Page 1

MetalPlateKit

ZMaster

ModelNo.125-4790

®

FormNo.3378-515RevA

Commercial2000SeriesRidingMower

InstallationInstructions

Note:Keepthemowerdeckbeltinstalledduringthe

installationofthiskit.Thereisnointerferencewiththe

mowerdeckbelt.

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

Description

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Plate1

Starwasher

Thinatwasher

Flangenut(3/8inch)

Thickatwasher

Qty.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Use

–

–

–

–

1

1

2

1

Checkthefueltank.

Installthefueltank.

Removethepulleys.

Inspecttheidler-armpulley .

Installtheplate.

CAUTION

Ifthemachinehasbeenrunning,themuferand

exhaustsystemwillbeveryhotandcancause

seriousburnsifyoutouchthem.

Allowthemachinetocoolcompletelybefore

performingthisprocedure.

CheckingtheFuelTank

Note:Ensureanewfueltankandidlerpulleyareorderedif

thereisanywearontheexistingfueltank.

Checkthefueltankforanywearundertheidlerpulley(Figure

1).

•Ifyouseeorfeelwithyourngernail,agrooveinthefuel

tankfromtheidlerpulley,replacethefueltankandidler

©2013—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

pulley(Figure1).Orderanewfueltankandanewidler

pulley.ProceedtoReplacingtheFuelTank(page2).

•Ifthefueltankdoesnothaveanywearfromtheidler

pulley,proceedtoRemovingthePulleys(page4).

