Page 1

ChuteGateKit

Mid-SizeWalkBehindMowers

ModelNo.1 15–4190

ModelNo.1 15–4195

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3361-286RevA

InstallationInstructions

ProcedureDescription

1

2

3

4

5

6

Nopartsrequired

Sidedischargechute

Bolt,(5/16x7–1/2inches)

Locknut,(5/16inch)

Plasticspacer1

Spring

Handleassembly1

Bolt,(1/4x3/4inches)

Locknut(1/4inch)

Bracket1

Handleassembly1

Bolt,(1/4x1-3/4inches)

Bolt,(1/4x3/4inches)

Locknut(1/4inch)

Bracket1

Handleassembly1

Bolt,(1/4x1-3/4inches)

Bolt,(1/4x3/4inches)

Locknut(1/4inch)

Bracket1

Plasticties2

Adhesivebackmount2

Qty.

Use

–

1

1

1

1

4

4

2

2

4

2

2

4

Removetheexistingsidedischarge

chute.

Installthesidedischargechutewith

gate.

InstallthehandletoaT-BarHydro

Machine

InstallthehandletoaT-BarGear

Machine

InstallthehandletoaPistolGrip

Machine

Installingthecables.

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

1

2

RemovingtheExistingSide

DischargeChute

NoPartsRequired

Procedure

1.DisengagethePTO,settheparkingbrake,andchock

orblockthedrivewheels.

2.Turnofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethelocknut,bolt,springandspacerholding

