Page 1

INSTRUCTION BOOK

WARRANTY....

and workmanship at the date of purchase. This warranty does not cover any component parts damaged by use

or modification. In no case shall Top Flite Models' liability exceed the original cost of the purchased kit. Further,

Top Flite reserves the right to change or modify this warranty without notice.

In that Top Flite has no control over the final assembly or material used for final assembly, no liability

shall be assumed nor accepted for any damage resulting from the use by the user of the final user-assembled

product.

By the act of using the user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, he is advised

to immediately return this kit in new and unused condition to the place of purchase.

READ THROUGH THIS INSTRUCTION BOOK FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Top Flite Models guarantees this kit to be free of defects in both materials

TOP FLITE MODELS, P.O. BOX 721, URBANA, IL 61801

TECHNICAL ASSISTANCE - CALL (217) 398-6300

Page 2

2

INTRODUCTION

Precautions....................................................3

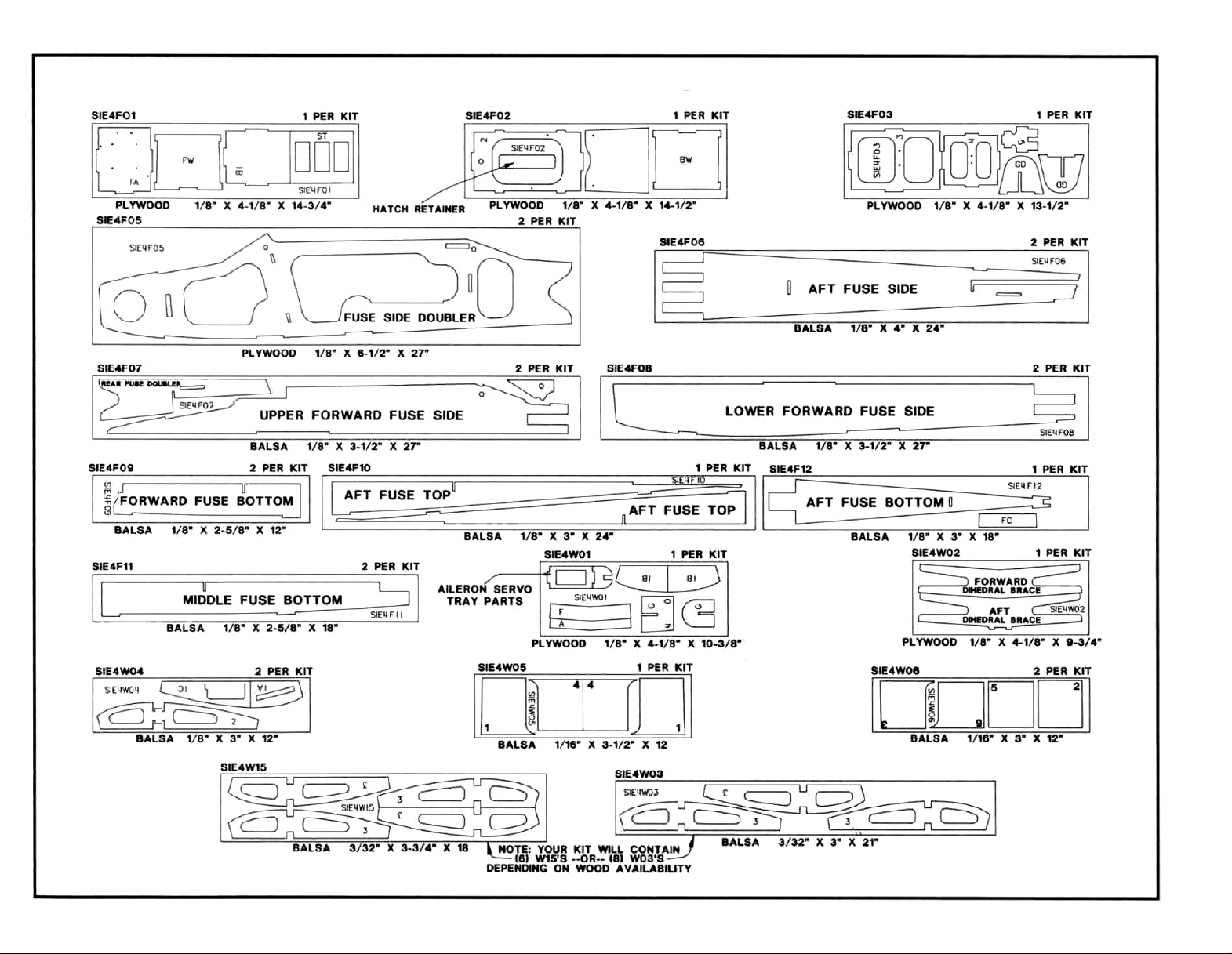

DIE PATTERNS

DECISIONS YOU MUST MAKE EARLY

IN THE BUILDING SEQUENCE....................5

Engine and Mount Selection

Other Items Required

Supplies and Tools Needed ...........................5

Common Abbreviations ..................................6

Types of Wood ...............................................6

Get Ready to

USING GLUE

NOTES ON SANDING...................................7

BUILD THE TAIL SURFACES

Hinge Slots.....................................................8

BUILD THE FUSELAGE

BUILD THE WING

Guide Tool......................................................16

Left Wing Panel Assembly

No Aileron Version

Aileron Version............................................... 19

............................................3

.............................................4

..........................5

.....................................5

Build

.........................................6

.................................................6

......................7

...............................9

.........................................16

.............................16

.........................................18

TABLE OF CONTENTS

Wing Tips....................................................... 19

Right Wing Panel Assembly........................... 19

Join the Wing .................................................19

Bolt on Wing ...................................................21

Rubber Band on Wing ....................................22

Install the Ailerons ..........................................22

Center Section Sheeting ................................23

FINAL ASSEMBLY........................................ 24

Bolt-on Wings.................................................25

Rubber Band-on Wings..................................26

Mount the Tail Surfaces .................................26

Tailwheel Assembly (optional) .......................27

Mount the Engine

FINISHING.....................................................30

Balance the Airplane Laterally .......................30

Final Sanding .................................................30

Covering.........................................................30

Covering Tips Using Monokote®......................30

Recommended Covering Sequence ..............31

Fuel Proofing..................................................31

Hinging...........................................................31

Final Control Hookup .....................................32

Aileron Control Hookup ..................................33

How to Make Z-bends ....................................33

Control Surface Throws .................................34

Apply Decals and Trim ............................35,36

Install Receiver, Battery, Switch..................... 36

...........................................28

Install

the Fuel Tank

BALANCE YOUR MODEL

FINAL CHECKS

PRE-FLIGHT

Charge the Radio Batteries............................38

Find

a Safe

Ground Check the Model ...............................38

Range Check your Radio

ENGINE SAFETY PRECAUTIONS............... 38

AMA SAFETY CODE

General ..........................................................39

Radio Control.................................................39

FIRST

Take Off.........................................................40

Flying..............................................................40

Landing

Landing Pattern Drawings..............................41

PARTS LIST

2-VIEW DRAWING

Place

FLIGHTS

..........................................................41

.......................................36

............................37

............................................37

to Fly

.................................38

...............................38

....................................39

............................................39

..................................................43

........................................44

Page 3

WARNING! THIS IS NOT A TOY!

3

2. You must take your time to build straight true

and strong.

The model you will build from this kit is not a toy! It is capable of serious bodily harm

and property damage. IT IS YOUR RESPONSIBILITY AND YOURS ALONE - to build

this kit correctly, properly install all R/C components to test fly the model, and fly it

ONLY with experienced, competent help using common sense and in accordance with

all safety standards as set down in the Academy of Model Aeronautics Safety Code.

It is suggested that you join the AMA to become properly insured before you attempt

to fly the model. IF YOU ARE JUST STARTING R/C MODELING, CONSULT YOUR

LOCAL HOBBY SHOP OR WRITE TO THE ACADEMY OF MODEL AERONAUTICS

TO FIND AN EXPERIENCED FLYING INSTRUCTOR IN YOUR AREA.

Academy of Model Aeronautics

1810 Samuel Morse Drive

Reston, VA 22090 (703) 435-0750

INTRODUCTION

Thank you for purchasing the Top Flite

GOLD EDITION Sierra.

The Top Flite Sierra is an excellent trainer model

designed to get you off to a great start in learning to

build and fly. After you learn to fly, the Sierra also has

enough maneuverability to perform most basic aerobatics and provide many hours flying enjoyment.

The easy construction, great lines, and included

decals make it easy for you to build a great-looking

model.

The Top Flite Sierra is designed to fly as good as

it looks. Its thick, flat-bottom wing offers strong lift at

slow speeds and great strength. The computerdesigned, interlocking structure allows you to build a

straight and true model with smooth confidence-

boosting flight qualities.

Please inspect all parts carefully before

starting to build! If any parts are missing, broken

or defective, or if you have any questions about

building or flying this model, please call us at

(217) 398-6300 and we'll be glad to help. If you

are calling for replacement parts, please look up

the part numbers and the kit identification number (stamped on the end of the carton) and have

them ready when calling.

PRECAUTIONS

1. You must build the plane according to the plans

and instructions. Do not alter or modify the model,

as doing so may result in an unsafe or unflyable

model. In a few cases the plans and instructions may

differ slightly from the photos. In those instances you

should assume the plans and written instructions are

correct.

3. You must use a proper R/C radio that is in first

class condition, the correct engine size and correct

components (fuel tank. wheels, etc.) throughout

your building process.

4. You must properly install all R/C and other components so that the model operates properly on the

ground and in the air.

5. You must test the operation of the model before

the first and each successive flight to insure that all

equipment is operating, and to make certain that the

model has remained structurally sound. Be sure to

check external nylon clevises often. Replace them

if they show signs of wear.

6. You must fly the model only with the competent

help of a well experienced R/C pilot, if you are not

already an experienced R/C pilot at this time.

NOTE: We, as the kit manufacturer, can provide

you with a top quality kit and great instructions,

but ultimately the quality and flyability of your

finished model depends on how you build it;

therefore, we cannot in any way guarantee the

performance of your completed model, and no

representations are expressed or implied as to

the performance or safety of your completed

model.

Remember: Take your time and follow the directions to complete a well-built model that is

straight and true.

Page 4

4

DIE PATTERNS

Page 5

5

EARLY IN THE

BUILDING SEQUENCE

ENGINE AND MOUNT SELECTION

The recommended engine size range is as follows:

.28-.40-.46 cu. in.

.40-.48-.60 cu. in. 4-cycle

NOTE: The displacement in bold type is the

most highly recommended. However, all

these engines will fly the Sierra well.

The supplied MM40 motor mount should

hold most of the two strokes in the range and

some of the four strokes. It is permissible to file

the inside of the mount slightly to fit larger engines

(see photo on page 28). Some engines may

require you to buy a different mount from your

hobby dealer. Study the plans and the engine

mounting section of this bookformore information

and sample installations.

BOLT-ON OR

RUBBER BAND-ON WINGS

The Sierra has been designed and tested

with rubber band-on or bolt-on wings. The rubber band on wings will better absorb the shocks

of a crash or landing accident such as a cartwheel.

If you have a good instructor and flying site or

already have some flying experience, you may

want to use the bolt-on wing option.

3 OR 4 CHANNELS

The Sierra flies very well with or without

ailerons. The 3-channel version will be cheaper

and easierto build. The 4-channel version offers

the extra flexibility of aileron control. Ailerons

2-cycle

of

make cross wind take offs and landings easier

to control, so many instructors recommend

ailerons.

TRICYCLE OR TAILDRAGGER

GEAR

The tricycle landing gear is considered

standard. We recommend the tricycle gear if

this is your first airplane because it offers the

best ground handling as well as straight ahead

take offs and landings. The tricycle gear also

does a better job of protecting the propeller

during bouncy take offs and landings. If you

are sport flying the Sierra or want to learn to fly

a taildragger, provisions have been made to

allow you to build the Sierra as a taildragger.

The Great Planes #L-7 tail wheel assembly

may be purchased from your dealer and

modified slightly to match the drawing on the

fuselage plans.

SELECTION OF WHEELS

The standard recommended wheels

two 2-3/4" main wheels and one 2-1/2" nose

wheel. If you are flying off grass or an uneven

surface, you may wish to use larger wheels

than those recommended. The standard

wheels have been tested off of grass and work

fine, but 3" wheels all the way around would

work even better.