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

*3378-515*A

Page 2

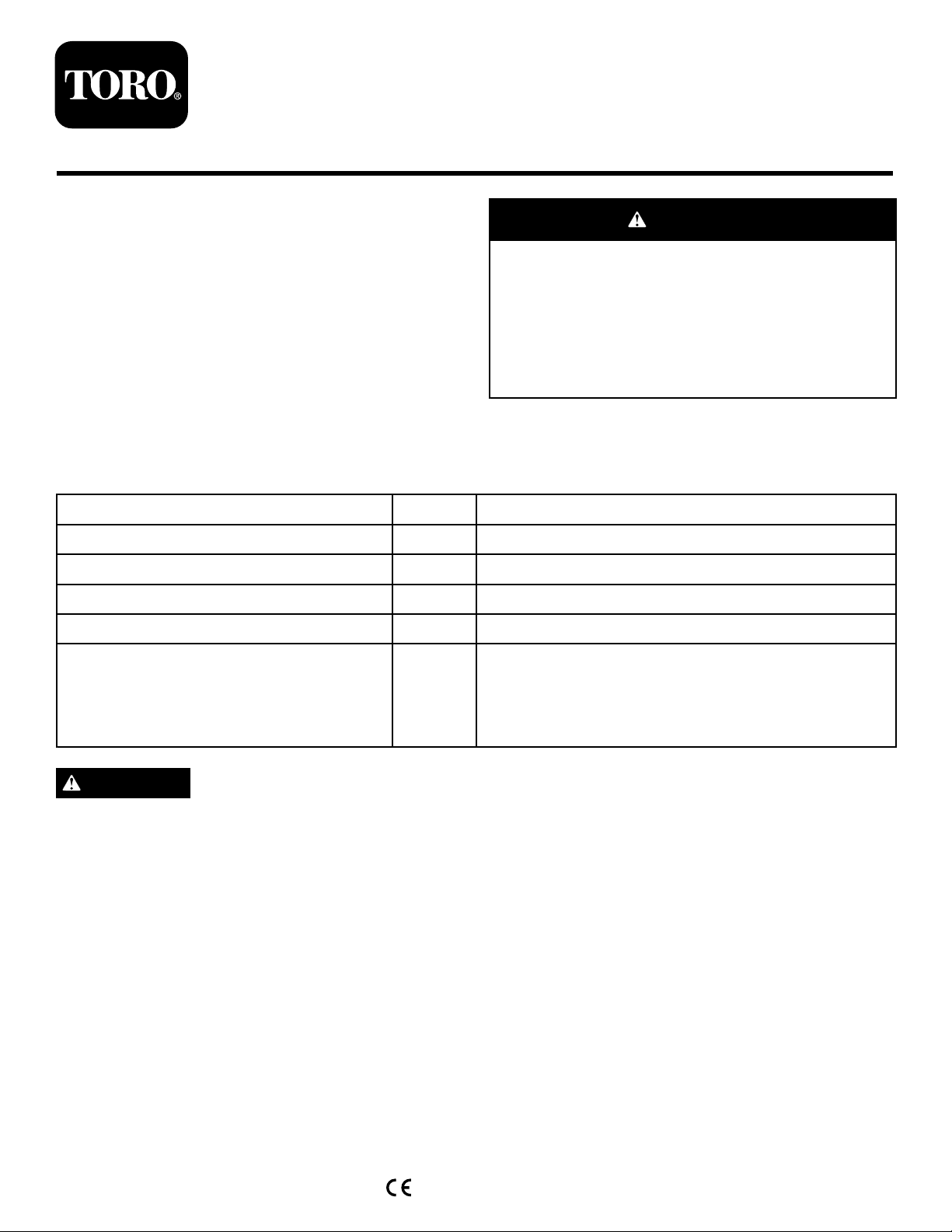

g021893

1 2

g018378

1

2

Figure2

g018380

1

Figure1

1.Wearareaonfueltank

2.Idlerpulley

ReplacingtheFuelTank

Note:Onlyreplacethefueltankwhenthereiswearonthe

existingfueltankfromtheidlerpulley.

1.Drivethemachinetoalevelsurface.

2.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedposition,andsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Movetheseatthefurthestrearpositiontoexposethe

frontnuts.

5.Loosenthefrontnuts.Thenutsdonotneedtobe

removed.

1.Seat

2.Frontnutswithkeyhole

9.Removetheseatandbasefromthemachine.

10.Unplugtheharnessconnectorfromtheseatswitch

locatedundertheseat(Figure3).

6.Movetheseatthefurthestforwardpositiontoexpose

therearnuts.

1.Harnessconnector

Figure3

7.Loosentherearnuts.Thenutsdonotneedtobe

removed.

8.Slidetheseatandseatplateforwardtoallowthefront

nutstogothroughthekeyhole(

Figure2).

11.Removethetwoboltsholdingtheleftsidemotion

controlleverbracket.

12.Rotatethemotioncontrolleverbrackettoallowthe

frontpaneltoberemoved(

Figure4).

