Page 1

InternationalShipKit

G009027

1

2

RT1200Trencher

ModelNo.131-2883

Introduction

ReadtheOperator’sManualforyourmachineandthe

attachmentscarefullytolearnhowtooperateandmaintain

yourproductproperlyandtoavoidinjuryandproduct

damage.Youareresponsibleforoperatingtheproduct

properlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedToroServiceDealer

orToroCustomerServiceandhavethemodelandserial

numbersofyourproductready.

Important:Thismachinewasmanufacturedaccording

totheappropriateregulatorystandardsineffectatthe

timeofmanufacture.Modifyingthismachineinany

waymaycauseittobeoutofcompliancewiththose

standardsandwiththeinstructionsinthis

Man ual.

onlybyanAuthorizedToroServiceDealer.

Modicationstothismachineshouldbemade

Operator’ s

FormNo.3396-716RevA

InstallationInstructions

CAUTION

Thismachineproducessoundlevelsthatcancause

hearinglossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

Figure2

1.Wearsafetyglasses.

2.Wearhearingprotection.

Contents

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Introduction..................................................................1

ConguringtheMachineforShipping...............................2

PreparingtheMachine.............................................2

PreparingtoRemovetheROPS.................................2

RemovingtheROPS................................................7

AssemblingtheMachineforShipping........................9

PreparingtoMovetheMachine................................11

PreparingtheMachinefortheCustomer...........................12

PreparingtoMovetheMachine................................12

PreparingtheMachine............................................13

RemovingtheShippingConguration

Components......................................................13

InstallingtheROPS................................................16

InstallingtheRearFendersandtheRearControl

Cover................................................................18

InstallingtheDashPanelandConsole

Panel.................................................................19

InstallingtheTurbocharger-ExhaustPipe..................21

InstallingtheMuferExtensionandRain

Cap...................................................................25

SwitchingntheBatteryandInstallingtheSide

Panels...............................................................25

©2015—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3396-716*A

Page 2

Conguringthe

MachineforShipping

LooseParts

Description

Shippingplate

Hearingprotector1Wearpersonalprotectiveequipment.

Quantity

1Installtheshippingplate.

PreparingtheMachine

Lifting-equipmentcapacity:408kg(900lb)minimum

1.Ensurethatthemachinetiltislevelandthetilt-lockout

pinisinstalled;refertotheOperator’sManualforthe

machine.

2.Movethemachinetoalevelsurfacethatisbelowthe

liftingequipmentwiththespeciedliftcapacity.

3.Lowerallattachments,stoptheengine,andremove

thekeyfromtheKEYSWITCH;refertotheOperator’ s

Manualforthemachine.

4.Allowtheexhaustsystemtocoolcompletely.

PreparingtoRemovethe ROPS

Use

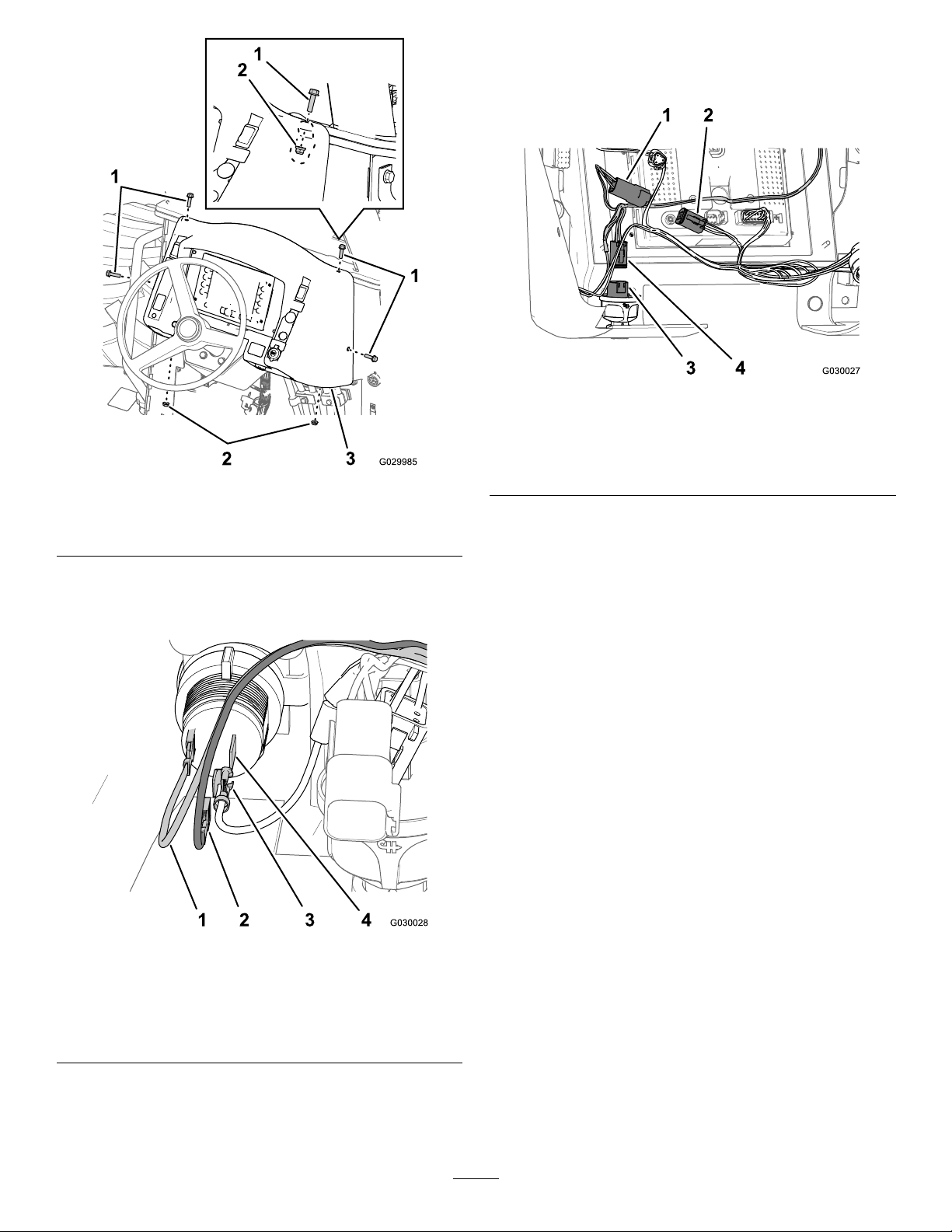

RemovingtheSidePanelsand

DisconnectingtheBattery

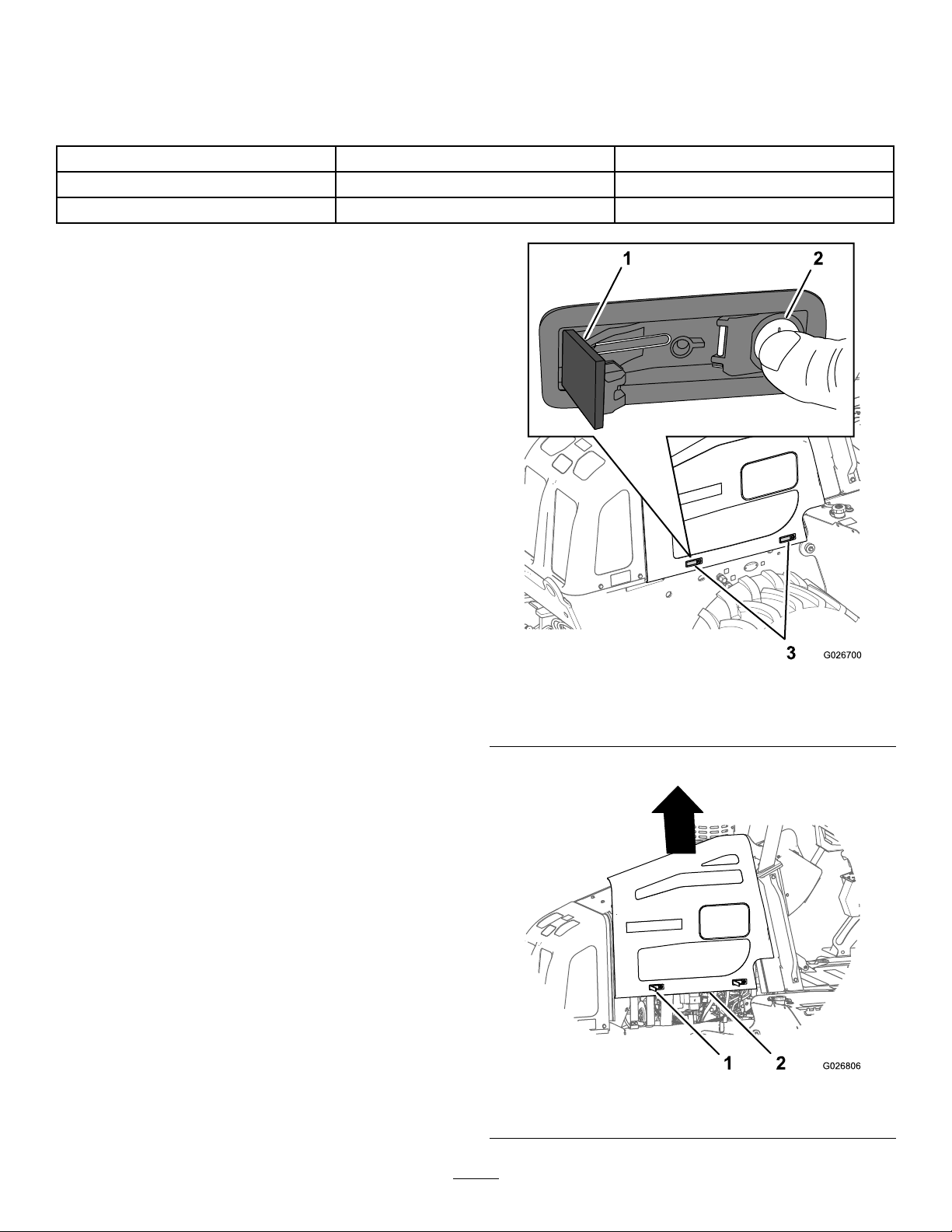

1.Pressinthebuttonportionofeachlatch—thepartof

thelatchincludingthelockcylinder(Figure3).