If you will be flying a taildragger off of

grass, we recommend using 3" to 3-1/4" main

wheels and a 1" to 1-1/4" tailwheel.

are

OTHER ITEMS REQUIRED

Three or Four-channel radio with 3 or 4 servos

Engine

Propellers (Top Flite Power Point recommended-see

engine instructions for sizes)

2-1/4" Prop Spinner

Fuel Tank (Most 6 to 10 oz. tanks will tit)

2-3/4" Main Wheels (2)

2-1/2" Nose Wheel (1) (or 1" Tailwheel)

5/32" Wheel Collars - (4-6)

Top Flite MonoKote"

*Model shown covered with 2 rolls of Yellow, plus Missile

Red, and Orange for trim

Silicone Fuel Tubing

Latex Foam Rubber Padding (1/4" thick)

#64 Rubber Bands (10-12 for rubber band-on wings)

1/8" Foam Wing Seating Tape (optional)

SUGGESTED SUPPLIES

AND TOOLS

2 oz. Thin CA Adhesive (Hobbico Bullet Glue is Recommended)

2 oz. Medium CA Adhesive (Hobbico Bullet Glue is Recommended)

15-Minute Epoxy (Hobbico Bullet Glue is Recommended)

Hand or Electric Drill

Drill Bits: 1/16", 3/32", 1/8", 5/32", 3/16", 1/4"

Top Flite Heat Sealing Tool

Top Flite Heat Gun

Hobby Saw (X-acto Razor Saw)

X-acto Knife, #11 Blades

Pliers

Screw Drivers

T-Pins

Straightedge

Short ruler

Masking Tape (Suggested for construction)

Sandpaper (coarse, medium, fine grit)*

T-Bar Sanding Block (or similar)

Waxed Paper

Lightweight Balsa Filler

1/4-20 Tap. Tap Wrench (optional bolt on wings)

IsopropyI Rubbing Alcohol (70%)

Dremel Moto Tool or similar (optional)

NOTE: On our workbench, we have four 11" T-Bar sanders,

equipped with #80, #100, #150, and #220-grit sandpaper. This

setup is all that is required for almost any sanding task.

Sanding blocks can be made from balsa for sanding hard to

reach spots. We also keep some #320-grit wet-or-dry

sandpaper handy for finish sanding before covering

Page 6

6

COMMON ABBREVIATIONS USED

IN THIS BOOK AND ON THE PLANS:

Deg. = Degrees Lt = Left

Elev = Elevator Ply = Plywood

Fuse = Fuselage Fit = Right

LE = Leading Edge (front) Stab = Stabilizer

LG

= Landing Gear TE = Trailing

= Box to check after step " = Inches

is completed.

Edge (rear)

Save all scraps. If any of the die-cut parts are difficult

to punch out, do not force them! Instead, first cut

around the parts with an X-acto knife. After punching

out the die-cut parts, use your T-Bar or sanding block

to lightly sand the edges to remove any die-cutting

irregularities.

3. As you identify and mark the parts, separate

them into groups, such as fuse (fuselage), wing, fin

and stab (stabilizer), and hardware.

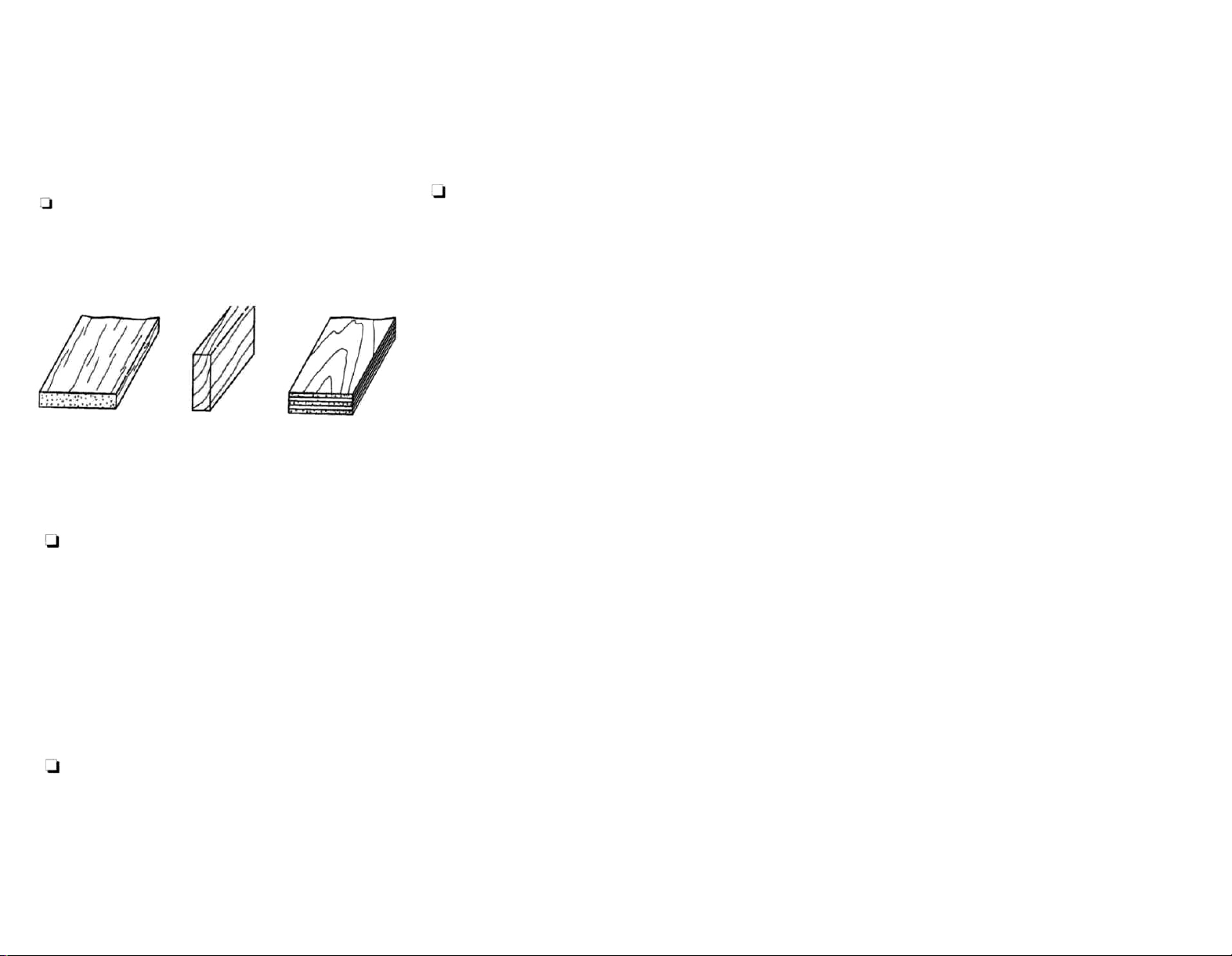

USING GLUE

There are two types of glue that are recom-

mended for building this model: CA and Epoxy.

gaps, require slight repositioning, or involve

hardwoods. Medium CA can be used to make

small fillets between parts in high stress areas.

Medium CA is a very good general purpose

glue and many people use it for the majority of

their building.

Some medium CA glues can be slow to set,

especially when used to fill gaps. A product

known as CA accelerator is available to speed

things up. It is sprayed onto the joint after the

glue is applied and chemically reacts with the

glue causing it to set very rapidly. There are a

few precautions to consider when using an

accelerator...

Balsa Basswood Plywood

GET READY TO BUILD

1. Unroll the plan sheets. Re-roll the plans inside

out to make them lie flat. The wing plan sheet has a

cut-line across it. If you have a small building space

you may cut the wing plan into two pieces along this

line.

The fuselage plan sheet does not have a cut-line

across it. It is used mostly for reference and not

much building is done over it. There is not much

benefit in cutting it apart, but you may do so if you

wish.

2. Remove all parts from the box. As you do,

figure out the name of each part by comparing it with

the plans, die-cut patterns, and the parts list at the

back of this book. Using a felt tip pen, write the part

name or size on each piece to avoid confusion later.

Use the die-cut patterns shown on page 4 to identify

the die-cut parts and mark them before punching out.

CA (cyanoacrylate) glue is used for general construction. It is available in a variety of

viscosities. We recommend you have the following two types.

Thin CA has a viscosity similar to water

and is used to glue together parts that fit

together very well and do not require repositioning after glue is applied. Thin CA is especially effective for gluing balsa to balsa. It can

be used to glue hardwoods such as plywood,

spruce, or bass but it is usually necessary to

fillet the joint afterwards with some medium CA.

Thin CA has the ability to "wick" into joints. This

means it will be drawn into very fine gaps

between parts. This characteristic makes thin

CA very useful for a lot of tasks, such as gluing

seams that are already clamped together or

installing CA hinges. Thin CA usually sets very

rapidly, so do not expect to move parts at all

after glue is applied. This rapid reaction may

also produce fumes and a significant amount of

heat. Always use CA glues in a well-ventilated

area.

The other type of CA glue we recommend

is medium (or gap filling). Medium CA is used

in

general construction for parts which have

Use it in a well ventilated area. The rapid

reaction can release irritating fumes at a higher

rate than normal. Do not use CA accelerator on

thin CA!

Be careful when using the accelerator

around plastics. Certain accelerators may

attack some plastics and the vapors may fog

clear canopies. It is best to test the glue and

accelerator on a scrap piece of plastic if one is

available.

Using too much accelerator may cause the

CA glue to react very rapidly and literally boil.

This will result in a joint with a chalky white color

which is not nearly as strong as a normal joint.

Epoxy is used on high-stress joints that

require toughness and vibration resistance.

Epoxy also works well in areas that may encounter fuel. Its slower cure time allows parts

to be clamped, checked, and realigned if necessary before the epoxy sets. Epoxy is available in many different formulas having different

cure times. The single best type of epoxy to

have available when building your Sierra is one

that sets in 15 minutes, but you may also find 5minute epoxy handy to have around.

Page 7

NOTES ON SANDING

1. Use a block orT-barwhereever possible when

sanding. The flat block will "ignore" glue and

changing wood density and give you a true and

even shape.

2. Always use fresh, sharp sandpaper. Sharp

sandpaper will cut through glue and hard materials easily, giving an even surface. Older, dull

sandpaper will require more pressure and may

gouge the surface.

BUILD THE TAIL

SURFACES

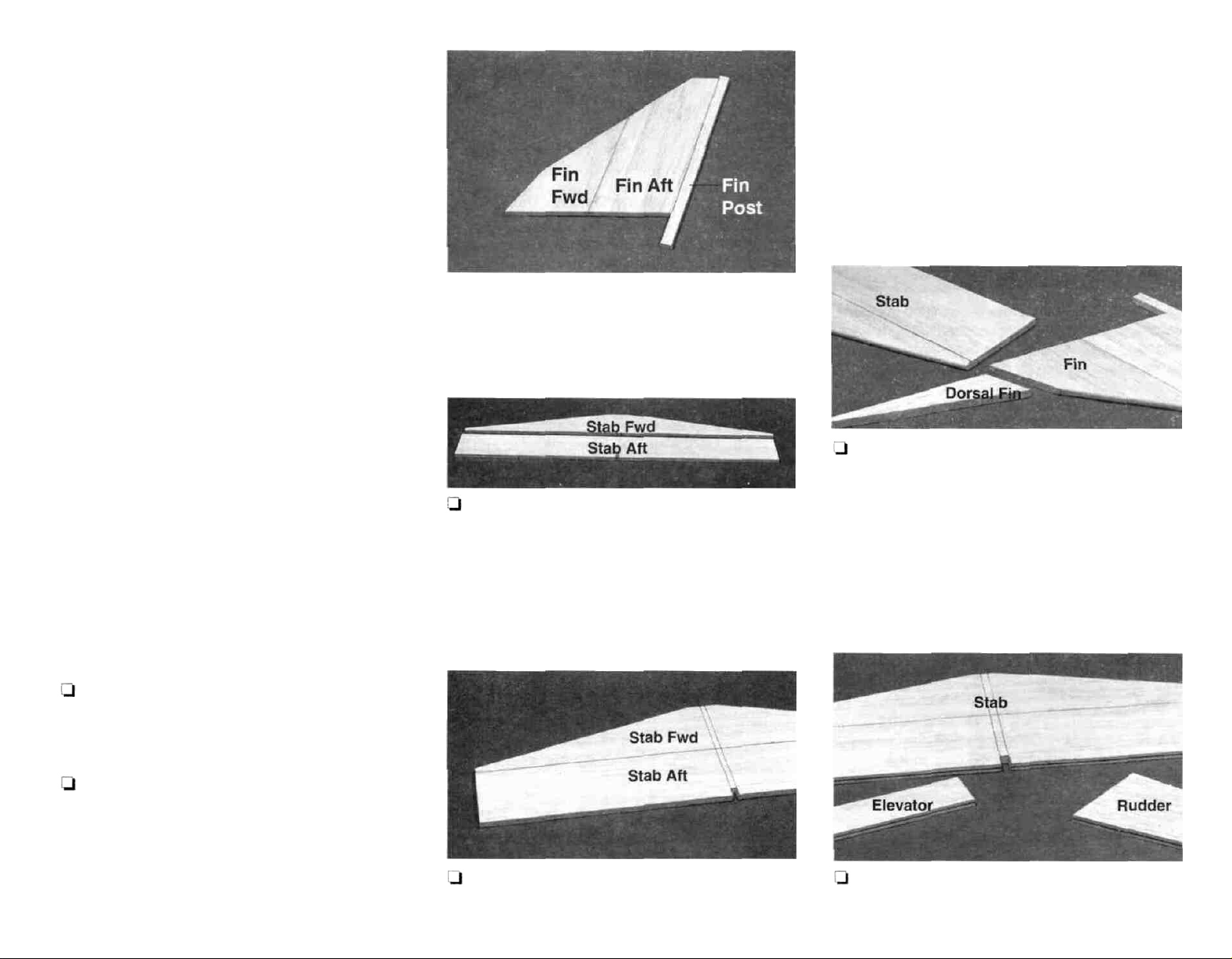

To build the tail surfaces, you will need the following:

1/4" shaped balsa fin fwd

1/4" shaped balsa fin aft

1/4" shaped balsa rudder

1/4" shaped balsa stab fwd

1/4" shaped balsa stab aft

Tapered balsa elevator

1/8" bent wire elevator joiner

of a paper towel to make sanding easier. Flip the

parts over and apply some thin CA to the other side

of the joint.

