Page 1

HydraulicMotorKit

TRX-16orTRX-20Trencher

ModelNo.131-0667

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3411-315RevA

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ProcedureDescription

1

2

3

4

5

Nopartsrequired

Cabletie

Hydraulicmotor1

Spacerplate

Coupler

Socket-headbolt(1/2x1-3/4inches)

Lockwasher(3/4inch)

Thread-lockingcompound1

Nopartsrequired

Nopartsrequired

Qty.

–

1Removethehydraulicmotor.

1

1

2

2

–

–

Preparethemachine.

Installthehydraulicmotor.

Connectthehydraulichoses.

Checkforleaksandservicethe

hydraulicuid.

Use

©2016—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3411-315*A

Page 2

1

2

PreparingtheMachine

NoPartsRequired

Procedure

1.Movethemachinetoalevelsurfaceandlowerthe

boom.

2.Engagetheparkingbrake,shutofftheengine,and

removethekeyfromtheignitionswitch.

3.Allowthehydraulicsystemtocool.

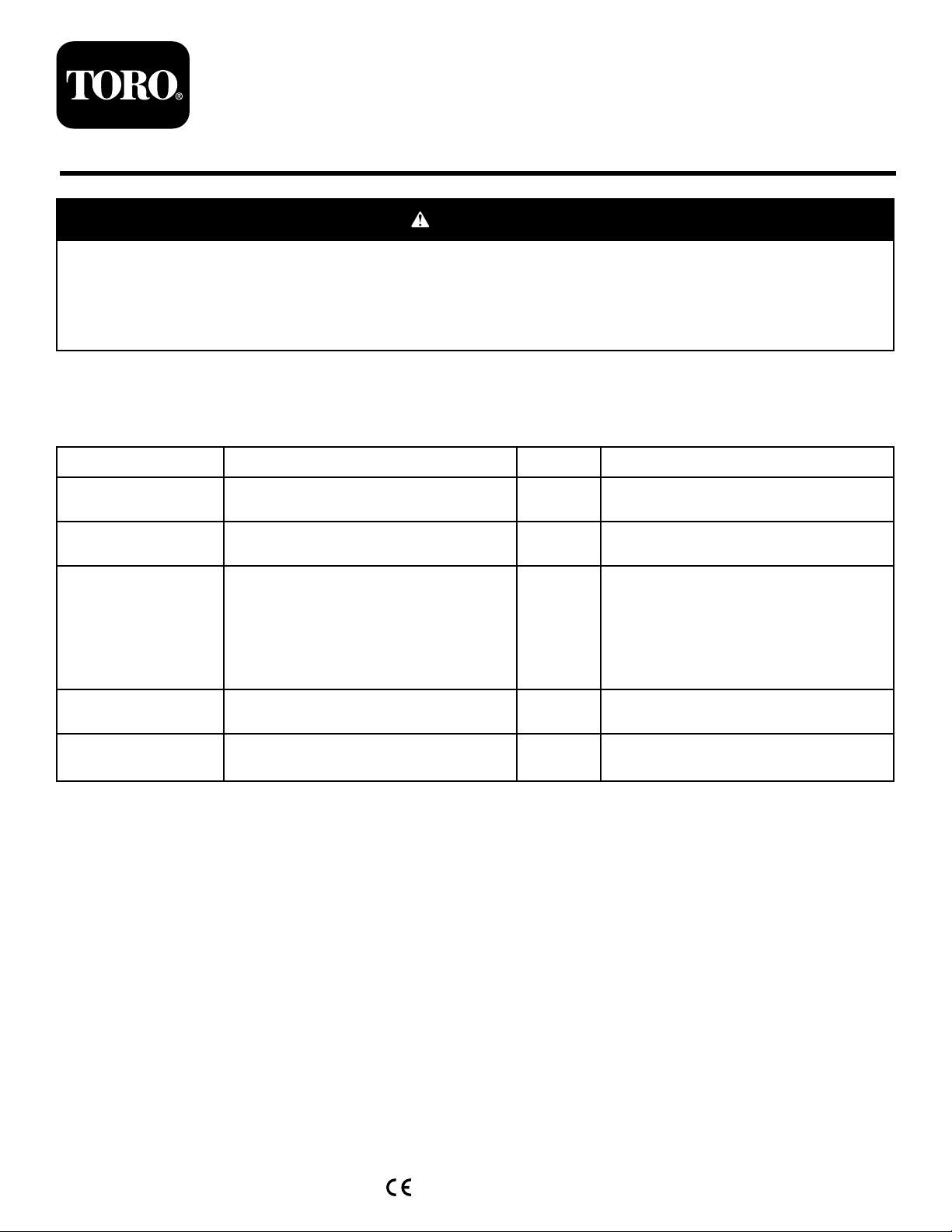

4.Rotatethetrenchercontrolclockwise(AofFigure1).

5.Movethetrencher-controlleverfullytotheforward

position(BofFigure1)andbackwardposition(Cof

Figure1)4or5times.

RemovingtheHydraulicMotor

fortheTrencherDrive

Partsneededforthisprocedure:

1

Cabletie

Procedure

1.Alignadrainpanunderthehydraulicmotorforthe

trencherdrive.

