Page 1

valve & automation

TREAE SERIES

ELECTRICAL ACTUATOR

USER MANUAL

NOVEMBER / 2018

PLEASE READ THE INSTRUCTIONS BEFORE USE

www.smstork.com

Page 2

CONTENT

1. PURPOSE OF DOCUMENT ....................................................................................................................................................3

2. PRODUCT OVERVIEW ............................................................................................................................................................3

a. Intended Use of the Product ..............................................................................................................................................3

b. Product Coding System .......................................................................................................................................................4

c. Product and Part Pictures ...................................................................................................................................................5

d. Labeling Details ...........................................................................................................................................................................6

3. PRODUCT OPERATION ..........................................................................................................................................................7

a. Storage Conditions ...................................................................................................................................................................7

b. Operation Conditions .............................................................................................................................................................7

4. PRODUCT INSTALLATION ..................................................................................................................................................8

a. Valve Mounting .............................................................................................................................................................................8

b. Manual Working ...........................................................................................................................................................................11

c. Adjusting Cam and Limit Switches .............................................................................................................................12

d. Technical Dimensions ............................................................................................................................................................13

e. Wiring Schemes ........................................................................................................................................................................15

f. Warnings ..........................................................................................................................................................................................17

5. PRODUCT LIFE ..............................................................................................................................................................................17

6. PRODUCT CARE AND MAINTENANCE ..................................................................................................................18

a. Troubleshooting ........................................................................................................................................................................19

7. PRODUCT SPARE PARTS ....................................................................................................................................................19

8. GENERAL CARE, REPAIR AND CLEANING .......................................................................................................20

9. PRODUCT SHIPMENT ...........................................................................................................................................................20

10. WARRANTY CONDITIONS ............................................................................................................................................20

2

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

Page 3

1. PURPOSE OF DOCUMENT

This document is prepared for showing TORK brand named TREAE series electrical

actuators’ installation, operation and maintenance information.

Security Notifications:

Warning: This sign show personal and product’s security notifications. It warns

user about probably dangers. If cautions are not regarded personal injuring or

product damaged is become unavoidable.

2. PRODUCT OVERVIEW

Electrical actuators are equipment converting electrical power to mechanical power

used for valve control. Electric motor’s torque is transmitted to valve shaft through the

electrical actuator gearbox. This torque makes the valve open or close. Gearbox provides

a steady torque while turning.

TREAE series electric actuators are produced as “On / Off Controlled Electric Actuator “.

Electrical actuators manufactured by SMS-TORK do not use asbestos, PCB, mercury and

other prohibited chemicals.

a. Intended Use of the Product

Electrical actuator is one the most used valve control equipment. The purpose of an

electrical actuator is poening or closing the valve. This opening or closing can be full open/

close or proportional open/close. This can be changed according to process application.

Electrical actuators can be used on ball valve, butterfly valve, plug valve and other proper

valve types.

Advantages of electrical actuators are,

• Electric power is accessible.

• High output torque can be produced with low energy.

• Products have longer life.

• Products are compact and have light weight.

• Sensitive control.

• High protection class.

• Wide power supply range.

• Wide turn angle range.

