Page 1

FormNo.3395-583RevA

ExhaustKit

RT1200TractionUnit

ModelNo.131-2814

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Installation

1

PreparingtoInstallthe

ExhaustKit

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Lowerallattachments,stoptheengine,andremovethe

keyfromtheKEYSWITCH.

3.Removetheright-sidepanel;refertoOperator’sManual

forthemachine.

4.Allowtheexhaustsystemtocoolcompletely.

2

Note:Thebatterycoverislocatedbetweenthe

operatorseatandtherearROPSbulkhead.

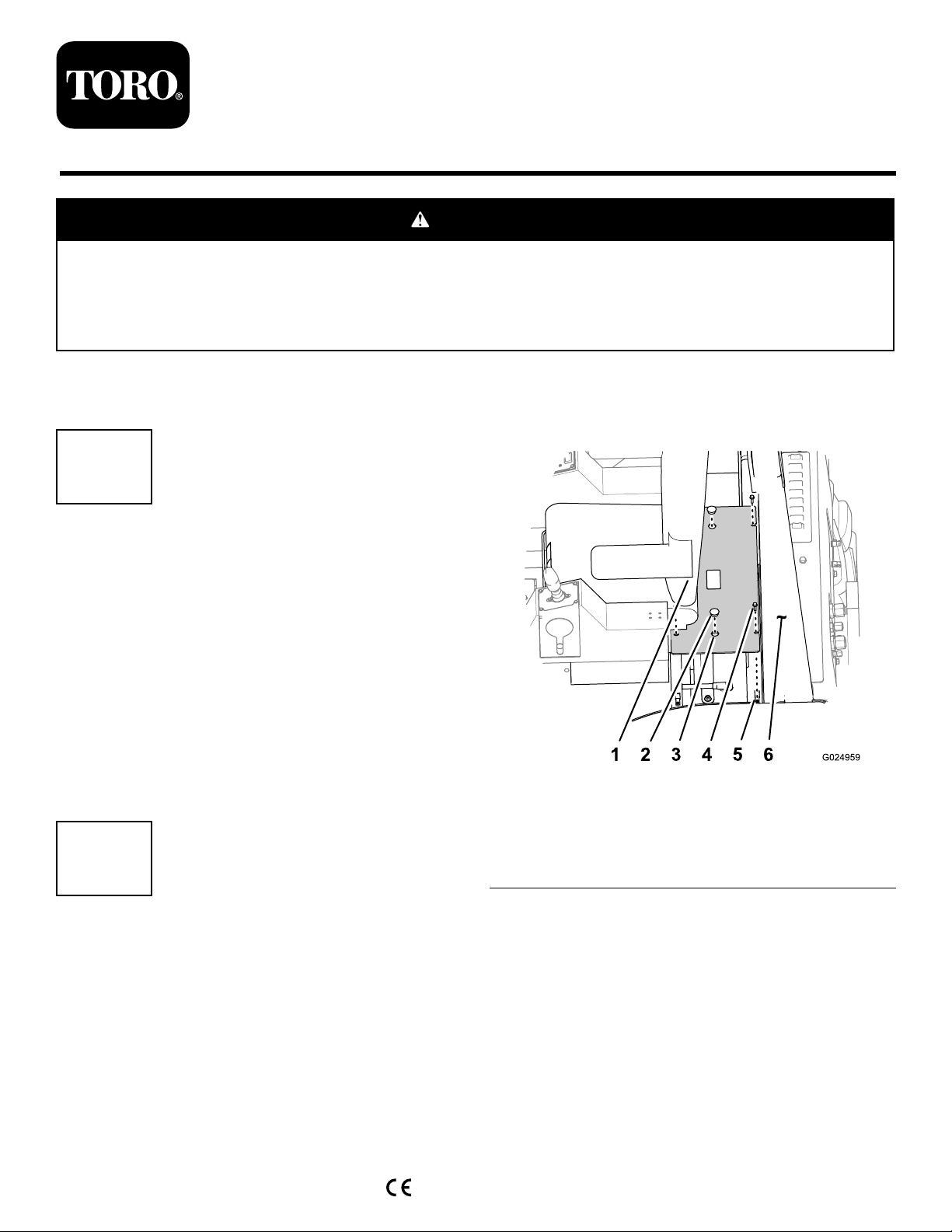

Figure1

1.Operatorseat4.Flange-headbolts(5/16x

1inch)

2.Finger-pullcover5.Nutclip

3.Hole(batterycover)6.ROPSbulkhead

RemovingtheRight-Cowl

Panel

NoPartsRequired

DisconnectingtheBattery

1.RotatetheBATTERY-DISCONNECTswitchtotheOff

position;refertoOperator’ sManualforthemachine.

