb X 1.3558 = N-m

No. 8 15 18 30 ± 5 in-lb

No. 10 12 16 38 ± 7 in-lb

No. 12 11 14 85 ± 15 in-lb

* Hole size, material strength, material thickness and

finish must be considered when determining specific

torque values. All torque values are based on nonlubricated fasteners.

N-cm X - 0.08851 = in-lb

N-cm X 0.73776 - ft-lb

2-6 Power Max Service Manual

Page 15

SPECIFICATIONS

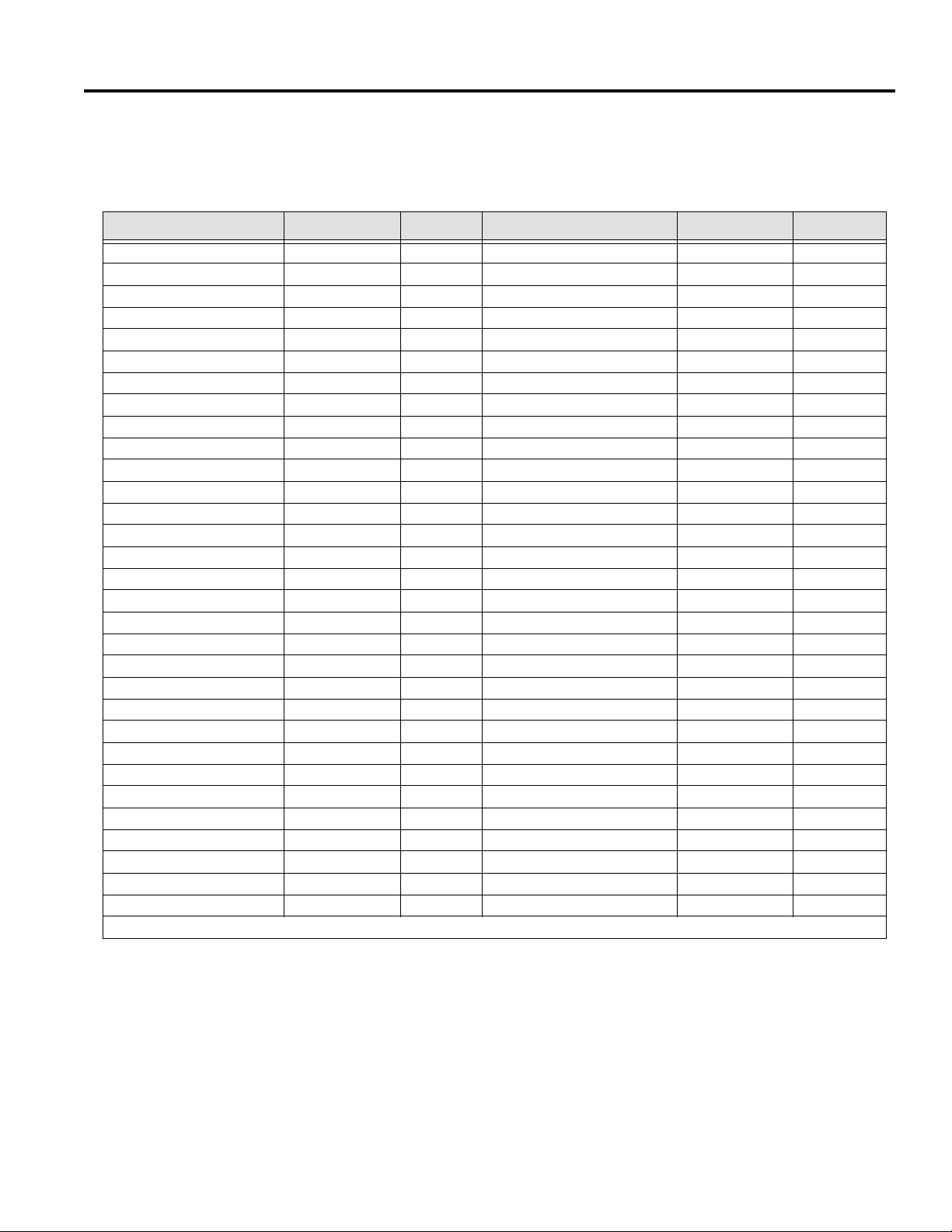

Equivalents and Conversions

Decimal and Millimeter Equivalents

Fractions Decimals mm Fractions Decimals mm

1/64 0.015625 0.397 33/64 0.515625 13.097

1/32 0.03125 0.794 16/32 0.53125 13.484

3/64 0.046875 1.191 35/64 0.546875 13.891

1/16 0.0625 1.588 9/16 0.5625 14.288

5/64 0.078125 1.984 37/64 0.578125 14.684

3/32 0.9375 2.381 19/32 0.59375 15.081

1/8 0.1250 3.175 5/8 0.6250 15.875

9/64 0.140625 3.572 41/64 0.640625 16.272

5/32 0.15625 3.969 21/32 0.65625 16.669

11/64 0.171875 4.366 43/64 0.671875 17.066

3/16 0.1875 4.762 11/16 0.6875 17.462

13/64 0.203125 5.159 45/64 0.703125 17.859

7/32 0.21875 5.556 23/32 0.71875 18.256

15/64 0.234375 5.953 47/64 0.734375 18.653

1/4 0.2500 6.350 3/4 0.7500 19.050

17/64 0.265625 6.747 49/64 0.765625 19.447

9/32 0.28125 7.144 25/32 0.78125 19.844

19/64 0.296875 7.541 51/64 0.796875 20.241

5/16 0.3125 7.541 13/16 0.8125 20.638

21/64 0.328125 8.334 53/64 0.828125 21.034

11/32 0.34375 8.731 27/32 0.84375 21.431

23/64 0.359375 9.128 55/64 0.859375 21.828

3/8 0.3750 9.525 7/8 0.8750 22.225

25/64 0.390625 9.922 57/64 0.890625 22.622

13/32 0.40625 10.319 29/32 0.90625 23.019

27/64 0.421875 10.716 59/64 0.921875 23.416

7/16 0.4375 11.112 15/16 0.9375 23.812

29/64 0.453125 11.509 61/64 0.953125 24.209

15/32 0.46875 11.906 31/32 0.96875 24.606

31/64 0.484375 12.303 63/64 0.984375 25.003

1/2 0.5000 12.700 1 1.000 25.400

1 mm = 0.03937 in. 0.001 in. = 0.0254 mm

2-7Power Max Service Manual

Page 16

SPECIFICATIONS

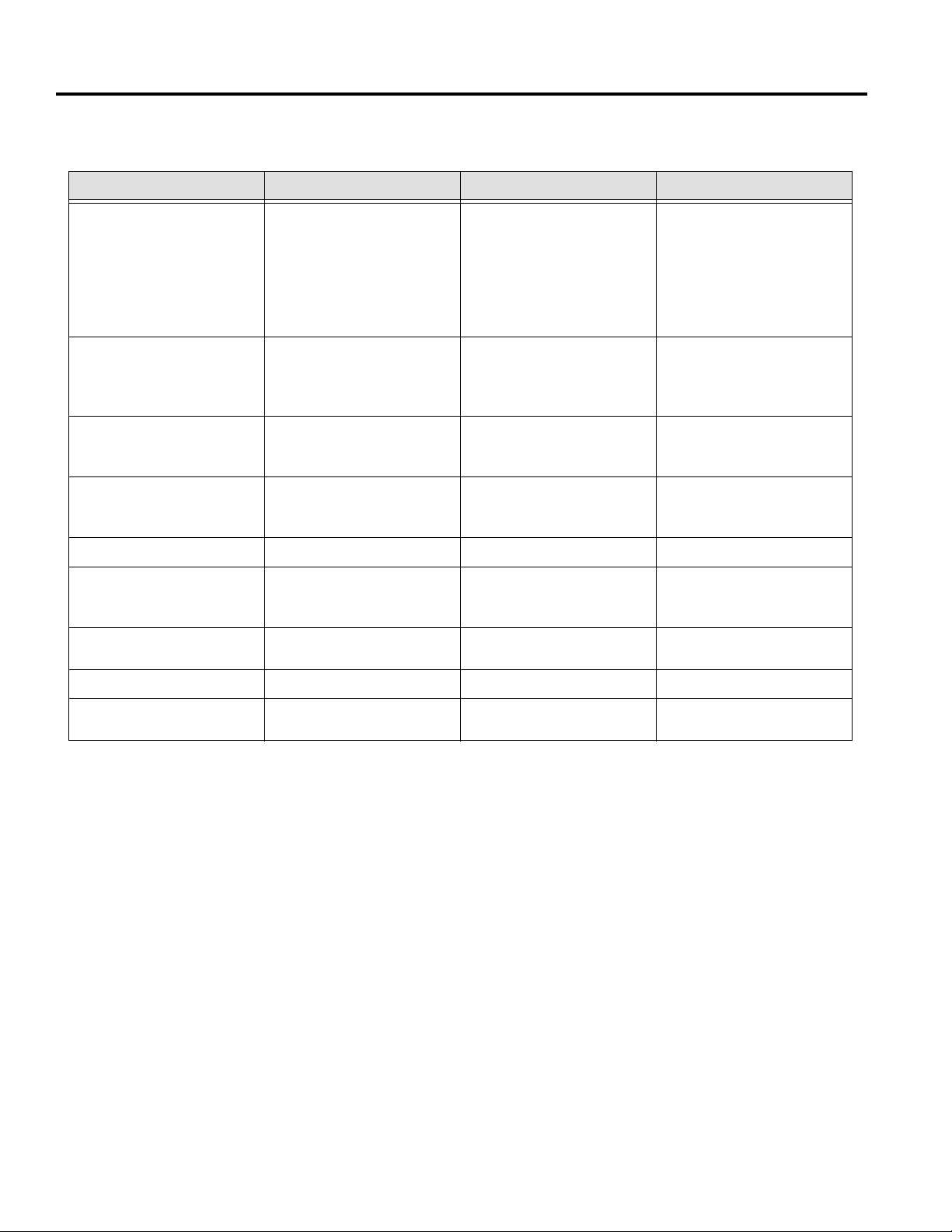

U.S. to Metric Conversions

To Conve r t Into Multiply By

Miles

Yar ds

Linear

Measurement

Area

Volume

Weight

Pressure

Work

Liquid Volume

Liquid Flows

Tempera t u re

Feet

Feet

Inches

Inches

Inches

Square Miles

Square Feet

Square Inches

Acre

Cubic Yards

Cubic Feet

Cubic Inches

Tons (Short)

Pounds

Ounces

Pounds/Sq. In. Kilopascal

Foot-pounds

Foot-pounds

Inch-pounds

Quarts

Gallons

Gallons/Minute Liters/Minute

Fahrenheit Celsius

Kilometers

Meters

Meters

Centimeters

Meters

Centimeters

Millimeters

Square Kilometers

Square Meters

Square Centimeters

Hectare

Cubic Meters

Cubic Meters

Cubic Centimeters

Metric Tons

Kilograms

Grams

Newton-Meters

Kilogram-Meters

Kilogram-Centimeters

Liters

Liters

1.609

0.9144

0.3048

30.48

0.0254

2.54

25.4

2.59

0.0929

6.452

0.4047

0.7646

0.02832

16.39

0.9078

0.4536

28.3495

6.895

1.356

0.1383

1.152144

0.9463

3.785

3.785

1. Subtract 32°

2. Multiply by 5/9

2-8 Power Max Service Manual

Page 17

ENGINE

Service Information

The Power Max snowthrowers have both 2-cycle and

4-cycle engines. The process for obtaining parts and

service information is different between them.

4-Cycle Engine

All 4 cycle models use a Tecumseh Snow King engine.

Service information can be obtained through Tecumseh

at the following address.

Tecumseh Products Company

Engine and Transmission Group

Service Division

900 North Street

Grafton, WI 53024

Phone 262-377-2700

2-Cycle Engine

All 2-cycle models use the Toro R tek engine. Service

is handled through the Toro system. Detailed engine

repair information is available in the “E” Engine Service

Manual, Form No. 492-0647.

Servicing the R tek Engine

Use the following process to service the R tek engine.