Figure3

1.Latchlever

2.Latchbutton

2.Liftthepanelupandawayfromthemachine(Figure4).

3.Side-panellatch

Figure4

1.Latch

2

2.Sidepanel

Page 3

3.Repeatsteps1and2forthesidepanelattheotherside

ofthemachine.

4.Placebothsidepanelsintotheshippingcontainer.

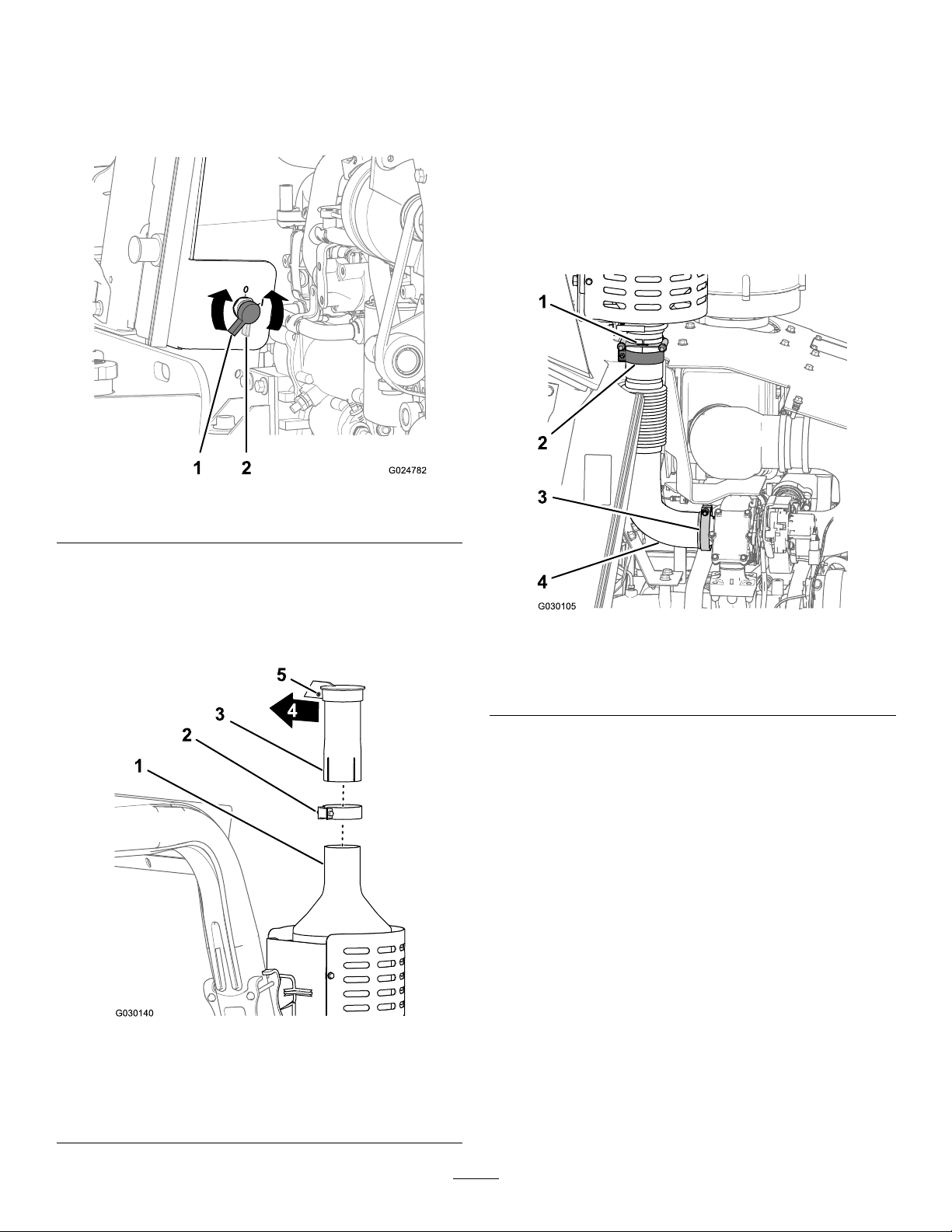

5.RotatetheBATTERYDISCONNECTswitch

counterclockwisetotheOFFposition(Figure5).

Figure5

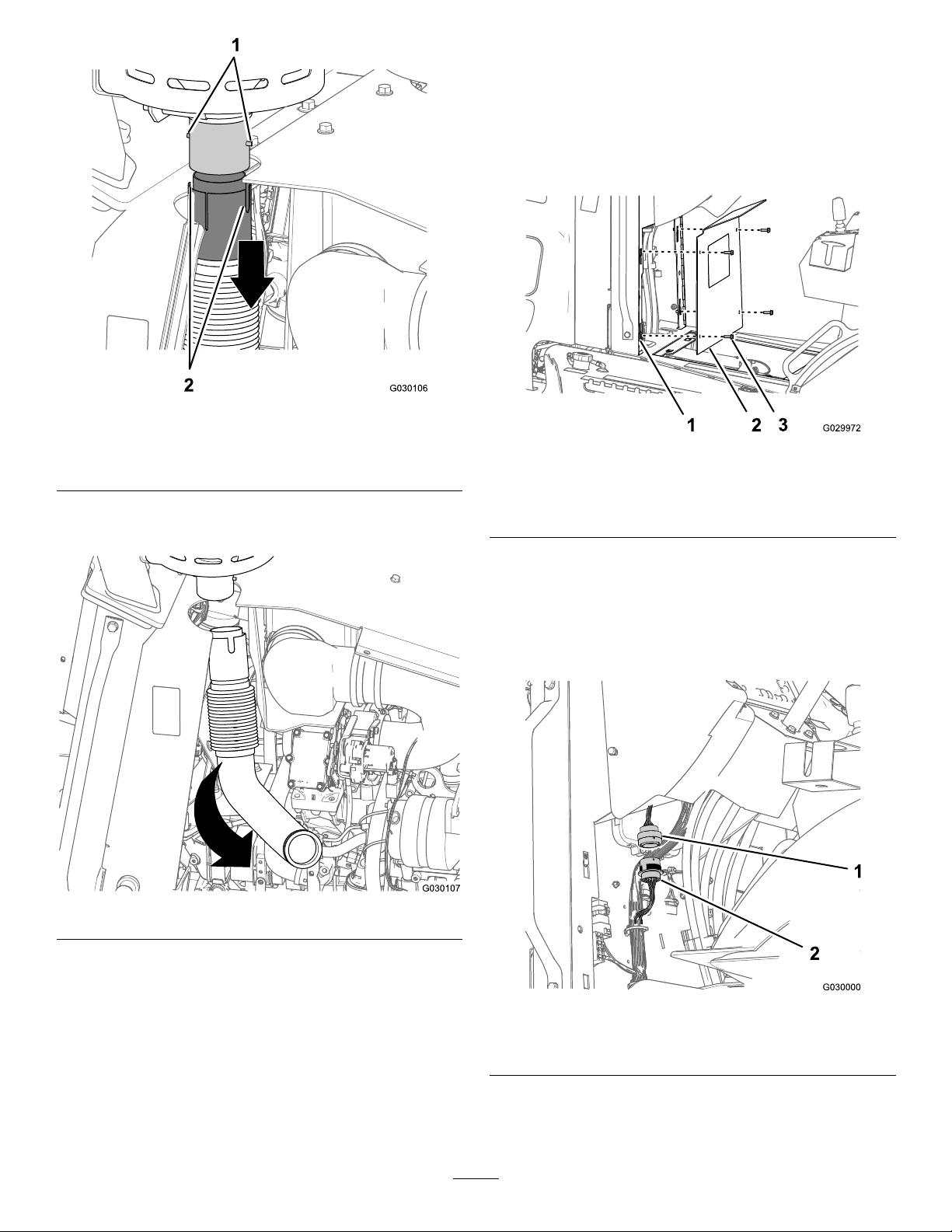

2.Removetheextension,raincap,andclampfromthe

mufer(Figure6).