3. The notch in the shaped 1/4" balsa stab aft

piece is positioned at the back edge of the stab so the

fin post can protrude through the notch later when

you are told to attach the tail surfaces to the fuselage.

Glue the shaped 1/4" balsa stab (stabilizer) fwd to

the stab aft in the same manner as the fin parts.

7

150 grit sandpaper to smooth out any unevenness.

Carefully block sand the edges and ends to correct

any slight bumps or mismatches. Align the notch at

the back edge of the stab and the stab TE with the

plans. Mark the fin location on the front edge of the

stab. Draw two lines from these marks to the notch

in the aft edge of the stab.

5. Refer to the cross section on the plans. Use

a sanding block to round the stab leading edge

(except the flattened center portion). Mark the

location of the dorsal fin on the forward edge of the

fin using the plans as a guide and round the fin only

above the dorsal fin. The fin, rudder, and stab should

have their tip edge corners rounded slightly for

easier covering (see the cross sections on the fuselage plans).

1. Work on a flat surface covered with waxed

paper. Refer

their

locations.

2. Put the shaped 1/4" balsa fin fwd, fin aft, and

the 1/4" x 3/8" x 8-7/8" balsa fin post together and

check how the parts fit. Block sand the mating

surfaces until they fit well. Hold the parts together

tightly and glue them together with thin CA. Imme-

diately wipe off any excess glue with a quick stroke

to the plans to identify the parts and

4. Block sand the surfaces of the fin and stab with

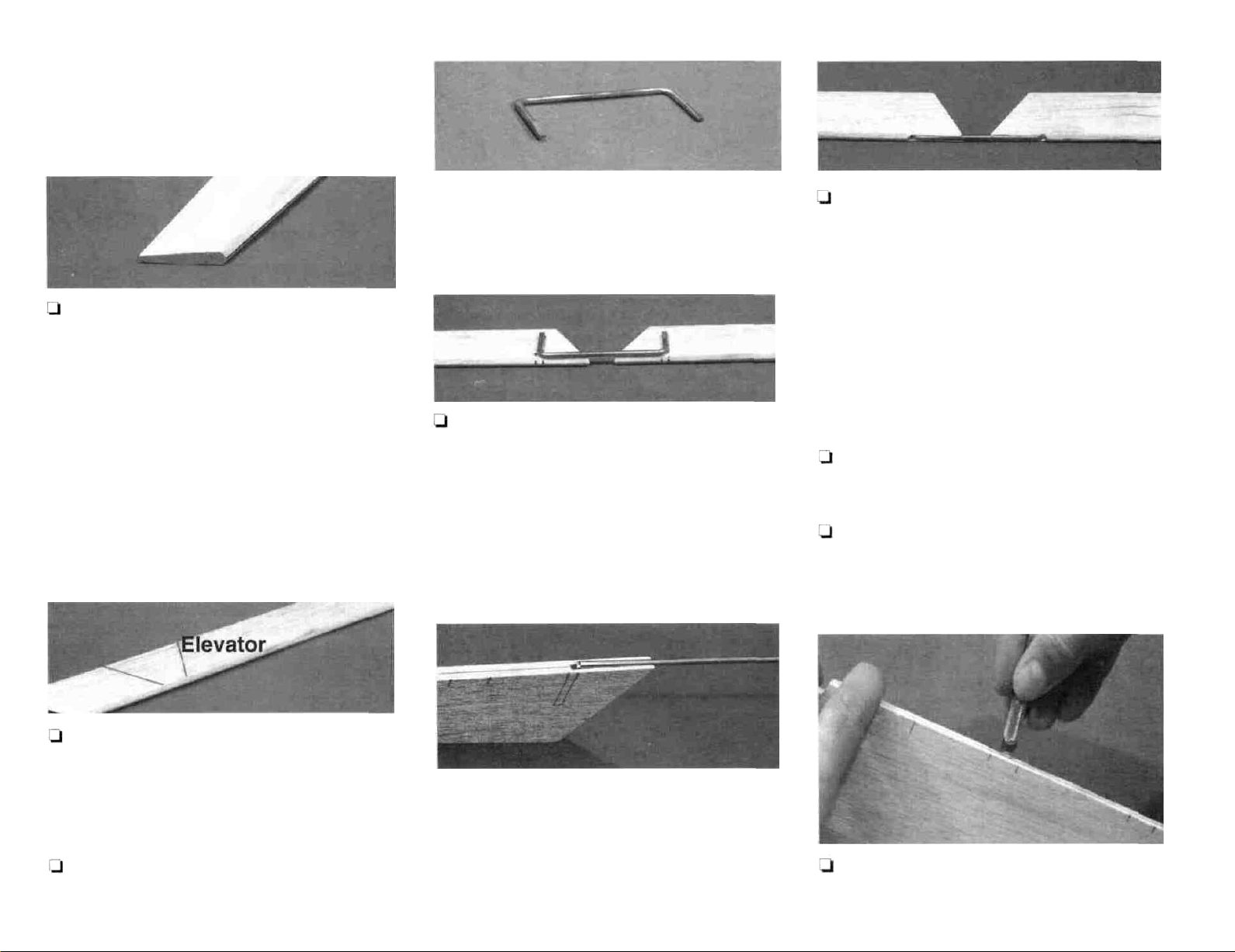

6. Use a smooth ball point pen to draw a

Page 8

8

centerline along the stab trailing edge, tapered balsa

elevator leading edge, fin trailing edge, and shaped

1/4" balsa rudder leading edge.

7. Referring to the cross sections on the plans,

carefully block sand the elevator and rudder leading

edges to a "V" shape. The centerlines you drew

earlier should remain for hinging later.

NOTE: The rudder may be left at a constant

thickness of 1/4" or you may taper it with a

sanding block to match the top view on the

fuselage plans. For a model that travels at a

relatively slow speed such as this one, it is not

necessary to taper the rudder to make the aircraft

fly properly. If you want to taper it for appearance

reasons, that is fine.

shown on the plans and in the photo. This will make

it easier to align the elevators.

10. Lay the elevators and the elevator joiner over

the plans. Mark where the joiner will insert into the

elevators. Start the hole in the elevators by cutting

a small 1/8" square notch with a sharp #11 knife.

Carefully drill a 1/8" hole into each elevator to the

depth shown on the plans. Use the knife to cut a

groove in the front of the elevator at the root end for

the joiner (as shown in the photo).

11. Make sure the joiner wire will fit all the way into

each elevator and that both elevators lie flat on the

work surface with the joiner installed. Bend the joiner

wire if necessary to make the elevators line up with

each other. Rough up the joiner wire with coarse

sandpaper and clean it with alcohol. Mix some 5minute epoxy and use a tooth pick or piece of wire to

push the epoxy into the hole and groove in the

elevator. Push the joiner into the elevators and wipe

away any excess glue. Lay the parts over the plans

to aid in alignment while the glue sets. It is important

that the elevator LE is straight so you will not have

problems when you hinge it later.

12. After the epoxy is cured apply some thin CA

to both sides of the balsa elevator over the joiner to

'harden' the area. Sand the cured glue smooth.

13. Place the fin and stab over the plans and mark

the hinge locations on the trailing edges. Transfer

the locations onto the elevator and rudder leading

edges.

8. Hold the tapered elevator stock over the plans

and mark the locations of the cuts at the center

where the elevator is cut away to allow for rudder

movement. Use a razor saw to cut away the right and

left elevators.

An alternate method to make a groove in a surface

for a torque rod is to sharpen the end of an appropriately sized (1/8") brass tube from the inside with a

#11 knife, then use the tube to cut out the notch for

9. Locate the bent 1/8" wire elevator joiner. Use

the torque rod.

14. Cut the hinge slots using

a flat file or a grinder to taper the ends slightly as described on the following page.

the

technique

Page 9

9

CAUTION!!! You must use extreme care to

avoid cutting yourself when cutting hinge

slots with an X-acto knife. If the balsa breaks

while you are pushing on the knife, the blade

could go into your hand before you know it!

A good precaution is to wear leather gloves

while performing this step.

A. Begin by carefully cutting a very shallow slit

at the hinge location. This first cut is to establish your

cut in the right place, so concentrate on staying on

the centerline and don't cut too deep!

B. Make three or four more cuts in the same line,

going slightly deeper each time. As you make

these additional cuts, work on going straight into the

wood. Continue this process while "wiggling" the

knife handle forward and backward until the blade

has reached the proper depth for the hinge.

C. Trial fit the hinge into the slot. If the hinge is

difficult to push in, re-insert the knife and move it

back and forth in the slot a few times to enlarge the

slot.