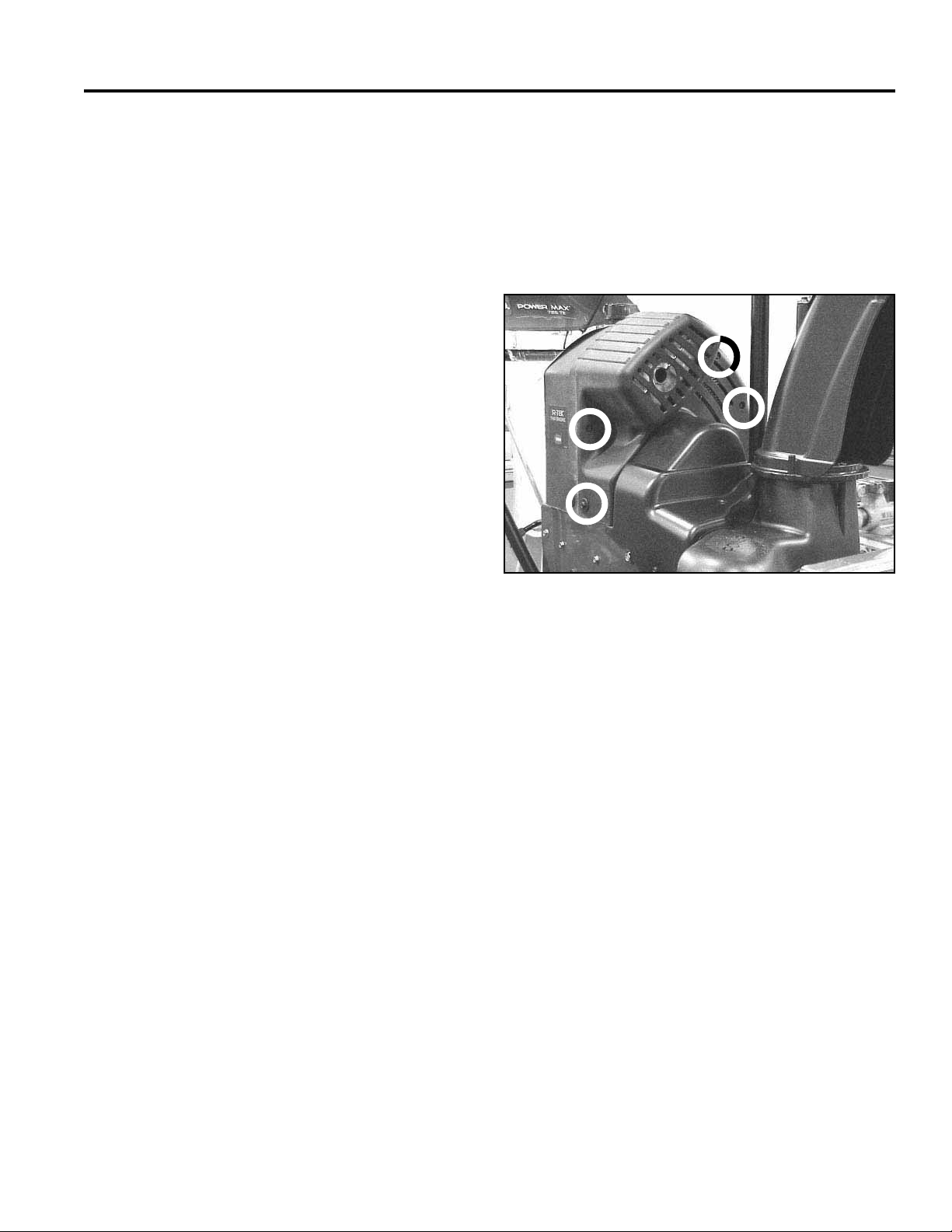

1. Remove the three screws across the front of the

engine shroud and 2 screws on each side where the

front and rear shroud meet (Fig. 003).

Fig 003 MVC-001X

2. Remove 4 screws securing the belt covers; remove

the belt covers. (Reassembly will be much easier if

the belt covers have been removed.

3-1Power Max Service Manual

Page 18

ENGINE

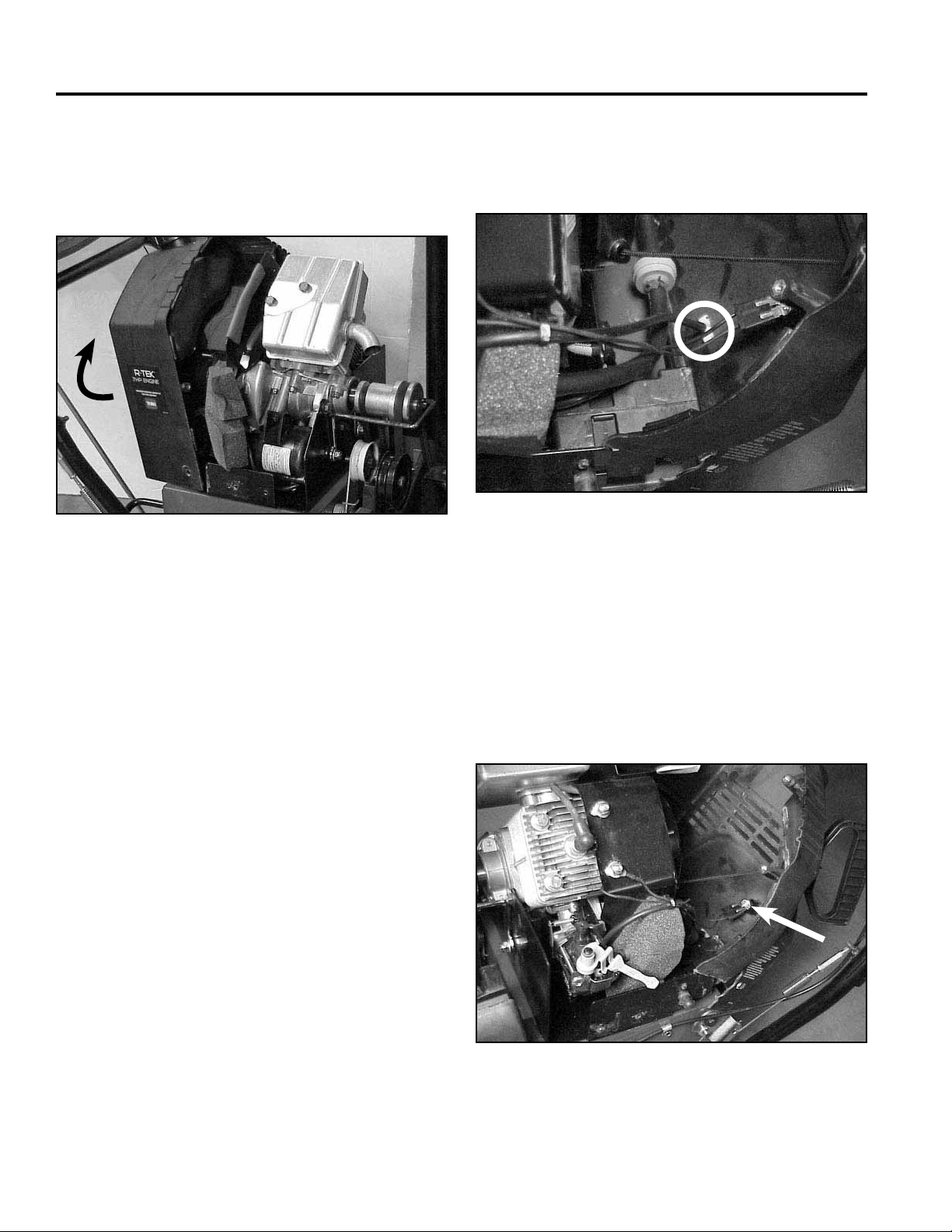

3. Pull the front shroud forward and up to remove. Slide

the rear cover to the rear and rotate it clockwise to

slip over the electric starter button and extension

cord plug located in the left rear corner (Fig. 004).

Fig 004 MVC-900XB

Primer Button

When depressed the primer button pressurizes the

carburetor bowl. Fuel is forced up the main tube to

the carburetor venturi. This line and button are the

atmospheric vent for the carburetor bowl. If the line

is kinked or the vent hole in the bulb is plugged, the

carburetor may fl ood.

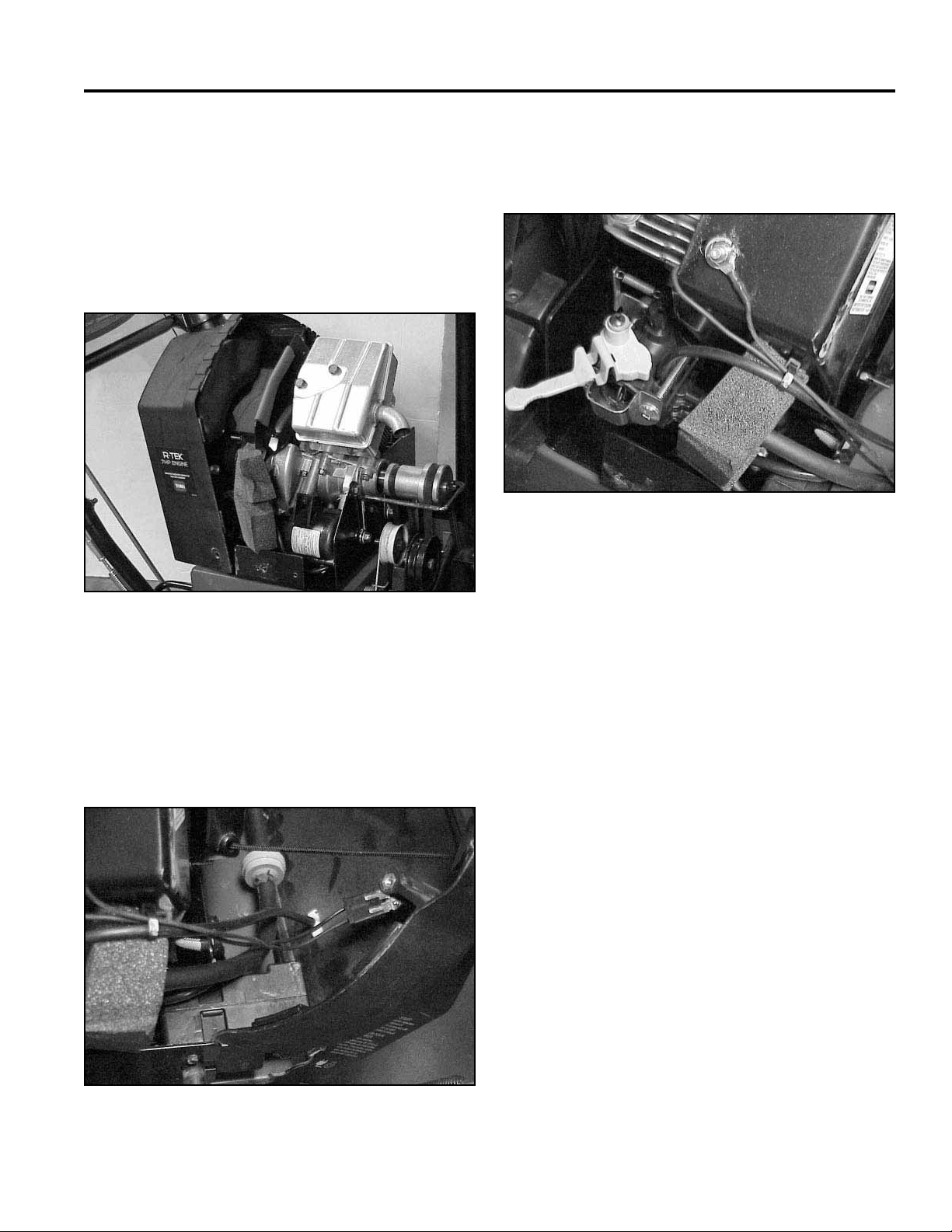

To remove the primer button, pull the primer line off the

stem and compress the tabs. The primer will push out to

the rear (Fig. 005).

Fig 005 MVC-865XA

Ignition Switch

To remove the ignition switch, pull the wire harness off

the switch terminals. The switch is a snap in type. To

remove the switch, depress the ears on the switch body

(Fig. 006) and push the switch out through the rear of

the shroud. Switch troubleshooting is provided in the

electrical section.

Fig 006 MVC-863XA

3-2 Power Max Service Manual

Page 19

ENGINE

Fuel Tank, Fuel Line and Fuel Filter

To remove the fuel tank, unscrew the gas cap, slip the

tank out of the shroud and install the cap. If there is

fuel in the tank, clamp the line, or drain the tank into a

suitable container. Remove the fuel line and fuel fi lter.

The tank is held in place by the bracket and shroud

surrounding it (Fig. 007).

Fig 007 MVC-000

Primer Line Routing

The primer line connects to the back side of the primer

then is routed over the fuel line, over the foam block

(Fig. 008).

It should be gathered and secured to the ignition switch

wires. It then goes down to the primer fi tting on top of the

carburetor (Fig. 009).

Fig 009 MVC-866XA

Engine Shroud Assembly

1. Ensure the ignition switch is in place and the wire

harness is plugged in, the primer line is attached to

the primer and the primer body is secure in its slot,

and the fuel tank, fuel line and fi lter are properly

installed.

Fig 008 MVC-865XA

3-3Power Max Service Manual

Page 20

ENGINE

2. Begin in the left rear corner; slip the shroud over

the electric start button and the plug terminal for the

extension cord (Fig. 010). Then rotate the shroud

clockwise into place.

Fig 010 MVC-893XC

3. While the engine shroud is still loose, install both belt

covers. Then install and secure the front and rear

engine covers to each other and to the chassis.

