Page 1

DeluxeSeatKit

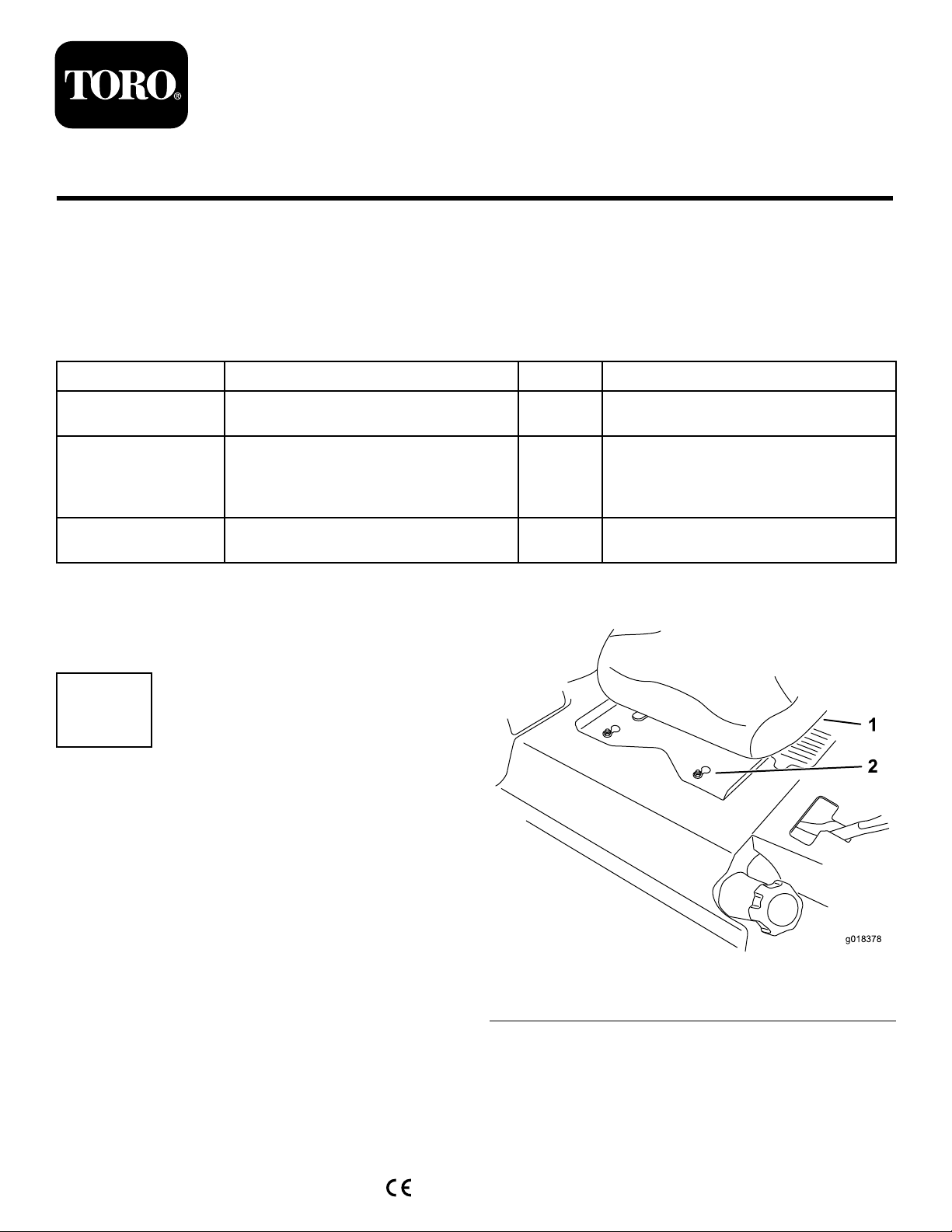

g018378

1

2

ZMaster

ModelNo.121-7595

ModelNo.78550

®

RidingMower

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3376-909RevB

InstallationInstructions

ProcedureDescription

1

2

3

Note:Forperformanceandsafety,2000Seriesmachines

with48inchmowerdecksrequireaweightkit(No.121-7576)

afterthedeluxeseatkitisinstalled.Obtainthecorrectweight

kitfromanAuthorizedServiceDealer.

Nopartsrequired

Seat

Spacer

Flangenut(5/16inch)

Plasticcabletie4

Nopartsrequired

1

RemovingtheSeat

NoPartsRequired

Qty.

–

1

4

4

–

7.Unplugtheharnessconnectorfromtheseatswitch

locatedundertheseat.