www.smstork.com

3

Page 4

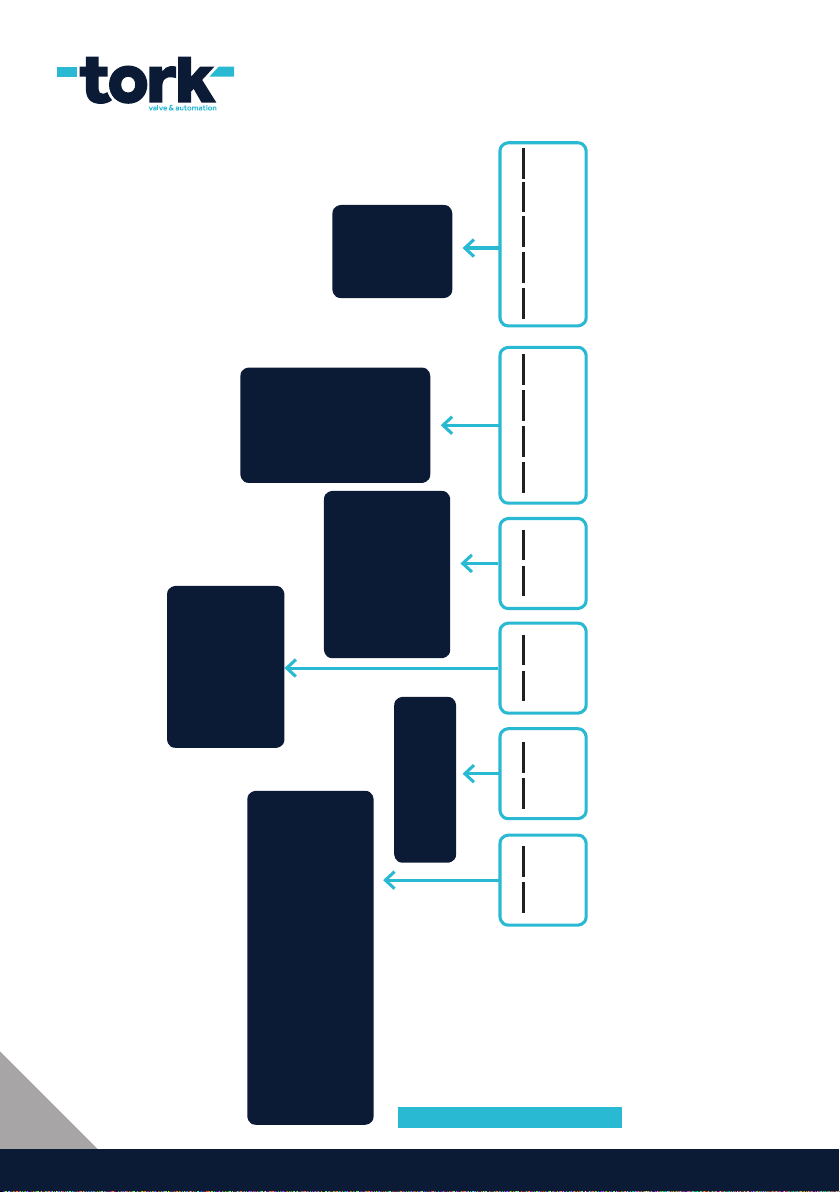

b. Product Coding System

TREAE XXXX XX XX XX XX

There may not be all the

variations at the product

coding table. For more

details, please contact us.

0200

0300

.....

PROTECTION

CLASS

01 IP 67

02 IP68

03 Explosion Proof

04 IP65

Rotary

Electric

Actuator

Economic

TORQUE

0040

0060

0080

0100

0150

01 230VAC

02 24VDC

03 230VAC/24

VDC Multiboard

02 PROPORTIONAL

SERIES

Tork

OUTPUT

OPERATING

VOLTAGE

CONTROL TYPE

01 ON-OFF

Display)

