Page 1

1

Operation & Maintenance Manual

For Commercial Use Only

SWB 26/8

Battery Sweeper

Form No L9730 © 2011 Tornado Industries, LLC Issue A 06/2011

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 2

2

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 3

3

Table of content

1 Safety information ...................................................................................................................................... 4

1.1 Safety and Warning Symbols ........................................................................................................... 4

1.2 General information .......................................................................................................................... 4

1.3 Operating information ....................................................................................................................... 4

1.4 Maintenance information .................................................................................................................. 5

1.5 Particular risks .................................................................................................................................. 5

1.6 Environmental protection .................................................................................................................. 6

1.7 Labels on the machine ..................................................................................................................... 6

2 Starting Up .................................................................................................................................................. 7

2.1 Unpacking and assembling .............................................................................................................. 7

2.2 Instruction ......................................................................................................................................... 8

2.3 Initial battery charge ......................................................................................................................... 8

2.4 Prior to starting up ............................................................................................................................ 8

2.5 Operation .......................................................................................................................................... 8

2.6 Stopping the machine ....................................................................................................................... 8

2.7 After completing work ....................................................................................................................... 9

3 Operation .................................................................................................................................................... 9

3.1 Method of operation ......................................................................................................................... 9

3.2 Operating and indicator elements .................................................................................................. 10

4 Technical Data .......................................................................................................................................... 11

5 Maintenance and Service ........................................................................................................................ 12

5.1 Maintenance Plan ........................................................................................................................... 12

5.2 Battery system ................................................................................................................................ 13

5.3 Side brushes ................................................................................................................................... 14

5.4 Rotary brush ................................................................................................................................... 15

5.5 Debris container ............................................................................................................................. 16

5.6 Dust vacuum ................................................................................................................................... 16

EC Declaration of Conformity ................................................................................................................... 17

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 4

4

1 Safety information

1.1 Safety and Warning Symbols

All paragraphs in this manual referring to your

personal safety, the safety of your machine and

the environment protection are attributed one of

the following warning symbols:

Symbol

Hazardous for

Description

Safety Provisions

persons and goods

Safety Provisions in dangerous situation

caused by misuse inaccurate adherence

of instructions or prescribed work

routine.

CAUTION

the machine

Important information on handling the

machine in order to maintain operability.

Ecological hazard

the environment

Due to use of substances representing

an inherent danger to health of

environment

1.2 General information

In addition to the information provided

Before starting up the machine for the first

time, read the operating manual supplied

with it thoroughly as well as any separate

manuals provided with additional or

attachment devices and observe all the

information during work.

The equipment may only be operated,

serviced and repaired by personnel trained in

the operation of its use.

Particular attention should be paid to the

information regarding safety. Technical

expertise is the key to preventing errors

when operating the machine and ensuring

trouble-free operation.

The operating manual must always be kept

at the operating location of the machine and,

as a result, should be kept in a safe place on

the equipment.

The warning labels attached to the machine

provided important information concerning

safe operation. Illegible or missing labels

must be replaced by new ones.

For reasons of safety, always use original

spare parts.

1.3 Operating information

Before starting the machine up for the first

time, the battery to be used must be fully

charged, properly, by implementing the initial

battery charge routine. Please pay attention

to the operating manual provided with the

charging unit as well as the manual from the

battery manufacturer.

Tornado assumes no liability for damage to

the battery caused by a fault when the

battery is charged for the first time.

Check the operational safety of the machine

each time before starting it up! Clear any

faults immediately!

Before starting work, the operator must be

fully familiar with all adjustment, operating

and control elements as well as their

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 5

5

respective function! It is too late to do this

when the machine is actually in operation!

Always wear heavy duty, non-slip footwear

when working with the machine.

The machine may only be used on those

surfaces which have been approved by the

contractor or person appointed by him.

When using the machine, it is essential to

pay attention to third parties, especially

children.

Accelerate the machine immediately after

switching on the brush head drive, otherwise

imprints of the brush could be produced.

The machine is not suitable for clearing up

hazardous, inflammable or explosive fluids,

dust or substances.

It is forbidden to use the machine in

potentially explosive atmospheres.

The side brush must be raised in order to

transport the machine.

The machine has been conceived for use on

level surfaces with a maximum gradient of

2%.

1.4 Maintenance information

Operating personnel must complete the

necessary daily and weekly maintenance

work. All other maintenance work must be

completed at your local Tornado authorized

service center.