2.Removethe2nger-pullcoversfromtheholesinthe

batterycover(Figure1).

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

3.Removethe4ange-headbolts(5/16x1inch)that

securethebatterycovertotheROPSplatform(Figure

1).

4.Usingthengerpulls,liftthebatterycoverupto

removeitfromtheROPSplatform(Figure1).

5.Removethelock-washernut(3/8inch)securingthe

negative-batterycableandringterminaltothenegative

studofthebatteryandremovethecablesfromthe

battery(Figure2).

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3395-583*A

Page 2

2.Atthebattery-disconnectswitch,removethescrewthat

securestheknobtotheshaftoftheswitch(Figure4).

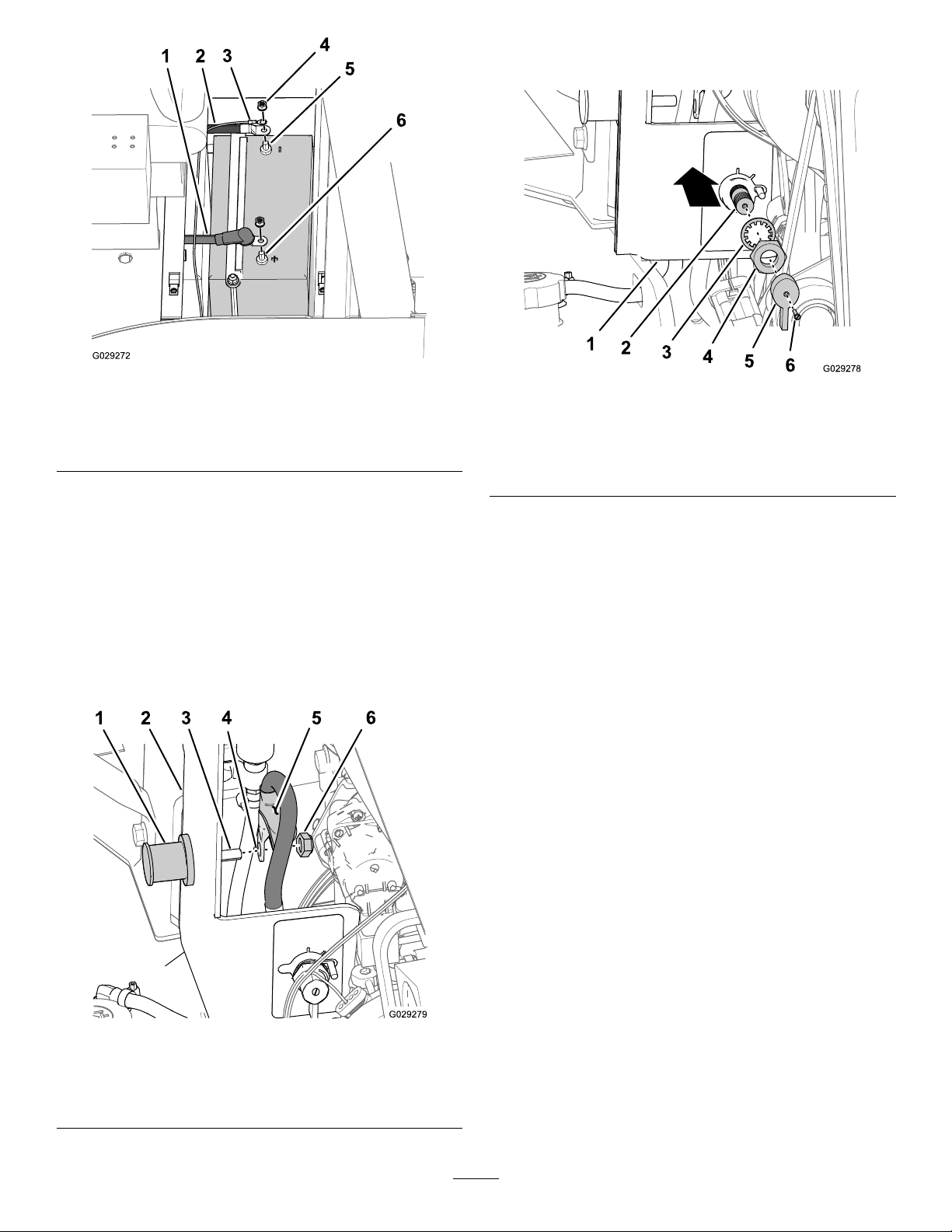

Figure2

1.Positive-batterycable

2.Negative-batterycable

3.Ringterminal

4.Lock-washernut(3/8inch)

5.Negativestud(battery)

6.Positivestud(battery)

6.Movebacktheinsulatorbootandremovethe

lock-washernut(3/8inch)securingthepositive-battery

cabletothepositivestudofthebatteryandremovethe

cablefromthebattery(Figure2).

DisconnectingtheBattery-Disconnect

Switch

1.Attheinboardsideofthejumppost,movebackthe

insulatorboot,removethenut,andremovethecable

formthethreadedstud(Figure3).

Figure4

1.Right-cowlpanel4.Jamnut

2.Shaft(battery-disconnect

switch)

3.Lockwasher

5.Knob

6.Screw

3.Removethejamnutandlockwasherthatsecurethe

disconnectswitchtotheright-cowlpanel(Figure4).

4.Pushtheshaftofthebattery-disconnectswitch

rearwardtoseparatetheswitchfromthecowlpanel

(Figure4).

