Page 1

Page 2

Congratulations! You now own the most accurate R/C scale kit ever produced.

We at Top Flite are sure that you will find this model among the most

pleasant-to-build, inspiring to look at, and exciting to fly that you have constructed.

It is honest to point out, however, that while this model is no more difficult

—in fact is simpler than most comparable models—to make, R/C Scale models

generally are not for the newcomer to this hobby. Some previous modeling experience and careful attention to craftsmanship are necessary. Even the "old hand"

will do well to study the instructions and hints in this booklet.

It is our aim to have you say: "This is the finest model I have ever made."

TOP FLITE MODELS, INC.

Page 3

INTRODUCTION

The S. E. 5A has always been a modeler's favorite. Among all airplanes,

and certainly of those which were born and flew to fame and distinction during

World War I, the S. E 5 was one of the best and most attractive Not the least

of the reasons for its great appeal to modelers is the great suitability of its design

as a flying model Let's explain this.

To make a successful flying model, without changes to the outline or sections which would destroy its essential character, we need the following features:

a. The nose length of the airplane ought to be enough to guarantee a

good balance without adding large amounts of weight in the front end;

b. The tail surfaces (stabilizer and fin) control the stability of a model

to a large extent If the model is more stable in flight, it will be easier

and safer to fly We require that the stab and fin be big enough to

insure good stability without enlargement.

c The airplane should be fairly simple in design to eliminate building

complexities

d. Size is important too. For reasons of transportation and ability to

fly in a reasonable wind, experience has shown that the wing span of

the model (for a .40 - .60 engine) should be in the 50 - 60 range In

order to eliminate headaches in small and fussy details, a scale of

2"= 1' is found very suitable. This means our subject real plane needs

to be 24' - 30' wing span.

How does the S. E. 5A shape up?

First, it has just about as long a nose as is found in fighter airplanes

of the period. Balance will not be a problem—a tail-heavy S. E. 5 would be

difficult to come up with.

Secondly, the areas of the tail feathers have been found to give excellent

stability just as they are. A model of the S. E. 5A will be a stable and safe

model—so stable, in fact, that it can be flown very successfully with single-

channel R/C equipment controlling only the rudder.

Thirdly, the S. E. 5A has clean, functional and straightforward outlines

and shapes that are easy to model.

Lastly, the wing span of 26' 7-1/2" gives our 2"=1' model an ideal span of

a bit over 53" This size model will fit into most cars without disassembly, saving

a lot of trouble.

So we see that our requirements are amply met in these respects. Some

other planes are Just as suitable — but lack one final important requirement

They are obscure or little-known subjects that somehow never rang the bell

The S. E. 5A, on the other hand, is a glorious and immortal plane that every

scale modeler has made or hopes to make some day.

BEFORE YOU START—READ THIS!

These instructions have been carefully developed after building several

prototype models. We urge you, in your own interest, not to ignore them. Our

aim is to insure that the model goes together in a reasonably quick time and

without annoying snags.

Regardless of previous modeling experience follow the directions carefully,

checking them off as you go.

Notice the instructions often call for some items to be started before others

are complete This is to allow time for important glue joints to dry properly,

yet not hold up building progress. Also, in order to help modelers of less experience,

we have tended to the easier jobs first, leaving those requiring more care until

later as skill increases

Do not separate parts from die cut sheets until you need them! This will

save loss or breakage of some of the small or delicate pieces.

1

Page 4

After removing any pins from the crutch that will get in the way, glue side

pieces F-l and F-2 to the crutch. Use the "TRI-AIDS" provided to insure the

sides are truly vertical

Glue the 1/4" sq. bottom longerons to F-l and F-2, followed by F-28 and the

vertical spacers Use the side view of the fuselage for the correct lengths

The previously-cut horizontal cross-braces are glued in next, also F-lA's, F-18 and

F-5 (ply) Glue in F-6 (ply) and the other 3/8" x 3/4" x 3-3/4" hardwood block for wing

mounting (Special note if it is intended to install a Top Flite 2" scale pilot, this

hardwood block should be glued in only lightly at this time—later it should be

removed to allow the pilot to be slid up into place from the wing opening After

the pilot is installed, the wing mount block can be glued firmly in place.)

