y

XC9116 Series

ETR0407-005

Step-Up DC/DC Converter-Backlight LED Driver

■GENERAL DESCRIPTIO N

The XC9116 series is a fixed frequency, constant current step-up DC/DC converter ideal for driving LEDs used in backlighting

applications such as cellular phones, PDAs and digital cameras. Output voltage of up to 17.5V can be derived, therefore four

white LEDs in series can be driven. Since an LED current can be set by an external resistor when LEDs are in-series

connection, all white LEDs can be turned on equably. A network of two parallel legs with three in each LED can be also

driven. Luminance of the LEDs is controlled by changing the duty cycle of a PW M signal applied to the CE pin. Efficiency is

high with the low feedback reference voltage ensuring the R

RDSON of 2.0 Ω is used. A low profile and small board area solution can be achieved using a chip coil and an ultra small

ceramic output capacitor (CL) of 0.22⎧F as a result of the high 1.0MHz switching frequency.

The 'B' type of XC9116 has an additional fault detection circuit. If the LEDs are disconnected or damaged, excess or run a way

output voltage is prevented by stopping the drive of the internal MOSFET.

■APPLICATIONS

●For White LED drivers

●Mobile phones, PHS

●PDAs

●Digital still cameras

■TYPICAL APPLICATION CIRCUIT

LED losses are minimal. In addition, an internal MOSFET with an

■FEATURES

Input Voltage Range : 2.5V ~ 6.0V

Output Voltage Range : Up to 17.5V externally set-up

: Reference voltage 0.2V +

Oscillation Frequency : 1.0MHz, ±20%

ON Resistance : 2.0Ω

Efficiency : 86% (XC9116B Type)

: 84% (XC9116D Type)

(V

Control : PWM control

Standby current : ISTB=1.0μA (MAX .)

Load Capacitor : 0.22μF, ceramic

Lx Limit Current : 325mA

Lx Overvoltage Limit : XC9116B series

No Lx Overvoltage Limit : XC9116D series

Package : SOT-25, USP-6B

Environmentall

Friendly : EU RoHS Compliant, Pb Free

IN=3.6V, ILED=20mA when

driving 3 white LEDs in series)

■TYPICAL PERFORMANCE

CHARACTERISTICS

●XC9116B Type

5%

1/22

r

XC9116 Series

■PIN CONFIGURATION

SOT-25 (TOP VIEW)

■PIN ASSIGNMENT

PIN NUMBER

SOT-25 USP-6B

1 2 Lx Switch

2 3 VSS Ground

3 1 FB Voltage Feedback

4 6 CE Chip Enable

5 4 VIN Power Input

- 5 NC No Connection

■CE PIN FUNCTION

CE PIN OPERATIONAL STATE

H Operation

L Shut-down

■PRODUCT CLASSIFICATION

●Ordering Information

XC9116①②③④⑤⑥-⑦

(*1)

DESIGNATOR DESCRIPTION SYMBOL DESCRIPTION

① Lx Overvoltage Limit

②③ FB Voltage 02 0.2V

④ Oscillation Frequency A 1MHz

⑤⑥-⑦

(*1)

The “-G” suffix indicates that the products are Halogen and Antimony free as well as being fully RoHS compliant.

(*2)

The device orientation is fixed in its embossed tape pocket. For reverse orientation, please contact your local Torex sales office o

representative. (Standard orientation: ⑤R-⑦, Reverse orientation: ⑤L-⑦)

Packages

Taping Type

6

5

4

1

2

3

USP-6B (BOTTOM VIEW)

PIN NAME FUNCTION

B Available

D Not available

MR SOT-25

(*2)

DR-G USP-6B

DR USP-6B

*The dissipation pad of the USP-6B package

should be left open. If the circuit needs to

be connected to other pin, it should be

connected to the V

SS pin.

2/22

A

■BLOCK DIAGRAMS

●XC9116B02A

●XC9116D02A

■

VIN

FB

CE

VIN

FB

CE

Error Amp

-

+

0.2V

Compensation

Error Amp

-

+

Compensation

0.2V

Phase

CE

Phase

CE

Current

Feedback

Ramp Wave

Generator, OSC

Current

Feedback

Ramp Wave

Generator, OSC

BSOLUTE MAXIMUM RATINGS

+

PWM Comparater

+

PWM Comparater

PARAMETER SYMBOL RATINGS UNITS

VIN Pin Voltage VIN VSS – 0.3 ~ 7.0 V

Lx Pin Voltage VLx VSS – 0.3 ~ 22.0 V

FB Pin Voltage VOUT VSS – 0.3 ~ 7.0 V

CE Pin Voltage VCE VSS – 0.3 ~ 7.0 V

Lx Pin Current ILx 1000 mA

Power Dissipation

SOT-25 250

USP-6B

Pd

Operating Temperature Range Topr - 40 ~ + 85

Storage Temperature Range Tstg - 55 ~ +125

MAX Duty

Limit

120

Current

Sense & Limit

Lx Over Voltage

Limit

Buffer Driver

Current

Sense & Limit

Buffer Driver

Ta = 25OC

mW

O

C

O

C

XC9116

Series

Lx

VSS

LX

VS S

3/22

,

{[(

)]}

XC9116 Series

■ELECTRICAL CHARACTERISTICS

XC9116B02AMR

PARAMETER SYMBOL CONDITIONS MIN. TYP. MAX. UNIT. CIRCUIT

FB Control Voltage VFB FB 0.19 0.20 0.21 V 1

Output Voltage Range VOUTSET VIN - 17.5 V 1

Input Voltage Range VIN 2.5 - 6.0 V 1

Supply Current 1 IDD1 - 450 750 μA 2

Supply Current 2 IDD2 VIN=Lx, VFB=0.4V - 60 140 μA 3

Standby Current I

Oscillation Frequency f

V

STB

0.8 1.0 1.2 MHz 2

OSC

=0V, VLX=5.0V - 0 1.0 μA 3

CE

Maximum Duty Cycle (*1) MAXDTY 86 92 98 % 2

Efficiency (*2) EFFI

Current Limit ILIM

Lx Overvoltage Limit VLxOVL

When connected to ext.