3-4 Power Max Service Manual

Page 21

CONTROLS

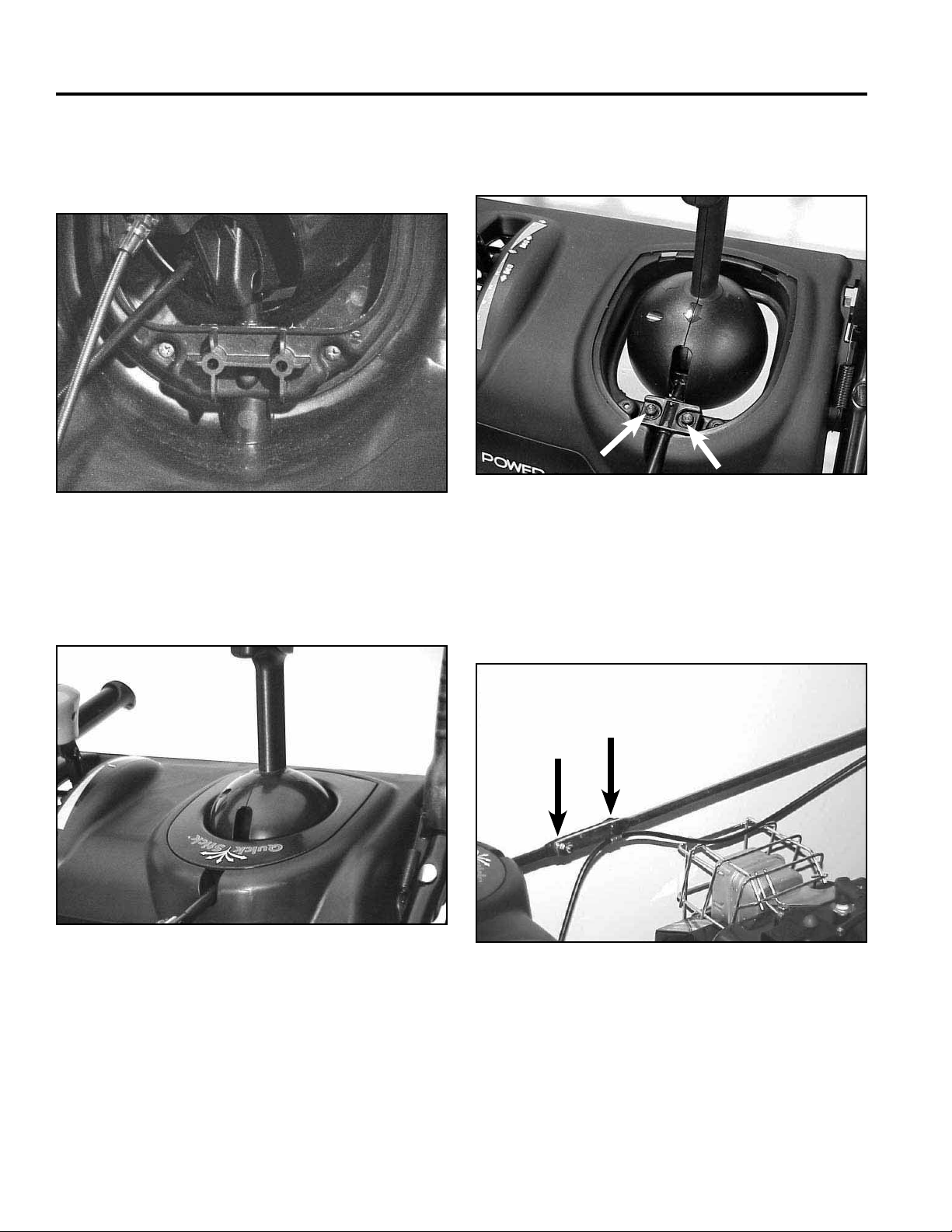

QUICK STICK

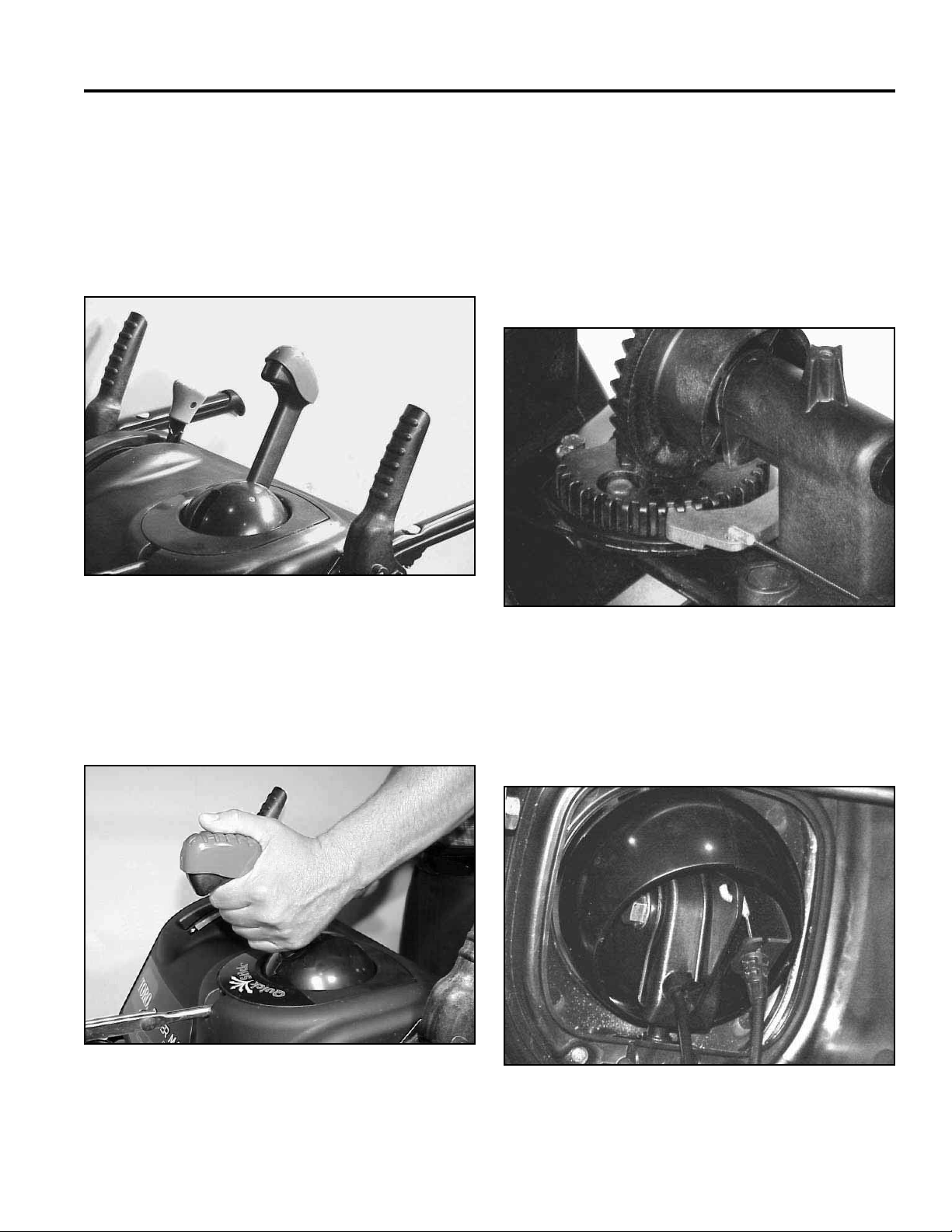

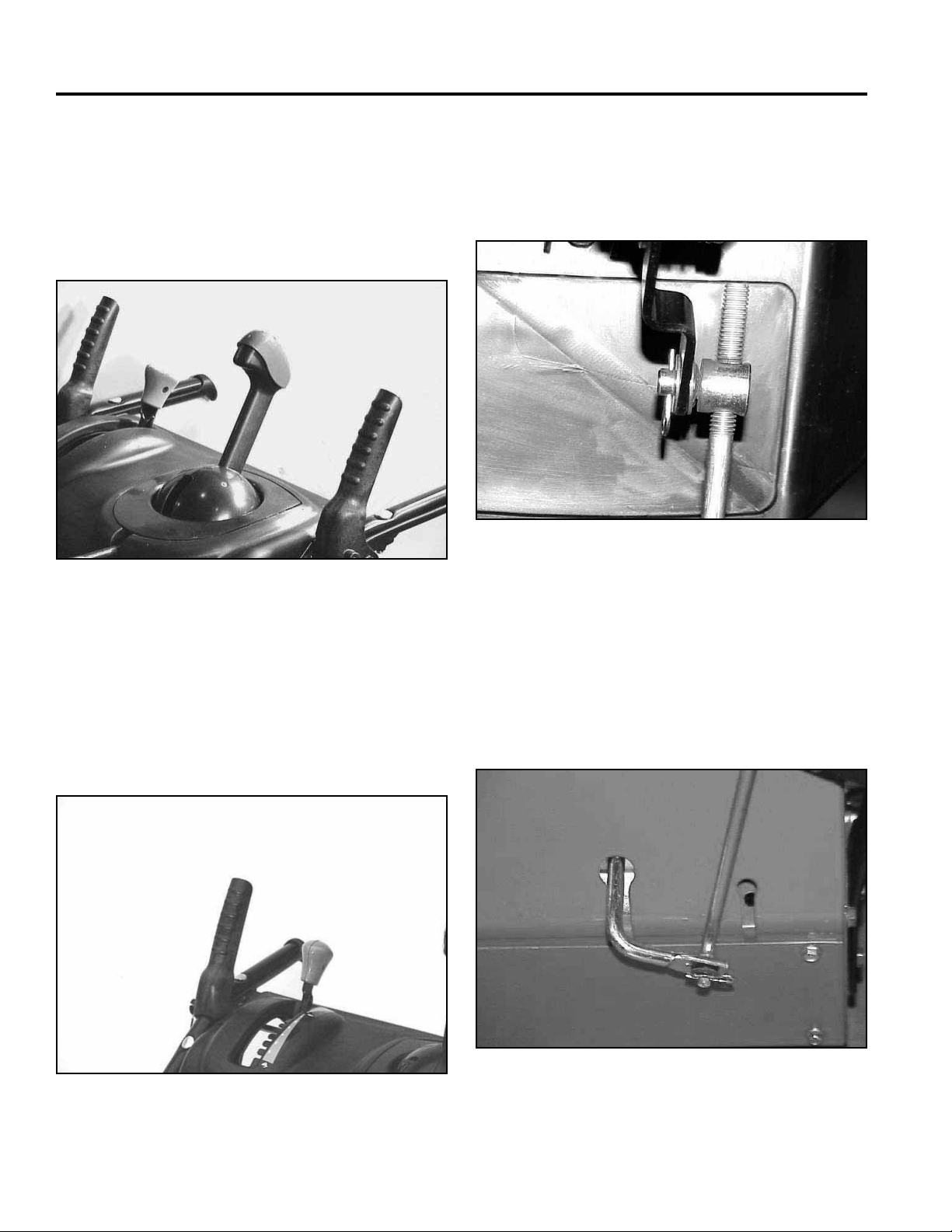

Operation

The Quick Stick is a single lever control for chute sideto-side movement and vertical movement of the defl ector

(Fig. 011).

The defl ector up and down motion is unlatched inside

the quick stick itself and a cable controls the up and

down motion.

Removing the cover just behind the chute allows access

to the chute rotation gears and chute latch (Fig. 013).

Since these gears are plastic they do not require

lubrication. The latch cable adjustment is covered in the

control adjustment section.

Fig 011 MVC-775X

When the operator places their hand on the stick the

cover is depressed, which draws a cable to unlatch the

chute (Fig. 012). Side to side motion rotates the rod and

gear and causes the chute to pivot side to side.

Fig 013 MVC-772X

Removal

1. To remove the Quick Stick, unhook the Z bend and

disconnect the defl ector cable from the underside of

the Quick Stick (Fig. 014).

Fig 012 MVC-039F

Fig 014 MVC-870XA

4-1Power Max Service Manual

Page 22

CONTROLS

2. On the underside of the control panel, remove the

two screws holding the Quick Stick cover in place

(Fig. 015).

Fig 015 MVC-1869X

3. Lift the front cover and pull forward to release the

latch tabs on the rear. Set the cover aside (Fig. 016).

4. Remove the two screws that retain the rod support

to the control panel (Fig. 017).

Fig 017 MVC-819X

5. Remove the two carriage bolts and nuts on the chute

control rod and lift the Quick Stick out of the control

panel. Note the location of the cable clamp, as it is

necessary for latch cable function (Fig. 018).

Fig 016 MVC-902X

Fig 018 MVC-725F

4-2 Power Max Service Manual

Page 23

CONTROLS

Disassembly

1. To begin disassembly of the Quick Stick, remove the

screw retaining the blue lever cap and remove the

cap (Fig. 019).

Fig 019 MVC-546F

3. Remove the locknut and fl at washer from the

shoulder bolt. Slide the chute control rod off and

remove the rubber washer and friction plate

(Fig. 021).

Fig 021 MVC-832S

2. Remove the two screws on the right hand side of the

chute control cover (the part that looks like a ball).

Remove both halves and set aside (Fig. 020).

Fig 020 MVC-547F

4. Hold the Quick Stick so the three screws holding

the handle halves are facing up. Remove the three

screws and lift off the top handle half (Fig. 022).

Fig 022 MVC-8335X

4-3Power Max Service Manual

Page 24

CONTROLS

5. Lift the metal latch pawl off the hex on the cable

lever. Lift out the latch trigger and spring. Note the

orientation of the pawl to the lever for reassembly

(Fig. 023).