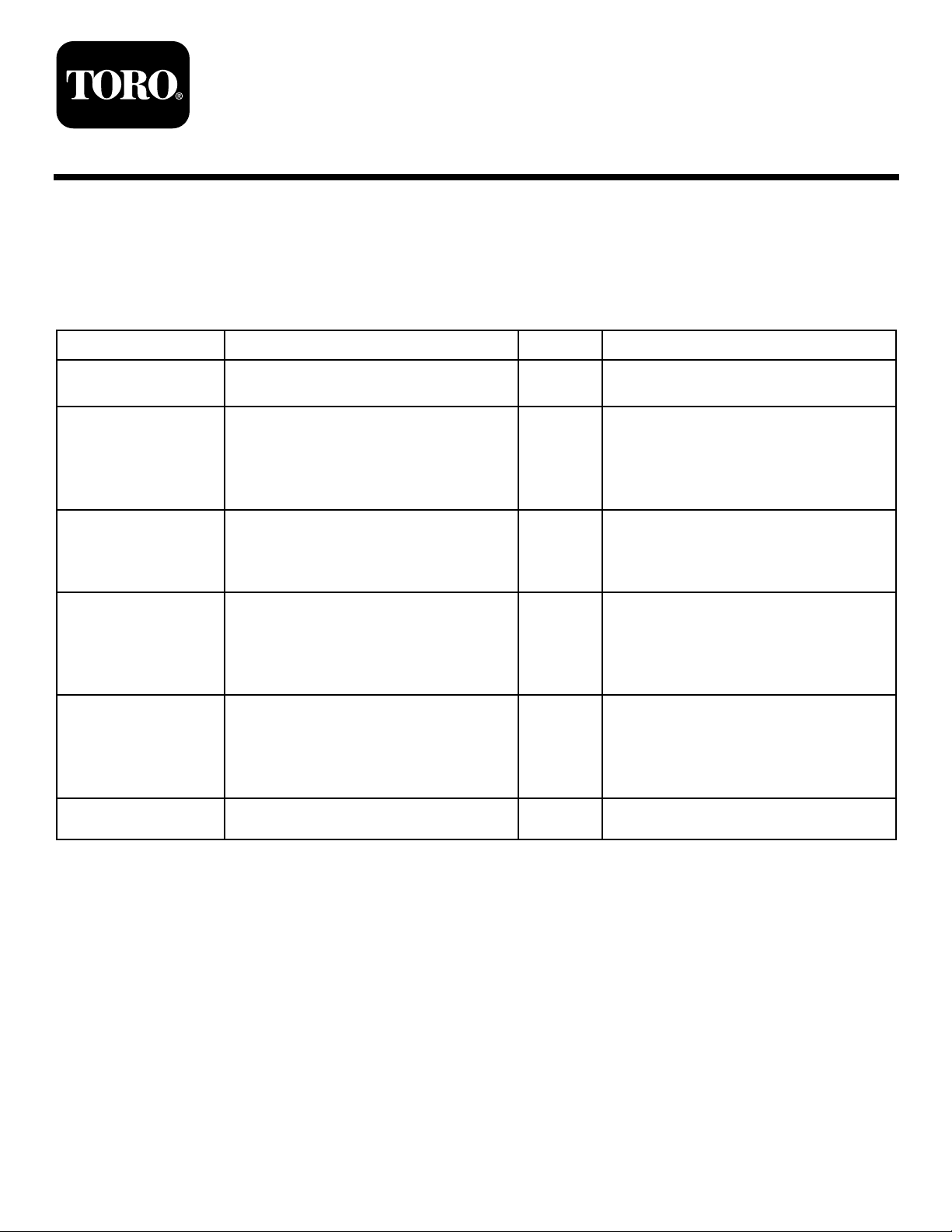

thedeectortothepivotbrackets(Figure1).

Removethegrassdeector.

InstallingtheSideDischarge

ChutewithGate

Partsneededforthisprocedure:

1

Sidedischargechute

1

Bolt,(5/16x7–1/2inches)

1

Locknut,(5/16inch)

1Plasticspacer

1

Spring

Procedure

Anuncovereddischargeopeningcouldallow

thelawnmowertothrowobjectsinthe

operator’sorbystander’sdirectionandresult

inseriousinjury.Also,contactwiththeblade

couldoccur.

Figure1

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring8.Jhookendofspring

5.Springinstalled

7.Lendofspring,place

behinddeckedgebefore

installingbolt

•Neveroperatethelawnmowerunlessyou

installacoverplate,amulchplate,oragrass

chuteandcatcher.

•Makesurethegrassdeectorisinthedown

position.

Note:Ensurethegrassdeectorisinstalledinthe

lowerholesinthemowerdeckbrackets.

1.Placethenewspacerandspringontograssdeector.

Placeoneendofspringbehinddeckedge.

Note:Makesuretheendofthespringisinstalled

behindthedeckedgebeforeinstallingtheboltas

showninFigure2.

2.Installboltandnutinthelowerhole.Placetheend

ofthespringaroundthegrassdeector(Figure2).

3.Tightenthenutuntiltheendoftheboltisushwith

theendofthenut.Donotovertighten.

Important:Thegrassdeectormustbeableto

lowerdownintoposition.Liftthedeectorup

totestthatitlowersintothefulldownposition.

2

Page 3

Figure2

1.Bolt

2.Spacer5.Springinstalled

3.Locknut

4.Spring

6.GrassDeector

3

InstallingtheHandletoaT-Bar

HydroMachine

Partsneededforthisprocedure:

1Handleassembly

4

Bolt,(1/4x3/4inches)

4

Locknut(1/4inch)

