Page 1

Bio-DieselFuelFilterKit

Daihatsu-PoweredRidingMowers

ModelNo.115–3550

Afterthiskitisinstalled,thismachinecanusea

biodieselblendedfuelofuptoB20(20%biodiesel,80%

petrodiesel).Thepetrodieselportionshouldbelowor

ultralowsulfur.

FormNo.3360-692RevA

InstallationInstructions

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Nopartsrequired

Mountingplate1

Locknut(1/4inch)

Fuellterclamp

Bolt(5/16x1-3/4inches)

Bolt(5/16x3/4inch)

Locknut(5/16inch)

Waterseparator1

Hose1

Hoseclamp3

J-clamp1

Plastictie2

Lowsulfurdecal

Fuelcap2

Dieseldecal1

•Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

Qty.

–

1

1

1

1

2

2

Removetheexistingwaterseparator

Installthewaterseparator.

Installingandconnectingthefuelhoses.

Installthedecalsandfuelcaps.

Use

5

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Nopartsrequired

Registeratwww.T oro.com.

–

Verifytheconnections.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

1

RemovingtheExistingWater

Separator

NoPartsRequired

Procedure

Important:Allowtheenginetocoolbefore

installingthiskit.

1.Drivethemachinetoawellventilatedareaaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

2.Disengagethepowertakeoff(PTO)andsetthe

parkingbrake.

3.Turnofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Disconnectthenegativebatterycablefromthe

battery.

5.Allowtheenginetocoolbeforeinstallingthiskit.