3.Placeextension,raincap,andclampintotheshipping

container.

RemovingtheTurbocharger-Exhaust

Pipe

1.Removethebandclampandthelowerguillotineclamp

thatsecurethemufertotheturbocharger-exhaust

pipe(Figure7).

1.BATTERYONposition2.BATTERYOFFposition

RemovingtheMuferExtensionand

RainCap

1.Loosentheclampthatsecuresthemuferextension

andraincaptotheoutletpipeofthemufer(Figure6).

Figure7

1.Guillotineclamp

2.Bandclamp4.Turbocharger-exhaust

3.Flangeclamp

pipe

2.Removetheangeclampthatsecurestheangeofthe

turbocharger-exhaustpipetotheoutletangeofthe

turbocharger(Figure7).

3.Movetheturbocharger-exhaustpipedownuntilthe

alignmentpinsofthemufer-inletpipecleartheslots

intheturbocharger-exhaustpipe(Figure8).

Important:Donotbendordamagethepleated

sectionoftheturbocharger-exhaustpipewhile

removingthepipetothemachine.

Figure6

1.Mufer-outletpipe4.Inboardofthemachine

2.Clamp5.Pivot(raincap)

3.Muferextensionandrain

cap

3

Page 4

Figure8

RemovingtheConsolePanelandthe

DashPanel

RemovingtheConsolePanel

1.Removethe4ange-headbolts(5/16x1inch)that

securetheconsolepaneltotheframeoftheconsole

(Figure10).

1.Alignmentpin(mufer-inlet

pipe)

2.Slots

(turbocharger-exhaust

pipe)

4.Removetheturbocharger-exhaustpipefromthe

machine(Figure9).

Figure10

1.Consoleframe3.Flange-headbolts(5/16x

1inch)

2.Consolepanel

2.Removethepanelfromthemachine(Figure10).

RemovingtheDashPanel

1.Disconnectthe23-pinconnectorofthedashwiring

harnessfromthe23-socketconnectorforthemachine

wiringharness(Figure11)

Figure9

5.Placetheturbocharger-exhaustpipe,bandclamp,

guillotineclamp,andangeclampintotheshipping

container.

Figure11

1.23-pinconnector(dash

wiringharness)

2.23-socketconnector

(machinewiringharness)

2.Removethe4angebolts(8x30mm)and2ange

locknuts(8mm)thatsecurethedashpaneltotheframe

oftheconsole(Figure12).

4

Page 5

5.Removethe6-socketconnectorofthewiringharness

forthemachinefromtheconnectorforthestarter

switch(Figure14).

Figure14

Figure12

1.Flangebolt(8x30mm)

2.Flangelocknut(8mm)

3.Dashassembly

3.Removethepiggybackterminalofthewiringharness

forthemachinefromthebladeterminalofthe

auxiliary-powerport(Figure13).

1.6-pinconnector(wiring

harnessforthemachine)

2.6-socketconnector(dash

harness)

3.Starter-switchconnector

4.6-socketconnector(wiring

harnessforthemachine)

6.Removethe6-pinconnectorofthewiringharnessfor

themachinefromthe6-socketconnectorofthedash

harness(Figure14).

7.Carefullyremovethedashpanelfromtheconsole

(Figure12).

Note:Setasidethedashpanel,angebolts,and

locknutsforassemblyinAssemblingtheMachinefor

Shipping(page9).

Figure13

1.Bluewire(dashharness)3.Piggybackterminal(wiring

2.Socketterminal—black

(ground)wire(dash

harness)

harnessforthemachine)

4.Bladeterminal

(auxiliary-powerport)

4.Removethesocketterminalfortheblackwireofthe

dashharnessfromthepiggybackterminalofthewiring

harnessforthemachine(Figure13)

5

Page 6

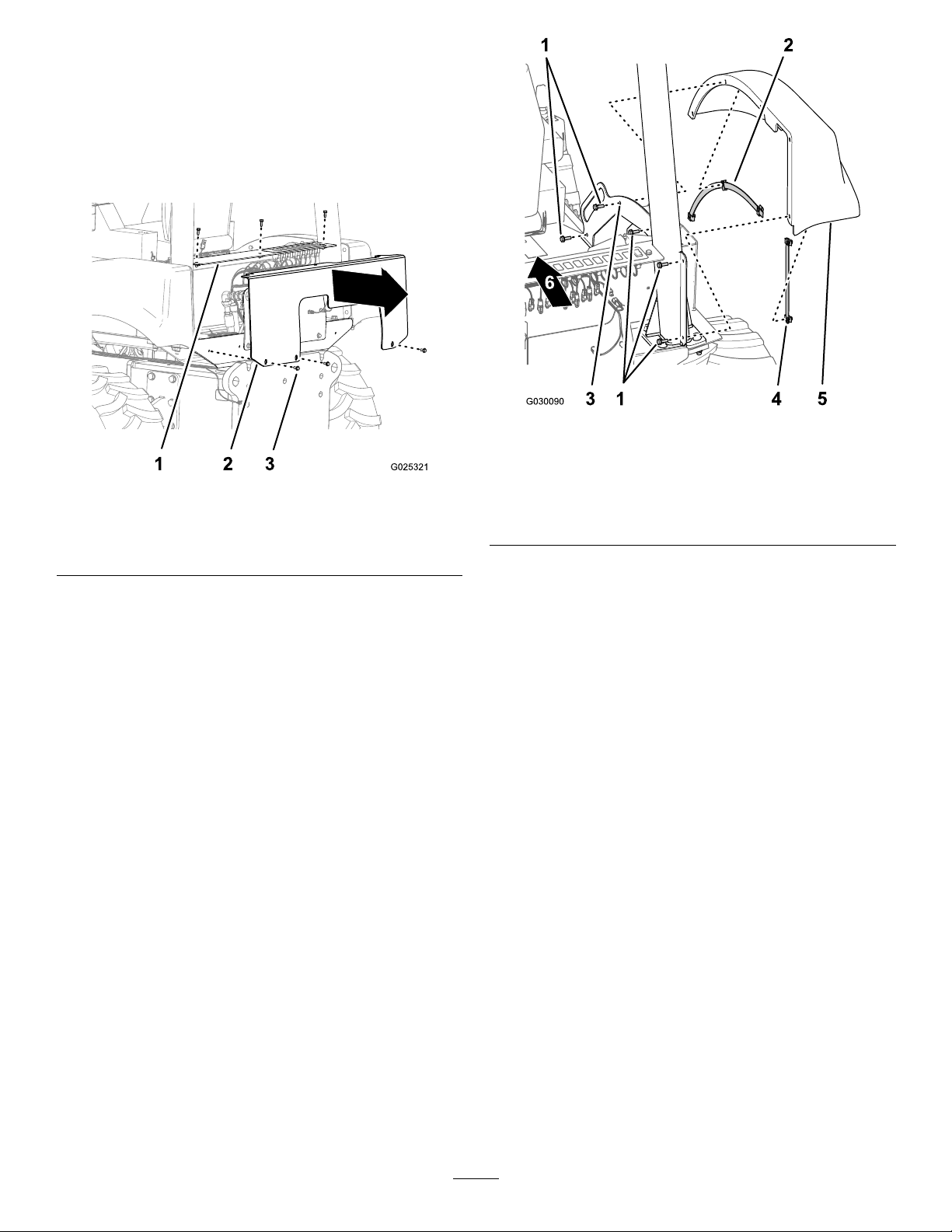

RemovingtheRearControlCoverand

RearFenders

RemovingtheRearControlCover

1.Removethe6ange-headbolt(12x30mm)that

securetherearcontrolcovertotherearbulkheadof

themachine(Figure15).

Figure16

Figure15

1.Bulkhead

2.Rearcoverplate

3.Flange-headbolt(12x30

mm)

2.Removethecontrolcoverfromthemachine.

Note:Setasidethecontrolcoverandange-head

boltsforassemblyinAssemblingtheMachinefor

Shipping(page9).

RemovingtheRearFenders

1.Removethe5ange-headbolts(10x30mm)and2

reinforcementplates(withtheattachednutclips)that

securethefendertothechassisofthemachine(Figure

16).

Note:Haveanotherpersonsupporttherearfender

whileyouremovethemountinghardware.

1.Flange-headbolts(10x

30mm)

2.Curvedreinforcement

plateandclipnuts

3.Fendermount

4.Straightreinforcement

plateandclipnuts

5.Fender

6.Frontofthemachine

2.Removethefenderfromthemachine.

3.Repeatsteps1and2fortherearfenderattheother

sideofthemachine.

Note:Setasidethefenders,reinforcementplates

(withtheattachedclipnuts),andange-headbolts

forassemblyinAssemblingtheMachineforShipping

(page9).