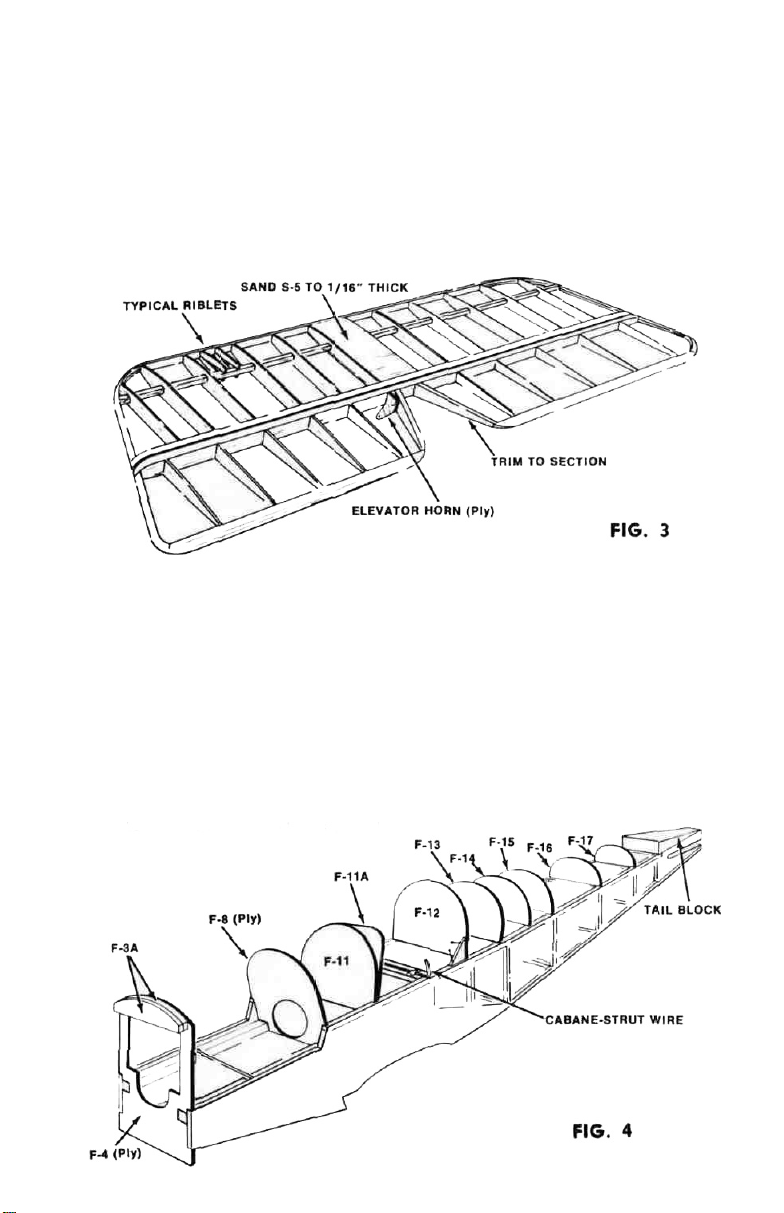

6. While this assembly is drying start on the stabilizer See Figure 3. Pin down

the 1/4" x 1/2" stab trailing edge (T E) to the plan Cut a piece of 1/4" sq to length

for the spar and thread ribs S-1, S-2 and S-3 onto the spar in correct order Do not

glue the joints yet. Glue and pin the ribs to the T E Note that the center two ribs

must be shimmed up 1/16" to bring the ribs centered on the TE

Laminate the two S-4 parts that make each tip Cut leading-edge (LE) to length

from 1/4" sq and glue to all ribs, with 1/8" shim under it Now glue all rib-to-spar

joints, and glue tips S-4 in place Sheet over center two ribs with piece S-5. Set

aside to dry

7 Remove fuselage assembly from board and turn right-side up At this time

you can put aside the fuselage plan-view as no more fuselage construction will be

done on the board Sand fuselage, trimming bottom longeron at F-l. See Figure 4.

Glue two F-3A pieces together and glue both to F-4. Glue F-ll to F-11A and

F-14 to F-14A. Lay these items aside to dry.

3

Page 5

File notches into the rear cabane-strut wire and attach to the hardwood blocks in

the crutch, using metal clips and woodscrews provided. Glue the shaped tail block

in position on the fuselage, also formers F-17, F-16, F-15, F-14 and 14A, F-13,

F-ll and 11A, F-8 and F-4. Formers 8, 11 and 13 must be glued at correct angles

(see side view). Take care here, as the fit of the cut panels F-23 to F-27 depends

on the accuracy of the angles on the formers.

8. Remove stabilizer from plan. Turn upside down and glue second S-5 in place.

Pin down 1/4" x 1/2" elevator L. E. Glue laminated E-2's together for tips. Pin

1/8" x 3/8"

and E-2 tips in place, also center ribs from

T.E.'s in position, shim underneath

1/4"

at rear edge. Glue all E-l ribs

1/4" x 1/2"

cut to length.

9. Sand the stabilizer smooth, rounding off the L. E. and tips. The small riblets

are simply cut from 1/16"x 1/8" and glued in place, then sanded to conform to

section when dry. These riblets are marked "optional" on the plan, since they could

be omitted without affecting the strength of the stab. However, for the sake of the

scale appearance it is worth taking the small extra time to incorporate them.

10.

When elevators have dried, remove from plan and sand smooth like the

stab. Glue in 1/16" ply elevator horn E-3. The stab and elevator can now be

hinged together using the material provided cut to length — see plan for positions.

Glue a small piece of 1/16" scrap sheet alongside the elevator horn to support the

covering. The stab is now finished.

PLY DIHEDRAL-BRACE

FIG.

5

11.

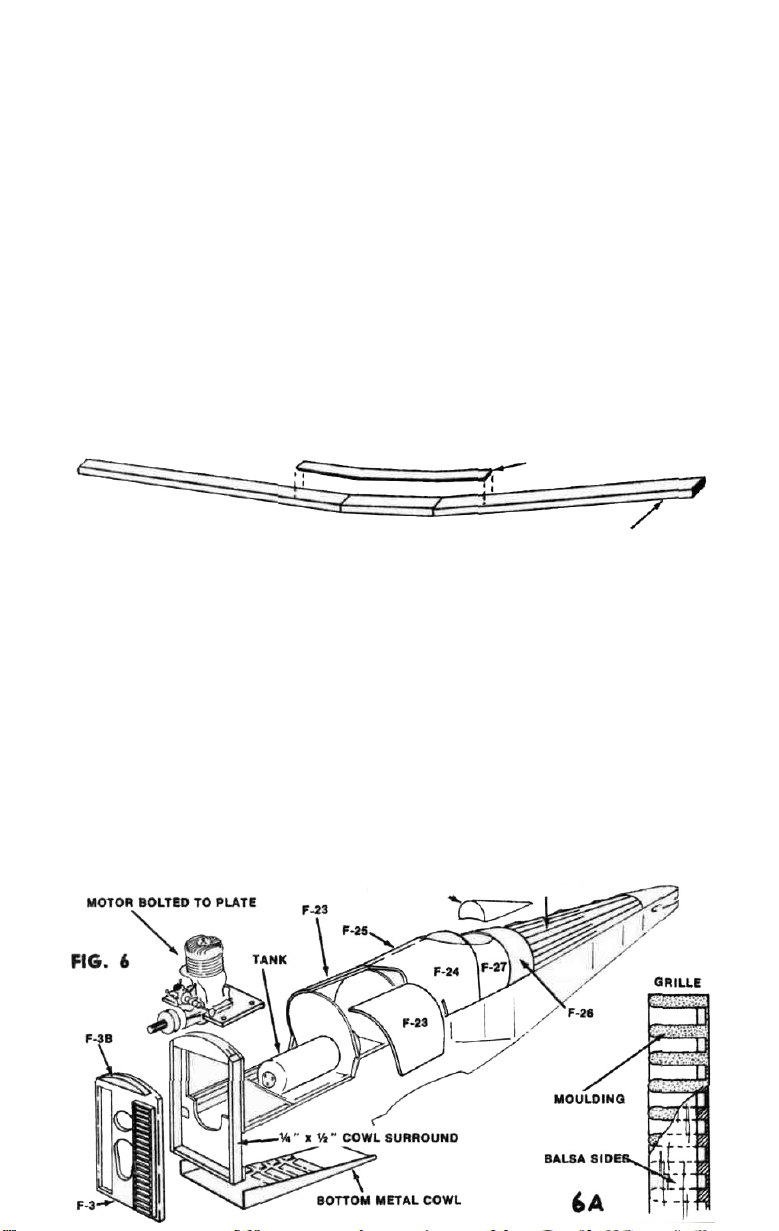

Make up the wing spars (see Figure 5) as follows: Take the 1/4" x 3/8" and

1/4" x 1/4"