Removetheseat.

Installtheseat.

Testthesafetyinterlocksystem.

Use

Removinga2000SeriesZMaster

MowerSeat

1.Toexposethefrontnuts,movetheseattothefurthest

rearposition.

2.Loosenthefrontnuts.Thenutsdonotneedtobe

removed.

3.Toexposetherearnuts,movetheseattothefurthest

forwardposition.

4.Loosentherearnuts.Thenutsdonotneedtobe

removed.

5.Slidetheseatandseatplateforwardtoallowthefront

nutstogothroughthekeyholes(

6.Removetheseatandbasefromthemachine.

©2013—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1).

Registeratwww.T oro.com.

Figure1

1.Existingseat2.Frontnutswithkeyhole

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

*3376-909*B

Page 2

Removinga5000or6000SeriesZ

MasterMowerSeat(TiltingSeat)

1.Unlatchtheseatandtiptheseatforward.

2.Removethenutsholdingtheseattotheseatframe

(Figure2).

3.Disconnectthewireharnessfromtheseatswitch.

4.Removetheseatfromtheframe.

Removinga3000SeriesorInternational

5000and6000SeriesZMasterMower

Seat(FixedSeat)

1.Forinternationalmachinesonly,removethehydraulic

unitshroudfromthemachine(Figure4).Save

hardwareandshroud.

