Page 1

Form No. 3328-286

Update Kit

Workman 1 100 and Twister 1400 Utility Vehicle

Part No. 104-7272

Installation Instructions

Position the machine on a level surface, stop the engine,

remove the key, and disconnect the negative (–) battery

terminal.

Caution

If you leave the key in the ignition switch,

someone could accidently start the engine and

seriously injure you or other bystanders.

Remove the key from the ignition switch before

you do any maintenance.

Replacing the Accelerator

Pedal

1. If you have a floor mat, remove it from around the

accelerator and brake pedals.

2. Remove the metal plate on the floor surrounding the

pedals.

3. Disconnect the accelerator cable and spring from the

accelerator pedal.

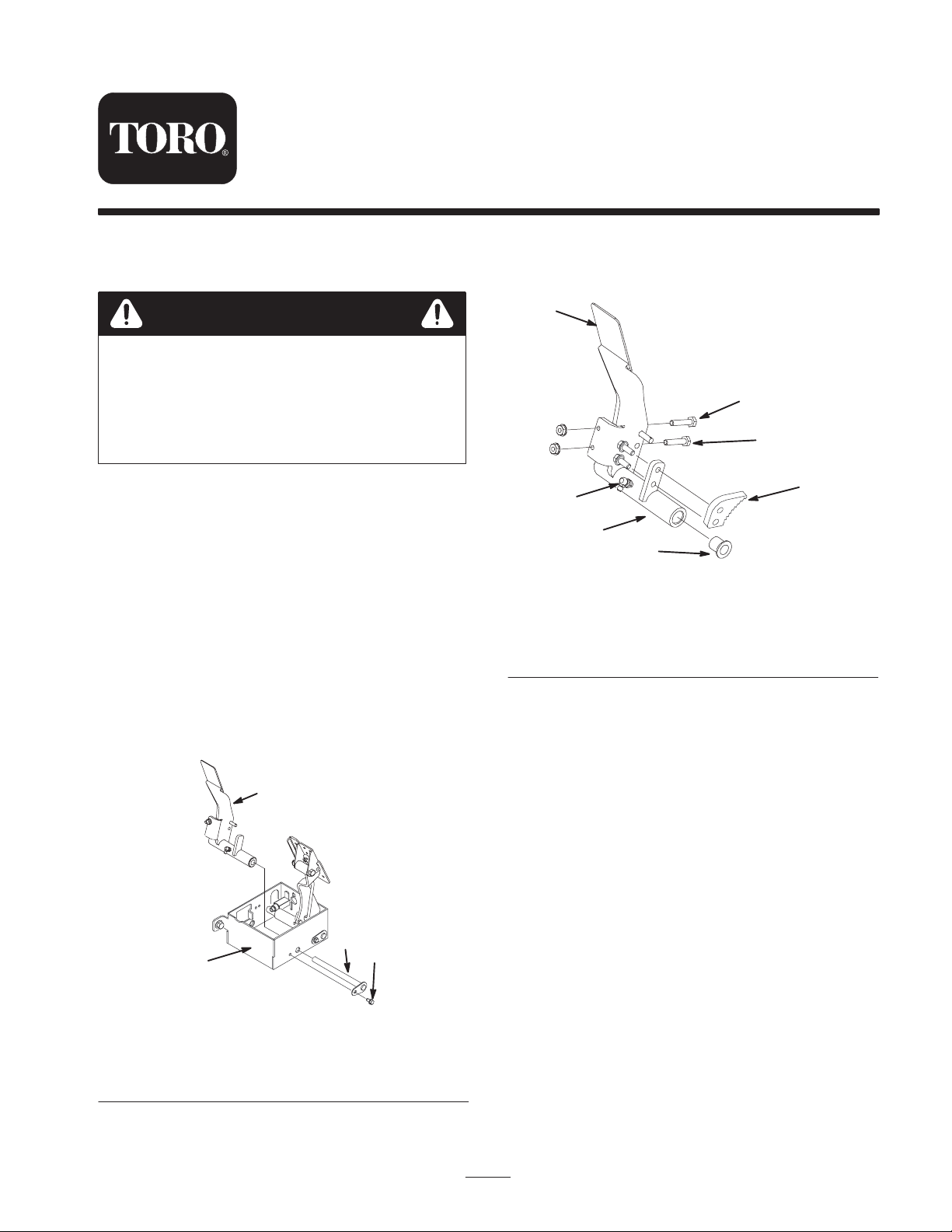

5. Remove the accelerator pedal (Fig. 1).

6. Remove the brake pawl from the old accelerator pedal

(Fig. 2).