basswood spars and cut two 8" lengths of each size. Glue these in the

BASSWOOD WING SPARS*

center of ply parts D-1 and D-2. Then glue long spars to each side at the same

angle as the ply parts, over the plan sheet #1. Construct four such spars: two from

1/4" x 3/8" and two from

1/4" x 1/4"

. It will help to pin these to the board right next

to each other while they dry, so as to have identical angles on all sets.

12.

Glue ply F-7 between fuselage sides, lower front. The two holes are for

excess engine oil to drain away from the engine bay, and should be positioned just

ahead of former F-5. Glue the 1/4" x 1/2" strip parts on the front of F-4 and complete

the noseblock by glueing F-3 in place. Figure 6 shows these details. The radiator

grille is made from the mouldings supplied. Join two grille pieces and trim

long. Glue

4-3/4"

long pieces of

1/16" x 3/16"

on

each side

to

complete

the

to

4-3/4"

"box."

Make sure that all of the cross-bars are glued to these sides; and that the sides are

level with the front (open) side of the moulding. Later, when the glue dries, the

web holding all the cross-bars at the rear is sanded off, making an open grille very

easily and accurately. See Figure 6A. Repeat the whole process for the other grille

and cement the finished grilles over the large rectangular holes in F-3. Glue F-3B

in place. (Discard second F-3B in other Sheet 2).

HEADREST STRINGERS

Page 6

13.

Cut proper size hole in

1/4"

phenolic engine plate for the engine you are

going to use. Drill holes to suit and mount the engine. Fit the plate up to the

fuselage (remove the needle valve temporarily if necessary) and when you have

it fitting snugly down on the mounts, drill through plate and mounts simultaneously

to insure accuracy for the mounting screws. Screw plate in place using the

3/4"

woodscrews provided. Slide fuel tank in position and connect to engine with fuel

tubing.

14.

It is a good plan at this time to install the R/C equipment and the pushrod

to the throttle. Due to the enormous variations in available equipment it is not

possible to give precise diagrams for every R/C equipment installation: however,

the motor-control servo should be fitted between F-8 and F-ll. In the original prototype models, a Kraft proportional KP-4B outfit was used, and it was found very

convenient to mount the three KPS-10 servos for engine, elevator and rudder sideby-side on two

1/8" x 3/8"

basswood cross-spacers, so that all 3 servos were between

F-8 and F-ll. In this case the radio receiver was glued to the rear face of F-11A

via a small foam rubber pad.

The battery will fit in the space between F-5 and F-8. While it is true than an installation where the servos are ahead of the receiver is uncommon, this was one of

the cases where it was warranted. So plan your own equipment installation at this

stage. If you are a beginner at this, get the help of an experienced R/C builder!

We cannot put too much emphasis on this point. It is probably true to say that a

very high percentage of equipment malfunctions can be directly attributed to sloppy

or defective installation. Remember a long life for your model (and the safety of

spectators) depends vitally on good equipment installation.

15. After connecting the throttle to the motor-control servo, check for easy

frictionless movement over the whole range of throttle travel. When satisfied, remove the engine, tank and servos before continuing with building, so as not to get

any balsa dust, etc. in delicate equipment.

16.

READ THIS COMPLETE INSTRUCTION BEFORE STARTING.

The sheet panels F-23, 24, 25, 26 and 27 can now be glued in place. This may

appear at first to be a very difficult job to do without breaking the pieces. In truth,

it is very easy as long as the correct method is followed closely. We will explain

using one example piece, and the rest of the panels all follow the same general

idea. This is how to proceed: —

Take one F-23 piece and glue the lower edge to the right fuselage side (use regular

balsa cement). Let this joint dry thoroughly! If you try to continue too soon, the

joint will come apart and you'll be back at the start, and have to re-glue and wait

again. When dry, thoroughly dampen the outside of F-23, being careful not to wet

the glue joint just made. You can wet the wood with a cloth and water. After

a few moments, try pulling the sheet around the formers that it will be glued to.

You will find that it will bend to the required curve very easily. Spread glue (this

time use Titebond or white glue—not balsa cement) on the edges of F-8 and F-ll,

and pin the wrapped sheet firmly to the formers to set. Masking tape also can be

used to get firm contact.

The other panels are done in the same way. Glue F-26 in place before F-27. Wet

and attach one panel at a time. Start at the front again on the left-hand side. Notice

the panels are of slightly over-width as cut—this is to allow final trimming of the

left-hand pieces to exactly fit the right-hand ones already in position.

About the only panel that may give a little trouble is F-24 on the left side. (This

is why we had you do the right panels first—to get experience!) This is because

of the tight radius at the front over F-11A; so do not be concerned if a small split

develops here. After the panel has dried you can run some glue in the split or fill

with vinyl-spackle (purchase this at a hardware store). Notice also, that a small

clearance-cutaway must be made in F-25 and F-24 for the rear-strut wire. Any

oversize of these holes can be filled later with vinyl-spackle.

17.

From the 3/16" sq. supplied, cut seven pieces about 11-1/2" long and eight

pieces about 6" long. These will be the rear stringers. Trim one of the long pieces

to exactly fit from F-14A to the tail block and glue it into the notches in the center

5

Page 7

of formers F-14A • F-17. All stringers are to be glued in "diamond-fashion "

This was done to get sharp impressions on the covering, like the real S. E 5A

had, and yet have stringers big enough not to warp after covering Glue in the rest

of the stringers, observing that they are alternately long and short (see Figure 6).

