Page 1

www.smstork.com

valve & automation

JUNE 2018

PLEASE READ THE INSTRUCTIONS BEFORE USE

PNEUMATIC ACTUATORS

USER MANUAL

Page 2

CONTENTS

1. GENERAL DESCRIPTION OF THE EQUIPMENT ..................................................................................................3

a. Intended Use Of The Equipment ................................................................................................................................3

b. Product Coding System ....................................................................................................................................................4

c. Exploded Drawings and Part Lists ............................................................................................................................5

d. General Features ........................................................................................................................................................................9

e. Warning Signs and Labeling ..........................................................................................................................................14

2. OPERATION OF THE EQUIPMENT ..............................................................................................................................15

a. Operation of Double Acting Actuators ...............................................................................................................15

b. Operation of Spring Return Actuators ..............................................................................................................16

c. Operation of 3 Position Actuator ...............................................................................................................................17

3. INSTALLATION OF THE EQUIPMENT.......................................................................................................................18

a. Mounting the Actuator to Valve Assembly .....................................................................................................18

b. Stroke Adjustment ..............................................................................................................................................................20

c. Mounting the Namur Solenoid to Actuator Assembly..............................................................................21

d. Mounting the Switch Box to Actuator Assembly........................................................................................22

e. Mounting the Position Indicator to Actuator Assembly..............................................................................22

f. Ground Connection ..............................................................................................................................................................23

g. Actuator Supply Condition ...........................................................................................................................................23

4. SAFETY MANUAL ................................................................................................................................................................... 24

5. FUNCTIONAL SAFETY RELEVANT SPECIFICATIONS ........................................................................... 25

6. OPERATION AND MAINTENANCE ......................................................................................................................... 26

4. WARRANTY CONDITION .............................................................................................................................................28

5. EXCLUSIONS OF WARRANTY (USAGE DEFECTS) ..................................................................................28

6. WARRANTY CERTIFICATE .............................................................................................................................................29

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

valve & automation

Page 3

1. GENERAL DESCRIPTION OF THE EQUIPMENT

a. Intended Use Of The Equipment

TORK Pneumatic Actuators are powerful, reliable and compact double rack pinion units for use with ball, butterfly and plug valves

and any device requiring accurate fast or slow or proportional 90 ° turn motion. TORK Pneumatic Actuators are manufactured

7 different sizes both double acting and single acting spring return type. Besides standard manufacturing program, optionally

pneumatic actuators can be manufactured with ± %10 stroke adjustable, 180° turn and 3- position types (open, half open, closed).

Any power operated device used to operate a valve. The device is designed to operate using motive energy which may be electrical,

pneumatic, hydraulic, etc., or a combination of these. Movement is limited by travel, torque or thrust Pneumatic Actuator is an

automatic control device which open and close the rotating valves with the help of compressed air.

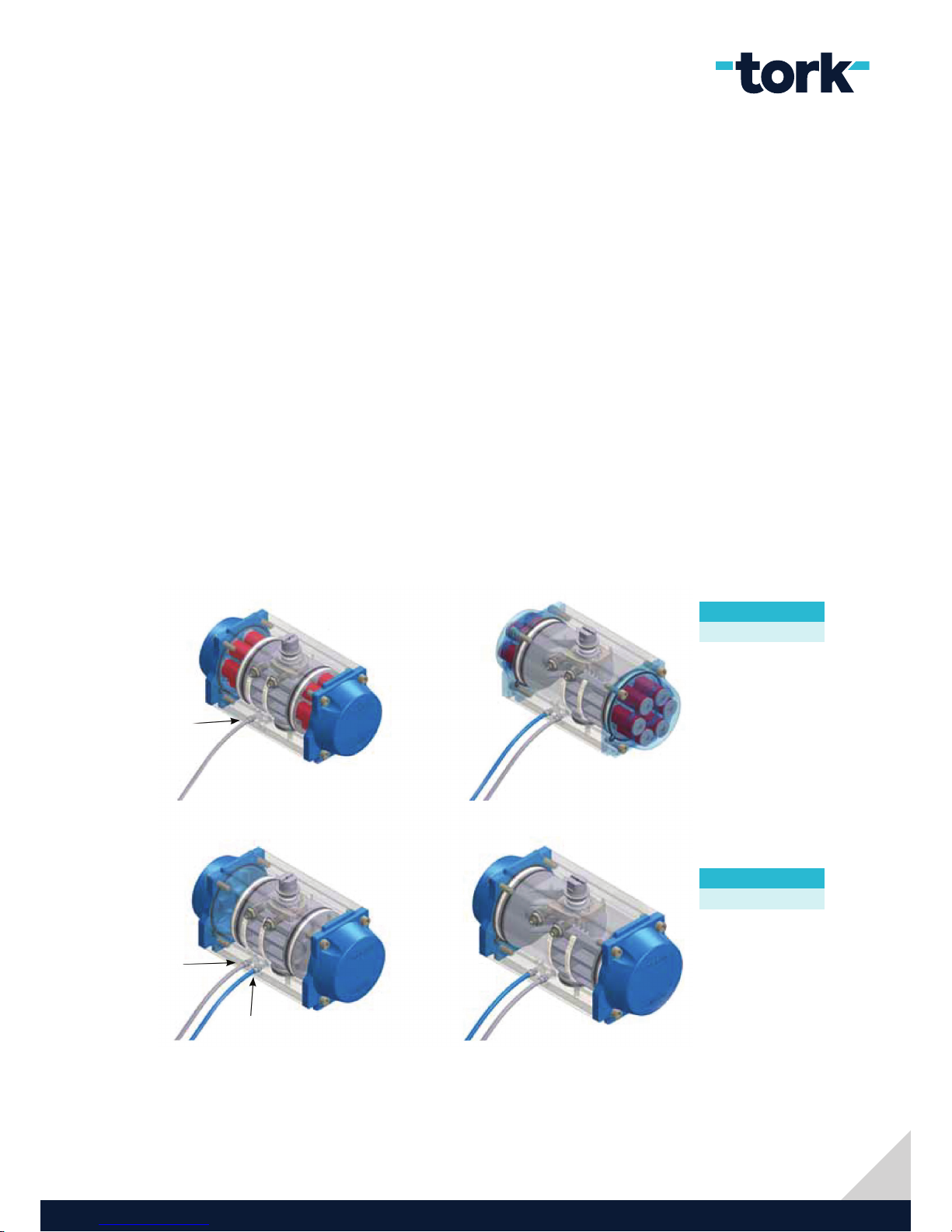

Pneumatic Actuators can be separated into two general groups: 1- Spring Return Actuators. 2- Double Acting Actuators. In Spring

Return Actuators (Fig 1) the opening operation is done by pressurized air and the closing is done by springs. In Double Acting

Actuators (Fig 2) opening and closing operations both are done by pressurized air.

Pneumatic actuators are using in different piping systems to open or close the valves. This equipment also

related to the fluids, flow in the pipes can be used in explosive regions(ZONE I).