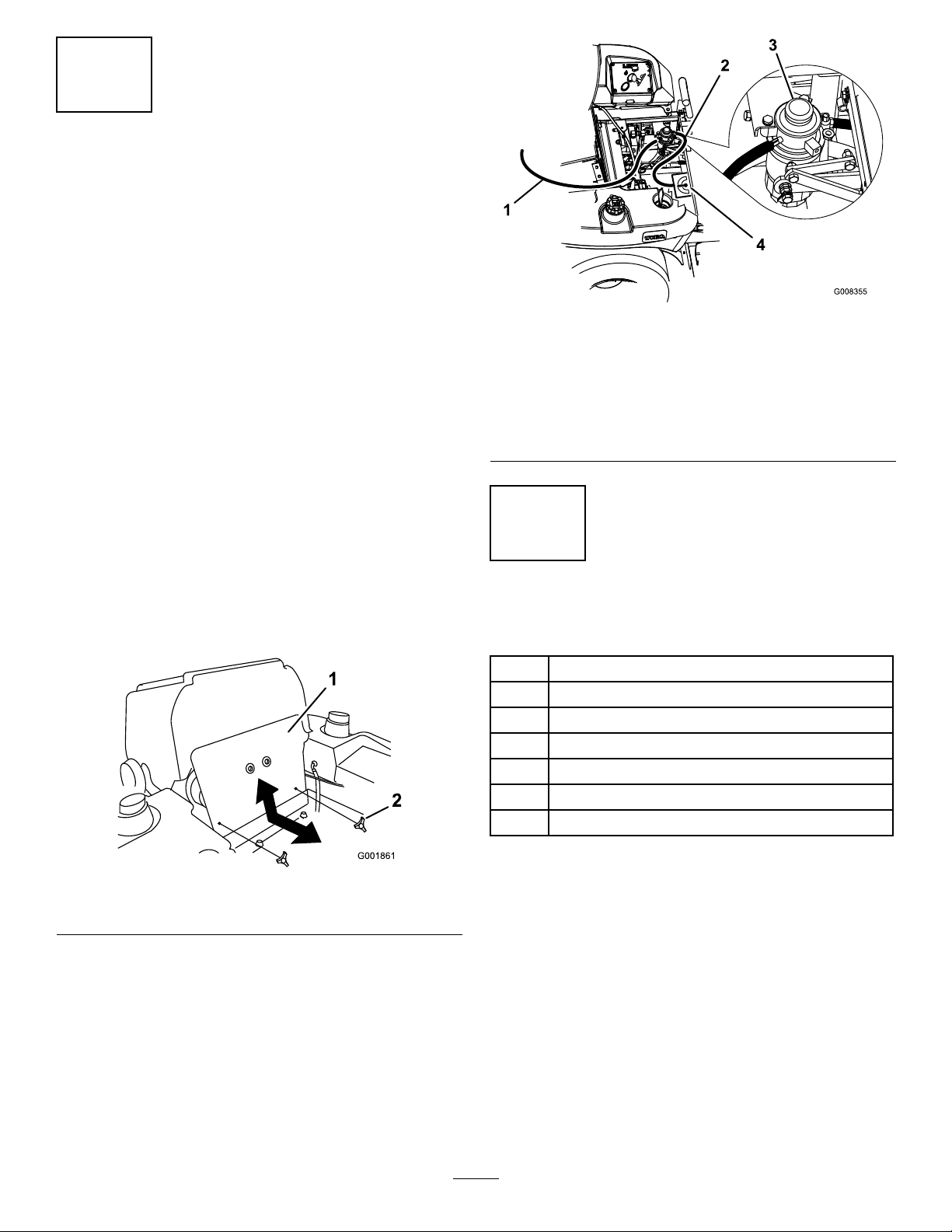

6.Tilttheseatforwardandremovethefrontengine

panel(Figure1).

7.Closethefuelselectorvalve.

1.Fuelhosefromthe

separatortotheengine

(makenotewherethe

connectionisonthe

engine)

2.Hosefromfuelselector

valve

2

InstallingtheWaterSeparator

Partsneededforthisprocedure:

Figure2

3.Existingwaterseparator

4.Fuelselectorvalve

Figure1

1.Knob2.Frontenginepanel

8.Locatethehosebetweenthewaterseparatorandthe

fuelselectorvalve.Removethefuelhosefromthe

fuelselectorvalve(Figure2).

9.Locatethehosebetweenthewaterseparatorandthe

fuelselectorvalve.Removethefuelhosefromthe

theengine(Figure2).Rememberthelocationwhere

thefuelhosewasconnectedtotheengine.

10.Removetheexistingwaterseparatorfromthe

machine.

1Mountingplate

1

Locknut(1/4inch)

1

Fuellterclamp

1

Bolt(5/16x1-3/4inches)

1

Bolt(5/16x3/4inch)

2

Locknut(5/16inch)

