Page 1

Bio-DieselFuelKit

2006andBeforeDaihatsu-PoweredZMasterRidingMowers

ModelNo.115–3563

Afterthiskitisinstalled,thismachinecanusea

biodieselblendedfuelofuptoB20(20%biodiesel,80%

petrodiesel).Thepetrodieselportionshouldbelowor

ultralowsulfur.

FormNo.3360-694RevA

InstallationInstructions

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

Fuelselectorvalvewithhoses1

Nopartsrequired

Mountingplate1

Locknut(1/4inch)

Fuellterclamp

Bolt(5/16x1-3/4inches)

Bolt(5/16x3/4inch)

Locknut(5/16inch)

Waterseparator1

Hose1

Hoseclamp8

J-clamp1

Plastictie6

Lowsulfurdecal

Fuelcap2

Dieseldecal1

•Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

Qty.

Installthenewfuelselectorvalve.

–

1

1

1

1

2

2

Removetheexistingwaterseparator

Installthenewwaterseparator.

Installingandconnectingthefuelhoses.

Installthedecalsandfuelcaps.

Use

6

©2008—TheToro®Company

8111LyndaleA venueSouth

Bloomington,MN55420

Nopartsrequired

Registeratwww.Toro.com.

–

Verifytheconnections.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

1

InstallingtheNewFuel

SelectorValve

Partsneededforthisprocedure:

1Fuelselectorvalvewithhoses

Procedure

10.Drainthefuelfromtheoppositetank.

Important:Allowtheenginetocoolbefore

installingthiskit.

1.Drivethemachinetoawellventilatedareaaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

2.Disengagethepowertakeoff(PTO)andsetthe

parkingbrake.

3.Turnofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Disconnectthenegativebatterycablefromthe

battery.

5.Closethefuelselectorvalve.

6.Allowtheenginetocoolbeforeinstallingthiskit.

