Page 1

FormNo.3396-283RevA

ColdStartKit

RT1200TractionUnit

ModelNo.131-2859

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Installation

1

PreparingtoInstalltheCold

StartKit

NoPartsRequired

PreparingtheMachine

1.Movethemachinetoalevelsurface,shutoffthe

engine,andremovethekeyfromthekeyswitch.

2.Allowtheengineandhydraulicsystemtocool.

RemovingtheSidePanelsand

DisconnectingtheBattery

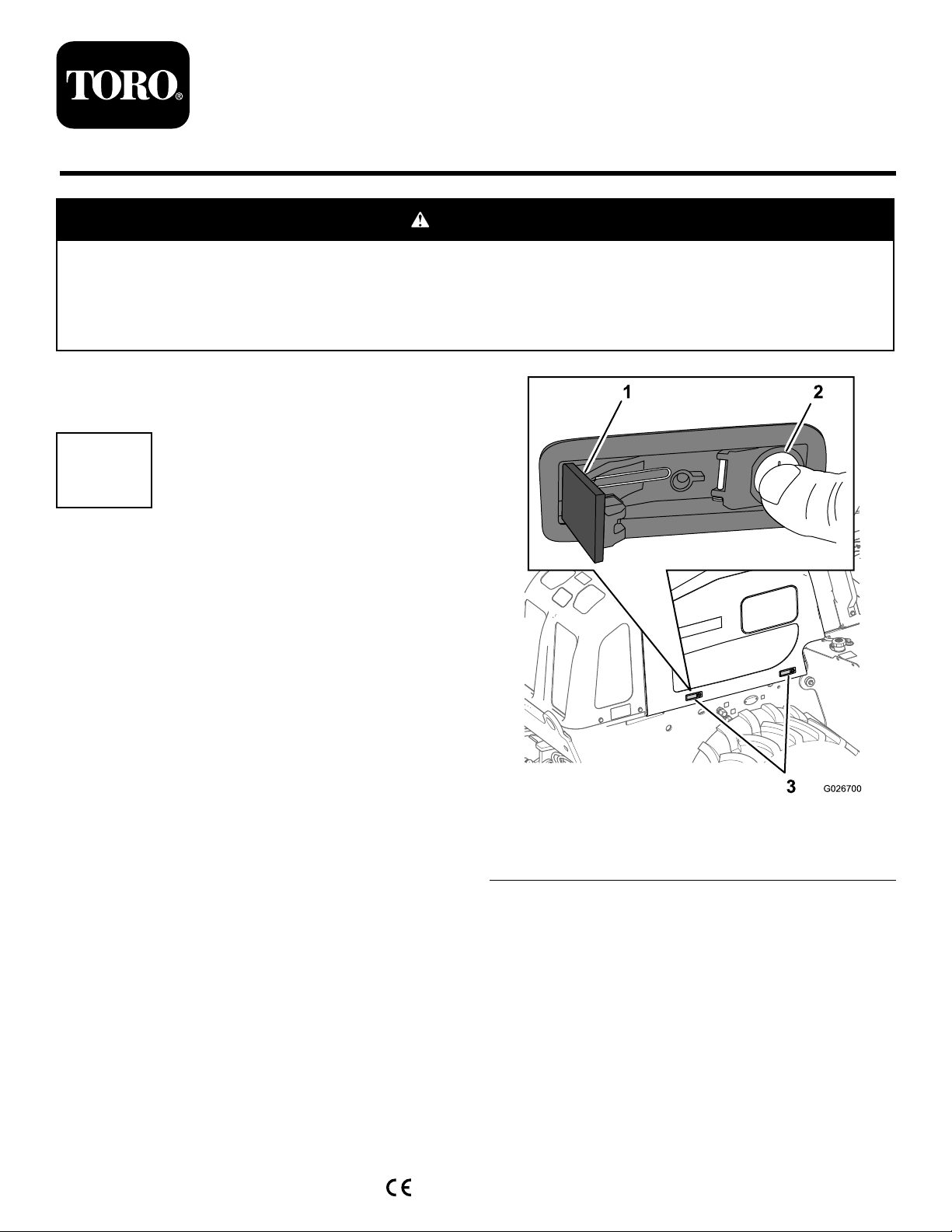

1.Pressinthebuttonportionofeachlatch—thepartof

thelatchincludingthelockcylinder(Figure1).

Figure1

1.Latchlever

2.Latchbutton

2.Liftthepanelupandawayfromthemachine(Figure2).