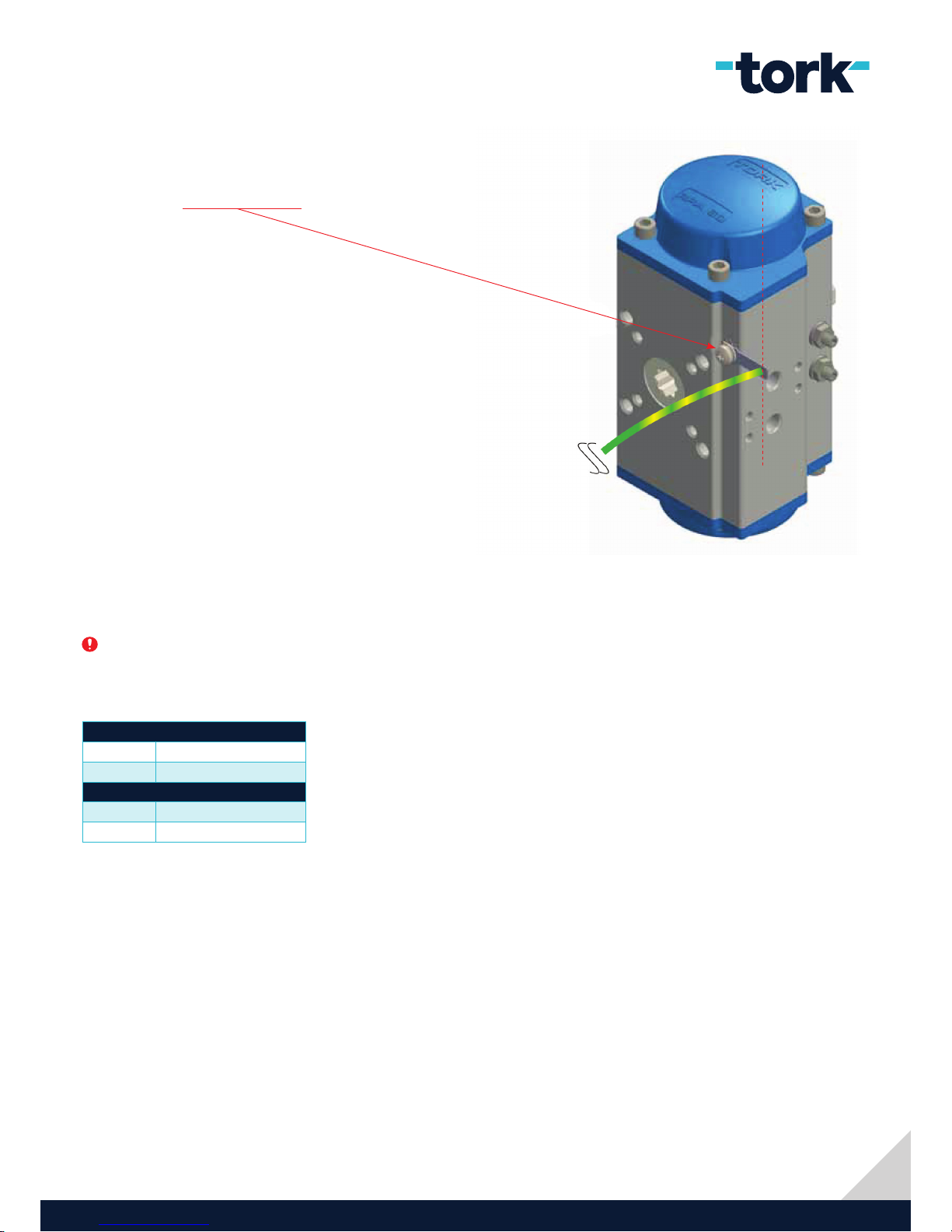

Fig 1. Spring Return Actuators

Pressurized

Pressurized

Non Pressurized

Non Pressurized

Fig 2. Double Acting Actuators

CLOSE

Port A

Port A and Port B

Port A and Port B

Port A

Port B

OPEN

OPEN

CLOSE

www.smstork.com

3

valve & automation

Page 4

b. Product Coding System

EXTERNAL FLANGE CONNECTION

Single Flange 000

Ø 50 050

Ø 70 070

Ø 102 102

Ø 140 140

INTERNAL FLANGE CONNECTION

Ø 36 036

Ø 42 042

Ø 50 050

Ø 70 070

Ø 102 102

Ø 125 125

Ø 140 140

Ø 165 165

SQUARE HEAD DIMENSION

09 17 36

11 22

14 27

BODY DIMENSION

032 080 143 350

040 100 160 400

060 120 200 270

SPECIFICATION

RA STANDARD

RX EXPROOF

TYPE

SR SPRING RETURN

DA DOUBLE ACTING

3 P 3 POSITION

8 D 180

0

C TURN

2 D 120

0

C TURN

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

4

valve & automation

Page 5

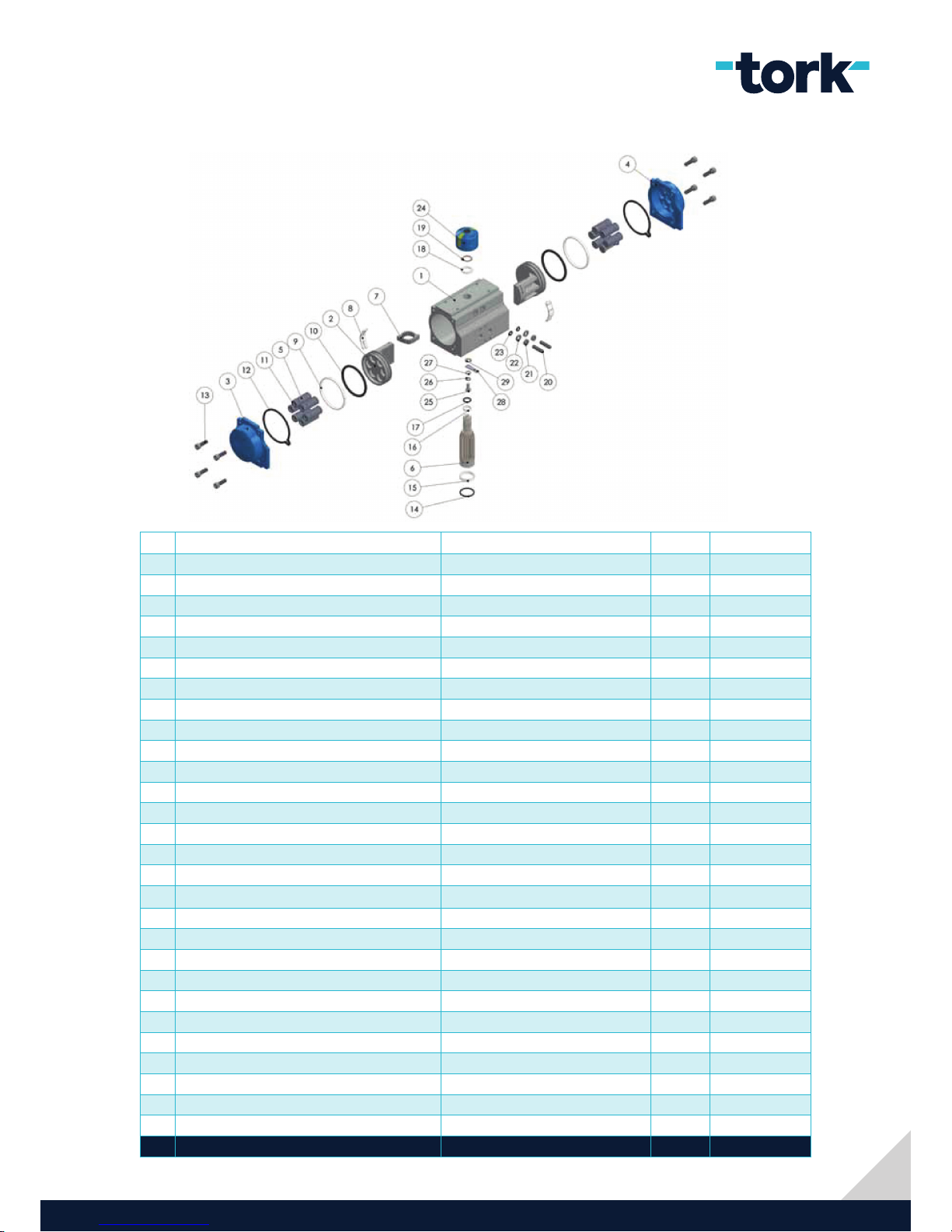

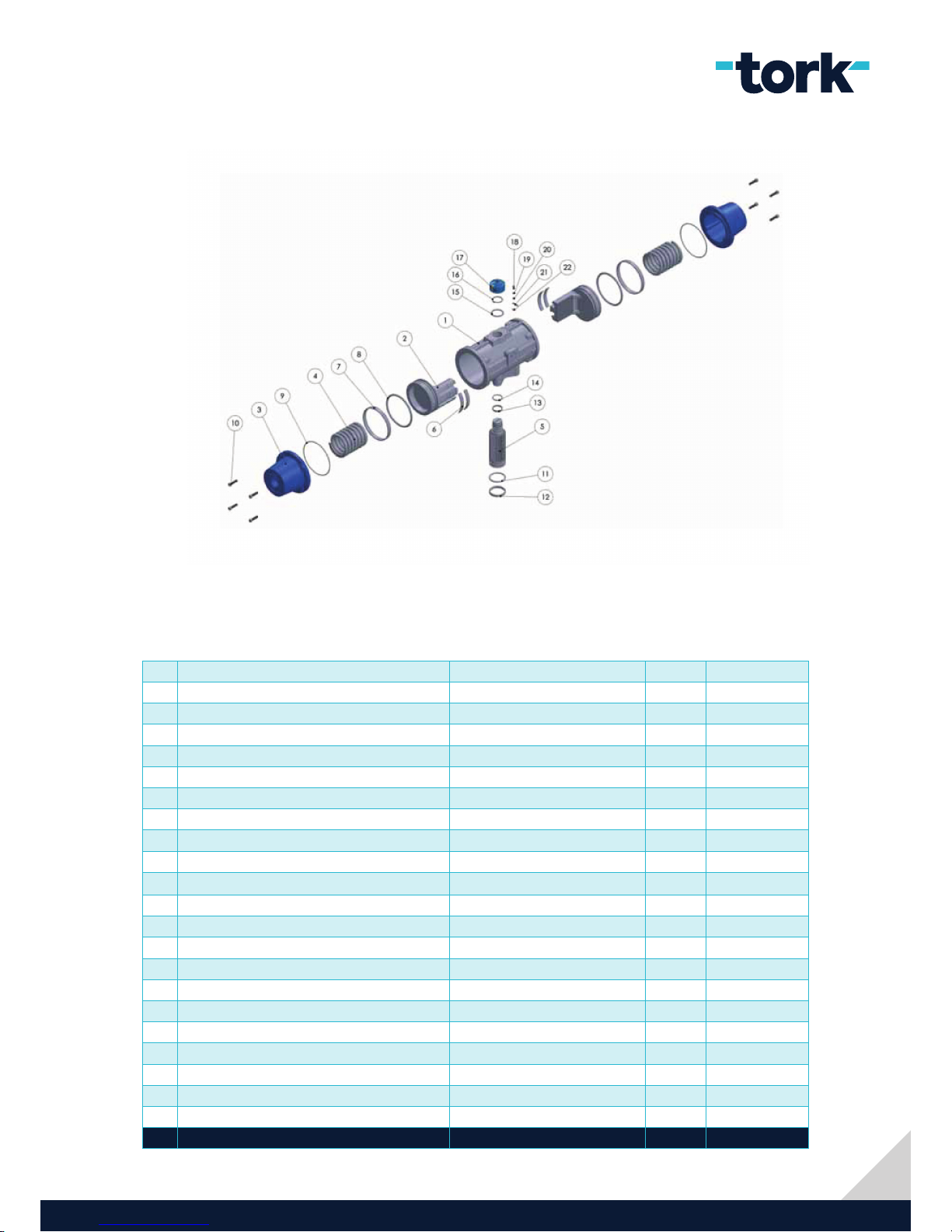

c. Exploded Drawings and Part Lists

29 SERRATED LOCK WASHER DIN 6798 M5 STAINLESS STEEL NOS 1

28 GROUND CONNECTOR BRASS NOS 1

27 WASHER DIN 125 M5 STAINLESS STEEL NOS 1

26 SPRING WASHER DIN 6799 M5 STAINLESS STEEL NOS 1

25 BOLT DIN 7985 M5X16 STAINLESS STEEL NOS 1

24 INDICATOR ABS NOS 1

23 O-RING (STOP SET SCREW) NITRILE (NBR 70) NOS 2

22 STOP SET SCREW WASHER DIN 125 M6 STAINLESS STEEL NOS 2

21 STOP NUT DIN 934 M6 STAINLESS STEEL NOS 2

20 STOP SET SCREW DIN 916 M6X25 STAINLESS STEEL NOS 2

19 SPRING CLIP (PINION) DIN 471/15 STEEL ALLOY NOS 1

18 THRUST BEARING (PINION) POLYPHTALAMIDE NOS 1

17 O-RING (PINION TOP) NITRILE (NBR 70) NOS 1

16 BEARING (PINION TOP) POLYPHTALAMIDE NOS 1

15 BEARING (PINION BOTTOM) POLYPHTALAMIDE NOS 1

14 O-RING (PINION BOTTOM) NITRILE (NBR 70) NOS 1

13 COVER BOLT DIN 912 M5X16 STAINLESS STEEL NOS 8

12 O-RİNG (COVER) NITRILE (NBR 70) NOS 2

11 SPRING HOLDER POLYPROPLYLENE + GF NOS min.5 / max.12

10 O-RING (PISTON) NITRILE (NBR 70) NOS 2

9 BEARING (PISTON SLIDING) POLYPHTALAMIDE NOS 2

8 BEARING (PISTON BACK) POLYPHTALAMIDE NOS 2

7 CAM (STOP ARRANGEMENT) STAINLESS STEEL NOS 1

6 PINION STEEL ALLOY NOS 1

5 SPRING HIGH ALLOY SPRING STEEL NOS min.5 / max.12

4 COVER RIGHT DIE CAST ALUMINIUM NOS 1

3 COVER LEFT DIE CAST ALUMINIUM NOS 1

2 PISTON DIE CAST ALUMINIUM NOS 2

1 BODY EXTRUDED ALUMINIUM ALLOY NOS 1

No Part Name Material Unit Quantity

Tab 1. Part list of Spring Return Actuators (RA032-RA040-RA060-RA080-RA100-RA120)

Fig 3. Exploded drawing of Spring Return Actuators

(RA032-RA040-RA060-RA080-RA100-RA120)