03 RBU (With Chargeable Battery Unit)

4

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

OPTIONS

00 NA

01 PIU (With Potentiometer Unit)

02 LCU (Local Control Unit With LCD

Table 1. Product Coding System

Page 5

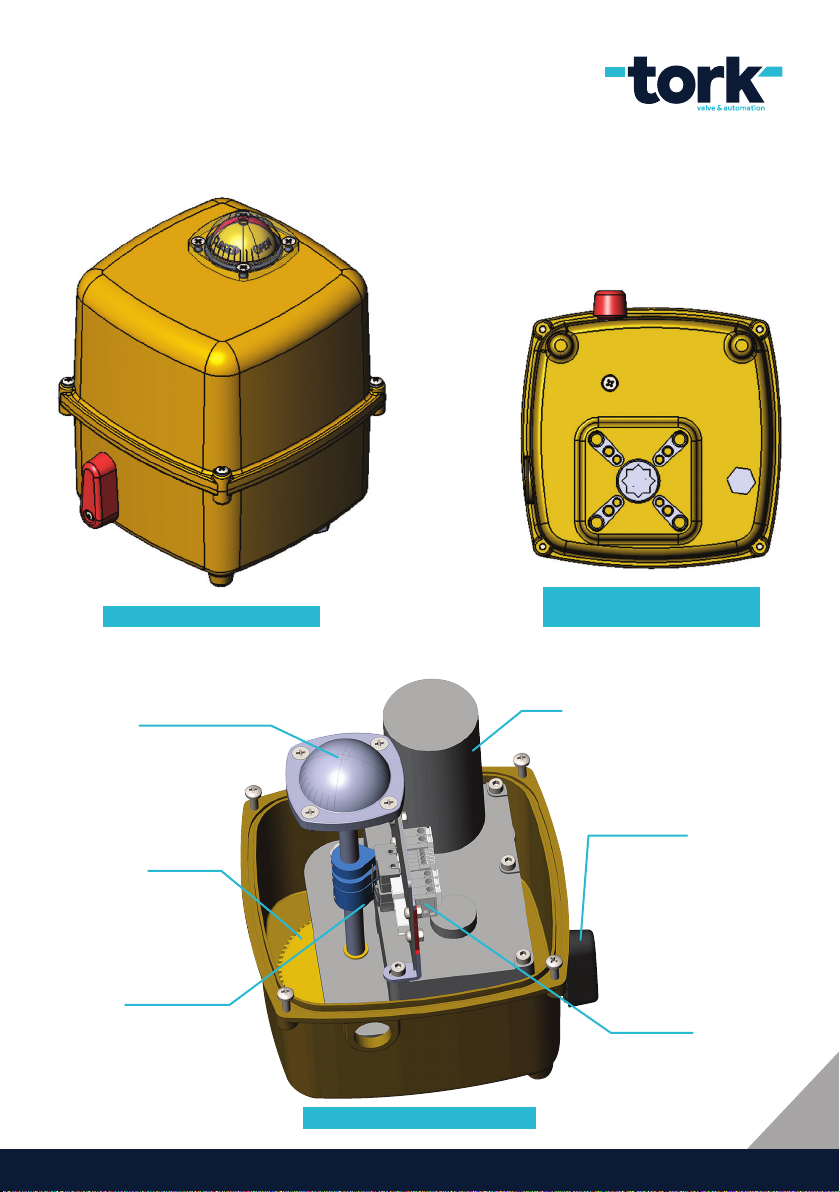

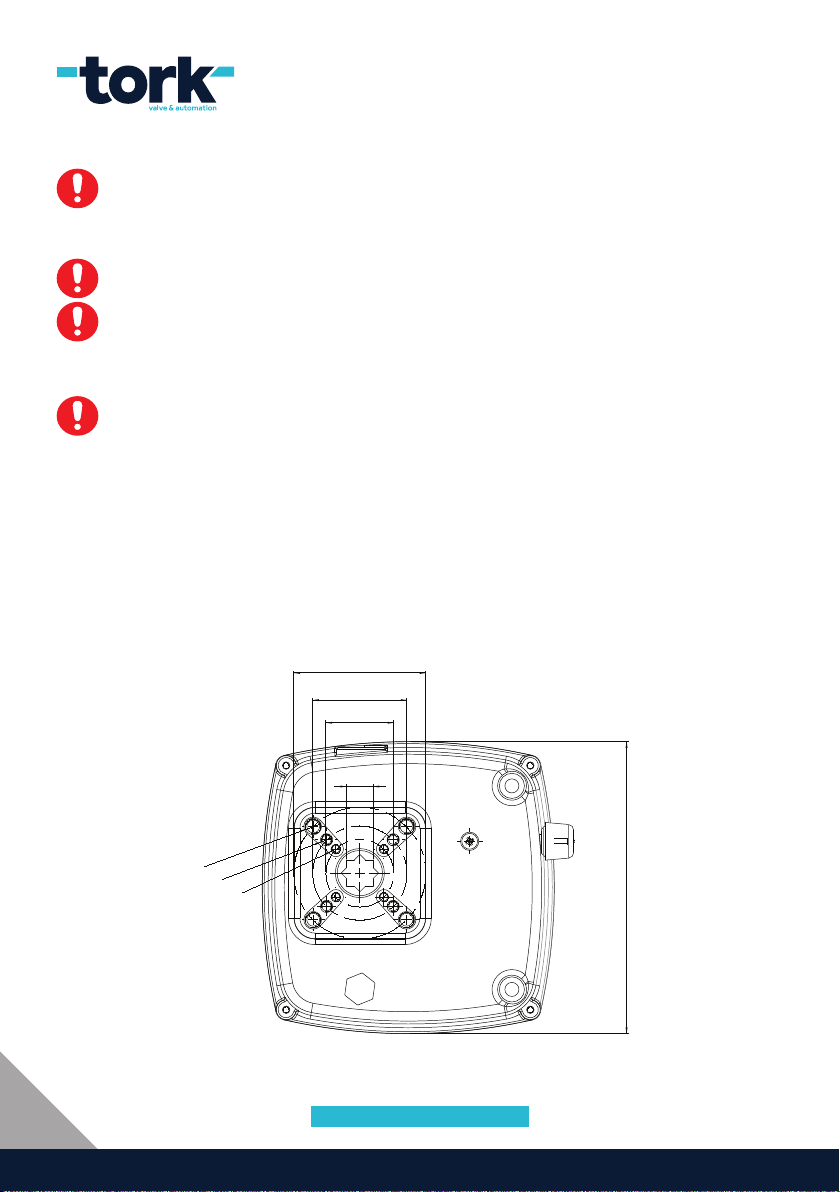

c. Product and Part Pictures

Fig 1. TREAE Electrical Actuator

Fig 2. TREAE Electrical

Actuator Valve Connection Point

Position Indicator

Gear

Cams and Limit

Switches

Fig 3. Electrical Actuator Parts

Motor

Manual Control

Lever

Control Card

5

www.smstork.com

Page 6

d. Labeling Details

Electrical actuators’ general information must be written on their labels. Fig 3 shows a

sample label and the information it contains. For more detailed information, the user

manual, technical support department or sales department can be helpful.

Electrical actuator label contains these informations:

• Model

• Type

• Serial No

• Protection Class

• Ambient Temperature

• Output Torque

• Operation Voltage

• Power

• Operation Time

• Optional Units

Manufactured By Sms-tork Co. Inc.

Model : TREAE006001010100

Type : ON - OFF

Serial No : TREAE60-17-0001

Protection Class : IP67

Ambient Temperature : -20

6

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

0

C, +600C

Fig 4. Label Details

www.smstork.com

Electric Actuator

Output Torque : 60Nm

Operating Volyage : 230V AC 50Hz

Power : 6W 20 VA

Operation Time : 14 SEC / 90

0

Option :

Page 7

3. PRODUCT OPERATION

When supply voltage (100 - 240 VAC or 24VAC/DC) applied to the electrical actuator,