Fig 023 MVC-837X

Reassembly

1. Begin assembly by dropping the latch spring over

the boss. The straight end of the spring should be

down with the hooked end up (Fig. 025).

Fig 025 MVC-759F

6. Rotate the cable until the barrel fi tting slides off the

cable lever (Fig. 024).

Fig 024 MVC-554F

2. Slide the latch trigger over the boss until it is fully

seated, making sure that the stop on the trigger

lever is above the stop on the quick lever, as shown.

While holding the trigger lever in place, rotate the

hooked end of the spring until it hooks under the

front edge of the trigger lever as shown (Fig. 026).

A

Fig 026 MVC-758F

A. Latch trigger

4-4 Power Max Service Manual

Page 25

CONTROLS

3. Reverse the disassembly process for the remainder

of the assembly.

Installation

Reverse the removal process for installation.

Note: The cable clamp must be installed on the

chute control rod or the cable latch will not

function.

CONTROL INTERLOCK

For operator convenience there is an interlock between

the auger and traction lever. Once both are engaged

you only need to hold the auger lever. This allows a

free hand to change chute direction without having to

stop. The latch mechanism is located under the dash

(Fig. 027).

Disassembly

1. Disconnect the auger and traction cables from the

levers. If this is a wheel clutch model, disconnect the

wheel clutch cables (Fig. 028).

Fig 028 MVC-171X

Fig 027 MVC-872X

2. Remove the Shoulder Screw under the left handgrip

(Fig. 029). When it is removed the Lockout Latch,

Torsion Spring, Flat Washer, and Locknut will drop

out.

Fig 029 MVC-167X

4-5Power Max Service Manual

Page 26

CONTROLS

3. To remove the lockout rod, go to the right hand end.

There are 2 roll pins on the right side (Fig. 030) and

one in the lockout cam on the left (Fig. 031).

Fig 030 MVC-169X

4. Once they are driven out the lockout rod can be

moved to the side and removed (Fig. 032). The

lockout link can now be removed from the lockout

rod.

Fig 032 MVC-172X

Fig 031 MVC-170X

5. Since the auger and traction levers pivot on the

lockout rod this is the method required to replace the

levers (Fig. 033).

Fig 033 MVC-174X

Note: Steps 1 and 2 above do not need to be done

in that order. In fact you can remove the rod

without removing the shoulder bolt and vice

versa.

4-6 Power Max Service Manual

Page 27

CONTROLS

Assembly

Reverse the above process for assembly.

Note the spring on the lockout latch. The end with the

slight bend goes behind the lockout latch and the hooked

end goes over the small tab. It is easiest to install the

latch mechanism then hook the end of the spring with a

wire and pull it into place (Fig. 034).

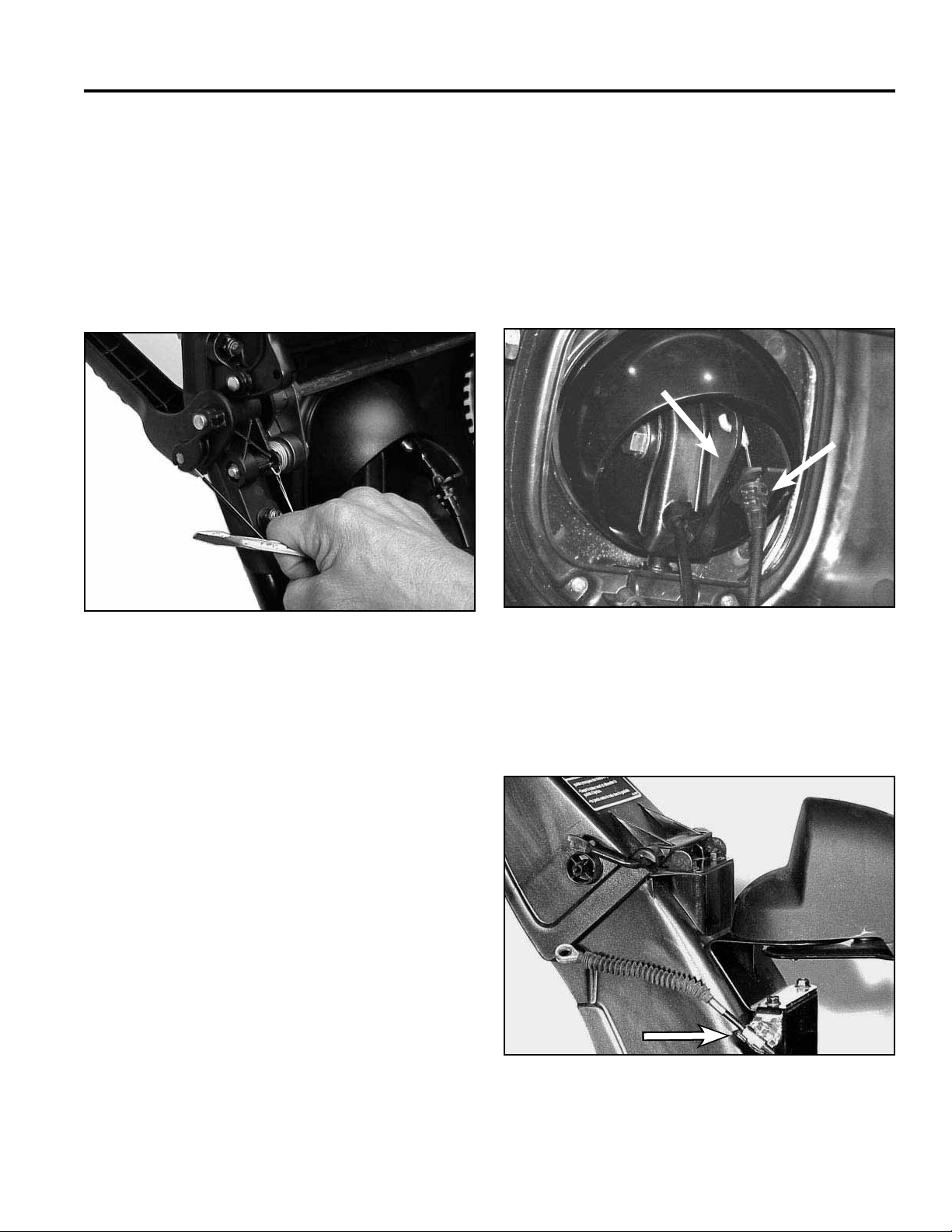

CONTROL OPERATION,

REPLACEMENT, AND ADJUSTMENT

Defl ector Cable

1. To remove the defl ector cable, depress the tabs that

retain the cable in the bracket, under the control

panel. Disconnect the Z bend on the end (Fig. 035).

Fig 034 MVC-176X

Fig 035 MVC-870X

2. Remove the cable clamp and disconnect the cable

end from the defl ector. Reverse this process to

install a new cable (Fig. 036).

Fig 036 MVC-882X

4-7Power Max Service Manual

Page 28

CONTROLS

Defl ector Cable Adjustment

Make sure the Quick Stick is in the maximum rear

position and centered (Fig. 037); ensure the defl ector

is in the full upward position. Draw the slack out of the

cable and secure the clamp (Fig. 036).

Fig 037 MVC-775X

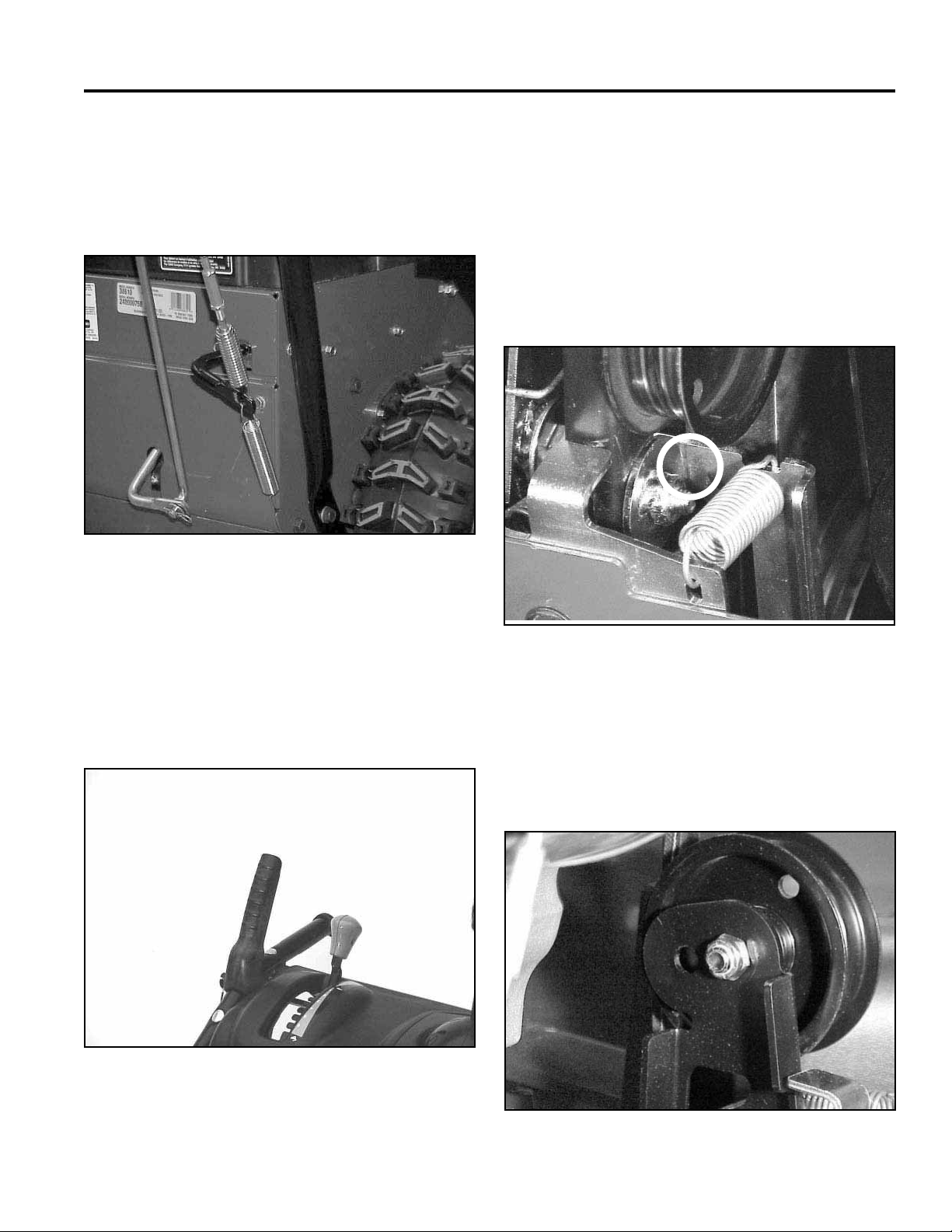

Shift Rod Adjustment

1. The adjustment point is a trunion on the upper end

of the shift rod (Fig. 039).

Fig 039 MVC-561F

SHIFT LEVER

The shift lever on the control panel is connected to the

friction wheel in the traction drive by a shift rod. Moving

the shift lever moves the friction wheel to change wheel

direction and speed (Fig. 038).

2. Pull the shift rod and arm upward as far as they will

go. With the shift lever in R2, adjust the trunion to

take the slack out and resecure (Fig. 040).

Note: Excessive slack in the linkage may cause the

drive to be in reverse when shifted into fi rst

gear.