www.smstork.com

5

valve & automation

Page 6

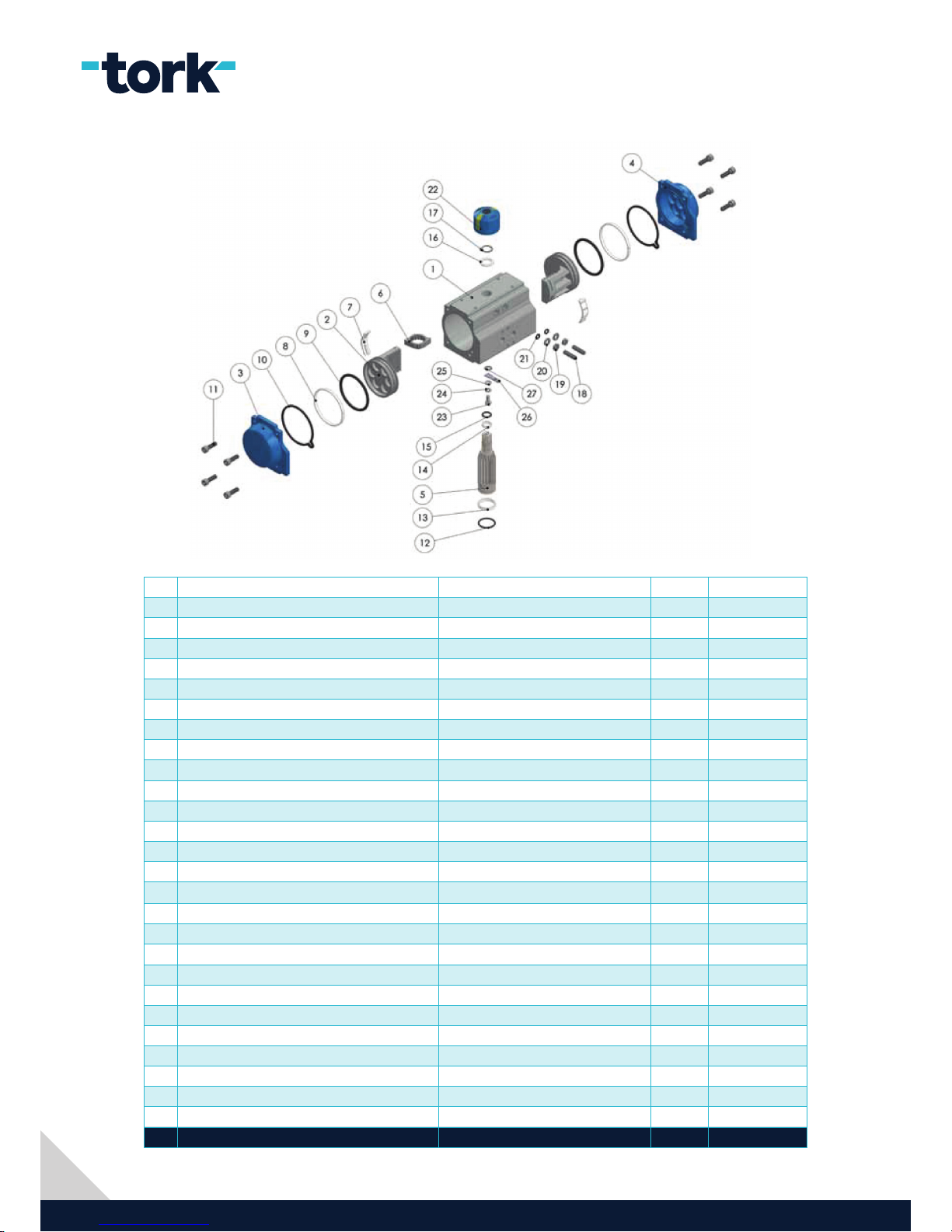

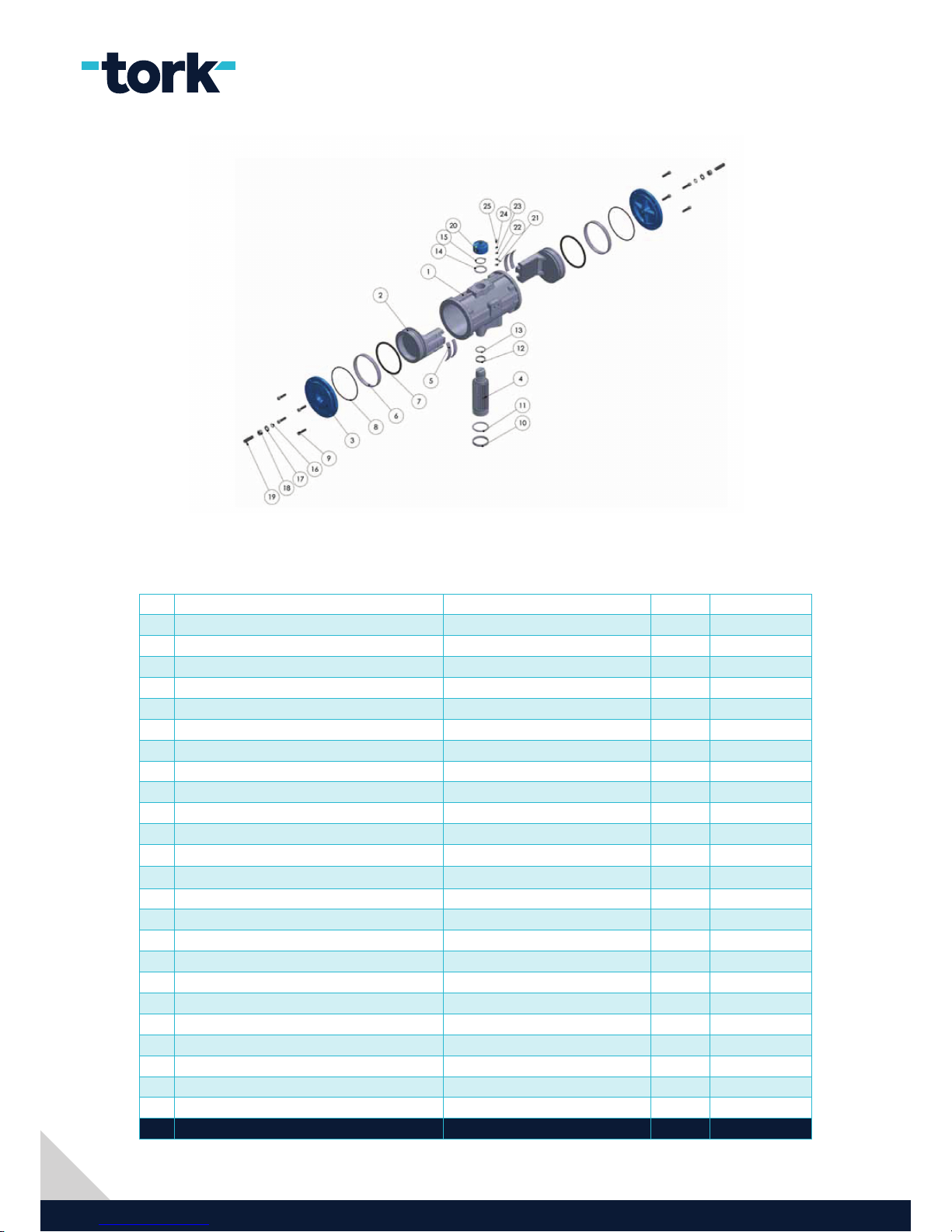

c. Exploded Drawings and Part Lists

27 SERRATED LOCK WASHER DIN 6798 M5 STAINLESS STEEL NOS 1

26 GROUND CONNECTOR BRASS NOS 1

25 WASHER DIN 125 M5 STAINLESS STEEL NOS 1

24 SPRING WASHER DIN 6799 M5 STAINLESS STEEL NOS 1

23 BOLT DIN 7985 M5X16 STAINLESS STEEL NOS 1

22 INDICATOR ABS NOS 1

21 O-RING (STOP SET SCREW) NITRILE (NBR 70) NOS 2

20 STOP SET SCREW WASHER DIN 125 M6 STAINLESS STEEL NOS 2

19 STOP NUT DIN 934 M6 STAINLESS STEEL NOS 2

18 STOP SET SCREW STAINLESS STEEL NOS 2

17 SPRING CLIP (PINION) DIN 471/15 STEEL ALLOY NOS 1

16 THRUST BEARING (PINION) POLYPHTALAMIDE NOS 1

15 O-RING (PINION TOP) NITRILE (NBR 70) NOS 1

14 BEARING (PINION TOP) POLYPHTALAMIDE NOS 1

13 BEARING (PINION BOTTOM) POLYPHTALAMIDE NOS 1

12 O-RING (PINION BOTTOM) NITRILE (NBR 70) NOS 1

11 COVER BOLT DIN 912 M5X16 STAINLESS STEEL NOS 8

10 O-RİNG (COVER) NITRILE (NBR 70) NOS 2

9 O-RING (PISTON) NITRILE (NBR 70) NOS 2

8 BEARING (PISTON SLIDING) POLYPHTALAMIDE NOS 2

7 BEARING (PISTON BACK) POLYPHTALAMIDE NOS 2

6 CAM (STOP ARRANGEMENT) STAINLESS STEEL NOS 1

5 PINION STEEL ALLOY NOS 1

4 COVER RIGHT DIE CAST ALUMINIUM NOS 1

3 COVER LEFT DIE CAST ALUMINIUM NOS 1

2 PISTON DIE CAST ALUMINIUM NOS 2

1 BODY EXTRUDED ALUMINIUM ALLOY NOS 1

No Part Name Material Unit Quantity

Tab 2. Part list of Double Acting Actuators (RA032-RA040-RA060-RA080-RA100-RA120)

Fig 4. Exploded drawing of Double Acting

Actuators (RA032-RA040-RA060RA080-RA100-RA120)

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

6

valve & automation

Page 7

c. Exploded Drawings and Part Lists

22 SERRATED LOCK WASHER DIN 6798 M5

STAINLESS STEEL NOS

1

21 GRAUND CONNECTOR

BRASS NOS

1

20 WASHER DIN 125 M5

STAINLESS STEEL NOS

1

19 SPRING WASHER DIN 6799 M5

STAINLESS STEEL NOS

1

18 BOLT DIN 7985 M5X16

STAINLESS STEEL NOS

1

17 INDICATOR ABS

NOS

1

16 SPRING CLIP (PINION) DIN 471/38

STEEL ALLOY NOS

1

15 THRUST BEARING (PINION)

POLYPHTALAMIDE NOS

1

14 O-RING (PINION TOP) NITRILE

NOS

1

13 BEARING (PINION TOP)

POLYPHTALAMIDE NOS

1

12 BEARING (PINION BOTTOM)

POLYPHTALAMIDE NOS

1

11 O-RING (PINION BOTTOM) NITRILE

NOS

1

10 COVER BOLT DIN 912 M8X35 PASLANMAZ ÇELİK

NOS

8

9 O-RING (COVER) NITRILE

NOS

2

8 O-RING (PISTON) NITRILE

NOS

2

7 BEARING (PISTON SLIDING)

POLYPHTALAMIDE NOS

2

6 BEARING (PISTON BACK)

POLYPHTALAMIDE NOS

2

5 PINION

STEEL ALLOY NOS

1

4 SPRING HIGH ALLOY SPRING STEEL

NOS

2

3 COVER CASTING ALUMINIUM

NOS

2

2 PISTON CASTING ALUMINIUM

NOS

2

1 BODY CASTING ALUMINIUM ALLOY

NOS

1

No

Part Name Material Unit Quantity

Tab 3. Part list of Spring Return Actuators (RA143-RA160-RA200-RA400)

Fig 5. Exploded drawing of Spring

Return Actuators (RA143-RA160-RA200RA400)

www.smstork.com

7

valve & automation

Page 8

c. Exploded Drawings and Part Lists

25 BOLT

STAINLESS STEEL NOS

1

24 SPRING WASHER

STAINLESS STEEL NOS

1

23 WASHER

STAINLESS STEEL NOS

1

22 GROUND CONNECTOR

BRASS NOS

1

21 SERRATED LOCK WASHER

STAINLESS STEEL NOS

1

20 INDICATOR ABS

NOS

1

19 O-RING (STOP SET SCREW)

NITRILE NOS

2

18 STOP SET SCREW WASHER

STAINLESS STEEL NOS

2

17 STOP NUT

STAINLESS STEEL NOS

2

16 STOP SET SCREW

STAINLESS STEEL NOS

2

15 SPRING CLIP (PINION)

STEEL ALLOY NOS

1

14 THRUST BEARING (PINION)

POLYPHTALAMIDE NOS

1

13 O-RING (PINION TOP)

NITRILE NOS

1

12 BEARING (PINION TOP)

POLYPHTALAMIDE NOS

1

11 BEARING (PINION BOTTOM)

POLYPHTALAMIDE NOS

1

10 O-RING (PINION BOTTOM)

NITRILE NOS

1

9 COVER BOLT

STAINLESS STEEL NOS

8

8 O-RİNG (COVER)

NITRILE NOS

2

7 O-RING (PISTON)

NITRILE NOS

2

6 BEARING (PISTON SLIDING)

POLYPHTALAMIDE NOS

2

5 BEARING (PISTON BACK)

POLYPHTALAMIDE NOS

2

4 PINION

STEEL ALLOY NOS

1

3 COVER

DIE CAST ALUMINIUM NOS

2

2 PISTON

DIE CAST ALUMINIUM NOS

2

1

BODY EXTRUDED ALUMINIUM ALLOY NOS

1

No

Part Name Material Unit Quantity

Tab 4. Part list of Double Acting Actuators (RA143-RA160-RA200-RA400)

Şekil 6. Çift Etkili Aktüatör patlamış

resmi (RA143-RA160-RA200-RA400

RA270-RA350)

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

8

valve & automation

Page 9

d. General Features

• High performance

• High cycle life (1.000.000 operation)

• High torque value

• Standard position indicator

• For quarter turn valve automation (9Nm - 5162Nm)

• One compact design for double and single acting models

• Dual piston rack and pinion

• According to international standards (NAMUR, ISO5211)

• Body: Extruded aluminium

• Piston & Caps: Die cast aluminium

• 90˚ turn, two external travel stop adjustment ±5%

• 100% adjustable travel stop (on request)

Pressure : Double acting: 2.5 bar .... 8 bar

Single acting : 4 bar .... 8 bar

Temperature : Standard -20˚C ..... 80˚C

On request -20˚C ..... 150˚C, -30˚C .... 80˚C

• TORK Pneumatic actuators have been manufactured since 1986

• Lubrication : All moving parts are factory lubricated

• On request; exproof model (II 2G EEx c IIB T4)

Anodized Body

(Standard)

Epoxy Coated

Body

Nickel Coated

Body

PTFE Coated Body

100% Adjustable

on request

e. Design Features of TORK RA Serie Actuators

1) Actuator Body Aluminium extruded and honed surface body. Internal and external parts corrosion protected

2) Indicator It is standard on all actuators, it shows visual position of valve

3) Cover Provide max. resistance against corrosive elements, same cap design for double and single types actuators

4) Travel Adjustment Permits adjustment of ± 5% in both directions

5) Springs Springs provide high performance in safe emergency shutdown operation. Cartridge design & corrosion resistant

6) Bearing & Piston Guides High cycle life,wide operation temperature range,lubricating provide high performance

7) Nuts & Bolts Stainless steel body. Provide long term corrosion resistance.