When dry, cut back short stringers level with rear of F-16 Carve and sand tail block

to conform to fuselage shape

Shape the headrest block provided to section, and tack-glue in position so it won't

get lost.

18.

Glue R-l and R.2 together, also R-4 and R-5. Glue F-10 (ply) on front of F-8,

screw nylon brackets for upper cowl fastening onto F-10 and F-4: see fuselage side

view for positions

19.

Screw upper and lower metal cowls onto fuselage Shape and sand nose

block to correct contours and add dummy radiator-cap (made from scrap) Drill

upper cowl tor needle valve in required position by temporarily installing engine.

While upper cowl is removed from fuselage, shape cylinder fairings from blocks

provided, screw to upper cowl and finish making exhaust pipes from hardwood

dowels provided Figure 7 shows final appearance

20.

Cut a suitable hole in upper fuselage decking and tack-glue Vickers gun in

position, then cut out stiff card gun-fairing to template on plan and glue in position

Build

up windscreen,

lightly

tack-glue

on fuselage Sand fin and

rudder

parts.

Hinge together with material provided.

21. The whole stabilizer assembly, and the underfin (R-4 and R-5) may now be

glued permanently to the fuselage Take care while installing these parts to get

them properly aligned Lightly tack-glue the fin in position on the fuselage. Glue

rudder horn to rudder

22 Screw rudder and elevator servos in place Make pushrods to rudder and

elevator and check radio for smooth and free action of control surfaces. Bear in

mind here, that the type of pushrods required will depend upon how much interior

cockpit detail you intend to incorporate If you want, as we did, a completely

furnished cockpit with instrument board, pilot, seat and all the rest of the details,

it obviously will not do to have two big pushrods running through the center of

the cockpit In the prototype models we used short lengths of nylon tubing with

metal wire cable inside, from the servo back as far as F-14. From here back the

pushrods became 3/8 sq in the normal way The nylon tubing section was fastened

to the cockpit sides where it is hardly noticeable

If it is not intended to incorporate a full cockpit layout, normal 1/8 sq pushrods

all the way from the servos to the tail end will be all that is needed.

6

Page 8

Specific details cannot be given for these pushrods, because as with the radio and

engine, etc., requirements and equipment will differ from one builder to another.

Whichever layout is chosen it will be found that there is ample space inside the

model to carry out any desired positioning. However, we repeat to newcomers that

the advice of an experienced R/C modeler will be invaluable.

23.

Break up and discard false former F-12 from the fuselage. Smear a coat

of glue over the planking joint so exposed. Do not attempt to install cabane struts

at this time. For this job we will need the wings, so let's start those.

24. Refer to Figure 8 which shows the first section of the wing to be made—

the lower right-hand panel. Take one of the prejoined 1/4" x 1/4" basswood wing spars

and trim to exact length over the plan. Note that this is the longer rear spar. Slide

one W-3, one W-4 and six W-5 wing ribs in this order loosely onto the spar, pushing them toward the center of the spar temporarily. The dihedral brace on the

spar

faces

forward.

Cut

two

pieces

8-7/8" long

from

the1/8"x1/4"

balsa

strip

provided,

and glue these on top and underneath this rear spar at its outer end.

3/8" x 1/4" SPAR CAPPING

25. Take one of the pre-joined 3/8" deep basswood spars and cut to exact

length over the plan. This is the shorter forward spar. Spread out the ribs on the

rear spar and feed the forward spar through them from the root end, making sure

dihedral brace faces rear. Slide three W-6 and one W-7 ribs onto the forward spar

in correct order. Slide all ribs back and forth along both spars until they are all

in approximately the correct positions.

26.

Place scraps of 3/16" sheet or square balsa shims over the spar positions

on the plan, except at the outer end of the rear spar, where the shims should only

be 1/16" thick. Lay down the wing framework on the plan, with the spars held up

by the shims. As it is not practical to pin through the hardwood spars, hold the

assembly down with a few small weights, making sure it cannot move.

27.

Shuffle ribs to exact position over the plan (tweezers are handy for this job)

and lightly spot-glue each rib-to-spar joint. This will hold these joints while the

structure is completed; later on all these joints should be carefully and completely

glued when the wing is lifted off the plan and access is available all around each

joint.

28. Cut a piece of pre-formed L.E. section to correct length and glue in place,

shimming it up to the steps in the ribs with scrap 1/16" balsa. Pin and glue the preformed T.E. to the ribs, shimming up 1/16".

29. Glue two W-11 pieces together for wing tip. While these dry, slip W-8

riblets into place and glue. Trim front of outermost W-6 and glue laminated tip

W-11 in place and complete the tip with short length of 1/4" sq. to rear spar. Glue

in 1/16" x 1/4" stiffener against outermost W-5 rib, then riblets W-9 and W-10. Glue

W-17 in place.

30.

Glue in W-12R (ply) bellcrank bearer, noting that it lays at an angle. See

full-size drawing of wing section at this point on the Plan Sheet.

7

Page 9

31.

Remove wing from plan Slide four W-14 ribs over projecting ends of wing,

spars, getting them in approximately correct position in the wing center panel As

with the panel just made, weight down the spars with 3/16" shim under them

Slide ribs to exact position and glue See Figure 9 and 10. Glue in W-13 and

1/2" x 3/4" x 4" bass block Glue on L. E, the balsa block T. E Pieces and cap spars

with 1/16" x 1/4" to support the center 1/16" sheeting, which is now glued in place.

Don't forget to bevel one edge where the sheet sticks to the L E

32. Tilt the whole wing so the projecting spar-ends are now flat to the plan

and construct the left hand panel in the same way as the right Remember that ribs

W-3, 4 and 5 must be threaded onto the spars before the 1/8"

x 1/4"

rear spar capping

is glued on

33

. At this point turn the wing upside down and attach the formed rear landing

gear wire strut onto the hardwood block in the center panel, using the metal clips

provided Make sure you stay clear of the hole positions in this lower block.

34.