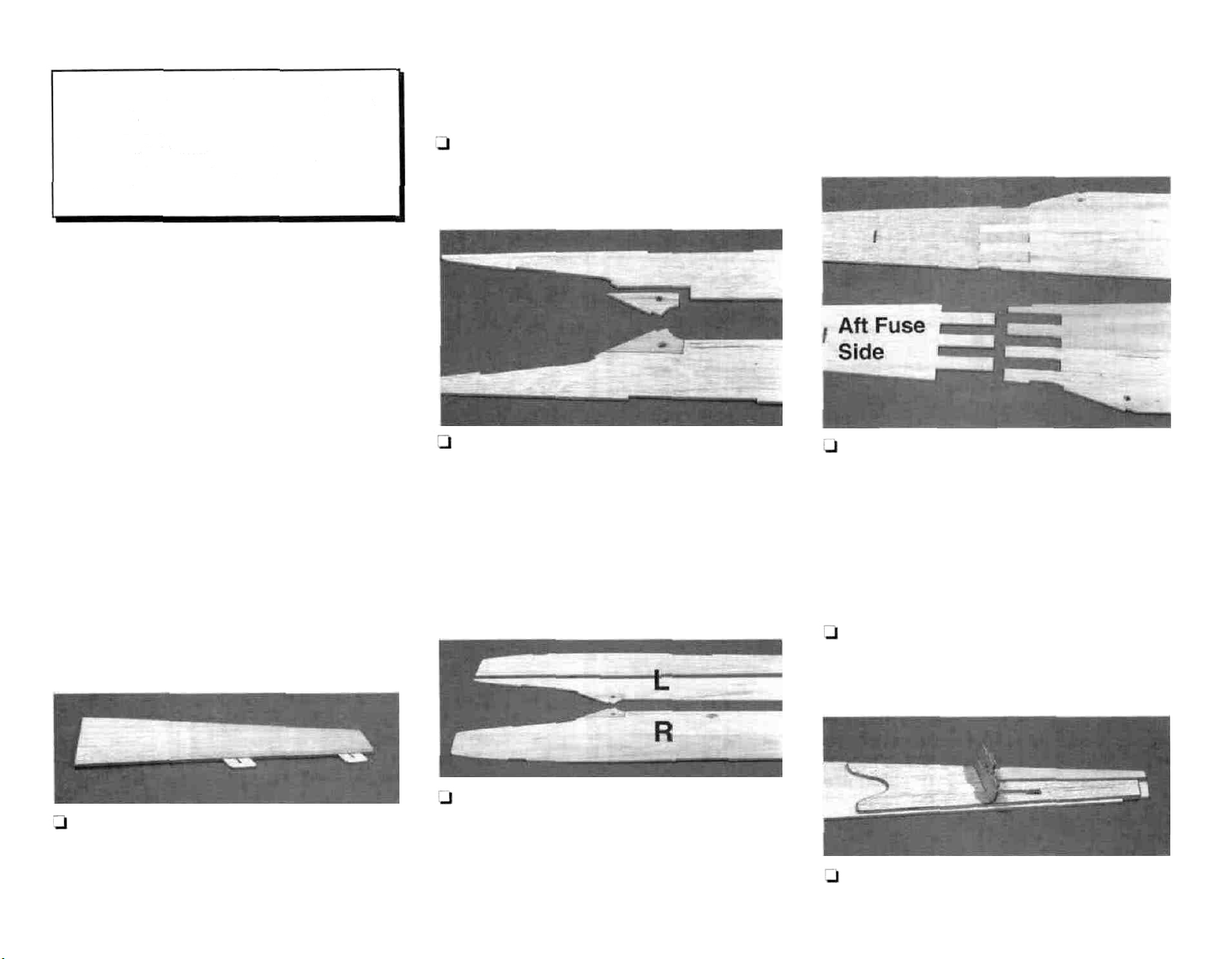

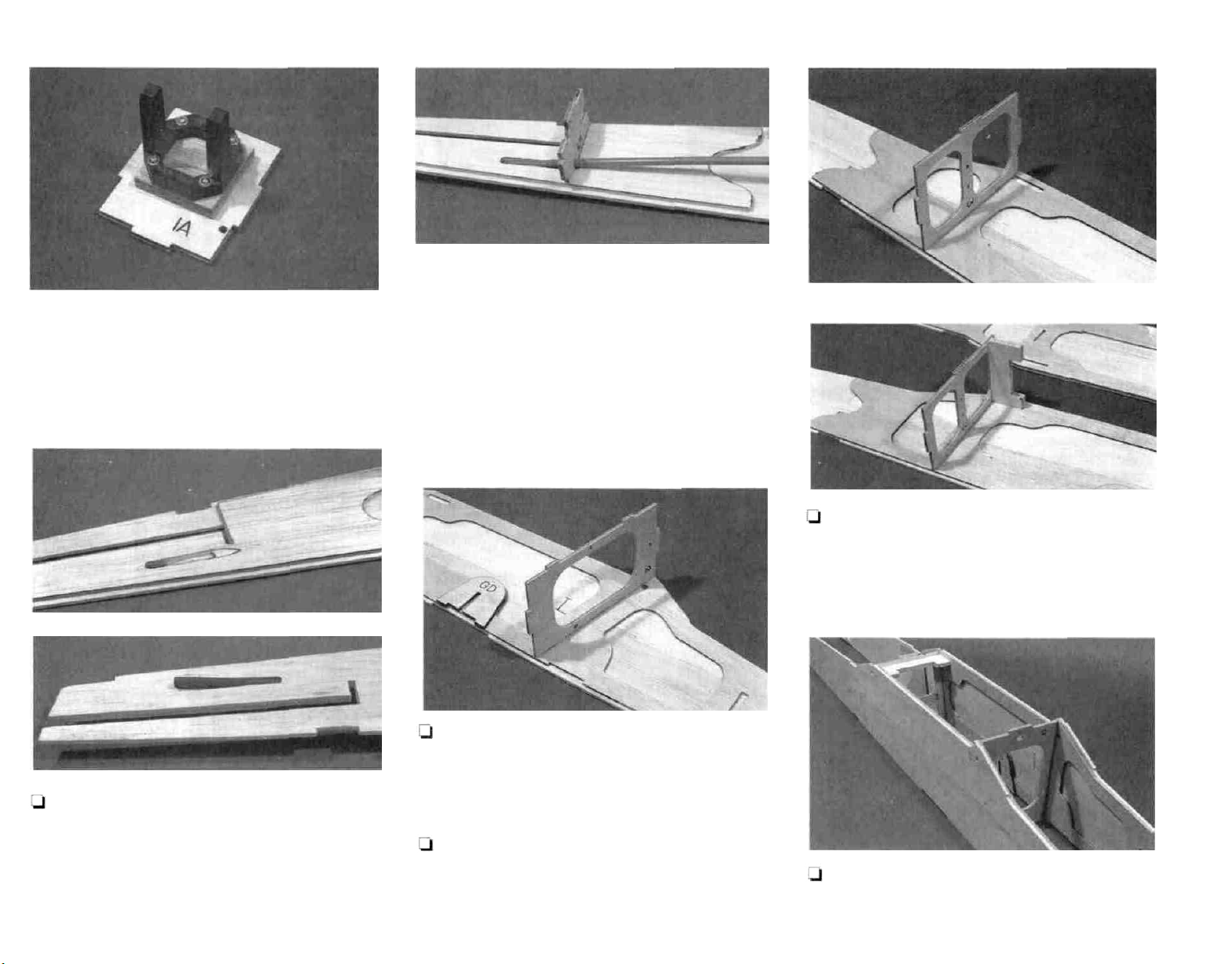

BUILD THE FUSELAGE

1. Place the fuselage plan side view on your work

table. Cover it with waxed paper.

2. Use thin CA to glue the separately die-cut

corner of the die-cut 1 /8" balsa upper forward fuse

sides in place as shown in the photo. These parts

are located in the same die-cut sheets (SIE4F07).

Remember that you will be making a right and a left

fuselage side. You may wish to glue from opposite

sides of the wood in order to reduce sanding.

NOTE: The plans may shrink or expand slightly

due to humidity. Do not worry if the parts are not

exactly the same size as the plans.

4. Plug the die-cut 1/8" balsa aft fuse sides into

the forward fuse sides. Sand them lightly if necessary to make them fit. Before gluing be sure to align

the parts over the plans. Any "bend" in the fuse sides

will cause the fuselage to twist later. When the fuse

sides are well aligned with the plans, glue the forward

and aft pieces together with thin CA. Add medium

CA to any joints that are not tight fitting.

15. Trial fit the hinges in the slots and trial fit the

rudder and elevator in place on the fin and stab. Do

not glue the hinges until after you have covered

the model.

3. Glue the upper forward fuse sides to the diecut 1/8" balsa lower forward fuse sides using thin

CA. Mark the inside surface of the fuse sides with the

letters 'R' and 'L to designate the inside of the Right

and Left fuselage sides. Be sure to make a RIGHT

and a LEFT fuselage side.

5. Use a sanding block to sand smooth all of the

joints you have made on the fuse sides.

6. Position the die-cut 1/8" balsa rear fuse

doubler in its place on the inside surface at the rear

Page 10

10

of the fuselage side. Use the die-cut 1/8" plywood

former F-5 to help you position the doubler (do not

glue the former in until told to do so later). Notice that

the pushrod exit holes do not line up (this is normal

and makes the pushrod installation in later steps

easier). Apply several beads of medium CA to the

doubler and position it on the fuselage side. When

it is aligned properly, press it firmly down to spread

out the beads of glue. Repeat this step for the other

side. Be sure to make a RIGHT and a LEFT.

carefully in position. Apply thin CA around the all

edges of the doubler to reinforce it. Glue the

doublers to the inside of both the left and the right

fuse sides.

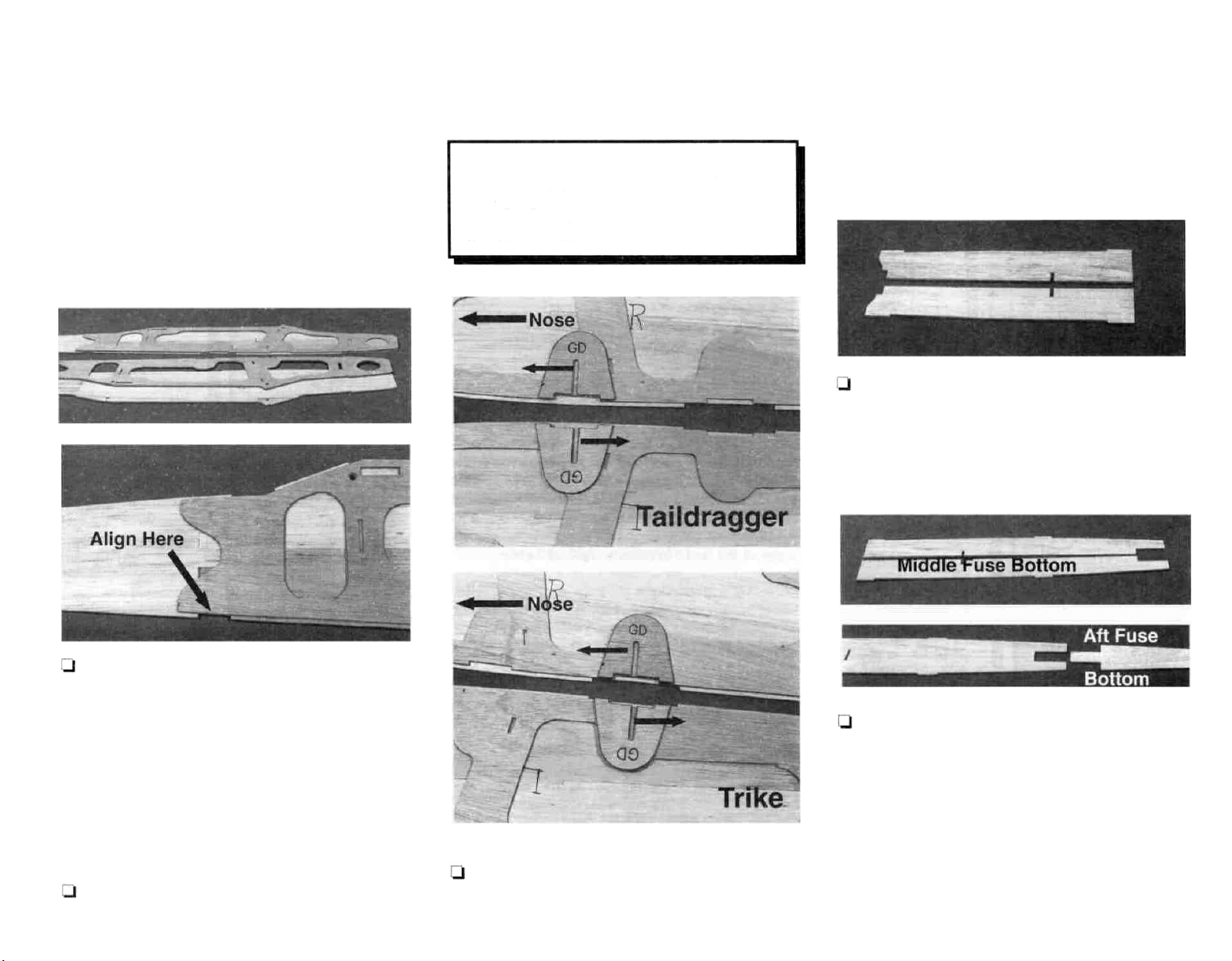

AT THIS POINT YOU MUST DECIDE

WHETHER YOU ARE GOING TO BUILD

A TAILDRAGGER OR A TRIKE GEAR

MODEL. THE POSITION OF THE LANDING

GEAR DOUBLER (GD) DEPENDS ON THIS.

may be placed in two different positions (forward for

taildragger gear, aft for trike gear). Note also the offcenter slot in the doubler. The slot should be offcenter toward the aft end of the left fuselage side,

and the forward end of the right fuselage side. Glue

the gear doublers in the position chosen.

10. Glue the right and left die-cut 1/8" balsa

forward fuse bottom pieces together with thin CA.

Add medium CA to any gaps.

fuselage doubler over the inside of the fuselage

sides. Notice that it should fit perfectly at the very

front of the fuselage, and then be offset 1/8" in from

the edge of the fuselage sides most of the rest of the

way back. The photos and plans will help you

determine the proper location of the doublers. Use

the front edges and the lock notch in the fuse side

near the lower aft portion of the doubler to align the

doubler.

8. Apply medium CA to the doubler and press it

9. Study the fuselage plans in the landing gear

area. The die-cut 1/8" plywood gear doublers (GD)

11. Glue the right and left die-cut 1/8" balsa

middle fuse bottom pieces together with thin CA.

Place the die-cut 1/8" balsa aft fuse bottom piece

into the notch at the back end of the middle fuse

bottom. Notice that there is a gap in the middle. This

is for former F-4 to key into later. Check that these

parts are properly aligned by positioning them over

the fuselage top view on the plans. Glue with thin

CA. Add medium CA to any gaps.

Page 11

12. Glue the right and left die-cut 1/8" balsa aft

fuse top pieces together with thin CA. Note the diecut "bumps" at the aft end of the aft fuse top. Trim

these off with a straightedge and a sharp knife.

13. Use medium CA to glue the die-cut 1/8"

plywood firewall F-1A (1A) to F-1B (1B). F-1A is

centered on the slightly larger F-1 B. Make sure the

side of F-1A with the punch marks on it remains

visible. (See the photo at step 14).