Fig 040 MVC-560F

Fig 038 MVC-901XA

4-8 Power Max Service Manual

Page 29

CONTROLS

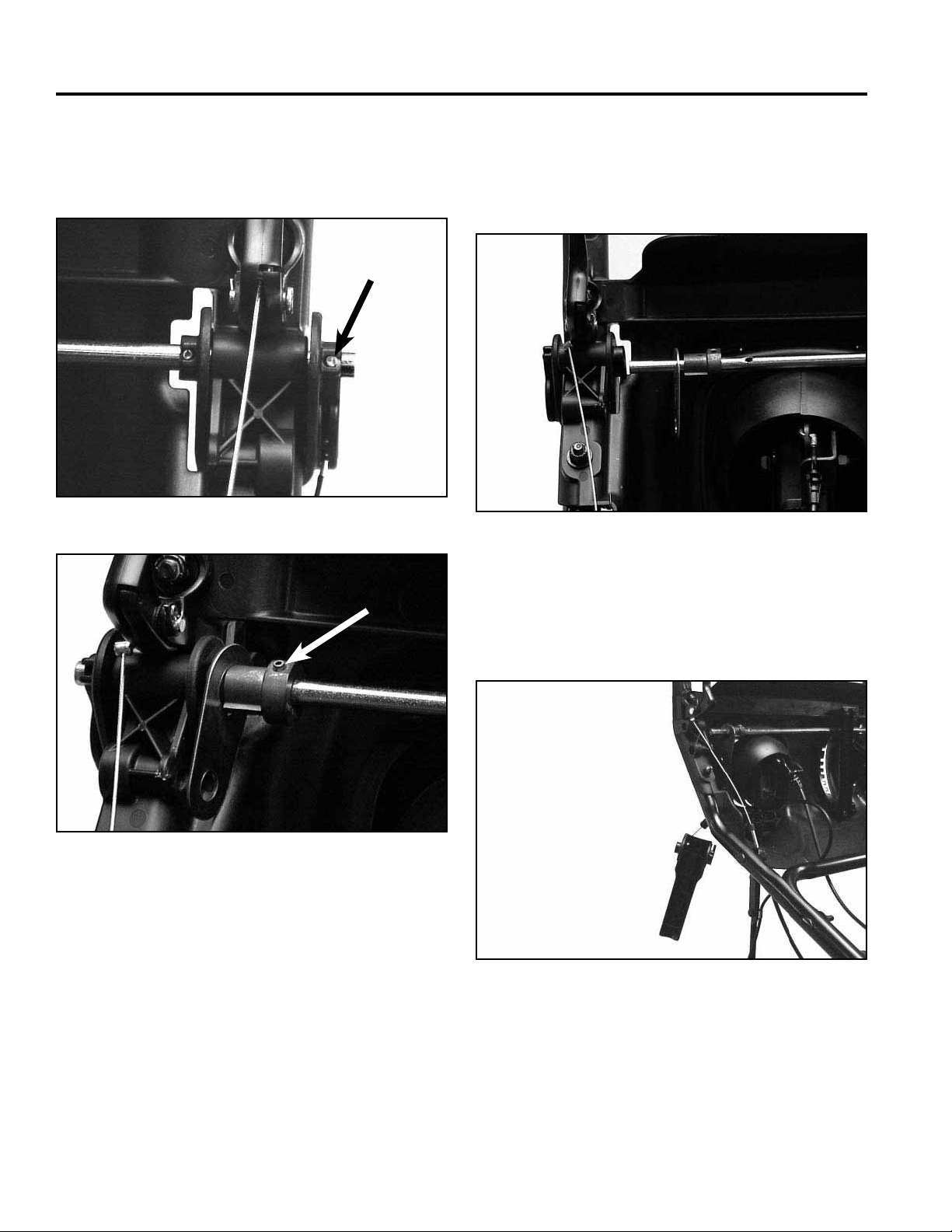

Auger Control

The bail on the right hand handle is the auger control.

Squeeze the bail and the cable causes an idler to pivot

tensioning the auger belt (Fig. 041).

Fig 041 MVC-816X

2. Loosen the jam nut. The cable is adjusted using the

turnbuckle on the lower end of the auger cable.

Note: When rotating the turnbuckle, hold the cable

so it does not twist (Fig. 041).

3. Remove the right side belt cover. Adjust the

turnbuckle until there is a 1/16” (1.5mm) gap

between the stop and the auger clutch assembly.

Secure the jam nut on the turnbuckle (Fig. 043).

Auger Cable Adjustment

1. The auger cable adjustment should be checked after

the fi rst 2 hours of use and annually thereafter. To

begin, ensure the auger lever is in the full up position

(Fig. 042).

Fig 042 MVC-901XA

Fig 043 MVC-876X

Beginning with 2005 production there are two holes

in the idler arm (Fig. 044). The idler pulley is initially

installed in the outer hole. If necessary, the idler

can be moved to achieve the correct tension. 2004

models have only one hole in the idler.

Fig 044 MVC-016X

4-9Power Max Service Manual

Page 30

CONTROLS

To determine if the pulley should be moved, proceed

as follows: remove the right side belt cover. With the

engine off, engage the auger lever. If there is more than

1” 2.5cm) gap between the idler arm and the stop, move

the pulley to the inner hole (Fig. 045). If the gap is less

than 1” (2.5cm) keep the pulley in the outer hole.

Note: If you move the idler pulley, it will be

necessary to readjust both the auger brake

and the auger cable.

If adjustment is necessary, loosen the bolt through the

welded washer/nut and rotate the washer/nut to achieve

the gap. Secure the bolt (Fig. 046).

Fig 046 MVC-876X

Traction Control

Fig 045 MVC-892XA

Auger Brake Adjustment

1. As the auger cable is adjusted to maintain proper

belt tension, the idler will move towards the brake

arm. The gap between the idler arm and brake arm

may be reduced. Periodically, verify the gap as

follows to make sure the brake engages properly.

2. Remove the belt cover and check the gap between

the welded washer/nut assembly and the brake arm

tab.

The gap should be .100” (2.5mm)

The traction bail is on the left handle and when

squeezed engages the wheel drive system (Fig. 047).

Fig 047 MVC-899XA

4-10 Power Max Service Manual

Page 31

Traction Cable Adjustment

1. The traction lever should be in the full upright

position with some slack in the traction cable to

begin adjustment (Fig. 047).

2. Adjust using the turnbuckle; hold the cable to

prevent twisting (Fig. 048).

CONTROLS

Fig 049 MVC-895X

REPLACE AND ADJUST WHEEL

CLUTCH CABLES (wheel clutch

models only)

Fig 048 MVC-894X

3. Locate the traction rod on the left side just below the

belt cover.

Adjust the cable turnbuckle until there is a slight gap

between the end of the rod and the front of the slot

(maximum 1/16” [1.5mm]). Secure the jam nut on

the turnbuckle (Fig. 049). The left hand belt cover

has been removed only for clarity.

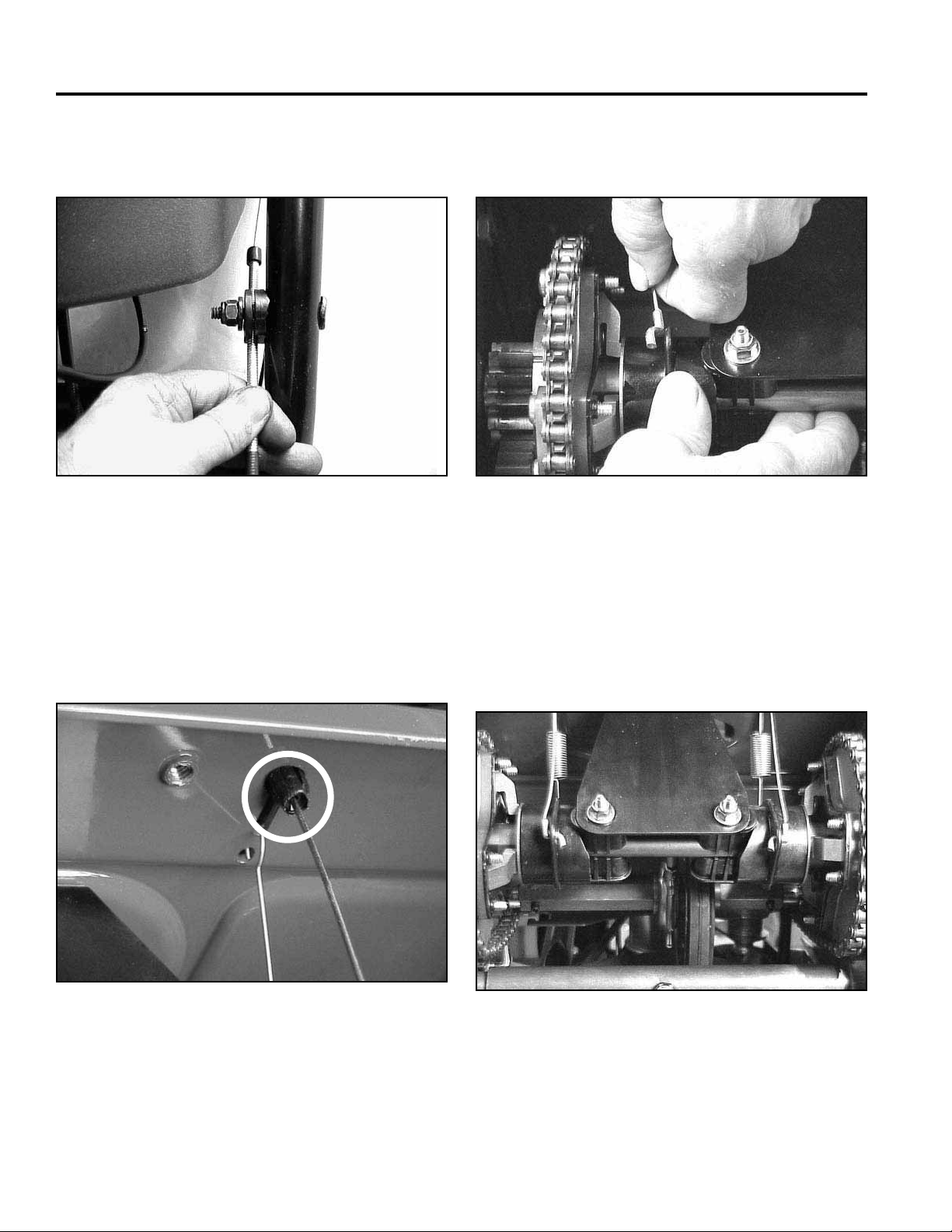

Clutch Cable Replacement

1. To replace the clutch cables, drain the fuel tank and

stand the machine on the auger. Remove both lower

covers (Fig. 050). The wheels and the bottom cover

can also be removed if desired.

Fig 050 MVC-892X

4-11Power Max Service Manual

Page 32

CONTROLS

2. Remove nut and washer that attach the cable clamp

to the handle (Fig. 051).

Fig 051 MVC-889XYL

3. Slip the cable Z bend out of the wheel clutch lever

on the handle.

4. Reach under the shift plate and compress the small

ears on the cable fi tting (Fig. 052). The cable fi tting

can then be pushed out of the shift plate.

5. Disconnect the lower end of the cable from the shift

collar (Fig. 053).

Fig 053 MVC-898XB

Assembly

1. Feed the lower end of the cable through the shift

plate and snap the cable into the plate. Install the

lower end of the cable into the shift collar outside in,

as shown (Fig. 054).

Fig 052 MVC-899X

4-12 Power Max Service Manual

Fig 054 MVC-878XYZ1

Page 33

CONTROLS

2. Hook the upper end of the cable to the wheel clutch

lever and install the cable clamp to the handle.

Go to Adjusting Clutch Cables for the adjustment

procedure before securing the clamp.

3. Install the covers and test run the unit.

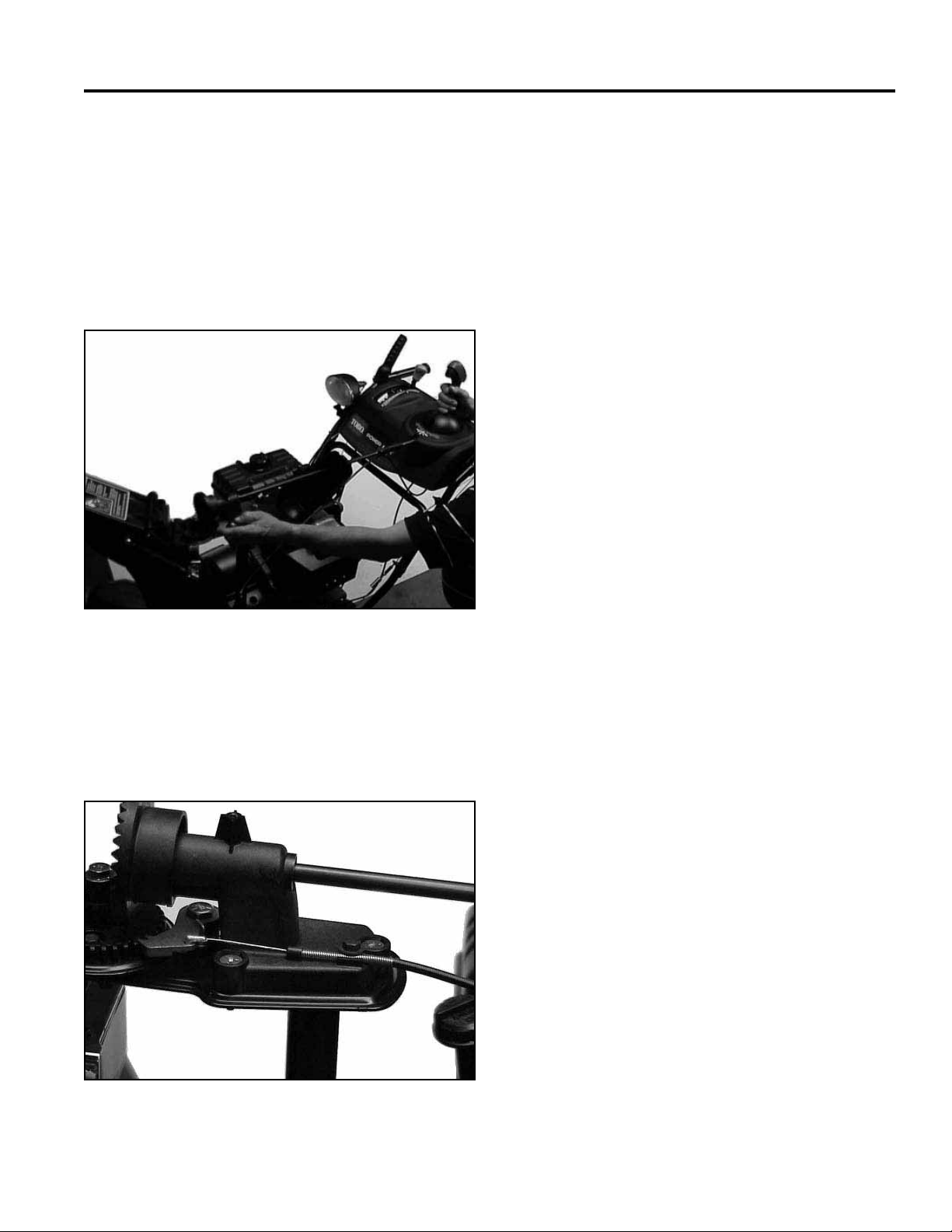

Adjusting Clutch Cables

1. Loosen the cable clamp nut (Fig. 055).

2. Pull the cable jacket down gently until the wheel

clutch lever is down and the slack is out of the

cable, and then tighten the cable clamp nut securely

(Fig. 056).