1Waterseparator

Procedure

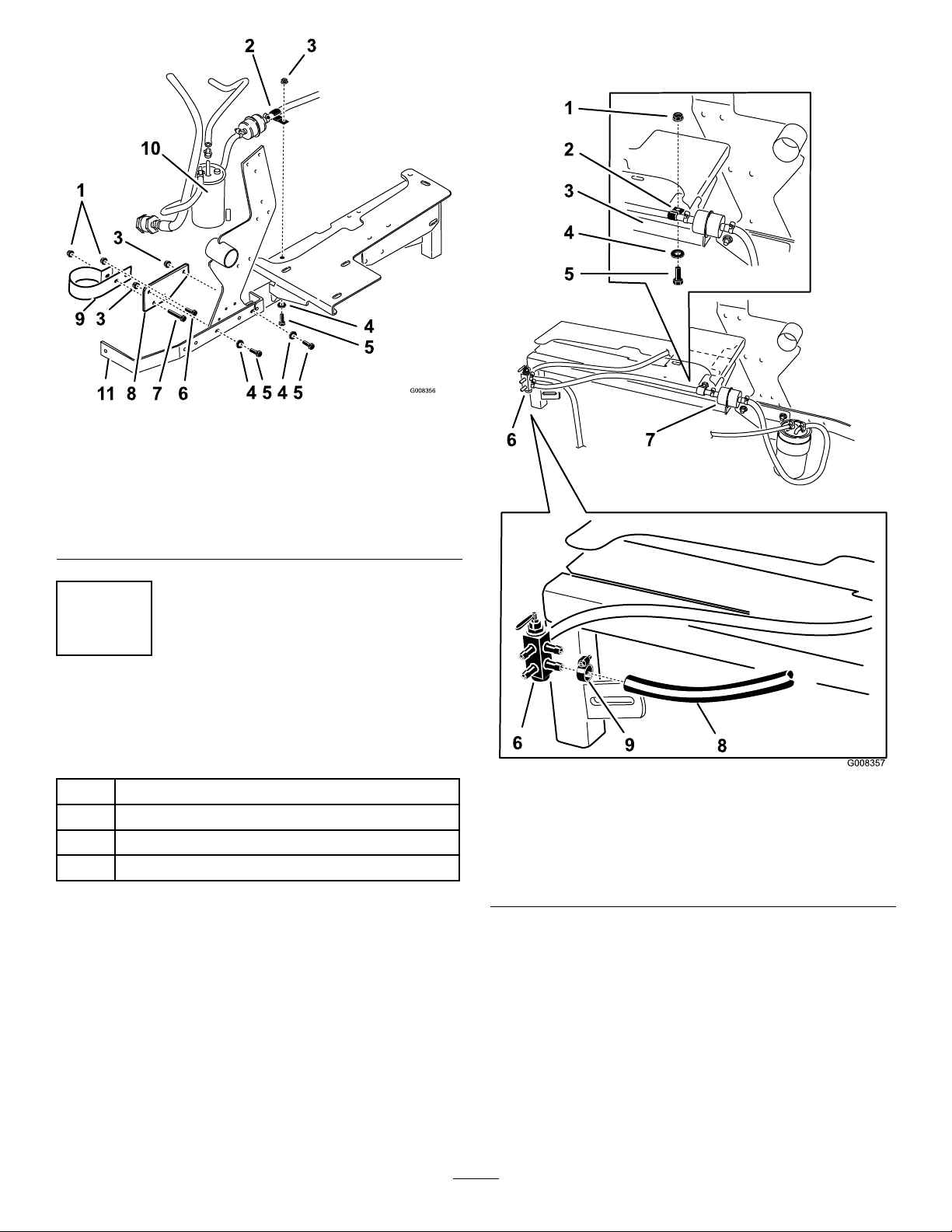

1.Removetheexistinghardwarefromtheenginestrap

(Figure3).

2.Installthemountingbrackettotheenginestrapwith

thepreviouslyremovedhardware(Figure3).

3.Installthewaterseparatorintothefuellterclamp

andinstallittothemountingbracketwithabolt

(5/16x1-3/4inches),abolt(5/16x3/4inch),and

2locknuts(5/16inch)(Figure3).

2

Page 3

Figure3

1.Locknut(5/16inch)7.Bolt(5/16x1-3/4inches)

2.J-clamp8.Mountingplate

3.Existinglocknut

4.Existingwasher10.Waterseparator

5.Existingbolt11.Enginestrap

6.Bolt(5/16x3/4inch)

9.Fuellterbracket

5.Installtheplastictiestosecurethehosesfrom

touchinganyhotpartsofthemachine.

3

InstallingandConnectingthe

FuelHoses

Partsneededforthisprocedure:

1Hose

3Hoseclamp

1J-clamp

2Plastictie

Procedure

1.Routethefuellterandfuelhosetowardsthefuel

selectorvalve.Makesurenopartsorhosesare

touchingthemachineinareasthatwillgethot.

2.RemovetheexistinghardwareandintalltheJ-clamp

totheengineframe(Figure3andFigure4).

3.Installthefuelhoseconnectedtothefuellterinto

theJ-clamp(Figure4).

Figure4

1.Existinglocknut6.Fuelselectorvalve

2.J-clamp

3.Engineframe

4.Existingwasher9.Hoseclamp

5.Existingbolt

7.Fuellter

8.Fuelhose

4.Installthenewfuelhoseontofuelselectorvalvewith

ahoseclamp(Figure4).

3

Page 4

6.Installthenewfuelhosetothewaterseparatorand

G008099

1

2

G008999

1

G008998

1

totheenginefuelconnectionwith2hoseclamps

(Figure5).Theconnectiontotheengineisthe

samepositionasthefuelhosethatwaspreviously

removed.