3.Side-panellatch

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3396-283*A

Page 2

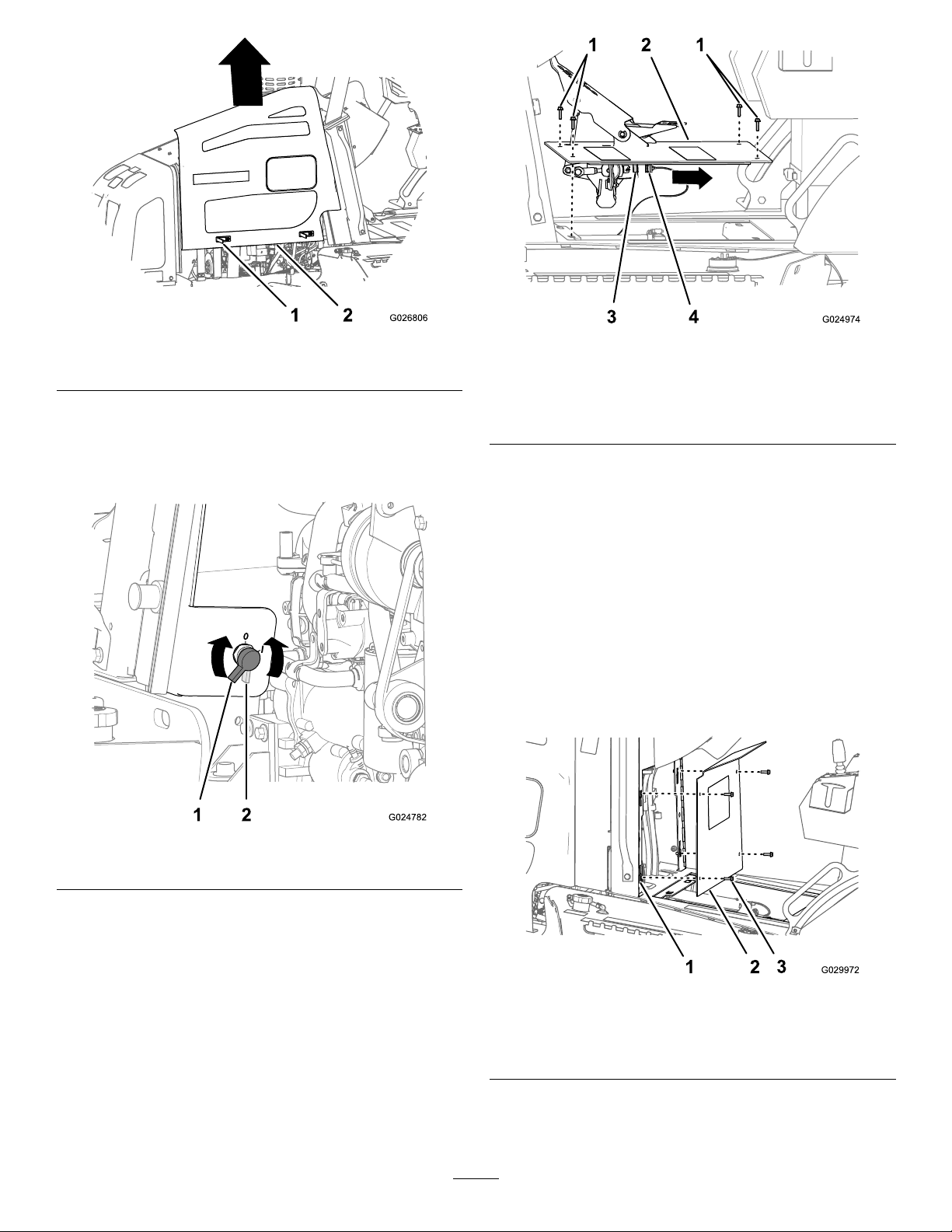

Figure2

Figure4

1.Latch

2.Sidepanel

3.Repeatsteps1and2forthesidepanelattheotherside

ofthemachine.

4.RotatetheBATTERYDISCONNECTswitch

counterclockwisetotheOFFposition(Figure3).

1.Flange-headbolts(5/16x

1inch)

2.Traction-pedalassembly4.6-socketconnector

3.6-pinconnector

(traction-pedalsensor)

(machineharness)

2.Removethecabletiesecuringthetraction-pedal

harness.

3.Disconnectthe6-socketconnectorofthemachine

harnessfromthe6-pinconnectorofthetraction-pedal

sensor(Figure4).

4.Removethetraction-pedalassemblyfromthemachine

(Figure4).

RemovingtheConsolePanel

1.Removethe4ange-headbolts(5/16x1inch)that

securetheconsolepaneltotheframeoftheconsole

(Figure5).

Figure3

1.BATTERYONposition2.BATTERYOFFposition

RemovingtheTraction-PedalAssembly

Removethetraction-pedalassemblyasfollows:

1.Removethe4ange-headbolts(5/16x1inch)that

securethattraction-pedalassemblytothechassisofthe

machine(Figure4).

Figure5

1.Flange-headbolts(5/16x

1inch)

2.Consolepanel

3.Consoleframe

2.Removetheconsolepanelfromthemachine(Figure5).