The maintenance work and maintenance

intervals prescribed in the operating manual

must be adhered to.

Suitable tools must be used for cleaning and

maintenance work.

The machine must be inspected by a

recognized technical expert in respect of

operational safety, within the terms of the

applicable accident prevention laws, at

reasonable intervals (we recommend at least

once a year) and following modification or

repairs.

Spare parts must comply with the minimum

technical requirements stipulated by the

manufacturer! This is ensured by the use of

original spare parts.

The machine must be switched off prior to

cleaning or servicing it or to replacing parts.

The drive bar must be out of operation!

Always disconnect the battery plug before

starting any work on the electrical

installation.

When working in the area of the raised hood,

it must be hinged open fully to prevent it

being knocked shut or further open and down

unintentionally.

It is not permitted to clean the machine with a

pressure washer or steam blaster.

It is not permitted to use aggressive and

corrosive cleaning agents.

Allow the machine to dry after being cleaned,

e.g. over the weekend.

Only start the machine up when all the safety

equipment has been installed and brought to

its protecting position.

1.5 Particular risks

Electronics

In the case of defects in the electrical

installation, switch the machine off

immediately and clear the fault.

Work on the electrical equipment may only

be carried out by electricians who have

received the necessary training

The machine's electrical equipment must be

inspected/checked at regular intervals.

Defects, such as loose connections and

cable damage, must be rectified immediately.

Batteries

It is possible that sparking will occur when

connecting the batteries.

Batteries may only be handled and changed

by properly skilled maintenance personnel.

The machine has been set up for operation

using maintenance-free batteries. If other

battery types are used, the machine must be

set up for use with them by an authorized

Tornado service center.

Never lay any metallic objects or tools on

batteries - risk of short circuit!

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 6

6

1.6 Environmental protection

A certain factual expertise is required in

order to use substances which could

represent a risk to health and the

environment.

Observe the applicable laws and local

regulations when disposing of waste.

Used batteries with the recycling symbol

contain reusable commodities. In accordance

with symbol with the crossed out bin, these

batteries must not be disposed of in domestic

waste.

1.7 Labels on the machine

The following safety and warning labels are

attached to the machine where easily legible.

Missing or illegible labels must be replaced

immediately.

Company logo

Rating plate

Maximum permissible

gradient

Filter shaker

Wear compensator for

side brush

Read and observe the

operating manual

Wear compensator for

rotary brush

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 7

7

2 Starting Up

2.1 Unpacking and assembling Fig 1

Open the box, two people are required

to remove the machine from the protective

wrap and place it on the floor.

1. To fix the side brush (Fig 1/1) align the drive

pins on the side brush drive plate and secure

with the wing bolt and washer supplied.

2. Loosen the two knurled screws (Fig. 1/2)

holding the handle a few revolutions until the

handle can be raised and positioned. Set the

handle to a height comfortable for the user

and then tighten the knurled screws.

3. Remove the locking bolt (Fig 1/3) holding

the hood and pivot the hood open.

4. Fix the disassembled cable lug (Fig. 2) to the

corresponding battery contact. It is possible

that sparking will occur when connecting the

batteries!

5. Close the hood and lock in place with the

bolt.

6. The unit is now ready to operate.

Fig 2

Fig 1/2

Fig 1/1

Fig 1/3

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 8

8

2.2 Instruction

Instructions to operators are required before

putting the machine into service.

Only technicians from your local, authorized

Tornado dealer are allowed to provide initial

instruction on how to use the machine.

2.3 Initial battery charge

Before starting the machine up for the

first time, the batteries to be used must

be fully charged, properly, by

implementing the initial battery charge

routine.

2.4 Prior to starting up

Carry out the following checks before starting the

machine:

1. Check the charge status of the batteries.

2. Check the levels of wear on the rotary brush

and side brush.

3. Check the fill level of the debris

container.

2.5 Operation

Please read the Safety Information in

Chapter 1. Before switching the machine

on, ensure that the drive bar (Fig.

3/3) on the handle has not been actuated.

1. Switch the machine on using the (Fig. 3/1)

button: rotary brush drive, dust vacuum and

side brush drive are ready to operate.

2. Lower the side brush to its working position

using the lever (Fig. 3/4). When working

without the side brush: do not lower the side

brush and press the button (Fig. 3/2) for the

side brush once. The green control lamp

goes out.