motor and gearbox produce a rotary force. This force makes the valve acting. According

to this act valve is opened or closed.

a. Storage Conditions

Electrical actuators must be stored in clean, dry and cool ambient. Electrical actuators’

cover screws must be tightened up and cable entries must be closed. When electrical actuators are stored in an open ambient, they must be protected from weather conditions.

b. Operation Conditions

• Small, light and compact design

• On/Off control

• 60 Nm torque value

• High moment with low energy consumption

• Mechanically manual control

• Manual control by electronic card

• 14 sec. opening and closing time

0

• 90

rotation angle

• Torque limiter with current control

• Body Ingress Protection: IP67

• Body Material: Plastic Injection

• Ambient Temperature: -20

• Electric Supply: 100-240VAC, 24VDC, 24VAC

• Limit Switches: 2x OPEN/CLOSE SPDT, 250VAC 3A, 125 VAC 5A

• Aux. Limit Switches : 2x OPEN/CLOSE SPDT, 250VAC 3A, 125 VAC 5A

• Position Indicator : Continuous, as OPEN/CLOSE

• Manual Control: With no 15 switches

• Cable Entrances : M20x1,5

• Greasing : Gear Oil

• Motor operation rate: S4

• Adjustable at different angles

0

C...+700C

www.smstork.com

7

Page 8

4. PRODUCT INSTALLATION

Before installation, it must be checked if there is any damage on the product and

there is any missing part. If there is any damage or missing part, product must not be accepted.

Before the installation inform on the labels and the boxes must be checked.