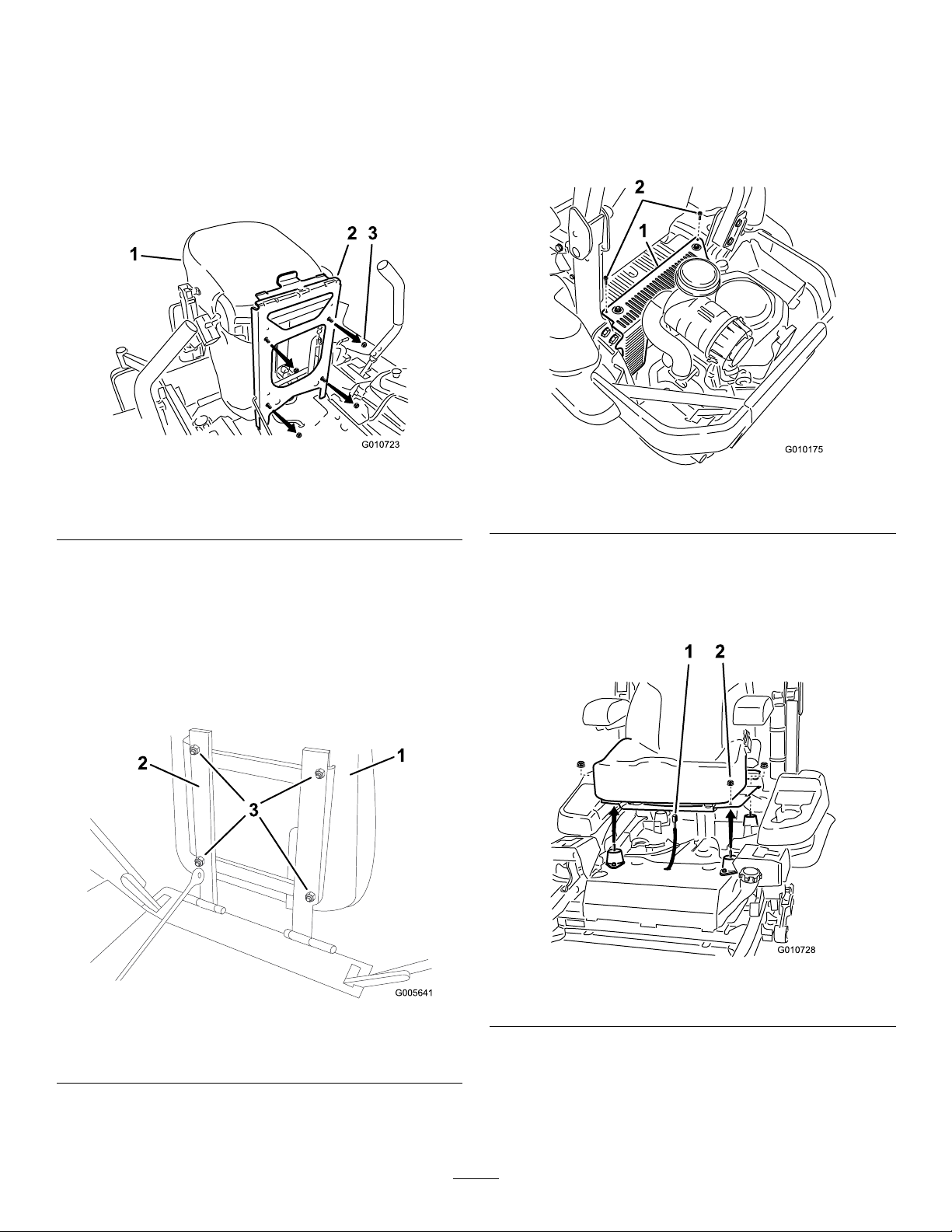

Figure2

1.Seat

2.Seatframe

3.Nut

Removinga7000SeriesZMaster

MowerSeat

1.Unlatchtheseatandtiptheseatforward.

2.Removethenutsholdingtheseattotheseatframe

(Figure3).Retainthenuts.

3.Removetheseatfromtheframe.

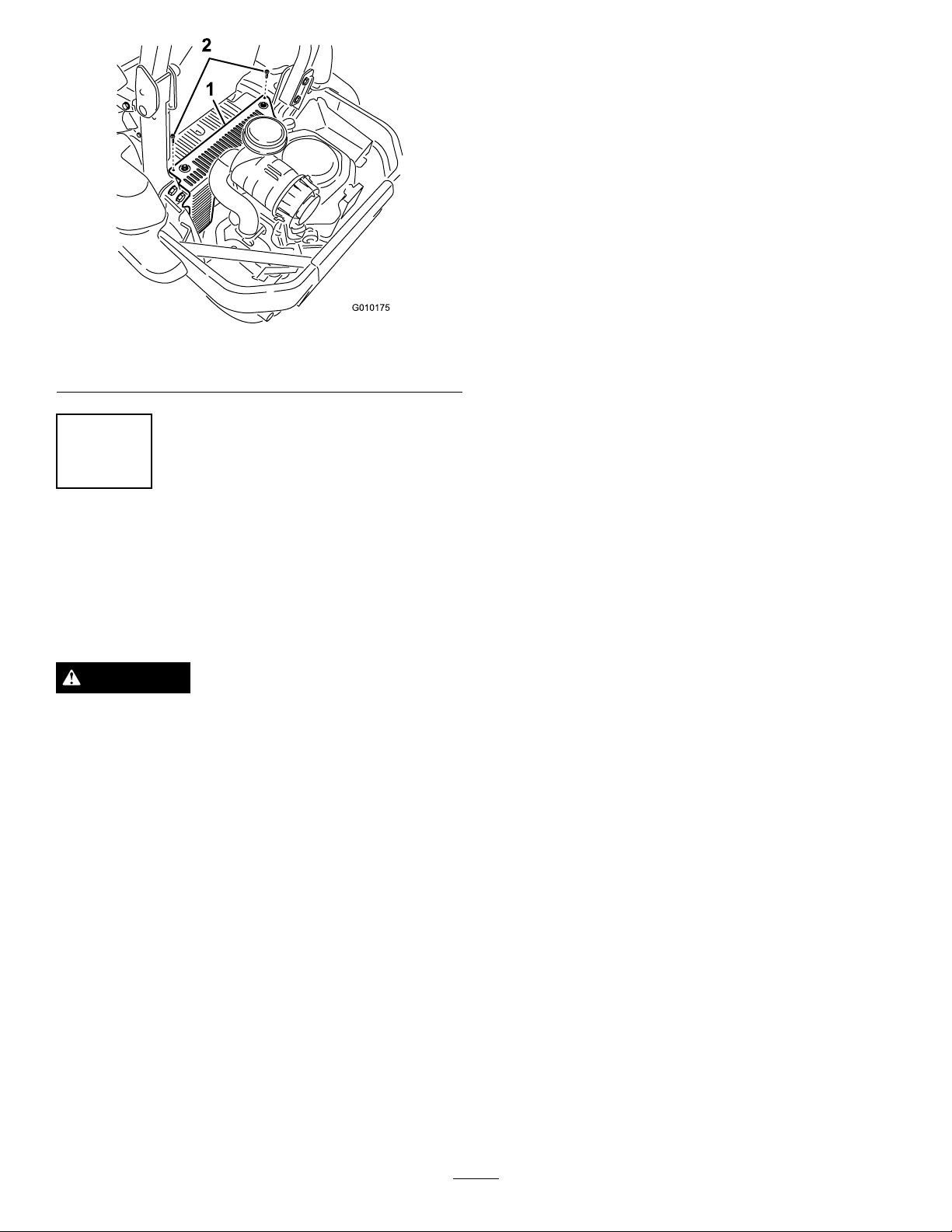

Figure4

1.Hydraulicunitshroud2.Bolts

2.Removethe4angenutsholdingtheseattothe

machine(Figure5).