Figure3

1.Jumppost

2.Right-cowlpanel5.Insulatorboot

3.Threadedstud6.Locknut

4.Cableterminal

2

Page 3

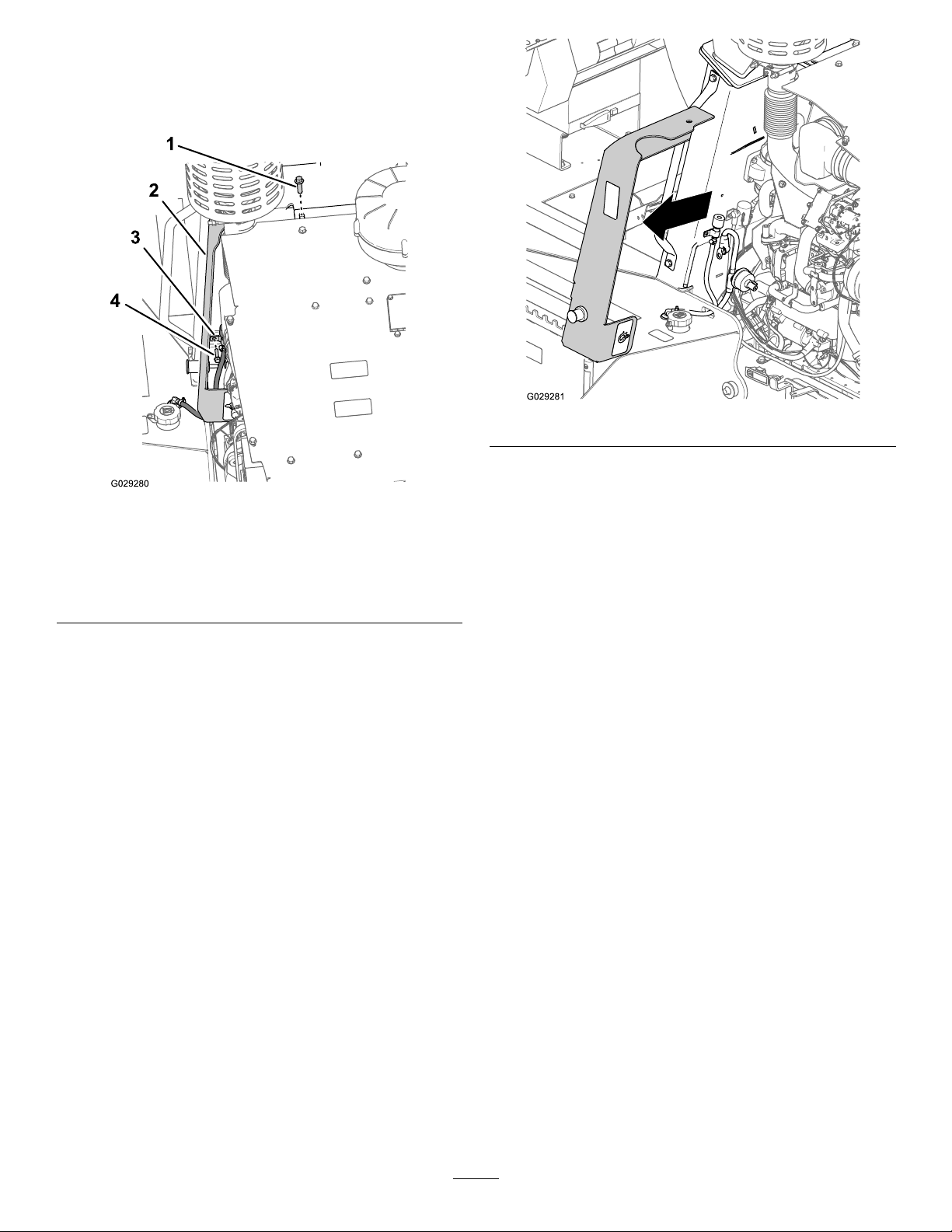

RemovingtheSide-CowlPanel

1.Removetheange-headbolt(12x40mm)thatsecures

theright-cowlpaneltotheROPS-mountingplate

(Figure5).

Figure6

Figure5

1.Flange-headbolt(12

x40mm)—upper

ROPS-mountingplate

2.Right-cowlpanel

3.Clamp(hydraulic-tank

breather)

4.Flange-headbolt(8x35

mm)—rewall

2.Removetheange-headbolt(8x35mm)thatsecures

theclampforthehydraulic-tankbreatherandthe

right-cowlpaneltotherewall(Figure5)

3.Removetheright-cowlpanelfromthemachine(Figure

6).

Note:Rotatethepanelasneededtocleartheexhaust

systemcomponents.

