Page 1

WheelSpacerKit

ZMasterMowerwith52inor60inCuttingUnit

ModelNo.114–1183

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

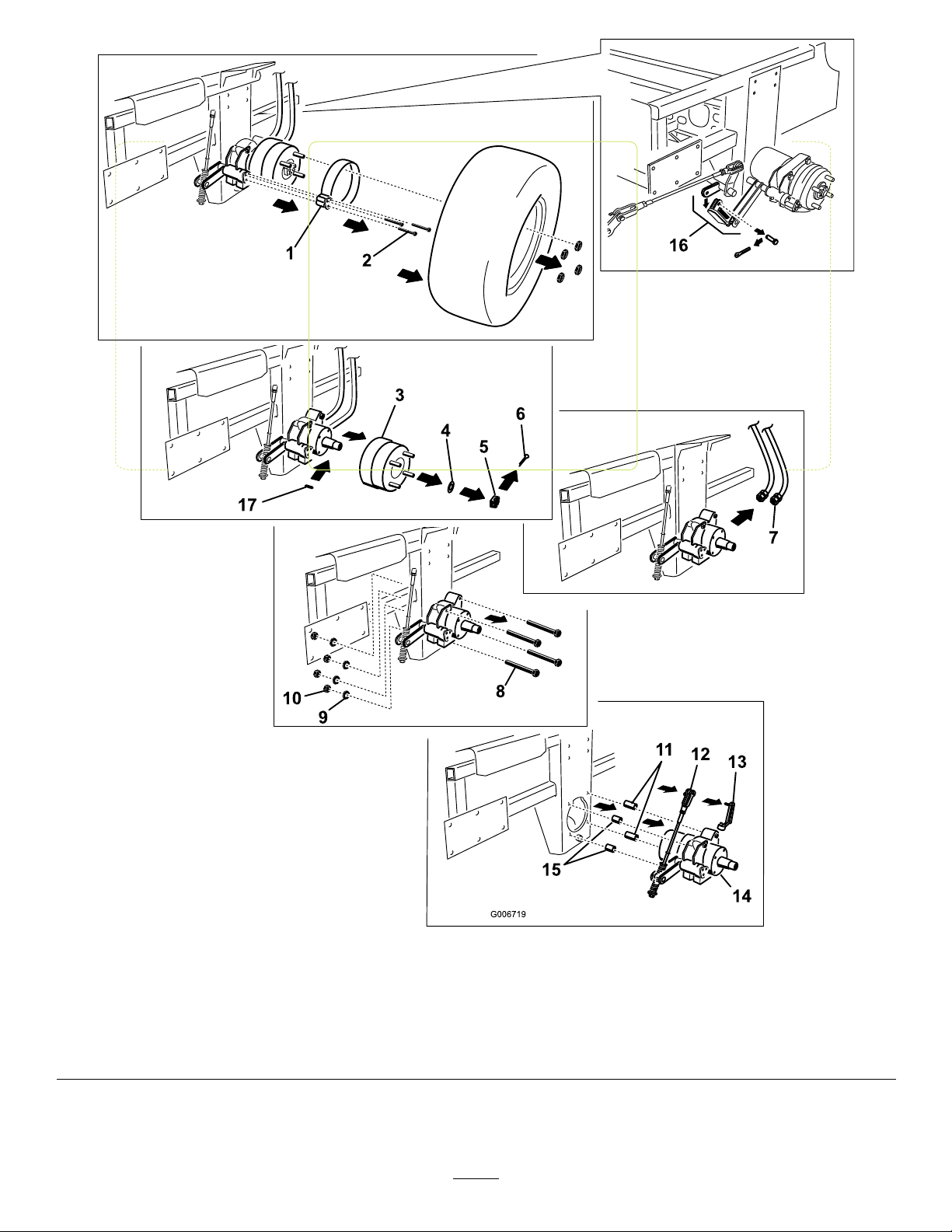

10.Removetheretainerpinfromtheyokeatthetopof

thebrakelinkage(Figure1).