1

5

6

7

4

2

3

m-5778

Figure 2

1. Accelerator pedal

2. Pedal mounting tube

3. Pivot bushing

4. Brake pawl

5. Start switch bolt

(Workman 1 100 only)

6. Stop bolt

7. Grease fitting

4. Remove the bolt securing the accelerator pedal pivot

rod (front rod) and pull out and discard the rod

(Fig. 1).

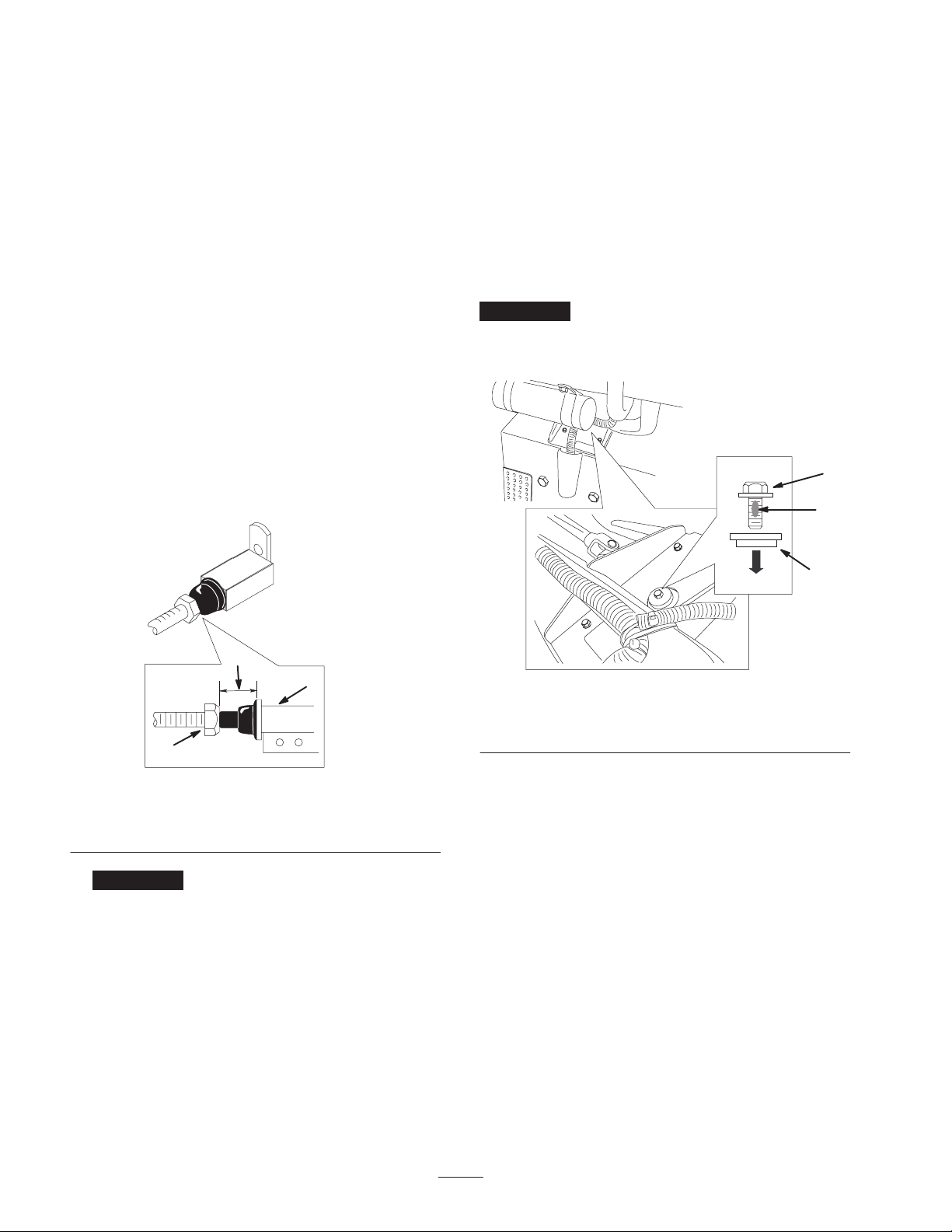

2

3

1

m-5780

4

Figure 1

1. Pedal box

2. Accelerator pedal

3. Accelerator pedal pivot

rod

4. Bolt

7. Install the brake pawl on the new accelerator pedal

(Fig. 2). Use red Locktite 272 or equivalent on the

bolts.

