Page 1

●SOT-25 Power Dissipation

Power dissipation data for the SOT-25 is shown in this page.

The value of power dissipation varies with the mount board conditions.

Please use this data as one of reference data t aken in the described condition.

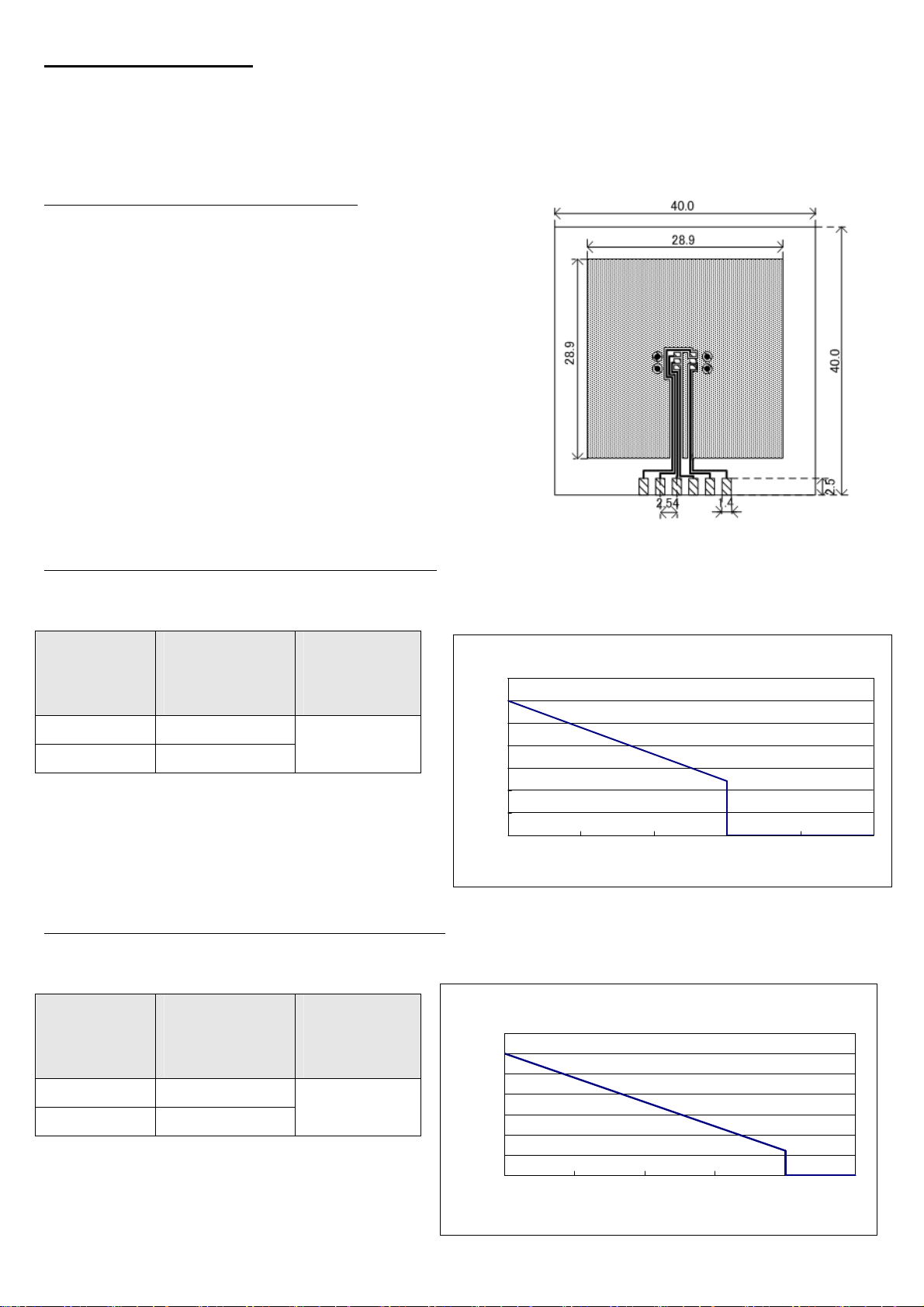

1. Measurement Condition (Reference data)

Condition : Mount on a board

Ambient : Natural convection

Soldering : Lead (Pb) free

Board : Dimensions 40×40mm(1600mm

2

in one side)

Copper (Cu) traces occupy 50% of the board area

In top and back faces

Package heat-sink is tied to the copper traces

(Board of SOT-26 is used)

Material : Glass Epoxy(FR-4)

Thickness : 1.6mm

Through-hole : 4 x 0.8 Diameter

2. Power Dissipation vs. Ambient temperature(85℃)

Board Mount ( Tjmax=125℃)

Ambient

Temperature

(℃)

Power

Dissipation

Pd (mW)

25 600

85 240

Thermal

Resistance

(℃/W)

166.67

Evaluation Board (Unit: mm)

Pd vs Ta

700

600

500

400

300

200

100

Power Dissipation Pd(mW)