8) Piston Rack and Pinion Provides wear resistance and protect against corrosion. Die cast pistons anodized aluminium fitted with

high quality seals and guides.

9) Connections

• Solenoid valves, switch box, positioners: Namur VDI/VDE 3845

• Bottom valve connection: ISO5211, DIN3337 standard

www.smstork.com

9

valve & automation

Page 10

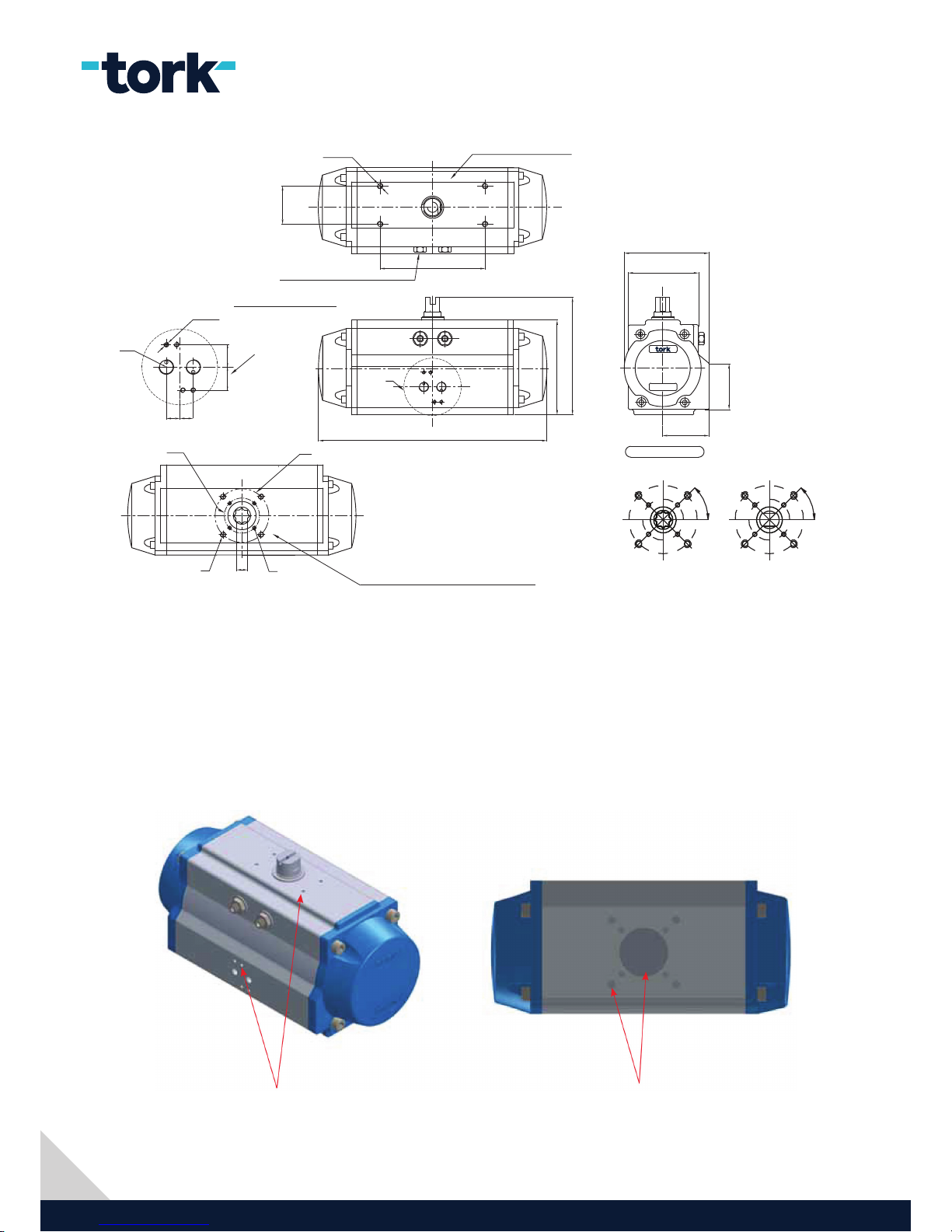

Fig 8. General Dimensions of TORK Actuators

VDI/VDE 3845 (NAMUR) ISO 5211

Interface for accessories according

to VDI/VDE 3845

Star Square

(General Application)

Connection according to ISO5211/DIN3337

DETAIL A2

Namur Valve

A2

A

B

R

Connection According to

VDI/VDE 3845

Namur Standard

(Mountaing for

Solenoid Valves)

12 12

H

L

N

K

J

Oval Square

(On Request)

BOTTOM VIEW

Manual Stroke Adjusment

M

M5x8

1616

D

C

O

P

45

0

45

0

DA

M5XE

F

G

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

10

valve & automation

Page 11

Tab 8. General Dimensions of 180° Turn Actuators

Interface for accessories according

to VDI/VDE 3845

Star Square

(General Application)

Connection according to ISO5211/DIN3337

DETAIL A2

Namur Valve

A2

A

B

R

Connection According to

VDI/VDE 3845

Namur Standard

(Mountaing for

Solenoid Valves)

12 12

H

L

N

K

J

Oval Square

(On Request)

BOTTOM VIEW

Manual Stroke Adjusment

M

M5x8

1616

D

C

O

P

45

0

45

0

DA

M5XE

F

G

RA/RX/RAM 270 SR

RA/RX/RAM 200 SR

RA/RX/RAM 160 SR

RA/RX/RAM 143 SR

RA/RX/RAM 350 DA

RA/RX/RAM 200 DA

RA/RX/RAM 160 DA

RA/RX/RAM 143 DA

RA/RX/RAM 120 DA/SR

RA/RX/RAM 100 DA/SR

RA/RX/RAM 80 DA/SR

RA/RX/RAM 75 DA/SR

RA/RX/RAM 60 DA/SR

RA/RX/RAM 52 DA/SR

RA/RX/RAM 40 DA/SR

RA/RX/RAM 32 DA

775.5

680

558

514

586.3

458

374

342

360.0

282.0

242.0

242.0

172.6

172.6

137.2

98

354

268

216

190

440

268

216

190

160.0

130.0

116.9

116.9

85.2

85.2

70.0

45

-

242

202

182

-

242

202

182

116.2

95.0

91.8

91.8

62.0

62.0

52.0

45

330

242

202

182

440

242

202

182

150.0

121.0

109.2

109.2

82.7

82.7

70.6

-

8

8.0

8.0

8.0

8

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

130

80.0

80.0

80.0

130

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

50

30

30.0

30.0

30.0

30

30.0

30.0

30.0

30.0

30.0

30.0

30.0

30.0

30.0

30.0

25

-

M16

M10

M10

-

-

M10

M10

M8

M8

M6

M6

M5/M6

M5/M6

M5

M5

M20

M20

M16

M16

M20

M20

M16

M16

M10

M10

M8

M8

M8

M8

M6

-

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/8"

1/8"

1/8"

1/8"

1/8"

1/8"

46/55

36

22/27

22/27

46

36

22/27

22/27

17/22

17

14

14

9/11/14

9/11/14

9/11

9

-

121

101

91

-

121

101

91

82.0

61.0

54.8

54.8

47.0

47.0

45.0

-

-

121

101

91

-

121

101

91

87.2

65.0

58.3

58.3

47.0

47.0

39.7

-

384

288

236

210

470

288

236

210

190.0

160.0

136.9

136.9

105.2

105.2

90.0

76

-

-

F10

F10

-

-

F10

F10

F07

F07

F05

F05

F04/F05

F04/F05

F03/F04

F03

F16

F14/F16

F14

F14

F16

F14/F16

F14

F14

F10

F10

F07

F07

F07

F07

F05

-

165

140/165

140

140

165

140/165

140

140

102.0

102.0

70.0

70.0

70.0

70.0

-

-

-

-

102

102

-

-

102

102

70

70

50

50

42/50

42/50

36/42/50

36

ACTUATOR MODELS

DIMENSIONS (mm)

A B C ED F G H J K L M N O P R

ISO

FLANGE

FOR H

ISO

FLANGE

FOR J

RA/RX/RAM 350 SR 866.5 440 - 440 8 130 30 - M20 1/4" 46 - - 470 - F16165-

Tab 6. General Dimensions of TORK Actuators

RA / RAM 120.2D

RA / RAM 100.2D

RA / RAM 80.2D

RA / RAM 60.2D

RA / RAM 40.2D

400

329

275

197.6

143.7

160

130

117

85.2

70

116.2

95

91.8

62

52

150

121

109

82.7

70.6

8

8

8

8

8

80

80

80

80

80

30

30

30

30

30

M8

M8

M6

M5/M6

M5

M10

M10

M8

M8

M6

1/4"

1/4"

1/8"

1/8"

1/8"

17/22

17

14

9/11/14

9/11

82

61

55

47

45

87.2

65

58

47

40

190

160

137

105

90

F07

F07

F05

F04/F05

F03/F04

F10

F10

F07

F07

F05

102

102

70

70

-

70

70

50

42/50

36/42/50

ACTUATOR MODELS

DIMENSIONS (mm)

A B C ED F G H J K L M N O P R

ISO

FLANGE

FOR H

ISO

FLANGE

FOR H

Aktüatör Alt Bağlantı (Küresel, Kelebek, Plug Vana)

ISO/DIN 3337 Standardına göre

Namur Solenoid Vana

Bağlantı

VDI/VDE 3845

Namur Standardına göre

Aktüatör üst (Switch box, pozisyoner) bağlantı

VDI/VDE 3845 Standartlı

El Strok Ayarı

Yıldız Köşeli Bağlantı

(Genel Uygulama)

Oval Köşeli Bağlantı

(İstek Üzerine)

A

DETAY A

K

J

N H

L

M

M5XE

G

M5X8

1616

D

O

R

B

C

P

A

F

45

0

45

0

DA

12 12

Tab 7. General Dimensions of 120° Turn Actuators

Interface for accessories according

to VDI/VDE 3845

Star Square

(General Application)

Connection according to ISO5211/DIN3337

DETAIL A2

Namur Valve

A2

A

B

R

Connection According to

VDI/VDE 3845

Namur Standard

(Mountaing for

Solenoid Valves)

12 12

H

L

N

K

J

Oval Square

(On Request)

BOTTOM VIEW

Manual Stroke Adjusment

M

M5x8

1616

D

C

O

P

45

0

45

0

DA

M5XE

F

G

RA/RX/RAM 270 SR SR

RA/RX/RAM 200 SR 6.41SR

RA/RX/RAM 32 DA

ACTUATOR MODELS Air Volume Opening (L) Air Volume Closing (L)

Opening Time (sec.)

