Toro 115-3564 Installation Instructions

Bio-DieselKit

2006andBeforeKubota

ModelNo.115–3564

Thiskitisformachineswithaserialnumberof

269999999andBelow .

Afterthiskitisinstalled,thismachinecanusea

biodieselblendedfuelofuptoB20(20%biodiesel,80%

petrodiesel).Thepetrodieselportionshouldbelowor

ultralowsulfur.RefertotheOperationSectionforfuel

precautions.

FormNo.3360-696RevA

®

-PoweredZMaster

®

RidingMowers

InstallationInstructions

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosed

trailer.

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

Fuelselectorvalvewithhoses1

Template(locatedinthebackofthese

instructions)

SmallR-clamp

Bolt(1/4x1–1/4inches)

Locknut(1/4inch)

LargeR-clamp1

Bolt(5/16x1-3/4inches)

Bolt(5/16x3/4inch)

Locknut(5/16inch)

Waterseparator1

Hose1

Hoseclamp8

Fuelpumpharness1

Lowsulfurdecal

Fuelcap2

Dieseldecal1

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

Qty.

Installthenewfuelselectorvalve.

1

1

1

1

1

1

2

2

Drillholesforthewaterseparatorand

fuelpumpbrackets.

Installthewaterseparatorandfuel

pump.

Connectthefuelhosesandthefuel

pumpharness.

Installthedecalsandfuelcaps.

Use

6

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Nopartsrequired

Registeratwww.Toro.com.

–

Verifytheconnections.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

8.Todrainthefueltank,placeacleancontainerunder

000

0000

0000

thefrontfueltankconnection,removethefuelhose

1

fromtheconnectionorcutthefuellineanddirect

thefuellineintothecontainer(Figure2).

InstallingtheNewFuel

SelectorValve

Partsneededforthisprocedure:

1Fuelselectorvalvewithhoses

Procedure

Important:Allowtheenginetocoolbefore

installingthiskit.

1.Drivethemachinetoawellventilatedareaaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

2.Disengagethepowertakeoff(PTO)andsetthe

parkingbrake.

3.Turnofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Disconnectthenegativebatterycablefromthe

battery.

5.Closethefuelselectorvalve.

6.Allowtheenginetocoolbeforeinstallingthiskit.

7.Tilttheseatforwardandremovethefrontengine

panel(Figure1).

9.Allowthefueltodrainintothecontainerandwipe

upanyspilledfuel.Ensurethefuellineisremoved

fromthetankconnection(Figure2).

10.Drainthefuelfromtheoppositetank.