1.Enginehood

Figure6

2.Lowsulfurdecal

Figure5

1.Hoseclamp3.Waterseparator

2.Newfuelhose,connect

thisendtotheenginefuel

intake

4

InstallingtheDecalsandFuel

Caps

Partsneededforthisprocedure:

2

Lowsulfurdecal

2Fuelcap

1Dieseldecal

4.Cleantheexistingfrontdecalandtheareaaroundit

andletitdry(Figure7).

5.Installthenewdieseldecalovertheexistingone.See

Figure7.

Figure7

1.Dieseldecal

6.Removebothexistingfuelcapsandreplacethem

withthenewfuelcaps(Figure8).

Procedure

1.Lowertheenginehood.

2.Removetheexistingdecaloneachside.

3.Installalowsulfurdecaloneachsideoftheengine

hood.SeeFigure6forthecorrectposition.

Figure8

1.Newfuelcap

4

Page 5

Operation

5

VerifyingtheConnections

NoPartsRequired

Procedure

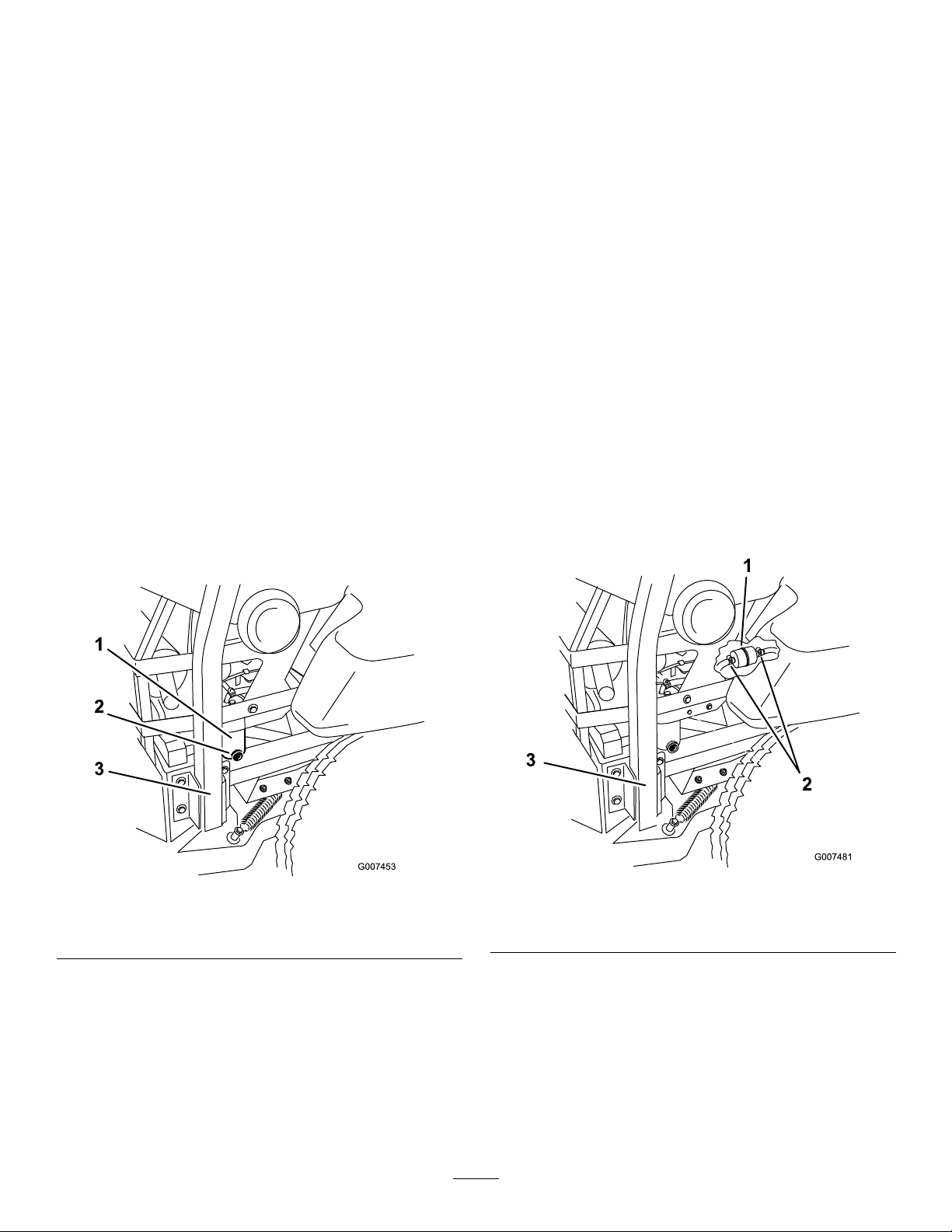

1.Openthefuelselectorvalve.

2.Openthewaterseparatordrainvalveuntilfuelstarts

todrainoutandclosethevalve(Figure9).

3.Ensuretherearenoleaksatthefuelhose

connections.

4.Installthenegativebatterycableontothebattery.

5.Starttheengineandensuretherearenoleaks.

AddingFuel

Afterthiskitisinstalled,thismachinecanusea

biodieselblendedfuelofuptoB20(20%biodiesel,

80%petrodiesel).Thepetrodieselportionshouldbe

loworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontendof5%)orlesserblend

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradeovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

1.Waterseparator

2.Drainvalve

Figure9

3.Rightsideofmachine

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

Purchasefuelinquantitiesthatcanbeusedwithin

30daystoensurefuelfreshness.

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergradedieselfuel(No.

1-DorNo.1-D/2-Dblend)below20°F(-7°C).Useof

wintergradedieselfuelatlowertemperaturesprovides

lowerashpointandpourpointcharacteristics,

thereforeeasingstartabilityandlesseningchances

ofchemicalseparationofthefuelduetolower

temperatures(waxappearance,whichmaypluglters).

Useofsummergradedieselfuelabove20°F(-7°C)will

contributetowardlongerlifeofthepumpcomponents.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

5

Page 6

