Page 1

ReplacementOguraClutchKit

For2006through2007Kubota-PoweredZMasterRidingMowers

ModelNo.114–8150

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3360-571RevA

InstallationInstructions

ProcedureDescription

1

2

Nopartsrequired

Clutchadapter

Key1

Clutch

Retainer1

Flatwasher(.469x.922inch)

Curvedwasher(7/16inch)

Locknut(5/16inch)

Carriagebolt(5/16x1inch)

Spacer

Clutchstop

Flatwasher(.344x.688inch)

Bolt(5/16x1inch)

Locknut(5/16inch)

1

RemovingtheExistingClutch

Qty.

Use

–

1

1

1

2

3

1

3

1

4

1

3

Removetheexistingclutch

Installthenewclutch.

NoPartsRequired

Procedure

Important:Allowtheenginetocoolbefore

installingthiskit.

1.Disengagethepowertakeoff(PTO)andsetthe

parkingbrake.

2.Turnofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Allowtheenginetocoolbeforeinstallingthiskit.

4.Tilttheseatforwardandremovethefrontengine

panel(Figure1).

©2008—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

Figure1

1.Frontenginepanel2.Knob

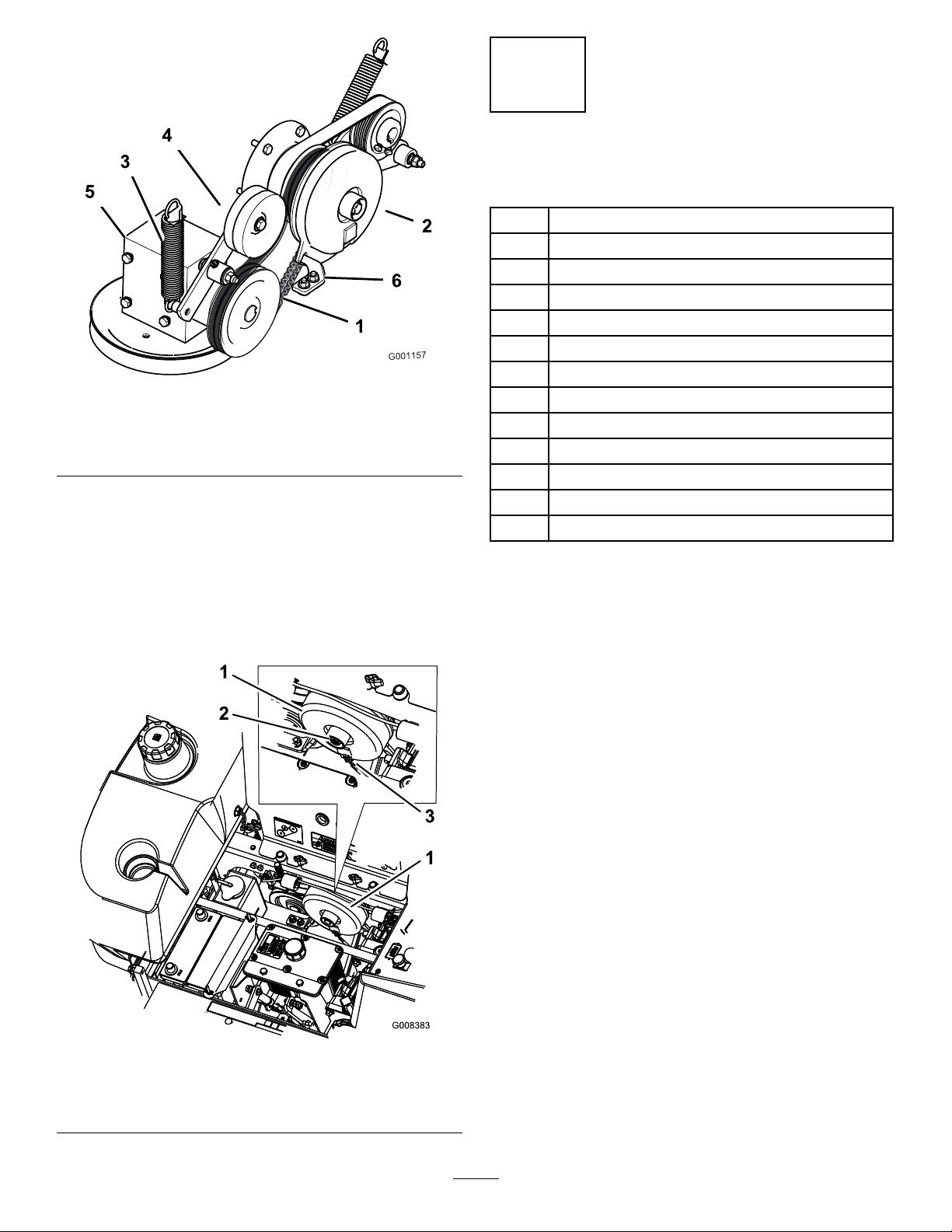

5.Removethespringfromtheidlerarm(Figure2).