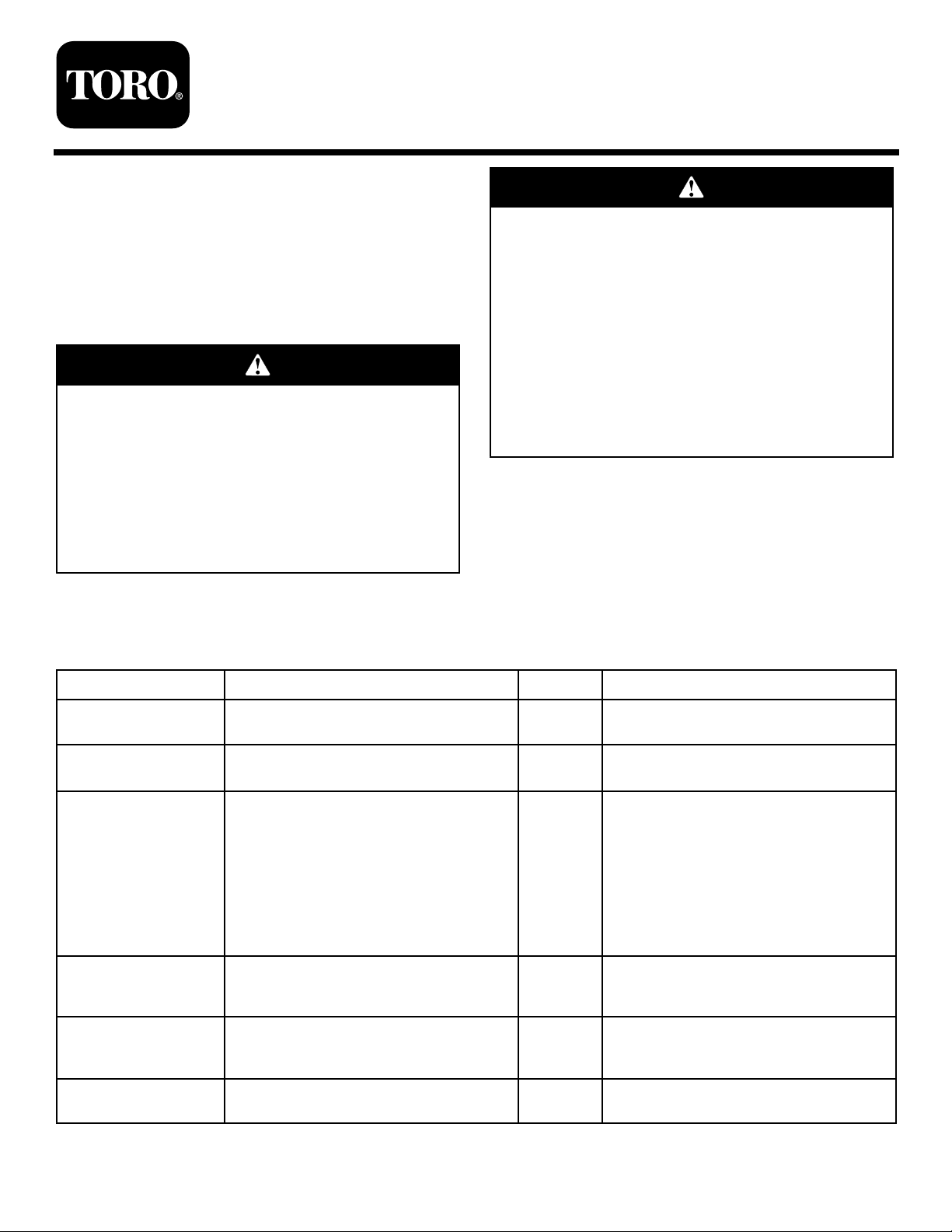

Figure2

1.Righthandfueltank

shown

2.Rearfueltankconnection

3.Frontfueltankconnection

11.Followthefuelhosesfromtheexistingselector

valveandremovethehosesfromthefuellterand

thefueltanks.

12.Disconnecttheelectricalconnectionforthefuel

pumpfromthemainwireharness.Rememberthe

locationofthisconnectionbecauseitwillbeused

forthenewfuelpump.

13.Removetheexistingfuelhosefromtheengineand

removetheexistingfuelltersfromthemachine

(Figure3).