1Bracket

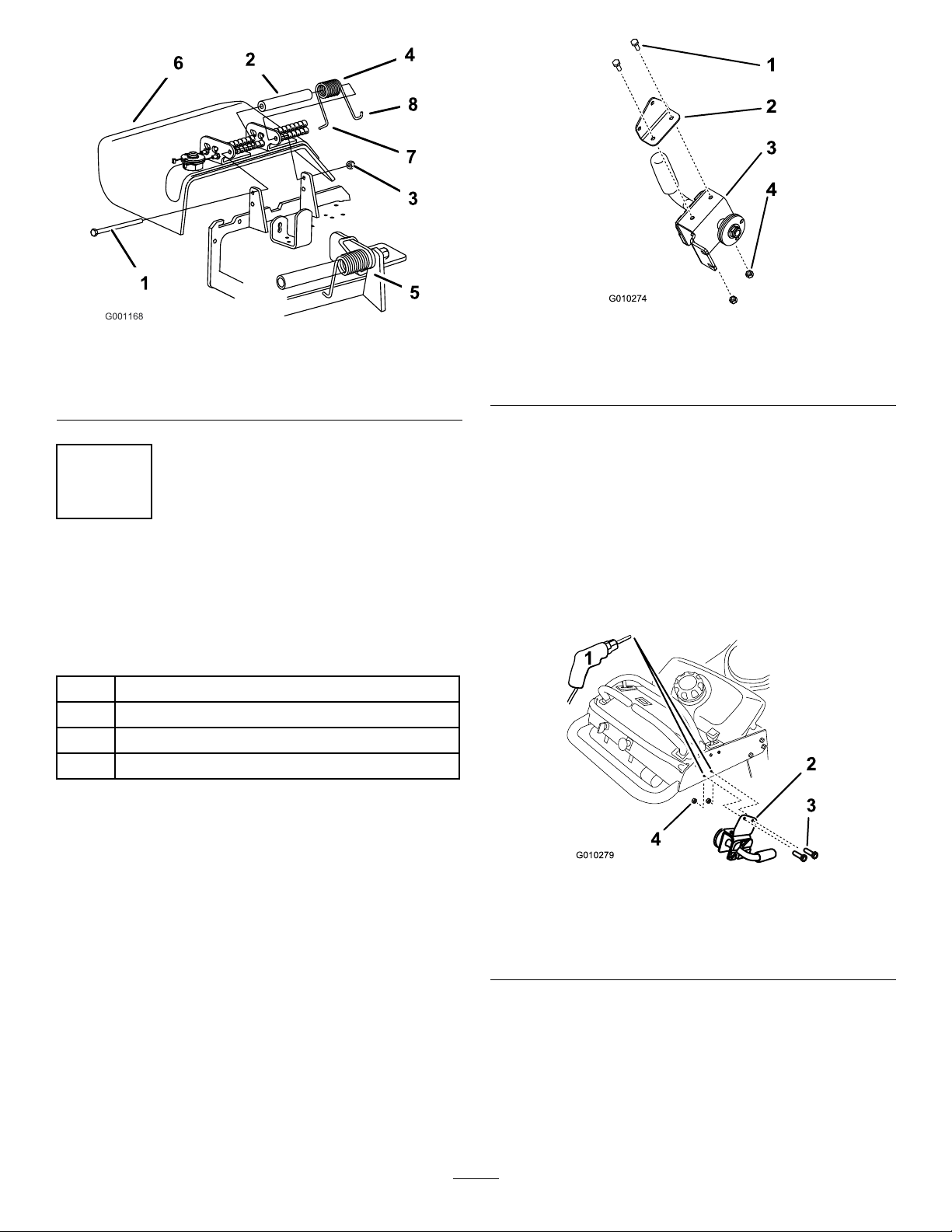

Figure3

1.Bolt(1/4x3/4inches)

2.Bracket,ensurethe

correctoneshownisused

3.Handleassembly

4.Locknut(1/4inch)

2.Checkifthereareholesexistingtomountthehandle.

3.Ifneeddrillholestomountthehandle.Markand

drill2holes,9/32indiameter,ontherightsideof

themachinebelowthecontrols(Figure4).

4.Installthehandleassemblytothemachinewith

2bolts(1/4x3/4inches)and2locknuts(1/4

inch)(Figure4).

Procedure

1.Installthehandleassemblytotheanglebracket

with2bolts(1/4x3/4inches)and2locknuts(1/4

inch)(Figure3).Ensuretousethecorrectbracket.

1.Ifneeded,drillholeshere

(9/32india.)

2.Handleassembly

3

Figure4

3.Bolt(1/4x3/4inches)

4.Locknut(1/4inch)

Page 4

4

InstallingtheHandletoaT-Bar

GearMachine

Partsneededforthisprocedure:

1Handleassembly

2

Bolt,(1/4x1-3/4inches)

2

Bolt,(1/4x3/4inches)

4

Locknut(1/4inch)

1Bracket

Procedure

1.Installthehandleassemblytotheanglebracket

with2bolts(1/4x3/4inches)and2locknuts(1/4

inch)(Figure5).Ensuretousethecorrectbracket.