2

Page 3

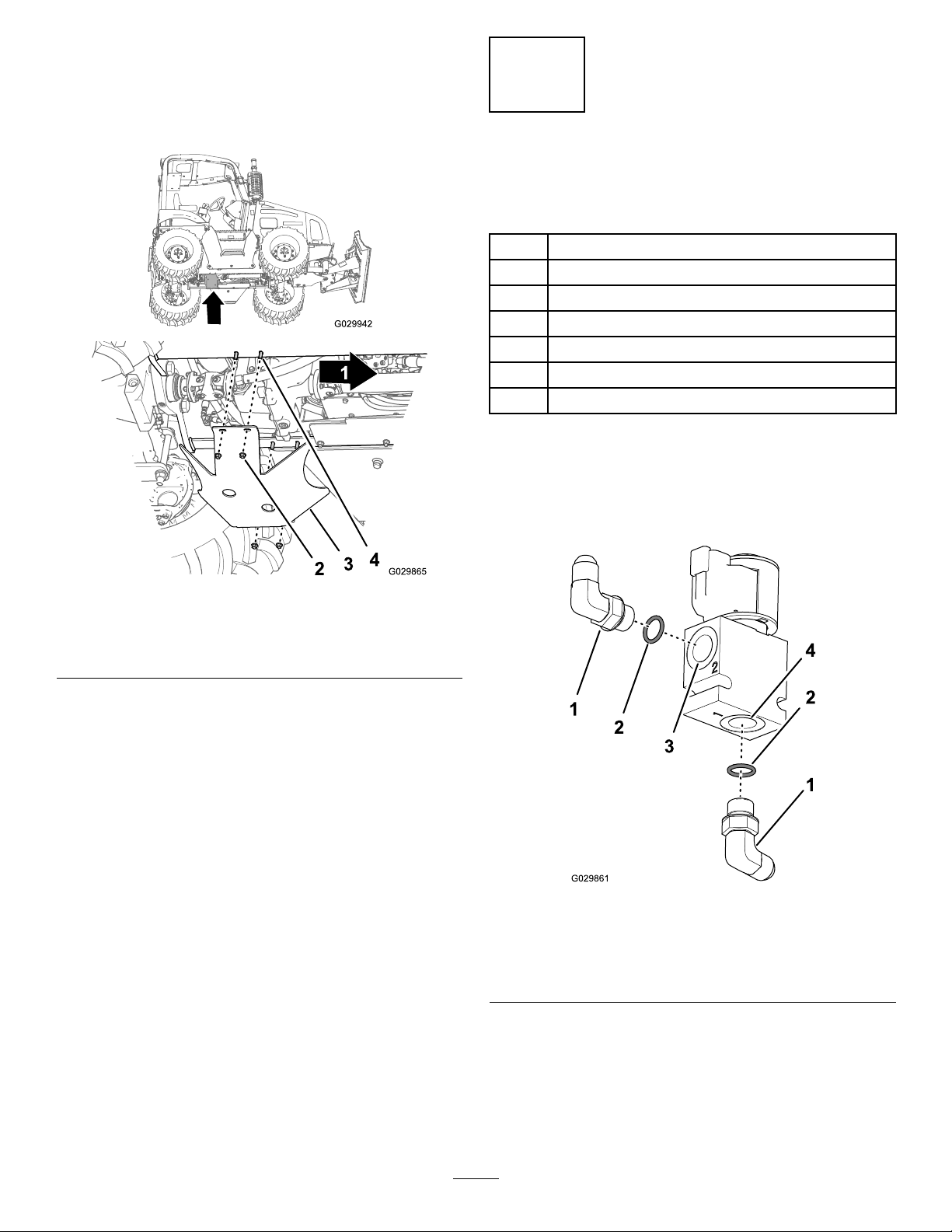

RemovingtheTransmissionShield

1.Removethe4angedlocknuts(1/2inch)from4

carriagebolts(1/2x1-1/2inch)thatsecurethe

transmissionshieldtotheframeofthemachine(Figure

6).

2

Assemblingthe2-Way

SolenoidValve

Partsneededforthisprocedure:

12-waysolenoidvalve

2

O-ring

2

90ºhydraulicttings

1Valve-mountplate

2

Carriagebolt(1/4x1-3/4inch)

2

Locknut(1/4inch)

2

Hose(1/4x16-1/4inch)

Procedure

1.Installthe2hydraulicttings(90°)andO-ringsinto

port1andport2ofthe2-waysolenoidvalveasshown

inFigure7.

Figure6

1.Frontofthemachine

2.Flangedlocknuts(1/2

inch)

2.Removethetransmissionshieldfromthemachine

(Figure6).

Note:Donotremovethecarriageboltsfromthe

frame.

3.Transmissionshield

4.Carriagebolts(1/2x1-1/2

inch)

Figure7

1.90ºhydraulicttings3.Port2(2-waysolenoid

valve)

2.O-ring4.Port1(2-waysolenoid

valve)

2.Assemblethe2-waysolenoidvalvetothevalve-mount

plate(Figure8)withthe2carriagebolts(1/4x1-3/4

inch)and2locknuts(1/4inch).