Before the installation, line voltage and voltage written on the label must be checked

if they are in the same range. Before the installation product’s suitability to the system

must be checked.

Before the installation, the line voltage must be switched OFF. Be careful about

during the installation if anybody can switch it ON. This probability must be prevented

and must be sure about it.

a. Valve Mounting

Electrical actuators are manufactured so that the valve can be mounted according to ISO

5211 standard.

Ø 70

Ø 50

Ø 36

M8

M6

M5

8

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

14

155

Fig 5. ISO5211 Mounting Surface

Page 9

Fig 6. Valve Mounting

9

www.smstork.com

Page 10

10

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

Fig 7. Valve Mounting with Bracket

Page 11

b. Manual Control

Manual

Control

Lever

Fig 8. Manual Control Lever

There are two different manual control ways. First way is with manual control lever, and

the second way is by buttons on PCB card.

1) Controlling with manual control lever is only recommended to use in case of emergency as power failure or interreptuion of the control signal. The reason for this is, even the

valve’s position changed with manual control lever while there is control signal on electric

actuator. In this control system, manual control lever which is located near to the body

is pull down. By this way, motor’s connection with gears is cut. Switch under the body is

opened and closed by no 15 switch. For switch to automatic control mode, manual control

lever is pull up, then motor will activated and actuator will be controlled automatically.

When the manual arm is pulled down, there is a high possibility of strain. To prevent

this strain and prevent the manual arm from breaking, the keyway under the handle must

be loosened by moving the handle 15 to the left and right while the manual arm is being

pulled down. In this way, it is easily transitioned into manual mode and the motor is disconnected from the gears. Otherwise, the manual arm may break. Manual arm breakage

caused by force is not covered by guarantee.

www.smstork.com

11

Page 12

2) When card is on energy, press both direction buttons on the card. Red LEDs next

to buttons on and off 3 times and be on continuosly; and switch to manual control. After that, on and off process is controlled by direction butttons. Information coming from

control signal information do not take into account at the manual mode. To exit manual

mode, press both direction buttons. After LEDs on and off 3 times, it be off and switch

to automatic mode. Control can be done by control signals. By doing on and off process,

one of the LEDs work.

c. Adjusting Cams and Limit Switches

SW4

OPEN

CAMS

OLS

SW2

OPEN LIMIT

SWITCHES

EOLS

SW1

CLOSE

CAMS

ECVLS

SW3

CLOSE LIMIT

SWITCHES

CLS

Fig 8. Cams and Limit Switches

Firstly, loosen the setscrew on cams, so they can move easily. Bring the valve to CLOSE

position manually. While it is in CLOSE position, the cams are turned by pressing cams to

CLOSE LIMIT SWITCHES 3.(SW1) and 4. (SW3), and press the CLOSE switch. After that,

3. and 4. cams are squeezed and fastened. Follow same instructions for OPEN position.

At this time, 1. (SW4) and 2. (SW2) cams position are adjusted.

12

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

Page 13

d. Technical Dimensions

M8

M6

M5

Ø 70

Ø 50

Ø 36

14

155

193,80

M 20 X1,5

165,30

Fig 10. TREAE Electrical Actuator ABC Measures

13

www.smstork.com

Page 14

LED Meanings

LED NAME LED POSITION EXPLANATION

Left

Right

Switch 1 Stop

Switch 2 Stop

Open

Close

Open

Close

Open Valve way is open.

Close Valve way is in the middle.

Open Valve way is close.

Close Valve way is in the middle.

1) There is valve open control signal.

2) It works on manual mode, if it light up

with right LED.

1) No energy on card.

2) No First Control Signal

1) There is valve close control signal.

2)It works on manual mode, if it light up

with left LED.

1) No energy on card.

2) No First Control Signal

Table 2. LED meanings

14

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

Page 15

e. Wiring Schemes

100 - 240 VAC On-Off Wiring Schemes

www.smstork.com

15

Page 16

24 VDC / VAC On-Off Wiring Schemes

16

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

Page 17

h. Warnings

If electrical actuator’s wiring is damaged, it must be changed by producer company,

certificated service or someone having technical qualification, for preventing any

dangerous conditions,

If the product is to be used in outdoor, explosive or in environments where harmful

animals such as mice live, It is necessary that the supply cables and the connection

materials have the appropriate specifications (armor-plated, atex, etc.).

