Toro 130-2100 Installation Instructions

FormNo.3379-751RevB

FuelTankServiceKit

MB-1600MudBuggy

ModelNo.130-2100

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Nopartsrequired

Nopartsrequired

Nopartsrequired

Tank1

Fuelhose1

Hoseclamp2

Fuelcap/gauge

Nopartsrequired

Nopartsrequired

Venthose1

Hoseclamp2

Cabletie

Qty.

Use

–

–

–

1

–

–

1

Removetheenginecowl.

Drainthefueltank.

Removethefueltank.

Preparethefueltank.

Installthefueltank.

Installthefuelhose.

Replacetheventhose.

8

9

©2013—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Nopartsrequired

Nopartsrequired

Registeratwww.T oro.com.

–

–

Checkthefuelsystem.

Installtheenginecowl.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3379-751*B

1

G019281

1

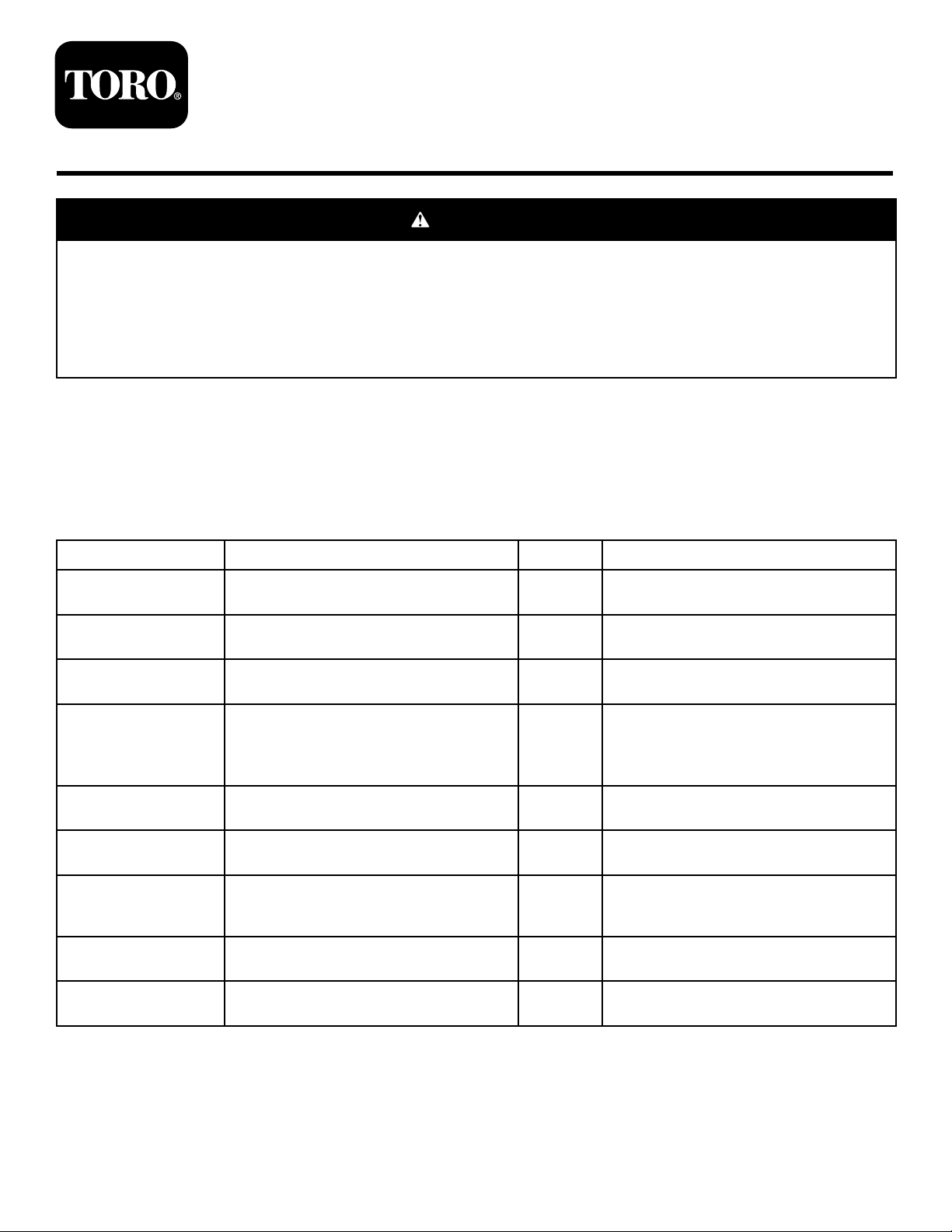

RemovingtheEngineCowl

NoPartsRequired

Procedure

1.Movethemachinetoalevelsurfaceandsettheparking

brake;refertotheOperator’ sManualforthemachine.

2.Positionthehopperinthedumpposition;refertothe

Operator’sManualforthemachine.

3.Shutofftheengine;refertotheOperator’ sManualfor

themachine.

4.Removethe4latchesthatsecuretheenginecowltothe

machineatthe4latchposts(Figure1).