3

Page 4

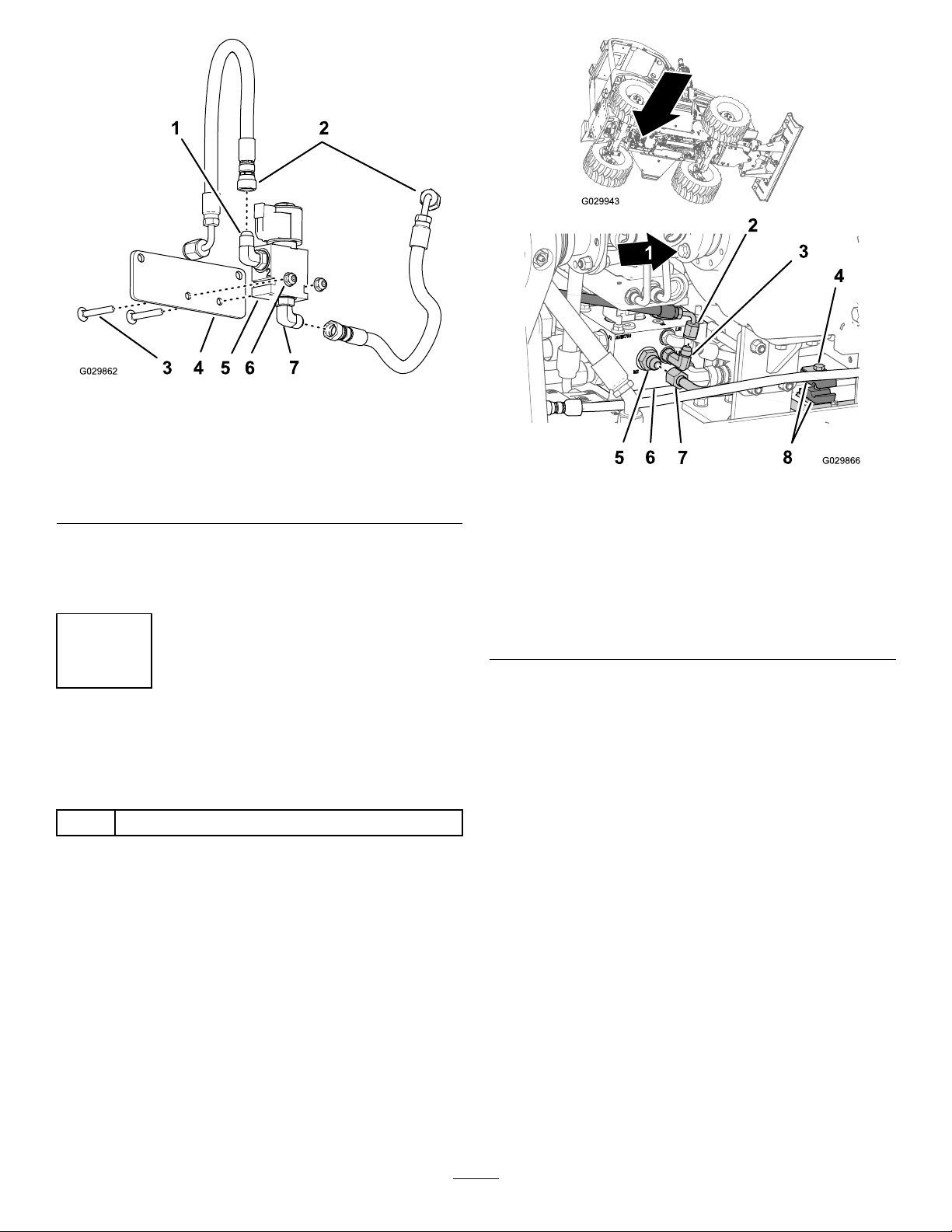

Figure8

1.90ºhydraulictting(port2)

2.Hoses(1/4x16-1/4inch)6.Locknut(1/4inch)

3.Carriagebolt(1/4x1-3/4

inch)

4.Valve-mountplate

3.Assemblethestraightttingsofthehoses(1/4x

16-1/4inch)ontothe90ºhydraulicttingsandtighten

thettingsbyhand(Figure8).

5.2-waysolenoidvalve

7.90ºhydraulictting(port1)

3

InstallingtheOriceInsertinto

theHIC-FanValve

Partsneededforthisprocedure:

1

Oriceinsert

Procedure

1.Loosenthebolt(5/16x1-1/2inch)thatsecuresthe

tubeforthefanmotorandtheclampblocks(Figure9).