3.Unplugtheharnessconnectorfromtheseatswitch

locatedundertheseattowardsthefront(Figure5).

1.Seat

2.Seatframe

Figure3

Figure5

1.Harnessconnector2.Flangenuts

3.Nut

4.Removetheseatplatefromtheseatbyremovingthe4

spacersand4angenuts(Figure6).

2

Page 3

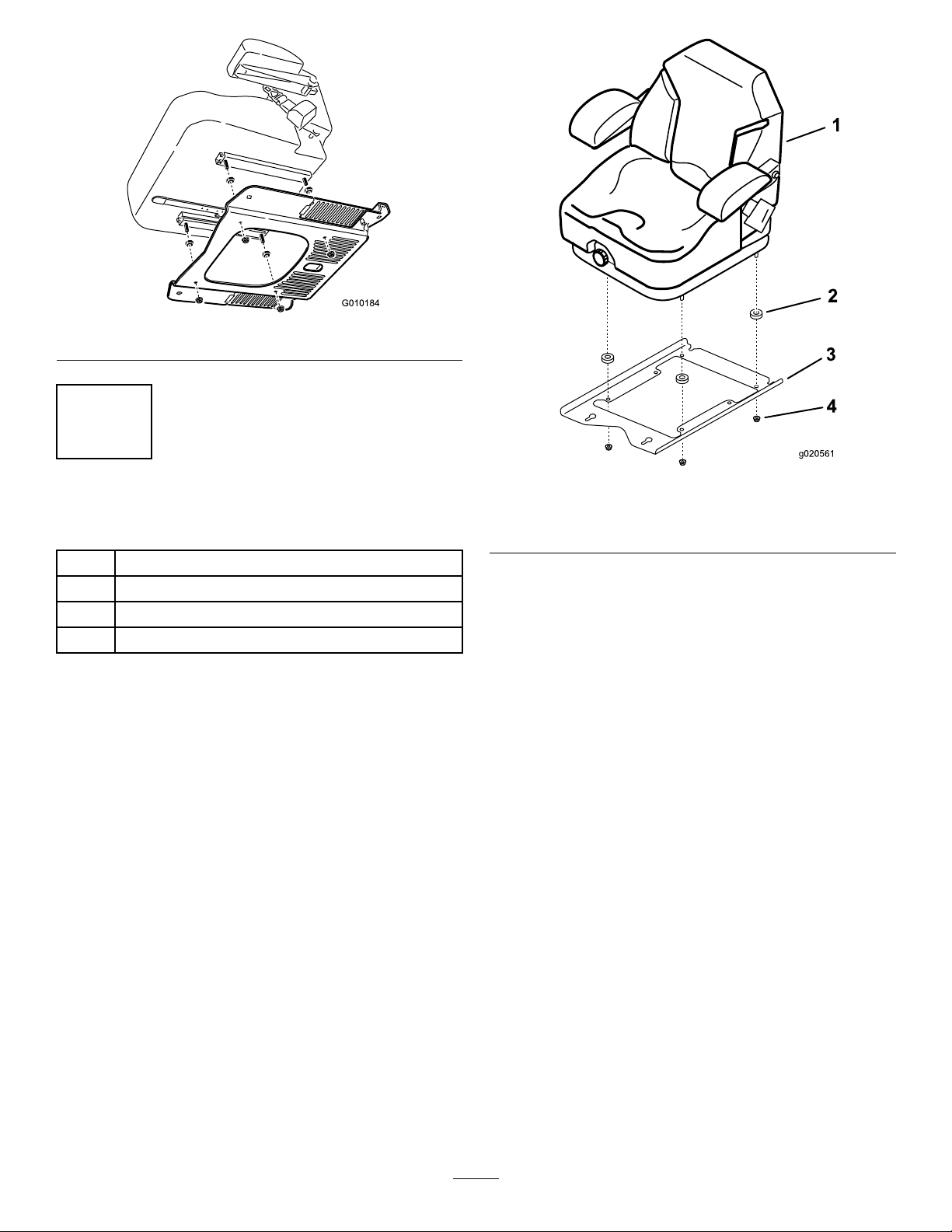

Figure6

g020561

4

2

InstallingtheSeat

Partsneededforthisprocedure:

1

Seat

4

Spacer

4

Flangenut(5/16inch)

4Plasticcabletie

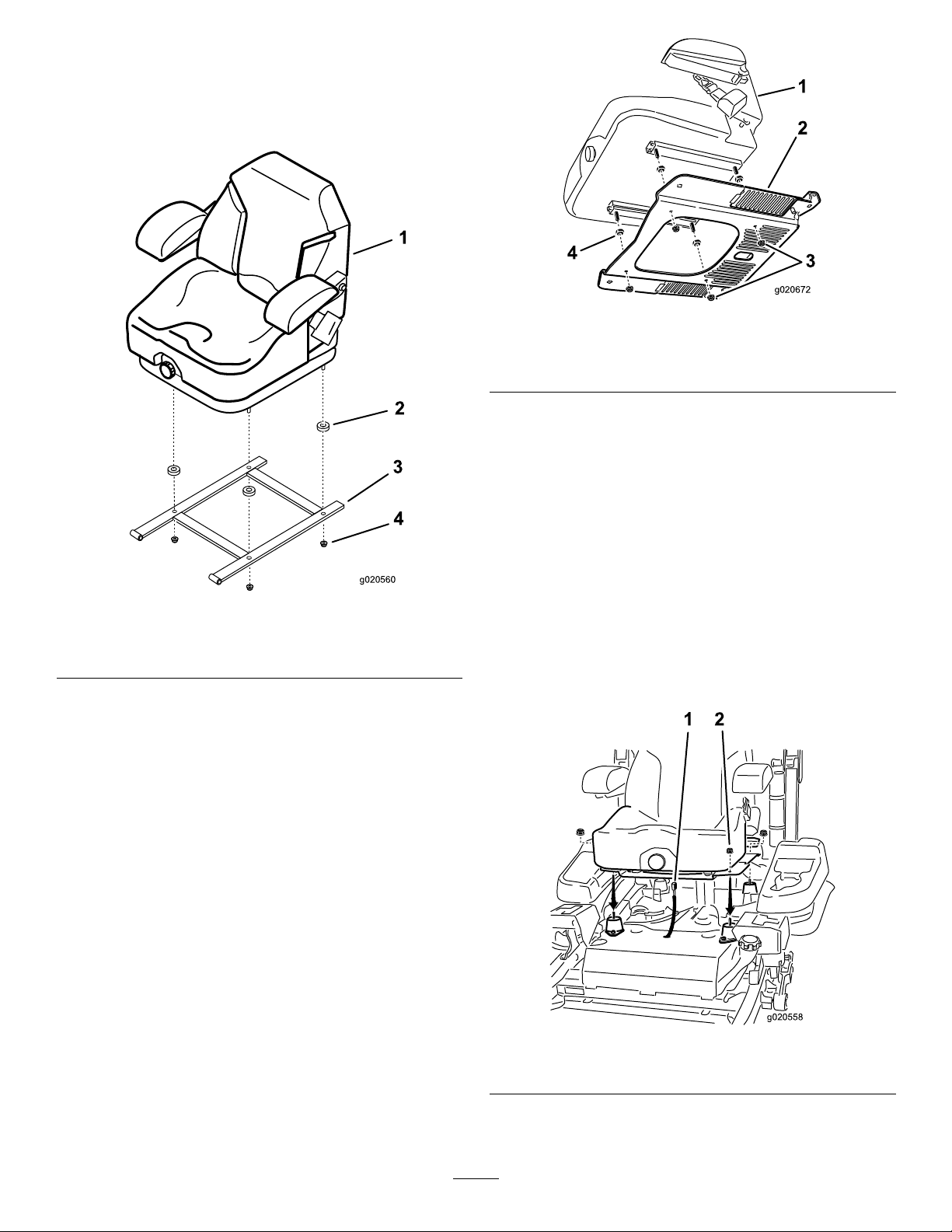

Installinga2000SeriesZMasterMower

Seat

1.Removetheplasticpackingcoversguardingtheseat

studs.

2.Installaspacerontoeachseatstud(Figure7).

3.Securetheseatframetotheseatwith4angenuts

(5/16inch)(Figure7).

4.Torquethenutsto30.5N-m(22.5ft-lb).

Figure7

1.Newseat

2.Spacer

5.Plugtheharnessconnectorintotheseatswitchlocated

undertheseattowardsthefront(Figure13).

6.Carefullylowertheseatdownandensuretheharness

doesnotgetpinched.