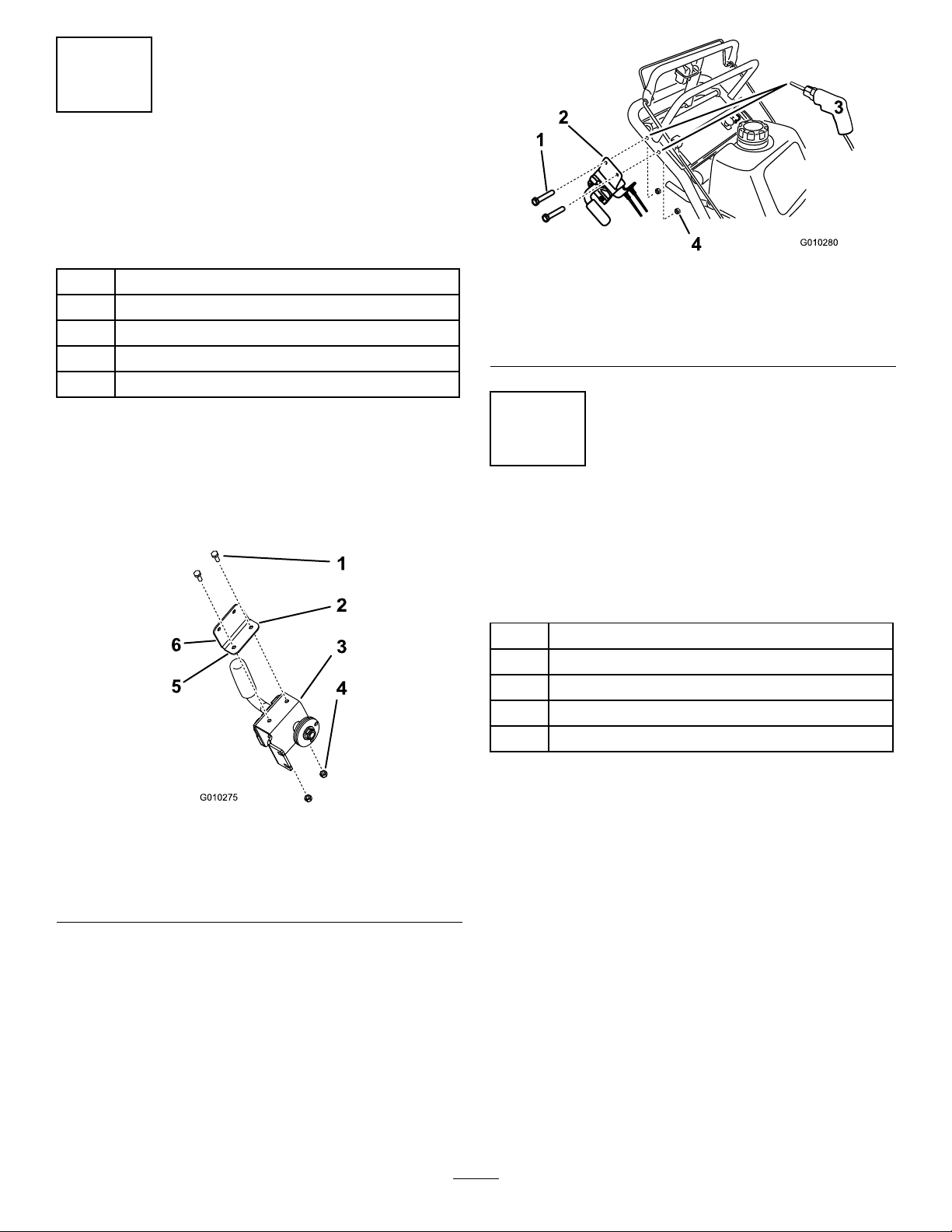

Figure6

1.Bolt(1/4x1-3/4inches)3.Drilltwoholeshere(9/32in

2.Handleassembly

dia.)