6

Page 7

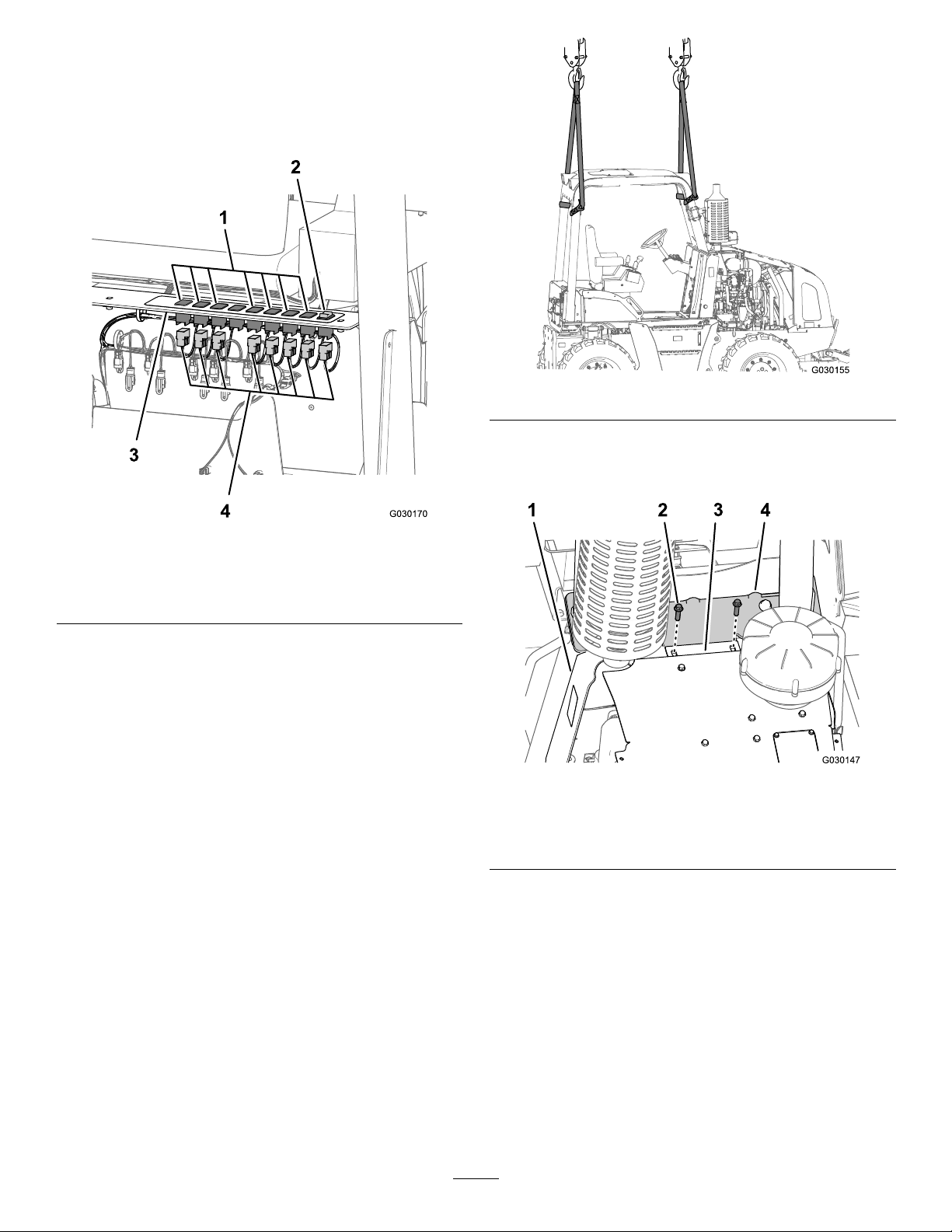

DisconnectingtheAuxiliary-Control

PanelWiring

1.Attheauxiliary-controlpanel,removethe10-socket

connectorattheendofthemain-wiringharnessfrom

the10-pinconnectorforthetiltswitch(Figure17).

Figure18

2.Removethe2ange-headbolts(12x40mm)that

securethehoodplate,ROPS-mountingplate,leftcowl

panel,andrightcowlpanel(Figure19)

Figure17

1.Plugs3.Auxiliary-controlpanel

2.Tiltswitch4.10-socketconnectors

(main-wiringharness)

2.Removethe7remaining10-socketconnectorsofthe

main-wiringharnessfromthe7rocker-switchplugsin

theauxiliary-controlpanel(Figure17).

RemovingtheROPS

Lifting-equipmentcapacity:408kg(900lb)minimum

AdditionalEquipment:hand-operatedwinch

1.SupporttheROPSframeandmuferwithlifting

equipmenthavingaminimumliftcapacityof408kg

(900lb)asshowninFigure18.

Note:TheROPSframeandmuferisweighted

towardtherear.YouwillneedtotilttheROPSframe

andmufertoremovetheROPS.Wheneverpossible,

use2piecesofliftingequipmenttolifttheROPSframe

andmufer.

Figure19

1.Leftcowlpanel3.Hood-plateange

2.Flange-headbolt(12x40

mm)

4.ROPS-mountingplate

3.Removethe2ange-headbolts(16x50mm)

and2angelocknuts(16mm)thatsecurethe

ROPS-mountingplatetotheframeoftheconsole

(Figure20).

Note:Ifyouhavedifcultyremovingthebolts,

theROPSframetubesareundertension.Usea

hand-operatedwinchtopullthefrontROPStube(s)

towardthereartube(s)torelievesheeringpressure

fromthebolts.

Note:Discardthe2ange-headbolts(16x50mm)

and2angelocknuts(16mm).

7

Page 8

Figure20

1.ROPS-mountingplate3.Flange-headbolts(16x

50mm)

2.Flangelocknuts(16mm)4.Consoleframe

4.AttherearframetubesfortheROPS,removethe8

ange-headbolts(16x70mm)and8angelocknuts

(16mm)thatsecuretheROPStubestothechassisof

themachine(Figure21).

Figure21

1.Flangelocknuts(16mm)3.ROPStube

2.Flange-headbolts(16x

70mm)

5.Usingtheliftingequipment,raisethebackoftheROPS

slightly.

6.Usingtheliftingequipment,movetheROPSrearward

andupuntiltheROPS-mountingplateclearsthehood

plateandcowlpanels(Figure19).

Note:PayattentiontotheROPS-mountingplateasit

separatesfromthehoodplateandcowlpanels,andas

themountingplateclearsthesteeringwheel.

7.LifttheROPSandmuferandremovetheROPSfrom

themachine(Figure22).

Note:Ifyouhavedifcultyremovingthebolts,

theROPSframetubesareundertension.Usea

hand-operatedwinchtopulltheROPStubestogether

torelievesheeringpressurefromthebolts.

Note:Discardthe8ange-headbolts(16x70mm)

and8angelocknuts(16mm).

Figure22

8.MovetheROPSandmufertotheshippingcontainer.