7.Installtheplastictiestopreventthewireharnessfrom

beingpinched.

8.Installtheseattothemachineframebyaligningthe

frontnutswiththekeyholeintheseatplate.

9.Slidetheseatandseatplaterearwardtolockthefront

nutsintothekeyholeandtherearnutsintotheslots

Figure1).

(

10.Torquethenutsto47.5N-m(35ft-lb).

3.Seatframe

4.Nut

3

Page 4

Installinga5000or6000SeriesZ

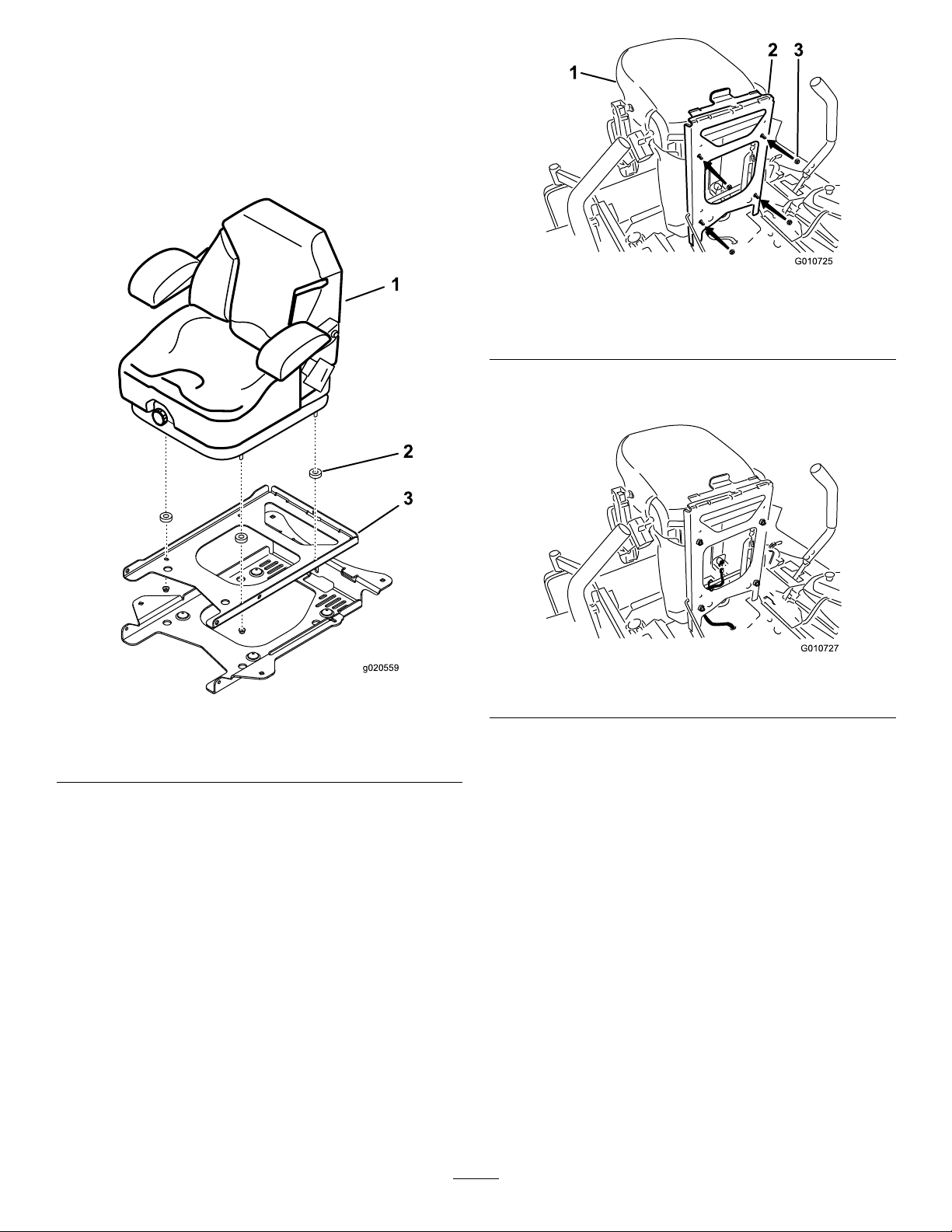

g020559

MasterMowerSeat(DomesticOnly)

1.Tilttheseatframeup.

2.Removetheplasticpackingcoversguardingtheseat

studs.

3.Installaspacerontoeachseatstud(Figure8).