8. Measure the height of the stop bolt on the old

accelerator pedal (from the back of the pedal to the top

of the bolt head) and then remove it and the start

switch bolt (Workman 1100 only), discarding the rest

of the accelerator pedal assembly (Fig. 2).

9. Install the stop bolt and nut on the new accelerator

pedal, adjusting it to the same height it was set to on

the old pedal (Fig. 2), but do not tighten the jam nut.

10.On Workman 1100 vehicles, loosely install the start

switch bolt (Fig. 2), but do not tighten the jam nut.

11. Install a new grease fitting into the accelerator pedal

mounting tube (Fig. 2).

Note: Use only low temperature, lithium grease in this

fitting (Toro part number 505-101 or equivalent).

12.Install 2 bushings into the ends of the mounting tube of

the new accelerator pedal (Fig. 2).

2002 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

1

Printed in the USA

Page 2

13.Insert the accelerator pedal assembly into the pedal

box and secure it into the front position using the new

black pivot rod supplied with the kit and the bolt

removed previously (Fig. 1).

2. Install the floor mat if necessary.

Replacing the Steering Pitman

14.Connect the accelerator cable and spring to the

accelerator pedal.

Adjusting the Stop Bolt

1. Press the brake in as far as possible and set the parking

brake.

2. Turn out the stop bolt until it contacts the pedal box.

3. Set the jam nut on the stop bolt to secure it.

Checking and Adjusting the Start Switch

Bolt (Workman 1100 Vehicles Only)

1. Release the parking brake.

2. Check and/or set the distance between the head of the

start switch bolt and the body of the start switch to

5/8 inch (1.6 cm) (Fig. 3).

Arm Retaining Bolt

1. Remove the existing retaining bolt and washer (located

under the dash) and discard them (Fig. 4).

2. Install a new flange-head bolt with blue patch lock and

a step washer with the step pointing down into the

steering pitman arm (Fig. 4).

Important Never reuse a steering pitman arm

retaining bolt once you have removed it.

3. Torque the bolt to 30 ft-lb (41 N⋅m).

1

3

2

3

2

1

Figure 3

1. Start switch bolt

2. Start switch

Important The engine should not turn over when

you are setting the parking brake. If it does, check

the start switch bolt adjustment and adjust it as needed

by reducing the distance from the bolt to the switch

body. Do not bottom out the bolt head against the

switch body.

3. 5/8 inch (1.6 cm)

m-6156

Completing the Installation

1. Install the metal plate surrounding the pedals.

Figure 4

1. Flange-head bolt

2. Step washer

3. Blue patch lock

Checking and Adjusting

Neutral

If the vehicle has a neutral position on the shift lever,

which controls the neutral in the transaxle, take the

following steps to ensure that the neutral shift lever

operates the transaxle neutral correctly:

1. Set the shift lever into the Neutral position.

2. Ensure that the neutral bracket is in the neutral

position (level) by turning the drive clutch (Fig. 5).

The vehicle should not roll back and forth. If it does,

manually move the neutral bracket to the neutral

position.

m–6160

2

Page 3

2

1

Figure 5

1. Neutral bracket 2. Locknuts

3. Tighten one of the locknuts (Fig. 5) just enough to take

the slack out of the shift cable.

Note: You must hold the threaded shaft below the bracket

to tighten the locknut on top.

4. Tighten the other locknut just enough to take the slack

out of the other shift cable.

5. Pull up on each shift cable an ensure that there is no

gap between the nut/washer and the neutral bracket

(Fig. 6). If there is a gap, tighten the nut.

2

4

3

5

1

2

m–6184

Figure 6

1. Neutral bracket

2. Pull up

3. Cable boot

4. Wrong, must tighten the

nut

5. Correct adjustment

6. Start the engine and shift into Forward, Reverse, and

Neutral several times to ensure that the neutral bracket

is operating properly.

3

3

Page 4

Loading...

Loading...