NOTE: For the following steps, refer to the firewall

cross section drawing on the fuselage plans. At this

point you must know which engine you will use. If you

are using a recommended 2-cycle engine which fits

into the supplied mount, all the punch marks on F-1A

will be drilled to their appropriate size (in the following

steps). If you are using a 4-cycle engine or an engine

that requires a different mount, you will need to

determine the mounting, throttle pushrod exit, steering

pushrod exit, and fuel line exit hole locations for your

installation. (HINT: Use the four standard mount

punch marks on F-1A to help you locate an alternate

mount by drawing an "X" between them to find the

engine centerline). Regardless which engine you are

using, mount it on this centerline.

drill. Use the firewall (F-1) cross-section on the

fuselage plans to positively identify these hole locations. While you have the 5/32" drill bit out, drill 5/32"

holes through the two punch marks in the die-cut

1/8" ply landing gear plate (LGP).

15. Drill 1/4" fuel line exit holes at the top edge

of F-1. The punch mark locations should be OK for

most engine installations.

16. Drill a 3/16" throttle pushrod hole in F-1 in the

location you determined. A punch mark indicates

the "standard" pushrod exit location.

17. If you are using the tricycle landing gear, drill

a 3/16" pushrod exit hole in F-1 at

the

appropriate

punch mark location.

11

NOTE: At this point you should determine if you

need to use the 9mm x 2" x 2" plywood spacer

plate in your engine installation. Study the

engine installation drawings on the fuse plan

sheet. Short engines such as the OS .40 FP

require the use of this plate. Longer engines

such as the OS .40 SF or 4-cycle engines do not

require the use of this plate.

19. If you are using the 9mm spacer plate, center

the MM40 motor mount on one side of the plate and

mark the four mounting hole locations. Drill the holes

in the spacer plate with a 1/8" drill bit.

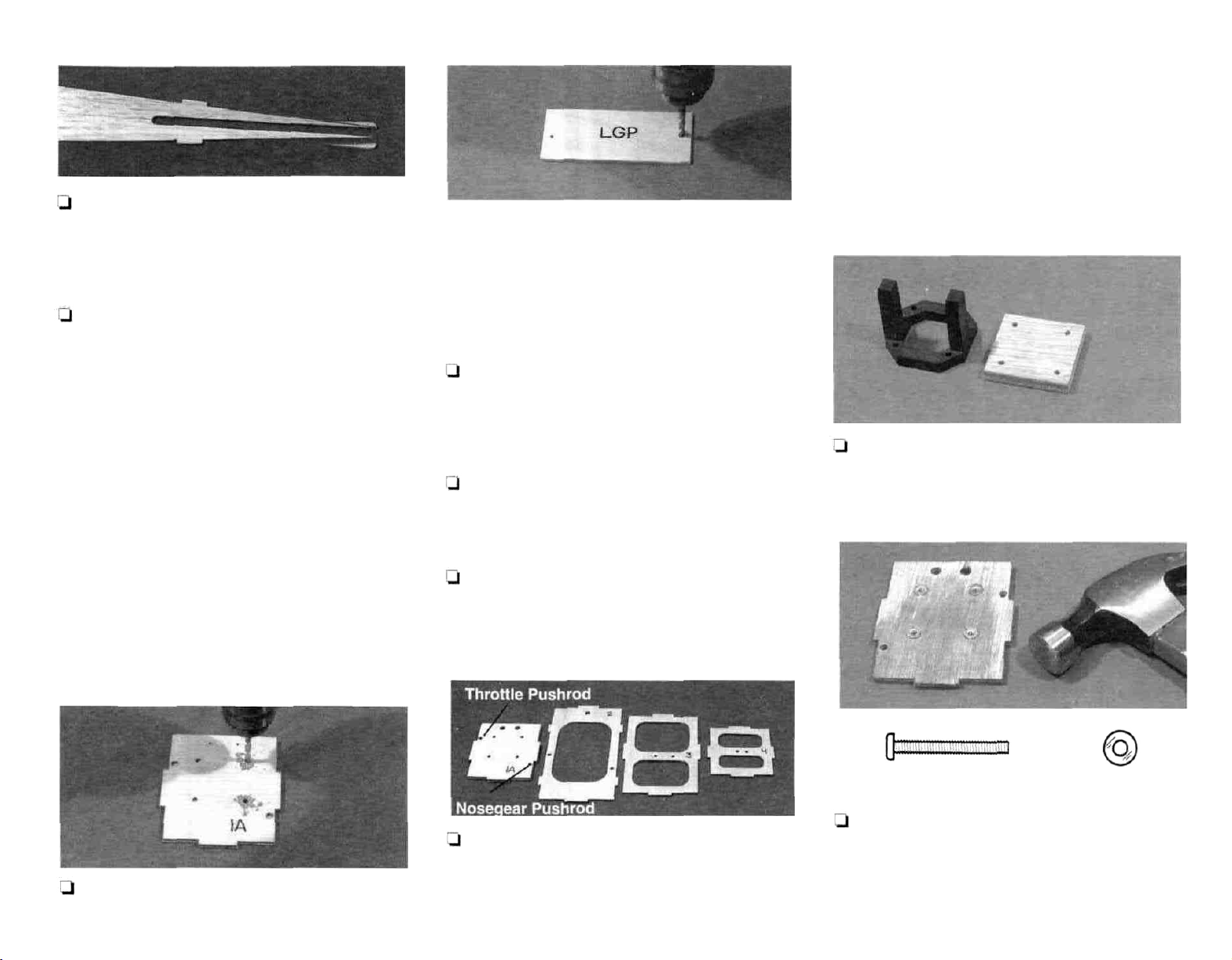

14. If you are using the supplied mount, drill the

four punch marks in the middle of F-1 with a 5/32"

18. Drill 3/16" pushrod holes at the punch marks

in die-cut 1/8" plywood formers F-2 (2), F-3 (3), and

F-4 (4). Refer to the cross-sections on the fuselage

plans to confirm the pushrod locations.

4-40 x 1" Machine Screw No. 4 Flat Washer

20. Gently tap the 4-40 blind nuts into the back

(F-1 B) side of the firewall. Bolt the motor mount (and

the 9mm spacer if required) to the firewall using the

supplied 4-40 x 1" machine screws and

#4

wash-

ers. Carefully apply a small drop of thin CA to the

Page 12

12

perimeter of the flange on each 4-40 blind nut.

Remove the motor mount.

1/8" plywood former F-5 (5) in place to confirm a

good fit.

IMPORTANT NOTE: All formers (F-1 through

F-5) are glued in with the stamped numbers

facing forward and upright as shown in the

photos. This is necessary to maintain proper

pushrod routing.

21. Use a small round file to blend the pushrod

exits at the aft end of both the fuselage sides to allow

the outer pushrod tubes to exit at the proper angle

as shown on the fuselage top view and in the photos.

If you do not have a file, use a #11 knife to shape the

pushrod exits as shown in the photo. Hold die-cut

22. Use medium CA to glue the die-cut 1/8"

plywood former F-2B to the left fuselage side. Use a

90 degree triangle to keep the former perpendicular

to the fuse side while gluing.

23. Glue the die-cut 1/8" plywood former F-3 to

the left fuse side in the same manner as F-2. (The

photo for this step is at the top of the next column).

24. Push the 1 /4" ply wing bolt plate into position

just ahead of F-3 but do not glue yet. If the fit of this

plate is too tight, sand it slightly till it fits comfortably.

(Install this plate for strength even if you are using

rubber band-on wings.)

side structure. When all the alignment tabs on F-2

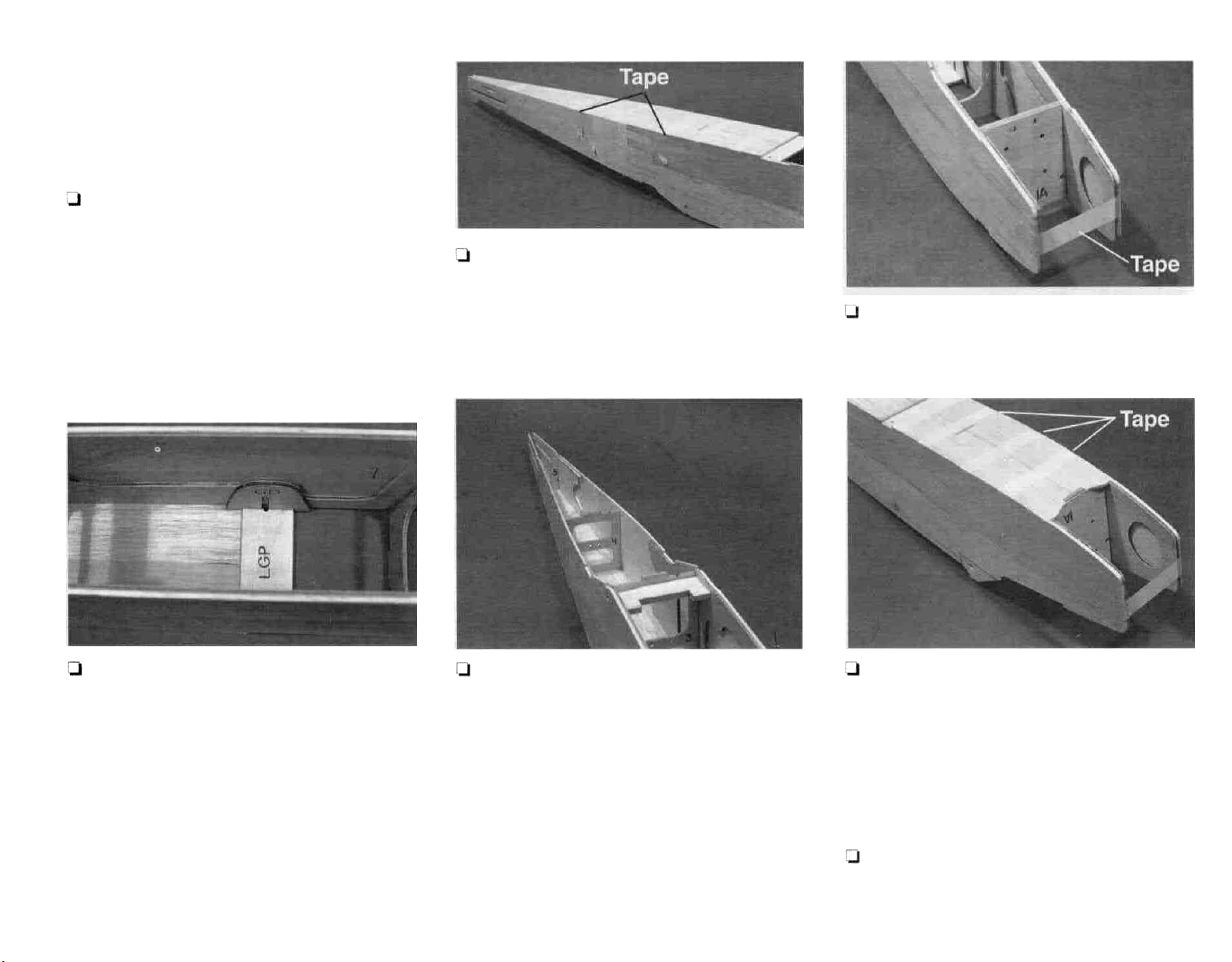

Page 13

and F-3 are thoroughly engaged by the right fuselage side, turn the fuselage upright as shown in the

photo and apply medium CA glue to the joints of the

right fuse side and F-2 and F-3.

26. See the photo above step 29 for the proper

position and orientation of the die-cut 1/8" plywood

former F-4. Use medium CA to glue former F-4 in its

place between the fuselage sides. Snap the die-cut

1/8" plywood former F-5 into position at the back of

the fuselage but do not glue yet; instead, use some

masking tape to hold the fuselage together. Re-

member all of the former I.D. numbers face forward.

28. Work the aft fuselage bottom pieces (assembled earlier) into position between the fuselage

sides, sanding if necessary for a good fit. Use some

masking tape to hold the fuse together.

13

30. Position the firewall (F-1A/B) in place between the fuselage sides. Use a strip of masking

tape to hold the fuse sides together at the front. Do

not glue the firewall yet.

27. Snap the landing gear plate (LGP) into

position at the fuse bottom. If you are building a

taildragger, make a duplicate of LGP (but without the

holes) out of scrap 1/8" balsa and substitute it at the

tricycle LGP location. The plywood LGP will be

installed in step 31 for the taildragger. Check to see

that the holes for the landing gear line up with the

slots in the gear doublers (GD). Do not glue yet.

29. Check the previously assembled, unglued

parts for fit and alignment. Correct any problems.

Apply medium CA from the inside of the fuselage to

any unglued joints involving the following parts: F-3,

F-4, F-5,and LGP. Use thin CA to glue the fuse

bottom to the fuse sides from its front edge back to

F-5. The very aft portion will be glued later when the

tail surfaces are installed.