3. Actuate the drive bar (Fig. 3/3) on the

handle: the machine starts to work.

Start work immediately after actuating

the drive bar, otherwise imprints could

be produced on the floor. Release the

drive bar when driving over thresholds.

Fig.3

2.6 Stopping the machine

When the drive bar is released, the rotary brush

drive, dust vacuum and side brush drive switch

off automatically.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 9

9

2.7 After completing work

1. Drive to an appropriate maintenance area.

2. Stop the machine. Raise the side brush to its

idle position and switch the machine off.

3. Actuate the filter shaker.

4. Empty the debris container.

5. Check the brush space for accumulations of

dirt.

6. Check the charge status of the batteries.

It is not permitted to clean the machine

with a pressure washer or steam

blaster.

3 Operation

3.1 Method of operation

The Tornado SWB 26/8 is a machine designed to

sweep and clean waste from hard floors and

carpets. The side brush (Fig. 4/1) sweeps the dirt

from corners to a position in front of the rotary

brush (Fig. 4/2). The rotary brush sweeps the

larger particle dirt overhead into the debris

container (Fig. 4/3). The finer dust picked up is

drawn up by the suction turbine, fed into the filter

system (Fig. 4/4) and filtered out.

Only dust-free air is fed back into the ambient air.

The machine is equipped with maintenance- free

batteries (Fig. 4/5), a specially adapted, fully

automatic battery charger (Fig. 4/6) and a total

discharge signal transducer to protect it against

total discharge.

Fig. 4

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 10

10

3.2 Operating and indicator elements

3.2.1 Operating panel

1. Control lamp for rotary brush drive, side

brush drive and suction turbine

2. ON/OFF button for rotary brush drive, side

brush drive and suction turbine

3. Control lamp for side brush drive

4. ON/OFF button for side brush drive

5. Control lamp for battery charger operation

6. Charge control indicator

7. Drive bar

Fig. 5/7

Fig. 5

ON/OFF button for rotary brush, side

brush and suction turbine (Fig. 5/1)

The button activates the rotary brush drive, side

brush drive and suction turbine so they are ready

to operate.

The side brush drive can be switched off

separately. The suction turbine cannot be

switched off separately which prevents the dust

vacuum being activated by accident.

To prevent unauthorized use of the

machine, switch the machine off using

the button (Fig. 5/1).

Control lamp for rotary brush drive, side

brush drive and suction turbine (Fig. 5/2)

The green control lamp indicates that the rotary

brush drive and suction turbine are ready to

operate. If the rotary brush or suction turbine is

overloaded, a safety shutdown is triggered and

the control lamp flashes.

ON/OFF button for side brush drive (Fig. 5/3)

The button can be used to switch off the side

brush drive independently of the rotary brush

drive and to activate it for use again.

Control lamp for side brush drive (Fig. 5/4)

The green control lamp indicates that the side

brush drive is ready to operate. If the side brush

is overloaded, a safety shutdown is triggered and

the control lamp flashes.

Control lamp for battery charger operation

(Fig. 5/5)

This control lamp indicates that the batteries are

being charged

Charge control indicator (Fig. 5/6)

During the charging process, the machine's

electronics system controls the machine is not

switched on inadvertently and indicates the

charge status. The battery charge status is

indicated by 4 green and 1 red LED.

The battery voltage is depicted in 5 levels:

> 25.1 V = all green LEDs on

> 24.5 V = bottom 3 green LEDs on

> 23.9 V = bottom 2 green LEDs on

> 22.7 V = bottom green LED on

< 22.7 V = red battery LED flashes

Drive bar (Fig. 5/7)

The drive bar switches all the drives which are

ready to operate on or off.

The drive bar serves to prevent damage.

If the drive bar is released during operation, all

the drives are switched off.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 11

11

3.2.2 Operating elements on the machine

1 Knurled screw for the handle

2 Shaking device lever

3 Debris container lock

4 Side brush lever

5 Charger cable flap

Fig. 6

Knurled screws for handle (Fig. 6/1)

The two knurled screws enable the handle

to be adjusted to a comfortable

height for the user.

Shaking device lever (Fig. 6/2)

In order to clean the filter in the dust

vacuum, switch the shaking device lever

several times quickly to the left and

right.

Debris container locks (Fig. 6/3)

Pull the lock lever up in order to remove

the debris container.