Fig 056 MVC-889XYL

Fig 055 MVC-889XYL

3. Squeeze the lever fully, and then check the gap

between the bottom of the handle and the wheel

clutch lever end.

Note: The gap should be approximately 1/4 inch

(6mm). If it is greater, loosen the cable clamp

nut, slide the cable jacket up slightly, tighten

the cable clamp nut, and check the gap again.

Repeat steps for other cable (Fig. 057).

Fig 057 MVC-891XLY

4-13Power Max Service Manual

Page 34

THIS PAGE INTENTIONALLY LEFT BLANK

4-14 Power Max Service Manual

Page 35

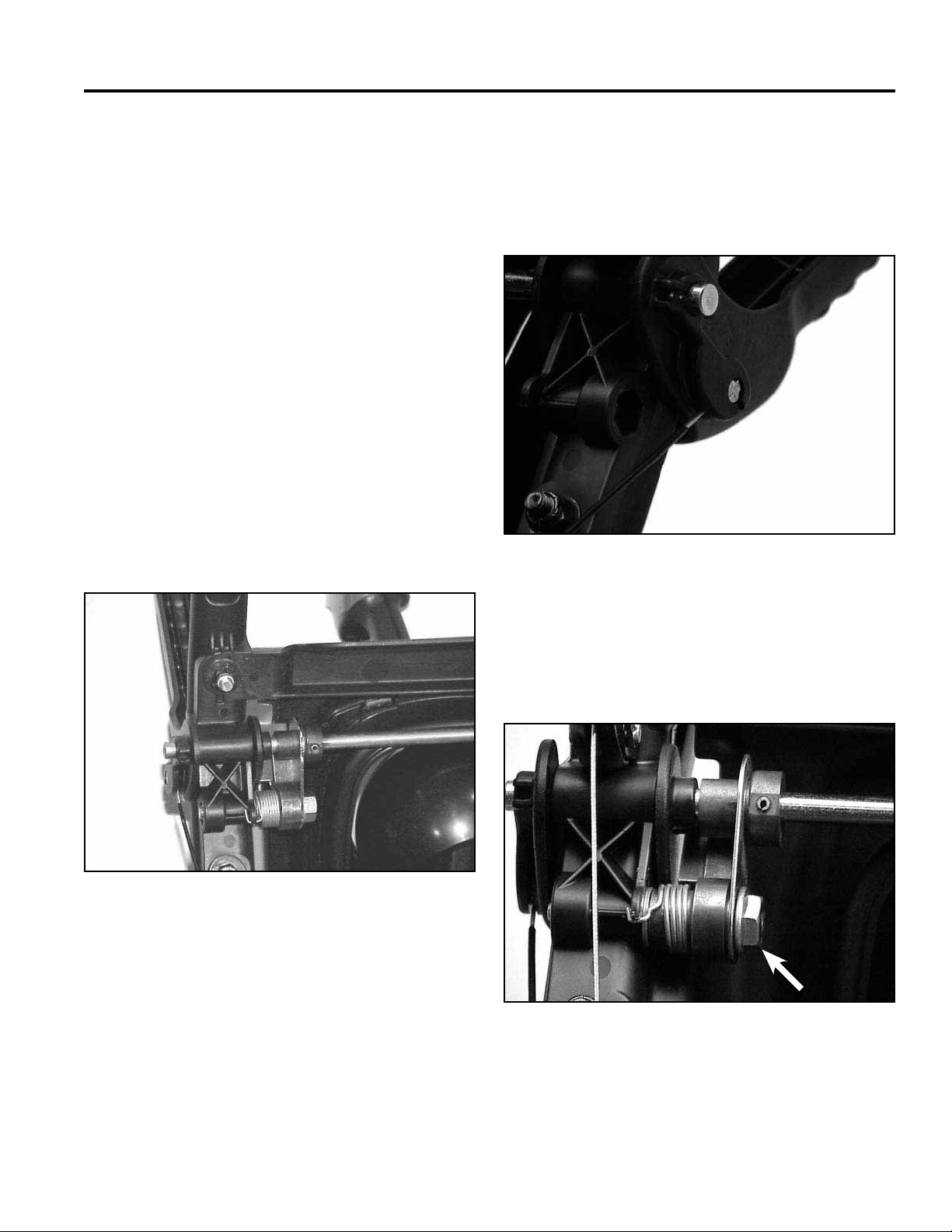

BELT REPLACEMENT

AUGER BELT

1. To replace the belts begin by removing both belt

covers (Fig. 058). (On 2-cycle models only, remove

3 screws holding the front half of the engine shroud

to the chassis and the rear shroud. The belt cover

slides under the front of the engine shroud so this

will make belt cover removal much easier.)

3. Remove the brake assembly for more working room.

Disconnect the spring, then remove the two bolts

through the side plate (Fig. 060).

B

A

C

Fig 060 MVC-1883X

A. Spring C. Bolts

B. Brake Assembly

Fig 058 MVC-006XB

2. Remove the belt guide. Be careful to avoid bending

the guide (Fig. 059).

Fig 059 MVC-007F

4. The brake assembly can be lifted out of the chassis

(Fig. 061).

A

Fig 061 MVC-067X

A. Brake Assembly

5-1Power Max Service Manual

Page 36

BELT REPLACEMENT

(Fig. 064)

5. Remove the bolt securing the engine pulley to

the crankshaft. If necessary, you can hold the

hub between the pulley and engine to keep the

crankshaft from turning. Remove the pulley fl ange

and the auger belt from the crankshaft (Fig. 062).

Fig 062 MVC-747X

TRACTION BELT

To replace the traction belt, perform steps 1-5 above to

remove the auger belt. Then proceed with the following

steps.

1. Slip the center section of the crankshaft pulley off

the crankshaft

(Fig. 064).

6. The auger belt can now be removed from the

impeller pulley (Fig. 063).

Fig 063 MVC-886XB

Reverse the process to install a new belt. Use Loctite

242 and torque the engine pulley to 29 ft-lbs. (39.3 Nm)

Fig 064 MVC-887X

2. On the left side of the machine, remove the hairpin

cotter from the speed control link (Fig. 065).

Fig 065 MVC-897X

5-2 Power Max Service Manual

Page 37

BELT REPLACEMENT

3. Move the link to the side and let it rest in the saddle

provided (Fig. 066). Reach down alongside the link

and remove the belt from the lower pulley. Then

remove the belt from the crankshaft pulley.

Fig 066 MVC-888XB

Belt Adjustment

Belt adjustments are made by adjusting the control

cables. See the Controls Section for the procedure.

4. Reverse the process to install a new belt.

5. Check for proper clearance between the belt and

belt guide. Engage the auger belt and look between

the belt and belt guide on the left side. There should

be about 1/8” (3.2mm) gap (Fig. 067). Tighten the

belt guide mounting bolts.

Fig 067 MVC-822X

5-3Power Max Service Manual

Page 38

THIS PAGE INTENTIONALLY LEFT BLANK

5-4 Power Max Service Manual

Page 39

AUGER HOUSING

AUGER HOUSING COMPONENTS SCRAPER

The Power Max snow throwers are offered in two widths:

26” and 28” (66cm and 71cm). The augers, auger shaft,

housing, and scrapers are made in both widths, but all

other auger components are the same. The auger case

halves, gears, impeller and impeller shaft, chute, etc. are

interchangeable.

Removal of the auger and traction system components

from the auger housing is covered in the Auger Gearbox

Section and in the two traction drive systems sections

(non-wheel clutch and wheel clutch).

SKIDS

The skids are located on each side of the auger. The

skids are intended to be the component that touches

the ground and supports the auger. They are also the

means to adjust the auger height for different conditions

(Fig. 068).

The scraper is a replaceable surface attached to the

leading edge of the auger housing. It is a wear part and

will need to be replaced periodically in the life of the

machine. There are two types of scrapers, fi xed and

pivoting.

Fixed Scraper

Because the fi xed scraper is bolted solidly to the auger

housing it is intended to be raised slightly off the ground

to minimize catching on pavement cracks and solid

objects. The amount that it should be raised depends on

how rough the ground is. The scraper is adjustable as

the mounting holes are slotted (Fig. 069).

Fig 068 MVC-769X

See the scraper adjustment procedure to adjust the

skids.

Note: The skids are reversible. When one side

becomes worn out, remove the skid and turn

it over for a new surface.

Fig 069 MVC-896X

Scraper Replacement

The scraper is attached with fi ve carriage head bolts with

locknuts. Install the new scraper but do not tighten the

bolts until the scraper is adjusted.

6-1Power Max Service Manual

Page 40

AUGER HOUSING

Adjusting the Skids and Scraper - Fixed

Scraper models

1. Check the tire pressure. It must be between 17 and

20 psi (116-137 kPa) and the same on both sides so

the machine sets level.

2. Loosen the nuts that secure both skids so the skids

can slide up and down easily.

3. Support the side plates so they are at least ½”

(13mm) above a level surface (Fig. 070).

1/2”

(13mm)

Pivoting Scraper

A pivoting scraper is more complex but has advantages

when used on paved surfaces. It can be set to scrape

down to the surface. Should it hit something solid, it

will slide rearward; two springs return it to the operating

position once it clears the object. However, use on a

gravel driveway may jam or damage the scraper, as

rocks can be forced between the scraper and housing.

Therefore, the pivoting scraper should not be used on

gravel surfaces (Fig. 071).

Fig 070 m-6938

4. Adjust the scraper to a minimum of 1/8” (3.2mm)

above and parallel to a level surface. Secure with

carriage bolts and locknuts.

5. Move the skids down until they are even with the

ground.

6. Firmly tighten the nuts securing both skids to the

auger sides.

7. Check to ensure that the rotating part of the auger

does not touch the ground. This can damage the

pavement as well as the auger.

Important: If the machine is to be used on rough,

broken or uneven pavement, adjust the skids to raise

the scraper. For gravel surfaces, adjust the skids further

down to prevent the snowthrower from picking up rocks.

Fig 071 MVC-761X

Scraper Replacement and Adjustment

The scraper pivots on the auger shaft bearings on each

side of the auger. It is necessary to remove the auger

assembly to replace the scraper. See auger gearbox

removal.

6-2 Power Max Service Manual

Page 41

Adjusting the Skids and Scraper - Pivoting

Scraper Models

1. Check the air pressure in the tires. They must be

between 17 and 20 psi (116-137 kPa) and the same

on both sides so the machine sets level.

2. Move the snowthrower onto a level surface.

3. Loosen the nuts that secure both skids to the auger

sides until the skids slide up and down easily.

4. For use on a smooth paved surface, push down on

the handles to raise the auger. This will allow the

scraper to move fully forward. Set the auger down so

the scraper contacts the ground.

5. Move the skids down until they contact the ground

and secure them.

Note: If the surface that this machine will be used

on is really smooth, the skids can be raised

slightly, approximately 1/8-1/4” (3-6mm) to

increase the scraping action.

AUGER HOUSING

If you must use a pivoting scraper on a gravel

surface, set the skids all the way down,

raising the auger to prevent the scraper from

picking up rocks.

6. Check to ensure the rotating part of the auger does

not touch the ground. This can damage the auger as

well as the pavement.

6-3Power Max Service Manual

Page 42

THIS PAGE INTENTIONALLY LEFT BLANK

6-4 Power Max Service Manual

Page 43

AUGER GEARBOX

The auger gearbox contains a worm gear and a helical

gear. It is driven by a clutched belt from the engine.

The fi rst step in making repairs to the auger gearbox is

to remove the auger assembly from the auger housing.

AUGER GEARBOX REMOVAL,

PRIMARY METHOD (MINIMUM

DISASSEMBLY)

1. (2-cycle models only) Remove the 3 screws

connecting the front and rear engine cover. Also

remove two screws, one on each side, from the

lower rear edge of the front cover. If the front engine

cover is loose it will make removing the belt cover

much easier (Fig. 072).

2. (All models) Remove the two-piece belt cover

(Figs. 073 and 074).

Fig 073 MVC-006XB

Fig 072 MVC-000

Fig 074 MVC-005X

7-1Power Max Service Manual

Page 44

AUGER GEARBOX

3. Remove the belt guide around the crankshaft pulley

(Fig. 075). Be careful to avoid bending the guide.

Fig 075 MVC-007F

4. Remove 2 capscrews for the auger brake assembly

(Fig. 076).