Preventing from any short circuit fault, a 4A B type automat fuse must be used in the

power line that electrical actuator connected.

Every electrical actuator must be supplied with voltage written on it. Every electrical

actuator must be mounted the proper valve according the output torque written on it.

When it is necessary in some fluid applications, a filter must be used. Because, some

sediments gathered in the valve cause corrosion and forcing the electrical actuator. This

forcing makes difficult to open or close the valve and can damage the electrical actuator.

When manual hand wheel has traced to its limits, it must not be turned over more.

Preventing from any short circuit or open circuit fault, the electrical actuator cables

must not have any damage(twisting, smashing) on them.Moreover, the cable twisting on

the cable entries can cause to moisture or water entrance to the body. To prevent from

this, proper cable diameter must be selected according to the cable entries.

Used cable must have minimum 3x 0.75 mm

2

section.

5. PRODUCT LIFE

Electrical actuators’ operating times change according to their models. Product’s

life changes according to application and ambient conditions. Periodic preventative

maintenance extends the product’s operating life.

The duty class level of the motors used in our electric actuators is S4. Therefore, in AC ONOFF electrical actuators, the motors can be operated continuously for up to 30 minutes,

then the motor must not run until the motor temperature is equal to ambient temperature.

www.smstork.com

17

Page 18

6. PRODUCT CARE AND MAINTENANCE

Under normal conditions, the electrical actuator must be checked in every 6 months. For

more hazardous conditions, it must be checked more frequently.

Before electrical actuator displaced from the system, the power on the electrical actuator

must be switched OFF and pressure in the pipe must be zero.

• Be sure about valve and actuator mounting is right.

• Be sure about all electrical wiring is isolated and wired regularly.

• Be sure about all screws are mounted and tightened up.

• Be sure about the parts in the electrical actuator is clean.

• Be sure about cable glands and blind plugs are mounted and dry.

• Be sure about if there is no humidity in actuator.

• Be sure about inner heater is working. The internal heater prevents the formation of

moisture inside the actuator and prevents the electronic parts from breaking down.

• Be sure about is manual hand wheel is operating.

• Be sure about actuator’s position indicator and valve position are correlate.

• Be sure about label is readable. If it is necessary request to change the label with more

readable one.

During both installation and maintenance be careful about sensitive inner parts.

They must not be damaged. Before and after any maintenance electrical wirings must

be controlled, electrical precautions must be taken; valve must be tested if it is working

proper with actuator.

18

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

Page 19

a. Troubleshooting

Problem Probably Case Corrective/Preventive Action

The motor is not spinning.

There is no energy on the

product.

Manual on / off handle turns

hardly.

Valve only opens or closes.

Manual on / off handle does

not control the valve.

The motor is turning but the

valve is not opening /

closing.

There is an open in control

circuit.

Motor isolation is damaged.

There is no supply voltage.

Valve shaft does not greased

enough.

Actuator gear greased has

problem.

Valve has jammed.

Limit siwtch adjusting

has gone off.

Gears turn useless.

Manuel handwheel’s shaft has

broken down.

Valve shaft has broken down. Valve shaft must be changed.

Gears turn useless.

Wiring scheme must be

checked.

Motor windings must be

checked with Megger Test.

Supply voltage and insurance

must be checked.

Valve shaft must be

greased.

Gears must be geared with

proper one.

Valve maintenance must be

repeated.

Limit switches must be checked

and must be adjusted again

if it necessary.

Stripped gears must be

changed with proper one

Broken shaft must be changed

with proper one.

Stripped gears must be

changed with proper ones.

7. PRODUCT SPARE PARTS

Electrical actuators’ spare parts are;

• Gears

• Motor

• Electronic Control Cards

• Position Indicator

• AC-DC Converter

You must choose spare parts according to your actuator model. For supplying spare

parts and detailed information please contact to SMS TORK.

www.smstork.com

19

Page 20

8. GENERAL CARE, REPAIR AND CLEANING

The device must be checked by the user before used. All cables must be checked for breakage, crushing, cracking etc; whether device’s connections are applicable according to

use manual; whether taking protection for leakage. Before cleaning the device, cut off the

electricity. Use soft cleaning solution and dry cloth. Do not use abrasive materials.