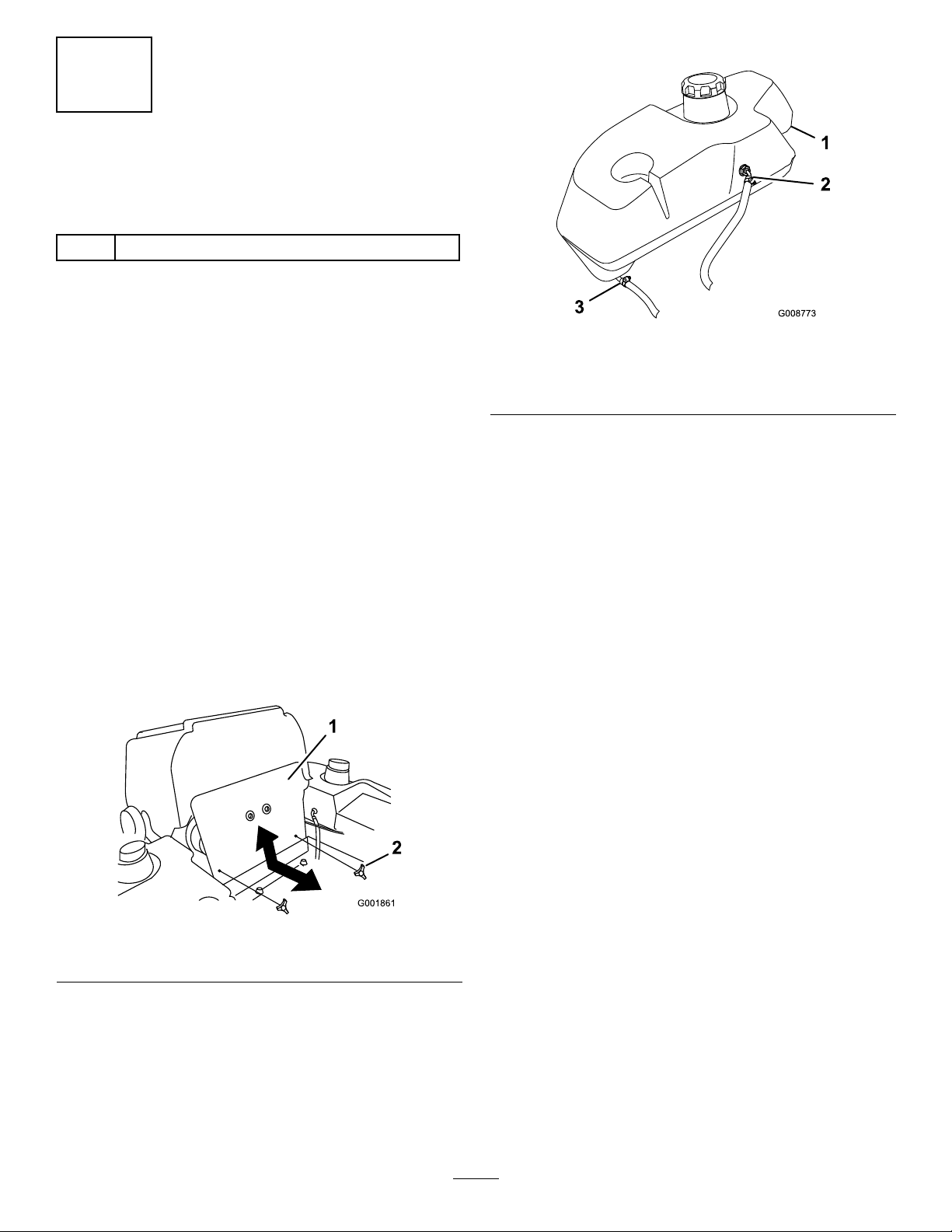

7.Tilttheseatforwardandremovethefrontengine

panel(Figure1).

Figure2

1.Righthandfueltank

shown

2.Rearfueltankconnection

11.Followthefuelhosesfromtheexistingselector

valveandremovethehosefromthefuellterand

thefueltanks.

12.Removetheexistingfuelhosefromtheengineand

removetheexistingfuellterfromthemachine.

13.Removetheexistingfuelselectorvalve.Referto

Figure3.Savetheexistinghardware.

14.Usingthepreviouslyremovedhardware,installthe

newfuelselectorvalve(Figure3).

3.Frontfueltankconnection

Figure1

1.Frontenginepanel2.Knob

8.Todrainthefueltank,placeacleancontainerunder

thefrontfueltankconnection,removethefuelhose

fromthefrontconnectionorcutthefuellineand

directthefuellineintothecontainer(Figure2).

9.Allowthefueltodrainintothecontainerandwipe

upanyspilledfuel.Ensurethefuellineisremoved

fromthetankconnection(Figure2).