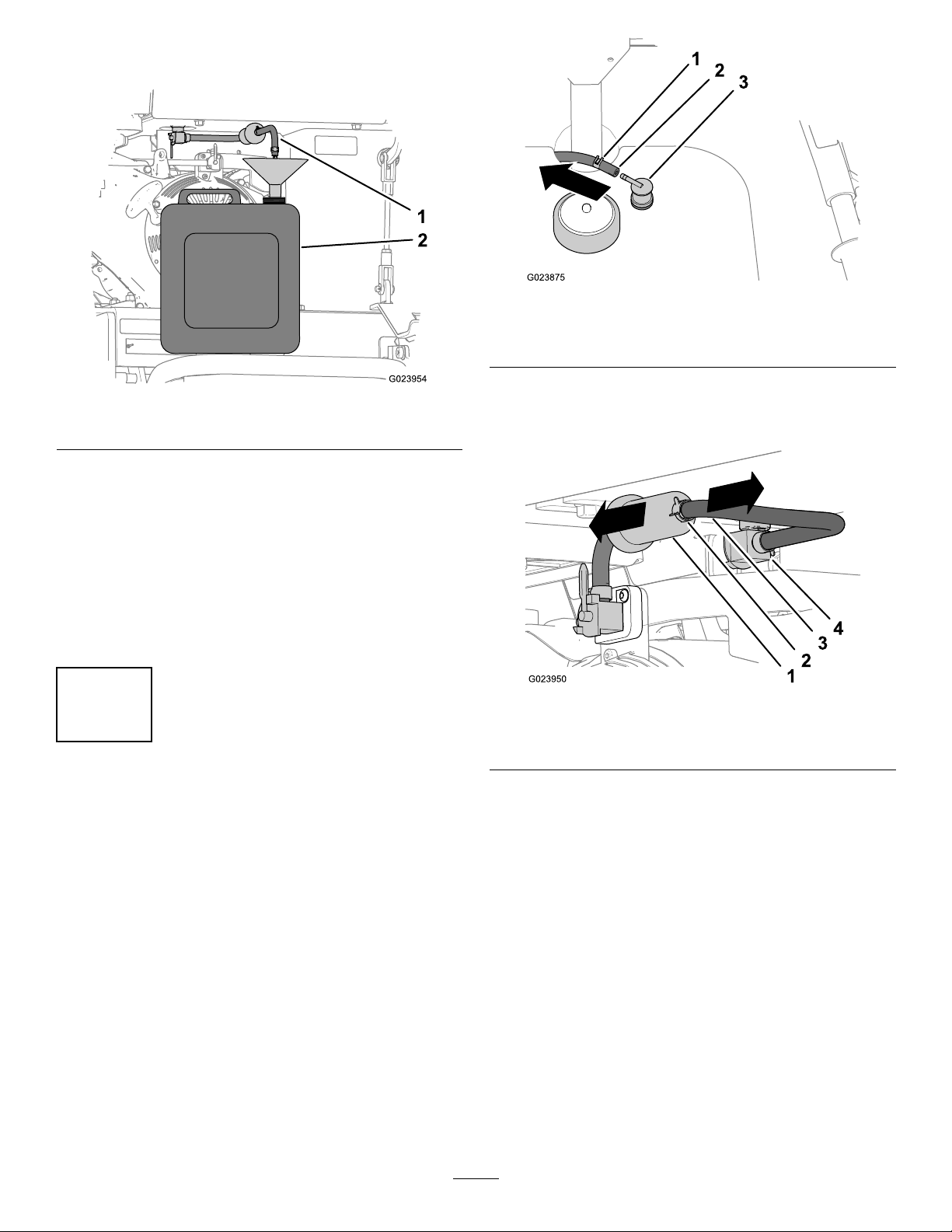

Figure2

1.Forward

2.Shutoff-valveleverforthe

fueltank(Offposition)

2.Starttheengineandrunthemachineuntiltheengine

stops.

3.Rotatetheleverfortheengineswitchclockwisetothe

Stopposition,andallowtheenginetocool(Figure2).

4.Carefullyremovethespark-plugwirefromtheterminal

ofthesparkplug.(Figure3).

3.Engine-switchlever(Stop

position)

Figure1

1.Enginecowl3.Latch

2.Latchpost

5.Lifttheenginecowlupandremoveitfromthemachine

(Figure1).

2

DrainingtheFuelTank

NoPartsRequired

Procedure

1.Rotatetheleverforthetank-shutoffvalveforwardand

uptotheOffposition(Figure2).

Figure3

1.Spark-plugwire

5.Removethehoseclampandhosefromthebarbed

ttingatthetopoftheengineswitch(Figure2).

2

6.Alignthehoseintoanapprovedfuelcontainerwitha

26.5L(7USgallon)capacity(Figure4).

Figure5

1.Hoseclamp3.Ventvalve

2.Venthose

Figure4

1.Fuelhose2.Fuelcontainer

7.Rotatetheshutoffvalveforthefueltankbackand

downtotheOnposition(Figure2).

Note:Allowthefueltanktodraincompletely .

8.Installthehoseandhoseclampontothebarbedtting

atthetopoftheengineswitch(

Note:Ensurethatthebarbedttingisfullyinserted

intotheendofthefuelhoseandthattheclampis

centeredoverthebarbedareaofthetting.

Figure2).

3

RemovingtheFuelTank

NoPartsRequired

2.Removethehoseclampthatsecuresthefuelhoseto

thebarbedttinginthefuellter,andremovethehose

(Figure6).

Figure6

1.Fuellter

2.Hoseclamp

3.Removethe4ange-headboltsthatsecurethefuel

tanktothemachine,andremovethetankfromthe

machine(Figure7).

3.Fuelhose

4.Tank-shutoffvalve

Procedure

1.Removethehoseclampandtheventhosethatare

attachedtotheventvalveinthefueltank(Figure5).

Note:Becarefulwhenliftingthetankuptoensure

thattheshutoffvalveforthefueltankandthefuel

hosearecenteredwhilepassingthroughtheholeinthe

tank-supportplatefortheshutoffvalve.

3

Loading...

Loading...