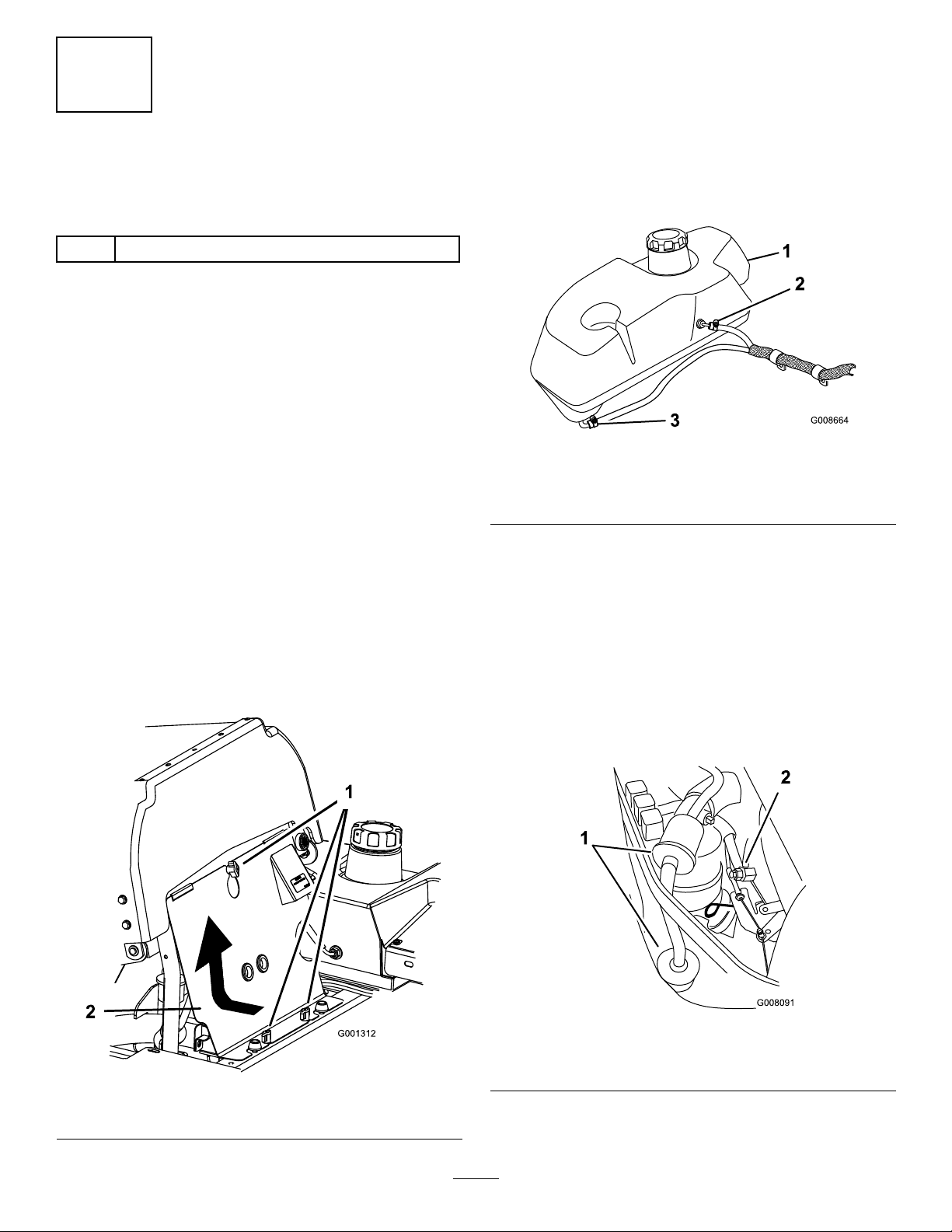

Figure3

2.Fuelhoseconnectedto

engine

Figure1

1.Knob2.Frontenginepanel

1.Existingfuellters

14.Removetheexistingfuelselectorvalve.Referto

Figure4.Savetheexistingsoftware.