3

Page 4

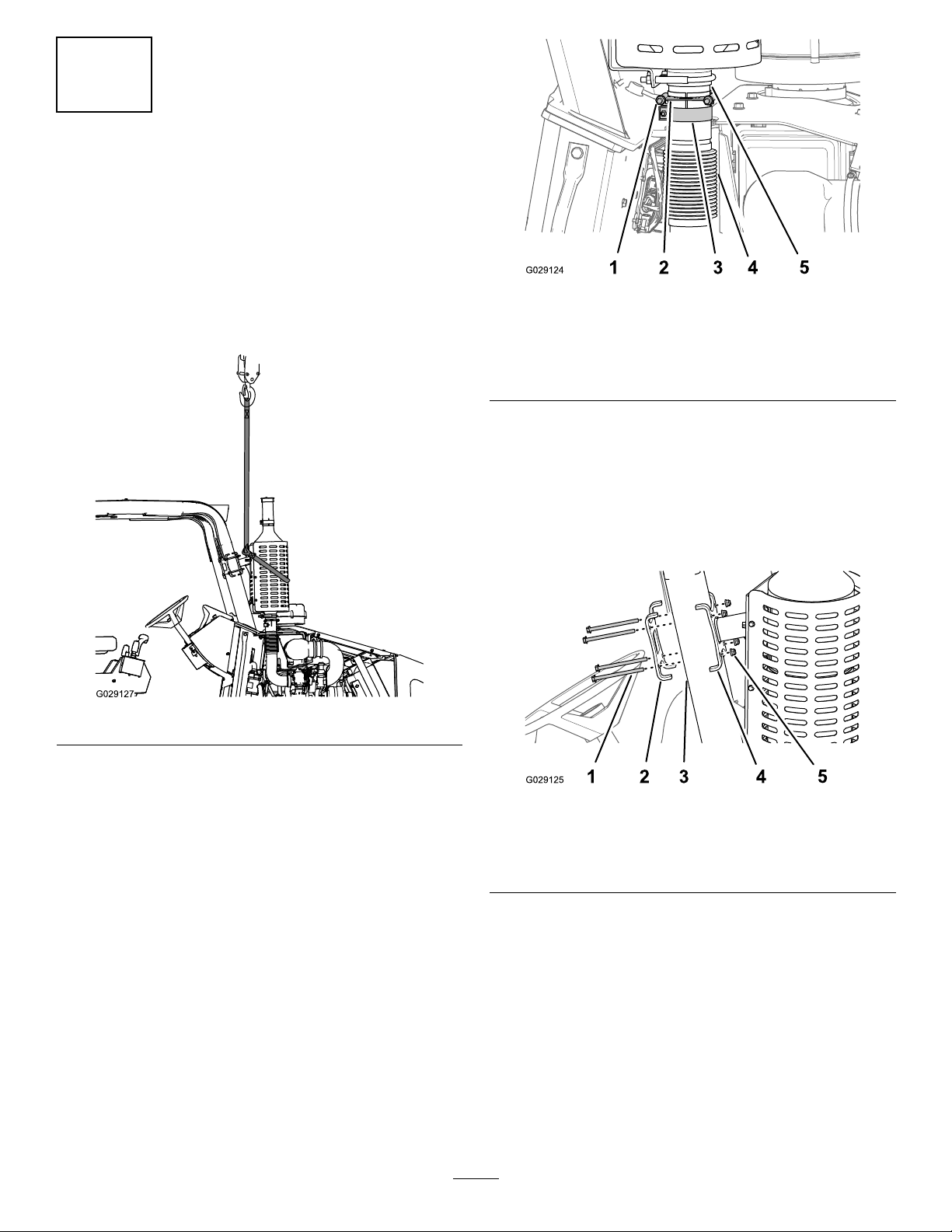

3

RemovingtheExhaustSystem

NoPartsRequired

RemovingtheMuferandHeatShield

Note:Exhaustsystemweight:approximately39.5kg(88

lb).

1.Supporttheexhaustsystemwithliftingequipment

(Figure7).

Figure8

1.Flangenut4.Turbocharger-exhaust

pipe

2.Guillotineclamp5.Muferinletpipe

3.Bandclamp

3.Removethe4angelocknuts(8mm),4bolts(8x

120mm),andrearmountingplatethatsecurethe

exhaust-systemmounttothefrontrightROPStube

(Figure9).

Note:Retainthelocknuts,bolts,andmountingplate

forinstallationinAssemblingtheMufertothe

TurbochargerOutletPipe(page7).

Figure7

2.Removethebandclampandthelowerguillotineclamp

thatsecuresthemufertotheturbocharger-exhaust

pipe(Figure8).

Note:RetaintheclampsforinstallationinInstalling

theBellows-AlignmentJig(page5)andInstallingthe

GuillotineClampandtheBandClamp(page8).

Figure9

1.Bolts(8x120mm)

2.Rearmountingplate

3.ROPStube

4.Separatethemuferfromtheturbocharger-exhaust

pipeandremovethemuferfromthemachine(Figure

10).

Note:Donotremovetheheatshieldfromthemufer.

4.Exhaust-systemmount

5.Flangelocknuts(8mm)

4

Page 5

Figure10

5.Removetheangeclampthatsecurestheangeofthe

turbocharger-exhaustpipetotheoutletangeofthe

turbochargerandremovetheexhaustpipefromthe

machine(Figure11).

Note:Retaintheangeclampforinstallation

inInstallingtheTurbocharger-ExhaustPipeand

Pipe-AlignmentJig(page6);discardtheold

turbocharger-exhaustpipe.

4

Preparingthe

Turbocharger-ExhaustPipe

NoPartsRequired

PreparingtheMufer

1.Cleantheexteriorsurfaceoftheinletpipeforthe

mufer(Figure12).