2

Page 3

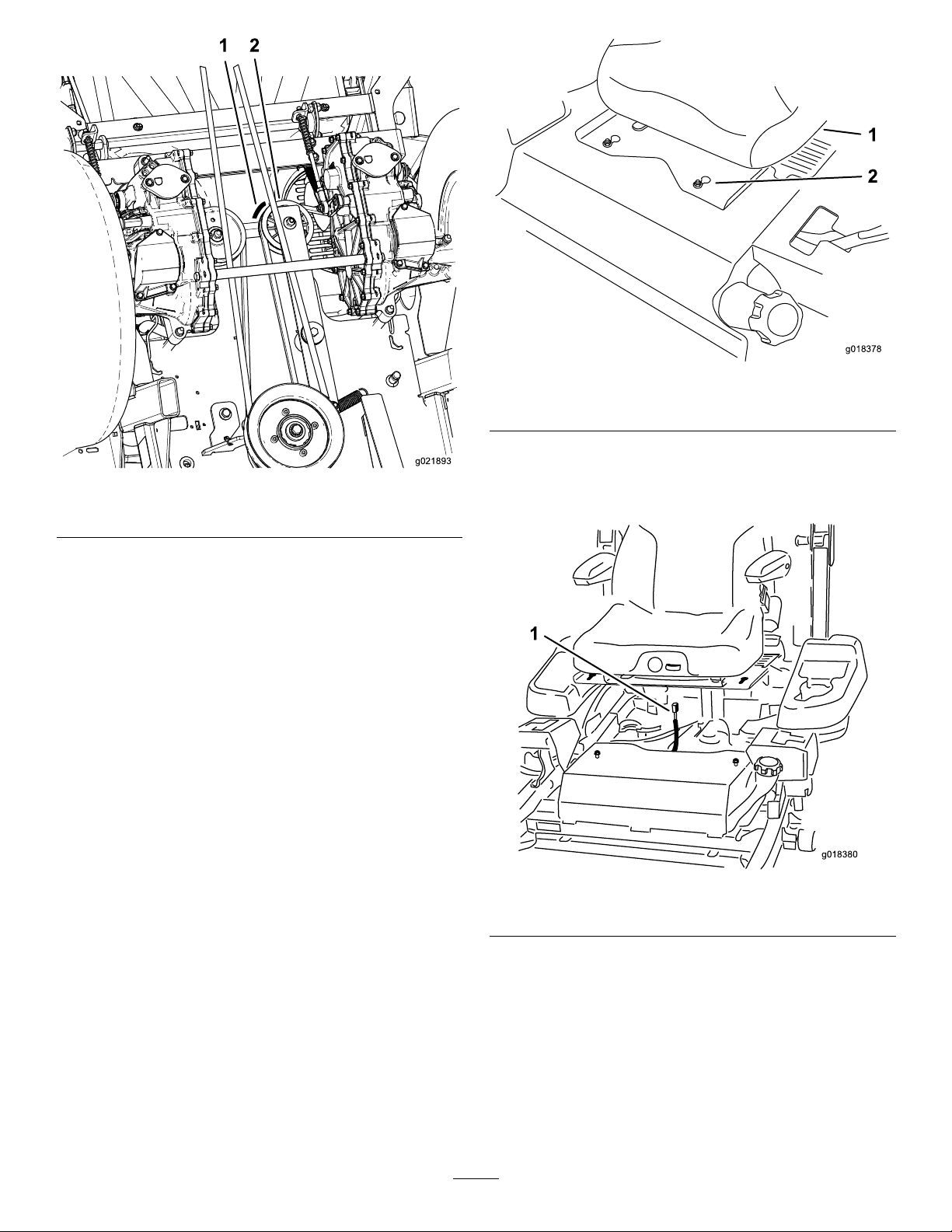

g019593

3

1

2

Figure4

g019590

1 2

1

3

1

2

g019591

1

3

4

2

1

1.Motioncontrollever

bracket

2.Removethetwobolts

3.Rotatethemotioncontrol

leverbracket

13.Removethefourboltsholdingthefrontpanelinplace

andremovethefrontpanel(Figure5).

1.Fuelhose3.Fueltank

2.Venthose4.Hoseclamp

Figure6

16.Removeanyfuelfromthetankbypumpingitoutinto

afuelcan.

17.Removethetankfromthemachine.

18.Installthenewfueltankbyreversingsteps4through

17.

19.Destroytheoldfueltankbyoneofthefollowing

processes:

•Drilla1/4inchholeinthebottomofthefueltank

Figure7).

(

•Cutthellerneckoffofthefueltank(Figure7).

1.Removethesebolts3.Motioncontrollever

2.Frontpanel

14.Usingapliers,loosenthefuelhoseclampandslideit

downthefuelhose.

15.Removethefuelventhoseandfuelhosefromthefuel

tank(

Figure6).