4.Locknut(1/4inch)

Figure5

1.Bolt(1/4x3/4inches)4.Locknut(1/4inch)

2.Bracket,ensurethe

correctoneshownisused

3.Handleassembly6.Longside

5.Shortside

2.Drillholestomountthehandle.Usingthebracketas

atemplate,markanddrill2holes,9/32indiameter,

ontherightsideofthehandle.Centertheholes

onthetubeandoneithersideofthereferencebar

(Figure4).

3.Installthehandleassemblytothemachinewith

2bolts(1/4x1-3/4inches)and2locknuts(1/4

inch)(Figure6).

4

Page 5

5

InstallingtheHandletoaPistol

GripMachine

Partsneededforthisprocedure:

1Handleassembly

2

Bolt,(1/4x1-3/4inches)

2

Bolt,(1/4x3/4inches)

4

Locknut(1/4inch)

1Bracket

Procedure

1.Installthehandleassemblytotheanglebracket

with2bolts(1/4x3/4inches)and2locknuts(1/4

inch)(Figure7).Ensuretousethecorrectbracket.

Figure8

1.Bolt(1/4x1-3/4inches)4.Locknut(1/4inch)

2.Handleassembly

3.Drilltwoholeshere(9/32in

dia.)

5.Controlpanel

6

Figure7

1.Bolt(1/4x3/4inches)

2.Bracket,ensurethe

correctoneshownisused

2.Drillholestomountthehandle.Usingthebracketas

atemplate,markanddrill2holes,9/32indiameter,

ontherightsideofthehandle.Centertheholeson

thetubeandjustbelowthecontrolpanel(Figure4).

3.Installthehandleassemblytothemachinewith

2bolts(1/4x1-3/4inches)and2locknuts(1/4

inch)(Figure8).

3.Handleassembly

4.Locknut(1/4inch)

InstallingtheCables

Partsneededforthisprocedure:

2Plasticties

2Adhesivebackmount

Procedure

1.Routethecablesfromthedischargechutetotherear

ofthemachineontopoftheengineplatformand

alongtherightsideoftheengine.Ensurethecables

passunderanyhydrauliclinesandfuellines.

2.Fastenthecablestotheenginedeckandmower

deckwithaplastictiesandadhesivebackmounts

(Figure9andFigure10).

Ensurethecablesdonotinterferewiththereartires,

themuferandanymovingparts.

5

Page 6

Figure9

1.Cables

2.Plasticcabletie

Figure10

1.Plasticcabletie3.Adhesivebackmount

2.Cables

3.Loosenthelocknutandinsertthecableends

betweenthepulley .Itisimportanttoinstallthe

cablesasshowninFigure11.Thiswillensurethe

chuteoperatesasshownintheOperationSection.

4.Installthecableintotheslotandthenpushthe

plasticretainerintothehole(Figure11).

Figure11

1.Handle

2.Endofcable,install

betweenpulley

3.Insidecable7.Loosenlocknut

4.Outsidecable

5.Chutegate

6.Installcableintoslotand

thenpushplasticretainer

intohole

6

Page 7

Operation

UsingtheChuteGate

Thechutegatedoesnotsealthedischarge

opening.Grassandobjectsmaybethrownin

abystander’sdirectionandresultinserious

injury.

•Beawareofthemowerdischargedirection

anddonotpointitatanyone.

•Removeobstaclessuchasrocks,treelimbs,

etc.fromthemowingarea.

•Neverputyourhandsorfeetunderthe

mowerordischargearea.

•Nevertrytoclearthedischargeareaor

mowerbladesunlesstheengineisoffand

thekeyisremoved.

Usethechutegatetotemporarilystopordeectgrass

clippingsawayfromsidewalks,parkinglots,patios,or

anywhereyoudonotwantgrassclippingstoland.The

chutegatehas3positions:open,45degreeangle,and

closed.

•Rotatethechutegatehandletotheopenpositionto

allowgrassclippingstodischarge(FigureFigure12).

•Rotatethechutegatehandletothe45degreeangle

todeectthegrassclippings(FigureFigure12).

•Rotatethechutegatehandletotheclosedposition

tostopthegrassclippings(FigureFigure12).