Side brush lever (Fig. 6/4)

Use the lever to lower or raise the side

brush.

Charger cable flap (Fig. 6/5)

The battery charger cable is located behind the

flap to the right beside the operating

panel. Pull the lock downwards

to open the flap.

Technical Data

Machine length

cm/in

80/32

Machine height (handle folded)

cm/in

60/24

Machine width

cm/in

70/28

Working width

cm/in

66/26

Rotary brush width

cm/in

40/16

Rotary brush diameter

cm/in

19/7

Area Coverage, theoretical

m²/sqft/h

2400/26000

Debris Container Volume

Liter/Gal

40/9

Filter Surface

m²/sqft

1.1/12

Nominal Voltage

V

24

Power Consumption, rotary brush drive

W/A

210/8.75

Power Consumption, side brush drive

W/A

48/2

Power Consumption, suction turbine

W/A

60/2.5

Weight without batteries

kg/lbs.

42/93

Weight with batteries

kg/lbs

56/124

Noise emission value

The sound pressure level (LpA) (at the ear of the operator)

measured according to DIN IEC 60335-2-72 under normal

working conditions:

dB (A)

70

Measurement inaccuracy (KpA):

dB (A)

2

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 12

12

5 Maintenance and Service

General information

It is essential to pay attention to the information

in Chapter "Safety Information" before

completing any service or maintenance work!

By adhering to the maintenance work

recommended by us, you can be sure that the

machine is always ready to be put into operation.

Maintenance and repair work necessary on a

daily and weekly basis can be carried out by an

operator trained to complete the work, all other

Tornado system maintenance may only be

completed by personnel who are correspondingly

qualified and trained.

Please contact your nearest Tornado service

center or Tornado authorized dealer.

Failure to observe this annuls any rights to

claims under the terms of guarantee in respect of

resulting damage or consequential damage.

Always specify the serial number in the case of

inquiries and spare parts orders, refer to section

1.7 - Rating plate.

5.1 Maintenance Plan

System maintenance, customer

The following maintenance work must be

completed by the customer at the intervals

stipulated.

Activity

Interval

Daily

Weekly

Check the battery charge; recharge if necessary

o

Empty the debris container

o

Clean the brush space

o

Check the filter in the dust vacuum; clean, if necessary

o

Check the rotary brush and side brush; clean, if necessary

o

Check the sweeping pattern; readjust, if necessary

o

Check the sealing strips on the rotary brush for signs of wear; clean, if

necessary

o

Check the gasket on the debris container

o Check the function of the suction turbine

o Check the debris container lock

o Test drive and function test

o

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 13

13

5.2 Battery system

1. Battery indicator for charger

2. Charge control indicator

3. Charger

4. Flap for charger mains power cable

5. Connection cable

6. Lashing straps

7. Batteries

8. Hood

9. Connection plan

Batteries may only be handled and

changed by properly skilled

maintenance personnel.

The charge control indicator (Fig. 7/2)

indicates the charge status of the

batteries during operation. When the

batteries are discharged, the red LED

flashes. The machine functions are

restricted. Charge the batteries

immediately!

Fig. 7

5.2.1 Charging batteries

The charge control indicator (Fig. 7/2) indicates

the charge status of the batteries during

operation. The batteries must be charged

immediately the red LED lights up. The batteries

(Fig. 7/7) are charged using the integrated

battery charger (Fig. 7/3). The charger is

connected by means of the power cable

(Fig. 7/4).

While the battery is being charged, the battery

indicator on the charger (Fig. 7/1) lights up.

Before starting the machine up for the

first time, the batteries to be used must

be fully charged, properly, by

implementing the initial battery charge

routine. Tornado assumes no liability

for damage to the battery caused by a

fault when the battery is charged for

the first time.

5.2.2 Total discharge signal transducer (TSG)

The machine is equipped with a total discharge

signal transducer to protect the batteries against

total discharge.

The total discharge signal transducer is

integrated in the electronics.

5.2.3 Servicing the driving batteries

Never leave discharged batteries lying

around; recharge them immediately!

5.2.4 Removing the batteries

1. Park the machine on a level area of floor.

2. Switch off the machine.

3. Loosen the locking bolt holding the hood

(refer to Figure 1/3) and pivot the hood open.