components, V

IN=3.6V, RLED=20 Ω

When connected to ext. components,

IN=3.6V

V

Voltage which Lx pin voltage holding

“H” level V

IN > 2.5V

- 86 - % 1

225 325 425 mA 4

18.0 19.0 22.0 V 2

Lx ON Resistance RSWON VIN=3.6V, VLx=0.4V - 2.0 - Ω 2

Lx Leakage Current ILxL Same as I

CE “High” Voltage VCEH

CE “Low” Voltage VCEL

CE applied voltage when Lx starts

oscillation

CE applied voltage which Lx pin

voltage holding “H” level

- 0 1.0 μA 3

STB

0.65 - - V 2

- - 0.2 V 2

CE “High” Current ICEH Same as IDD2 -0.1 - 0.1 μA 3

CE “Low” Current ICEL Same as I

-0.1 - 0.1 μA 3

STB

FB “High” Current IFBH Same as IDD2 -0.1 - 0.1 μA 3

FB “Low” Current IFBL Same as I

Unless otherwise stated, VIN=3.0V, VCE=3.0V, VFB=0V, Vpull=5.0V

NOTE: *1: The duty ratio is forcibly reduced when maximum duty cycle periods are repeated.

*2 : LED : NSPW310BS x 3

XC9116D02AMR

EFFI =

output voltage) x (output current)] / [(input voltage) x (input current

-0.1 - 0.1 μA 3

STB

x 100

PARAMETER SYMBOL CONDITIONS MIN. TYP. MAX. UNIT CIRCUIT

FB Control Voltage VFB FB 0.19 0.20 0.21 V 1

Output Voltage Range VOUTSET VIN - 19.5 V 1

Lx Operating

Voltage Range

V

Lx - - 20.0 V 1

Operating Voltage Range VIN 2.5 - 6.0 V 1

Supply Current 1 IDD1 - 450 750 μA 2

Supply Current 2 IDD2 VIN=Lx, VFB=0.4V - 50 120 μA 3

Standby Current I

Oscillation Frequency f

VCE=0V, VLx=5V - 0 1.0 μA 3

STB

0.8 1.0 1.2 MHz 2

OSC

Maximum Duty Cycle MAXDTY 86 92 98 % 2

Efficiency (*1) EFFI

Current Limit ILIM

When connected to ext.

components, V

IN=3.6V, RLED=20 Ω

When connected to ext. components,

IN=3.6V

V

- 84 - % 1

225 325 425 mA 4

Lx ON Resistance RSWON VIN=3.6V, VLx=0.4V, Rpull=10 Ω - 2.0 3.6 Ω 2

Lx Leakage Current ILxL Same as I

CE “High” Voltage VCEH

CE “Low” Voltage VCEL

CE applied voltage when Lx starts

oscillation

CE applied voltage which Lx pin

voltage holding “H” level

- 0 1.0 μA 3

STB

0.65 - - V 2

- - 0.2 V 2

CE “High” Current ICEH Same as IDD2 -0.1 - 0.1 μA 3

CE “Low” Current ICEL Same as I

-0.1 - 0.1 μA 3

STB

FB “High” Current IFBH Same as IDD2 -0.1 - 0.1 μA 3

FB “Low” Current IFBL Same as I

Test conditions: Unless otherwise stated, VIN=3.0V, VCE=3.0V, VFB=0V, Vpull=5.0V, Rpull=100 Ω

Notes: *1: LED: NSPW310BS x 3, EFFI = {[(output voltage) x (output current)] / [(input voltage) x (input current)]} x 100

-0.1 - 0.1 μA 3

STB

Ta = 25OC

Ta = 25OC

4/22

XC9116

■TYPICAL APPLICATION CIRCUITS

●XC9116B02A ●XC9116D02A

■EXTERNAL COMPONENTS

SYMBOL VALUE PART NUMBER MANUFACTURER

L 22μH VLF3010A-220MR TDK

(*1)

SBD

-

CIN 4.7μF JMK107BJ475MA-B TAIYO YUDEN

(*3)

CL

0.22μF TMK107BJ224KA-B TAIYO YUDEN

(*4)

ZD

18V MAZ8180 PANASONIC

R1 100 Ω - -

NOTE :

*1: Please use a Schottky barrier diode (SBD) with a low junction capacitance, Cj.

*2: For using the XBS053V15R-G with four white LEDs in series, please be noted with a direct reverse voltage (V

■OPERATIONAL EXPLANATION

repetitive peak reverse voltage (V

*3: Use ceramic capacitors processing a low temperature coefficient.

*4: Please refer to the LED Open-circuit Protection at Application Information for setting the Zener diode.

RM=30V).

The series consists of a reference voltage source, ramp wave circuit, error amplifier, PWM comparator, phase

compensation circuit, Lx overvoltage limit circuit, N-channel MOS driver transistor, current limiter circuit and others. The

series ICs compare, using the error amplifier, the voltage of the internal voltage reference source with the feedback

voltage from the FB pin. Phase compensation is performed on the resulting error amplifier output, to input a signal to the

PWM comparator to determine the turn-on time during switching. The PWM comparator compares, in terms of voltage

level, the signal from the error amplifier with the ramp wave from the ramp wave circuit, and deliv ers the resulting outp ut

to the N-channel MOS driver transistor to cause the Lx pin to output a switching duty cycle. This process is continuously

performed to ensure stable output voltage. The current feed back circuit detects the N-channel MOS driver transistor's

current for each switching operation, and modulates the error amplifier output signal. T his enables a stable feedback

loop even when a low ESR capacitor, such as a ceramic capacitor, is used, ensuring stable output voltage.