DA 0.03 0.02 0.1 0.1 0.4

RA/RX/RAM 160 SR SR 3.25

RA/RX/RAM 143 SR SR 2.85

RA/RX/RAM 350 DA DA 25

RA/RX/RAM 200 DA 6.41DA

RA/RX/RAM 160 DA 3.25DA

RA/RX/RAM 143 DA 2.85DA

RA/RX/RAM 120 DA/SR 1.61

DA

SR

RA/RX/RAM 100 DA/SR 0.73

RA/RX/RAM 80 DA/SR 0.50

RA/RX/RAM 75 DA/SR 0.50

RA/RX/RAM 60 DA/SR

RA/RX/RAM 52 DA/SR

RA/RX/RAM 40 DA/SR

DA

SR

DA

SR

DA

SR

DA

SR

0.17

DA

SR

0.95

1.15

0.52

0.63

0.39

0.48

0.39

0.48

0.27

0.33

0.27

0.33

1.15

1.47

0.63

0.95

0.48

0.57

0.48

0.57

0.33

0.38

0.33

0.38

9.60

11.40

4.90

6.10

3.80

4.40

3.80

4.40

1.70

1.80

1.70

1.80

0.17

DA 0.22 0.26

SR

0.09

0

0

0

19.40

5.50

2.56

1.95

4.80

3.80

3.20

5.20

3.40

2.60

2.40

4.40

3.50

3.00

4.90

3.20

2.30

2.20

45.90

26.80

17.60

125.00

33.40

19.10

13.00

2.45

1.15

0.79

0.79

0.28

0.28

0.16

0.26 0.34

0.85

1.02

Closing Time (sec.)

Approximate Weigt (kg)

RA/RX/RAM 270 SR

RA/RX/RAM 200 SR

RA/RX/RAM 160 SR

RA/RX/RAM 143 SR

RA/RX/RAM 350 DA

RA/RX/RAM 200 DA

RA/RX/RAM 160 DA

RA/RX/RAM 143 DA

RA/RX/RAM 120 DA/SR

RA/RX/RAM 100 DA/SR

RA/RX/RAM 80 DA/SR

RA/RX/RAM 75 DA/SR

RA/RX/RAM 60 DA/SR

RA/RX/RAM 52 DA/SR

RA/RX/RAM 40 DA/SR

RA/RX/RAM 32 DA

775.5

680

558

514

586.3

458

374

342

360.0

282.0

242.0

242.0

172.6

172.6

137.2

98

354

268

216

190

440

268

216

190

160.0

130.0

116.9

116.9

85.2

85.2

70.0

45

-

242

202

182

-

242

202

182

116.2

95.0

91.8

91.8

62.0

62.0

52.0

45

330

242

202

182

440

242

202

182

150.0

121.0

109.2

109.2

82.7

82.7

70.6

-

8

8.0

8.0

8.0

8

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

130

80.0

80.0

80.0

130

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

50

30

30.0

30.0

30.0

30

30.0

30.0

30.0

30.0

30.0

30.0

30.0

30.0

30.0

30.0

25

-

M16

M10

M10

-

-

M10

M10

M8

M8

M6

M6

M5/M6

M5/M6

M5

M5

M20

M20

M16

M16

M20

M20

M16

M16

M10

M10

M8

M8

M8

M8

M6

-

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/8"

1/8"

1/8"

1/8"

1/8"

1/8"

46/55

36

22/27

22/27

46

36

22/27

22/27

17/22

17

14

14

9/11/14

9/11/14

9/11

9

-

121

101

91

-

121

101

91

82.0

61.0

54.8

54.8

47.0

47.0

45.0

-

-

121

101

91

-

121

101

91

87.2

65.0

58.3

58.3

47.0

47.0

39.7

-

384

288

236

210

470

288

236

210

190.0

160.0

136.9

136.9

105.2

105.2

90.0

76

-

-

F10

F10

-

-

F10

F10

F07

F07

F05

F05

F04/F05

F04/F05

F03/F04

F03

F16

F14/F16

F14

F14

F16

F14/F16

F14

F14

F10

F10

F07

F07

F07

F07

F05

-

165

140/165

140

140

165

140/165

140

140

102.0

102.0

70.0

70.0

70.0

70.0

-

-

-

-

102

102

-

-

102

102

70

70

50

50

42/50

42/50

36/42/50

36

ACTUATOR MODELS

DIMENSIONS (mm)

A B C ED F G H J K L M N O P R

ISO

FLANGE

FOR H

ISO

FLANGE

FOR J

RA/RX/RAM 350 SR 866.5 440 - 440 8 130 30 - M20 1/4" 46 - - 470 - F16165-

RA/RX/RAM 350 SR SR 25 0 6.20 5.30 155

13.75 0 5.3 4.75 68

Tab 8. Special Dimensions of TORK Actuators

RA 120.8D

RA 100.8D

RA 80.8D

RA 60.8D

RA 40.8D

481

402

333

241.6

178.2

160

130

117

85.2

70

116.2

95

91.8

62

52

150

121

109

82.7

70.6

8

8

8

8

8

80

80

80

80

80

30

30

30

30

30

M8

M8

M6

M5/M6

M5

M10

M10

M8

M8

M6

1/4"

1/4"

1/8"

1/8"

1/8"

17/22

17

14

9/11/14

9/11

82

61

55

47

45

87.2

65

58

47

40

190

160

137

10

90

F07

F07

F05

F04/F05

F03/F04

F10

F10

F07

F07

F05

102

102

70

70

-

70

70

50

42/50

36/42/50

ACTUATOR MODELS

DIMENSION (mm)

A B C ED F G H J K L M N O P R

ISO

FLANGED

FOR H

ISO

FLANGE

FOR J

www.smstork.com

11

valve & automation

Page 12

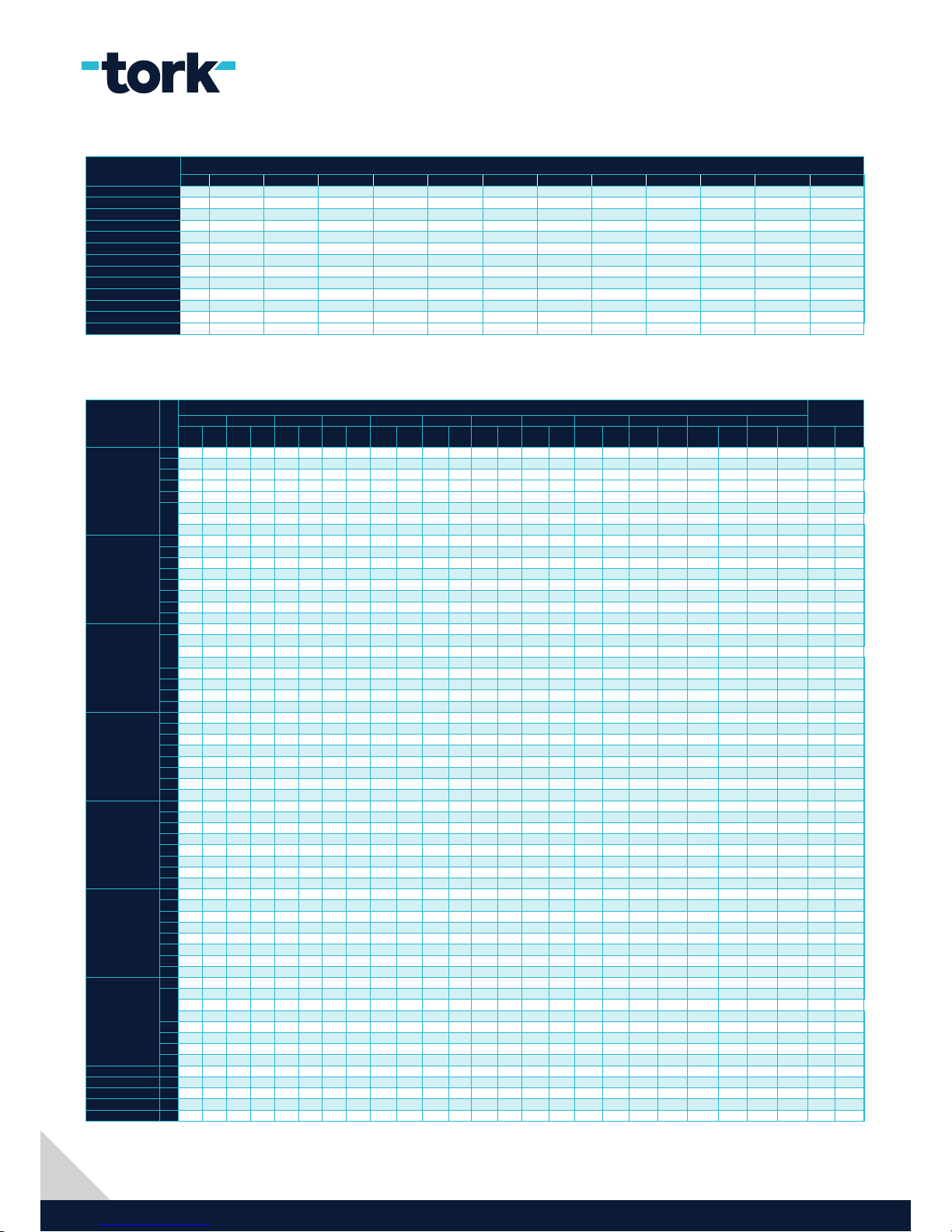

2 3 4 5 6 7 8

5,5 7,0 8,5

13,0 16,1 19,3

14,4 17,9 21,5

9,9 11,4 12,9 14,4

22,5 25,6 28,8 32,0

25,0 28,5

35,7 44,0 52,2

39,7 48,9 58,0

65,4 80,1 94,9

124,9 152,5 180,2

60,4 68,7

32,0 35,5

9

15,8

35,1

39,0

10

17,3

38.3

11

18,8

44,1

42.5 46,1

76,9 85,1 93,3 101,6

67,1 76,3

109,6 124,4

207,9 235,6

85,4 94,6 103,7

139,2 153,9 168,7

263,2 290,2 318,6

240,0 288,0 336,0 385,0 433,0 480,0 529,0 578,0

321,0 385,0 450,0 510,0 576,0

628,0 752,0 878,0 1000,0 1127,0

1234,88 1493,13 1751,39 2009,64 2267,89

642,0 705,0 765,0

112,9

183,4

346,3

109,8

12

13

20,3

44,6

49,6

118,0

122,0

198,2

373,9

626,0 674,0

833,0 897,0

131,2

21,7

47,8

53,1

126,3

140,3

213,0 227,7

401,6 439,3

722,0 770,0

963,0 1024,0

1252,0 1377,0 1500,0 1630,0 1752,0 1880,0 2005,0

2526,14 2784,40 3042,65 3300,90 3559,15 3817,41 4075,66

MODEL

Operating Pressure(bar)

RA/RX/RAM 32 DA

RA/RX/RAM 40 DA

RA/RX/RAM 52 DA

RA/RX/RAM 60 DA

RA/RX/RAM 75 DA

RA/RX/RAM 80 DA

RA/RX/RAM 100 DA

RA/RX/RAM 120 DA

RA/RX/RAM 143 DA

RA/RX/RAM 160 DA

RA/RX/RAM 200 DA

RA/RX/RAM 270 DA

2124,0 2558,0 2992,0 3426,0 3860,0 4294,0 4728,0 5162,0 5596,0 6030,0 6464,0 6898,0

RA/RX/RAM 350 DA

2,5 bar 3 bar

3,5 bar 4 bar 4,5 bar 5 bar 5,5 bar 6 bar 6,5 bar 7,5 bar

8 bar

7 bar

Tablo 11. TORK Tek Etkili Aktüatörlerin Tork Değerleri (N.m)

Tab 10. Double Acting Actuator Torque Ratings (Nm)