Figure12

1.Chutegateopen3.Chutegateclosed

2.Chutegateat45degree

angle

7

Page 8

Kitdepuertadelconductodedescarga

Cortacéspedesdirigidosdetamañomedio

Nºdemodelo115–4190

Nºdemodelo115–4195

Instalación

Piezassueltas

Utilicelatablasiguienteparavericarquenofaltaningunapieza.

FormNo.3361-286RevA

Instruccionesdeinstalación

Procedimiento

1

2

3

4

5

6

Nosenecesitanpiezas

Conductodedescargalateral

Perno,(5/16x7-1/2pulg.)

Contratuerca,(5/16inch)

Espaciadordeplástico1

Muelle1

Conjuntodelmanillar

Perno,(1/4x3/4pulg.)

Contratuerca(1/4inch)

Soporte

Conjuntodelmanillar

Perno(1/4x1-3/4pulgadas)

Perno,(1/4x3/4pulg.)

Contratuerca(1/4inch)

Soporte

Conjuntodelmanillar

Perno(1/4x1-3/4pulgadas)

Perno,(1/4x3/4pulg.)

Contratuerca(1/4inch)

Soporte

Sujetacablesdeplástico

Soporteautoadhesivo

DescripciónCant.

–

1

1

1

1

4

4

1

1

2

2

4

1

1

2

2

4

1

2

2

Retirarelconductodedescargalateral

actual.

Instalarelconductodedescargalateral

conpuerta.

Instalarlapalancaenunamáquina

T-Barcontransmisiónhidrostática

Instalarlapalancaenunamáquina

T-Barcontransmisióndeengranajes

Instalarlapalancaenunamáquinacon

empuñadurastipopistola

Instalarloscables.

Uso

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registresuproductoenwww.Toro.com.

Traduccióndeloriginal(ES)

ImpresoenEE.UU.

Reservadostodoslosderechos

Page 9

1

2

Retiradadelconductode

descargalateralactual

Nosenecesitanpiezas

Procedimiento

1.Desengranelatomadefuerza,pongaelfreno

deestacionamientoycalceobloqueelasruedas

motrices.

2.Pareelmotor,retirelallaveyespereaquese

detengantodaslaspiezasenmovimientoantesde

abandonarelpuestodeloperador.

3.Retirelacontratuerca,elperno,elmuelleyel

espaciadorquesujetaneldeectoralossoportesde

pivote(Figura1).Retireeldeectordehierba.

Instalacióndelconductode

descargalateralconpuerta

Piezasnecesariasenestepaso:

1

Conductodedescargalateral

1

Perno,(5/16x7-1/2pulg.)

1

Contratuerca,(5/16inch)

1Espaciadordeplástico

1Muelle

Procedimiento

Sielhuecodedescargasedejadestapado

elcortacéspedpodríaarrojarobjetoshacia

eloperadorohaciaotraspersonasycausar

lesionesgraves.Tambiénpodríaproducirseun

contactoconlacuchilla.

Figura1

1.Perno5.Muelleinstalado

2.Espaciador

3.Contratuerca

4.Muelle8.ExtremoenJdelmuelle

6.Deectordehierba

7.ExtremoLdelmuelle;

coloquedetrásdelreborde

delaplataformaantesde

instalarelperno

•Nooperenuncaelcortacéspedsintener

instaladounatapa,unaplacadepicadooun

conductodehierbaybolsaderecortes.

•Compruebequeeldeectordehierbaestá

bajado.

Nota:Asegúresedequeeldeectordehierbaestá

instaladoenlostaladrosinferioresdelossoportesdela

plataformadelcortacésped.

1.Coloqueelespaciadoryelmuellenuevoenel

deectordehierba.Coloqueunextremodelmuelle

detrásdelrebordedelaplataforma.

Nota:Asegúresedecolocarelextremoendel

muelledetrásdelrebordedelaplataformaantesde

instalarelperno,segúnsemuestraenFigura2.

2.Instaleelpernoylatuercaeneltaladroinferior.

Coloqueelextremodelmuellealrededordel

deectordehierba(Figura2).