6.Removetheclutchstopbracketfromthemachine.

Theholesfortheclutchstopwillbeusedforthe

newclutch(Figure2).

7.RemovethePTOdrivebeltfromtheclutch

(Figure2).

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

Figure2

1.PTOdrivebelt4.Springloadedidlerpulley

2.Clutch5.Gearbox

3.Spring6.Clutchstopbracket

8.Unplugtheelectricalconnectionattheclutch

(Figure3).

9.Toremovetheclutchbolt,useawrenchtoholdthe

enginecrankshaftattherearoftheengine.

10.Removetheboltinthecenteroftheclutchandslide

theclutchofftheengineshaft(Figure3).Savethe

boltforinstallingthenewclutch.

2

InstallingtheNewClutch

Partsneededforthisprocedure:

1

Clutchadapter

1Key

1

Clutch

1Retainer

1

Flatwasher(.469x.922inch)

2

Curvedwasher(7/16inch)

3

Locknut(5/16inch)

1

Carriagebolt(5/16x1inch)

3

Spacer

1

Clutchstop

4

Flatwasher(.344x.688inch)

1

Bolt(5/16x1inch)

3

Locknut(5/16inch)

Procedure

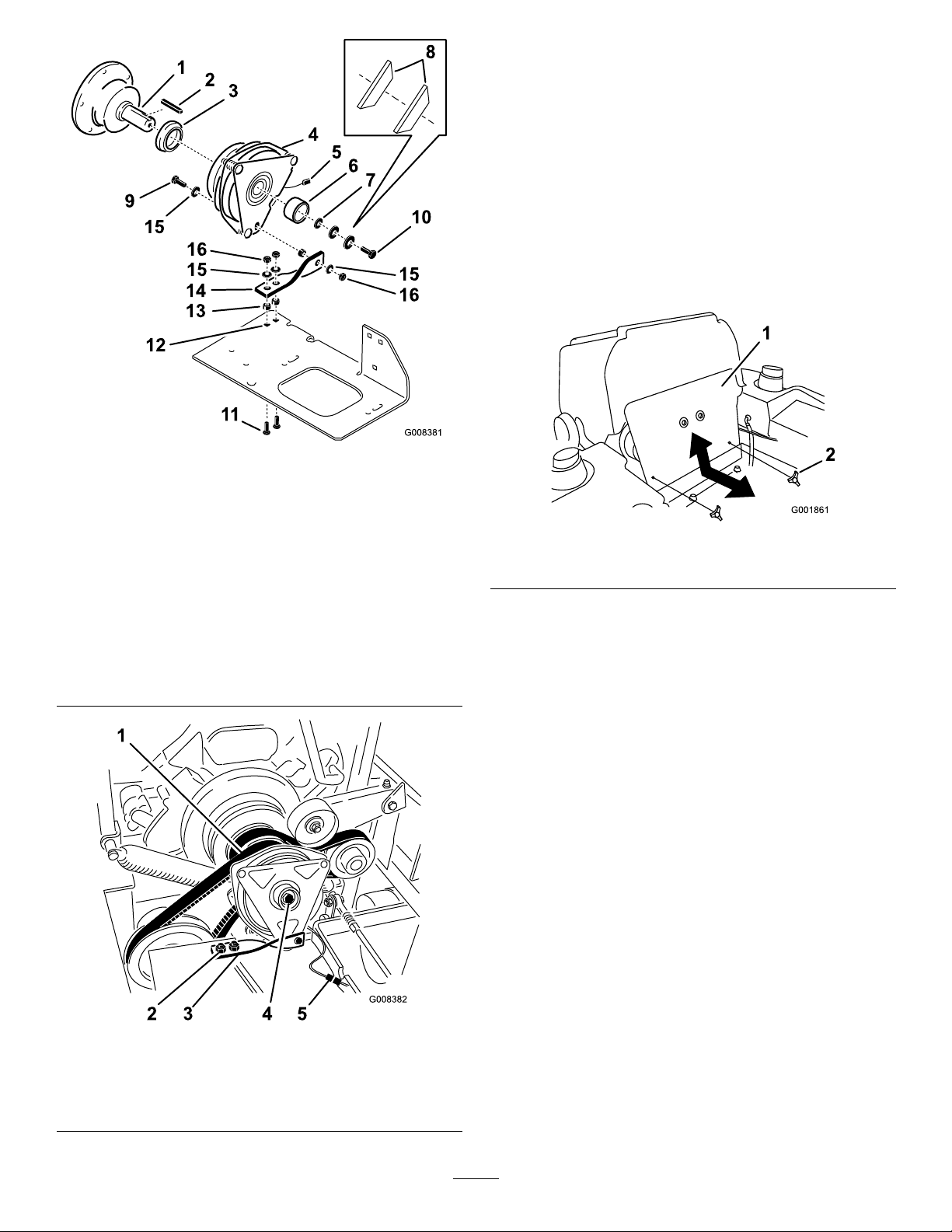

1.Installthenewclutchstoptotheclutchwithabolt

(5/16x1inch),2atwashers(.344x.688inch),a

spacerandalocknut(5/16inch)(Figure4).