Figure12

1.Flange

(turbocharger-exhaust

pipe)

2.Nut(angeclamp)

Figure11

1.Inletpipe(mufer)

2.Applyalightcoatofhigh-temperature,anti-galling

compoundtotheexteriorsurfaceofthemufer-inlet

pipe.

5

Installingthe

Turbocharger-ExhaustPipe

Partsneededforthisprocedure:

1Bellows-alignmentjig

1Turbocharger-exhaustpipe

3.Flange(turbocharger

outlet)

1Pipe-alignmentjig

InstallingtheBellows-AlignmentJig

1.Alignthebellows-alignmentjigtothenew

turbocharger-exhaustpipewiththeshorttabofthejig

belowthebellows(Figure13).

5

Page 6

Figure13

1.Guillotineclamp5.Leftleg(bellows-alignment

2.Flangenut

3.Bellows

(turbocharger-exhaust

pipe)

4.Insideradius

(turbocharger-exhaust

pipe)

jig)

6.Shorttab

(bellows-alignmentjig)

7.Rightleg

(bellows-alignmentjig)

2.Assembletheguillotineclampthatyouremovedinstep

2ofRemovingtheMuferandHeatShield(page4)to

thebellows-alignmentjig(Figure13).

3.Aligntheleftlegofthejigtotheoutsideradiusofthe

bendinthepipeandtherightlegtotheinsideradius

ofthebendasshowninFigure13.

4.Tightentheangenutsoftheguillotineclampto19

to25N-m(14to18ft-lb).

InstallingtheTurbocharger-Exhaust

PipeandPipe-AlignmentJig

Figure14

1.Turbocharger-exhaust

pipe(withthebellowjig

installed)

2.Flangeclamp

3.Turbocharger-outletange

2.Loosenthe2ange-headbolts(10x20mm)that

securetheupper-rearheatshieldtothestandoffsofthe

exhaustmanifold(AofFigure15).

Note:Youwillhavetoloosentheboltssothatyou

have5mm(3/16)ormoreclearancebetweenthehead

oftheboltandtheheatshield.

1.Assemblethenewturbocharger-exhaustpipetothe

outletangeoftheturbochargerwiththeangeclamp

thatyouremovedinstep5ofRemovingtheMufer

andHeatShield(page4)andtightentheangenutonly

enoughtokeepthepipealignedtotheturbocharger

(Figure14).

6

Page 7

6

InstallingtheMuferandHeat

Shield

Partsneededforthisprocedure:

3

Shim1.5mm(0.06inch)

1

Shim0.8mm(0.03inch)

AssemblingtheMufertothe

TurbochargerOutletPipe

1.Alignthebandclamparoundtheturbocharger-exhaust

pipe

2.Aligntheinletpipeofthemuferwiththe

turbocharger-exhaustpipe(Figure16).

Note:Ensurethatthealignmentpinsofthe

muferinletpipearealignedwiththeslotsinthe

turbocharger-exhaustpipeange.

Figure15

1.Turbocharger-exhaust

pipe

2.Flange-headbolts(10x

20mm)

3.Flangeclamp

4.Upper-rearheatshield

3.Assemblethepipe-alignmentjigontotheheatshield

andundertheange-headbolts(AofFigure15)and

tightentheboltsto17to21N-m(47to57ft-lb).

Note:Ensurethatthealignmentjigispushedinward

sothattheboltsarefullyseatedintheslotsofthejig.

4.Rotatetheexhaustpipesothatthesurfaceofthepipe

isushtothesmallangeofthepipe-alignmentjig

(BofFigure15).

Note:Thesmallangeofthepipe-alignmentjig

shouldalignbetweenthe2legsofthebellows-alignment

jig.Ifthebracketsarenotaligned,loosentheguillotine

clamp,positionthebellowsjig,andtightentheange

nutsoftheguillotineclampto19to25N-m(14to

18ft-lb).

5.Tightenthenutoftheangeclampsecurely.