Figure5

bracket

3

Page 4

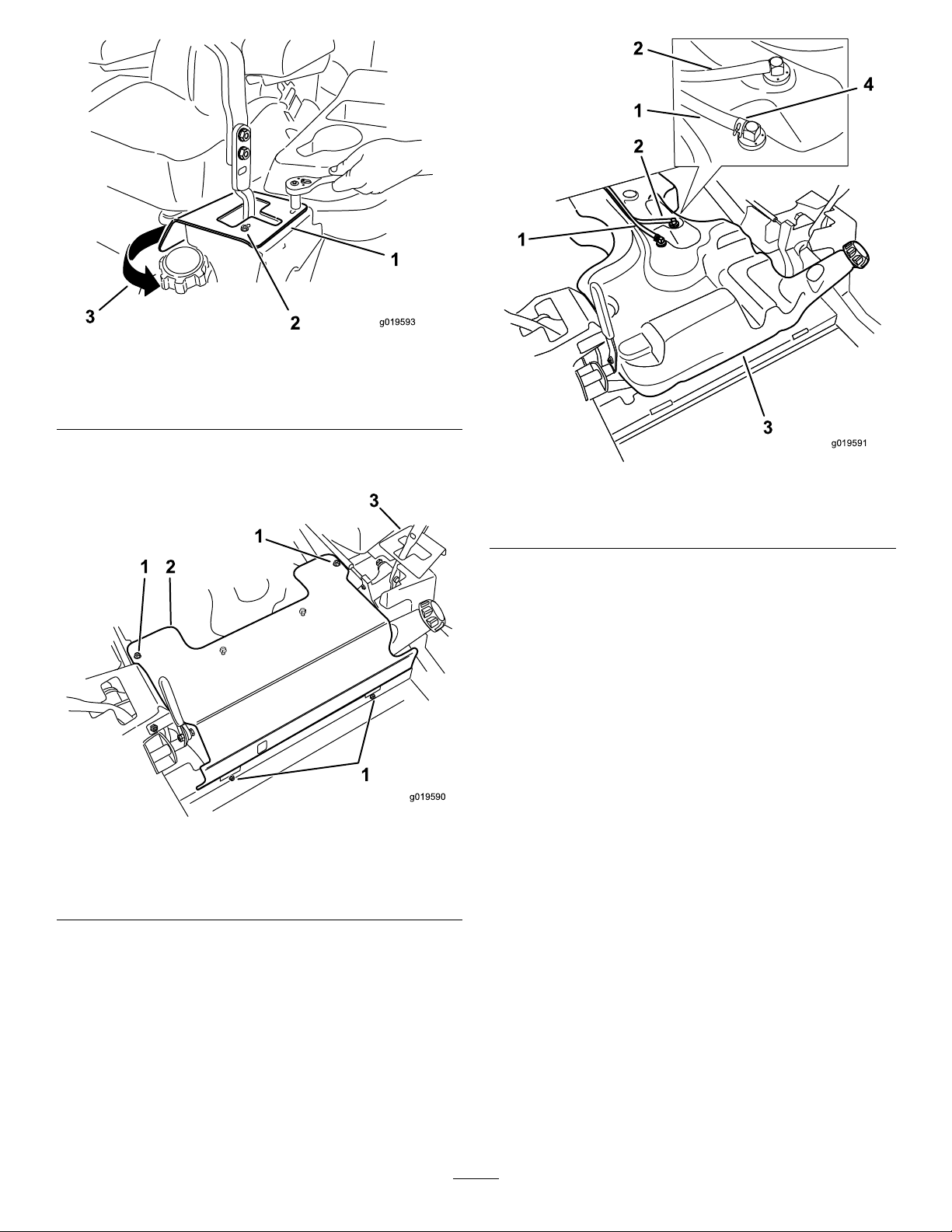

g019797

1

2

Figure7

g021894

1

2

3

1.Cutthellerneckoff2.Drilla1/4inchhole

RemovingthePulleys

Figure8

1.Idler-springpost

2.Spring

3.Clutchpulley

6.Removetheidlerarmbolt,washer,rubberwashers,

innerspacer,idlerarm,largespacerandtheangenut

abovetheenginedeck(Figure12andFigure13).

WARNING

Mechanicalorhydraulicjacksmayfailtosupport

machineandcauseaseriousinjury.

Usejackstandswhensupportingmachine.

1.Drivethemachinetoalevelsurface.