31. (If you are making the taildragger version, put

the 1 /8" plywood LGP in place between the fuselage

sides at the taildragger position shown on the fuselage plans.) Work the 1 /8" forward fuse bottom sheet

joined earlier into position between the fuselage

sides. Use masking tape to hold the fuse bottom in

place.

32. Flex the fuselage sides outward and apply

medium CA or epoxy to the edges of the firewall.

Use

masking tape to hold the joint closed while the

Page 14

14

glue cures. Glue the forward bottom sheeting to the

fuse sides, the firewall, LGP, and former F-2 with thin

CA followed with a fillet of medium CA.

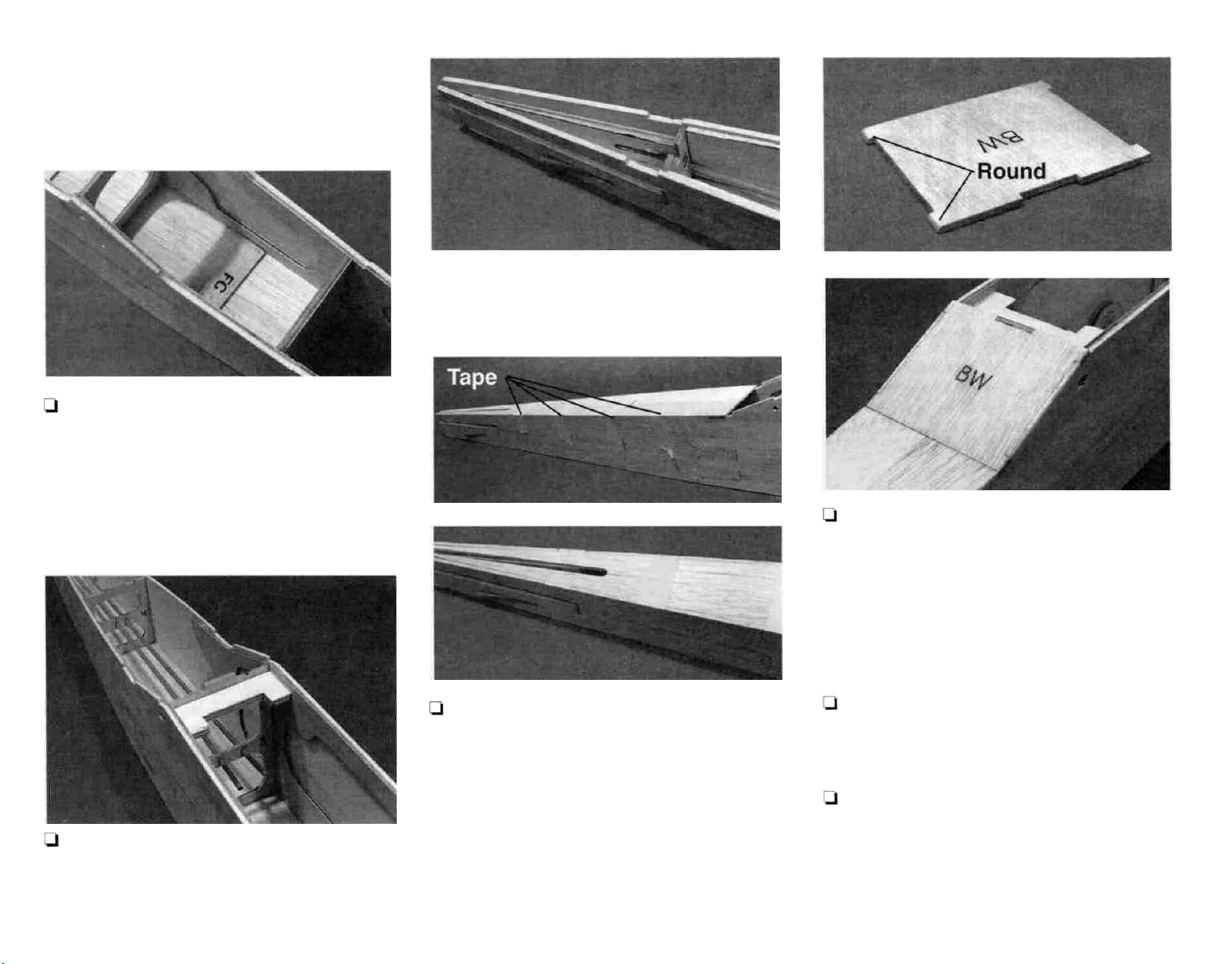

33. Glue the die-cut 1/8" balsa fuselage cross

member (FC) to the forward bottom sheeting as

shown on the fuse plan side view. This piece simply

stiffens the fuselage floor in the tank area.

rudder and elevator pushrods. Glue them securely

to the fuselage sides, F-5, F-4, and F-3.

34. Sand the outside of two of the 24" outer

pushrod tubes so glue will stick to them. Work

these into position as shown on the plans for the

35. Snap the previously joined aft fuse top into

place on top of the fuselage. Use masking tape to

hold the fuse top in place. Wick thin CA glue into its

joints with the fuse sides and the formers. Do not

glue the area behind F-5 yet. Remove the tape and

run thin CA down the joints again to make sure they

are thoroughly glued.

36. Trial fit the die-cut 1 /8" plywood back window

(BW) in its place on the fuse top. Refer to the

fuselage side view; for best results, bevel the fore

and aft edges of the window to provide a better fit.

HINT: To eliminate difficult sanding later, round the

"lock tabs" on the outside edges of the plywood

windows to a radius similar to that shown on the plan

cross-sections before gluing the windows in.

37. Glue the back window in with thin CA. Then

add some medium CA if required.

38. Wick thin CA into all joints involving the wing

bolt plate. After this has cured, apply a fillet of epoxy

or medium CA around the wing bolt plate.

Page 15

39. Round the outside of the "lock tabs" on the

die-cut 1/8" plywood front window (FW) as you did

on the back window. Fit the front window into place.

Glue with thin and medium CA. You may round the

corners of the fuselage to match the cross sections

as you go, or you may wait until the fuselage is done.

40. Sand the edges of the die-cut 1/8" plywood

fuel tank hatch till they are smooth. Test fit the

hatch in place. Trim the hatch or trim back the notch

in the front of the fuse side doublers until the hatch

fits well. Round the right and left edges of the hatch

to a radius like that shown in the firewall (F-1) cross

section.

No. 2 x

15

the LGP to allowthe main landing gearto be installed

(as shown on the fuselage plans). The pre-cut 1/8"

x 9/32" x 3-3/4" plywood LG aligner strips are the

same ones used for the tricycle gear. Fill the gap in

the 1/8" balsa bottom sheeting at the tricycle gear

location with scrap 1/8" balsa.

44. Test fit the wire main landing gear into the

holes in the fuse bottom. In orderforthe landing gear

to lie flat on the bottom of the fuse, it is necessary to

remove a little material from the inside edge of the

5/32" holes to allow for the bends in the wire. Do this

with a round file or a knife.

3/8 Sheet Metal Screw

41. Use CA to glue the die-cut 1 /8" plywood hatch

retainer tab to the inside of the hatch as shown in the

photo and on the fuse side view.

42. The punch marks in the front of the hatch

indicate the location of the No. 2 x 3/8" sheet metal

screws used to hold the hatch on. Check to make

sure these will direct the screws into the firewall.

Tape the hatch in place on the fuselage. Drill a 1/16"

hole through the punchmarks into the firewall. Remove the hatch and enlarge the holes in the hatch

only to 3/32". Screw the hatch down with the sheet

metal screws to confirm a good fit.

43. If you are building a taildragger, you need to

cut a gap in the forward fuse bottom sheeting under

45. Put the two bent wire main landing gear

pieces in place on the fuselage bottom. Slide the

pre-cut 1/8" x 9/32" x 3-3/4" plywood LG aligner strips

in place fore and aft of the main landing gear. Sand

the edges of the strips if necessary for a good fit.

Glue these strips in place with medium CA, being

careful not to glue in the landing gear wires.

Page 16

16

No. 2 x 3/8 Sheet

Metal Screw

46. Put the main landing gear back in position and

place two molded nylon landing gear straps over

the wire LG as shown in the picture. Mark, then drill

four 1/16" pilot holes. Use four No. 2 x 3/8" sheet

metal screws to hold down the LG straps. The

landing gear may be removed until after covering.

Nylon Landing Gear Strap

This completes the basic construction of the

fuselage.

BUILD THE WING

is a very flat board that you can pin into. "Celotex,"

a type of board you can find at a hardware store or

home center, is an example of one). Cover the left

wing panel section with waxed paper so you won't

glue the wing to the plan.

2. Assemble the wing guide tool from the die-cut

1/8" plywood pieces marked "G". The "0" degree

(from vertical) side of the tool can be used to check

the ribs to see if they are vertical. The "4" degree

side will be used later. Do not glue the tool to-

gether.

3. The shaped and notched balsa leading edges

and trailing edges are joined by a thin layer of balsa.

These are cut apart in one of two ways:

A. Break the pieces apart and clean up the

rough edges with a sanding block.

-OR-

Xacto knife

Hold knife at an angle

when cutting apart

LEADING EDGE

B. Carefully run a knife down the edge between

the parts to cut them cleanly apart.

NOTE: The Sierra was designed to use

symmetrical leading and trailing edges (they

have no top or bottom). They do, however, have

a root end and a tip end.

4. The tip ends of the leading and trailing edges

are the ends with a notch very close to the end. Mark

the leading and trailing edges with a "T" to designate

the tip. T-Pins

T-Pins

NOTE: The SIERRA wing, much like the fuse, is

designed so all the major components can be fit

together without glue. This allows you to check

that the pieces are properly fit and aligned before

applying glue to the joints. The wing plan may

be cut in half along the line provided if you wish.

1. Tape the LEFT WING PANEL portion of the

plan over your work surface. (The best work surface

Spar

Work Surface

5. Use the criss-cross pin technique shown in

the illustration to pin a 3/8" x 3/8" x 30" balsa spar

over its location on the plans. Pin the spar in 3 or 4

places. (The photo for this step is at the top of the

next column)

Page 17

17

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

STRAIGHT WING

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

WARPED WING

Photo for Step 5

6. Remove the wing ribs

R-1's,

R-2's, and

R-3's from the die-cut sheets. Slide twelve 3/32"

balsa R-3 ribs into place on the bottom spar.

8. Insert the back of the ribs into the notches

in the trailing edge.

NOTE: The plans may shrink or expand slightly

due to humidity. Do not worry if the parts are not

exactly the same size as the plans.

9. Adjust the positions of the leading and

trailing edges left or right until the ribs line up with the

plans. Pin the leading and trailing edges tothe board

so they won't move.

11. Insert the 3/8" x 3/8" x 30" top spar into the

notches in the ribs.

12. Make sure all the R-3 ribs and the leading

and trailing edges are resting on the flat work surface. Make sure the ribs are inserted all the way into

the notches. The "guide tool" is used to check that

the ribs are vertical.

7. Insert the front of the ribs into the notches

in the leading edge. Remember to orient the LE with

the

"T"

at

the tip.

10. Lay two pieces of scrap 1 /16" balsa (from

the die-cut center section sheeting SIE4W05 or

SIE4W06) near the leading and trailing edges under

the location of rib R-2 (this will shim up the rib to allow

for the sheeting later). Push rib R-2 into place as

shown on the plans. Make sure the ends of the rib

engage the notches in the leading and trailing edges.

13. Apply thin CA to all the joints involving the

ribs, spars, leading edges, and trailing edges.

NOTE: When gluing the spars to R-2, make sure

the spars are centered between the dihedral

brace notches in R-2.

14. Remove the pins holding the spar in place

but leave the panel pinned flat on the board by the

leading and trailing edges.

Page 18

18

17. Position the 4 deg. side of the guide tool

exactly where the end of the bottom spar is shown on

the plans. Use a pen to mark an angled line on the

top and bottom spars.

ends of the spars and leading and trailing edges

flush with the outermost R-3 rib.

If you are building the 3-channel wing (without

functioning ailerons), follow the instructions in

the shaded box. If you are building the 4-channel

wing, skip to step 24.

15. With the panel held flat on the table, use

medium CA to glue in the pre-cut 1/16" x 1-1/2" x2"

balsa shear webs between the R-3 Ribs. Refer to

the plans. Notice there are shear webs on both

sides of the spars outside the first two R-3 ribs and

only behind the spars between the remainder

of

the R-3's.

NOTE: The function of the shear webs is to keep

the spars from collapsing. They will not and need

not touch or be glued to the ribs. They should be

thoroughly glued to the spars.

16. Make sure the wing panel is still lined up

properly over the plan.

18. Use the guide tool to mark angled lines

on

the leading and trailing edges from where their

bottom ends are shown on the plans.