3.Aprietelatuercahastaqueelextremodelpernoesté

enrasadoconelextremodelatuerca.Noapriete

excesivamente.

Importante:Eldeectordehierbadebepoder

bajarasuposición.Levanteeldeectorpara

vericarquepuedebajardeltodo.

2

Page 10

Figura2

1.Perno4.Muelle

2.Espaciador5.Muelleinstalado

3.Contratuerca6.Deectordehierba

3

Instalacióndelapalanca

Figura3

1.Perno(1/4x3/4pulg.)3.Conjuntodelapalanca

2.Escuadra;asegúresede

usarlacorrecta(ilustrada)

4.Contratuerca(1/4inch)

2.Compruebesiyaexistentaladrosparamontarla

palanca.

3.Siesnecesario,practiqueunostaladrosparamontar

lapalanca.Marqueypractique2taladrosde7,1mm

(9/32pulg.)dediámetroenelladoderechodela

máquina,debajodeloscontroles(Figura4).

enunamáquinaT-Barcon

transmisiónhidrostática

Piezasnecesariasenestepaso:

1

Conjuntodelmanillar

4

Perno,(1/4x3/4pulg.)

4

Contratuerca(1/4inch)

1

Soporte

Procedimiento

1.Instaleelconjuntodelapalancaenlaescuadracon

2pernos(1/4x3/4pulg.)y2contratuercas(1/4

inch)(Figura3).Asegúresedeutilizarlaescuadra

correcta.

4.Instaleelconjuntodelapalancaenlamáquinacon2

pernos(1/4x3/4pulgadas)y2contratuercas(1/4

inch)(Figura4).

Figura4

1.Siesnecesario,practique

lostaladrosaquí(diámetro

7,1mm[9/32pulg.])

2.Conjuntodelapalanca4.Contratuerca(1/4inch)

3.Perno(1/4x3/4pulg.)

3

Page 11

4

Instalacióndelapalanca

enunamáquinaT-Barcon

transmisióndeengranajes

Piezasnecesariasenestepaso:

1

Conjuntodelmanillar

2

Perno(1/4x1-3/4pulgadas)

2

Perno,(1/4x3/4pulg.)

4

Contratuerca(1/4inch)

1

Soporte

Figura6

1.Perno(1/4x1-3/4pulg.)

2.Conjuntodelapalanca4.Contratuerca(1/4inch)

3.Practiquelostaladrosaquí

(diámetro7,1mm[9/32

pulg.])

Procedimiento

1.Instaleelconjuntodelapalancaenlaescuadracon

2pernos(1/4x3/4pulg.)y2contratuercas(1/4

inch)(Figura5).Asegúresedeutilizarlaescuadra

correcta.

Figura5

1.Perno(1/4x3/4pulg.)4.Contratuerca(1/4inch)

2.Escuadra;asegúresede

usarlacorrecta(ilustrada)

3.Conjuntodelapalanca

5.Ladocorto

6.Ladolargo

5

Instalacióndelapalanca

enunamáquinacon

empuñadurastipopistola

Piezasnecesariasenestepaso:

1

Conjuntodelmanillar

2

Perno(1/4x1-3/4pulgadas)

2

Perno,(1/4x3/4pulg.)

4

Contratuerca(1/4inch)

1

Soporte

Procedimiento

1.Instaleelconjuntodelapalancaenlaescuadracon

2pernos(1/4x3/4pulg.)y2contratuercas(1/4

inch)(Figura7).Asegúresedeutilizarlaescuadra

correcta.

2.Practiquetaladrosparamontarlapalanca.Usandola

escuadracomoguía,marqueypractique2taladrosde

7,1mm(9/32pulg.)dediámetroenelladoderecho

delmanillar.Centrelostaladroseneltuboyencada

ladodelabarradereferencia(Figura4).

3.Instaleelconjuntodelapalancaenlamáquinacon2

pernos(1/4x3/4pulgadas)y2contratuercas(1/4

inch)(Figura6).