Again, cap the spars with 1/8" x 1/4" and sheet the whole underside with 1/16"

balsa

35. Refer to Plan Sheet I and study the full-size view of the lower wing center

section Fasten formed front landing gear wire strut to F-9 with metal clips

Glue F-22's onto wing Glue two F-9A's together, and set aside to dry. Glue F-9 to

F-22's. Then sheet in lower edge with parts

36.

Bring up the lower wing to the fuselage Trim or adjust parts if necessary

F-19, F-20

and F-21.

Aim for a perfect fit When this is achieved, take off wing, check that the laminated

F-9A's fit well into the hole in F-8. Sand if necessary When satisfied, glue F-9A

on the front of F-9, immediately putting lower wing in position on fuselage so that

F-9A will be in exactly the right position When glueing F-9A on, do not use too

much glue, else some may ooze out of the side and glue up the whole assembly

when the wing is positioned

37. While these parts are drying, slip two solder-tabs on each front LG leg,

then solder the landing gear plates to the legs Use acid flux here, as a strong

joint is essential'

38.

After carefully marking the positions of the holes for the nylon wing mounting screws on the underside of the wing center panel, drill right through wing and

the block

Redrill

in

the fuselage at one

the holes

through

time

the

Use a

wing

No

29

with a No

(.136")

19

or No

drill

Remove

18

(.166"-.170")

the

wing

drill

to clear nylon screw Tap the No 29 holes in the fuselage block with a 8-32 tap

Trim away F-19 to allow the heads of the nylon screws to seat right down against

the wing block When the model is finished, these recessed screw heads will be

barely discernable, and will not spoil scale appearance

Try screwing the wing into place See that all fits are perfect, trimming away or

adding if necessary

39. Slide the tabs on the front LG leg to the top of the leg, then glue all balsa

pieces LG-1 to LG-6 to landing gear legs, clamp up securely and set aside to dry

thoroughly Give these parts at least two hours—overnight if possible, before sanding down

When the legs are sanded down, bind them with

the 1/2"

tape supplied, wrapping

the tape tightly in spiral formation Rub glue into the tape This tape will strengthen

the landing gear and add to the scale effect

8

Page 10

40.

All four ailerons are identical—except of course that two are left and two

are right. Laminate each tip from two W-12 pieces. Construct flat on plan as in

Figure 11. When dry, carve and sand L. E. and tips to correct section: see Figure 12.

41.

Hinge ailerons to bottom wing—see diagram on Plan Sheet 1. The hinges

should be held in place by toothpicks after drilling through wood and hinge material

together. Cut down the nylon aileron horns supplied to correct size indicated on

plan and glue between closely-spaced aileron ribs, using Titebond liberally to fill

holes in horn. Clamp and let dry.

42.

Install nylon aileron bellcranks on W-12 (ply) bellcrank bearers. Connect

bellcranks and horns with supplied connecting links. Use small scrap of 1/16" sheet

to support covering where link exits from wing under surface.

43.

Mount aileron servo in lower wing center section. It will be necessary to

make two right-angled brackets in most cases. For this purpose, two drilled metal

strips are provided which can be bent and re-drilled to suit the application. Connect servo and bellcranks with 1/16" music wire pushrods, making the holes through

the ribs in the positions required by the equipment involved. Try to keep the holes

small—3/32" dia. is about right. Try out the ailerons using the radio, and do not

be satisfied with less than perfectly free and smooth movement over the whole

range of travel.

44.

The top wing is made in three stages just as the lower wing, so detailed

instructions are not necessary. The only points of difference are in the slightly

altered rib-spacings, the lack of servo or bellcranks, and the center section which

is rather simpler.

When making the center-section, note that the 1/16" sheet covering extends from

leading edge to the rear spar on the upper surface.

45.

So far we have a complete fuselage and tail, with a lower wing which is

mounted in position and an upper wing not yet attached. The next job is to bring

these two items together to make a fairly complete S. E. 5A. This stage is a little

tricky, so work slowly and carefully. Study the drawing of the strut attachment

fittings on Plan Sheet 1. This nylon ball-and-socket joint is a new idea that we at

Top Flite have worked out to greatly simplify the traditionally difficult job of

rigging biplanes. This new system is far less demanding of super-accuracy than the

usual wire-bending methods. Also, assembly and dis-assembly is easier and quicker

and appearance much neater. (These fittings, incidentally, are available separately

packaged, and biplane builders will find them very useful—they will take up any

angle of strut attachment . . . sideways, backwards, forwards or combinations

of these. Ask your hobby dealer for Top Flite E-51 package).

46.

From the

a 3/16" dia. hole in 8 of these 11/16" from one end and centered in the

width. Glue these to the spars (on top of lower wing spars, and underneath upper

wing spars) so the drilled hole lines up with the first W-6 rib. Trim away ribs

and riblets slightly where required. Refer to full-size plans to check location.

The 4 undrilled pieces are glued to the forward spars in line with the drilled strips

already attached. These 4 strips will provide a covering-support for your left palm

when snapping the struts in place.

Next cut 4 pieces of 1/8" x 3/8" basswood 7/8" long, drill 3/16" in the center

piece and glue to the bottom of the spars in the lower wing at the dihedral-break,

again trim away ribs to suit.

1/8" x 3/8"

basswood strips supplied, cut 12

9

pieces 1-7/8"

long.

of each

the

Drill

3/8"

Page 11

The nylon plates (sockets) are intended to be permanently screwed in place after

covering and clear doping and prior to coloring the model However, screw them

in place temporarily at this time to aid in the further construction of the model.

They should be removed later (see covering instructions)

47. Take one of the shaped hardwood wing-struts (1/4 x 3/4 streamline section)

and cut off a piece about 8" long This will be one of the forward cabane struts

(see Fuselage Side View Plan Sheet #2) Sand a slight angle at the top end of this

strut—see Figure 13. Drill a 7/64 dia hole into the strut from the end(Figure 14).

The hole should be about 1" deep and 1/4" from the L E of the strut Fill the hole

with Titebond or epoxy glue and push in the threaded shaft of the nylon ball strut

fitting (Figure 15).

This joint must be allowed to completely dry before anything more can be done

with the strut

BALL FITTINGs

FRONT VIEW

Fig.