<Reference Voltage Source>

The reference voltage source provides the reference voltage to ensure stable output voltage of the IC.

<Ramp Wave Circuit>

The ramp wave circuit determines switching frequency. The 1MHz (TYP.) of frequency is fixed internally.

Clock pulses generated in this circuit are used to produce ramp waveforms needed for PW M operation.

<Error Amplifier>

The error amplifier is designed to monitor output voltage. The amplifier compares the reference voltage with the FB pin

voltage. When a voltage lower than the reference voltage is fed back, the output voltage of the error amplifier is

increased. Gain and frequency characteristics of the error amplifier outp ut are fixed internally as an optimize signal.

XBS053V15R-G (*2) TOREX

MA2Z720 PANASONIC

R=20V) and a

Series

5/22

XC9116 Series

■OPERATIONAL EXPLANATIONS (Continued)

<Current Limit>

The current limit circuit of the XC9116 series monitors the current flowing through the N-channel MOS driver transistor

connected to the Lx pin, and features a combination of the constant-current type current limit mo de and the duty cycle

limit of the next pulse.

1When the driver current is greater than a specific level, the constant-current type current limit function operates to

■NOTES ON USE

turn off the pulses from the Lx pin at any given timing.

2The IC controls the next pulse to be smaller than the first pulse.

Current Limit

I

L

L

X

①

The c ur re nt w ill be of f w he n t he c o il c ur r ent

reaches the value of the c onstant cur rent limit.

Current Limit

②

Limit some duty pulses after the

limit.

<Lx Overvoltage Limit Circuit>

XC9116B series' Lx overvoltage limit circuit monitors the Lx pin voltage. When the Lx pin voltage exceeds than 19V

(TYP.), the IC performs the function of latching the OFF state of the driver transistor, and goes into operation suspension

mode. In suspension mode, operations can be resumed by restoring power to the V

IN pin. The suspension mode

does not mean a complete shutdown, but a state in which pulse output is suspended; therefore, the internal circuitry

remains in operation.

<Maximum Duty Cycle Limit>

The XC9116B series' maximum duty cycle limit circuit monitors the duty cycle. When the maximum duty cycle is

repeated for a certain time, the IC controls the error amplifier output so that the duty cycle of the ne xt pulse becomes

smaller than that of the first pulse.

<CE Pin Function>

The operation of the XC9116 series will enter into the shut down mode when a low level signal is input to the CE pin.

During the shut down mode, the supply current is 0μA (TYP.), with high impedance at the Lx pin. The IC starts its

operation with a high level signal to the CE pin. The input to the CE/MODE pin is a CMOS input and the sink current is

0μA (TYP.). 100μs after disable, the IC goes into suspe nsion mode an d supply curr ent is minimal. After this, the IC

will be in stand-by mode and the supply current will be 0μA (TYP.).

<Lx (Pin 1): Switch Pin>

Please connect the anode of a Schottky barrier diode and an inductor to the Lx pin.

<FB (Pin 3): Voltage Feedback Pin>

The reference voltage is 200mV (TYP.). A resistor (R

LEDs and a constant current value. The resistance value can be calculated by the fol lowing equation.

R

LED=0.2 / ILED

I

LED=Setting constant current value

LED) should be connected to the FB pin for setting the cathode of

Typical example:

ILED RLED ILED RLED

5mA 40 Ω 13.3mA 15 Ω

10mA 20 Ω 20mA 10 Ω

<CE (Pin 4): Chip Enable Pin>

An ENABLED state is reached when the CE voltage exceeds 0.65V and a DISABLED state when the CE Voltage falls

below 0.2V.

IN (Pin 5): Power Supply Pin>

<V

Please connect an inductor and an input by-pass capacitor (C

IN) to the VIN pin.

6/22

A

■

PPLICATION INFORMATION

<Dimming Control>

1. Applying PWM signal to the CE pin

The XC9116 repeats on/of f operations by a PWM signal applied to the CE pin. The magnitude of LED current, ILED, when

the diode is on, is determined by R

proportional to the positive duty ratio of the PWM signal.

The frequency of the PWM signal can be controlled to the optimum value between 100Hz and 10kHz. With regard to the

amplitude of the PWM signal, the high level should be higher than the "H" voltage of CE, V

than the "L" voltage of CE, V

20μs / div

2. Step-Wise Regulation of LED Current

In some applications, it may be necessary to incorporate step-wise regulation of LED current, I

of LED illumination is achieved by connecting a switch element SW1 in parallel with R

turning SW1 on and off, as shown below. Choose a r esistance of R

when switch element SW1 is off. The resistance of R

through the LED is gained when the switch element is on.

Ex.) Current ILED = 5mA and 15mA

R

R

LED = 200mV / 5mA = 40

LED1 = 200mV / (15mA – 5mA) = 20

LED. The magnitude is zero when the diode is off. The average of LED current is

CEH, and the low level, lower

CEL.

20μs / div

4 series

200μs / div 200μs / div

LED. Step-wise regulation

LED and in series with RLED1 and

LED so that the minimum necessary current is gained

LED1 should be such that a desired increase of current passed

Ω

L

VIN

Ω

CIN

ON/OFF

VIN Lx

CE FB

VSS

SD

ILED

RLED

RLED1

signal

CL

SW1

XC9116

Series

Figure : Circuit using Step-wise Regulation of LED Current

7/22

A

XC9116 Series

■

PPLICATION INFORMATION (Continued)

<Dimming Control (Continued)>

3. Using DC Voltage

If in an application it is necessary to control the LED curr ent by a variable DC voltage, illumination control of LED is

achieved by connecting R1 and R2 and applying a direct-current voltage to R2, as shown below.

