Page 1

RC-38 PHASOAR 035 INSTRUCTION MANUAL

I. INTRODUCTION

The PHASOAR 035 from Top Flite Models,

Inc., utilizes its unique looks and design

to deliver electric-powered performance at

the flying field! All of the latest

technology has been employed in designing

this model, starting with the silent, but

powerful, ASTRO FLIGHT Cobalt 035 Electric

Motor. This motor, with a GRAUPNER 7x3

folding propeller unit and a SR 1000 or

"Magnum" 1250 mAh battery pack (6-cell),

has rocketed our prototype PHASOARS to 700

feet in 55 seconds! This was done up to

five times on a single charge!

Aerodynamically, your PHASOAR has a light,

straight-forward and strong airframe.

There's no need to disassemble the model to

get at the batteries because its singlescrew release allows quick access to the

battery pack. This allows you to charge

batteries while still in the pod or remove

them for charging while a second pack is

being used. The full-flying stabilator

allows the model to be quickly and

dynamically trimmed for power-on/power-off

flight. The PHASOAR"s airfoil allows

flying in wind conditions that would ground

most of the flat-bottom types and, yet,

provides a great thermal-hunting glide.

The generous rudder area and the

appropriate polyhedral of the wing panels

allow quick detection of the core of the

smallest thermals for long unpowered

flights.

Finally, the PHASOAR is perfectly sized to let you

take it most anywhere and enjoy true, highperformance electric flight.

IMPORTANT NOTE:

If you are a beginner to the sport of R/C flying,

we would urge you to seek and use experienced

assistance in constructing and- flying this

airplane. All model airplane hobbyists should

remember that:

Flying this or an other radio-controlled model

aircraft is a PRIVILEGE and not a RIGHT and this

privilege begins with the utmost safety

considerations to others and yourself as well. An

TOP FLITE MODELS INC.

2635 S. WABASH AVENUE • CHICAGO, ILLINOIS 60616

R/C model airplane in inexperienced hands has the

potential of doing serious personal or property

damage. These safety considerations start at the

building board by following instructions, seeking

competent help when you are confused and avoiding

short-cuts. These considerations have to be

carried over to the flying field where safety must

come first.

done so, to:

1. Send for and obtain your Academy of Model

We

urge you, if you have not already

Aeronautics (AMA) membership which provides

insurance for your R/C activities'-DO NOT

RELY ON HOMEOUNERS INSURANCE.

Page 2

2. Join an AMA-sanctioned R/C flying club in

your area where you can obtain experienced

guidance and instruction in trimming and

learning how to fly this model.

Many local hobby shops have the required AMA forms

or can advise how/where they can be obtained.

WARNING!!!

A radio controlled model is NOT a "toy." Care and

caution must be taken in properly building the

model, as well as in the installation and use of

the radio control device. It is important to

follow all directions as to the construction of

this kit as well as installation and use of the

engine and radio gear. The advice and assistance

of a well-experienced builder and pilot is highly

recommended. Don't take chances! Improper

building, operation, or flying of this model could

result in serious property damage and/or in serious

bodily injury to yourself or others.

II. PRE-CONSTRUCTION NOTES

The PHASOAR, like other Top Flite kits, employs the

use of die-cut wood to ease the task of

construction, part fit and identification. Die-cut

parts may be removed from their sheets by first

lightly sanding the back of each sheet before

carefully removing each part. Use a light garnet

paper for the sanding and keep a sharp hobby knife

with a #11 blade handy for assistance in removing

any parts that might not have been completely cutthrough by the dies. Parts which oppose one

another must be precisely uniform (such a ribs,

etc.) and should be carefully "matched" after their

removal from the part sheets. Matching is the

process of holding the pieces together with either

pins or tape, or by spot gluing and lightly sanding

the edges of the parts until they are identical. A

sanding block with light garnet paper is most

useful for this.