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepgasawayfromeyesandskin.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsfueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerandkeep

itoutofthereachofchildren.Neverbuy

morethana30-daysupplyoffuel.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundeachfueltankcapandremovethe

cap.Addfueltobothfueltanks,untilthelevelis

1/4to1/2inch(6to13mm)belowthebottomof

thellerneck.Thisspaceinthetankallowsthefuel

toexpand.Donotllthefueltankscompletelyfull.

3.Installfueltankcapssecurely.Wipeupanyfuelthat

mayhavespilled.

4.Ifpossible,llthefueltankaftereachuse.Thiswill

minimizepossiblebuildupofcondensationinside

thefueltank.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfromafuel

dispensernozzle.

•Ifafueldispensernozzlemustbeused,keep

thenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

6

Page 7

Maintenance

ServicingtheFuelFilter

ChangingtheFuelFilter

ServiceInterval:Every400hours/Yearly(whichever

comesrst)(moreoftenindirtyor

dustyconditions).

DrainingtheWaterSeparator

ServiceInterval:Every40hours

1.Positionthemachineonalevelsurface.

2.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

3.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Locatethewaterseparatoratthebackleftofthe

machine.

5.Placeadrainpanbelowthewaterseparator.

6.Openthedrainvalveonthewaterseparator

approximatelyoneturntoallowwaterandother

contaminatestodrain(Figure10).

7.Closethedrainvalvewhenonlydieselfuelcomes

out(Figure10).

Neverinstalladirtyfuellterifitisremovedfromthe

fuelline.

1.Allowthemachinetocooldown.

2.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

3.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Closethefuelshut-offvalve.

5.Loosenthetwohoseclampsanddisconnectthefuel

linesfromthefuellter(Figure11).

6.Installanewlter.Connectthefuellinestothefuel

lterandinstallthetwohoseclamps.

7.Openthefuelshut-offvalve.

8.Starttheengineandcheckforleaks.

1.Waterseparator

2.Drainvalve

Figure10

3.Rightsideofmachine

Figure11

1.Fuellter3.Rightsideofmachine

2.Hoseclamps

7

Page 8

Loading...

Loading...