Pig.

13

14

Fig.

15

48. Meanwhile, cut the other cabane struts and also the interplane struts from

the formings Always leave 1/4" or so of extra length, to allow for final tailoring

at the assembly stage One end of each strut can be angled and drilled, however,

and the ball sections glued in Note that the cabane struts are rectangular in side

view (as the struts are supplied) while the interplane struts have a curved taper at

each end Carve this shape into the interplane struts and sand rectangular edges

back to airfoil section

49. When the first strut (front LH cabane) is set, snap the nylon ball into

its mating socket, which is the nylon plate screwed under the forward spar of the

top left-hand wing at the dihedral joint

The diameter of the hole in the flat nylon piece has been designed to resist the

ball-end on the strut to a fair degree Therefore a firm push will be required Once

snapped in, however, the joint should be quite free to assume correct angle

50. With both left and right forward cabane struts snapped into place on the top

wing, cut out a hole in the fuselage sides immediately behind F-8; see Figure 16.

Enlarge until the bottom ends of both cabane struts can be fed into the slots Cut

two pieces

of

scrapwood,

one

2-1/2"

long, the

other

3-3/8"

long Pin these

to

the

T.

E.

and L E respectively for use as incidence and height gauges See Figure 17. When

the whole assembly is fitting well, check that the wing is properly squared-up to the

fuselage in plan view and front view (Sight by eye using the attached bottom wing

Fig.

16

HEIGHT-GUAGES - LONGEST AT L. E.

TRIM HOLE UNTIL STRUT CAN

SLIDE IN AT CORRECT ANGLE

10

FIG.

17

REAR CABANE-STRUT WIRE

Page 12

as a reference) When satisfied, run some Titebond into the holes at the strut-fuselage

joint When this glue has dried and the top wing will not move out of alignment

remove the bottom wing so that access can be had to the inside of the fuselage and

liberally glue the struts to F-8.

51. At this point in the construction, all the most difficult work is done; now

we re coming down the home stretch'

Snap the rear cabane struts into the top wing fittings Mark length and angle down

to the stub wire projecting from the fuselage Disengage strut A good way to

unsnap the ball is to insert the blade of a wide screwdriver in the gap between the

wing and the end of the hardwood strut Twist the screwdriver and the fittings will

disengage Cut and drill lower end to take wire Replace and remove struts, trim

ming

as

necessary

in struts with glue and slip into place on the wire snapping top fittings together

to hold alignment perfect while glue sets When dry, remove balsa height gauges

52. Fit the four interplane struts First cut the struts to exact length to fit

between the nylon plates Then cut off 3/16" of length drill struts and glue ball

fittings in place Constantly check that wings are parallel and at same incidence

(L E top wing to L E bottom wing distance should be same as T E top to T E

bottom)

53. Install all solder-tabs in position to be used later for wire rigging attachment

54. Solder the axle into the landing-gear plates. Trim the shaped hardwood

axle fairing to proper length and angle, and glue to the legs with the axle running

in the groove visible from the top

A completely rigid landing gear is, in our experience, by far the best for this type

of model The small amount of springing incorporated into the axles of the fullsize aircraft of the period, has proven of no value in cushioning landing shocks on

models, and in fact, causes ground looping problems on take-off

55. The scale propeller is supplied as a shaped blank ready

section Carving propellers is an acquired art If you doubt your ability to make

a good Job have an experienced modelling friend do it for you The many exterior

details may now be built

cockpit detail and so on

Smooth off rib edges, etc., and remove any bumps of glue that would spoil the

covering Job

Disassemble interplane struts and wings from model and remove nylon fittings

from wing panels Remove from the model all tack glued items such as fin and

rudder, guns, cowls, headrest, windscreen, etc. Remove engine, R/C equipment

and also the pushrods if possible

Completely disassemble the whole model as far as possible into its separate

elements After again making sure that all structure is smooth, we are ready to

cover the model

WARNING: Some of the heavier fabric covering materials, such as nylon,

heavy silks and blends of silk and nylon, are not suitable for models of this type

They have too much shrinking power and will warp the structure Use only regular

lightweight or Japanese silk to cover this model!

Start by giving all wood which will come into contact with the silk two coats

of clear dope Use dope liberally, allowing each coat to dry

Sand doped areas lightly to remove the fuzz raised by the dope

Cut panels of silk to oversize and lay on model Paint around outlines with

clear dope The dope will penetrate the silk and form a bond with the dope pre

viously applied Stretch out all wrinkles as you go

Do

not be concerned if the covering is a little

drumtight

or

folds

When the dope has dried, lightly spray the silk with water An airbrush or

perfume spray will be ideal When the silk dries it should have shrunk quite tight

until

the

fit

is

right

and installed temporarily, such as gun rail and gun,

at this time—the important t

Finally,

COVERING

hing

with

strut off the fuselage,

is that there should be no wrinkles

11

loose. It does not have to be

fill

holes

to be carved to

Page 13

If there are places where it has not tightened properly or there are wrinkles or

folds remove that panel of silk and do it over. Never expect the shrinking action

of the clear dope that is applied next to pull out a bad covering job. It never does —

dope will not shrink out wrinkles that water cannot remove. Clear shrinking dope

can only make an excellent job of an already good one.

When you have a good covering job, give the model 3 or 4 coats of clear

dope. Thin the dope out. Two thin coats are better than one thick syrupy one.

If

you have a spray you will get a better job.

One piece of advice regarding clear-doping is worth passing on: When doping

the wings, give a coat to the top of one panel and immediately coat the bottom

of that panel. In this way the wing will be subjected to even stresses all around

and warping will be minimized. Do one panel at a time. The same goes for the

stabilizer, elevators and ailerons.

Inspect the wings, ailerons, and stabilizer for warps. Remove any that are

present by holding near (not too near!) heat and twisting gently in the opposite

direction. Take care here, as warps will have a very bad influence on the flying

characteristics.

When the clear doping is completed, proceed to the color. Color dope should

be sprayed if at all possible. The nylon strut fittings can be replaced prior to color

doping. Give at least 3 coats of all colors.