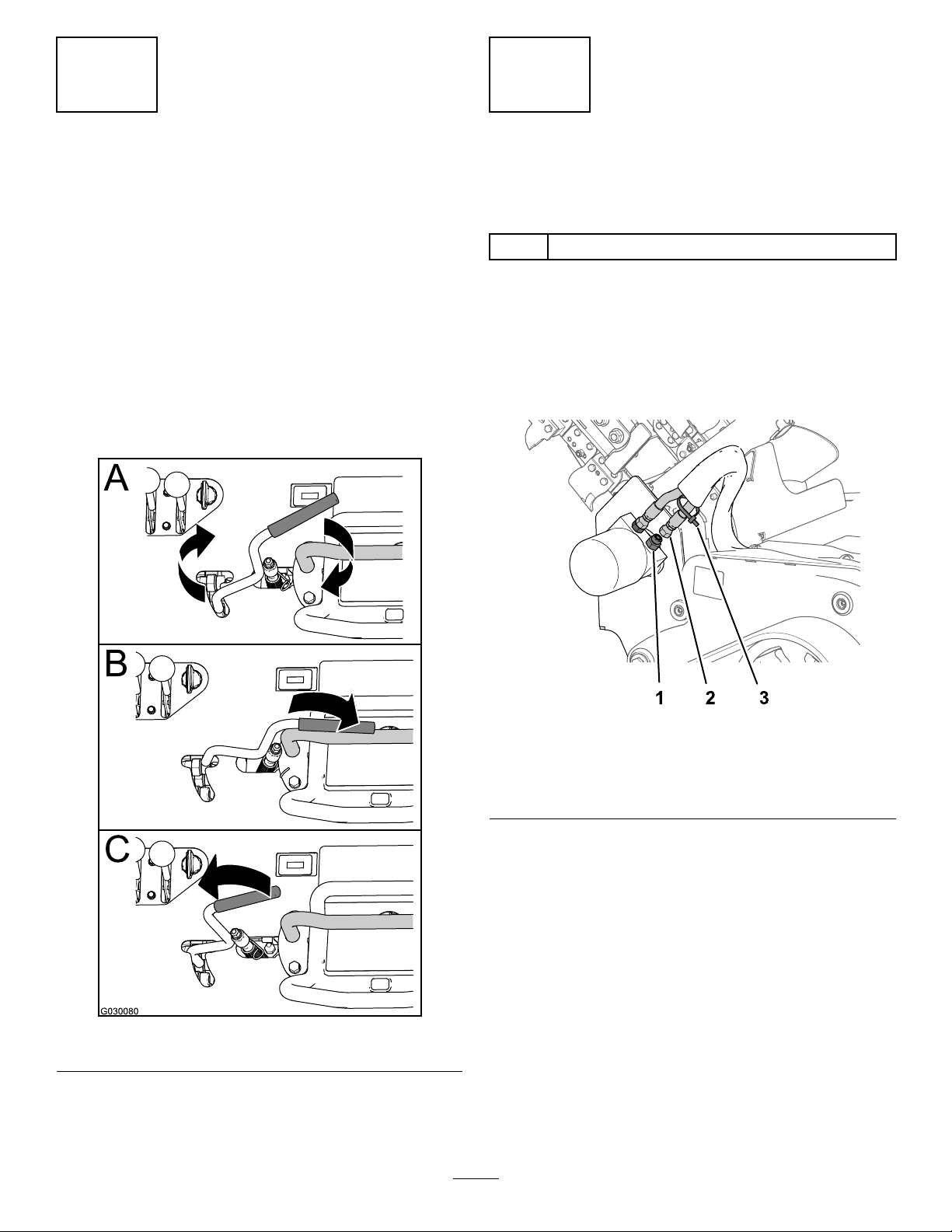

2.Wipecleanthehydraulichosesandttingsatthe

hydraulicmotorforthetrencherdrive(Figure2).

Figure1

Note:Movingthetrencher-controlleverbleeds

hydraulicpressurefromthehosesforthetrencher

motor.

g191412

Figure2

1.Straighthydraulictting

(rear)

2.Hose(rear)

3.Securethecabletietotherearmosthydraulichoseat

thehydraulicmotorforthetrencherdrive(Figure2).

4.Removethe2hydraulichosesfromthestraight

hydraulicttinginthehydraulicmotor(Figure3).

g030080

3.Cabletie

2

Page 3

3

InstallingtheHydraulicMotor

Partsneededforthisprocedure:

1Hydraulicmotor

1

Spacerplate

1

Coupler

2

Socket-headbolt(1/2x1-3/4inches)

2

Lockwasher(3/4inch)