5. Remove the brake spring (Fig. 077).

Fig 077 MVC-008X

6. Remove the auger brake assembly (Fig. 078).

Fig 078 MVC-067X

Fig 076 MVC-1883X

7-2 Power Max Service Manual

Page 45

AUGER GEARBOX

7. Remove the crankshaft pulley capscrew (Fig. 079),

the front section of the pulley and the belt.

Fig 079 MVC-011X

8. Loosen the 2 set screws on the auger pulley. A long

extension and a ratchet will be necessary

(Fig. 080).

9. Remove two capscrews on each side that secure the

auger bearings to the auger side plate (Fig. 081).

Fig 081 MVC-769X

10. Disconnect the spring on both ends of the pivoting

scraper (Fig. 082).

Fig 080 MVC-003F

Fig 082 MVC-787F

7-3Power Max Service Manual

Page 46

AUGER GEARBOX

11. Pull the auger forward a little, slide the pulley from

the auger gearbox input shaft and pull the key out of

the shaft. The auger assembly should pull out to the

front.

Note: If you cannot remove the pulley from the input

shaft, it will be necessary to separate the

auger and traction assemblies to get better

access to the auger pulley. See Separating the

Auger and Traction Assemblies, page 7-4.

12. Slide the bearing off each end of the auger shaft.

If this model has a pivoting scraper, it can now be

removed.

13. Remove the capscrew connecting each auger to

the auger shaft and slide the auger off the shaft

(Fig. 083).

SEPARATING THE AUGER

AND TRACTION ASSEMBLIES

SECONDARY METHOD

Should you be unable to remove the pulley from the

auger gearbox input shaft, it will be necessary to

separate the auger and traction assemblies. After

performing steps 1-7 listed above, proceed as follows:

1. Disconnect the defl ector cable from the defl ector

(Fig. 084).

Fig 083 MVC-900XA

14. The auger gearbox is now ready for disassembly

and repair.

Fig 084 MVC-771X

2. Remove the cover over the chute gears. Free the

chute latch cable from its clamp and disconnect the

chute latch cable (Fig. 085).

Fig 085 MVC-774X

7-4 Power Max Service Manual

Page 47

AUGER GEARBOX

3. Remove the two carriage bolts on the chute control

rod (Fig. 086).

Fig 086 MVC-725F

4. Support the auger and traction with blocks of wood.

5. Remove three capscrews down each side

connecting the auger to the traction assembly and

separate the sections (Fig. 087).

GEARBOX INSTALLATION

1. Apply a light coat of anti-seize to the auger shafts

and the impeller shaft. Install the impeller and

augers and secure with the capscrews and locknuts.

On models with the pivoting scraper, install the

scraper over the ends of the auger shaft. Slide the

auger shaft bearings on the ends of the auger shaft.

2. Insert the impeller shaft through the bearing in the

rear of the auger housing. The bearing mounting

bolts should be slightly loose at this time. (Note: if

the auger and traction assemblies are connected,

apply a light coat of anti-seize to the impeller shaft

and install the auger pulley at this time. If not, the

pulley can be installed in step 5.)

3. Secure the auger shaft bearings to the auger side

plates with 2 capscrews on each side. On models

with the pivoting scraper, install the scraper springs.

4. To ensure the impeller shaft bearing has aligned

itself with the shaft, strike it a couple of times with a

rubber mallet. If the auger and traction assemblies

are not separated, use a block of wood. Place it on

the auger shaft and strike the wood with a hammer.

The jolt to the shaft aligns the bearing. Secure the

bearing.

Fig 087 MVC-1135X

6. Once separated, the auger pulley is in the open.

Once the pulley and key have been removed,

perform the preceding steps 12-14 to complete

auger removal.

5. Apply a light coat of anti-seize to the impeller shaft

and install the impeller pulley. Push the auger shaft

to the rear and push the pulley forward and secure.

There should be no more than 1/8” (3mm) front to

back movement in the shaft.

7-5Power Max Service Manual

Page 48

AUGER GEARBOX

AUGER GEARBOX REPAIR

Lubrication

The proper lubricant is 90-weight gear oil. A multi-weight

such as 85-120 is acceptable as long as it encompasses

the 90-weight rating. The oil must also have an extreme

pressure (EP) rating of GL5 or higher. With the gearbox

setting approximately level, fi ll until oil runs out of the fi ll/

check plug. Total capacity is about 4 oz. (118ml).

Gearbox Disassembly and Repair

1. All models use a cap screw and locknut to secure

the augers to the auger shaft. Remove the cap

screw and slide the auger off of the shaft (Fig. 088).

4. The impeller shaft can now be removed (Fig. 089).

A

B

C

Fig 089 DSC-0061

A. Ring C. Worm gear

B. Impeller Shaft/Worm

Fig 088 MVC-900XA

2. The impeller is attached to the impeller shaft with

two cap screws and locknuts. Remove the cap

screws and slide the impeller off of the shaft.

3. Even if you have drained the oil, we recommend

supporting the gearbox over a drain pan when you

separate the case halves. Remove the screws and

separate the case halves.

5. Clean the output shaft and slide the case halves off.

Remove and discard the seals.

6. Clean and inspect the auger shaft bushings in the

case halves. If they are damaged or worn, press

them out of the case halves at this time.

7. Slide the worm gear off of the shaft. Remove the

woodruff key.

8. Slide the bushing, thrust washers, thrust bearing,

snap ring, and seal from the impeller shaft.

7-6 Power Max Service Manual

Page 49

AUGER GEARBOX

9. Now inspect the worm and worm gear. If either

are damaged replace them both. When gears run

together, they develop wear patterns unique to the

two of them. Replacing only one gear will result in

early failure (Fig. 090).

Fig 090 DSC-0028

Failure Analysis

The square cut ring on the impeller shaft is not an oil

seal. It is a wiper ring that has a tendency to pull down

to the shaft when the shaft begins to turn. The bushing

next to the ring defl ects most of the oil that is thrown

towards that area. The loose fi t provides a vent for the

case (Fig. 091).

Occasionally a drop of two of oil will get between the

bushing and ring. When the auger drive is disengaged,

the ring will relax and that oil might drip into the auger

housing. At this rate the machine can be used for several

years without any signifi cant oil loss. The yearly oil check

is more than adequate to compensate for this.

If there is a signifi cant amount of oil coming out of this

area, it would indicate that the gearbox has been at a

severe operating angle or the bushing is badly worn.

Oil on the bottom of the gearbox can result from a leak

on any part of the case. As there is no internal pressure,

any leaking oil runs down the side of the case and

collects on the bottom until there is enough to drip off.

The source of the leak can be diffi cult to see. Sprinkling

some powder on the outside of the gearbox will usually

show the oil trail. The type of powder used is not

important. Just something that will stick to the oil.

When you open a gearbox that has had the gears

fail, the remaining oil will likely appear as a small

puddle of very thick grease in the bottom. Worm gears

normally create friction due to their sliding action. When

something goes wrong, not enough oil, poor quality oil, a

problem with the gears, or just a gear or bearing wearing

out, the friction becomes abnormally high. The remaining

oil is cooked down to a very thick residue. This can be

the result of a failure, not the cause.

Fig 091 DSC-0061

7-7Power Max Service Manual

Page 50

AUGER GEARBOX

Gearbox Assembly

1. Use a wire brush or fi ne sandpaper to clean the

auger shaft. A clean, smooth shaft will help avoid

damage when installing new bushings and seals.

Clean the old seal material from the case mating

surfaces. Scrape, then use liquid gasket remover.

(Fig. 092).

3. Insert the key into the shaft and slide the worm gear

into place. Note: There is a large letter R and an

arrow stamped into the side of the gear. This gear

MUST be installed such that the R and the arrow

are on the right hand side and the arrow is pointing

forward, from the operator’s point of view (Fig. 094).

This is a two-piece gear that is bonded together. If it

is installed backwards, the forces try to separate the

gear and can result in failure.

Fig 092 DSC-1167

2. If new bushings are to be installed in the gear case

halves, now is the time. Apply a thin coat of Loctite

Blue #242 or equivalent to the OUTSIDE of the

bushing and press in fl ush with the INSIDE of the

case (Fig. 093). This will allow space for the seal on

the outside. Wipe up any Loctite that is visible. The

Loctite must not get into the gear or seal area.

Fig 094 MVC-047X

4. Install the thrust washers and slide the case halves

on. Note the direction to keep the gear markings on

the right side.

Fig 093 MVC-710X

7-8 Power Max Service Manual

Page 51

AUGER GEARBOX

5. To assemble the worm shaft, start with the end

opposite the worm. Install a snap ring (sharp edge

towards the rear of the gearbox), thrust washer,

thrust bearing, thrust washer, bushing and seal.

There is also a bushing on the worm end of the seal

(Fig. 095).

Fig 095 DSC-0028

7. Clean the case halves by scraping; then apply a

liquid gasket remover. To ensure a good seal case

halves must be clean and dry. Apply a thin coat of

Hylomar (Toro PN 505-129) to both halves. Allow

it to cure until it is dull and tacky, at least one hour.

Then assemble.

8. Apply a light coat of oil or anti-seize to the gear case

screws. Tighten them in an X pattern to 120 in-lbs.

(15kg/m) (Fig. 097).

3

9

5

2

1

8

7

6. Apply a VERY light coat of Loctite Blue # 242 or

equivalent to the outer diameter of the bearing. The

Loctite should not squeeze out when everything is

tightened or you used too much (Fig. 096).

Fig 096 DSC-0059

6

Fig 097 MVC-844XA

9. Lightly oil a seal protector and slide new seals down

the auger shaft. The lip of the seal should face

towards the inside. Seat the seals so the outer edge

is just fl ush with the outside of the gearcase.

4

7-9Power Max Service Manual

Page 52

THIS PAGE INTENTIONALLY LEFT BLANK

7-10 Power Max Service Manual

Page 53

TRACTION DRIVE SYSTEM

GENERAL DESCRIPTION

The traction drive system begins with a belt from the

engine crankshaft to a combination pulley/drive plate.

The belt is tensioned by a spring loaded idler so the

pulley/drive plate rotates whenever the engine is running

(Fig. 098).

NON-WHEEL CLUTCH

In forward the wheel will contact the left side of the drive

plate (Fig. 099).

A

A

Fig 098 MVC-009F.jpg

A. Idler

Perpendicular to the drive plate is a rubber coated

friction wheel. In neutral there is a gap between the plate

and wheel. When the traction bail is squeezed the drive

plate pivots to the rear and begins to drive the friction

wheel. This in turn causes the hex shaft, chain, gears

and axle to rotate. The direction of rotation and speed

are determined by the point on the drive plate the wheel

makes contact. Moving the wheel from side to side will

change direction of rotation and the farther out from

center the wheel contacts the plate, the faster the speed.

B

Fig 099 MVC-003A.jpg

A. Friction Wheel B. Drive Plate

Disassembly

To disassemble the traction drive assembly, proceed as

follows:

1. Drain the fuel tank and stand the unit on end.

Remove the belt covers.

8-1Power Max Service Manual

Page 54

NON-WHEEL CLUTCH

TRACTION DRIVE SYSTEM

2. Remove the upper and lower covers and bottom pan

(Fig. 100).

A

B

C

Fig 100 MVC-9012X.jpg

A. Upper Cover C. Bottom Pan

B. Lower Cover

4. Pull the right hand end of the shaft out of the traction

housing. Optional: The chain contains a master link,

which also can be removed (Fig. 102).

5. Slide the shaft out of the sprocket, slip the chain off,

then remove the sprocket.

Note: There is a thrust washer that may stick to the

bushing on the sprocket (Fig. 102).

A

3. Remove the screw securing each end of the

sprocket shaft (Fig. 101).

Fig 101 MVC-9022X.jpg

Fig 102 MVC-771X.jpg

A. Thrust Washer

8-2 Power Max Service Manual

Page 55

NON-WHEEL CLUTCH

TRACTION DRIVE SYSTEM

6. Remove the large hairpin on either end of the axle

(Fig. 103).

A

Fig 103 MVC-1900X.jpg

A. Hairpin Cotter

8. Remove the two capscrews securing the bearing

retainers to each side of the traction frame. Slide

the bearings and retainers off the hex shaft (Fig.

105). The bearings are secured to the retainers with

Loctite and are replaced as an assembly.

A

Fig 105 MVC-864XYZ.jpg

7. Slide the axle a little to the right. Move both axle

bearings inward (Fig. 104) then slide to the right until

the left end of the axle comes out of the side plate.

Withdraw the axle and remove the thrust washers,

bearings, gear and key.

A

Fig 104 MVC-1904X.jpg

A. Bearing Retainer

9. Remove the two screws securing the shift bracket to

the frame (Fig. 106).

Fig 106 MVC-1001X.jpg

A. Axle Bearing

8-3Power Max Service Manual

Page 56

NON-WHEEL CLUTCH

TRACTION DRIVE SYSTEM

10. Now the shift rod bracket and hex shaft can be

moved to separate the shift rod from the trunion (Fig.

107).

A

B

Fig 107 MVC-1002X.jpg

A. Shift Rod B. Trunion

11. Remove the hairpin from the speed control link

(Fig. 108). This is most easily accessed from the

top of the machine. The link is on the left side under

the belt cover. Slide the link out of the pulley pivot

assembly.