When R1>>R

LED = (VREF - R1 / R2 (VDC - VREF)) / RLED

I

REF = 0.2V (TYP.)

V

Ex.1) When R1 = 10k

In the range of 0.2V to 2.2V DC, I

(LED current) varies between 20mA to 0mA.

Ex.2) When R1 = 10k Ω, R2 = 100k Ω, R3 = 10k Ω,

C1 = 0.1μF, RLED = 10Ω, the average LED current will

<Prevent Emission Caused by White LEDs Leakage>

When the input voltage (V

happens, please connect a transistor to between the LED and the FB pin. B y driving the CE sign al in-phase and cutting

the pass to current, the minimum illumination can be prevented.

LED, ILED which flows into LEDs can be calculated by the following equation;

Ω, R2 = 100k Ω, RLED = 10 Ω,

LED

VDC

be 10mA by inputting a PWM signal of CE ‘H’ level:

2.2V, CE ’L’ level: 0V, duty cycle: 50%, oscillation

frequency: 100Hz. As well as the way of dimming

control by applying the PWM signal to the CE pin, the

average LED current increases proportionally with the

PWM

positive duty cycle of the PWM signal.

Figure : Circuit inputting a PWM signal to the FB pin

IN) is high, minimum illumination may occur even if the CE pin is in the disable state. If this

ILED

ZD

XC9116

( )

FB

R2 R1

Figure : Circuit using DC voltage

ILED

ZD

XC9116

( )

FB

R3

R2

R1

C1

RLED

RLED

8/22

A

■

PPLICATION INFORMATION (Continued)

<Illumination of Six in Total White LEDs>

It is possible to illuminate three-series two parallel white LEDs, six in total, using an input voltage V

<Use as Flash>

An LED current 65mA (MAX.) can be supplied to two white LEDs.

L

VIN

VIN Lx

CIN

ON/OFF

<Separate Supply Source of the Step-up Circuit (V

CE FB

VSS

IN) from VIN Pin>

Supply source of the step-up circuit can be used separately from V

Circuit example of separating supply source of

the step-up circuit from V

IN pin ( 3 LEDs)

Note: Please input 2.5V~6V to the VIN pin when you use.

SD

ILED

RLED

CL

RLED1

signal

IN pin.

SW1

Circuit example of separating supply source of

the step-up circuit from VIN pin ( 2 LEDs)

XC9116

Series

IN≧3.2V.

9/22

XC9116 Series

■APPLICATION INFORMATION (Continued)

<LED Open-circuit Protection>

If white LEDs are opened or damaged, the FB pin is pulled down, so that the o perating dut y ratio reaches the maximum .

Accordingly, the output voltage continues to increase, possibly causing the Lx pin voltage to exceed the absolute

maximum rating of 22V.

In the case of the B type products, if white LEDs are opened or damaged, the detector built in the Lx pin causes the IC to

stop oscillating, preventing excessive increase of the output voltage. However, the detector may detect an overvoltage if

the Lx pin voltage exceeds 18V, which is the overvoltage limit, even when no LEDs are open. Therefore, care must be

taken if four LEDs each having a forward voltage of 4.45V or more are connected in series.

In the case of the D type products (no overvoltage limit circuit), a Zener diode (ZD) and a resistor (R1) can be externa lly

connected to serve as a load in the case that LEDs are opened, preventing the incre ase of the Lx pin voltage. The ZD

voltage should be set to no more than 20V and no less than the product of each white LED’s maximum forward voltage

multiplied by the number of the connected LEDs, so that the Zener diode will not load the LEDs during normal operation.

If the Zener diode becomes load, the current that runs through the white LEDs is reduced, decreasing illumination.

Note : The XC9116B02A series requires nei ther the Zener diode (ZD) nor the resisto r 1 (R1).

<Startup Inrush Current>

The XC9116 series has no soft-start circuit built-in in order to minimize delay at startup. The inrush current can reach up

to the current limit, I

In some cases, overshoot can occur.

VIN

2.5V~6.0V

CIN

4.7uF

LIM.

L:22uF

VLF3010A

VIN Lx

CE FB

VSS

SD

XBS053V15R

MAZ8180

R1

100ohm

RLED

10ohm

CL

0.22uF

20mA

10/22

A

■

PPLICATION INFORMATION (Continued)

<Instruction on Pattern Layout>

1. In order to stabilize V

possible to the V

2. Please mount each external component as close to the IC as possible.

3. Wire external components as close to the IC as possible and use thick, short connecting traces to reduce the circuit

impedance.

4. Make sure that the PCB GND traces are as thick as possible, as variations in ground potential caused by high ground

currents at the time of switching may result in instability of the IC.

●XC9116B Series Pattern Layout (SOT-25)

●XC9116D Series Pattern Layout (SOT-25)

IN's voltage level, we recommend that an input by-pass capacitor (CIN) be connected as close as

IN & VSS pins.

LED

RLED

CE

VOUT

GND

CL

4

5

132

VIN

SBD

L

LED

RLED

D

Z

CE

GND

4

5

1

R

CL

132

VOUT

VIN

SBD

L

XC9116

Series

11/22

XC9116 Series

■ TEST CIRCUITS

●Circuit ① XC9116B02A series

●Circuit ②

OSC

V

A

IN

V

IN

1uF

CE FB

V

CE

V

SS

Lx

Rpull

220uF

Vpull

V

FB

●Circuit ④

V

IN

1uF

V

CE FB

VCE

OSC

10ohm 300ohm

IN

Lx

SS

V

2SK583

1uF

11kohm

1.1kohm

0.01uF

1. The measurement method of LX ON Resistance R

Using the circuit ②, Lx ON resistance can be measured by adjusting Vpull voltage to set Lx voltage VLx 0.4V when the

driver transistor is ON.