19. Use a razor saw to cut off the spars and the

leading and trailing edges at the marked angles. A

T-bar is used to "clean up" the angled ends of the

spars, leading edges, and trailing edges.

20. Use a razor saw and a T-bar to trim the tip

NOTE: The LEFT WING PANEL plan and its

cross-sectional view show the "no aileron"

version.

Page 19

19

21. The 17/32" x 1-1/2" x 30" tapered

balsa aileron stock fits against the trailing

edge stock with its lower surface flat on the

table. Glue the aileron stock to the trailing

edge of the wing. (See the photo on the

previous page.)

22. Trim the tip end of the aileron stock

flush with the end of the wing.

23. Trim and sand the root end of the

aileron to match the 4-degree angle of the TE

and spars.

SKIP TO STEP 27

to the wing trailing edge at the tip as shown on the

RIGHT WING PANEL drawing. (This is done to the

right and left wing.)

26. Trim and sand the aileron stock flush with

the tip of the wing.

MAKE THE WING TIPS

27. Look at the FRONT VIEW of the wing on

the plans to see the proper orientation of the 15/32"

x 1-5/8" x 11-1/4" tapered balsawingtips. Thesmall

end of the taper is positioned at the bottom edge of

the wing.

it to final shape. HINT: Put masking tape over the

surrounding structure when sanding items such as

the wing tips to protect areas you don't want sanded.

REPEAT STEPS 5-29 OVER THE

RIGHT WING PANEL PLANS TO

BUILD THE RIGHT WING.

JOIN THE WING

24. Carefully cut a 1-5/8" long piece off the

17/32" x 1-1/2" x 30" tapered balsa aileron stock .

25. Glue the 1 -5/8" long piece of aileron stock

28. Hold the wing tip up to the end of the wing.

Trace the top of the airfoil onto the wing tip. Saw or

carve the wing tip to the rough shape of the wing,

leaving it slightly oversized.

29. Glue the wing tip to the wing. Block sand

braces. Put reference marks at the center of the

braces. NOTICE: The dihedral brace with the "lock

bumps" for the aileron servo tray is positioned on the

aft side of the spars (these bumps may be trimmed

off if you are not using ailerons).

31. Test fit the two wing panels together with the

dihedral braces in place. Check to see that the

spars, leading edges, and trailing edges match up

well. Make adjustments if necessary.

The dihedral angle (the angle at which the wings

are "bent up") is not considered critical. This

angle is established by aligning the spars with

Page 20

20

the dihedral braces. For your reference, if one

wing panel is resting flat on the table, the other

wing tip should be approximately 4" off the table.

32. Look ahead to the photos with steps 33 and

34 for a view of the joined wing. Spread a layer of 15-

minute epoxy onto the matching surfaces of the

dihedral braces and the LEFT wing panel spars.

Align the dihedral braces with the top and bottom

edges of the spars. Clamp or tape the braces in

position until the glue sets.

NOTE: If there are any small gaps between the

ends of the spars or LE's or TE's, do not be

overly concerned. They will not significantly

weaken the structure. After the wing joining

process is complete, fill them with scrap balsa

and medium CA glue.

34. The die-cut 1 /8" plywood forward center brace

(F) is glued in next. It should be centered on the

leading edge so the 1/16" balsa top and bottom

center sheeting will lap onto it. Align the left and right

leading edges and glue the brace in place with CA or

epoxy.

36. Glue the two die-cut 1/8" balsa R-1A's (1A)

together to form a 1/4" thick part. Glue the two diecut 1/8" R-1C's (1C) together to form a 1/4" thick

part.

37. If you are using the bolt-on wing option, draw

two lines forward from the slot in R-1A as shown in

the photo, for later reference.

33. When the epoxy is set, apply a thin film of

epoxy to the dihedral brace and the right wing

spars, slide the two wing panels together, and

carefully align the spars with the dihedral braces.

After the epoxy is cured, if any of the dihedral brace

joints do not appear to be thoroughly glued, apply an

extra fillet of epoxy to them.

35. The die-cut 1 /8" plywood aft center brace (A)

is centered on the trailing edges. Align the left and

right trailing edges and glue the brace in with CA or

epoxy (if you are building the 3-channel version, the

fixed aileron stock should be aligned and glued

together at this time).

NOTE: If you are building the 3-channel version,

do not punch out the cutout for the aileron servo

in R-1C. Instead, glue it permanently in place.

Punch it out as shown in the photo at the top of

the next column for the 4-channel version.

38. Use medium CA to glue R-1C in place. It is

centered to allow for the top and bottom center

section sheeting as shown in the cross-section

drawing beside the right wing panel.

39. Put R-1A in place as shown in the cross

Page 21

section. If you are using rubber band on wings, glue

it with CA. If you are using bolt on wings, transfer the

marks from R-1A onto the forward center brace (F)

and remove R-1A.

DO STEPS 40 - 49 FOR

BOLT ON WINGS

40. Draw a vertical center line on the forward

center brace.

21

45. Cut away the material in front of the slot

in R-1A to allow the dowel to pass through the

front of the wing into the slot.

42. Use the R-1 cross section on the wing

plan to determine where the dowel will exit the

leading edge, and mark this location. Drill a 1/

8" pilot hole from the front of the wing through

this mark, then through the previously drilled

pilot hole in the forward center brace.

41. Drill a 1/8" pilot hole into the forward

center brace (see the photo). The angle of this

hole will obviously not be correct, so you need

not go all the way through the balsa leading

edge. Just go through the plywood.

43. Gradually increase the size of the drill

until you reach 1/4". Test fit a 1/4" wing dowel

through the hole.

44. Replace R-1 A and glue with medium CA.

Remember that it is centered vertically to allow

for the 1/16" sheeting.

46. Insert a 1/4" dowel into the leading edge

and push it all the way into the slot. Put a mark

on the dowel 1/2" ahead of the leading edge of

the wing. Remove the dowel and cut it at the

mark. Round the end of the dowel slightly to

allow easy wing mounting.

47. Glue the dowel in place with thin CA.

Page 22

22

48. Test the fit of the die-cut 1 /8" plywood R1 B's (1 B) against the R-1 A's. Trim the Ft-1 B's

if necessary for a good fit. The dowel may also

need to be flattened slightly with a sanding block

to allow the R-1 B's a good fit.

49. Glue in the R-1 B's with 15-minute epoxy.

Photo for Step 51

53. Sand the root ends of the tapered and

grooved balsa trailing edge center pieces so

they will meet properly when they are held

together against the TE. Mark the parts so you

can identify the bottom of the left and right parts.

50. For rubber band on wings, glue the die-cut

1/8" plywood R-1 B's to the R-1 A's, forward center

brace (F), and dihedral brace with epoxy.

DO STEPS 51 - 62 IF

INSTALLING AILERONS

51. Cut out and remove the remaining

piece of balsa from across the servo bay in the

bottom side of R-1 C using a knife or razor saw

(see photo at top of next column).

52. Snap the die-cut 1/8" plywood aileron

servo tray and servo tray support in place as

in the photo. Use medium CA to glue in the

servo tray support while using the servo tray to

hold it in position. Do not glue the servo tray in

at this time.

54. Hold the trailing edge center pieces over

the right wing panel plan. Mark where the

torque rods will exit the bottom of the trailing

edge. The root cross-section gives a view of the

cut-out. Cut a notch in the trailing edge center

pieces to allow the torque rod to exit.

55. Hold the trailing edge center pieces up

to the wing. Transfer the notch locations onto

Page 23

23

the wing. Use a knife to cut small notches into

the wing TE.

56. Use coarse sandpaper to roughen the

nylon tube on the bent wire aileron torque rod.

Slide the tube toward the threaded end of the

rod. Apply a small amount of petroleum jelly to

the ends of the nylon tube to prevent glue from

wicking into the bearing tube.

57. Assemble the parts as shown in the

photo. Apply a small amount of medium CA to

glue the torque rod bearing tube to the balsa

trailing edge center.

60. Following the instructions on page 8,

step 10 for installing the elevator joiner, transfer

the location of the aileron torque rods onto the

ailerons. Drill a 3/32" hole into each aileron to

accept a torque rod. Notch the front edge of

each aileron to accept the rest of the torque rod.

bar to sand the front edge of the ailerons to a "V"

shape to match the cross section on the plans.

WING CENTER SECTION SHEETING

63.

Lightly write the identity (1-6) of each piece

of die-cut 1/16" balsa wing sheeting using the cut

patterns on page 4 as a reference. Remove the

individual sheets from the blanks.

WRONG

RIGHT

58. Use medium CA to glue the trailing edge

center assemblies to the trailing edge of the

wing. Do not get glue in the bearing tube.

59. Trim the left and right tapered aileron

stock pieces to length so they fit between the

wing tip and the center pieces with about a 1/16"

gap at each end.

61. Draw a center line on the LE of the

ailerons and the trailing edge of the wing, use

the plans as a reference to mark the location of

the hinges. Make slots for the hinges using the

same technique as you did for the elevator and

rudder.

62. Use a razor plane (if available) and a T-

64. Pieces 1, 2, and 3 form the top wing skins;

4,

5, and 6 form the bottom wing skins. Over waxed

paper, glue the 2's and 3's together to form a left and

a right top aft wing skin (as shown in the photo). Glue

the 5's and 6's together to form a left and right bottom

aft wing skin.

Page 24

24

65. Fit the pieces 5-6 in place behind the spar on

the bottom of the wing. Cut a notch to go around the

aileron servo tray support if present. Glue the wing

skin in place.

and cut out a slightly oversized opening for the

aileron servo.

68.

Fit the forward bottom wing skins (4) to the

wing, and glue in place.

70. Sand the joints in the center of the

a block and sharp 220 grit sandpaper.

wing with

FINAL ASSEMBLY

1. Fit the wing on the fuselage wing saddle. Trim

the aft edge of the wing trailing edge at the center

with a sanding block if necessary for a good fit.

66. If you are using ailerons, cut a couple of 1/4"

wide strips from scrap 3/32" balsa, glue them in as

shown in the photo to stiffen the bottom wing skin

where the servo cut-out will be made.

67. For planes with ailerons, snap the aileron

servo tray in position and trace the shape of the cutout on the bottom wing skin. Remove the servo tray

69. Fit and glue on the top wing skins (1 and 2-

3).

ELONGATE HOLE

IF NECESSARY

NOTE: For bolt on wings, the wing dowel hole in

F-3 may be oblonged some if required to let the

wing sit flat on the saddle or to allow for wing

seating tape. If the hole requires oblonging, do

so with a round file or a #11 knife.

2. Remove the wing from the fuselage. Mark a

centerline on the 1/16" x 1-7/8" x 5-1/2" plywood

Page 25

4. Drill two 3/16" pilot holes through the

trailing edge plate and wing TE at the intersection of the lines. Be sure to drill perpendicular

to the surface of the trailing edge plate.

25

the photo) in the slot at the back end of the fuse.

Put a pin vertically into the piece on the fuselage

centerline. Attach a length of string to the pin.

Use the string to check if the wing is on straight

(see diagram).

trailing edge plate.

to cut about 1/2 way through the plate on the center-

line. Bend the plate away from the cut until it starts

to break. Place the plate on top of the wing, and

adjust if necessary. Glue the plate to the wing with

medium CA.

Use a knife and a straightedge

DO THESE STEPS FOR

BOLT ON WINGS

3. Referring to the right wing plan. Mark a

line 5/8" from the trailing edge. Mark two lines

1-3/8" from the wing centerline as shown.

Both distances must

be equal!

B=B

A=A

5. Place the wing on the fuselage. Pin a

piece of scrap 1 /4" balsa (or the fin as shown in

6. Once the wing is straight, use some

masking tape hold it in place. Drill through the

3/16" pilot holes perpendicular to the trailing

edge plate and through the wing bolt plate in

the fuselage with a #10 (or 13/64") drill.

7. Remove the wing and re-drill the holes in

the wing only to 1/4" or 17/64".

8. Use a 1/4-20 tap and a tap wrench to cut

threads in the plywood wing bolt plate.

Page 26

26

9.

Harden the threads in the wing bolt plate

with thin CA glue, then re-tap the threads after

the glue has completely hardened.

1"

1/4-20x2" Nylon Bolt

two inch portion of the stab/fuse junction only. Re-

move the fin. Thoroughly glue the forward two

inches of the stab to the fuselage from the inside

(through the fin slot) and outside (do not go all the

way back to the aft end of the fuse until you are told

to). Be sure to also glue the stab to former F-5.

Photo for Step 1

2. Temporarily slide the fin into place. Check the

fit of the parts. The bottom edge of the fin should rest

on the stab.

10. Cut approximately 1" off the threaded

portion of the 1 /4-20 x 2" nylon wing bolts. Bolt

the wing onto the fuselage.