4

Page 12

6

Instalacióndeloscables

Piezasnecesariasenestepaso:

2

Sujetacablesdeplástico

2

Soporteautoadhesivo

Figura7

1.Perno(1/4x3/4pulg.)3.Conjuntodelapalanca

2.Escuadra;asegúresede

usarlacorrecta(ilustrada)

4.Contratuerca(1/4inch)

2.Practiquetaladrosparamontarlapalanca.Usandola

escuadracomoguía,marqueypractique2taladrosde

7,1mm(9/32pulg.)dediámetroenelladoderecho

delmanillar.Centrelostaladroseneltuboyjusto

pordebajodelpaneldecontrol(Figura4).

3.Instaleelconjuntodelapalancaenlamáquinacon2

pernos(1/4x3/4pulgadas)y2contratuercas(1/4

inch)(Figura8).

Procedimiento

1.Paseloscablesdesdeelconductodedescargahasta

lapartetraseradelamáquina,porencimadela

plataformadelmotoryjuntoalladoderechodel

motor.Asegúresedepasarloscablespordebajode

cualquiermanguitohidráulicootubodecombustible.

2.Sujeteloscablesalaplataformadelmotorcon

sujetacablesdeplásticoysoportesautoadhesivos

(Figura9yFigura10).

Asegúresedequeloscablesnopuedantocarlos

neumáticostraseros,elsilenciadorocualquierpieza

móvil.

Figura8

1.Perno(1/4x1-3/4pulg.)4.Contratuerca(1/4inch)

2.Conjuntodelapalanca

3.Practiquelostaladrosaquí

(diámetro7,1mm[9/32

pulg.])

5.Paneldecontrol

Figura9

1.Cables2.Sujetacablesdeplástico

5

Page 13

Figura10

1.Sujetacablesdeplástico3.Soporteautoadhesivo

2.Cables

3.Aojelacontratuercaeintroduzcalosextremosde

loscablesenlapolea.Esimportanteinstalarlos

cablessegúnseindicaenFigura11.Deestomodo

seaseguraqueelconductofuncionesegúnseexplica

enlasecciónUso.

4.Coloqueelcableenlaranuraeintroduzcaelreténde

plásticoapresióneneloricio(Figura11).

Figura11

1.Palanca5.Puertadelconducto

2.Extremodelcable;instalar

enlapolea

3.Cableinterno7.Aojelacontratuerca

4.Cableexterno

6.Coloqueelcableenla

ranuraeintroduzcael

reténdeplásticoapresión

eneloricio

6

Page 14

Operación

Usodelapuertadelconducto

dedescarga

Lapuertadelconductonosellalaaberturadel

conductodedescarga.Puedensalirlanzados

recortesdehierbayotroobjetoshaciael

operadorohaciaotraspersonasycausar

lesionesgraves.

•Estéatentoalsentidodedescargadel

cortacéspedynoorienteladescargahacia

nadie.

•Retirecualquierobstáculo,comopor

ejemplopiedras,ramasdeárboles,etc.,de

lazonadesiega.

•Nocoloquenuncalasmanosolospies

debajodelcortacéspedodelazonade

descarga.

•Nointentenuncadespejarlazonade

descargaolascuchillasdelcortacéspedsin

antespararelmotoryretirarlallave.

Utilicelapuertadelconductoparadetenerodesviar

temporalmentelosrecortesdehierbaparaqueno

caiganenaceras,aparcamientos,patiosuotrossitios

dondenoconvienequecaigan.Lapuertatiene3

posiciones:abierta,ángulode45grados,ycerrada.

•Girelapalancadelapuertadelconductoala

posicióndeabiertaparapermitirquesedescarguen

losrecortesdehierba(FiguraFigura12).

•Girelapalancadelapuertadelconductoala

posiciónde45gradosparadesviarlosrecortesde

hierba(FiguraFigura12).

•Girelapalancadelapuertadelconductoala

posicióndecerradapararetenerlosrecortesde

hierba(FiguraFigura12).

1.Puertadelconducto

abierta

2.Puertadelconductoenun

ángulode45grados

Figura12

3.Puertadelconducto

cerrado

7

Page 15

Notas:

8

Page 16

Loading...

Loading...