5.Pipe-alignmentjig

6.Standoff(exhaust

manifold)

7.Smallange

(pipe-alignmentjig)

8.Pipesurface

(turbocharger-exhaust

pipe)

Figure16

1.Alignmentpin(muferinlet

pipe)

2.Bandclamp

3.Inserttheinletpipeintotheexhaustpipeintotheinlet

pipeisfullyseated(Figure16)

Note:Youshouldalignthepinatthemuferinletpipe

nearthebottomoftheslotintheturbocharger-exhaust

pipe.

Note:Donottwistthemuferwhileassemblingit

totheturbocharger-exhaustpipeoryoumaydamage

thebellows.

3.Slot

(turbocharger-exhaust

pipeange)

7

Page 8

4.Aligntheexhaust-systemmounttothefront,right

ROPStube(Figure17).

Figure17

InstallingtheGuillotineClampandthe

BandClamp

1.Removethe2ange-headboltsthatsecure

theguillotineclamp,bellows-alignmentjig,and

turbocharger-exhaustpipe,andremovethejig(Figure

18).

1.Rearmountingplate

2.Flange-headbolts(8x120

mm)

3.ROPStube7.Shim1.5mm(0.06inch)

4.Exhaust-systemmount

5.Flangelocknut(8mm)

6.Shim0.8mm(0.03inch)

5.Looselyassembletherearmountingplatetotheto

theexhaust-systemmount(Figure17)withthe4

ange-headbolts(8x120mm)and4angelocknuts

(8mm)thatyouremovedinstep3of3Removingthe

ExhaustSystem(page4).

6.Checkthegapbetweentheexhaust-systemmountand

theROPStube(Figure17).

Note:Ifneeded,addshimsbetweenthe

exhaust-systemmountandtheROPStubetomaintain

theaxialalignmentbetweenthemuferinletpipeand

theturbocharger-exhaustpipe.

7.Torquetheange-headboltsandangelocknutsto17

to21N-m(23to29ft-lb).

Figure18

1.Bellows-alignmentjig3.Bandclamp

2.Guillotineclamp

4.Turbocharger-exhaust

pipe

2.Assemblethebandclampjustbelowthealignmentpin

ofthemuferinletpipe(Figure16andFigure18).

3.Assembletheguillotineclampbetweenthealignment

pinandtheendoftheturbocharger-exhaustpipe

(Figure18).

4.Tightentheangenutsoftheguillotineclampand

tightentheboltandnutofthebandclamp.

5.Loosenthe2ange-headboltssecuringthe

pipe-alignmentjigtotheheatshieldandremovethe

alignmentjig(Figure19).

8

Page 9

Figure20

Figure19

1.Flange-headbolt2.Pipe-alignmentjig

6.Torquetheange-headboltsto34to42N-m(47to

57ft-lb).

7.Lookattheturbocharger-exhaustpipefromtheside

andconrmthatthebellowsisstraight.

Note:Ifthebellowsisnotalignedstraight,perform

thefollowing:

A.Loosentheange-headboltsandangelocknuts

thatsecuretheexhaust-systemmounttothe

ROPStube(Figure17).

B.Addorremoveshimstotheexhaust-system

mountasneededtoalignthebellows;refertostep

6inAssemblingtheMufertotheTurbocharger

OutletPipe(page7).

C.Torquetheange-headboltsandangelocknuts

fortheexhaust-systemmountto17to21N-m

(23to29ft-lb).

1.Flange-headbolts(6x16

mm)

2.Clipnut(6mm)

3.Flange-headbolts(6x30

mm)

4.Muferstrap

5.Heatshield

B.Loosentheange-headbolts(6x30mm)that

securethemuferstrapstotheexhaust-system

mount(Figure20).

C.Loosenthe2ange-headbolts(1/2x1inch)

andserratedangenuts(1/2inch)thatsecure

thelower-mufersupporttotheexhaust-system

mount(Figure21).

8.Lookattheturbocharger-exhaustpipefromthefront

andconrmthatthebellowsisstraight.

Note:Ifthebellowsisnotalignedstraight,perform

thefollowing:

A.Removethe6ange-headbolts(6x16mm)that

securetheheatshieldtotheexhaust-systemmount

andremovetheheatshield(Figure20).