A

Fig 108 MVC-897X.jpg

At this point the friction wheel can be replaced. The

hex shaft, sprocket, trunion and spacers are a single

assembly.

A. Hairpin Cotter

12. Slip the traction idler off the traction belt. This can be

done from either the top or the bottom. The traction

idler will rotate to this position (Fig. 109).

A

Fig 109 MVC-1003X.jpg

A. Traction Idler

8-4 Power Max Service Manual

Page 57

NON-WHEEL CLUTCH

TRACTION DRIVE SYSTEM

13. Remove the snap ring from both ends of the pulley

pivot assembly shaft (Fig. 110). The nylon bushings

can be removed now or when the pulley pivot

assembly is removed.

A

Fig 110 MVC-1004X.jpg

A. Snap Ring

15. Slip the belt off of the pulley and slide the pivot

assembly to the side to remove the rod ends from

the side plate (Fig. 112).

A

Fig 112 MVC-1007X.jpg

A. Pivot Assembly

14. Reach up to the far left corner of the pulley pivot

assembly and unhook the spring from the pivot

assembly (Fig. 111).

B

A

Fig 111 MVC-1005X.jpg

A. Spring B. Pivot Assembly

16. To separate the pulley from the pulley pivot

assembly use a box end wrench and screwdriver to

loosen the nut (Fig. 113).

Fig 113 MVC-870XB.jpg

8-5Power Max Service Manual

Page 58

NON-WHEEL CLUTCH

TRACTION DRIVE SYSTEM

Reassembly

Reassemble in reverse order.

Reassembly notes:

1. If you removed the master link from the chain, it

must be assembled with the closed end of the

master link going in the direction of rotation in

forward gear (Fig. 114).

Fig 114 MVC-051X.jpg

2. Fastener Torque

A. All fasteners seated against plastic should be

securely tightened but not deform the plastic.

B. Self tapping screw for the ends of the

intermediate shaft. 170 - 300 in-lbs.

(196 - 345kg/com).

3. Lubrication

A. Light coat of engine oil to intermediate shaft.

B. Apply light coat of anti-seize to outer 5” of axle

shaft (circumference of 44 tooth axle gear).

8-6 Power Max Service Manual

Page 59

WHEEL CLUTCH

TRACTION DRIVE SYSTEM

GENERAL DESCRIPTION

The Freewheel Steering system is used on 28” models.

Handle mounted triggers allow clutching the wheels

simultaneously or independently, so one or both wheels

can “freewheel.” This feature makes turning, reversing,

and traction control simple and effi cient.

When the drive is engaged, it is engaging the friction

wheel. The hex shaft turns and drives the chain(s) to the

32 tooth gear in turn driving the 44 tooth gear powering

the wheels. Each wheel is declutched by engaging its

handle mounted trigger; this pulls the clutch cable, which

rotates the shift collar. The shift collar, following a cam, is

forced outwards, toward the wheel, in turn, pushing into

the spring loaded pawls to disengage the 11 tooth pinion

gear from the 32 tooth gear.

DISASSEMBLY

1. Disconnect shift linkage and remove tires (Fig 115).

2. Remove upper and lower covers (Fig. 116).

Fig 116 MVC-892XB.jpg

3. Remove bottom plate (Fig. 117).

Fig 115 MVC-889X.jpg

Fig 117 MVC-893XB.jpg

9-1Power Max Service Manual

Page 60

WHEEL CLUTCH

TRACTION DRIVE SYSTEM

4. Remove 2 cap screws securing the bearing retainers

that hold the hex shaft to each side of the traction

assembly and remove both bearing retainers (Fig.

118).

Note: This will ease removal and reinstallation of the

drive chains.

Fig 118 MVC-786.jpg

6. Remove extension spring - Unhook spring from

lower clutch collar and housing (Fig. 120).

Fig 120 MVC-897springX.jpg

7. Remove clutch cables - Rotate the shift collar up to

release tension on the clutch cable and maneuver Z

bend of the cable end out of the upper clutch collar

(Fig. 121).

5. Remove both bolts that hold the wheel clutch

assembly to the housing (Fig. 119).

Fig 119 MVC-895X.jpg

Fig 121 MVC-898XB.jpg

9-2 Power Max Service Manual

Page 61

WHEEL CLUTCH

TRACTION DRIVE SYSTEM

8. Unbolt upper end of shift brace from housing (Fig.

122 and 123).

Fig 122 MVC-2200X.jpg

9. Remove both roller chains from 32-tooth gears and

lift wheel clutch assembly from traction unit (Fig.

124).

Fig 124 MVC-900XC.jpg

Note: Install a screw and washer into each end of

the shaft to keep the parts from sliding off

(Fig. 125).

Fig 123 MVC-894XYX.jpg

Fig 125 MVC-901XB.jpg

To continue with disassembly of the clutch

mechanism, go to page xx.

9-3Power Max Service Manual

Page 62

WHEEL CLUTCH

TRACTION DRIVE SYSTEM

10. Remove both hairpins on either side of the axle of

44-tooth gear (Fig. 126).

Fig 126 MVC-853X.jpg

11. Remove woodruff key from one side of axle shaft by

sliding the 44-tooth gear inward towards the center

of the shaft to expose the woodruff key. Pry up on

the outside edge of the key to remove it (Fig. 127).

12. Slide axle shaft out through bearing retainer one at a

time, holding onto the 44 tooth gear (Fig. 128).

Fig 128 MVC-858X.jpg

13. Slide tube of axle shaft through housing (Fig. 129).

Fig 129 MVC-859XYZ.jpg

Fig 127 MVC-856X.jpg

9-4 Power Max Service Manual

Page 63

TRACTION DRIVE SYSTEM

14. Now you can remove the other half of the axle shaft

with the 44-tooth gear (Fig. 130).

WHEEL CLUTCH

Fig 132 MVC-860X.jpg

Fig 130 MVC-860XYZ.jpg

15. Remove the two screws from the shift rod bracket

and remove the traction control lever and bracket

assembly from the friction wheel (Fig. 131 and 132).

Fig 131 MVC-859X.jpg

16. If not already done, remove the bearing retainer that

holds the hex shaft (Fig. 133).

Fig 133 MVC-864XYZ.jpg

9-5Power Max Service Manual

Page 64

WHEEL CLUTCH

TRACTION DRIVE SYSTEM

17. Remove hex shaft clutch assembly / friction wheel

from housing (Fig. 134).

Fig 134 MVC-867X.jpg

18. Remove friction wheel from hex shaft by removing

the 3 nuts and bolts that hold the friction wheel to the

plate on the hex shaft (Fig. 135).

19. Move snowthrower to the upright position and

remove belt cover (Fig. 136).

Fig 136 MVC-861XB.jpg

20. Remove extension cover (Fig. 137).

Fig 137 MVC-862X.jpg

Fig 135 MVC-858X2.jpg

9-6 Power Max Service Manual

Page 65

WHEEL CLUTCH

TRACTION DRIVE SYSTEM

21. Remove hairpin cotter connecting speed control

linkage to the pivot pulley plate assembly (Fig. 138).

Fig 138 MVC-863XB.jpg

22. Remove extension spring from housing (Fig. 139).

23. Slide speed control linkage from pivot pulley plate

assembly (Fig. 140).

Fig 140 MVC-865XB.jpg

24. Turn the snowthrower back onto the auger housing.

Fig 139 MVC-864X.jpg

9-7Power Max Service Manual

Page 66

WHEEL CLUTCH

TRACTION DRIVE SYSTEM

25. Remove retaining ring from both sides of housing

(Fig. 141) and slide the nyliner bushing off the pivot

pulley plate shaft (Fig. 142).

Fig 141 MVC-866XB.jpg

26. Tilt pivot pulley assembly to release the traction belt

tension and remove belt from traction pulley (Fig.

143).

Fig 143 MVC-868X.jpg

27. Remove the pivot pulley plate assembly from the

housing (Fig. 144).

Fig 142 MVC-866Xny.jpg

Fig 144 MVC-869X.jpg

9-8 Power Max Service Manual

Page 67

WHEEL CLUTCH

TRACTION DRIVE SYSTEM

28. Remove the locknut from pivot pulley and separate

pulley from pivot plate (Fig. 145 and Fig. 146).

Fig 145 MVC-870XB.jpg

DRIVE SYSTEM REASSEMBLY

1. Install pivot plate assembly into the housing and

install belt. The idler pulley should be pushed away

from you to install the pivot plate (Fig. 147).

A

Fig 147 MVC-036X.jpg

Fig 146 MVC-010X.jpg

A. Idler Pulley

2. Install the two bushings and the two “C” clips onto

the pivot plate shaft (Fig. 148).

Fig 148 MVC-037X.jpg

9-9Power Max Service Manual

Page 68

WHEEL CLUTCH

A

B

TRACTION DRIVE SYSTEM

3. Install the speed control linkage through the pivot

plate and install the hair clip into the hole of the

speed control linkage on the outside of the pivot

plate (Fig. 149).

A

B

Fig 151 MVC-041X.jpg

Fig 149 MVC-039X.jpg

A. Hairpin Cotter B. Speed Control Link

4. Install long end of spring to cut out on the pivot plate

(Fig. 150) and the short end of the spring to the

frame (Fig. 151).

A

5. Install friction wheel assembly. You can lay the

shift mechanism onto the housing and insert shift

shaft into friction wheel assembly in the direction

shown. It is important that the friction wheel and shift

mechanism are to the right of the snowthrower (Fig.

152).

Note: Make sure the wheel is free of dirt, oil, anti-

seize or any other lubricant.

Fig 152 MVC-031XYX.jpg

Fig 150 MVC-039X.jpg

A. Spring

9-10 Power Max Service Manual

Page 69

WHEEL CLUTCH

TRACTION DRIVE SYSTEM

6. Before mounting the friction wheel assembly, install

the chains onto the 8-tooth sprockets making sure

the closed end of the master link is going in the

direction of rotation in the forward gears (Fig. 153

and 154).

Fig 153 MVC-051X.jpg

7. Install both bearing retainers (If both were removed)

(Fig. 155).

Fig 155 MVC-864XYZ.jpg

8. Before installing the axle with the 44-tooth sprockets

apply a light coat of anti-seize to the outer 5 inches

of both ends of the axle shaft. Also apply a light coat

to the inside diameter at both ends of the tube about

4 inches (Fig. 156).

Fig 154 MVC-867X.jpg

Fig 156 MVC-046X.jpg

9-11Power Max Service Manual

Page 70

WHEEL CLUTCH

TRACTION DRIVE SYSTEM

9. Make sure the axle bearing end that is holding the

axle shaft is on the bottom (Fig. 157).

Fig 157 MVC-857X.jpg

10. 44-tooth gears should have hub facing inward (Fig.

158).

A

11. Slide one end of the axle shaft with tube into the

housing (Fig. 159).

Fig 159 MVC-052X.jpg

12. With the woodruff key out of the other side of the

shaft as well as all the other components, install

axle bearing onto housing and then slide the shaft

in though the bearing and housing, through the two

washers and 44-tooth gear sprocket into the tube

(Fig. 160).

Fig 158 MVC-871XYZ.jpg

A. Hub

Fig 160 MVC-056X.jpg

9-12 Power Max Service Manual

Page 71

WHEEL CLUTCH

TRACTION DRIVE SYSTEM

13. Insert the woodruff key onto the axle shaft evenly

and make sure the 44-tooth gear can ride over the

shaft freely (Fig. 161).

Fig 161 MVC-059X.jpg

14. Position the hole for the hairpin cotter between the 2

washers and push the hairpin cotter into place (Fig.

162). Repeat for the other side.

15. Lightly coat the 44-tooth sprocket with anti-seize

(Fig. 163).

Fig 163 MVC-2205X.jpg

16. Before installing the wheel clutch assembly, lightly

coat the 11-tooth gear of the wheel clutch with antiseize (Fig. 164).

A

Fig 162 MVC-061X.jpg

A. Hairpin Cotter

Fig 164 MVC-035X.jpg

9-13Power Max Service Manual

Page 72

WHEEL CLUTCH

TRACTION DRIVE SYSTEM

17. Install wheel clutch assembly with the brace shift

plate facing away and up towards housing making

sure collars are correctly installed with the “RIGHT”

and “LEFT” facing inward and the right and left

fl anges are facing you (Fig. 165).

A

Fig 165 MVC-2200X.jpg

A. Left Collar B. Right Collar

B

19. Attach the shift brace plate to the housing (Fig. 167).

Fig 167 MVC-894XYX.jpg

20. Torque the two intermediate shaft screws to 170 to

300 in-lbs. (19.2 to 33.9 Nm) (Fig. 168).

18. Route the chains around the 32-tooth gear of the

clutch assembly (Fig. 166).

Fig 166 MVC-2207X.jpg

Fig 168 MVC-8562X.jpg

9-14 Power Max Service Manual

Page 73

WHEEL CLUTCH

TRACTION DRIVE SYSTEM

21. Install the 2 extension springs from the lower part of

the shift collar fl ange (Fig. 169) to the housing (Fig.

170).

Fig 169 MVC-032XZV.jpg