Since most, if not all, S. E. 5A's were doped with matte comouflage dopes,

we now have to kill the unwanted high gloss that our regular model dopes give. The

best way to do this is to spray a coat of clear eggshell lacquer over the colors.

Be sure that the lacquer you use is fuelproof—polyurethane varnish is very suitable

and can be obtained from hardware stores or paint stores. Normally such varnishes

will not be found in model shops.

Finally, add the decals in positions indicated on the plan. Many S. E. 5A's

had the words "LIFT HERE" along the bottom longeron together with a small

white arrow. The particular S. E. 5A we chose, Mike Mannock's D'278 did not

have these markings, but if you choose to paint your model with a different serial,

you can use the words LIFT HERE and the small arrows which are provided on

the decal sheet.

FINAL DETAILS

Like all full-size aircraft, the S. E. 5A was loaded with small details, such

as radiator cap, pilot tube, sumps, and dozens more. Probably, most "Sunday

Fliers" will not want to incorporate these. But for the contest flier, or modeler

who is making this model for static display purposes, and wants to incorporate

these details, cockpit furnishings, etc., we have given drawings on the plan to enable

these details to be made.

If you intend to go this route, we recommend the book, "S. E. 5A" by

Charles L. Bourget available from World War I Aero Publishers, Box 142, West

Roxbury, Massachusetts 02132, at $1.95. The drawings in this book are the ones

we used in scaling the model, because we considered them the most accurate obtainable for this aircraft. We have reproduced these drawings on our plan, enlarged

to 1/2" = 1' scale as an aid to contest fliers in preparing their "Proof of Scale"

documents.

The "Profile" Publication of the S. E. 5A is also recommended, and will be

especially useful, along with our box label, in giving guidance to correct coloring of

the model. The "Profile" (No. #1) is obtainable at most hobby shops and costs 50c.

RIGGING

Due to the scale wing section being so thin, the wings are very flexible. In

our considered opinion the wings would not be strong enough for flying if left

unbraced. When correctly rigged, however, the strength of the "box-kite" wing

configuration is enormous, and will withstand any amount of severe maneuvering

in flight with strength to spare. To have made the wings sufficiently strong as

cantilever structures in the design stage would have been possible, but at the

expense of considerable damage to scale effect, by way of a wing section of twice

scale thickness and areas of sheeting. We chose to make the model true scale and

12

Page 14

make the rigging wires, which have to be added in any event, perform a real and

important function.

After all the dope on the model is completely dry, screw the lower wing in

place on the fus>elage. Snap the upper wing onto the cabane struts. Snap the four

interplane struts into the wings. The rigging wires are made from the 020" piano

wire supplied, and are called "flying" and "landing" wires — the "flying" wires

are the ones tensioned in flight, that is, the ones running from the fuselage up to

the upper wing the "landing" wires are the ones tensioned in a landing, that is,

the wires running from the top of the cabane struts down to the lower wing

As with the strut fastening method, we have given a good deal of attention

to figuring a simple and fast way to install the rigging wires. We did not want

to use turnbuckles. (the traditional method of getting the correct wire length)

because they are tiresome and must be reset every time the model is disassembled

for transportation

FIRST Z-BEND

FIG.

18

IMAGINARY "TABLE" AND "BLOCKS" DRAWN ONLY TO SHOW BEND DIRECTIONS

The method we have devised will take a little patience to bend the wires,

but once done, the wire length is set permanently, and the wires can all be removed and replaced in seconds. Follow this method:

a Start by making the longest wires first. This way, if you accidentally

bend one too short the same piece can be used for a shorter wire later

on, saving waste. Work through to the shortest wires, doing these last.

b Leaving the wire the full 30" length, make a small normal Z-bend at

one end. See Figure 18.

c. Hook this Z-bend into the solder tab at the top of the front interplane

strut on the left side

d. Holding the wire in slight tension, make a mark on the wire (use a

felt-tip pen) where the wire passes the solder-tab at the top of the front

L.

G.

leg.

e Unhook the Z-bend. Bend the wire at the pen mark 90°. Now make

another 90° bend about 1/8" further along perpendicular to the long

straight section. Again, see Figure 18.

f. Cut off the wire about 1/8" along the new direction. The wire is now

made. Let's see if it fits o.k.

g See Figure 19. Hook the original Z-bend back into the tab it came

from. Now, by grasping the wire at the lower end with pliers and

twisting it, hook the other end into the second solder-tab. We are using

the torque in the wire to keep the bottom bend in the tab, and unless

the rigging wire is twisted the bottom bend cannot disengage. This

cannot happen in flight: however, removal is simply performed by

grasping the wire near the bottom with pliers and twisting until the

wire disengages.

13

Page 15

HOOK UPPER Z-BEND IN FIRST.

FIG.

TO DISASSEMBLE REVERSE INSTRUCTIONS

19

h Test the wire for tension When plucked the wire should feel taut

If the wire is slack this is no good and a new wire must be made—note

how much shorter it has to be If, on the other hand, the wire is

bent too short it cannot be engaged at all since it will not reach the

second solder tab

i All of this might seem terribly difficult to get "just right" but we can

assure you that after making one or two mistakes, you will be making

almost all of the rest of the rigging wires "dead on" first time! Your

judgment quickly attunes to the requirements of the wire

With all the rigging wires in place on the model, a method of identifying

each wire must be seen to A good way is to color code each wire with a small

Jab of dope at one end Keep a list of the wires and the color-coding in your

flying field kit

AILERON CONNECTORS

These units are very simple Cut the tiny horns out of scrap 1/16" ply after

drilling the 1/16" dia hole Make a small slit in the covering and glue the horns

in position—top of lower ailerons and bottom of upper ailerons

With the wings completely wire rigged, set the lower ailerons dead neutral,

using the links to adjust as necessary

Bend one end of the 9" long 1/16 wire supplied 1/4" from the end and a

90° angle Fasten this end to the lower aileron using a nylon button retainer to

keep it in place Hang a connecting link in the upper horn, cut the wires level

with each other and join with a short tube soldered in place See Figure 20.

Adjust the connecting link so the upper aileron is also at dead neutral

later,

when trimming

out

the model

in

flight,

each

aileron can thus

be

adjusted

individually for the best result

-NYLON BUTTON-RETAINER

FIG.