9

Page 10

Figure21

1.Exhaust-systemmount

2.Flange-headbolts(1/2

x1inch)—lowermufer

support

D.Movethemuferleftorrighttoalignthebellows

(Figure21).

E.Tightenthe2ange-headbolts(1/2x1inch)

andserratedangenuts(1/2inch)thatsecure

thelower-mufersupporttotheexhaust-system

mountto91to113N-m(67to83ft-lb).

F.Tightentheange-headbolts(6x30mm)that

securethemuferstrapsto972to1198N-cm

(86to106in-lb).

G.Assembletheheatshieldtoexhaust-systemmount

withthe6ange-headbolts(6x16mm)and

torquetheboltsto972to1198N-cm(86to106

in-lb).

3.Lower-mufersupport

4.Serratedangenuts(1/2

inch)

7

InstallingtheRightSideCowl

Panel

NoPartsRequired

InstallingtheCowlPanel

1.Aligntheholesintherightside-cowlpanelwiththe

holesintheROPSplateandtherewall;refertoFigure

5inRemovingtheSide-CowlPanel(page3).

2.AssemblethecowlpaneltotheROPSplatewiththe

ange-headbolt(12x40mm)thatyouremovedin

step1ofRemovingtheSide-CowlPanel(page3).

3.Assembletheclampforthehydraulic-tankbreatherand

side-cowlpaneltotherewallwiththeange-headbolt

(8x35mm)thatyouremovedinstep2inRemoving

theSide-CowlPanel(page3).

Note:Ensurethatthebreatherisverticallyaligned.

4.Tightenthe12mmboltattheROPSplateto80to100

N-cm(59to73ft-lb)andtightenthe10mmboltatthe

rewallto44to57N-cm(34to42ft-lb).

AssemblingtheBattery-Disconnect

Switch

1.Assembletheelectricalcablethatyouremovedinstep

1ofDisconnectingtheBattery-DisconnectSwitch

(page2)ontothreadedstudofthejumppost(Figure

3)withthelocknut.

2.Aligntheelectricalcableatthestudofthejumppost

upward,tightenthelocknut,andaligntheinsulator

bootoverthenutandstud.

3.Assemblethebattery-disconnectswitchintothe

openingatthemountingangeoftherightside-cowl

panel(Figure4)withthelockwasherandjamnutthat

youremovedinstepof3andtightenthejamnut.

Note:Ensurethatthealignmentpinofthedisconnect

switchisalignedwiththeslotinthemountingange

ofthepanelandtheswitchisushtotheange.

4.Installtheknobontotheshaftofthedisconnect

switchwiththescrewthatyouremovedinstep2of

DisconnectingtheBattery-DisconnectSwitch(page2).

10

Page 11

ConnectingtheBattery

1.Assemblethepositive-batterycableintothepositive

studofthebattery(Figure2)withthelock-washernut

(3/8inch)thatyouremovedinstep6ofDisconnecting

theBattery(page1).

2.Torquethelock-washernutto(10to15ft-lb)andalign

theinsulatorbootoverthenutandstud.

3.Assemblethenegative-batterycableintothenegative

studofthebattery(Figure2)withthelock-washernut

(3/8inch)thatyouremovedinstep5ofDisconnecting

theBattery(page1).

4.Aligntheholesinthebatterycoverwiththeclipnuts

atthemountingangeforthecover(Figure1).

5.Securethebatterycovertothemachinewiththe4

ange-headbolts(5/16x1inch)thatyouremovedin

step3ofDisconnectingtheBattery(page1).

6.Installthenger-pullcoverintotheholesinthebattery

cover.

8

CompletingtheInstallationof

theKit

NoPartsRequired

Procedure

1.Rotatethebattery-disconnectswitchtotheOn

position;refertoOperator’ sManualforthemachine.

2.Starttheengineandcheckforexhaustleaksatthe

turbocharger-exhaustpipeandthemufer.

Note:Repairallleaksbeforeinstallingthesidepanel.

3.Installtheright-sidepanel;refertoOperator’sManual

forthemachine.

11

Page 12

Loading...

Loading...