The oscilloscope is used for measuring the Lx voltage when the driver transistor is ON.

R

SWON = 0.4 / ((Vpull - 0.4) /10)

2. The measurement method of current limit ILIM

Using the circuit ④, current limit I

LIM can be calculated by the equation including Vpull voltage when FB voltage is

decreased while Vpull voltage is adjusted and Lx voltage V

The oscilloscope is used for measuring the Lx voltage when the driver transistor is ON.

ILIM = (Vpull - VLx) / Rpull

SWON

12/22

●Circuit ① XC9116D02A series

VIN

CIN

4.7uF

(ceramic)

L:22uF

VLF3010A

VIN Lx

CE FB

VSS

SD

XBS053V15R

OSC

●Circuit ③

V

A

V

IN

1uF

4.4V

Vpull

220uF

V

Lx when the driver transistor is ON.

IN

CE FB

A A A

V

V

CE

SS

MAZ8180

R1

100ohm

RLED

10ohm

Lx

V

CL

0.22uF

(ceramic)

V

V

FB

Lx

p

p

)

XC9116

Series

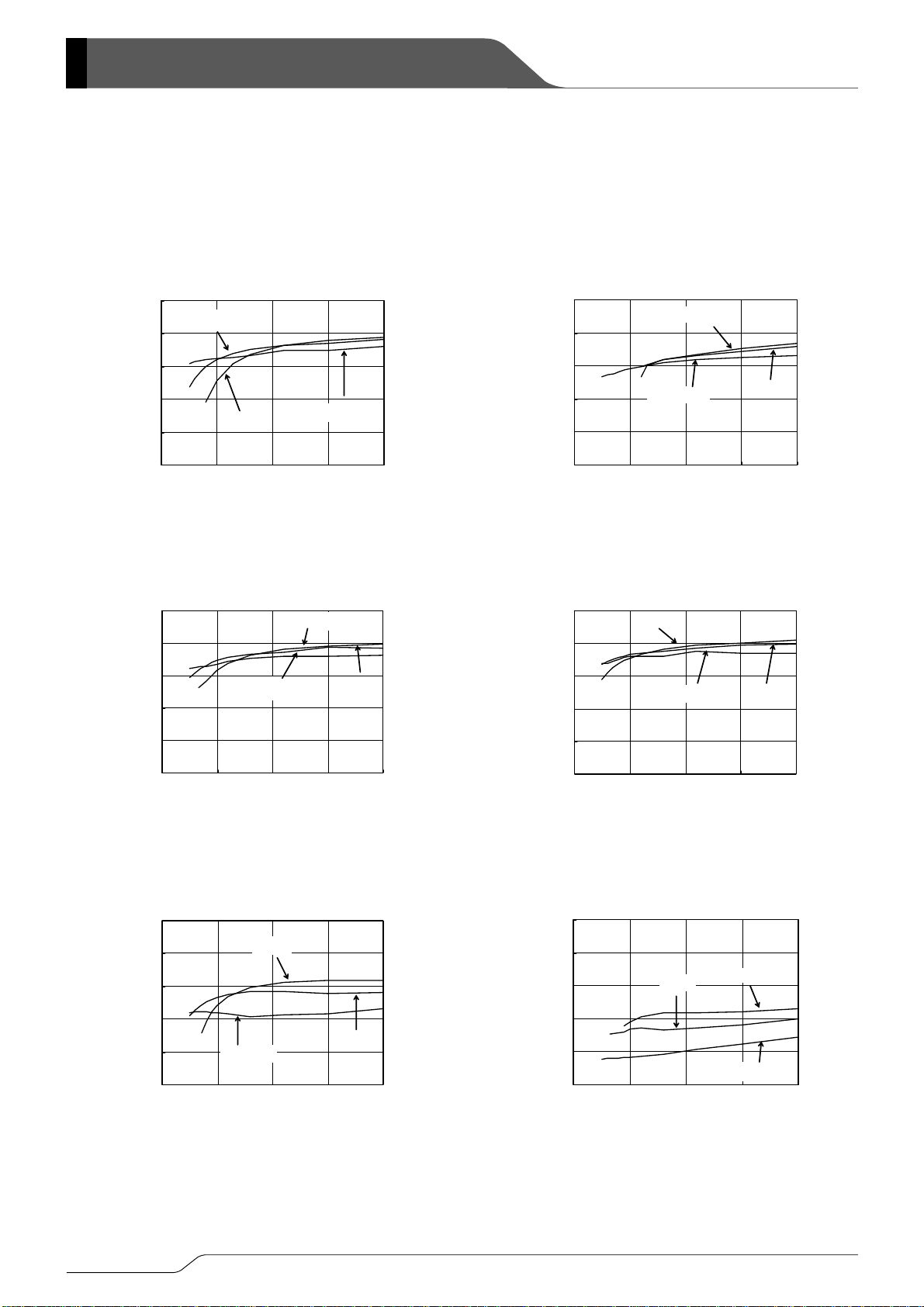

■ TYPICAL PERFORMANCE CHARACTERISTICS

(1) Supply Current 1 vs. Input Voltage (2) Supply Current 2 vs. Input Voltage

1200

1000

800

600

85oC

400

200

Supply Current 1 IDD1 (uA)

0

23456

Input Voltage VIN (V)

VCE=3.0V,VFB=0V

ull=5V,Rpull=100ohm

V

Ta=25oC

-40oC

140

120

100

80

60

40

20

Supply Current2 IDD2 (uA)

-40oC

0

23456

VIN=Lx,VCE=3.0V,VFB=0.4V

Ta=25oC

85oC

Input Voltage VIN (V)

(3) Oscillation Frequency vs. Input Voltage (4) Maximum Duty Cycle vs. Input Voltage

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

23456

Oscillat ion Fr equency Fosc (MHz)

Input Voltage VIN (V)