8

Page 9

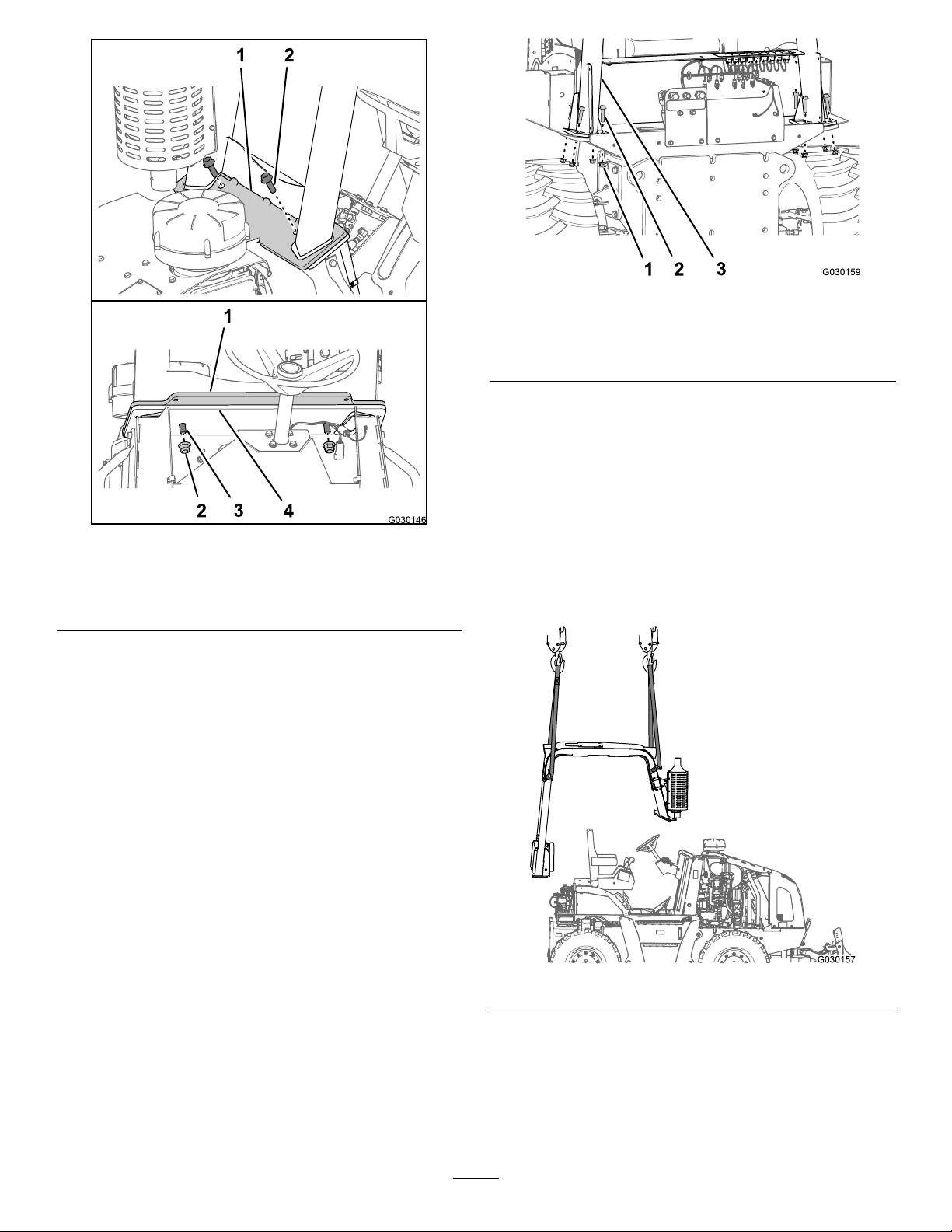

AssemblingtheMachinefor Shipping

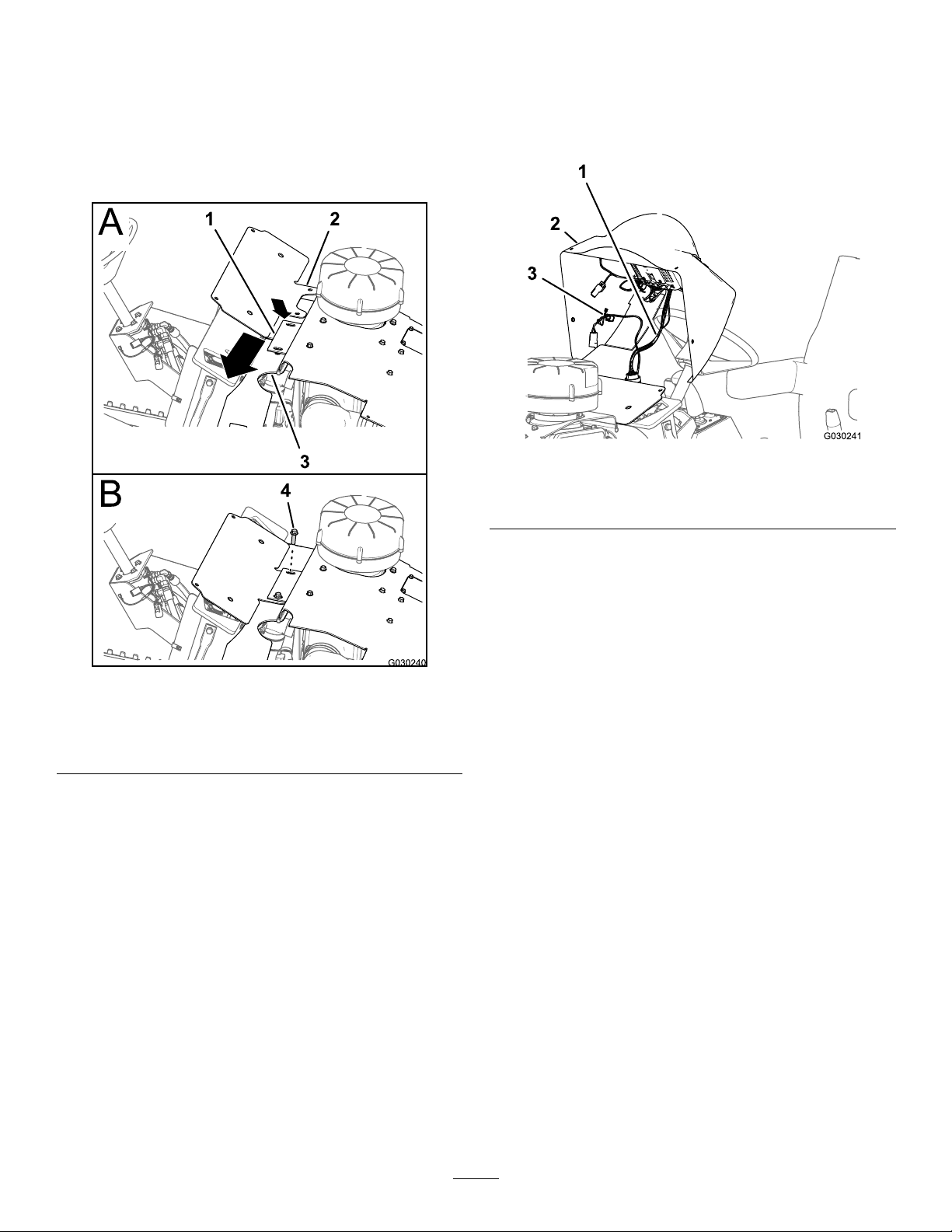

InstallingtheShippingPlate

1.Aligntheshippingplatebetweentheangeofthehood

plate,leftcowlpanel,andrightcowlpanel(Figure23).

AssemblingtheDashPaneland

ConsolePaneltotheMachine

AssemblingtheDashPanel

1.Alignthedashpaneltotheconsole(Figure24).

Figure24

1.Dashwiringharness3.Machinewiringharness

2.Dashpanel

Figure23

1.Hood-plateange3.Cowlpanel

2.Shippingplate4.Flange-headbolt(12x40

mm)

2.Assembletheshippingplate,hoodplateandcowl

panels(Figure23)withthe2ange-headbolt(12x

40mm)thatyouremovedinstep2inRemovingthe

ROPS(page7).

3.Tightentheange-headbolttoashippingtorqueof40

to50N-m(30to37ft-lb).

2.Connectthesocketterminalfortheblackwireof

thedashharnessontothepiggybackterminalofthe

wiringharnessforthemachine;refertoFigure13in

RemovingtheDashPanel(page4).

3.Connectthepiggybackterminalofthewiringharness

forthemachineontotheopenbladeterminalofthe

auxiliary-powerport;refertoFigure13inRemoving

theDashPanel(page4).

4.Connectthe6-socketconnectorofthewiringharness

forthemachineontotheconnectorforthestarter

switch;refertoFigure14inRemovingtheDashPanel

(page4).

5.Connectthe6-pinconnectorofthewiringharness

forthemachineintothe6-socketconnectorofthe

dashharness;refertoFigure14inRemovingtheDash

Panel(page4).

6.Aligntheholesinthedashpanelwithholesinthe

consoleframeandtheshippingplate(Figure25).

9

Page 10

Figure25

AssemblingtheRearFendersandRear

ControlCovertotheMachine

AssemblingtheRearFenders

1.Aligntheholesinthestraightreinforcementplate(with

theattachedclipnuts)thatyouremovedinstep1of

RemovingtheRearFenders(page6)withtherear2

holesintherearfender(Figure26).

1.Flangebolts(8x30mm)

2.Flangelocknuts(8mm)4.Consoleframe

3.Dashpanel

7.Assemblethedashpaneltotheconsoleandthe

shippingplate(Figure25)withthe4angebolts(8x

30mm)and2angelocknuts(8mm)thatyouremoved

instep2ofRemovingtheDashPanel(page4)

8.Tightentheange-headboltsandlocknutsatthefront

ofthedashuntiltheendoftheboltisushwiththe

lockingportionofthelocknut(Figure25)

9.Tightentheange-headboltsatthesideofthedash

paneltoashippingtorqueof120to140N-cm(108

to132in-lb).

10.Connectthe23-pinconnectorofthedashwiring

harnesstothe23-socketconnectorofthemachine

wiringharness;refertoFigure11inRemovingthe

DashPanel(page4).

AssemblingtheConsolePanel

1.Aligntheholesintheconsolepanelwiththeholes

intheframeoftheconsole;refertoFigure10in

RemovingtheDashPanel(page4).

Figure26

1.Fendermount

2.Frontofthemachine5.Straightreinforcement

3.Curvedreinforcement

plateandclipnuts

4.Rearfender

plateandclipnuts

6.Flange-headbolts(10x

30mm)

2.Assemblethestraightreinforcementplate(withthe

attachedclipnuts)tothefenderwiththe2ange-head

bolts(10x30mm)thatyouremovedinstep1of

RemovingtheRearFenders(page6)andtightenthe

boltssecurely(Figure26).