1385,6 207,2 1819,6 641,2 2253,5 1075,1 2687,5 1509,1 3121,4 1943,1

1181,08 643,02 1439,33901,27 1697,58 1159,521955,84 1417,78

3555,4

2214,09

2377,0

1617,03

3989,4 2811,0 4423,3

2472,34 1934,28 2730,59

3245,0

2192,53

4857,3 3678,9

2988,85 2450,79

234,8 588,7 359,8 713,7 484,8 836,7 607,8 966,7 737,8 1088,7

116,7 358,7 182,7 421,7 245,7 481,7 305,7 49,7 373,7 613,7

85,3 264,5 132,3 313,5 181,3 362,5 230,3 410,5 275,3 458,4

922,83 384,77

74,7 41,1

83,1

41,4

24,5

22,0 9,3

10,3

24,0

55,1

336,7 107,8 463,7

226,7 50,7 292,7

169,5 37,3 217,5

107,6 40,4 135,3 68,1 162,9 95,7 190,6 123,4 218,3 151,1 246,0 178,8 273,7

116,0 54,3 143,6 82,0 171,3 109,7 199,0 137,4 226,7 165,1 254,3 192,7 282,0

85,7 40,9 113,3 68,5 141,0 96,2 168,7 123,9 196,4 151,6 224,1 179,2 251,7 206,9 279,4 234,6 307,1

96,6 40,6 124,3 68,3 152,0 96,0 179,7 123,7

207,3 151,3 235,0 179,0 262,7 206,7 290,4

105,0 54,6 132,7 82,3 160,3 109,9 188,0 137,6 215,7 165,3 243,4 193,0 271,0 220,6 298,7

54,8 121,7 82,5 149,4 110,2 177,1 137,9 204,7 165,5 232,4 193,2 260,1 220,9 287,8 248,6 315,4

96,5 157,7 124,1 185,4 151,8 213,1 179,5 240,8 207,2 268,4 234,8 296,1 262,5 323,8

193,8 165,8 221,4 193,4 249,1 221,1 276,8 248,8 304,5 276,5 332,2

66,9 25,2 81,7 39,9 96,4 54,7 111,2 69,4 126,0 84,2 140,7

859,8

437,7

326,3

206,4

220,4

262,3

234,4

248,3

276,2

290,2

304,1

99,0

1216,7

679,7

506,5

301,3

309,7

334,8

318,0

326,4

343,1

351,5

359,8

155,5

987,8

503,7

374,3

234,1

248,1

290,0

262,0

276,0

303,9

1341,7

740,7

554,5

329,0

337,4

362,4

345,7

354,1

370,8

1112,8

564,7

422,3

261,8

275,8

317,6

289,7

303,7

331,6

317,9

331,8

113,7

71,7 33,4 86,5 48,2 101,2 62,9 116,0 77,7 130,7 92,5 145,5

68,8 130,1

82,7 138,4 110,4 166,1

61,7 26,9 76,5 41,7 91,3 56,5 106,0 71,2 120,8 86,0 135,5 100,7 150,3

138,1

51,8 20,4 66,5 35,2 81,3 50,0 96,0 64,7 110,8 75,5 125,6 94,2 140,3 109,0 155,1

56,6 28,7 71,3 43,5 86,1 58,2 100,8 73,0 115,6 87,8 130,4 102,5 145,1 117,3 159,9

22,2 61,3 37,0 76,1 51,7 90,9 66,5 105,6 81,3 120,4 96,0 135,1 110,8 149,9 125,5 164,7

61,1 45,2 80,9 60,0 95,7 74,8 110,4 89,5 125,2 104,3 139,9 119,1 154,7 133,8 169,5

100,4 83,0 115,2 97,8 130,0 112,6 144,7 127,3 159,5 142,1 174,2

48,8 14,8 58,0 24,0 67,1 33,1 76,3 42,3 85,4

51,9 20,7 61,0 29,9 70,2 39,0 79,3 48,1 88,5

45,8 17,5 54,9 26,6 64,1 35,7 73,2 44,9 82,4 54,0 91,5

48,8 23,3 58,0 32,5 67,1 41,6 76,3 50,8 85,4 59,9 94,6

51,9 29,2 61,0 38,4 70,2 47,5 79,3 56,7 88,5 65,8 97,6

107,2

115,5

123,8

132,0

140,3

148,6

156,8

51,4

57,3

63,2

69,1

74,9

160,3

165,1

169,8

174,6

179,4

184,2

189,0

94,6

97,6

100,7

103,7

106,8

122,0

130,3

138,5

146,8

155,1

163,3

379,1

387,5

170,2

175,0

179,8

184,6

189,4

194,2

199,0

345,5

359,5

128,5

136,7

145,0

153,3

161,6

169,8

178,1

171,6

60,6

66,4

72,3

78,2

84,1

54,9 35,1 64,1 44,2 73,2 53,4 82,4 62,5 91,5 71,7 100,7

30,5

38,8 70,9 53,5 85,7 68,3

42,7 20,1

16,8 45,8 26,036,7

39,7 22,7 48,8 31,8 58,0 41,0 67,1 50,1 76,3 59,3 85,4 68,4 94,6 77,6

94,0

102,4

110,7

46,6

51,4

56,2

33,6

30,2

12,3

11,1

4,7

RA/RX/RAM 350 SR

RA/RX/RAM 270 SR

RA/RX/RAM 200 SR

RA/RX/RAM 160 SR

RA/RX/RAM 143 SR

RA/RX/RAM

120 SR

RA/RX/RAM

100 SR

RA/RX/RAM

80 SR

RA/RX/RAM

75 SR

RA/RX/RAM

60 SR

RA/RX/RAM

52 SR

RA/RX/RAM

40 SR

MODEL

2,5 bar 3,5 bar3 bar 4 bar 4,5 bar 5 bar 5,5 bar 6 bar 6,5 bar 7 bar 7,5 bar 8 bar

Yay Tork

Değeri

Operating Pressure (bar)