1Thread-lockingcompound

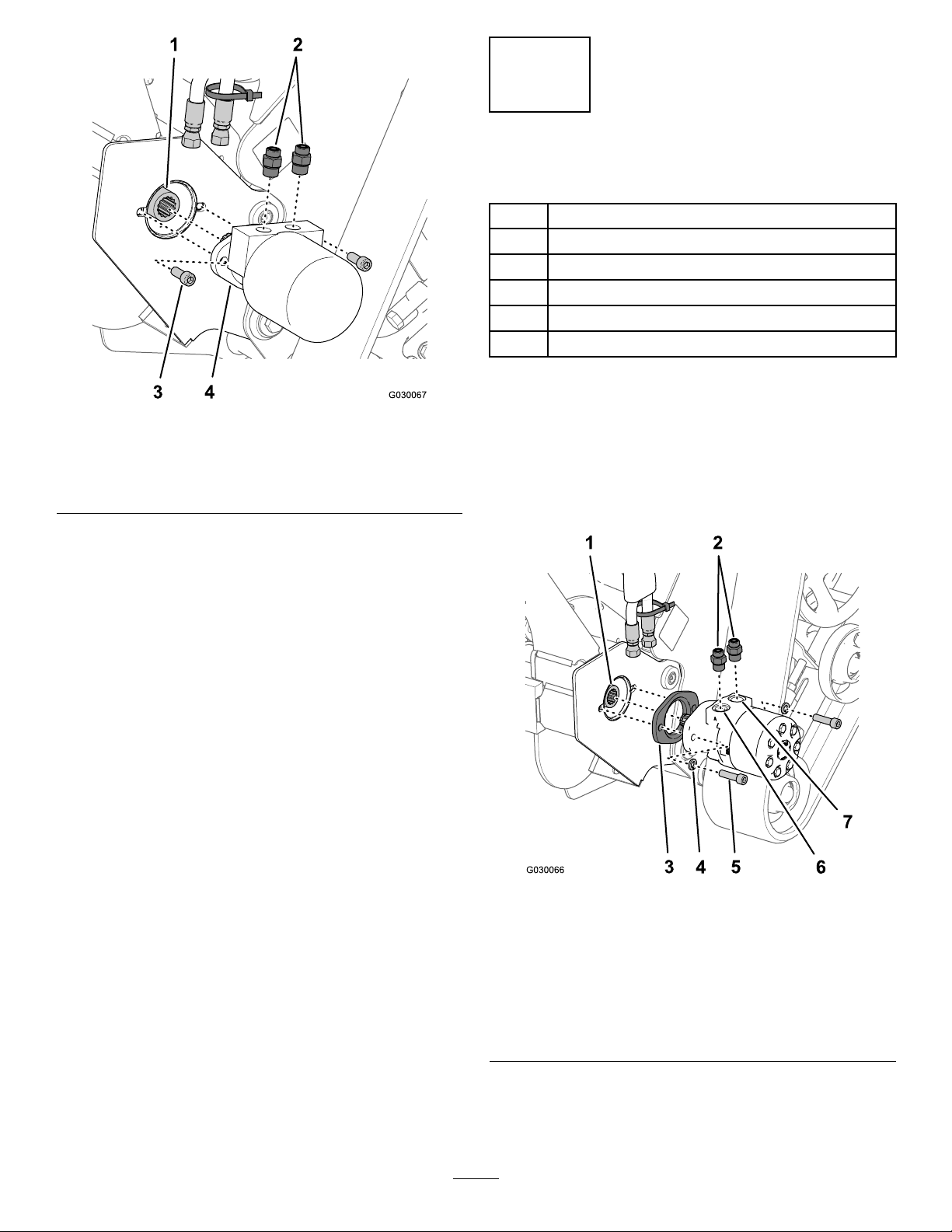

Figure3

1.Coupler(trencher-drive

shaft)

2.Straighthydraulictting4.Hydraulicmotor(old)

3.Socket-headbolts(1/2x

1-1/4inches)

5.Removethe2socket-headbolts(1/2x1-1/4inches)

thatsecurethehydraulicmotorforthetrencherdrive

totheheadofthetrencher,andremovethehydraulic

motor(Figure3).

Note:Discardthe2socket-headbolts(1/2x1-1/4

inches).

6.Drainthehydraulicuidfromthemotorintothedrain

pan.

7.Removethe2straighthydraulicttingsfromtheold

hydraulicmotor(Figure3).

Note:Discardtheoldhydraulicmotor.

8.Removethecouplerfromthetrencher-driveshaft

(Figure3).

Note:Discardtheoldcoupler.

g030067

Procedure

1.Slidethenewcouplerontothetrencher-driveshaft

(Figure4).

2.Assemblethe2straighthydraulicttingsintothenew

hydraulicmotorforthetrencherdrive(Figure4)and

torquethettingsto135to164N∙m(99to121ft-lb).

Figure4

1.Coupler(trencher-drive

shaft)

2.Straighthydraulictting6.PortA(hydraulic

3.Spacerplate7.PortB(hydraulic

4.Lockwashers(3/4inch)

5.Socket-headbolts(1/2x

1-3/4inches)

motor—new)

motor—new)