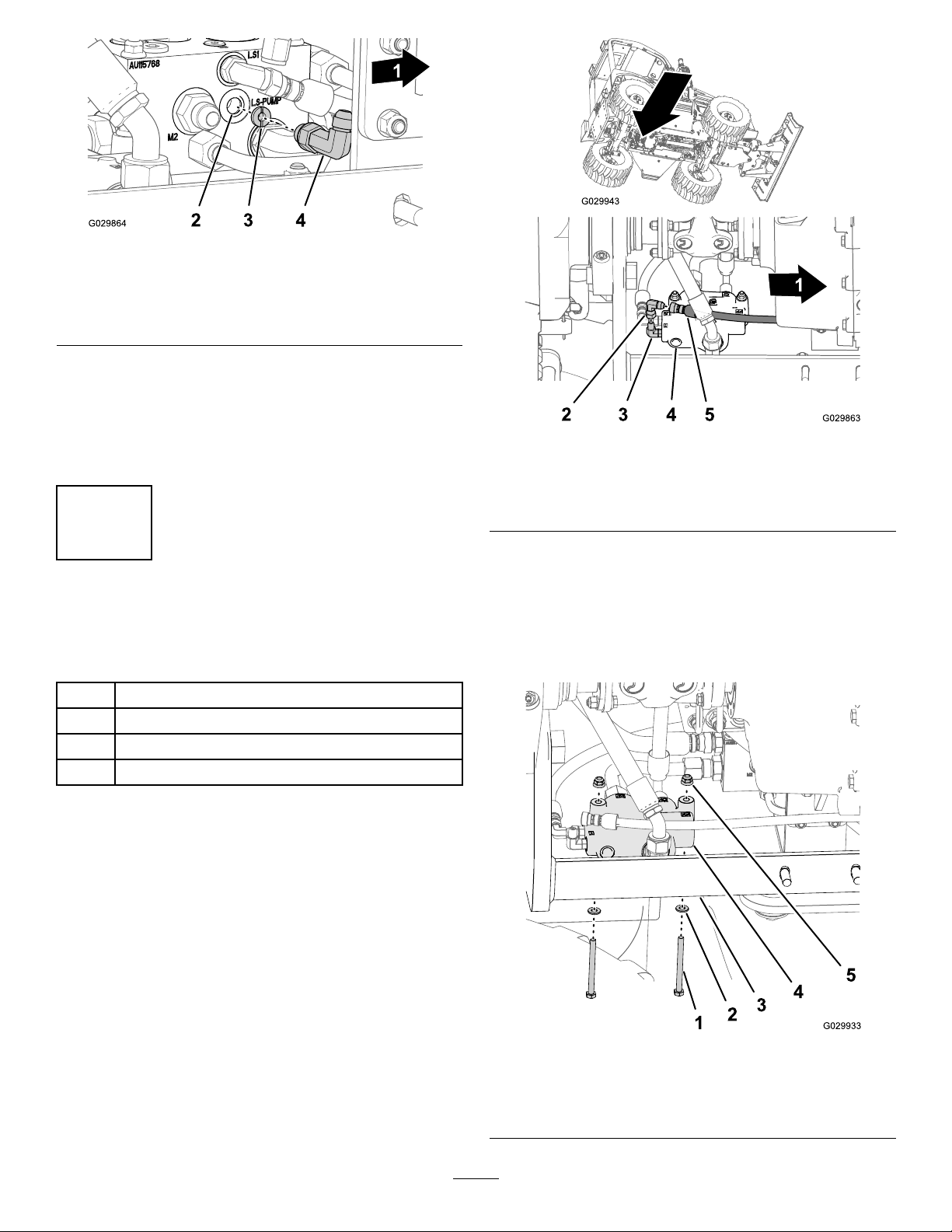

Figure9

1.Frontofthemachine5.Straight-hydraulictting

2.Hydraulichose(signalport

XtoLShydraulicpump)

3.90°hydraulic

adapter—long(LS-pump

port)

4.Bolt(5/16x1-1/2inch)8.Clampblock

2.Removethetubenutforthefan-motortubeandthe

straight-hydraulicttingatportM2oftheHIC-fan

valve(Figure9).

Note:Packtheareaaroundthettingwithragsto

absorbthehydraulicuid.

3.Removethehydraulichosefromthe90ºhydraulic

adapterattheLS-pumpportoftheHIC-fanvalve

(Figure9).

4.Removethe90ºhydraulicadapterattheLS-pumpport

(Figure9).

Note:ChecktheO-ringforthe90ºhydraulicadapter,

replacetheO-ringifitisdamagedorworn

(M2port)

6.HIC-fanvalve

7.Tube(hydraulic—fan

motor)

5.ThreadtheoriceinsertintotheLS-pumpportofthe

HIC-fanvalveandtightenbyhand(Figure10).

4

Page 5

Figure10

1.Frontofthemachine3.Oriceinsert

2.LS-pumpport4.90ºhydraulic

adapter—long(LS-pump

port)

6.Threadthe90ºhydraulicadapterintotheLS-pump

portoftheHIC-fanvalve(Figure10).

Note:Youwilltightenthejamnutforthe90º

hydraulicadapter,installstraight-hydraulictting,and

installthefan-motortubeinlatersteps.

Figure11

1.Frontofthemachine

2.90°swiveltting5.Hose(hydraulicreturn)

3.90°hydraulictting(T-port)

4.Flow-dividervalve

4

Installingthe2-WaySolenoid

ValveandHoses

Partsneededforthisprocedure:

2

Bolt(8x100mm)

2

Flangelocknut(8mm)

2

Washer(8mm)

2

T-tting

Assemblingthe2-WayValvetothe

Machine

1.Removethehydraulic-returnhosefromthe90°swivel

ttingthatisinstalledtothe90°hydraulicttingin

portToftheow-dividervalve(Figure11).

Note:Discardthe90°swiveltting.

2.Removetheswivelttingfromthe90°hydraulictting

inportToftheow-dividervalve(Figure11).

3.Removethe2angelocknuts(8mm),2bolts(8x90

mm),and2washersthatsecuretheow-dividervalve

totheleft,framechannelofthemachine(Figure12).

Note:Discardthebolts,nuts,andwashers.

1.Bolt(8x90mm)

2.Washer

3.Leftframechannel

5

Figure12

4.Flow-dividervalve

5.Flangelocknuts(8mm)

Page 6

4.Aligntheholesinthevalve-mountplateforthe2-way

solenoidvalve,theow-dividervalve,andtheleft

framechannel(Figure13).

Figure13

1.Flangelocknuts(8mm)4.Leftframechannel

2.Valve-mountplate(2-way

solenoidvalve)

3.Flow-dividervalve

5.Washer

6.Bolt(8x100mm)

InstallingtheSignalPort-XHose

1.AssembletheT-ttingontothe90ºhydraulicadapter

attheLS-pumpportoftheHIC-fanvalve(Figure14).

5.Assemblethemountplateand2-wayvalvetotheframe

with2bolts(8x100mm),2angelocknuts(8mm),

and2washersfromthekit(Figure13).

6.Torquetheboltsandnutsto23to29N-m(17to21

ft-lb).