0

0

Start

90

0

End

0

0

Start

90

0

End

0

0

Start

90

0

End

0

0

Start

90

0

End

0

0

Start

90

0

End

0

0

Start

90

0

End

0

0

Start

90

0

End

0

0

Start

90

0

End

0

0

Start

90

0

End

0

0

Start

90

0

End

0

0

Start

90

0

End

0

0

Start

90

0

End

0

0900

19,4 42,8 28,6 51,9 37,7 61,0 46,9 70,2 56,0 79,3 65,2 88,5 74,3 97,6 83,4

41,2 15,7 49,4 23,9 57,7 32,2 65,9 40,4 74,1 48,6

46,7 18,6 54,9 26,9 63,2 35,1 71,4 43,3

44,0 13,3 52,2 21,6 60,4 29,8 68,6 38,0

44,0 21,0 52,2 29,2 60,4 37,5 68,7 45,7 76,9 53,9

46,7 26,3 54,9 34,5 63,2 42,8 71,4 51,0 79,6 59,238,5 18,1

15,1 41,2 23,4 49,4 31,6 57,7 39,8 65,9 48,1 74,1 56,3 82,4 64,5

17,5 38,5 25,7 46,7

16,0

17,1

34,0 54,9 42,2 63,2 50,4 71,4 58,6 79,6 66,9 87,9 75,1

22,1 7,2 25,6 10,7 29,1 14,3

19,7 6,1 23,2 9,6 26,7 13,1 30,2 16,6

17,3 4,9 20,8 8,4 24,3 11,9 27,8 15,5 31,3 19,0

18,4 7,3 21,9 10,8 25,4 14,3 29,0 17,8 32,5 21,3

6,1 19,5 9,6 23,0 13,1 26,6 16,7 30,1 20,2 33,6 23,7

8,5 20,6 12,0 24,2 15,5 27,7 19,0 31,2 22,5 34,7 26,0

35,7 20,4 44,0 28,7 52,2 36,9 60,4 45,1 68,7 53,3 76,9 61,6 85,1 69,8

103,7

106,8

82,4

79,6

76,9

85,1

87,9

90,6

93,3

33,0

6,1 15,9 9,7 19,4

14,4

15,4

16,4 9,7

7,6

5,5

13,2 22,9 16,7 26,4 20,2 29,9 23,7 32,3 27,2 36,9 30,8

19,9 6,5 23,0 9,7 26,2 12,8

17,7 5,5 20,9 8,6 24,0 11,8 27,2 14,9

15,6 4,4 18,7 7,6 21,9 10,7 25,0 13,9 28,2 17,1

19,7 9,7 22,9 12,9 26,1 16,0 29,2 19,2

20,7 11,8 23,9 15,0 27,1 18,1 30,2 21,3

16,6 6,5

17,6 8,7

18,6 10,8 21,7 13,9 24,9 17,1 28,1 20,3 31,2 23,4

19,6 12,9 22,8 16,1 25,9 19,2 29,1 22,4 32,2 25,6

20,6 15,0 23,8 18,2 26,9 21,4 30,1

24,5 33,2 27,7

8,8 2,9 10,3 4,4 11,7 5,9

29,4

30,4

31,4

32,4

33,4

34,4

35,4

36,4

13,2

7,8 2,4 9,3 3,9 10,7 5,4 12,2 6,8

8,2 3,4 9,7 4,8 11,2 6,3 12,7 7,8

7,2 2,8 8,7 4,3 10,2 5,8 11,7 7,3 13,1 8,7

7,7 3,8 9,2 5,3 10,6 6,7 12,1 8,2 13,6 9,7

4,5

14,7 7,3 18,2 10,8 21,8 14,3 25,3 17,9 28,8 21,4 32,3 24,9 35,8 28,4

96,1

32,6

80,8

86,7

92,6

56,9

51,6

46,3

62,2

67,4

72,7

78,0

83,3

17,8

109,8

112,9

115,9

90,6

87,9

85,1

93,3

96,1

98,8

101,6

104,3

36,1

90,0

95,9

101,7

203,8

103,7

106,8

109,8

112,9

115,9

119,0

122,0

125,1

186,4

69,7

75,6

81,5

87,3

93,2

99,1

105,0

110,9

65,1

59,8

54,5

70,4

75,7

81,0

86,3

91,6

21,3

98,8

96,1

93,3

101,6

104,3

107,1

109,8

112,5

39,7

73,3

68,0

62,7

78,6

83,9

89,2

94,5

99,8

24,8

33,7

34,9

36,0

37,1

38,2

40,5

39,3

16,0

18,1

20,2

22,4

24,5

20,1

22,5

24,8

27,2

29,6

34,3

31,9

32,5

33,5

34,5

35,5

36,6

97,3

38,4

39,5

40,6

41,7

44,0

42,9

19,2

21,3

23,4

25,5

27,6

23,6

26,0

28,4

30,7

33,1

37,8

35,4

35,7

36,7

40,8

41,9

43,0

44,1

45,2

47,5

46,4

22,3

24,4

27,2

29,5

31,9

34,2

36,6

41,3

38,9

13,6 4,9

5,5 14,3 8,7 17,4 11,9

6,2 2,3

6,7 3,3 8,2 4,7 9,6 6,2 11,1 7,7 12,6 9,2 14,1 10,6

5,7 2,7 7,1 4,2 8,6 5,7 10,1 7,2 11,6 8,6 13,1 10,1 14,5 11,6

13,3 6,6

12,3

2,2 6,1 3,7 7,6 5,2 9,1 6,6 10,6 8,1 12,0 9,6 13,5 11,1 15,0 12,5

13,7

14,1

14,6

15,1

15,5

16,0

16,5

26,6

28,7

30,8

7,4

8,3

9,3

10,2

11,2

12,1

13,1

14,0

37,6

38,6

39,6

14,7

15,2

15,6

16,1

16,6

17,0

17,5

17,9

29,8

31,9

34,0

8,8

9,8

10,7

37,7

38,7

39,7

40,7

41,7

42,7

16,2

16,6

17,1

26,6

28,7

30,8

32,9

35,0

37,2

10,3

11,3

12,2

11,7

12,6

13,6

14,5

15,5

17,6

18,0

18,5

19,0

19,4

13,2

14,1

15,1

16,0

17,0

3129,2

1568,49

663,3

283,3

215,5

154,0

140,0

98,1

126,0

112,1

84,2

70,2

56,3

90,8

82,5

74,2

66,0

57,7

49,4

41,2

32,9

65,0

59,0

53,0

47,0

41,0

35,0

29,0

23,0

47,7

53,1

58,5

42,3

36,9

31,5

26,1

20,7

25,1

22,8

20,4

18,1

15,7

22,6

20,5

13,3

8,6

11,0

18,4

16,3

14,1

12,0

9,9

7,8

9,5

8,6

7,6

6,7

5,7

4,8

3,8

2,9

1950

1030,43

892,2

459,3

347,7

86,8

78,4

53,3

70,0

61,7

45,0

36,6

28,3

49,0

44,2

39,4

34,6

29,9

25,1

20,3

15,5

31,0

28,0

24,0

21,0

18,0

15,0

12,0

9,0

21,6

25,2

27,9

18,9

16,2

13,5

10,8

8,1

10,3

9,2

8,0

6,9

5,8

9,2

4,7

2,4

3,6

8,2

7,2

6,2

5,2

4,2

3,2

2,2

3,7

3,2

2,8

2,3

1,8

1,4

0,9

0,4

2,42,4

S02

S02

S02

S02

S02

S12

S11

S10

S9

S8

S7

S6

S5

S12

S11

S10

S9

S8

S7

S12

S11

S10

S9

S8

S7

S6

S5

S6

S5

S12

S11

S10

S9

S8

S7

S6

S5

S12

S11

S10

S9

S8

S7

S6

S5

S12

S11

S10

S9

S8

S7

S6

S5

S12

S11

S10

S9

S8

S7

S6

S5

Spring No

2 3 4 5 6 7 8

5,5 7,0 8,5

13,0 16,1 19,3

14,4 17,9 21,5

9,9 11,4 12,9 14,4

22,5 25,6 28,8 32,0

25,0 28,5

35,7 44,0 52,2

39,7 48,9 58,0

65,4 80,1 94,9

124,9 152,5 180,2

60,4 68,7

32,0 35,5

9

15,8

35,1

39,0

10

17,3

38.3

11

18,8

44,1

42.5 46,1

76,9 85,1 93,3 101,6

67,1 76,3

109,6 124,4

207,9 235,6

85,4 94,6 103,7

139,2 153,9 168,7

263,2 290,2 318,6

240,0 288,0 336,0 385,0 433,0 480,0 529,0 578,0

321,0 385,0 450,0 510,0 576,0

628,0 752,0 878,0 1000,0 1127,0

1234,88 1493,13 1751,39 2009,64 2267,89

642,0 705,0 765,0

112,9

183,4

346,3

109,8

12

13

20,3

44,6

49,6

118,0

122,0

198,2

373,9

626,0 674,0

833,0 897,0

131,2

21,7

47,8

53,1

126,3

140,3

213,0 227,7

401,6 439,3

722,0 770,0

963,0 1024,0

1252,0 1377,0 1500,0 1630,0 1752,0 1880,0 2005,0

2526,14 2784,40 3042,65 3300,90 3559,15 3817,41 4075,66

MODEL

Operating Pressure(bar)

RA/RX/RAM 32 DA

RA/RX/RAM 40 DA

RA/RX/RAM 52 DA

RA/RX/RAM 60 DA

RA/RX/RAM 75 DA

RA/RX/RAM 80 DA

RA/RX/RAM 100 DA

RA/RX/RAM 120 DA

RA/RX/RAM 143 DA

RA/RX/RAM 160 DA

RA/RX/RAM 200 DA

RA/RX/RAM 270 DA

2124,0 2558,0 2992,0 3426,0 3860,0 4294,0 4728,0 5162,0 5596,0 6030,0 6464,0 6898,0

RA/RX/RAM 350 DA

2,5 bar 3 bar 3,5 bar 4 bar 4,5 bar 5 bar 5,5 bar 6 bar 6,5 bar 7,5 bar

8 bar

7 bar

Double Acting Torque Rating (N.m)

Spring Return Torque Rating (N.m)

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

12

valve & automation

Page 13

Fig 9. General Dimensions of 3 Position Actuators

Tab 12. General Dimensions of 3 Position Actuators

Tab 13. General Dimensions of 3 Position 180° Actuators

RA / RAM 120.3P

RA / RAM 100.3P

RA / RAM 80.3P

RA / RAM 60.3P

RA / RAM 40.3P

400

329

275

197.6

143.7

160

130

117

85.2

70

116.2

95

91.8

62

52

150

121

109

82.7

70.6

8

8

8

8

8

80

80

80

80

80

30

30

30

30

30

M8

M8

M6

M5/M6

M5

M10

M10

M8

M8

M6

1/4"

1/4"

1/8"

1/8"

1/8"

17/22

17

14

9/11/14

9/11

82

61

55

47

45

87.2

65

58

47

40

190

160

137

105

90

F07

F07

F05/F07

F04/F05/F07

F03/F04/F05

102

102

70

70

-

70

70

50

42/50

36/42/50

RA

318,6

168,7

94,6

39

15,8

NM

Dimensions (mm)

Type/Order

Number

P: 6 bar

Toque

A B C ED F G H J K L M N O P R

ISO 5211

Flange

Yıldız Köşeli Bağlantı

(Genel Uygulama)

45

0

ALT GÖRÜNTÜ

458,5

347

263

116,9

85.2

70

91,8

62

52

109.2

82.7

70.6

8

8

8

80

80

80

30

30

30

M6

M5/M6

M5

M8

M8

M6

1/8"

1/8"

1/8"

14

9/11/14

9/11

54,8

47

45

58

47

40

136,9

105

90

F05/F07

F04/F05/F07

F03/F04/F05

70

70

-

50

42/50

36/42/50

94.6

39

15.8

Nm

Dimensions (mm)

P: 6 bar

Torque

A B C ED F G H J K L M N O P R

ISO 5211

Flange

RA / RAM 80.8P

RA / RAM 60.8P

RA / RAM 40.8P

RA

Type/Order

Number

RA / RAM 120.8P

RA / RAM 100.8P

585

550

160

130

116,295150

1218880803030

M8M8M10

M10

1/4"

1/4"

17/2217826187.265190

160

F07/F10

F07/F10

102

102

70

70

318

168

12

16 16

M5X8

M5XE

Namur Solenoid

Valve Connection

VDI/VDE 3845

According to Namur

Standard

Actuator Bottom Connection

(Ball, Butterfly, Plug Valve)

According to ISO/DIN 3337

Standard

Actuator Upper (Switch

box, positioner) Con

nection

VDI/VDE 3845 Standard

DETAIL A

M

K

N

HJ

A

A

G

F

B

B

R

L

12

D

C

P

www.smstork.com

13

valve & automation

Page 14

e. Warning Signs and Labeling

Pneumatic connections should be disconnected before any intervention.

Refer to the instruction manual before any intervention.

As pneumatic actuator can be used efficiently after 500.000 unpacking and packing, oring kits of product should be replaced.

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

14

valve & automation

Page 15

2. OPERATION OF THE EQUIPMENT

a. Operation of Double Acting Actuators

Inline position

Across position

Port A: Pressurized to open the valve. Actuator rotates CCW for opening.

Port B: Pressurized for close the valve. Actuator rotates CW for closing.

Before connect the actuator

and valve to the piping system,

check the position of the valve

and the actuator pinion

Before connect the actuator

and valve to the piping system,

check the position of the valve

and the actuator pinion

Port A: Pressurized to open the valve. Actuator rotates CCW for opening.

Port B: Pressurized for close the valve. Actuator rotates CW for closing.

www.smstork.com

15

valve & automation

Page 16

b. Operation of Spring Return Actuators

Inline position

Before connect the actuator

and valve to the piping system,

check the position of the valve

and the actuator pinion

Port A: Pressurized to open the valve. Actuator rotates CCW for opening.

Port A: Non-Pressurized and springs made their jobs for closing the valve. Actuator rotates CW for closing.

Port A: Pressurized to open the valve. Actuator rotates CCW for opening.

Port A: Non-Pressurized and springs made their jobs for closing the valve. Actuator rotates CW for closing.

Across position

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

16

valve & automation

Page 17

c. Operation of 3 Position Actuator

In order to operate the 3 position actuator, can be benefited from the 3/2 solenoid valve. (Figure 10)

a) Mounting: Fortriple 3/2 solenoid valve; the valve with number 1 should be connected to A port, the valve with number 2 to B port

and the valve with number 3 to C port.

b) Operating:

1) Pressure air is given to air input port.

2) The coil with number 1 is powered. In this way, the actuator turns 90° and switches to fully open position.

3) The coil with number 3 is powered and the power of coil with number 1 is shut off. In this way actuator is half closed. Half closed

position can be regulated between 30-60°.

4) The coil with number 2 is powered and the power of coil with number 3 is shut off. In this way actuator is fully closed.

Air Input

Setting Mechanism

2

B

3

C

1

A

Fig 10. 3 position actuator

www.smstork.com

17

valve & automation

Page 18

3. INSTALLATION OF THE EQUIPMENT

a. Mounting the Actuator to Valve Assembly

Inline position

I. Adjust the valve to closed position by usinga wrench.

II. Do not use hammer for adjusting the valve shaft.

III. Mount the bracket on valve by using

screws and nuts like in the picture. Place the

extension on valve piniondirectly.

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

18

valve & automation

Page 19

IV. When mounting the actuator pay attention to open

and close position of valve.

V. Mount the actuator to the valve with set

screw and nut by suitable tools.

Before connect the actuator

and valve to the piping system,

check the position of the valve

and the actuator pinion

www.smstork.com

19

valve & automation

Page 20

b. Stroke Adjustment

VI. Mount the actuator to the valve with

screw by suitable tools.

Double Acting Actuators (Open Position)

I. Connect the actuator to pressurized air

system. Give some pressure to “Port A” to open

the actuator.

II. Adjust the pistons to accurate position by

using wrench.

III. Turn the left set screw until an obstruction

is felt. Do not turn anymore and do not force it.

For lock the set screw use lock nut.

Double Acting Actuators (Close Position)

I. Connect the actuator to pressurized air

system. Give some pressure to “Port B” to close

the actuator.

II. Adjust the pistons to accurate position by

using wrench.

III. Turn the right set screw until an obstruction

is felt. Do not turn anymore and do not force it.

For lock the set screw use lock nut

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

20

valve & automation

Page 21

Spring Return Actuators (Open Position)

I. Connect the actuator to pressurized air

system. Give some pressure to “Port A” to

open the actuator.

II. Adjust the pistons to accurate position by

using wrench.

III. Turn the left set screw until an obstruction

is felt. Do not turn anymore and do not force

it. For lock the set screw use lock nut.

Spring Return Actuators (Close Position)

I. Release the pressure in “Port A”. Springs

would close the actuator.

II. Adjust the pistons to accurate position by

using wrench.

III. Turn the right set screw until an obstruction

is felt. Do not turn anymore and do not force

it. For lock the set screw use lock nut.

c. Mounting the Namur Solenoid

to Actuator Assembly

I. Mount the solenoid to the actuator with

socket head screw by suitable tools.

Note: To prevent the “water hammer”

connect the throttle valve(s) to the namur

solenoid exhaust(s) with suitable tool and

sealing. “Pressurized air discharge time can be

adjusted with throttle valve (s) thus the valves

Opening or Closing speed adjusted too.” For

this optional throttle valve, you should inform

us when ordering the pneumatic actuator.

Pneumatic connections should be

disconnected before any intervention.

For protection against potentially explosive

atmospheres use certified ex proof Namur

solenoid valves and “RX” code ex proof

pneumatic actuators.

www.smstork.com

21

valve & automation

Page 22

d. Mounting the Switch Box to

Actuator Assembly

I. Mount the switch box to the actuator with

set screw and nut by suitable tools.

e. Mounting the Position Indicator

to Actuator Assembly

I. Mount the position indicator to the

actuator with flat screw by suitable tool.

Before connect the actuator

and switch box, check the

position of the switch box and

the actuator pinion

Before connect the actuator

and switch box, check the

position of the switch box and

the actuator pinion

Pneumatic connections should be

disconnected before any intervention.

For protection against potentially explosive

atmospheres use certified ex proof switch box

and “RX” code exproof pneumatic actuators

Pneumatic connections should be

disconnected before any intervention.