4. Slacken the lashing straps (Fig. 7/6).

5. Disconnect the connection cable (Fig. 7/5)

from the batteries and remove the batteries.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 14

14

5.2.5 Inserting the batteries

Only the special batteries approved by

Tornado may be installed at the

prescribed position.

1. Install the two lower batteries in the battery

holder in accordance with Figure 7.

2. Lay the rubber mat on the batteries.

3. Place the other two batteries on the rubber

mat.

4. Tighten the lashing straps (Fig. 7/6).

5. Connect the battery poles to the connection

cables in accordance with the connection

plan (Fig. 7/9).

It is possible that sparking will occur when

connecting the batteries! Check a firm fit!

6. Close the hood (Fig. 7/8) and lock in place

with the locking bolt on the frame.

5.2.6 Disposing of batteries

Used batteries with the recycling symbol contain

reusable commodities. In accordance with

symbol with the crossed out bin, these batteries

must not be disposed of in domestic waste.

Fig 8

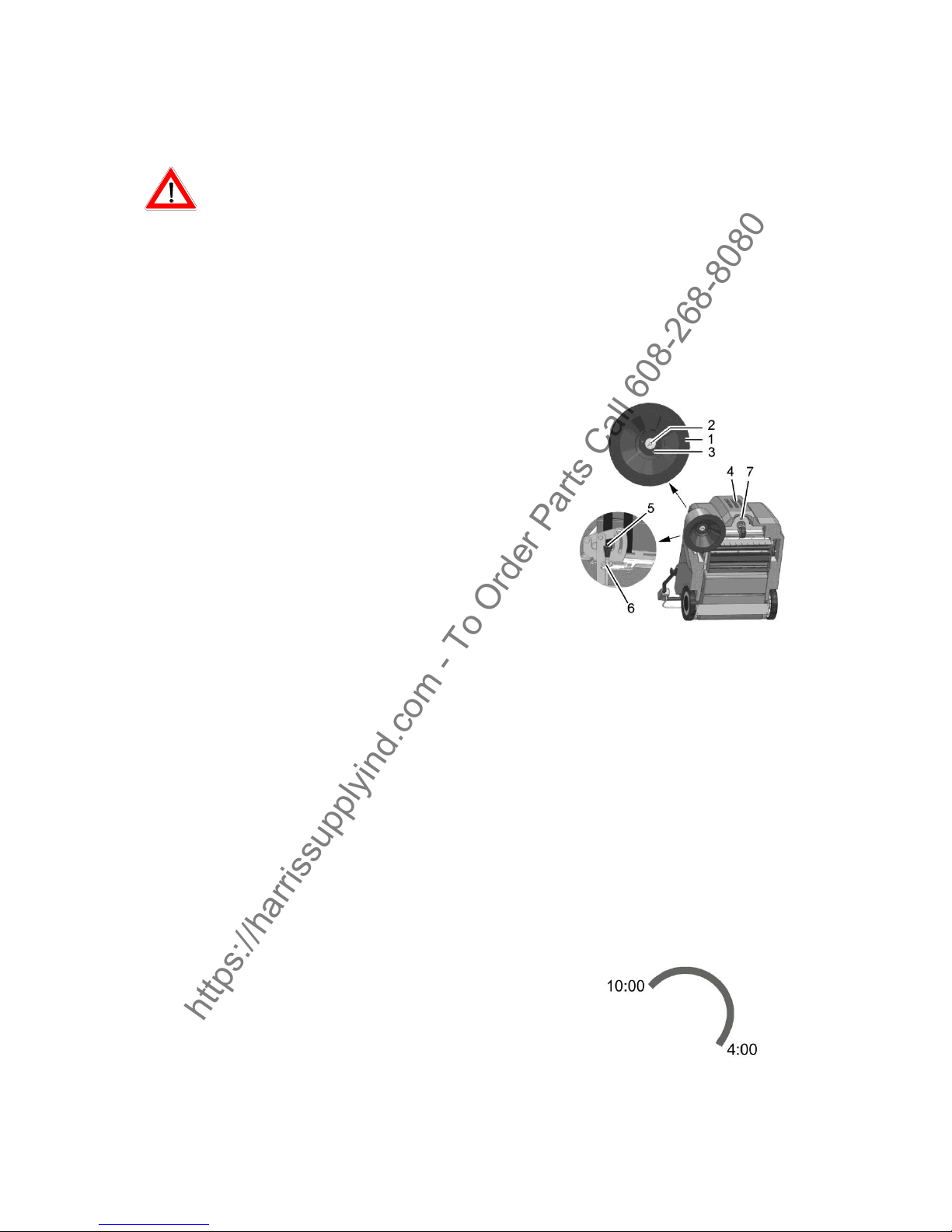

5.3 Side brushes

1. Side brushes

2. Wing bolt

3. Carrier

4. Hood

5. Adjusting bolt

6. Counternut

7. Locking bolt

5.3.1 Changing the side brush

Check the side brush (Fig. 8/1) weekly and change in the case of wear.