VCE=3.0V,VFB=0V

Vpull=5V,Rpull=100ohm

85oC

Ta= 25oC

-40oC

VCE=3.0V,VFB=0V

V

98

96

94

-40oC

92

90

Ta=25oC

88

Maxmum Duty Cycle MAXDTY(%)

86

23456

Input Voltage VIN (V)

ull=5V,Rpull=100ohm

85oC

(5) Stand-by Current vs. Input Voltage (6) Maximum LED Current vs. Input Voltage

(uA)

STB

Standby Current I

1.0

0.8

0.6

0.4

85oC

0.2

0.0

23456

Input Voltage VIN (V)

VCE=0V,VFB=0V,VLx=5V

Ta=25oC,-40oC

250

200

150

100

50

Max LED C urrent ILED_M AX (m A

0

o

C

Ta=25

VOUT=7V

23456

Input Voltage VIN(V)

VCE=3.0V,LED:NSPW310BS

L=22uH(VLF3010),CIN=4.7uF(Ceramic)

CL=0.22uF(Ceramic), SBD:XBS053V15R

10V

16V

13V

13/22

p

p

)

XC9116 Series

■ TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

(7) Lx On Resistance vs. Input Voltage (8) Current Limit vs. Input Voltage

)

6.0

Ω

(ohm)

5.0

VCE=3.0V,VLx=0.4V,R

ull=10ohm,Tr:2SK583

4.0

SWON

-40oC

Ta=25oC

3.0

2.0

1.0

85oC

0.0

Lx ON Resistance Rswon (

Lx ON Resistance R

23456

Input Voltage VIN (V)

(9) FB Voltage vs. Ambient Temperature (10) Lx Overvoltage Limit vs. Input Voltage

0.210

VCE=3.0V,LED:NSPW310BS

L=22uH(VLF3010),CIN=4.7uF(Ceramic)

CL=0.22uF( Ceramic), XBS053V15R

0.205

0.200

0.195

Feed Back Voltage VFB(V)

0.190

-50 -25 0 25 50 75 100

o

Ambient Temp Ta(

C)

(11) CE ’H’ Voltage vs. Input Voltage (12) CE ’L’ Voltage vs. Input Voltage

CE 'H' Voltage VCEH(V)

0.65

0.60

0.55

0.50

0.45

0.40

0.35

0.30

0.25

0.20

23456

VFB=0V,Vpull=5V,Rpull=100ohm

-40oC

85oC

Ta=25oC

Input Voltage VIN (V)

14/22

700

600

(mA)

500

LIM

I

400

300

200

100

Current Limit

0

22

21

20

19

Lx Over Voltage Limit VLxOVL(V

18

Lx Ov er Voltage Limit VLxOVL (V)

0.65

0.60

0.55

0.50

0.45

0.40

0.35

0.30

0.25

CE 'L' Voltage VCEL(V)

0.20

VCE=3.0V,VLx=0.4V,R

-40oC

Ta=25oC

ull=10ohm,Tr:2SK583

85oC

23456

Input Voltage VIN (V)

VCE=3.0V,VFB=0V,Rpull=300ohm

Ta=25oC

-40oC,85oC

23456

Input Voltage VIN(V)

VFB=0V,Vpull=5V,Rpull=100ohm

-40oC

85oC

Ta=25oC

23456

Input Voltage VIN (V)

)

V

)

V

)

V

)

V

)

V

)

V

XC9116

Series

■ TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

(13) Efficiency vs. Input Voltage

XC9116B02AMR, 3 LEDs in series

100

90

80

70

Efficiency EF FI (%

60

50

23456

LED:NSPW310BS,CIN =4.7uF(Cer amic)

CL=0.22uF(Ceramic), SBD:XBS053V15R

30mA

ILED=10mA

Input Voltage VIN (V)

100

90

LED:NSPW310BS,CIN =4.7uF(Cer amic)

CL=0.22uF(Ceramic), SBD:XBS053V15R

30mA

80

ILED=10mA

70

Efficiency EFFI(%

60

50

23456

Input Voltage VIN (V)

100

90

LED:NSPW310BS,CIN=4.7uF(Cer amic)

CL=0.22uF(Ceramic), SBD:XBS053V15R

80

70

Efficiency EFFI(%

60

ILED=10mA

50

23456

Input Voltage VIN (V)

VCE=3.0

20mA

Ta=25oC

VCE=3.0

20mA

Ta=25oC

VCE=3.0

30mA

20mA

Ta=25oC

LED:NSPW310BS,CIN=4.7uF(Ceramic)

100

CL=0.22uF(Ceramic), SBD:XBS053V15R

30mA

90

80

70

Efficiency EFFI(%

60

ILED=10mA

20mA

Ta=25oC

50

23456

Input Voltage VIN (V)

LED:NSPW310BS,CIN=4.7uF(Ceramic)

100

CL=0.22uF(Ceramic), SBD:XBS053V15R

30mA

90

80

70

ILED=10mA

Efficiency EFFI(%

60

Ta=25oC

50

23456

Input Voltage VIN(V)

VCE=3.0

100

LED:NSPW310BS,CIN=4.7uF(Cer amic)

CL=0.22uF(Ceramic), SBD:XBS053V15R

90

80

20mA

30mA

70

60

Efficiency EFFI(%

ILED=10mA

Ta=25oC

50

23456

Input Voltage VIN(V)

VCE=3.0

VCE=3.0

20mA

15/22

)

V

)

V

)

V

)

V

)

V

)

V

XC9116 Series

■ TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

(13) Efficiency vs. Input Voltage (Continued)

XC9116B02AMR, 4 LEDs in series

100

90

LED:NSPW310BS,CIN=4.7uF(Ceramic)

CL=0 . 22 uF(Ce ra mic), SBD:XBS0 53 V 15 R

20mA

80

70

Efficiency EF FI (%

60

30mA

50

23456

Input Voltage VIN (V)