FormNo.3360-515RevA

InstallationInstructions

1

InstallingtheWheelSpacers

Partsneededforthisprocedure:

4

Shortspacer

4Longspacer

8

Bolt(1/2x4-1/2inches)

8

Flangenut(1/2inch)

4

Thrustwasher(1/2inch)

Procedure

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Loosenthelugnutsorboltsonthereartires

(Figure1).

Note:Rememberthepositionofthespacers.The

longspacersareusedfortherearboltsandtheshort

spacersareusedforthefrontbolts.

11.Removethebolts,spacers,washersandnutsholding

thewheelmotortotheframeandremovethewheel

motorandbrakeassembly(Figure1).Discardthe

spacers.

12.Installeachwheelmotorandbrakeassemblytothe

framewiththe2newshort,2longspacers,4ange

nuts(1/2inch),4thrustwashers(1/2inch)and4

bolts(1/2x4-1/2inches)(Figure2).Ensurethe

spacersareinstalledinthecorrectposition.

13.Torquetheboltsto100ft-lb(136N-m).

14.Connectthehydrauliclinestothewheelmotorif

removeearlier(Figure2).

15.Installthewheelhubtothewheelmotorwiththe

woodruffkey,washer,andslottednut(Figure2).

4.Raisethemachinesothereartiresareofftheground

andsupportthemachinewithjackstands.

5.Removethelugnutsorboltsandreartiresfromthe

machine(Figure1).

6.Removethebrakebandboltsandremovethebrake

bandfromthewheelhub(Figure1).

7.Removethecotterpinfromtheaxlenutandremove

theaxlenutandwasher(Figure1).

8.Pullthewheelhubfromthewheelmotor(Figure1).

Thismayrequiretheuseofapulleypullertoremove

it.

Makesurethewoodruffkeyremainswiththewheel

motorshaft.

9.Ifneeded,removethehydrauliclinesconnectedto

thewheelmotor(Figure1).Raisetheendsabovethe

hydraulictanktopreventtheuidrunningoutand

plugthehydrauliclines.

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

Figure1

1.Brakeband

2.Brakebandbolts

3.Wheelhub8.Wheelmotorbolts13.Retainerpin

4.Washer9.Washers14.Wheelmotor

5.Slottednut

6.Cotterpin

7.Hydrauliclines(removeif

needed)

10.Nuts

11.Longspacer16.Brakelinkage

12.Yokeatthetopofthebrake

linkage

15.Shortspacer

2

17.Woodruffkey

Page 3

1.Newlongspacer

2.Yokeatthetopofthebrake

linkage

3.Retainerpin

4.Newshortspacer

Figure2

5.Bolt(1/2x4-1/2inches)9.Hydrauliclines(installif

6.Channel

7.Flangenut(1/2inch)

8.Thrustwashers(1/2inch)12.Slottednut16.Woodruffkey

removed)

10.Wheelhub14.Brakeband

11.Washer15.Brakebandbolts

13.Cotterpin

3

Page 4

16.Torquetheslottednutto125ft-lb(170N-m)

(Figure3).

17.Checkthedistancefrombottomofslotinnutto

insideedgeofhole.Twothreadsorlessshouldbe

showing(Figure3).

18.Ifmorethantwothreadsareshowingremovenut

andinstallwasherbetweenhubandnut.

19.Tightenthenutuntilthenextsetofslotslineup

withtheholeintheshaft(Figure3).

20.Replacethecotterpin(Figure2).

Figure3

1.SlottedNut3.Holeinthreadedshaft

2.Twothreadsorless

showing

4.Washer(ifneeded)

21.Installthetirewithwheelnutsorboltstothe

machine(Figure1).

Torquethewheelnutsto95ft-lb(128N-m).

4

Loading...

Loading...