8. PRODUCT SHIPMENT

During transportation be careful about electrical actuator’s not falling down and not being

subjected hard knocks. Don’t put any weight damaging the product on electrical actuator

boxes. Electrical actuators must be carried on their carton boxes.

9. WARRANTY CONDITIONS

1) The period of warranty shall start from the date of delivery of the product to the

customer and shall cover a period of 2 years.

2) Every and all parts of the product are under SMS Sanayi Malzemeleri Üretim ve Satışı

A.Ş. warranty coverage. (against any defect that may occur during production, assembly

and/or defective parts)

3) In the case that the product fails within warranty period, the time spent on the repair

work is added to the warranty period. Repair time of the product is maximum 20 (twenty)

working days. This time starts from the date on which the failure concerning the product

is notified to the service station and to seller of the product, dealer, agency, representative,

importer or producer. It is possible to make the consumer failure notification by telephone,

fax, e-mail, registered mail or similar. However, in case of disagreement, the obligation of

proof belongs to the consumer.

4) Product replacement or refund is mandatory depending on the choice of the consumer

in case one of the conditions below:

a) If failure occurs in the product at least four times in one year or six times with the

condition of being within the warranty period.

b) If the maximum time for its repair is exceeded.

c) In case a service station is not exist by a report issued by seller, dealer, agency,

representative, importer or producer respectively that, repair of the failure is not possible,

exchange process will be carried out free of charge.

d)The warranty period of the products changed during the warranty condition is limited

20

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

Page 21

to the remaining warranty period of the purchased products.

5)Free repair and product exchange obligations will be annulled under the following

conditions:

a) If the product becomes faulty due to use contrary to the terms or conditions stated in

the user guide,

b) If the product serial number has been altered or removed

c)The warranty labels have been destroyed,

d) If the product has been opened, used, or previously repaired by unauthorized persons,

e) Use of the product by plugging into inappropriate voltages or with faulty electric

installation without the prior knowledge of our authorized services,

f) If the fault or damage to the product occurred during the transportation outside of the

responsibility of SMS Sanayi Malzemeleri Üretim ve Satışı A.Ş.,

g) When our product is damaged due to use with accessories or devices purchased from

other firms or unauthorized services,

h) Those damages caused by natural disasters such as fire, lightning, flood, earthquake, etc.

6) A report prepared by the SMS Sanayi Malzemeleri Üretim ve Satışı A.Ş. will determine

whether the damage was caused by improper use.

7) The warranty certificate should be kept throughout the warranty period. The customer

must provide the warranty certificate during request for repair. Otherwise, the cost of

repair will be charged.

8) The warranty certificate attached to the product during sale should be fully completed

by the retailer and customer, signed and stamped. The customer copy must be

immediately provided to the customer, followed by the other piece to be mailed out to

SMS Sanayi Malzemeleri Üretim ve Satışı A.Ş. by the retailer.

9) In the case when you send the product via courier, please remember to add a

description your complaint, the photocopy of your warranty certificate, your address and

telephone number.

10) For possible problems which may arise concerning the warranty certificate, it can be

applied to the Ministry of Customs and Trade, Directorate General of Consumer Protection

and Market Surveillance.

www.smstork.com

21

Page 22

SECTOR

LEADER WITH

30 YEARS

EXPERIENCE

22

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

Page 23

Page 24

HEAD OFFICE Bostancı Yolu Cad. Kuru Sok. No:16 Y. Dudullu, 34776 Ümraniye İstanbul - TURKEY P +90 216 364 34 05 F +90 216 364 37 57

FACTORY İMES O.S.B.S Cad. No:5 Çerkesli - Dilovası KOCAELİ - TURKEY P +90 262 290 20 20 F +90 262 290 20 21

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti

www.smstork.com/SMSTORK /sms-tork

KUL45-TREAE.001 / 09.11.2018 / REV.01-EN

Loading...

Loading...