Page 1

Form No. 3353-877 Rev A

Track Kit

for 413 and 420 TX Compact Utility Loaders

Part No. 104–6106

Installation Instructions

Complete this procedure for each track.

Removing a Track

1. Lower the loader arms, stop the engine, and remove the

key.

2. Lift/support the side of the unit to be worked on so that

the track is three to four inches (7.6 to 10 cm.) off of the

ground.

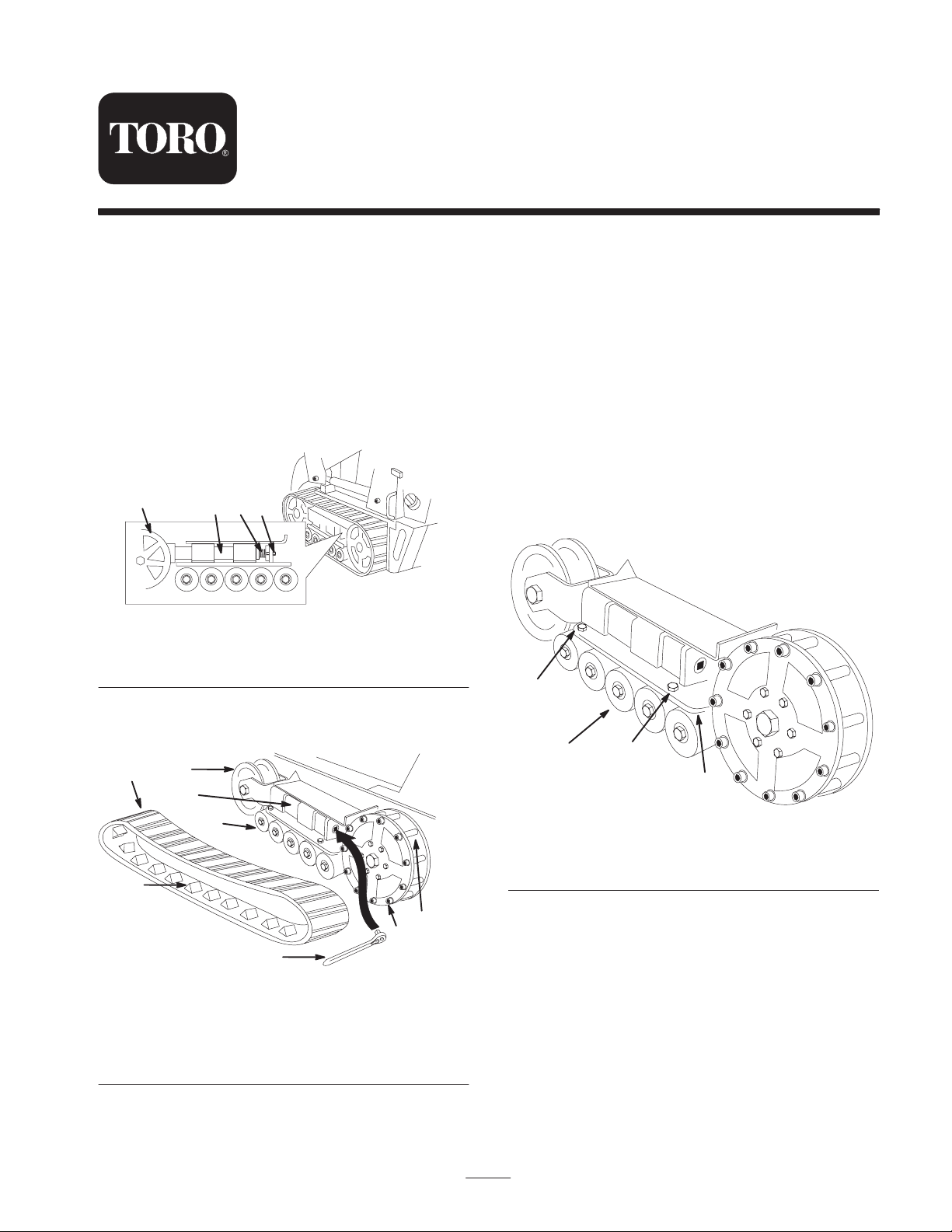

3. Remove the locking bolt and nut (Fig. 1).

4

1. Locking bolt

2. Tensioning screw

23

1

Figure 1

m–4747

3. Tension tube

4. Tension wheel

5. Push the tension wheel toward the rear of the unit to

move the fork tube against the frame (Fig. 2). (If it does

not touch the frame, continue turning the tensioning

screw until it does.)

6. Begin removing the track at the top of the tension

wheel, peeling it off of the wheel while rotating the

track forwards.

7. When the track is off of the tension wheel, remove it

from the drive sprocket and road wheels (Fig. 2).

Replacing the Road Wheels

1. Remove the 4 bolts and nuts securing the lower track

guide which contains the road wheels, and remove it

(Fig. 3).

3

4. Using a 1/2 in. drive socket, release the drive tension by

turning the tensioning screw clockwise (Fig. 1 and 2).

1

3

4

8

5

7

6

m–4774

2

Figure 2

1. Track

2. 1/2 in. socket

3. Tension wheel

4. Fork tube

W 2005 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

5. Track lug

6. Drive sprocket

7. Sprocket spacer

8. Road wheels

Original Instructions (EN)

1

3

2

Figure 3

1. Road wheels

2. Lower track guide

3. Track guide bolts (only

two shown)

2. Remove the 10 road wheels and discard them, saving

the fasteners for later use (Fig. 3).