TUBE

ADJUSTING-LINK

20

14

Page 16

PRE-FLIGHT CHECK

This is probably the most important Job to do on any model Right here is

where the complete success of the maiden flight is organized A somewhat tiresome task to do properly, but hurry here can lead to an expensive crash Let's

break down the pre-flight check into three units.

1. Balance

2. Alignment

3 Equipment

First, balance. The model should balance level to the ground or slightly

NOSE DOWN when supported by its wingtips on the fingers or some blocks at the

point marked CG on the plan (sheet 2) This is exactly half-way between the

leading and trailing edge of the upper wing

Due to the naturally good layout of the S E 5A for modeling, it will

almost always balance properly However, if it becomes necessary to alter the

balance point, try to do so first by moving some fairly heavy item of equipment

(such as the battery) to a new location If this is not possible, weight must be

added to nose or tail

However, much is needed this must be put in the model While it is admittedly

a shame to add, say, half a pound of dead weight, it is the only answer Never

be trapped into thinking that the extra weight will do more harm than incorrect

CG location'

If your model is nose heavy (CG too far forward) the worst that can happen

is a slight sluggishness in control response This presents no problem and can be

rectified before the second flight. With tail-heaviness, however, there is frequently

NO second flight'

Second, alignment. This check consists of finding out if the incidences of

the wings and stab are correct Proceed as follows Stand the model on its wheels

on a level surface—a dining room table will do fine Now block under the tailskid

with books, etc until the measurement from the table up to the L E of the stab

is the same as up to the T E of the stab It is important, of course, to have

previously set the elevator at dead neutral Having got the stab accurately parallel

to the table, measure the incidence of the lower wing

To do this, measure up from the table to the middle of the L. E at the

dihedral break Make a note of the figure Now measure from the table to the

T E point, at the same dihedral break This second figure must be somewhere

in the range of The same as the first figure to 3/16" less than that figure. (That is,

between 0° and +1° incidence)

Finally, check the upper wing incidence This is very simple At the same

dihedral break as used before, measure the L E bottom to-L E top wing then

the T E bottom to T E top wing The figures should be the same It is allowable

to have slight positive incidence on the upper wing relative to the bottom one

That is, if the T E -to T E measures 1/8" or so less than the L. E.-to-L. E. figure,

do not be concerned

As long as care was taken during the construction it is doubtful that the

alignment will prove to be wrong beyond the tolerances allowed If, however,

such is the case, make the necessary alterations by regarding the lower wing as

correct and aligning the upper wing and the stabilizer to this Trimming the length

of the two forward or the two rearward cabane struts will decrease or increase

the incidence of the upper wing respectively (also trim the interplane struts to

match), the stabilizer can be brought into alignment with the lower wing by cutting

it free from the fuselage and re glueing it back after trimming-out the rear fuselage

sides to change the angle as required

Lastly, equipment. Switch on the radio and check carefully all control surfaces

for free movement Eliminate any over freeness that could cause rattles Check

motor control Do not be satisfied with less than full 100% perfection in this area'

To lose a good model from accidental causes is bad, to lose one because of hurried

checking of RC equipment is unexcusable because it could have been avoided.

15

Page 17

PRE-FLIGHT RUN-UP

Before actually committing the model to the air, it is a very wise precaution

to perform a simple "flight-conditions" check by running-up the engine and check-

ing the radio on the ground. On arrival at the field, proceed as follows:

a. CHECK OPERATING FREQUENCIES OF OTHER MODELERS

PRESENT!

b. Remove upper cowl. Fill fuel tank and start engine. Adjust to correct

high—RPM.

c. Set engine for idling—RPM. Stop engine. Re-start and stop several

times to be sure you can start the engine easily and quickly when it is

at idling—RPM setting

(This latter point is very important! While starting, under some cir-

cumstances, flooding for instance, an engine will occasionally spit

burning fuel onto the model and begin to set it afire. This is no problem

when the engine is uncowled because it is easy to just blow the fire out:

however, you cannot do this after the cowl is screwed on. When the

engine is started at idle setting this occurance is prevented by the

exhaust-baffle blocking the exhaust port. We draw this matter to your

attention because "forwarned is forearmed").

d. With engine running, switch on radio and hold model up by its upper-

wing center-section. Check all controls, including motor RPM.

When satisfied with results of the run-up test, we are ready for the allimportant moment!

FLYING THE S. E. 5A

For

the expert at flying radio-controlled models the S. E. 5A will present

few problems. About the only area in which care will be needed is in the take-off

run, where there sometimes is a tendency to ground-loop. We have discovered

that this happens mostly when a take-off is attempted with gradually increasing

power. The answer is to snap the throttle open from idle quite sharply, the

resultant sudden power burst will allow the model to take off straight and well.

If possible, avoid rudder corrections during the take-off run as the model is

abnormally sensitive to rudder and it is easy to apply too much correction.

Ground-handling characteristics on slow engine speed, however, are very

good. "Slipping" the throttle for ground steering looks and sounds good on a

model of this type.

In common with other biplanes, with their high drag of struts, wires, etc.,

the glide of the S. E. 5A is flat but fairly steep. The airplane does not have the

aerodynamic "cleanness" to make long low approaches with a dead engine. Therefore

always try to land before the fuel is all used, so that the engine can be used for

making a good approach-path.

To the newcomer, or modelers of little flying experience, who need to know

the best method of handling the first flight of the model, our advice has to be

"Don't!" Give the model to an experienced clubmate or friend to make that allimportant first trimming-flight. Once trimmed, the model will be no more difficult

to fly than a regular Taurus-type model. Neither is it any easier. Flying experience

cannot be taught in written instructions such as these—it must be acquired over

a period of time. So proceed with caution—and get all the help you can during the

early stages of learning to fly.

In addition to the actual construction sequence of this model, we hope that

we have passed on to you some helpful ideas gathered from our own experience.

If you follow along these lines we know that building and flying your S. E. 5A

will be a rewarding experience.

Best of Luck!

TOP FLITE MODELS

16

Page 18

Loading...

Loading...