100

90

LED:NSPW310BS,CIN=4.7uF(Ceramic)

CL=0 . 22 uF(Ce ra mic), SBD:XBS0 53 V 15 R

80

ILED=10mA

70

Efficiency EFFI(%

60

50

23456

Input Voltage VIN(V)

100

90

LED:NSPW310BS,CIN=4.7uF(Ceramic)

CL=0 . 22 uF(Ce ra mic), SBD:XBS0 53 V 15 R

30mA

80

70

Efficiency EF FI(%

60

ILED=10mA

50

23456

Input Voltage VIN(V)

16/22

30mA

VCE=3.0

ILED=10mA

Ta=25oC

VCE=3.0

20mA

Ta=25oC

VCE=3.0

20mA

Ta=25oC

VCE=3.0

100

LED:NSPW310BS,CIN=4.7uF(Ceramic)

CL=0 . 22 uF(Ce ra mic), SBD:XBS0 53 V 15 R

30mA

90

80

70

Efficiency EFFI(%

60

ILED=10mA

20mA

Ta=25oC

50

23456

Inp ut Voltage VIN(V)

VCE=3.0

100

LED:NSPW310BS,CIN=4.7uF(Ceramic)

CL=0.22uF(Ceramic), SBD:XBS053V15R

30mA

90

80

ILED=10mA

20mA

70

Eff iciency EFF I(%

60

Ta=25oC

50

23456

Input Voltage VIN (V)

VCE=3.0

Ta=25oC

100

LED:NSPW310BS,CIN=4.7uF(Ceramic)

CL=0.22uF(Ceramic), SBD:XBS053V15R

90

80

20mA

30mA

70

Efficiency EFFI(%

60

ILED=10mA

50

23456

Inp ut Voltage VIN(V)

)

V

)

V

)

V

)

V

)

V

XC9116

Series

■ TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

(13) Efficiency vs. Input Voltage (Continued)

XC9116B02AMR, 2 parallel legs with 3 LEDs per leg

100

90

80

70

Efficiency EFFI (%

60

50

23456

L=22μH (VLF3010)

LED:NSPW310BS,CIN=4.7uF(Ceramic)

CL=0.22uF(Cer amic), SBD:XBS053V15R

ILED=10mA

30mA

20mA

Input Voltage VIN (V)

VCE=3.0

Ta=25oC

(14) Efficiency vs. LED Current

XC9116B02AMR, 3 LEDs in series

100

L:CDRH3D16

90

80

70

60

50

40

30

Efficiency EF FI(%

20

10

0

0 5 10 15 20 25 30

VLF3010A

L=10μH

LED:NSPW310BS,CIN=4.7uF(Ceramic)

CL=0.22uF(Ceramic), SBD:XBS053V15R

VCE=3.0

CBC2518

VIN=3.6V

100

L:CDRH3D16

90

80

70

60

50

40

30

Efficiency EFFI(%

20

10

0

0 5 10 15 20 25 30

L=22μH

LED:NSPW310BS,CIN=4.7uF(Ceramic)

CL=0 . 22 uF(Ce ra mic), SBD:XBS0 53 V15R

VLF3010A

VCE=3.0

CBC2518

VIN=3.6V

LED Current ILED(mA)

LED Current ILED(mA)

XC9116B02AMR, 4 LEDs in series

100

L:CDRH3D16

90

80

70

60

50

40

30

Efficiency EFFI(%

20

10

0

0 5 10 15 20 25 30

L=10μH

LED:NSPW310BS,CIN=4.7uF(Ceramic)

CL=0.22uF(Ceramic), SBD:XBS053V15R

VLF3010A

VIN=3.6V

LED Current ILED(mA)

VCE=3.0

CBC2518

L=22μH

LED:NSPW310BS,CIN=4.7uF(Ceramic)

100

L:CDRH3D16

90

80

70

60

50

40

30

Efficiency EFFI(%

20

10

0

0 5 10 15 20 25 30

CL=0.22uF(Ceramic), SBD:XBS053V15R

VLF3010A

LE D Current ILED(mA)

VCE=3.0

CBC2518

VIN=3.6V

17/22

XC9116 Series

■ TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

(15) Average LED Current vs. Input Voltage

25

20

15

10

5

Average LED C u rrent I LED _av e( m A)

0

2.53.03.54.04.55.0

L=22uH(VLF3010),CL=0.22uF(Ceramic)

R1=10ohm,SBD:XBS053V15R

100%

Dimmin g P WM Duty=50%

Ta= 85oC

25

-40

Input Voltage VIN (V)

25

20

15

10

o

C

o

C

5

Average LED C urrent I LED _ave (m A)

0

2.5 3.0 3.5 4.0 4.5 5.0

25

20

15

10

5

Average LED Current I LED _av e(m A)

0

2.53.03.54.04.55.0

L=22uH(VLF3010),CL=0.22uF(Ceramic)

R1=10ohm,SBD:XBS053V15R

Dimmin g P WM Duty=50%

Ta= 85oC

25

-40

Input Voltage VIN (V)

100%

25

20

15

10

o

C

o

C

5

Average LED C urrent I LED _ave(m A)

0

2.5 3.0 3.5 4.0 4.5 5.0

25

L=22uH(VLF3010),CL=0.22uF(Ceramic)

R1=10ohm,SBD:XBS053V15R

25

20

15

Dimmin g P WM Duty=50%

10

5

Average LED C urrent I LED _av e(m A)

0

Ta= 85oC

25

-40

2.5 3.0 3.5 4.0 4.5 5.0

Input Voltage VIN (V)

100%

o

C

o

C

20

15

10

5

Average LED C urrent I LED _av e(m A)

0

2.5 3.0 3.5 4.0 4.5 5.0

Note : Average LED Current denotes the average current which flows into LED when a PWM signal is input to the CE pin.