1.Clutch

2.Removethecenterbolt

2.Installtheclutchadapterontothestubshaft

(Figure4).Ensureitisinstalledasshown.

3.Installthekeyontothestubshaftandalignthekey

withtheclutch.Slidetheclutchontothestubshaft

(Figure4).

4.Securetheclutchtothestubshaftwiththeretainer,

atwasher(.469x.922inch),2curvedwashers

installedasshown(7/16inch),andthepreviously

removedboltfromthecenteroftheclutch.Apply

threadlockertotheboltandtorqueitto50ft-lb

(Figure4).

Important:Ensurethetwistintheclutchstop

isasshowinFigure4andFigure5.

Figure3

3.Unplugtheelectrical

connection

2

Page 3

Figure4

1.Stubshaft9.Bolt(5/16x1inch)

2.Key10.Existingclutchbolt,torque

3.Clutchadapter,installas

shown

4.Newclutch12.Existingholesinmachine

5.Electricalconnection

6.Retainer

7.Flatwasher(.469x.922

inch)

8.Topviewofcurved

washers,installasshown

to50ft-lb

11.Carriagebolt(5/16x1

inch)

13.Spacers

14.Clutchstop,ensuretheit

istwistedasshown

15.Flatwasher(.344x.688

inch)

16.Locknut(5/16inch)

5.InstallthePTOdrivebeltontotheclutch(Figure2).

Ensurethebeltisroutedcorrectly.

6.Installthespringfortheidlerarm.

7.Usingtheexistingholesfortheoldclutchstop,install

thenewclutchstoptothemachinewith2carriage

bolts(5/16x1inch),2spacers,2atwashers(.344

x.688),2locknuts(5/16inch)(Figure4).Ensure

thetwistintheclutchstopisasshowinFigure4

andFigure5.

8.Plugtheelectricalconnectionstogether(Figure5).

9.Installthefrontenginepanel(Figure6).

Figure6

1.Frontenginepanel2.Knob

Figure5

1.PTOdrivebelt4.Clutchbolt

2.Nutsandbolts5.Electricalconnection

3.Clutchstop,ensureitis

twistedasshown

3

Page 4

Maintenance

AdjustingtheElectricClutch

ServiceInterval:Every500hours

Theclutchisadjustabletoensureproperengagement

andproperbraking.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Unlatchtheseatandtipitforward.

4.Loosenthefrontenginepanelknobsandremove

thepanel.

5.PulluponthespringloadedidlerpulleyforthePTO

drivebeltandremovethebeltfromtheclutchpulley

(Figure7).

Figure8

1.Clutch4.Clutchcenterbolt

2.Twoboltsandnutsfor

clutchstrap

3.Rubberclutchstrap

5.Electricalconnection

9.Inserta0.015–0.021inch(0.381–0.533mm)feeler

gaugethroughoneinspectionslotinthesideofthe

assembly.Makesureitisbetweenthearmatureand

therotorfrictionsurfaces(Figure9).

10.Tightenthelocknutsuntilthereisslightbindingon

thefeelergaugebutitcanbemovedeasilywithinthe

airgap(Figure9).

11.Repeatthisfortheremainingslots.

12.Checkeachslotagainandmakeslightadjustments

untilthefeelergaugebetweentherotorandarmature

hasveryslightcontactbetweenthem.

Figure7

1.Springloadedidlerpulley3.PTOdrivebelt

2.Clutch4.Gearbox

6.Unplugtheelectricconnectionfortheclutch

(Figure8).

7.Removethetwoboltsholdingtherubberclutch

straptothemowerframe(Figure8).

8.Removethecenterboltholdingtheclutchto

theengineshaftandremovetheclutchandkey

(Figure8).

Figure9

1.Slot

2.Adjustingnut

3.Feelergauge

13.Installtheclutchtotheengineshaftwiththekey.

14.ApplyblueLoctite®(orequivalent)tothecenter

bolt.

15.Whileholdingthecrankshaftatthebackofthe

machine,installthecenterboltandtorqueitto50

ft-lbs(68N-m)(Figure8).

16.Installtherubberclutchstraptothemowerframe

withthetwopreviouslyremovedboltsandnuts

(Figure8).

4

Page 5

17.PulluponthespringloadedidlerforthePTOdrive

beltandinstallitontotheclutchpulley(Figure7).

18.Plugintheelectricconnectionfortheclutch

(Figure8).

19.Installthefrontenginepanelandtightentheknobs.

20.Lowerdowntheseat.

5

Page 6

Notes:

6

Page 7

Notes:

7

Page 8

Loading...

Loading...