1. Switch the machine off and lay it on its side.

2. Remove the wing bolt (Fig. 8/2) with the washer from underneath the side brush

(Fig. 8/1).

3. Pull the side brush off.

4. To fix the side brush align the drive pins on the side brush drive plate and secure with the wing bolt

and washer supplied.

5.3.2 Setting the sweeping pattern

In the case of brush wear and after changing the

side brush (Fig. 8/1), readjust the sweeping

pattern.

1. Switch the machine off; unscrew the locking

bolt (Fig. 8/7) and open the hood (Fig. 8/4).

2. Loosen the counternut (Fig. 8/6) and adjust

the sweeping pattern by turning the adjusting

bolt (Fig. 8/5) clockwise and counter

clockwise so that it touches the floor.

3. Tighten the counternut again and close the

hood.

4. Switch the machine on and allow the side

brush to run while standing still for a short

time.

5. Switch the machine off, raise the front a little

and pull it back.

6. Check the sweeping pattern, comparing it

with a clock viewed driving forward.

When set correctly, the sweeping pattern

must make an impression on the floor

between approx. 10:00 and 4:00 o' clock.

7. Repeat the process, if necessary, until the

sweeping pattern is set correctly.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 15

15

8. Close the hood (Fig. 8/4) and screw the

locking bolt (Fig. 8/7) back in.

5.4 Rotary brush

1. Rotary brush

2. Fillister head self-tapping screws

3. Rotary brush segment

4. Sealing strips

5. Sweeping pattern adjusting lever

6. Timing belt

7. Hood

8. Locking bolt

Fig 9

5.4.1 Cleaning the brush space

The brush space with rotary brush (Fig. 9/1) and

gaskets (Fig. 9/4) must be checked daily for

signs of dirt and cleaned, if necessary.

5.4.2 Changing the rotary brush

The rotary brush (Fig. 9/1) must be checked

weekly and changed in the case of wear.

1. Switch the machine off and lay it on its side.

2. Loosen the six fillister head screws (Fig. 9/2)

in the rotary brush and remove the two roller

segments.

3. Install the two new roller segments and fix in

place with the fillister head screws.

4. After changing the rotary brush, readjust the

sweeping pattern as necessary.

5.4.3 Setting the sweeping pattern

In the case of brush wear, and after changing the

rotary brush (Fig. 9/1), readjust the sweeping

pattern.

1. Switch the machine off, unscrew the locking

bolt (Fig. 9/8) and open the hood (Fig. 9/7).

2. Loosen the wing nut on the adjusting lever

(Fig. 9/5) and adjust the sweeping pattern

using the adjusting lever by pivoting it up and

down until it touches the floor.

3. Tighten the wing nut again and close the

hood.

4. Switch the machine on and allow the rotary

brush to run while standing still for a short

time.

5. Switch the machine off, raise the front a little

and pull it back.

6. When adjusted correctly, there must be an

approx. 50 mm wide sweeping pattern on the

floor which has parallel sides.

7. Repeat the process, if necessary, until the

sweeping pattern is set correctly.

8. Close the hood (Fig. 9/7) and screw the

locking bolt (Fig. 9/8) back in

5.4.4 Changing the sealing strips

The four sealing strips (Fig. 9/4) must

be checked weekly and changed in the

case of wear.

1. Switch the machine off and lay it on

its side.

2. Remove all four sealing strips (Fig.

9/2) with holders.

3. Loosen the screws in the holders

and remove the damaged sealing

strips.

4. Fix the new sealing strips on the

holders and reinstall them.

5. Adjust the sealing strips so that they

touch the floor lightly.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 16

16

5.4.5 Changing the timing belt

The timing belt (Fig. 9/6) must be

checked every 500 operating hours and

changed in the event of wear.

1. Switch the machine off, unscrew the

locking bolt (Fig. 9/8) and open the

hood (Fig. 9/7).