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

22

valve & automation

Page 23

f. Ground Connection

In exproof models mount the main supply

ground cable socket (color code is yellow

green) to the ground connector on the

pneumatic actuator.

g. Actuator Supply Condition

Before connect the air system to actuator, use air filter, pressure, and oiler. For the accurate operation temperature and pressure

ranges are listed below. Responsibility for supply condition belonged to the user. For any damage on or in the pneumatic actuator

cause of different supply condition listed below, company has no responsibility. Service actions would be taken with a fee.

Recommended piping for the inlet and outlet pneumatic connections to the actuator of the device is PVC tubing. The length of tubing

between the deviceand the actuator shall be kept as short as possible and if possible free of kinks.

Only dry air filtered to 50 micron or better is recommended. The process air pressure shall meet the requirements. The process air

capacity shall be sufficient to move the valve actuator within the required time.

Double Acting 2,5 bar ... 8 bar

Single Acting 4 bar ... 8 bar

Standard

-20

0

C ... 80 0C

On Request

-20

0

C ... 150 0C or -30 0C ... 80 0C

PRESSURE (bar)

TEMPERATURE (0C)

www.smstork.com

23

valve & automation

Page 24

4) SAFETY MANUAL

This section provides necessary information for meeting the IEC 61508 functional safety standards and to design, install, verify and

maintain a Safety Instrumented Function (SIF).

4.1 Responsibilities for Safety

The safety of design and operation of a safety-related system, in which the device is implemented, must be ensured by manufacturer

and operator.

4.1.1 Responsibility of Manufacturer

• Safe design of the device

• Providing of all safety-related information to the operator of the overall system

• Compliance to all regulations and guidelines that allow a safe commissioning

4.1.2 Responsibility of Operator

• Instructing of personnel working on the overall system

• Maintaining the safe operation of the overall system

• Compliance to all regulations and guidelines regarding occupational safety

• Ensuring of periodic test of the overall system by qualified employees

4.2 Terms and Abbreviations

Tab 14. Terms and Abbreviations

FMEDA

Failure Modes, Effects and Diagnostic Analysis

HFT

Hardware Fault Tolerance

PFD

AVG

Average Probability of Failure on Demand

SFF

Safe Failure Fraction

SIL

Safety Integrity Level

Discrete level (one out of a possible four) for specifying the safety integrity require

ments of the safety functions to be allocated to the E/E/PE safety-related systems

where Safety Integrity Level 4 has the highest level of safety integrity and Safety

Integrity Level 1 has the lowest.

SIF

Safety Instrumented Function

A set of equipment intended to reduce the risk due to a specific hazard (a safety

loop), Safety instrumented control/protection function

SIS

Safety Instrumented System

Implementation system of one or more Safety Instrumented Functions. A SIS is

composed of any combination of sensor(s), logic solver(s), and final element(s).

DC

Diagnostic Coverage Factor

(if diagnostic measures exist)

PTC

Proof Test Coverage Factor

Names how many dangerous undetected failures can be detected during Proof

Test

PFH

Average Frequency of a dangerous failure per hour

MTBF

(D)

Mean Time between (dangerous) Failures

4.3 Related Standards

Functional safety as IEC 61508 Parts 1,2,4,7:2010 CMV Commented version

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

24

valve & automation

Page 25

Tab 15. Device specific parameters

5) FUNCTIONAL SAFETY RELEVANT SPECIFICATIONS

5.1 Application and Environmental Limits

The tested device is intended for media such as Gas and Fluid. The applicable fluid shall be clean and non-corrosive fluid.Required

Air-quality-level in accordance to ISO 8573-1: 7–1–4 for particles – water – oil. The tested device is rated up to 4 bars and up to 8 bars.

For the detailed materials of construction of tested device, please refer to user manual, operation instruction, maintenance instruction.

The pneumatic actuator is intended for use in Indoor, Outdoor and/or Hazardous Area (ATEX II 2GD c T4) at temperaturerange of

–20 °C to 80 °C.

5.2 SIL Capability

The actuators are suitable for use in a safety instrumented system up to SIL 2 (low demand mode). Under consideration of the minimum

required hardware fault tolerance HFT = 1 the actuators may be used in a redundant architecture up to SIL 3.The development and

manufacturing process and the functional safety management applied by the manufacturer in the relevant lifecycle phases of the

product has been inspected and assessed as suitable for the use in applications with a maximum Safety Integrity Level of 3 (SC 3).

5.3 Requirements Of Other Components

In order to determine whether tested device is suitable for use in a certain safety-related system, it is necessary to determine the

PFDavg value of the overall system. Usually it is presumed that a final element (valve + actuator) uses up to 50 % of the total available

PFDavg value.

Route of Assessment 2H / 1S

Type of Sub-system Type A

Mode of Operation Low Demand Mode

Hardware Fault Tolerance

HFT

0

Lambda Dangerous

confidence level of calculation 1-α = 95 %

λ

D

3.50 E-07/h 350 FIT

Lambda Dangerous Undetected

assumed Diagnostic Coverage DC = 0 %

λ

DU

3.50 E-07/h 350 FIT

Mean Time To Dangerous Failure

MTTFD

2.86 E+06 h 326 a

Average Probability of Failure on Demand 1oo1

assumed Proof Test Interval T1 = 1 year

PFD

avg (T1

)

1.53 E-03

Average Probability of Failure on Demand 1oo2

assumed Proof Test Interval T1 = 1 year

assumed β1oo2 = 10 %

PFD

avg (T1

)

1.53 E-04

www.smstork.com

25

valve & automation

Page 26

6) OPERATION AND MAINTENANCE

• It is recommended that pneumatic actuators are operated every 3 months in case of long-term storage and inactivity. This will

prevent the flexibility of the sealing equipment and prevent permanent deformations.

• The amount of oil in the body should be checked once a year in working products and piston and moving surfaces must be

lubricated with grease.

• All air inlets and outlets should be closed for prevent pollutants or abrasive substances from entering not only in the actuator but

also in all equipment such as directional control valves or locators. All openings, such as the power line to the junction boxes, must

also be closed.

• Use appropriate silencers on actuator or directional valves.

• Actuators should not be stored in an atmosphere which is harmful to the sealing material. If it is, closed warehouse must be

preferred.

• It is recommended to replace piston and shaft sealing and lining elements once every 2 years in working products.

• The air quality to be used for the actuator must be comply with ISO 8573-1: 7-4-4 (Particle - Water - Oil) standards.

6.1 Proof Test Interval

The objective of proof testing is to detect failures within the device that are not detected by any automatic diagnostics of the system.

Of main concern are undetected failures that prevent the SIF from performing its intended safety function.The proof tests must be

performed at every year. The suggested proof test consists of the steps as described in the table 3.

Proof test coverage factor (PTC) = 95 %

6.2 Maintenance

After five years a complete maintenance and overhauling should be performed. Within this procedure aged and worn components

should be changed. The device must be maintained inaccordance to Installation, Operation and Maintenance manual.Due to the

intensive proof the Maintenance Coverage Factor can be set to: MTC = 100 %

6.3 Repair and Replacement

Repair procedures in the device Installation, Operation and Maintenance manual must be followed. The SIL rating of the device may

be voided if the repair is not performed with OEM parts and serviced by unqualified personnel.

Step

Action

1

Bypass the safety function and take appropriate action to avoid a false trip

2

The actuator is brought to the half-open position.

3

Closing time and pressure values from both channels are measured

4

Pressure values from both channels are measured again after nearly 10 seconds have

elapsed.

5

Determined if there is any air leakage. Air leakage shows to determine if the actuator

is damaged or the seals are broken.

6

The actuator is brought to the full-open position. The opening time is measured

7

The opening and closing times show to determine if the actuator is jammed or normal.

8

Inspect the appliance and other last components for any leakage, visible damage or

contamination.

9

Record the test results and any failures in your company’s SIF inspection database

10

Remove the bypass and restore normal operation

Tab 16. Proof test

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

26

valve & automation

Page 27

6.4 Useful Lifetime

A time of usage of more than 5 years (+ 1.5 years of storage) can only be favored under responsibility of the operator, consideration

of specific external conditions, and adequate test cycles.If it is periodical maintenance and appropriate use, the useful life is ten years.

But the non-ageing-resistant parts must be replaced during periodical shutdown maintenance.

6.5 Manufacturer Notification

All faults must be reported to manufacturer for recording purposes, by contacting the Quality Department at address below. All

defective devices must be returned to manufacturer for investigation and rectification. A device Return and Service Report form

(available upon request, from the address below) must be completed and returned with the device.

www.smstork.com

27

valve & automation

Page 28

WARRANTY CONDITIONS

1. If there is a fault caused by the production, the manufacturer will repair or replace the defective product in its sole discretion.

2. The warranty period is two (2) years and starts from the date of delivery of the product to consumers.

3. All products, including all sub-parts, covered by our warranty.

4. The maximum repair time is one (1) month and starts from the products’ arrival date to SMS factory.

5. Within the warranty period, both in material and workmanship, as well as in case of manufacturing defects, products will be

repaired without any charge under any name (labor costs, or the cost of replaced parts).

6. During the warranty period, provided that the products will be exchanged free of charge if the fault is sourced by production.

7. Damages caused by the using of the product contrary to the points listed in the operating instructions are excluded from warranty

coverage.

8. If there are complaints about the product please contact customer relations manager firstly.

9. For return or repair-maintenance of products send them to the factory to the customer relations department.

10. If products come to the factory, it doesn’t mean acceptance of return and received by officers. Returns accepted, with the

approval of the examination will be only after the relevant department managers.

11. Consult to General Directorate of Consumer and Competition Protection of the Ministry Industry and Commerce of Turkey about

the issues may arise with warranty certificate.

EXCLUSIONS OF WARRANTY (USAGE DEFECTS)

1. Malfunctions occurring after the expiration of the statutory warranty,

2. The faults caused by improper use of the product by the user, (improper using to the instruction manual),

3. Any relevant malfunctions caused by other equipment in use,

4. Changes and damages not caused by the product manufacturer; for example, the case of the opening of the product by not

authorized workshops,

5. All failures depend on the system (electricity, air, etc),

6. Failures depend on the intervention of unauthorized service,

7. Products with damaged or destroyed warranty label,

8. In case of damage to outer surface of the product,

9. The faults in the caused by falling, hit, etc,

10. Faults occurred on dusty, damp, extreme heat or cold environments,

11. Faults caused by natural disasters such as flood, fire, earthquake, lightning, etc,

12. Faults caused by electrostatic discharge (ESD) damage.

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

28

valve & automation

Page 29

Seller / Distrubutor Representative

Name / Surname :

Title :

Date :

Signature :

Manufacturer Representative

Name / Surname :

Title :

Date :

Signature :

WARRANTY CERTIFICATE

Manufacturer : SMS Sanayi Malzemeleri Üretim ve Satışı A.Ş.

Address : Head Office: Y.Dudullu Mh. Bostancı Yolu Kuru Sk.

No: 16 Ümraniye - İstanbul / TURKEY

Factory: İMES O.S.B 5. Cd. No: 6 Çerkeşli OSB Mh.

Dilovası - Kocaeli / TURKEY

Product : PNEUMATIC ACTUATORS

Trade Mark : TORK

Model :..............................................................................................

Serial Number : ..............................................................................................

Delivery Place & Date : ...............................................................................................

Warranty Period : 2 Years

Max. Repair Time : 20 working days

Seller / Distributor :...............................................................................................

Address :...............................................................................................

...............................................................................................

...............................................................................................

...............................................................................................

www.smstork.com

www.smstork.com

29

Page 30

SECTOR

LEADER WITH

30 YEARS

EXPERIENCE

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

Page 31

www.smstork.com

Page 32

HEAD OFFICE Bostancı Yolu Cad. Kuru Sok. No:16 Y. Dudullu, 34776 Ümraniye İstanbul - TURKEY P +90 216 364 34 05 F +90 216 364 37 57

FACTORY İMES O.S.B.S Cad. No:5 Çerkesli - Dilovası KOCAELİ - TURKEY P +90 262 290 20 20 F +90 262 290 20 21

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti

www.smstork.com/SMSTORK /sms-tork

‘’KUL45PNEUMATİC ACTUATORS-EN-REV03

Loading...

Loading...