3.Alignthecurvedreinforcementplate(withtheattached

clipnuts)thatyouremovedinstep1ofRemovingthe

RearFenders(page6)withtheforward,insideholesof

therearfender(Figure26).

2.Assemblethepaneltotheconsolewiththe4

ange-headbolts(5/16x1inch)thatyouremovedin

step1ofRemovingtheDashPanel(page4).

3.Tightentheange-headboltstoashippingtorqueof

989to2540N-cm(88to123in-lb).

4.Alignthefender,plate,andclipnutwiththeholeinthe

fendermountoftheoperator’splatform(Figure26).

Note:Haveanotherpersonsupporttherearfender

whileyouinstallthemountinghardware.

5.Assemblethefender,plate,andclipnuttothefender

mountwith3ange-headbolts(10x30mm)thatyou

removedinstep1ofRemovingtheRearFenders(page

6).

6.Tightentheange-headboltstoashippingtorqueof

24to29N-cm(17to21ft-lb).

10

Page 11

7.Repeatsteps1through6fortherearfenderatthe

G009027

1

2

othersideofthemachine.

AssemblingtheRearControlCover

1.Assemble3ange-headbolts(12x30mm)thatyou

removedinstep1inRemovingtheRearFenders(page

6)intothetop3clipnutsattheholesintherearcontrol

coverandtightensecurely(Figure27).

Figure28

1.BATTERYONposition2.BATTERYOFFposition

WearingPersonalProtectiveEquipment

Figure27

1.Flange-headbolts(12x

30mm)

2.Rearcontrolcover

2.Aligntheholesintherearcontrolcoverwiththeholes

intherearplatformframe(Figure27).

3.Assembletherearcontrolcovertotherearplatform

frame(Figure27)withthe3ange-headbolts(12x30

mm)thatyouremovedinstep1inDisconnectingthe

Auxiliary-ControlPanelWiring(page7).

4.Tightenthe3ange-headboltstoashippingtorqueof

40to50N-m(30to36in-lb).

3.Rearplatformframe

PreparingtoMovetheMachine

ConnectingtheBattery

RotatetheBATTERYDISCONNECTswitchtotheONposition

(Figure28).

CAUTION

Thismachineproducessoundlevelsthatcancause

hearinglossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

Figure29

1.Wearsafetyglasses.

1.Wearthesuppliedhearingprotectorwhenmovingthe

machineintotheshippingcontainer.

2.Whennishedmovingthemachineintotheshipping

container,attachthehearingprotectortothesteering

wheelofthemachine.

2.Wearhearingprotection.

DisconnectingtheBattery

RotatetheBATTERYDISCONNECTswitchtotheOFFposition

(Figure28).

11

Page 12

PreparingtheMachine

G009027

1

2

fortheCustomer

LooseParts

Description

Hearingprotector1Wearpersonalprotectiveequipment.

ROPSandmuferassembly

Flange-headbolt(16x50mm)

Flangelocknut(16mm)

Flange-headbolts(16x70mm)

Shim1.52mm(0.06inch)

Shim0.76mm(0.03inch)

Muferextensionandraincap

Clamp

Sidepanel(left)

Sidepanel(right)

PreparingtoMovetheMachine

ConnectingtheBattery

RotatetheBATTERYDISCONNECTswitchtotheONposition

(Figure30).

Quantity

1

2

10

8

3Aligntheturbocharger-exhaustpipe.

1Aligntheturbocharger-exhaustpipe.

1

1

1Installthesidepanels.

1Installthesidepanels.

AligntheROPStothemachine.

AssembletheROPStothemachine.

AssembletheROPStothemachine.

AssembletheROPStothemachine.

Installthemuferextensionandraincap.

Installthemuferextensionandraincap.

WearingPersonalProtectiveEquipment

CAUTION

Thismachineproducessoundlevelsthatcancause

hearinglossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Use

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

Figure31

1.Wearsafetyglasses.

2.Wearhearingprotection.

1.Removethehearingprotectorfromthesteeringwheel.

Figure30

1.BATTERYONposition2.BATTERYOFFposition

2.Wearthesuppliedhearingprotectorwhenmovingthe

machinefromtheshippingcontainer.

12

Page 13

PreparingtheMachine

Lifting-equipmentcapacity:408kg(900lb)minimum

1.Ensurethatthemachinetiltislevelandthetilt-lockout

pinisinstalled;refertotheOperator’sManualforthe

machine.

2.Movethemachinetoalevelsurfacethatisbelowthe

liftingequipmentwiththespeciedliftcapacity.

3.Lowerallattachments,stoptheengine,andremove

thekeyfromtheKEYSWITCH;refertotheOperator’ s

Manualforthemachine.

4.Allowtheenginetocoolcompletely .

RemovingtheShipping

CongurationComponents

RemovingtheRearControlCoverand

RearFenders

RemovingtheRearControlCover

RemovingtheRearFenders

1.Removethe3ange-headbolts(10x30mm)that

securetherearfenderandcurvedreinforcementplate

(withtheattachedclipnuts)tothefendermount,and

removethefender(Figure33).

Note:Haveanotherpersonsupporttherearfender

whileyouremovethemountinghardware.

1.Removethe3ange-headbolts(12x30mm)fromthe

clipnutsatthetop3holesintherearcontrolcover

(Figure32).

Figure32

Figure33

1.Fendermount

2.Frontofthemachine5.Straightreinforcement

3.Curvedreinforcement

plateandclipnuts

4.Rearfender

plateandclipnuts

6.Flange-headbolts(10x

30mm)

2.Removethe2ange-headbolts(10x30mm)and

straightreinforcementplate(withtheattachedclip

nuts)fromtherear2holesintherearfender(Figure

33).

3.Repeatsteps1and2fortherearfenderattheother

sideofthemachine.

4.Settheange-headbolts,reinforcementplates(with

theattachedclipnuts),andfendersforinstallationin

InstallingtheRearFenders(page18).

1.Flange-headbolts(12x

30mm)

2.Rearcontrolcover

3.Rearplatformframe

2.Removethe3ange-headbolts(12x30mm)that

securetherearcontrolcovertotherearplatformframe,

andremovethecoverfromthemachine(Figure32).

3.Setasidethecoverandange-headboltsforinstallation

inInstallingtheRearControlCover(page19).

13

Page 14

RemovingtheConsolePanelandthe

DashPanel

RemovingtheConsolePanel

1.Removethe4ange-headbolts(5/16x1inch)that

securetheconsolepaneltotheframeoftheconsole

(Figure34).

Figure34

2.Removethe4angebolts(8x30mm)and2ange

locknuts(8mm)thatsecurethedashpaneltotheframe

oftheconsole(Figure36).

1.Consoleframe3.Flange-headbolts(5/16x

1inch)

2.Consolepanel

2.Removethepanelfromthemachine(Figure34).

3.Setasidethepanelandange-headboltsforinstallation

inInstallingtheConsolePanel(page21).

RemovingtheDashPanel

1.Disconnectthe23-pinconnectorofthedashwiring

harnessfromthe23-socketconnectorforthemachine

wiringharness(Figure35)

Figure36

1.Flangebolts(8x30mm)

2.Flangelocknuts(8mm)4.Consoleframe

3.Dashpanel

3.Liftupthedashpaneluntilyoucanaccesstheelectrical

connectorsattheforwardsideofthepanel.

4.Removethepiggybackterminalofthewiringharness

forthemachinefromthebladeterminalofthe

auxiliary-powerport(Figure37).

1.23-pinconnector(dash

wiringharness)

Figure35

2.23-socketconnector

(machinewiringharness)

Figure37

1.Bluewire(dashharness)3.Piggybackterminal(wiring

2.Socketterminal—black

(ground)wire(dash

harness)

14

harnessforthemachine)

4.Bladeterminal

(auxiliary-powerport)

Page 15

5.Removethesocketterminalfortheblackwireofthe

dashharnessfromthepiggybackterminalofthewiring

harnessforthemachine(Figure37)

6.Removethe6-socketconnectorofthewiringharness

forthemachinefromtheconnectorforthestarter

switch(Figure38).

Figure38

RemovingtheShippingPlate

1.Removethe2ange-headbolt(12x40mm)that

securetheshippingplate,hoodplate,leftcowlpanel,

andrightcowlpanel(Figure40).

1.6-pinconnector(wiring

harnessforthemachine)

2.6-socketconnector(dash

harness)

3.Starter-switchconnector

4.6-socketconnector(wiring

harnessforthemachine)

7.Removethe6-pinconnectorofthewiringharnessfor

themachinefromthe6-socketconnectorofthedash

harness(Figure38).

8.Carefullyremovethedashpanelfromtheconsole

(Figure39).

Figure40

1.Flange-headbolt(12x40

mm)

2.Hood-plateange4.Shippingplate

3.Shippingplate

2.Movetheshippingplateoutwarduntiltheplateclears

theangeofthehoodplate,andremovetheshipping

platefromthemachine(Figure40).