Figure14

1.Frontofthemachine4.90ºhydraulicadapter

2.Hydraulichose(from

signalportXoftheLS

hydraulicpump)

3.T-tting

(LS-pumpportofthe

HIC-fanvalve)

5.HIC-fanvalve

2.InstallthehydraulichosefromsignalportXoftheLS

hydraulicpumptotheT-ttingattheHIC-fanvalve

asshownin(Figure14).

Note:Ifthe90°ttingofthehydraulichosedoesnot

alignwiththeT-ttingattheHIC-fanvalve,loosenthe

swivelttingatthe90°ttinginsignalportXofthe

LShydraulicpump(Figure15).

6

Page 7

1.Swiveltting(hydraulic

hose—signalportX)

Figure15

2.LShydraulicpump

Figure16

1.Frontofthemachine3.HIC-fanvalve

2.Hoses(1/4x16-1/4

inch)—Port1ofthe2-way

solenoidvalve

4.T-tting

InstallingtheLS-PumpHose

1.Installthehosethatisconnectedtothe90ºhydraulic

ttinginport1ofthe2-wayvalvetotheTttingat

LS-pumpportoftheHIC-fanvalve(Figure16).

2.Torquethehydraulicttings(Figure16)asspeciedin

thefollowingtablebelow:

Jamnutforthe90ºhydraulic

adapter—LS-pumpportofthe

HIC-fanvalve(Figure10)

T-tting—swivelnut(Figure

16)

Hydraulichose—fromsignal

portXoftheLShydraulic

pump(Figure14)

Hydraulichose—fromthe

90ºhydraulicttingatport1of

the2-wayvalve(Figure8)

47to58N-m(35to43ft-lb)

20to28N-m(15to21ft-lb)

20to28N-m(15to21ft-lb)

20to28N-m(15to21ft-lb)

7

Page 8

ConnectingtheFan-MotorTube

ConnectingtheHydraulicReturnHose

1.Installthestraight-hydraulicttingthatyouremoved

instep2of3InstallingtheOriceInsertintothe

HIC-FanValve(page4)andtorquethettingto47

to58N-m(35to43ft-lb).

1.AssembleaT-ttingontothe90°hydraulicttingin

portToftheow-dividervalve(Figure19).

Figure17

1.Frontofthemachine3.Straight-hydraulictting

2.LS-pumpport

4.Fan-motortube

2.Installthefan-motortubetothestraight-hydraulic

tting(Figure17)andtorquetheswivelnutforthe

tubeto45to55N-m(33to41ft-lb).

3.Alignthe2fan-motortubestotheclampblocks

(Figure18)andtightenthebolt(5/16x1-1/2inch)to

1978to2542N-cm(175to225in-lb).

Figure18

Figure19

1.Hoses(1/4x16-1/4

inch)—fromport2of

2-waysolenoidvalve

2.2-waysolenoidvalve6.Hydraulic-returnhose

3.Frontofthemachine

4.90°hydraulictting(port

T)

5.T-tting

7.Flow-dividervalve

2.Assemblethehydraulic-returnhosetotheT-ttingas

showninFigure19.

3.Assemblethehosefromthe90°hydraulicttingin

port2ofthe2-waysolenoidvalveontotheT-ttingas

showninFigure19.

4.TorquetheswivelnutoftheT-ttingto20to28N-m

(15to21ft-lb),andthehydraulic-returnhoseandthe

port2hoseofthe2-waysolenoidvalveto20to28

N-m(15to21ft-lb).

1.Fan-motortubes

2.Bolt(5/16x1-1/2inch

3.Clampblock

8

Page 9

5

InstallingtheWiringHarness

Partsneededforthisprocedure:

1Timerrelayandmountingtab

1

Self-adhesivecover

1

Wiringharness(cold-startkit)

2

Flangeheadbolt(#10–32x3./4inch)

2

Flangelocknut(#10–32)

PreparingtheTimerRelay

1.Insertthenarrowlegofthemountingtabintotheslot

inthecaseofthetimerrelaywiththeoffsetlegaway

fromthecase(Figure20).

2.Atthetopofthetimerrelay ,setswitch1totheON

(up)position(Figure20).

RemovingtheDashPanel

1.Disconnectthe23-pinconnectorofthedashwiring

harnessfromthe23-socketconnectorforthemachine

wiringharness(Figure21)

Figure21

1.23-pinconnector(dash

wiringharness)

2.23-socketconnector

(machinewiringharness)

Figure20

1.Clockwise(untilyoufeel

lightcontact)

2.Counterclockwise30°4.Mountingtab(part

3.Self-adhesivecover

includedwiththetimer

relay)

2.Removethe4angebolts(8x30mm)and2ange

locknuts(8mm)thatsecurethedashassemblytothe

frameoftheconsole(Figure22).

3.Setswitch2totheOFF(down)position(Figure20).

4.Rotatetheslotofthetimercontrolcounterclockwise

untilyoufeellightcontact(Figure20).

5.Rotatetheslotofthetimercontrolclockwise30°

(Figure20).

1.Flangebolt(8x30mm)

2.Flangelocknut(8mm)

9

Figure22

3.Dashassembly

Page 10

3.Removethedashfromtheconsole(Figure22).

ConnectingtheWiringHarnessofthe

Cold-StartKittotheDashPanel

1.Atthebackofthedash,removethe6-socketconnector

ofthedashharnessfromthebladeterminalofthe

starterswitch(Figure23).