2. Slacken the timing belt (Fig. 9/6) using

the tension pulley and remove

the belt.

3. Slacken the tension pulley and install

the new timing belt. The timing belt is

automatically tensioned by means of

a tension spring.

4. Close the hood (Fig. 9/7) and screw

the locking bolts (Fig. 9/8) back in.

5.5 Debris container

1 Debris container

2 Locking mechanism

3 Seal

4 Handle

Fig. 10

5.5.1 Emptying the debris container

Check the fill level of the debris container (Fig.

10/1) at regular intervals (max. load capacity 25

kg) and empty as necessary.

1. Switch the machine off and pull the locking

mechanism (Fig. 10/2) on the debris

container (Fig. 10/1) upwards.

2. Pull the debris container to the rear out of the

machine using the handle (Fig. 10/4) and

dispose of the waste according to the

applicable environmental laws.

3. Reinstall the debris container and press it

against the locking mechanism until it audibly

latches into place.

5.5.2 Changing the seal

Check the seal (Fig. 10/3) weekly for signs of

wear and change it as necessary.

1. Switch off the machine and pull the locking

mechanism (Fig. 10/2) on the debris

container (Fig. 10/1) upwards.

2. Pull the debris container (Fig. 10/3) to the

rear and out of the machine using the handle

(Fig. 10/4).

3. Pull the seal for the debris container from the

filter support frame. Install a new seal.

4. Reinstall the debris container and press it

against the locking mechanism until it audibly

latches into place

5.6 Dust vacuum

1 Filter

2 Sealing strip

3 Filter support frame

4 Shaking device

5 Wing bolts

6 Holders

Fig. 11

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 17

17

5.6.1 Cleaning the filter

Clean the filter (Fig. 11/1) in the dust vacuum as

necessary using the shaking device (Fig. 11/4).

In the case of extreme accumulation of dirt, clean

the filter as follows:

1. Switch the machine off and remove the

debris container.

2. Loosen the wing bolts (Fig. 11/5). Pivot the

filter support frame (Fig. 11/ 3) down and

remove it.

3. Remove the filter from the filter support

frame.

Beat the filter clean or use a vacuum cleaner.

Be careful not to damage the filter ribs!

4. Insert the correct side of filter in the filter

support frame. The sealing strip (Fig. 11/2)

must point towards the suction turbine!

5. Hook the filter support frame in the holder

(Fig. 11/6) and fix in place with the wing

bolts.

6. Reinstall the debris container

5.6.2 Changing the filter

Check the filter (Fig. 11/1) every 250 operating

hours for signs of wear and change it as

necessary.

1. Switch the machine off and remove the

debris container.

2. Unscrew the wing bolts (Fig. 11/5). Pivot the

filter support frame (Fig. 11/3) down and

remove it.

3. Remove the filter from the filter support

frame.

4. Insert the correct side of the new filter in the

filter support frame. The sealing strip (Fig.

11/2) must point towards the suction turbine!

5. Hook the filter support frame in the holder

(Fig. 11/6), if necessary, and fix in place with

the wing bolts.

6. Reinstall the debris container

5.6.3 Install the Lint filter

If the machine is mainly used on carpet, you

have to install the lint filter (7).

1. Switch the machine off and remove the

debris container.

2. Unscrew the wing bolts (Fig.11/5). Pivot the

filter support frame (3) down and remove it.

3. Mount the lint filter (7) between filter and the

filter support frame

4. Hook the filter support frame in the holder

(Fig.11/6), if necessary, and fix in place with

the wing bolts.

5. Reinstall the debris container.

Noise emission value

The sound pressure level (LpA) (at the ear of the

operator) measured according to DIN IEC 603352-72 under normal working conditions: 70 dB (A)

Measurement inaccuracy (KpA): 2 dB (A)

EC Declaration of Conformity (corresponds to

EC Directive 2006/42/EC)

Tornado Industries declares that the products

Tornado SWB 26/8

to which this declaration relates, conform

to the relevant provisions of the

safety and health requirements stipulated

in EC Directive 2006/42/EC and is in

accordance with 2004/108/EC.

Reference was made to the following standards

and/or norms and/or technical specifications to

ensure proper implementation of the safety and

health requirements in the EC Directive:

EN 60335-2-72

EN 55012

EN 61000-6-2

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Loading...

Loading...