Figure9

1.Seat3.Flangenut(5/16inch)

2.Seatframe

7.Plugtheharnessconnectorintotheseatswitchlocated

undertheseat(Figure10).

Figure8

1.Newseat

2.Spacer

3.Seatframe

4.Positionthenewseatintotheseatframe(Figure9).

5.Securetheseattotheseatframewith4angenuts

(5/16inch)(Figure9).

6.Torquethenutsto29.8N-m(20ft.-lb).

Figure10

8.Carefullylowertheseatdownandensuretheharness

doesnotgetpinched.

9.Movetheseattothefurthestrearposition.

10.Installtheplastictiestopreventthewireharnessfrom

beingpinched.

4

Page 5

Installinga7000SeriesZMasterMower

g020560

4

g020672

4

g020558

Seat

1.Tilttheseatframeup.

2.Installaspacerontoeachseatstud(Figure11).

Figure11

1.Newseat

2.Spacer4.Flangenut(5/16inch)

3.Installtheseattotheseatframewith4angenuts

(5/16inch)(

Figure11).

3.Seatframe

Figure12

1.Seat3.Flangenut(5/16inch)

2.Seatplate4.Spacer

5.Plugtheharnessconnectorintotheseatswitchlocated

undertheseattowardsthefront.

6.Carefullylowertheseatdownandensuretheharness

doesnotgetpinched.

7.Movetheseattothefurthestrearposition.

8.Ensuretheharnessdoesnotgetpinched.

9.Installtheplastictiestopreventthewireharnessfrom

beingpinched.

10.Installtheseattothemachineframewiththepreviously

removednuts(

Figure13).

Note:Theseatmayneedtobetiltedtoallowaccess

tothethreading.

11.Torquethenutsto47.5N-m(35ft.-lb.).

4.Plugtheharnessconnectorintotheseatswitchlocated

undertheseattowardsthefront.

5.Carefullylowertheseatdownandensuretheharness

doesnotgetpinched.

6.Movetheseattothefurthestrearposition.

7.Installtheplastictiestopreventthewireharnessfrom

beingpinched.

Installinga3000SeriesorInternational

5000and6000SeriesZMasterMower

Seat

1.Removetheplasticpackingcoversguardingtheseat

studs.

2.Installaspacer(Figure12).

1.Harnessconnector

3.Securetheseattotheseatframewith4angenuts

(5/16inch)(Figure12)

4.Torquethenutsto22.5ft.-lb.(30.5N-m).

12.Forinternationalmachinesonly,installthehydraulic

unitshroudtothemachine(Figure14).

5

Figure13

2.Flangenuts(3/8inch)

Page 6

Figure14

1.Hydraulicunitshroud2.Bolts

componentisinthecorrectposition,atrianglewilllightup

inthecorrespondingsquare.

Testthesafetyinterlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Sittingontheseat,engagetheparkingbrakeandmove

thebladecontrolswitch(PTO)toon.Trystartingthe

engine;theengineshouldnotcrank.

2.Sittingontheseat,engagetheparkingbrakeandmove

thebladecontrolswitch(PTO)tooff.Moveeither

motioncontrollever(outofneutrallockedposition).

Trystartingtheengine;theengineshouldnotcrank.

Repeatforothercontrollever.

3.Sittingontheseat,engagetheparkingbrake,movethe

bladecontrolswitch(PTO)tooffandmovethemotion

controlleverstoneutrallockposition.Nowstartthe

engine.Whiletheengineisrunning,releasetheparking

brake,engagethebladecontrolswitch(PTO)andrise

slightlyfromtheseat;theengineshouldstop.

3

TestingtheSafetyInterlock System

NoPartsRequired

Procedure

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Thesafetyinterlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Theparkingbrakeisengaged.

•Thebladecontrolswitch(PTO)isdisengaged.

•Themotioncontrolleversareintheneutrallocked

position

4.Sittingontheseat,engagetheparkingbrake,movethe

bladecontrolswitch(PTO)tooffandmovethemotion

controlleverstoneutrallockposition.Nowstartthe

engine.Whiletheengineisrunning,centereither

motioncontrolandmove(forwardorreverse);the

engineshouldstop.Repeatforothermotioncontrol.

5.Sittingontheseat,disengagetheparkingbrake,move

thebladecontrolswitch(PTO)tooffandmovethe

motioncontrolleverstoneutrallockposition.Try

startingtheengine;theengineshouldnotcrank.