3. Install new road wheels onto the track guide using the

fasteners your removed previously. Torque the road

wheel bolts to 135 to 165 ft-lb (183 to 223 N⋅m).

4. Install the track guide to the traction unit frame using

the fasteners you removed previously. Torque the bolts

and nuts to (67 to 83 ft-lb (91 to 112 N⋅m).

Contact us at www.Toro.com

All Rights Reserved

1

Printed in the USA

Page 2

Checking the Tension Wheel

Bearings and Drive Sprocket

Spacers

1. While looking at the bearing of the tension wheel

between the fork and the wheel, rotate the wheel and

ensure that the bearing rotates correctly and does not

rotate around the wheel axle.

2. Repeat step 1 for the bearing on the other side of the

tension wheel.

3. If a bearing is frozen and rotates around the wheel axle,

remove the wheel and replace the bearing.

4. Check the sprocket spacers on the drive sprocket and

replace any that are damaged or worn.

Installing the New Track

1. Beginning at the drive sprocket, coil the new track

around the sprocket, ensuring that the lugs on the track

fit between the spacers on the sprocket (Fig. 2).

2. Push the track under and between the road wheels

(Fig. 2).

3. Starting at the bottom of the tension wheel, install the

track around the wheel by rotating the track rearward

while pushing the lugs into the wheel.

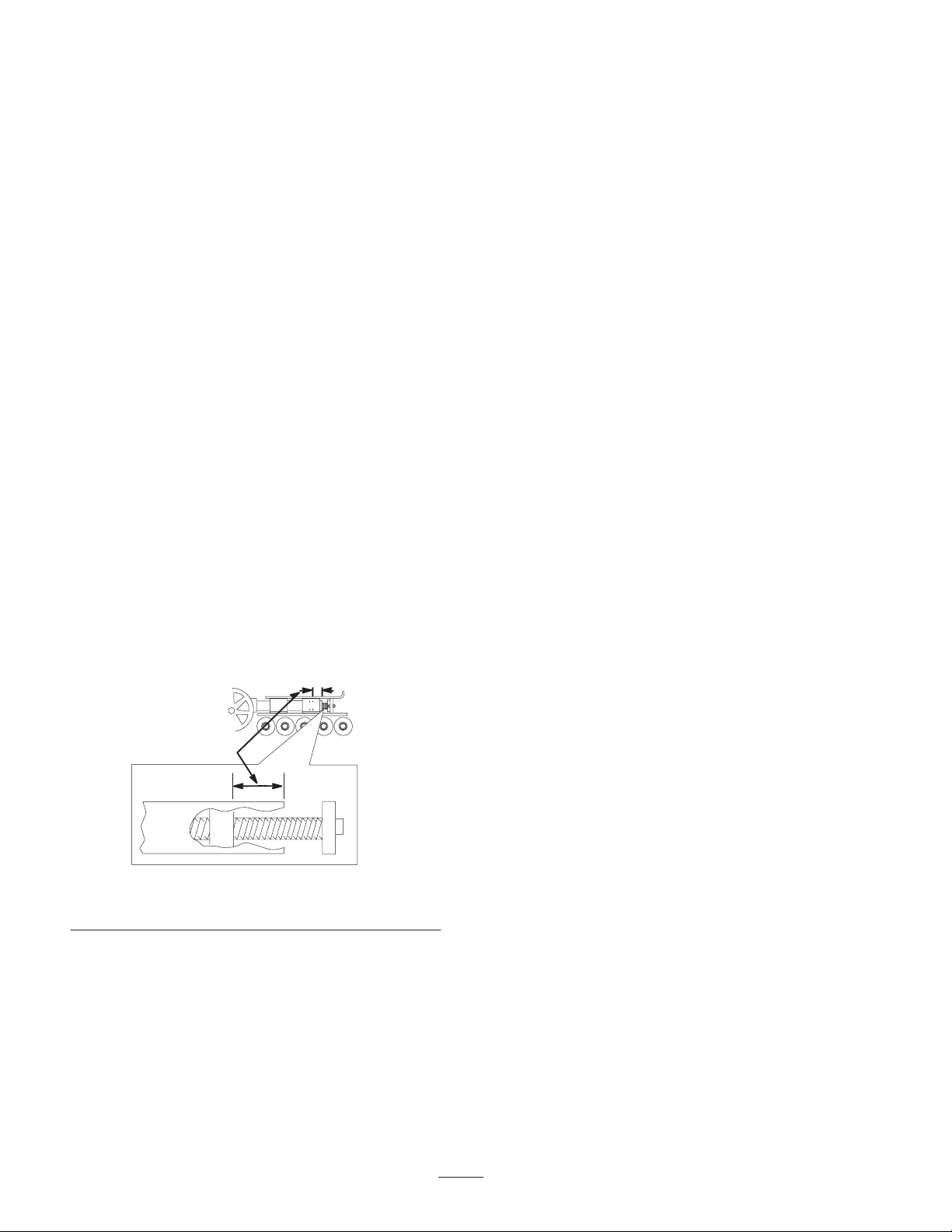

4. Turn the tensioning screw counter-clockwise until the

distance between the tension nut and the back of the

fork tube (Fig. 4) is 2 3/4 in. (7 cm.).

m–4775

1

Figure 4

1. 2-3/4 in. (7 cm)

5. Align the closest notch in the tension screw to the

locking bolt hole and secure the screw with the locking

bolt and nut.

6. Lower the traction unit to the ground.

2

Loading...

Loading...