Note:Retaintheange-headboltsforinstallation

inAssemblingtheROPStotheMachine(page17).

Discardtheshippingplate.

Figure39

1.Dashwiringharness3.Machinewiringharness

2.Dashpanel

9.Settheange-headbolts,locknuts,anddashpanelfor

installationinInstallingtheDashPanel(page19).

15

Page 16

InstallingtheROPS

AligningtheROPStotheMachine

Lifting-equipmentcapacity:408kg(900lb)minimum

Customerprovidedtool:hand-operatedwinch.

1.SupporttheROPSframeandmuferwithlifting

equipmenthavingaminimumliftcapacityof408kg

(900lb)asshowninFigure41.

Note:TheROPSframeandmuferisweighted

towardtherear.YouwillneedtotilttheROPSframe

andmufertoinstalltheROPS.Wheneverpossible,

use2piecesofliftingequipmenttolifttheROPSframe

andmufer.

Figure42

4.TipthefrontoftheROPSdowntoaligntheforward

ROPSplatebetweentheangeofthehoodplate,left

cowlpanel,andrightcowlpanel(Figure42andFigure

43).

Figure41

2.Usingtheliftingequipment,carefullyremovethe

ROPSandmuferfromtheshippingcontainerand

aligntheROPSabovethemachine(Figure41).

3.MovetheROPSforwardanddownuntilthe

ROPS-mountingplatetheclearssteeringwheel(Figure

42).

Figure43

1.Flange(hoodplate)3.ROPSplate

2.Leftandrightcowlpanels

16

Page 17

5.Atthebackofthemachine,checktheclearance

betweentherearbulkheadpaneloftheROPSandthe

wiringharnessofthemachine(Figure44)

Figure44

1.Flangefortherearframe

tube(ROPS)

2.ROPSmounts(chassis)4.Wiringharness(machine)

3.Rearbulkheadpanel

(ROPS)

6.Usingtheliftingequipment,carefullymovetheROPS

forwardanddownuntiltheholesinthehoodplate

andcowlsarealignedwiththeholesintheROPSplate

(Figure43).

7.AligntheangesattherearframetubesfortheROPS

withtheROPSmountsforthechassisofthemachine

(Figure44).

AssemblingtheROPStotheMachine

1.AssembletheROPSplatetotheframeoftheconsole

withthe2ange-headbolts(16x50mm)and2ange

locknuts(16mm)fromtheshippingkit,andtighten

theboltsandnutsbyhand(Figure45).

Figure45

1.ROPS-mountingplate3.Flange-headbolts(16x

50mm)

2.Flangelocknuts(16mm)4.Consoleframe

2.Applyacoatofmedium-grade,thread-locking

compoundtothethreadsofthe2ange-headbolts(12

x40mm)thatyouremovedinstep1inRemovingthe

ShippingPlate(page15).

3.Assemblethe2ange-headbolts(12x40mm)through

theholesintheangeofthehoodpanel,ROPSplate,

leftcowlpanel,andrightcowlpanel,andtightenthe

boltsandnutsbyhand(Figure46).

17

Page 18

Figure46

1.Leftcowlpanel3.Hood-plateange

2.Flange-headbolt(12x40

mm)

4.ROPS-mountingplate

4.Aligntheholesintheangeattherearframetubefor

theROPSwiththeholesintheROPSmountforthe

chassisofthemachine(Figure47).

Note:Ifyouhavedifcultyaligningtheholes,usea

hand-operatedwinchbetweentherearROPStubeand

afrontROPStubetopulltherearROPStubeforward

andaligntheholes.Usethehand-operatedwinch

betweentherearROPStubestopullthetubesinward

toaligntheholes(Figure47).

DescriptionTorquevalue

Flange-headbolts(16x50

mm)andangelocknuts

(16mm)—ROPSplateand

consoleframe(Figure45)

Flange-headbolts(12x40

mm)—hoodplate,ROPS

plate,leftandrightcowlpanel

(Figure46)

Flange-headbolts(16x70

mm)andangelocknuts(16

mm)—rearROPStubesand

chassis(Figure47)

319to400N-m(235to295

ft-lb)

80to10N-m(59to73ft-lb)

319to400N-m(235to295

ft-lb)

InstallingtheRearFenders andtheRearControlCover

InstallingtheRearFenders

1.Applyacoatofmedium-grade,thread-locking

compoundtothethreadsofthe10ange-headbolts

(10x30mm)thatyouremovedinsteps1and3of

RemovingtheRearFenders(page13).

2.Aligntheholesintherearfenderwiththeholesinthe

fendermountofthechassisandangeoftheROPS

tube(Figure48).

Note:Haveanotherpersonsupporttherearfender

whileyouinstallthemountinghardware.

Figure47

1.Flangelocknuts(16mm)3.ROPStube

2.Flange-headbolts(16x

70mm)

5.AssembletherearROPStubetothechassiswith4

ange-headbolts(16x70mm)and4angelocknuts

(16mm),andtightenbyhand(Figure47).

6.Repeatsteps4and5totherearROPStubeattheother

sideofthemachine.

7.Torquetheboltsandnutsasindicatedinthetablethat

follows:

1.Flange-headbolts(10x

30mm)

2.Curvedreinforcement

plateandclipnuts

3.Fendermount

18

Figure48

4.Straightreinforcement

plateandclipnuts

5.Fender

6.Frontofthemachine

Page 19

3.Alignthenutclipsonthereinforcementplateswiththe

holesinthefender(Figure48).

4.Assemblethefender,reinforcementplates,andnut

clipstothemachine(Figure48)withthe5ange-head

bolts(10x30mm).

5.Torquetheange-headboltsto47to57N-m(34to

42ft-lb).

6.Repeatsteps2through5fortherearfenderatthe

othersideofthemachine.

InstallingtheRearControlCover

1.Atthebackofthemachine,connectthe10-socket

connectorattheendofthemain-wiringharnessinto

the10-pinconnectorofthetiltswitch(Figure49).

Figure50

1.Bulkhead

2.Rearcoverplate

3.Flange-headbolt(12x30

mm)

5.Assembletherearcontrolcoverwiththeholesinthe

rearbulkhead(Figure50)withthe6ange-headbolt

(12x30mm).

Figure49

1.Plugs3.Auxiliary-controlpanel

2.Tiltswitch4.10-socketconnector

(main-wiringharness)

2.Assemblethe7remaining10-socketconnectorsinto

the7rocker-switchplugsintheauxiliary-controlpanel

(Figure49)

3.Applyacoatofmedium-grade,thread-locking

compoundtothethreadsofthe6ange-headbolts

(12x30mm)thatyouremovedinsteps1and2in

RemovingtheRearControlCover(page13).

4.Aligntheholesintherearcontrolcoverwiththeholes

intherearbulkheadofthemachine(Figure50).

6.Torquetheange-headboltto80to10N-m(59to

73ft-lb).

InstallingtheDashPaneland ConsolePanel

InstallingtheDashPanel

1.Alignthedashpaneltotheconsole(Figure48).

Figure51

1.Dashwiringharness3.Machinewiringharness

2.Dashpanel

2.Connectthesocketterminalfortheblackwireofthe

dashharnessontothepiggybackterminalofthewiring

harnessforthemachine(Figure52).

19

Page 20

Figure52

G030030

7.Aligntheholesinthedashpanelwithholesinthe

consoleframe(Figure54).

1.Bluewire(dashharness)3.Piggybackterminal(wiring

2.Socketterminal—black

(ground)wire(dash

harness)

harnessforthemachine)

4.Bladeterminal

(auxiliary-powerport)

3.Connectthepiggybackterminalofthewiringharness

forthemachineontotheopenbladeterminalofthe

auxiliary-powerport(Figure52).

4.Connectthe6-socketconnectorofthewiringharness

forthemachineontotheconnectorforthestarter

switch(Figure53).

Figure54

8.Assemblethedashpaneltotheconsole(Figure55)

withthe4angebolts(8x30mm)and2ange

locknuts(8mm).

Figure53

1.6-pinconnector(wiring

harnessforthemachine)

2.6-socketconnector(dash

harness)

3.Starter-switchconnector

4.6-socketconnector(wiring

harnessforthemachine)

5.Connectthe6-pinconnectorofthewiringharnessfor

themachineintothe6-socketconnectorofthedash

harness(Figure53).

6.Applyacoatofmedium-grade,thread-locking

compoundtothethreadsofthe4angebolts(8x30

mm)thatyouremovedinstep2ofRemovingtheDash

Panel(page14).

Figure55

1.Flangebolt(8x30mm)

2.Flangelocknut(8mm)

3.Dashassembly

9.Tightentheange-headboltsandlocknutstoanal

torqueof120to140N-cm(108to132in-lb).

20

Page 21

InstallingtheConsolePanel

1.Connectthe23-pinconnectorofthedashwiring

harnesstothe23-socketconnectorofthemachine

wiringharness(Figure56).