0

25 45 65 85 105 125

Ambient Temperature Ta(℃)

3. Power Dissipation vs. Ambient temperature(105℃)

Board Mount ( Tjmax=125℃)

Ambient

Temperature

(℃)

Power

Dissipation

Pd (mW)

25 600

105 120

Thermal

Resistance

(℃/W)

166.67

Pd vs Ta

700

600

500

400

300

200

100

0

Power Dissipation Pd( mW)

25 45 65 85 105 125

Ambient Temparature Ta(℃)

1/2

Page 2

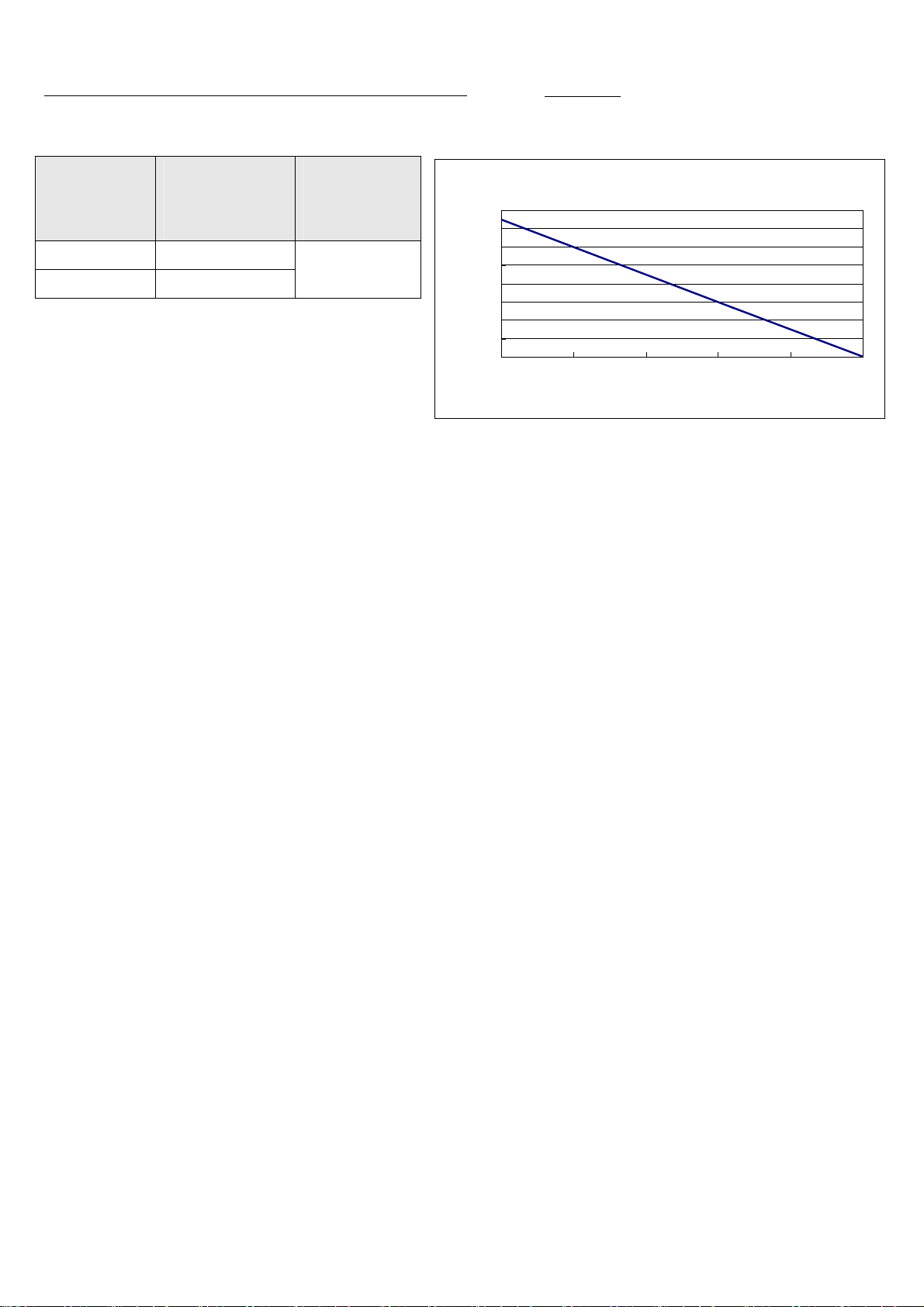

4. Power Dissipation vs. Ambient temperature(Tj=150℃)

Board Mount ( Tjmax=150℃)

Ambient

Temperature

(℃)

Power

Dissipation

Pd (mW)

25 750

105 270

Thermal

Resistance

(℃/W)

166.67

TVS DATA

Pd vs Ta

800

700

600

500

400

300

200

100

0

Power Dssipation Pd(mW)

25 50 75 100 125 150

Ambient TemperatureTa(℃)

2/2

Loading...

Loading...