3.Applyacoatofthread-lockingcompoundtothe

threadsofthe2newsocket-headbolts(1/2x1-3/4

inches).

3

g030066

Page 4

4.Assemblethespacerplateoverthenewhydraulic

motorwiththeinsetstepofthespacerplateagainstthe

mountingfaceofthemotor(Figure4).

5.Alignthesplinesofthenewhydraulicmotorwith

thesplinesofthecouplerforthetrencher-driveshaft

(Figure4).

6.Aligntheholesinthehydraulicmotorandthespacer

platewiththeholesintheheadofthetrencher(Figure

4).

7.Assemblethehydraulicmotorandspacertothehead

ofthetrencher(Figure4)withthe2socket-headbolts

(1/2x1-3/4inches)and2lockwashers(3/4inch).

8.Torquetheboltsto91to113N∙m(67to83ft-lb).

4

ConnectingtheHydraulic

Hoses

NoPartsRequired

Figure5

1.Hose(withthecabletie)3.Straighthydraulic

2.Straighthydraulic

tting—portA(hydraulic

motor)

4.Hose(withoutthecable

g030068

tting—portB(hydraulic

motor)

tie)

Procedure

1.Assemblethehydraulichosewiththecabletiethat

youinstalledinstep3of2RemovingtheHydraulic

MotorfortheTrencherDrive(page2)ontothestraight

hydraulicttinginportA(theforwardport)ofthe

hydraulicmotor(Figure5).