2

Page 3

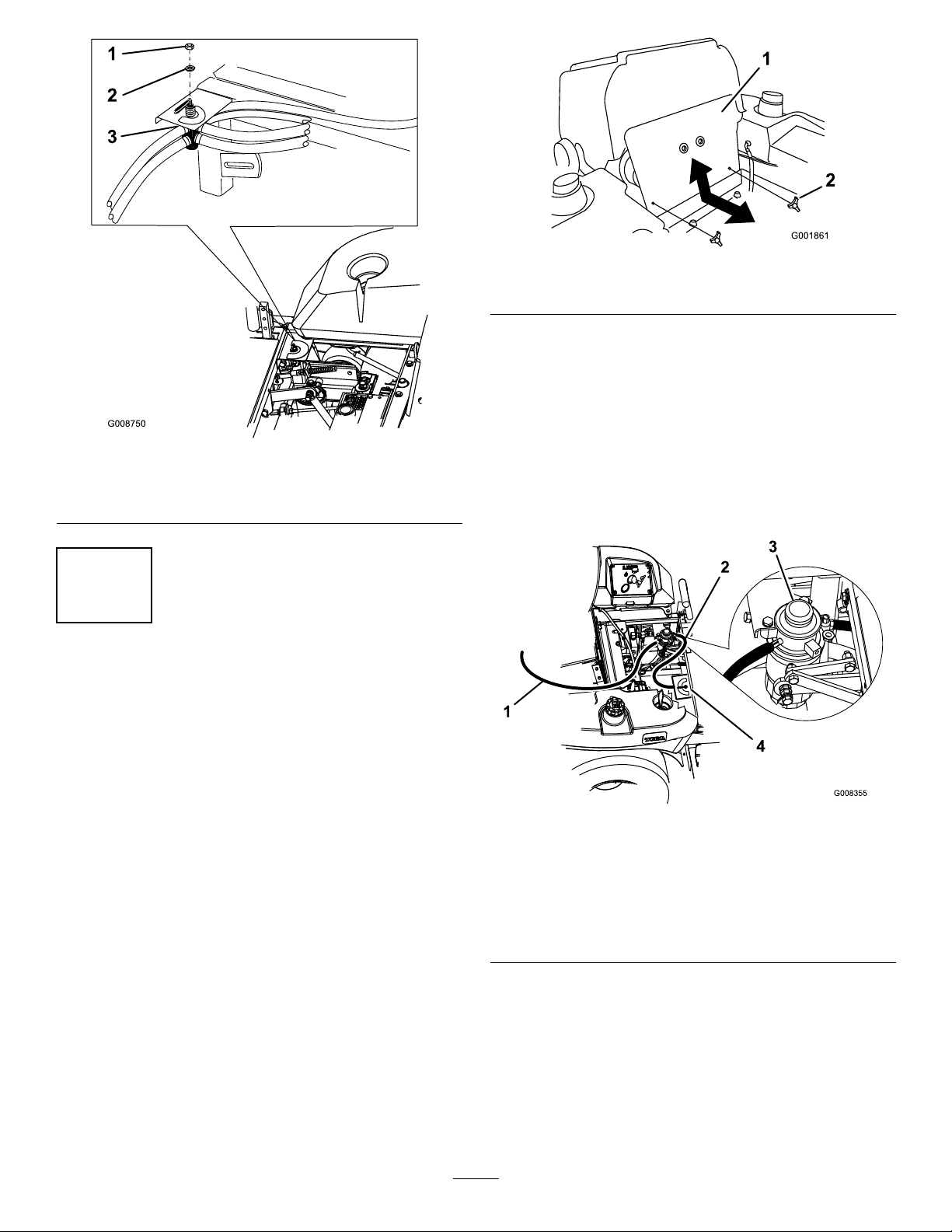

Figure3

1.Existingnut

2.Existingwasher

3.Newfuelselectorvalve

2

RemovingtheExistingWater

Separator

Figure4

1.Frontenginepanel2.Knob

3.Locatethehosebetweenthewaterseparatorandthe

fuelselectorvalve.Removethefuelhosefromthe

fuelselectorvalve(Figure5).

4.Locatethehosebetweenthewaterseparatorandthe

fuelselectorvalve.Removethefuelhosefromthe

theengine(Figure5).Rememberthelocationwhere

thefuelhosewasconnectedtotheengine.

5.Removetheexistingwaterseparatorfromthe

machine.

NoPartsRequired

Procedure

Important:Allowtheenginetocoolbefore

installingthiskit.

1.Tilttheseatforwardandremovethefrontengine

panel(Figure4).

2.Closethefuelselectorvalve.

1.Fuelhosefromthe

separatortotheengine

(makenotewherethe

connectionisonthe

engine)

2.Hosefromfuelselector

valve

Figure5

3.Existingwaterseparator

4.Fuelselectorvalve

3

Page 4

3

InstallingtheNewWater

Separator

Partsneededforthisprocedure:

1Mountingplate

1

Locknut(1/4inch)

1

Fuellterclamp

1

Bolt(5/16x1-3/4inches)

1

Bolt(5/16x3/4inch)

2

Locknut(5/16inch)