2.Attheauxiliary-powerport,removethesocketterminal

fortheblack(ground)wireofthedashharness(Figure

23).

Figure24

Figure23

1.6-socketconnector(dash

harness)

2.Starterswitch

3.Socketterminal—black

(ground)wire

4.Bladeterminal

(auxiliary-powerport)

3.Connectthesocketterminalfortheblackwireofthe

dashharnessontothepiggybackterminalofthewiring

harnessforthecold-startkit(Figure24).

1.Bluewire(dashharness)3.Piggybackterminal(wiring

2.Socketterminal—black

(ground)wire(dash

harness)

harnessforthecold-start

kit)

4.Bladeterminal

(auxiliary-powerport)

4.Connectthepiggybackterminalofthewiringharness

forthecold-startkitontotheopenbladeterminalof

theauxiliary-powerport(Figure24).

5.Connectthe6-socketconnectorofthewiringharness

forthecold-startkitontotheconnectorforthestarter

switch(Figure25).

Figure25

1.6-pinconnector(wiring

harnessforthecold-start

kit)

2.6-socketconnector(dash

harness)

3.Starter-switchconnector

4.6-socketconnector(wiring

harnessforthecold-start

kit)

6.Connectthe6-pinconnectorofthewiringharnessfor

thecold-startkitintothe6-socketconnectorofthe

dashharness(Figure25).

10

Page 11

RoutingtheWiringHarnessand

G030030

InstallingtheDashPanel

1.Routethelegsofthewiringharnesswiththe2-socket

connectorand5-socketconnectordownthrough

theconsoleandlongthemainwiringharnessofthe

machine(Figure26).

4.Routethelegofthewiringharnesswiththe2-socket

connectordownthroughthegrommetoftheoor

plate(Figure27).

Figure27

Figure26

1.2-socketconnector

2.5-socketconnector4.6-pinconnector,

3.Grommet

6-socketconnector,and

uninsulatedterminal

2.Securethedashpaneltotheconsolewiththe4ange

bolts(8x30mm)and2angelocknuts(8mm)that

youremovedinstep2ofRemovingtheConsolePanel

(page2).

1.Frontofthemachine

2.Wiringharness(cold-start

kit)

3.Hydraulicpump

5.Routethelegofthewiringharnesswiththe2-socket

connectordownrearwardalongthemainwiring

harnessforthemachine(Figure27).

6.Routethelegofthewiringharnesswiththe2-socket

connectordowntothe2-wayvalve(Figure28).

3.Connectthe23-pinconnectorofthedashwiring

harnesstothe23-socketconnectorofthemachine

wiringharness;refertoFigure21inRemovingthe

DashPanel(page9).

11

Page 12

Figure28

DrillingtheMountingHolesforthe

5-socketConnectorandTimerRelay

1.Attheleft,rearsideoftherewall,measurefromthe

oorplatevertically197mm(7-3/4inches)andmark

therewall(Figure30).

1.Wiringharness(cold-start

kit)

2.2-wayvalve

3.Frontofthemachine

7.Connectthe2-socketconnectorofthewiringharness

forthecold-startkitontothe2-pinconnectorofthe

2-wayvalve.

Figure30

1.Innersideofconsoleto

centerofhole103mm

(4-1/16inches)

2.5mm(3/16inch)drillbit7.Flange-headbolt(#10–32

3.Floorplatetocenter

ofhole197mm(7-3/4

inches)

4.Frontofthemachine9.Hole(rewall)

5.Wiringlegwiththe

6-pinconnector,

6-socketconnector,and

uninsulatedterminal

6.Wiringlegwiththe

2-socketconnector

x3/4inch)

8.5-socketconnector

1.2-socketconnector(wiring

harnessforthecold-start

kit)

Figure29

2.2-pinconnector(2-way

valve)

2.Fromtheinboardsideoftheleft-consolepanel,

measurehorizontally103mm(4-1/16inches)and

marktherewall(Figure30).

3.Centerpunchtherewallattheintersectionofthe2

marks.

12

Page 13

4.Atthecenterpunchmark,drilla5mm(3/16inch)

holethroughtherewall(Figure30).

Important:Coverthefuseblocktopreventmetal

shavingsfromtouchingtheblock.

5.Assemblethe5-socketconnectortotherewall(Figure

30)withaange-headbolt(#10-32x3/4inch).

6.Assemblethetimerrelaytothe5-socketconnector

(Figure31).

Figure31

1.5-socketconnector2.Timerrelay

8.Removethetimerrelayfromthe5-socketconnector,

removethe5-socketconnectorfromtherewall,and

centerpunchthemarkthatyoumadeinstep7.

9.Atthecenterpunchmark,drilla5mm(3/16inch)

holethroughtherewall(Figure32).

Important:Coverthefuseblockand5-socket

connectortopreventmetalshavingsfromtouching

theblockandconnector.

Assemblingthe5-socketConnector

andTimerRelaytotheFirewall

1.Securethe5-socketconnectortothelowerholeinthe

rewallwithaange-headbolt(#10-32x3/4inch)

andangelocknut(#10–32);refertoBinFigure30

andFigure33

7.Aligntherelayand5-socketconnectorverticallyand

marktheholeinthemountingtabforthetimerrelay

ontotherewall(AofFigure32).