Note:Thehose-to-portrelationshipisoppositefor

thenewhydraulicmotor.

2.Assembletheotherhydraulichoseontothestraight

hydraulicttingintheportB(therearport)ofthe

hydraulicmotor(Figure5).

3.Torquetheswivelnutsofthehosesto51to64N·m

(37to47ft-lb).

Note:Useabackupwrenchonthestraighthydraulic

ttings.

4

Page 5

5

CheckingforLeaksand

ServicingtheHydraulicFluid

NoPartsRequired

CheckingforHydraulicLeaks

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

Ifhydraulicuidisinjectedintotheskin,youmust

haveitsurgicallyremovedwithinafewhoursbya

doctorfamiliarwiththistypeofinjury.Gangrene

mayresultifthisisnotdone.

•Keepbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthigh-pressurehydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Makesurethatallhydraulic-uidhosesand

linesareingoodconditionandthatallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

1.Startthemachineandletitrunfor4or5minutes.

2.Checktherotationofthediggingchain(Figure6).

g030156

Figure6

3.Usingapieceofcardboard,checkforleaks.

Important:Repairallhydraulicleaks.

4.Shutofftheengineandremovethekeyfromthe

ignitionswitch.

ServicingtheHydraulicFluid

HydraulicFluidSpecication:

•ToroPremiumTransmission/HydraulicTractor

Fluid(refertoyourAuthorizedT oroDealerformore

information)

•ToroPremiumAll-SeasonHydraulicFluid(referto

yourAuthorizedToroDealerformoreinformation)

•IfeitheroftheaboveTorouidsarenotavailable,

youmayuseanotherUniversalTractorHydraulic

Fluid(UTHF),buttheymustbeonlyconventional,

petrolium-basedproducts.Thespecicationsmustfall

withinthelistedrangeforallofthefollowingmaterial

propertiesandtheuidshouldmeetthelistedindustry

standards.Checkwithyouroilsuppliertodetermineif

theoilmeetsthesespecications.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehindtheir

recommendations.

5

Page 6

MaterialProperties

G007808

1

g015379

1

2

cStat40°C:55to62 Viscosity,ASTMD445

cStat100°C:9.1to9.8

Viscosityindex,ASTMD2270

PourPoint,ASTMD97-37°to-43°C(-35°to-46°F)

IndustryStandards

APIGL-4,AGCOPoweruid821XL,FordNewHolland

FNHA-2-C-201.00,KubotaUDT ,JohnDeereJ20C,Vickers

35VQ25andVolvoWB-101/BM.

140to152

1.Wait4to5minutesaftershuttingofftheengine.

2.Checkthehydraulicuidlevelinthesiteglassatthe

frontoftherightpanel(Figure7).

Note:Whenthehydraulic-uidlevelinthetankis

correct,thehydraulic-uidlevelisvisibleinthesite

glass.

Figure8

1.Top-coverplate

2.Flange-headbolt(3/8x1

inch)

B.Removethecap/hydrauliclterfromtheller

neckofthehydraulictank(Figure9).

g015379

Figure7

1.Siteglass(hydraulicuid)

3.Ifyoucannotseetheuidlevelinthesiteglass,

performthefollowing:

A.Loosenthe1rearbolt(3/8x1inch)and2

forwardbolts(3/8x1-1/2inches)thatsecurethe

top-coverplatetothemachineandremovethe

coverplate(Figure8).

g007808

g007839

Figure9

1.Fillercap

2.Hydrauliclter

C.Addthespeciedhydraulicuidintotheller

neckuntiltheuidlevelcovershalfthesiteglass

(Figure7).

D.Installthecapandlterintothellerneck(Figure

9)andtorquetheboltatthetopofthecapto13

to15.5N·m(110to140in-lb).

E.Assemblethetop-coverplateontothemachine

(Figure8)andtorquethe3bolts(3/8inch

diameter)to38to45N·m(27to33ft-lb).

6

Page 7

Notes:

Page 8

Loading...

Loading...