Toro 139-4845 Installation Instructions

DipstickKit

TXL2000ToolCarrier

ModelNo.139-4845

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3431-601RevA

InstallationInstructions

Description

Nopartsrequired

Nopartsrequired

Dipstickguide1

Dipstick1

Bolt(M8x12mm)

Cabletie

PreparingtheMachine

1.Parkthemachineonalevelsurface.

2.Removeanyattachments;refertotheOperator’s

Manualforthemachine.

3.Raisetheloaderarmsandsecurethemwith

cylinderlocks.

4.Shutofftheengineandremovethekey.

Qty.

Use

–

–

1

1

Preparethemachine.

Removetheenginepanel.

Installthenewdipstick.

RemovingtheEnginePanel

Note:Reversetheproceduretoinstalltheengine

panelafterinstallingthekit.

1.Openthehood.

2.Removethescrewclampsecuringthehoseto

thehydraulic-tankbreatherontherightsideof

theenginepanel(Figure1).

©2019—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

Figure1

1.Hydraulic-tankbreather3.Hose

2.Screwclamp

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

g286600

*3431-601*A

3.Removethehosefromthebreather.

4.Ontheleftsideoftheenginepanel,remove

the2bolts(5/16inch)and2nuts(5/16inch)

securingtheleftgrilleplatetotheenginepanel

(Figure2).

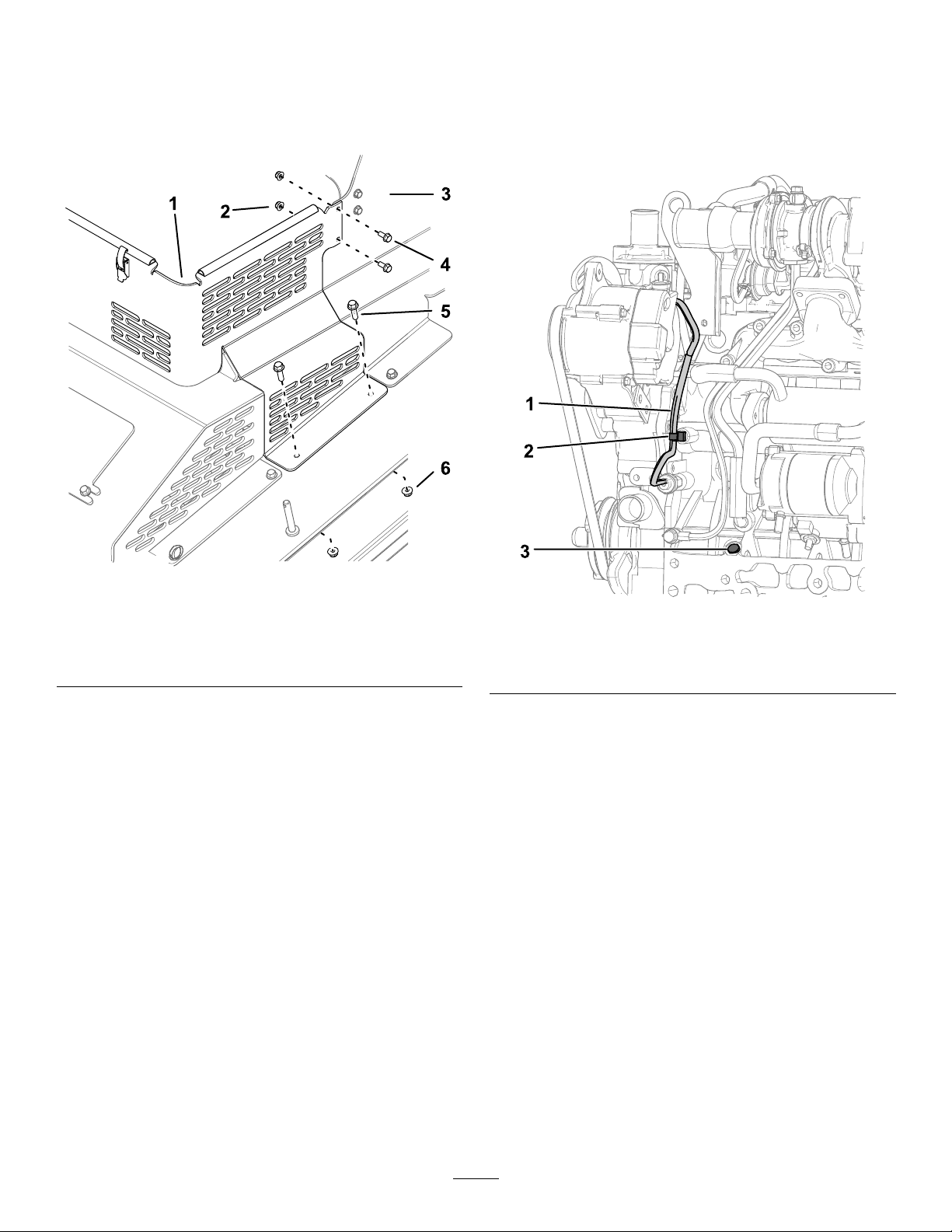

InstallingtheNewDipstick

Note:Theexistingdipstickandguidedoesnotneed

toberemoved.

1.Removetheplugontheleftsideoftheengine

(Figure3).

Figure2

1.Enginepanel

2.Nut—5/16inch(2)5.Bolt—3/8inch(2)

3.Leftgrilleplate6.Nut—3/8inch(2)

4.Bolt—5/16inch(2)

5.Removethe2bolts(3/8inch)and2nuts(3/8

inch)securingtheenginepaneltothemain

frameofthemachine(Figure2).

6.Repeatsteps4and5fortherightsideofthe

machine.

7.Removetheenginepanel.

g286599

g286748

Figure3

1.Wireharness3.Plug

2.Cabletie

2.Cutandremovethecabletiesecuringthewire

harnesstotheengine(Figure3).

3.Installthedipstickguideanddipstick(Figure4).

2

Loading...

Loading...