Figure56

Installingthe Turbocharger-ExhaustPipe

AssemblingtheTurbocharger-Exhaust

PipeontotheMachine

1.Aligntheturbocharger-exhaustpipe(fromtheshipping

kit)throughthenotchesintherightcowlpaneland

hoodpanelofthemachine(Figure58).

Important:Donotbendordamagethepleated

sectionoftheturbocharger-exhaustpipewhile

assemblingthepipetothemachine.

1.23-pinconnector(dash

wiringharness)

2.Applymedium-grade,thread-lockingcompoundtothe

4ange-headbolts(5/16x1inch)thatyouremovedin

step1ofRemovingtheConsolePanel(page14).

3.Aligntheholesintheconsolepanelwiththeholesin

theframeoftheconsole(Figure57).

2.23-socketconnector

(machinewiringharness)

Figure57

Figure58

2.Aligntheslotsintheturbocharger-exhaustpipewith

thealignmentpinsofthemufer-inletpipeand

assembletheexhaustpipeontothemufer(Figure59).

1.Consoleframe3.Flange-headbolts(5/16x

1inch)

2.Consolepanel

4.Assemblethepaneltotheconsole(Figure57)withthe

4ange-headbolts(5/16x1inch).

5.Tightentheboltstoanaltorqueof1978to2542

N-cm(175to225in-lb).

21

Page 22

Figure59

1.Alignmentpins

(mufer-inletpipe)

2.Slots

(turbocharger-exhaust

pipe)

3.Aligntheangesoftheturbocharger-exhaustpipeand

theoutletangeoftheturbocharger,assemblethe

angeclampovertheanges,andtightentheclampto

closet(Figure60).

Note:Whentheangesoftheturbochargeroutlet

andtheturbocharger-exhaustpipearealigned,the2

alignmentpinsforthemufer-inletpipeshouldhave

3.2mm(1/8inch)orgreaterclearancefromtheclosed

endofthe2slotsintheturbocharger-exhaustpipe.

4.Assemblethebandclamp(fromtheshippingkit)

belowthe2alignmentpinsofthemufer-inletpipe

andtightentheclamptocloset(Figure61).

Figure61

1.Guillotineclamp3.Alignmentpin(mufer-inlet

pipe)

2.Bandclamp

5.Assembletheguillotineclamp(fromtheshippingkit)

abovethe2alignmentpinsofthemufer-inletpipe

andtightentheclamptocloset(Figure61).

AligningtheTurbocharger-Exhaust

Pipe

MeasuringtheBellows

1.Turbocharger-exhaust

2.Flangeclamp

1.Atthefrontsideofthebellowsofthe

turbocharger-exhaustpipe,measurethedistancefrom

theupperedgeoftheupper-weldseamtothelower

edgeofthelower-weldseam.

Recordyourmeasurementhere:

Note:Ifyourfront-sidemeasurementislessthanor

greaterthan152.4mm(6inches)andthepleatsofthe

bellowsarenotverticallyaligned,performthestepsin

AligningtheMuferFronttoBack(page23).

Figure60

3.Turbochargeroutlet

pipe

22

Page 23

Figure62

AligningtheMuferFronttoBack

1.Loosenthe4ange-headbolts(8x120mm)and

angelocknuts(8mm)thatsecuretheexhaust-system

mounttotheROPStube(Figure63).

1.Upperedgeofthe

upper-weldseam

2.152.4mm(6inches)

3.Loweredgeofthe

lower-weldseam

2.Attherightsideofthebellows,measurethedistance

fromtheupperedgeoftheupper-weldseamtothe

loweredgeofthelower-weldseam.

Recordyourmeasurementhere:

Note:Ifyourrightsidemeasurementislessthanor

greaterthan152.4mm(6inches)andthepleatsofthe

bellowsarenotverticallyaligned,performthestepsin

AligningtheMuferLefttoRight(page24).

3.Ifthefrontandsidemeasurementsofweldseamsfor

thebellowsare152.4mm(6inches)andthepleatsof

thebellowsareverticallyaligned,skiptoSecuringthe

Turbocharger-ExhaustPipe(page24).

Figure63

1.ROPStube4.Shim0.76mm(0.03inch)

2.Exhaust-systemmount

3.Flange-headbolts(8x120

mm)—lowerpositions

5.Shim1.52mm(0.06inch)

2.Addshim(s)—fromtheshippingkitorremovethe

shim(s)totheexhaust-systemmountatthelower2

ange-headboltsasneededtoalignthepleatsofthe

bellows(Figure63).

Note:Changethetotalshimthicknessin0.76mm

(0.03inch)increments.

3.Torquetheange-headboltsandangelocknutsfor

theexhaust-systemmountto17to21N-m(23to29

ft-lb).

4.Measurethebellowsweld-seamdimensionandconrm

thatthepleatsofthebellowsarealignedstraight

(Figure62).

Note:Ifbellowsisnotaligned,repeatsteps1through

3untiltheweld-seamsmeasurementforthebellowsis

152.4mm(6inches)fronttobackandthepleatsofthe

bellowsarealignedstraight.

5.Iftheturbocharger-exhaustpipeisalignedlefttoright,

skiptoSecuringtheTurbocharger-ExhaustPipe(page

24).

23

Page 24

AligningtheMuferLefttoRight

1.Removethe6ange-headbolts(6x16mm)that

securetheheatshieldtotheexhaust-systemmountand

removetheheatshield(Figure64).

Figure64

1.Flange-headbolts(6x16

mm)

2.Clipnut(6mm)

3.Flange-headbolts(6x30

mm)

4.Muferstrap

5.Heatshield

2.Loosentheange-headbolts(6x30mm)thatsecure

themuferstrapstotheexhaust-systemmount(Figure

64).

3.Loosenthe2ange-headbolts(1/2x1inch)

andserratedangenuts(1/2inch)thatsecurethe

lower-mufersupporttotheexhaust-systemmount

(Figure65).

Figure65

1.Exhaust-systemmount

2.Flange-headbolts(1/2

x1inch)—lowermufer

support

3.Lower-mufersupport

4.Serratedangenuts(1/2

inch)

4.Movethemuferleftorrighttoalignthebellowsso

thattheweld-seammeasurementattheleftandright

sidesare152.4mm(6inches)andpleatsofthebellows

arealignedstraight(Figure65).

5.Tightenthe2ange-headbolts(1/2x1inch)

andserratedangenuts(1/2inch)thatsecurethe

lower-mufersupporttotheexhaust-systemmountto

91to113N-m(67to83ft-lb).

6.Tightentheange-headbolts(6x30mm)thatsecure

themuferstrapsto972to1198N-cm(86to106

in-lb).

7.Applyacoatofmedium-grade,thread-locking

compoundtothe6ange-headbolts(6x16mm)that

youremovedinstep1.

8.Assembletheheatshieldtoexhaust-systemmountwith

the6ange-headbolts(6x16mm)andtorquethe

boltsto972to1198N-cm(86to106in-lb).

9.Iftheturbocharger-exhaustpipeisalignedfrontto

back,skiptoSecuringtheTurbocharger-ExhaustPipe

(page24).

SecuringtheT urbocharger-ExhaustPipe

1.Tightenthenutoftheangeclampsecurely.

2.Tightentheangenutsoftheguillotineclampand

tightentheboltandnutofthebandclampsecurely.

24

Page 25

InstallingtheMuferExtension

SwitchingntheBatteryand

andRainCap

1.Aligntheraincapofthemuferextension(fromthe

shippingkit)totheoutletpipeofthemufersothat

thepivotfortheraincapisinboard(Figure66).

Note:Whentheraincapiscorrectlyalignedtothe

outletpipeofthemufer,exhaustfromthemufer

willblowoutwardandawayfromthemachine.

InstallingtheSidePanels

1.RotatetheBATTERYDISCONNECTswitchtotheON

position(Figure67).

Figure67

1.BATTERYONposition2.BATTERYOFFposition

Figure66

1.Mufer-outletpipe4.Inboardofthemachine

2.Clamp5.Pivot(raincap)

3.Muferextensionandrain

cap

2.Assemblethemuferextensionandraincaptothe

outletpipeofthemufer(Figure66).

Note:Ensurethattheendofthemufer-outletpipe

extendspasttheslotsinthemuferextension

3.Securethemuferextensionandraincap(Figure66)

withtheclamp76mm(3inch)fromtheshippingkit.

2.Alignthesidepanel(fromtheshippingkit)withthe

machineframe.

3.Alignthemountingboltatthetopofthesidepanel

withtheholeinthesupportangeofthehoodpanel

(Figure68).

Figure68

4.Applylightinwardpressureagainstthepanelat1of

thelatches.

5.Setthelatchbypushinginthelatchlever—thepartof

thelatchtotheleftofthelockcylinder(Figure69).

25

Page 26

Figure69

1.Latchlever

2.Latchbutton

3.Side-panellatch

6.Repeatsteps4and5attheotherlatch.

7.Repeatsteps2through6forthesidepanelattheother

sideofthemachine.

26

Page 27

Notes:

27

Page 28

Loading...

Loading...