Thesafetyinterlocksystemalsoisdesignedtostopthe

enginewhenthetractioncontrolsaremovedfromthelocked

positionwiththeparkingbrakeengagedorifyourisefrom

theseatwhenthePTOisengaged.

Thehourmeterhassymbolstonotifytheuserwhenthe

interlockcomponentisinthecorrectposition.Whenthe

6

Page 7

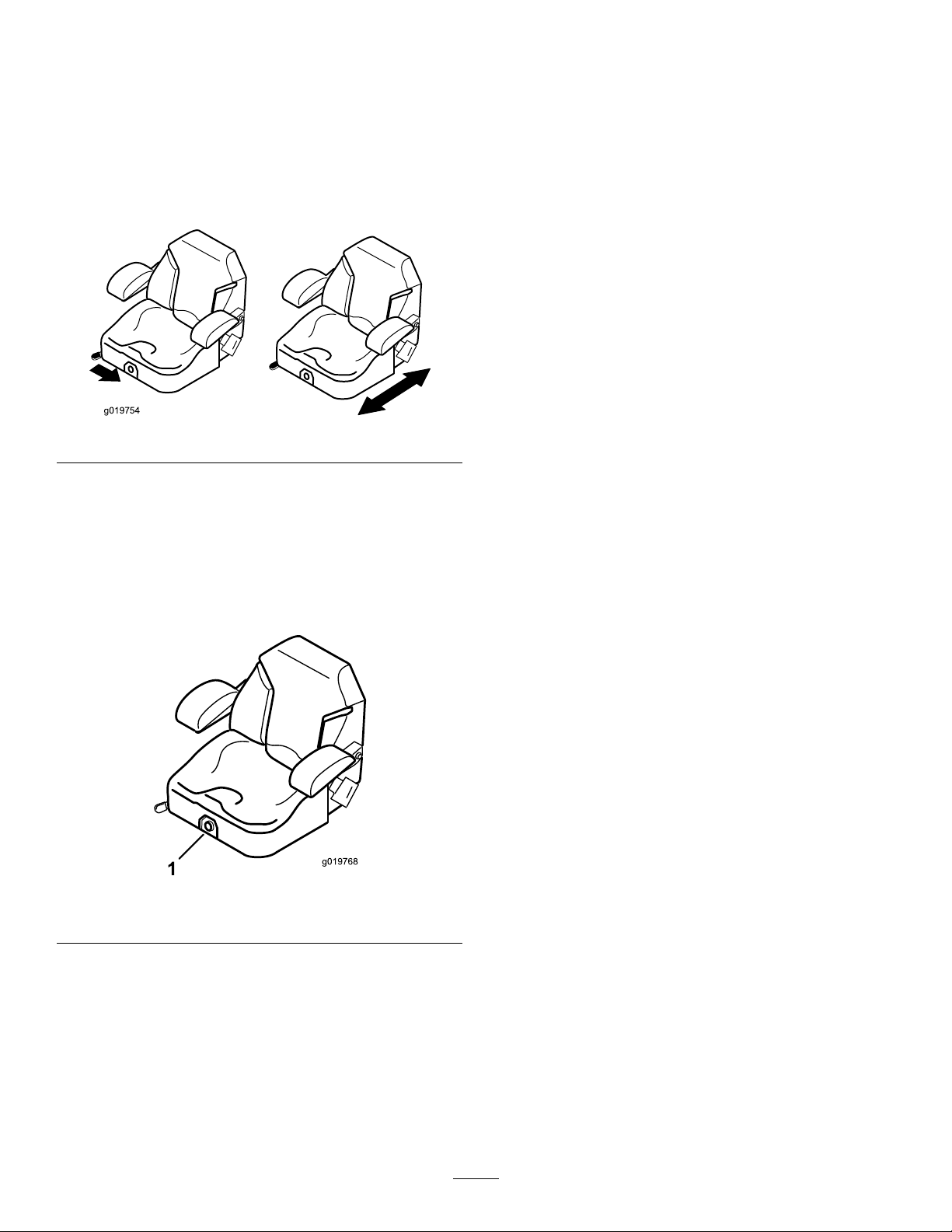

Operation

g019754

g019768

1

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

Toadjust,movetheleversidewaystounlockseat(Figure15).

Figure15

ChangingtheSeatSuspension

Theseatisadjustabletoprovideasmoothandcomfortable

ride.Positiontheseatwhereyouaremostcomfortable.

Toadjustit,turntheknobinfronteitherdirectiontoprovide

thebestcomfort(

1.Seatsuspensionknob

Figure16).

Figure16

7

Page 8

Loading...

Loading...