2.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedposition,andsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Raisetherearofmachineupandsupportitwithjack

stands.

5.Removethespringfromtheidler-springpost(

8).Thiswillreleasethetensiononthehydraulic-pump

belt.

Note:Donotremovethehydraulic-pumpbeltfrom

themachine;allowthehydraulic-pumpbelttolayloose

inthemachinewhileinstallingthiskit.

Figure

7.Removethexedidlerpulleyandwasherfromthe

machine(Figure11).Discardthewasher.

Note:Donotremovethexed-idlercarriagebolt.

4

Page 5

InspectingtheIdler-ArmPulley

1

2

3

4

g021906

5 6 7

8

g021896

1

2

InstallingthePlate

1.Inspecttheidler-armpulleytoensureitfreelyrotates

andhasnowobble.Replacethepulleyifnecessary.

2.Iftheidler-armpulleydoesnotneedtobereplaced,

torquetheidler-pulleyboltbetween27and33ft-lbs.

3.Ifthepulleyneedstobereplaced,removethepulley

fromtheidlerarm(Figure9).Makenoteofhowitis

installed.

4.Installthenewidler-armpulleywithanewangenut

(3/8inch)asshowninFigure9.

Note:Ensurethebushingisinstalledtowardsthe

idlerarm(Figure9).

5.Torquetheidler-pulleyboltbetween27and33ft-lbs.

1.Installthethinatwasherandstarwasherontothe

xed-idlercarriagebolt(Figure10).

Figure10

1.Thinatwasher2.Starwasher

2.Positiontheplateintothemachine,ushagainstthe

bottomoftheenginedeck(Figure11).

3.Installthenewthickatwasher,xed-idlerpulley

(correctorientation)andthenewlocknut(Figure11).

Note:Ensurethatthebushingisinstalledtowards

theplate(Figure11).

1.Idler-pulleybolt

2.Idler-armpulley

3.Spacer

4.Idlerarm

Figure9

5.Newangenut(3/8inch)

6.Bottomoftheidlerarm

pulley

7.Ensurethebushingis

installedtowardstheidler

arm

8.Topoftheidlerarmpulley

5

Page 6

g021897

1

2

3

4

8

5

6 7

Figure11

g021903

1

2

3

4

2

5

6

7

1.Plate

2.Newthickwasher6.Ensurethebushingis

3.Fixed-idlerpulley

4.Newangenut(3/8inch)8.Carriageboltwithat

5.Bottomofthexed-idler

pulley

installedtowardstheplate

7.Topofthexed-idler

pulley,installtowardsthe

plate

washerandstarwasher

4.Installthelargespacer,rubberwashers,idlerarm,inner

spacer,andwashertotheenginedeckwiththeidler

armboltandnewlocknut(Figure12andFigure13).

Note:Thisrequirestwopeopletocomplete;the

angenutislocatedontopoftheenginedeckandin

frontoftheengine(Figure13).

Figure12

1.Largespacer5.Washer

2.Rubberwasher6.Idler-armpivotbolt

3.Idlerarm7.Plateinstalled

4.Innerspacer

6

Page 7

g021877

1

2

3

Topviewofthemachine

g021895

1

6

2

3

4

5

9.Raisetherearofmachineup,removethejackstands,

andlowerthemachine.

Figure13

1.Engine

2.Rollbar

3.Newangenut(3/8inch)

5.Torquethenewangenutandcarriageboltatthe

xed-idlerpulleybetween27and33ft-lbs(Figure11).

6.Torquetheidler-armpivotboltbetween27and33

ft-lbs(Figure12).

7.Routethebeltaroundthepulleys(Figure14).

Note:Ensurethatthebeltisroutedaroundallpulleys.

Figure14

1.Idlerpulley4.Pumpdrivebelt

2.Idlerspringpost5.Right-handhydraulic

3.Enginepulley

8.Attachthespringtotheidler-springpost(Figure8).

pumppulley

6.Left-handhydraulicpump

pulley

7

Page 8

Loading...

Loading...