1Waterseparator

Procedure

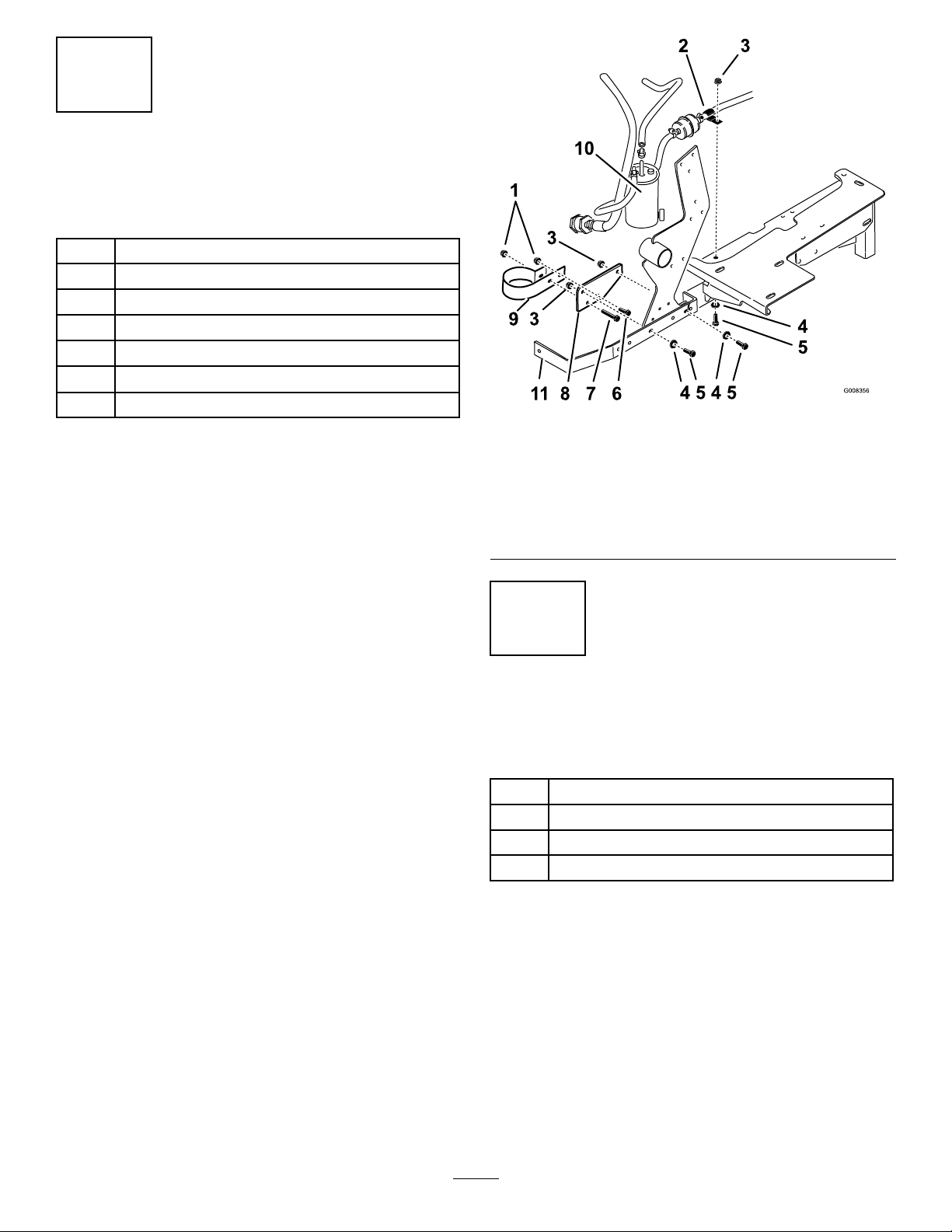

1.Removetheexistinghardwarefromtheenginestrap

(Figure6).

2.Installthemountingbrackettotheenginestrapwith

thepreviouslyremovedhardware(Figure6).

Figure6

1.Locknut(5/16inch)7.Bolt(5/16x1-3/4inches)

2.J-clamp8.Mountingplate

3.Existinglocknut

4.Existingwasher10.Waterseparator

5.Existingbolt11.Enginestrap

6.Bolt(5/16x3/4inch)

9.Fuellterbracket

3.Installthewaterseparatorintothefuellterclamp

andinstallittothemountingbracketwithabolt

(5/16x1-3/4inches),abolt(5/16x3/4inch),and

2locknuts(5/16inch)(Figure6).

4

InstallingandConnectingthe

FuelHoses

Partsneededforthisprocedure:

1Hose

8Hoseclamp

1J-clamp

6Plastictie

Procedure

1.Routethefuellterandfuelhosetowardsthefuel

selectorvalve.Makesurenopartsorhosesare

touchingthemachineinareasthatwillgethot.

2.RemovetheexistinghardwareandintalltheJ-clamp

totheengineframe(Figure6andFigure7).

3.Installthefuelhoseconnectedtothefuellterinto

theJ-clamp(Figure7).

4.Installthenewfuelhoseontofuelselectorvalvewith

ahoseclamp(Figure7).

4

Page 5

5.Installthenewfuelhosetothewaterseparatorand

totheenginefuelconnectionwith2hoseclamps

(Figure8).Theconnectiontotheengineisthe

samepositionasthefuelhosethatwaspreviously

removed.

Figure8

1.Hoseclamp3.Waterseparator

2.Newfuelhose,connect

thisendtotheenginefuel

intake

Figure7

1.Existinglocknut6.Fuelselectorvalve

2.J-clamp

3.Engineframe

4.Existingwasher9.Hoseclamp

5.Existingbolt

7.Fuellter

8.Fuelhose

6.Installtheshorthosetothefrontrighthandfuel

tankconnection(Figure9).

7.Installthelongerhosetotherearrighthandfuel

tankconnection(Figure9).

Figure9

1.Righthandfueltank

2.Rearfueltankconnection5.Frontfueltankconnection

3.Hoseclamp

4.Longhose

6.Shorthose

8.Installthelongerfuelhosetothefrontlefthand

fueltankconnection.SeeFigure10.forthecorrect

hoses.

5

Page 6

9.Installtheshorthosetothebacklefthandfueltank

G008099

1

2

G008999

1

G008998

1

connection(Figure10).