If you are using rubber band on wings, temporarily

slide the dowels into the holes in the fuselage

sides (enlarge the holes in the fuselage with a

round file if the fit is too tight). Align the wing and

attach it with several # 64 rubber bands.

MOUNT THE TAIL SURFACES

1. Slide the horizontal stabilizer (stab) into its slot

in the fuselage. Align the stab by looking down at the

stab reference lines through the fin slot in the upper

aft fuse sheeting. Put a couple of marks on the stab

outside the fuselage sides for reference after the

vertical fin (fin) is installed. (The photo for this step

is at the top of the next column)

CORRECT

INCORRECT

3. Sight the alignment of the fin and stab from the

front and back of the model with reference to the

wing. Also sight the fin and stab from the top to check

alignment. Make adjustments to the fuse slots if

necessary so the surfaces are not twisted or skewed.

4. Put a small amount of thin CA on the forward

5. Apply a generous bead of medium CA to the

bottom edge of the fin and to the fin slot in F-5. Slide

the fin into the slot in the fuselage. Check the

alignment to make sure the fin is not leaning. Also

glue the fuse joints at the top corners.

6. Wick thin CA into any remaining fin, stab, and

fuselage joints that are not thoroughly glued. Be

sure to flip the fuselage over and glue all stab, fin

post, and fuselage joints from underneath.

Page 27

7. Sand the joints at the back of the fuselage

smooth. For a nice touch, sand the outer pushrod

tubes flush as shown in the photo.

9. Slide the elevator into position using its hinges

to support it (do not glue the hinges yet.) Slide the

rudder into its place. Mark the location where the

elevator joiner contacts the rudder. Cut and sand a

notch in the rudder large enough so the elevator

joiner wire and the rudder do not contact each other

when the surfaces are moved through their range of

motion.

27

11. If you use a Great Planes L-7 tailwheel

wire, modify it slightly as shown on the fuselage

plan sheet.

Photo of completed tailwheel.

12. Drill into the rudder at the location shown

on the drawing with a 3/32" drill to allow the tail

wire to be inserted into it. Notch the LE of the

rudder to accept the nylon bearing. Harden the

bottom portion of the rudder around the tail wire

with thin CA before covering.

NOTE: Do these steps after the model is

covered with Monokote.

8. Round the top edge of the shaped 1/4" balsa

dorsal fin. Use the seam on the top of the fuselage

to help you center the dorsal fin. Glue it on with thin

CA followed by a small fillet of medium CA.

DO STEPS 10-14 IF YOU ARE

BUILDING A TAILDRAGGER

NOTE: Refer to the tailwheel section on the

fuselage plans for details and drawings.

10. You may make a tail wire from scratch

or purchase a Great Planes L-7 tail wire from

your hobby dealer.

13. Place a small amount of petroleum jelly

at both ends of the nylon bearing to keep glue

out. Use a toothpick to push glue into the 3/32"

hole in the rudder. Insert the tail wire and wipe

away any excess glue.

14.

Roughen the forward tab of the nylon

bearing and epoxy it into the fuselage during the

hinging process.

Page 28

28

MOUNT THE ENGINE

See the ENGINE AND MOUNT SELECTION section

on page 5 for additional information.

STALLATION OF AN IRVINE 40 ON THE SUPPLIED MOUNT.

NOTE: The assembly and installation of the fuel

tank and fuel lines is covered on page 36-37. You

may assemble and trial fit your tank while

installing the engine.

3. To determine the best fore and aft position of

your engine on the engine mount, install the spinner

on the engine. Using the plans as referance, place

the engine on the engine mount so that the spinner

is the same distance from the fuselage. Mark the

location of the mounting bolts and drill the holes with

a 7/64" (or #36) drill. NOTE: If you have access to a

drill press, use it for drilling these holes to insure they

are drilled vertically (See previous photo).

THIS PHOTO SHOWS THE INSTALLATION OF AN

OS .40 FP ON THE SUPPLIED MOUNT.

1. Study the different drawings on

plans that show engine installations.

that matches your installation closest.

2. You should already have determined if you

need to use the 9mm spacer plate during fuselage

construction. Use it as required.

NOTE: If the engine mount supplied in the kit

does not appear to fit your engine (example OS

40 SF), you may have to file the corners of the

engine mount rails to make room for the

crankcase. (See sketch and photo.)

File corners of

rails to fit your

Flat File

the fuselage

Find the one

engine

MM40

Mount

4. Mount the engine with the four #6 x 3/4" sheet

metal screws. (An alternate method is to drill the

holes with a #43 drill, tap them 4-40, then mount the

engine with 4-40 x 3/4" socket head cap bolts, not

included).

5. Remove the muffler and needle valve (if

necessary) from the engine. Bolt the engine and

mount to the fuselage. Determine if any cutouts are

necessary for the needle valve or muffler (see the

photos for ideas). Mark any cutouts that are required.

THIS PHOTO SHOWS THE INSTALLATION OF AN

OS .48 SURPASS ON A DAVE BROWN 60 FS

MOUNT. THIS MOUNT MAY BE PURCHASED

FROM YOUR HOBBY DEALER. IT MAY BE

DRILLEDTOINSTALLTRICYCLE LANDING GEAR.

THE FOLLOWING SEQUENCE SHOWS THE IN-

File Corner

NOTE: It is best to remove the engine before

cutting out clearance holes, but at least plug the

carburetor intake and the exhaust output port

before making dust.

Page 29

DO THESE STEPS FOR

TRICYCLE LANDING GEAR

29

8. One 5/32" wheel collar is pressed into the

nylon steering arm; then the 6-32 x 3/16"

machine screw is threaded in. This assembly

is used below the mount. The other 5/32" wheel

collar and the 6-32 socket head screw are used

above the mount to retain the nose gear. Assemble the parts as shown to determine the

location of a flat which will be made under the 632 x 3/16" machine screw. Disassemble the

parts.

6. Cut out any clearance holes or notches you

marked in the previous step. Mount the muffler.

7. If you are building a trike gear and are not

using the 9mm spacer, you will need make an

indentation into the firewall to provide clearance for the nylon steering arm. Mark the

location of this cutout under the mount. After

the mount is removed, relieve the area enough

to clear the steering arm (a Dremel Moto-Tool

is handy for this job).

NOTE: The steering arm is rotated away

from the firewall when the axle is aligned for

straight ahead steering. Refer to the photos

and plans for proper orientation.

9. Clamp the wire nose gear in a vise and use

the side of a flat file to make a flat spot at the

location you marked.

Page 30

30

FINISHING

BALANCE THE

AIRPLANE LATERALLY

SPECIAL NOTE: Do not confuse this procedure

with "checking the C.G." or "balancing the airplane fore and aft." That very important step will

be covered later in the manual.

Now that you have the basic airframe nearly

completed, this is a good time to balance the airplane

laterally (side-to-side). Here is how to do it:

1. Temporarily attach the

muffler) to the fuselage.

wing and engine (with

fore, before covering, you should make a final check

of the entire structure. Fix any dents with a lightweight filler, then sand the entire structure smooth

using progressively finer grades of sandpaper. Sand

major areas to be covered using MonoKote" with

#320 sandpaper just before covering

HINT: Small dents in balsa wood can often be

swelled back out by applying a small drop of water to

them.

COVERING

Follow the instructions included with your

covering material. Thoroughly read through

them before beginning.

MonoKote, and alcohol will remove them later (for

some tasks, you may be able to put your marks on

the backing where they will not need to be removed).

A metal straightedge and a sharp knife are great

tools to have around for cutting MonoKote.

2. With the wing level, lift the model by the engine

propeller shaft and the aft end of the fuselage (this

may require two people). Do this several times.

3. If one wing always drops when you lift, it means

that side is heavy. Balance the airplane by gluing

weight to the other wing tip. NOTE: An airplane

that has been laterally balanced will track better

in loops and other maneuvers.

FINAL SANDING

Carefully examine your fuselage comparing the

"corners" with the cross sectional drawings on the

plans. Sand (using a block where possible) the

corners of your fuselage until they match those

shown on the plans.

Nearly every imperfection in your wood structure will show through the covering material; there-

TIPS FOR COVERING WITH MONOKOTE:

Make copies of the 2 view drawing on page 44 of this

manual and use it to plan your trim scheme.

When covering surfaces with corners, cut the mate-

rial as shown to allow it to fold up and cover the

corners without gaps or bumps.

Precut strips for covering objects such as elevators.

A permanent marker will put reference marks on

When covering with Monokote® the top and bottom

of the stab, and the sides of the fin, allow about 1/8"

to 3/16" of covering to lap onto the fuselage as in the

photo.

Page 31

Cover the tips of the ailerons before the bottom and

top.

Recommended Covering Sequence:

1. Rudder left side

2. Rudder right side

3. Bottom of elevators

4. Top of elevators

5. Stab bottom

6. Stab top

7. Fin left side

8. Fin right side

9. Fuse bottom

10.

Fuse sides

11.

Fuse top

12.

Fuel tank hatch

13.

Ends of ailerons

14.

Bottom of ailerons

15.

Top of ailerons

16.

Wing TE plate

17.

Bottom of left wing

18.

Bottom of right wing

19.

Top of left wing panel

(overlap covering 1/4" at

20.

Top of right wing panel

(overlap covering 1/4" at the LE)

panel

panel

wing LE)

31

3. Fuel proof any external exposed wood.

MonoKote matching brush on Chevron Perfect Paint

works nicely here.

HINGING

NOTE: CA Hinges are hinges made specifically

to be used with CA glue. These hinges have a

plastic core which is laminated with fibers to

allow the CA to adhere to them.

(using

CA

hinges)

Cover the wing TE Plate before the rest of the wing.

NOTE: DO NOT, under any circumstances,

attempt to cut the covering material after it has

been applied to the fin and stab, except around

the leading and trailing edges and the tip.

Modelers who do this often cut through the

covering and part-way into the balsa stab. This

can weaken the stab to the point where it may fail

in flight!

When covering concave surfaces, follow the

with a damp cloth, pressing the covering down.

iron

FUEL PROOFING

1. Fuel proof the firewall area and the engine

compartment. Black K&B epoxy paint was used for

this on one of the prototypes. Thirty minute epoxy,

polyester resin, or polyurethane-based paints will

also work here.

2. Fuel proof the inside of the fuselage forward

of F-2. K&B polyester resin and a bent epoxy brush

were used for this on the prototypes. 30 minute

epoxy also works well for fuel proofing.

1. Find the slots you made earlier. Open them up

by cutting a small rectangle of MonoKote away with

a sharp X-acto knife.

NOTE: Keep a folded tissue handy to absorb any

thin CA that may drip onto the MonoKote by

accident. Any glue residue can be completely

removed with CA Debonder

Page 32

32

2. Push the hinges half way into the control

surfaces. Wick several drops of thin CA into the slot

from both sides of the hinges.

3. Fit the elevator and rudder onto the airframe.

Make sure that all of them fit and line up properly.

Wick several drops of thin CA into the hinge slots on

the elevator, then the rudder. Be sure to glue the

hinges in from both sides of the surface.

RIGHT WRONG

mark the location of the mounting holes. Drill 3/32"

mounting holes through the marks. Then wick some

thin CA glue into them to 'harden' the balsa. The

horns are screwed in place using 2-56 x 5/8" ma-

chine screws and nylon nut plates.

throttle use horns made out of large, "four armed"

horns. The aileron horn is set up to provide "differential throw." In this case it will cause the ailerons

to deflect "up" more than they deflect "down." The

horn shown is made out of a large, round Futaba

horn that is drilled on the "1" and "4" radial lines

where they intersect the "12.5mm" radius line. (See

the drawing on the wing plan).

4. Make the rudder and elevator pushrods: Cut

ten 5/16" lengths of the inner pushrod tube to act as

spacers. Distribute these on the 34" threaded end

.074" wire pushrods as shown on the fuselage top

view. Note: If the spacers are extremely tight on the

.074 wire, you may cut them down to 3/16". If the

spacers are loose on the .074 wire, use a tiny drop of

CA to glue them to the .074 wire. In any case, they

should not easily move on the wire.

4. Use a toothpick to push 15-minute epoxy into

the torque-rod holes in each aileron. Fit the aileron

in place. Then glue in the hinges using the technique

described above.

FINAL CONTROL HOOKUPS

2 - 56 x 5/8 Machine Screw

Nut Plate

Small Control Horn

1. Install the elevator and rudder small nylon

control horns in line with the pushrod exits as

shown on the plans. Hold the horns in position and

2. Mount the servos into the main servo tray

oriented as shown on the fuselage plan top view.

Mount the aileron servo (if used) in the aileron servo

tray.. Since the main servo tray is adjustable fore and

aft for small CG corrections, do not glue it in until told

to do so.

3. For easy setup and good control response, we

recommend you start off using servo horns resembling those shown on the plans. The rudder and

5. Screw the nylon clevises well onto the ends