Figure33

1.Frontofthemachine3.Flange-headbolt(#10-32

2.Locknut(#10-32)

x3/4inch)

4.Firewall

2.Assemblethetimerrelaytothe5-socketconnector

(Figure31).

1.Pencil

2.Mountingtab(timerrelay)

Figure32

3.5mm(3/16inch)drillbit

13

Page 14

Figure34

InstallingtheSidePanels

1.RotatethebatterydisconnectswitchtotheOn

position;refertoFigure3inRemovingtheSidePanels

andDisconnectingtheBattery(page1).

2.Alignthesidepanelwiththemachineframe.

3.Alignthemountingboltatthetopofthesidepanel

withtheholeinthesupportangeofthehoodpanel

(Figure35).

1.Flange-headbolt(#10-32

x3/4inch)

3.Securethemountingtabforthetimerrelaytothe

upperholeintherewallwithaange-headbolt

(#10-32x3/4inch)andangelocknut(#10–32);refer

toFigure33andFigure34.

2.Mountingtab(timerrelay)

6

FinishingtheInstallationthe

ColdStartKit

NoPartsRequired

InstallingtheTransmissionShield

1.Aligntheholesintheangeofthetransmissionshield

withthe4carriageboltsintheframeofthemachine

thatyoudisassembledinstep1ofRemovingthe

TransmissionShield(page3).

Figure35

4.Applylightinwardpressureagainstthepanelat1of

thelatches.

5.Setthelatchbypushinginthelatchlever;refertoFigure

1inRemovingtheSidePanelsandDisconnectingthe

Battery(page1).

6.Repeatsteps4and5attheotherlatch.

7.Repeatsteps2through6forthesidepanelattheother

sideofthemachine.

2.Securethetransmissionshieldtotheframeofthe

machinewiththe4angelocknutsthatyouremoved

in1ofRemovingtheTransmissionShield(page3).

3.Torquethenutsto91to113N-m(67to83ft-lb).

InstallingtheTraction-pedalAssembly

1.Connectthe6-socketconnectorofthemachineharness

tothe6-pinconnectorofthetraction-pedalsensor;

refertoFigure4inRemovingtheTraction-Pedal

Assembly(page2).

2.Aligntheholesintheplateofthetraction-pedal

assemblywiththeholesinthechassisofthemachine;

(Figure4).

3.Securethetraction-pedalassemblytothechassisof

themachinewiththe4hex-angedheadbolts(6x25

mm);refertoFigure4.

7

CheckingtheOperationofthe

Machine

NoPartsRequired

CheckingtheOperationoftheKit

Note:Youwillneedanotherpersontocheckthefunctionof

themachine.

1.Starttheengine.

Note:Lettheenginerunfor1to2minutes.

14

Page 15

2.Ensurethatthefanforthecoolingsystemstarts

running5secondsaftertheenginestarts.

ServicingtheHydraulicSystem

•Ifthefanstartsearlierthat5secondsafterthe

enginestarts,rotatetheslotofthetimerclockwise

toincreasethetimerdelay(Figure36).

Figure36

1.Clockwise—moretimer

delay

2.Counterclockwise—less

timerdelay

3.Self-adhesivecover

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

Ifhydraulicuidisinjectedintotheskinitmustbe

surgicallyremovedwithinafewhoursbyadoctor

familiarwiththistypeofinjury.Gangrenemay

resultifthisisnotdone.

•Keepbodyandhandsawayfrompin-holeleaks

ornozzlesthatejecthigh-pressurehydraulic

uid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Makesurethatallhydraulic-uidhosesand

linesareingoodconditionandthatallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

Hydraulic-uidspecication:T oroPremiumAll-season

HydraulicFluid

IfToroPremiumAll-seasonHydraulicFluidisnotavailable,

youmayuseMobilDTE15MSpecial(MobilDTE15Muid

withspecialantiwearadditivepackage).

1.Checkthemachineforhydraulicleaks.

•Ifthefanstartslaterthat5secondsaftertheengine

starts,rotatetheslotofthetimercontrolclockwise

todecreasethetimerdelay(Figure36).

3.Ensurethescreenofthecommandcenterisdisplaying

themachineandengineinformation.

4.Shutofftheengineandremovethekeyfromthekey

switch.

5.Removethereleasebackingfromtheself-adhesive

cover,alignitovertheswitchesandtimercontrol,and

pressthecovertothecaseofthetimerrelay(Figure36).

Note:Repairallhydraulicleaksbeforeoperatingthe

machine.

2.Checkthelevelofthehydraulicuidinthetankand

addthespeciedhydraulicuidasneeded;refertothe

Operator’sManualforthemachine.

Note:Youshouldseethatthehydraulic-uidlevelis

atthemidpointofthesightglassatthesideofthetank.

InstallingtheConsolePanel

1.Applymedium-gradethread-lockingcompoundtothe

4ange-headbolts(5/16x1inch)thatyouremovedin

step1ofRemovingtheConsolePanel(page2).

2.Aligntheholesintheconsolepanelwiththeholesin

theframeoftheconsole;refertoFigure5inRemoving

theConsolePanel(page2).

3.Assemblethepaneltotheconsolewiththe4

ange-headbolts(5/16x1inch).

4.Torquetheboltsto1978to2542N-cm(175to225

in-lb).

15

Page 16

Loading...

Loading...