Figure10

1.Lefthandfueltank4.Shorthose

2.Rearfueltankconnection

3.Hoseclamp

5.Longhose

6.Frontfueltankconnection

10.Installtheplastictiestosecurethehosesfrom

touchinganyhotpartsofthemachineorrubbing

againstthemachine.

Figure11

1.Enginehood

2.Lowsulfurdecal

4.Cleantheexistingfrontdecalandtheareaaroundit

andletitdry(Figure12).

5.Installthenewdieseldecalovertheexistingone.

SeeFigure12.

5

InstallingtheDecalsandFuel

Caps

Partsneededforthisprocedure:

2

Lowsulfurdecal

2Fuelcap

1Dieseldecal

Procedure

1.Lowertheenginehood.

2.Removetheexistingdecaloneachside.

3.Installalowsulfurdecaloneachsideoftheengine

hood.SeeFigure4forthecorrectposition.

Figure12

1.Dieseldecal

6.Removebothexistingfuelcapsandreplacethem

withthenewfuelcaps(Figure13).

Figure13

1.Newfuelcap

6

Page 7

Operation

6

VerifyingtheConnections

NoPartsRequired

Procedure

1.Openthefuelselectorvalve.

2.Openthewaterseparatordrainvalveuntilfuelstarts

todrainoutandclosethevalve(Figure14).

3.Ensuretherearenoleaksatthefuelhose

connections.

4.Installthenegativebatterycableontothebattery.

5.Starttheengineandensuretherearenoleaks.

AddingFuel

Afterthiskitisinstalled,thismachinecanusea

biodieselblendedfuelofuptoB20(20%biodiesel,

80%petrodiesel).Thepetrodieselportionshouldbe

loworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontendof5%)orlesserblend

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradeovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

1.Waterseparator

2.Drainvalve

Figure14

3.Rightsideofmachine

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

Purchasefuelinquantitiesthatcanbeusedwithin

30daystoensurefuelfreshness.

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergradedieselfuel(No.

1-DorNo.1-D/2-Dblend)below20°F(-7°C).Useof

wintergradedieselfuelatlowertemperaturesprovides

lowerashpointandpourpointcharacteristics,

thereforeeasingstartabilityandlesseningchances

ofchemicalseparationofthefuelduetolower

temperatures(waxappearance,whichmaypluglters).

Useofsummergradedieselfuelabove20°F(-7°C)will

contributetowardlongerlifeofthepumpcomponents.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

7

Page 8

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepgasawayfromeyesandskin.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsfueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerandkeep

itoutofthereachofchildren.Neverbuy

morethana30-daysupplyoffuel.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundeachfueltankcapandremovethe

cap.Addfueltobothfueltanks,untilthelevelis

1/4to1/2inch(6to13mm)belowthebottomof

thellerneck.Thisspaceinthetankallowsthefuel

toexpand.Donotllthefueltankscompletelyfull.

3.Installfueltankcapssecurely.Wipeupanyfuelthat

mayhavespilled.

4.Ifpossible,llthefueltankaftereachuse.Thiswill

minimizepossiblebuildupofcondensationinside

thefueltank.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfromafuel

dispensernozzle.

•Ifafueldispensernozzlemustbeused,keep

thenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

8

Page 9

Maintenance

ServicingtheFuelFilter

ChangingtheFuelFilter

ServiceInterval:Every400hours/Yearly(whichever

comesrst)(moreoftenindirtyor

dustyconditions).

DrainingtheWaterSeparator

ServiceInterval:Every40hours

1.Positionthemachineonalevelsurface.

2.DisengagethePTO ,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Locatethewaterseparatoratthebackleftofthe

machine.

5.Placeadrainpanbelowthewaterseparator.

6.Openthedrainvalveonthewaterseparator

approximatelyoneturntoallowwaterandother

contaminatestodrain(Figure15).

7.Closethedrainvalvewhenonlydieselfuelcomes

out(Figure15).

Neverinstalladirtyfuellterifitisremovedfromthe

fuelline.

1.Allowthemachinetocooldown.

2.DisengagethePTO ,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Closethefuelshut-offvalve.

5.Loosenthetwohoseclampsanddisconnectthefuel

linesfromthefuellter(Figure16).

6.Installanewlter.Connectthefuellinestothefuel

lterandinstallthetwohoseclamps.

7.Openthefuelshut-offvalve.

8.Starttheengineandcheckforleaks.

1.Waterseparator

2.Drainvalve

Figure15

3.Rightsideofmachine

Figure16

1.Fuellter3.Rightsideofmachine

2.Hoseclamps

9

Page 10

Notes:

10

Page 11

Notes:

11

Page 12

Loading...

Loading...