18/22

L=22uH(VLF3010),CL=0.22uF(Ceramic)

R1=10ohm,SBD:XBS053V15R

100%

Dimmin g P WM Duty=50%

Ta= 85oC

25

-40

Input Voltage VIN (V)

L=22uH(VLF3010),CL=0.22uF(Ceramic)

R1=10ohm,SBD :XBS053V15R

100%

Dimming PWM Duty=50%

Ta= 85oC

25

-40

Input Voltage VIN (V)

L=22uH(VLF3010),CL=0.22uF(Ceramic)

R1=10ohm,SBD:XBS053V15R

100%

Dimming PWM Duty=50%

Ta= 85oC

25

-40

Input Voltage VIN (V)

o

C

o

C

o

C

o

C

o

C

o

C

)

XC9116

Series

■ TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

(16) Average LED Current vs. Dimming PWM Duty

20

2.7V

16

3.2V

4.2V

5.0V

12

8

4

Average LED C urrent ILED_ave(m A)

0

0 20406080100

20

2.7V

16

3.2V

4.2V

5.0V

12

8

4

Average LED Current ILED_ave(mA

0

020406080100

20

2.7V

16

3.2V

4.2V

5.0V

12

8

4

Average LED C urren t I L ED _av e(m A)

0

0 20 40 60 80 100

Note : Average LED Current denotes the average current which flows into LED when an PWM signal is input to the CE pin.

L=22uH(VLF3010),CL=0.22uF(Ceramic)

R1=10ohm,SBD:XBS053V15R

VIN=2.5V

Dimming PWM DUTY (%)

L=22uH(VLF3010),CL=0.22uF(Ceramic)

R1=10ohm,SBD:XBS053V15R

VIN=2.5V

Ta=25oC

Dimming PWM Duty (%)

L=22uH(VLF3010),CL=0.22uF(Ceramic)

R1=10ohm,SBD:XBS053V15R

VIN=2.5V

Dimming PWM Duty (%)

Ta=25oC

Ta=25oC

L=22uH (VLF3010) ,CL=0.22uF(Cer amic)

20

VIN=2.5V

2.7V

16

3.2V

4.2V

5.0V

12

R1=10ohm,SBD:XBS053V15R

8

4

Average LED C urrent ILED_ave(m A)

0

0 20406080100

Dimming PWM DUTY (%)

L=22uH(VLF3010),CL=0.22uF(Ceramic)

R1=10ohm,SBD:XBS053V15R

20

VIN=2.5V

2.7V

16

3.2V

4.2V

5.0V

12

8

4

Average LED C urrent ILED _av e(m A)

0

Ta=25oC

0 20406080100

Dimming PWM Duty (%)

L=22uH (VLF3010) ,CL=0.22uF(Cer amic)

R1=10ohm,SBD:XBS053V15R

20

VIN=2.5V

2.7V

16

3.2V

4.2V

5.0V

12

8

4

Ta=25oC

Average LED C urren t I L ED _av e(m A)

0

0 20406080100

Dimming PWM Duty (%)

19/22

XC9116 Series

■PA CKAGING INFORMATION

●SOT-25

●USP-6B

Reference Pattern Layout

Reference Metal Mask Design

20/22

■ MARKING RULE

●SOT-25

●USP-6B

SOT-25

(TOP VIEW)

USP-6B

(TOP VIEW)

1 represents product series

MARK PRODUCT SERIES

F

* Character inversion used.

2 represents Lx overvoltage limit

MARK Lx OVERVOLTAGE LIMIT PRODUCT SERIES

B Available XC9116B02AM x

D Not Available XC9116D02AM x

3 represents oscillation frequency

MARK OSCILLATION FREQUENCY PRODUCT SERIES

A 1MHz XC9116 x 02AM x

4 represents production lot number

0 to 9 and A to Z, or inverted characters 0 to 9 and A to Z repeated.

(G, I, J, O, Q, and W excluded)

1 represents product series

MARK PRODUCT SERIES

K XC9116 x 02AD x

2 represents Lx overvoltage limit

MARK Lx OVERVOLTAGE LIMIT PRODUCT SERIES

B Available XC9116B02AD x

D Not Available XC9116D02AD x

34 represents FB voltage

MARK

③ ④

FB VOLTAGE (V) PRODUCT SERIES

0 2 0.2 XC9116 x 02AD x

5 represents oscillation frequency

MARK OSCILLATION FREQUENCY PRODUCT SERIES

A 1MHz XC9116 x 02AD x

6 represents production lot number

0 to 9 and A to Z repeated (G, I, J, O, Q, and W exclude d)

* No character inversion used.

XC9116

Series

XC9116 x 02AM x

21/22

XC9116 Series

1. The products and product specifications contained he rein are subject to change without

notice to improve performance characteristics. Consult us, or our representatives

before use, to confirm that the information in this datasheet is up to date.

2. We assume no responsibility for any infringement of patents, patent rights, or other

rights arising from the use of any information and circuitry in this datasheet.

3. Please ensure suitable shipping controls (including fail-safe designs and aging

protection) are in force for equipment employing products listed in this datasheet.

4. The products in this datasheet are not developed, designed, or approved for use with

such equipment whose failure of malfunction can be reasonably expected to directly

endanger the life of, or cause significant injury to, the user.

(e.g. Atomic energy; aerospace; transport; combustion and associated safety

equipment thereof.)

5. Please use the products listed in this dat asheet within the specified ranges.

Should you wish to use the products under conditions exceeding the specifications,

please consult us or our representatives.

6. We assume no responsibility for damage or loss due to abnormal use.

7. All rights reserved. No part of this datasheet may be copied or reproduced without the

prior permission of TOREX SEMICONDUCTOR LTD.

22/22

Loading...

Loading...