2

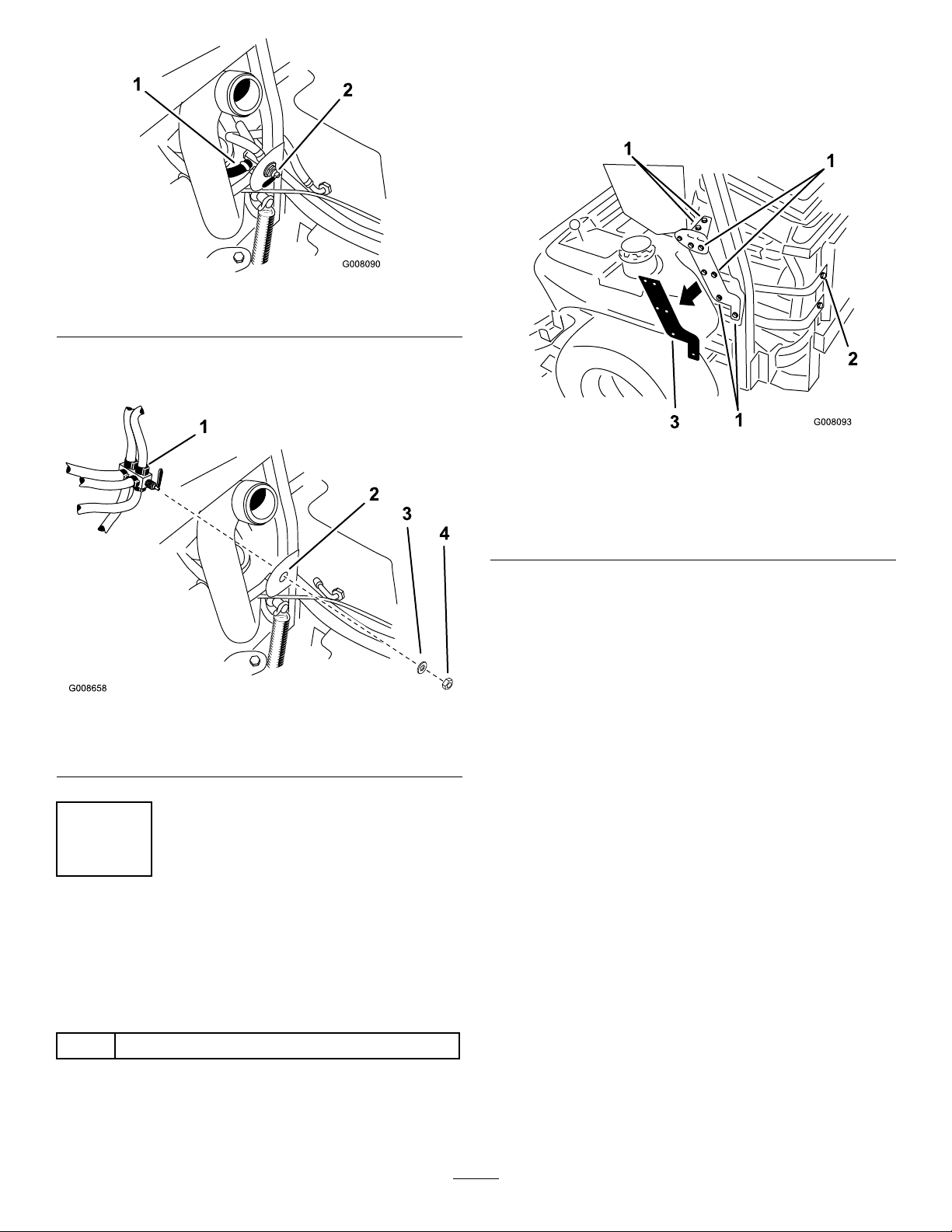

Figure4

1.Hosetoremove

15.Usingthepreviouslyremovedhardware,installthe

newfuelselectorvalve(Figure5).

2.Closefuelselectorvalve

2.Removethenutsandboltsholdingthehoodsupport

bracket.Savethenutsandbolts(Figure6).

3.Removetheboltforthetopengineguardstrapfrom

themachine(Figure6).

Figure6

1.Removethesenutsand

boltsfromthehood

supportbracket

2.Removethisboltfromthe

topengineguardstrap

3.Hoodsideplate

Figure5

1.Newfuelselectorvalve

2.Bracket4.Existingnut

3.Existingwasher

2

DrillingHolesfortheWater

SeparatorandtheFuelPump

Brackets

Partsneededforthisprocedure:

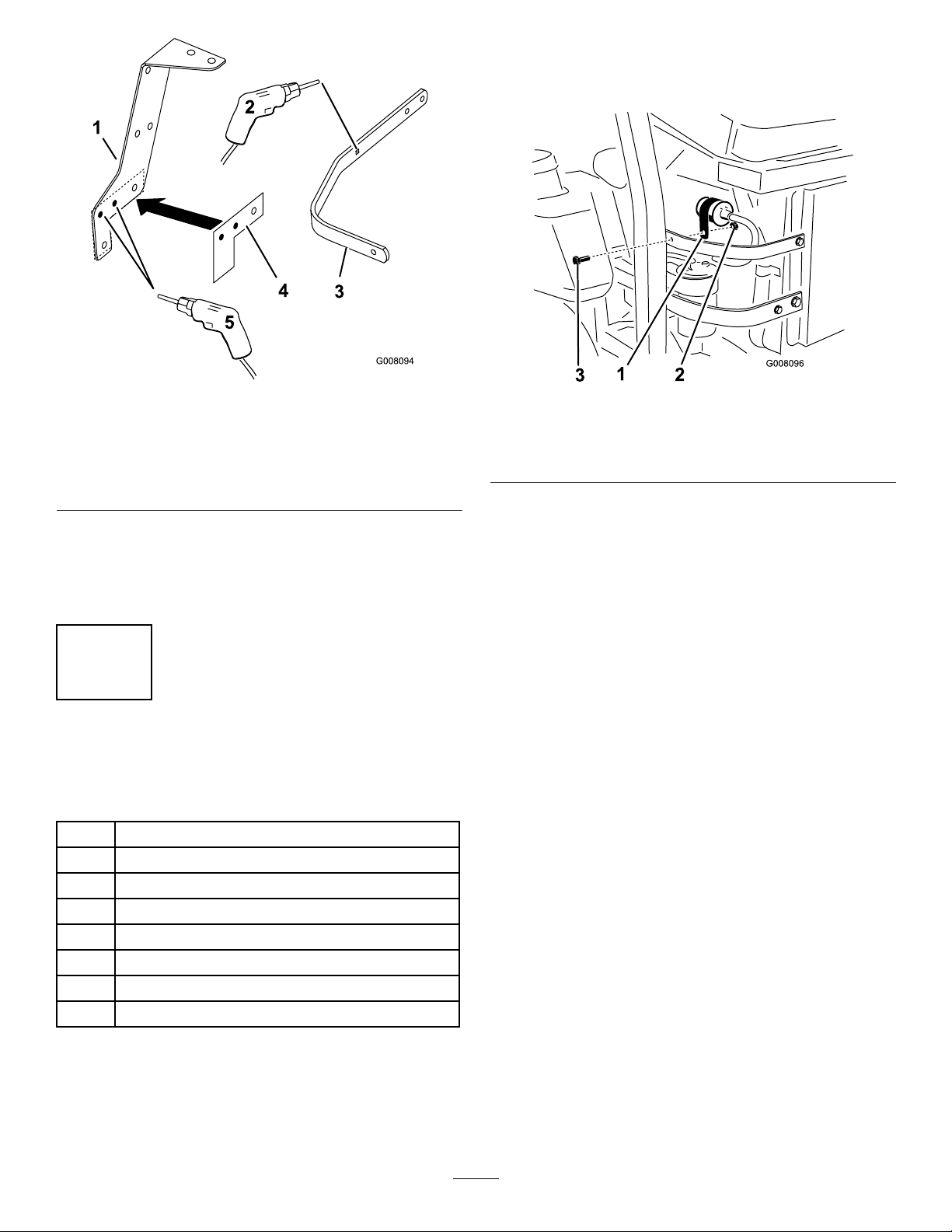

4.Usingthepapertemplateinthebackofthese

instructions,markanddrill2holes(11/32inch

diameter)intothehoodsupportbracket(Figure7).

5.Drilla17/64inchdiameterholeintotheexisting

holeintheengineguardstrap(Figure7).

1

Template(locatedinthebackoftheseinstructions)

Procedure

1.Raisethehoodontheengine.

3

2.InstallthesmallR-clamparoundthefuelpumpand

installittotheenginestrapwithabolt(1/4x1–1/4

inches)andnut(1/4inch)(Figure8).

Figure7

1.Hoodsideplate4.Template

2.Drilla17/64inchholeinto

theexistinghole

3.Enginestrap

5.Drilltwo11/32inchholes

intothehoodsupport

brackethere

6.Installtheengineguardstraptothebackofthe

machine.

7.Installthehoodsupportbracketwiththepreviously

removednutsandbolts.

3

InstallingtheWaterSeparator

andFuelPump

Partsneededforthisprocedure:

1

SmallR-clamp

1

Bolt(1/4x1–1/4inches)

1

Locknut(1/4inch)

1LargeR-clamp

1

Bolt(5/16x1-3/4inches)

1

Bolt(5/16x3/4inch)

2

Locknut(5/16inch)

1Waterseparator

Figure8

1.SmallR-clampwithfuel

pumpinstalled

2.Locknut(1/4inch)

3.Bolt(1/4x1–1/4inches)

3.InstallthewaterseparatorintothelargeR-clamp

andinstallittothehoodsupportbracketwithabolt

(5/16x1-3/4inches),abolt(5/16x3/4inch),and

2locknuts(5/16inch)(Figure9).

Procedure

1.Routethefuellterandfuelpumptowardsthe

backoftheengine.Makesurenopartsorhosesare

touchingthemachineinareasthatwillgethot.

4

Loading...

Loading...