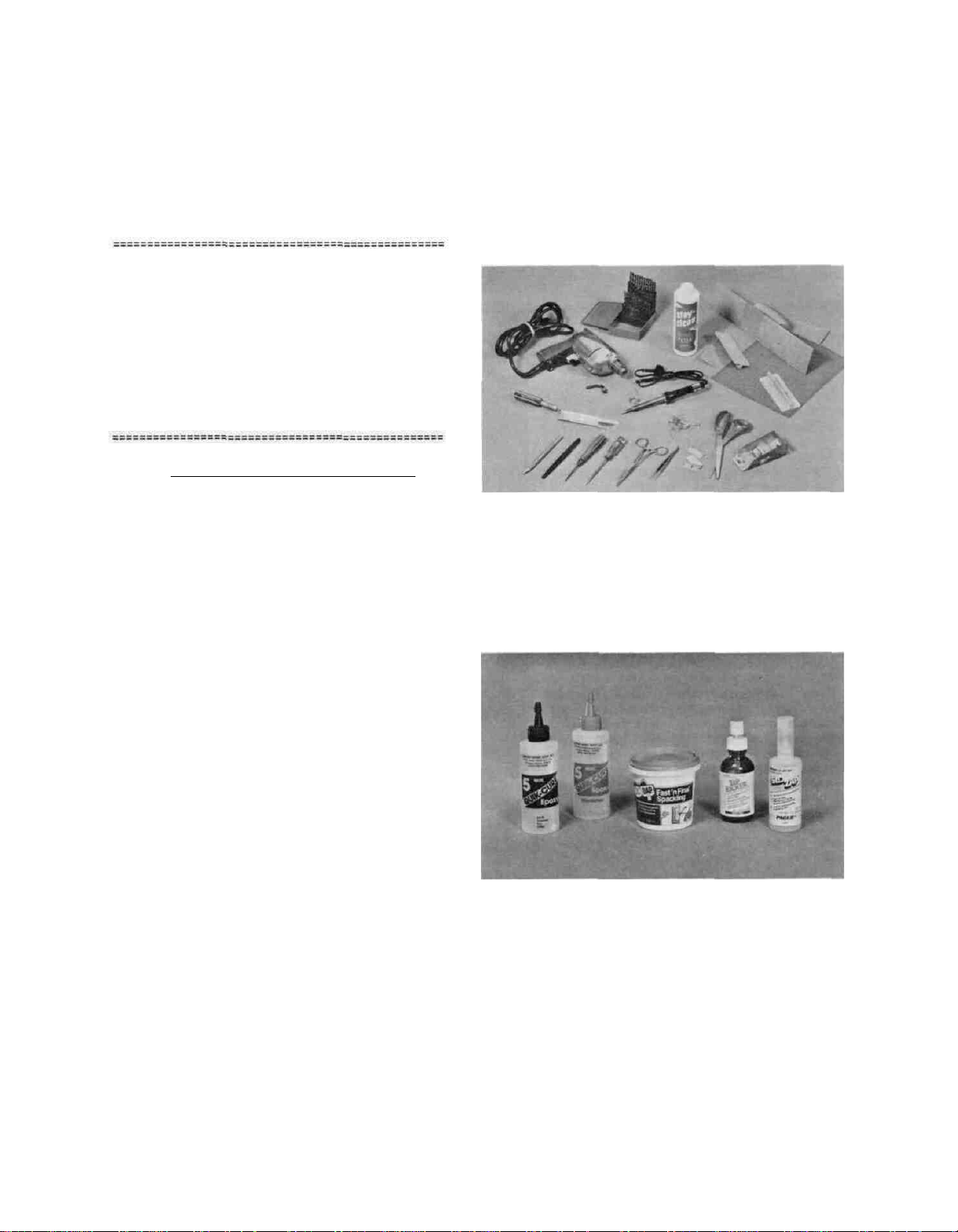

* Straight-edge, preferably metal, at least 36"

long

* 90" triangle

* Soldering iron, flux (such as HARRIS' Stay-

Clean) and solder (silver)

* Carbide cut-off wheel for wire cutting

* Small power jig-saw, such as a Moto-Saw

* Razor plane

* Tapes, such as masking and cellophane

Our PHASOARS were constructed using a variety of

common hobby adhesives including 5-minute epoxy and

cyanoacrylate (CA). Type of glue used may vary

according to individual preference. However,

during the construction there will be call outs for

certain types of adhesives, and we urge you not to

substitute since doing so could possibly cause

structural problems.

Your flat building surface should be at least large

enough to accommodate the wing, yet be able to

accept pins easily. A product such as Celotex

fiber board works well. Another good surface is a

2' x 4' fiber board ceiling tile.

As with most R/C kits that are constructed from

wood, a selection of tools and accessories greatly

help do the job correctly:

Hobby knife with sharp #11 blades

Single-edge razor blades

T-pins

Sanding blocks in assorted sizes

Sandpaper in various grits

Hand-held hobby saw, such as an X-Acto

* Dremel tool or power drill and assorted drill

bits

Left to right:

*Good quality 2-part 5-minute epoxy

*Good quality, sandable filler

*CA accelerator for CA glue

*Good quality, slow-set CA glue

Lastly, the sequence in which the PHASOAR is

assembled has proven to be the most straightforward and provides finished components in the

order in which you will need them to progress to

2

Page 3

the next assembly phase. Maintain the building

order presented here to avoid mistakes.

Spread the plans out on your work surface, cover

them with a clear plastic material, such as the

backing from a roll of MonoKote or plastic wrap,

and commence construction.

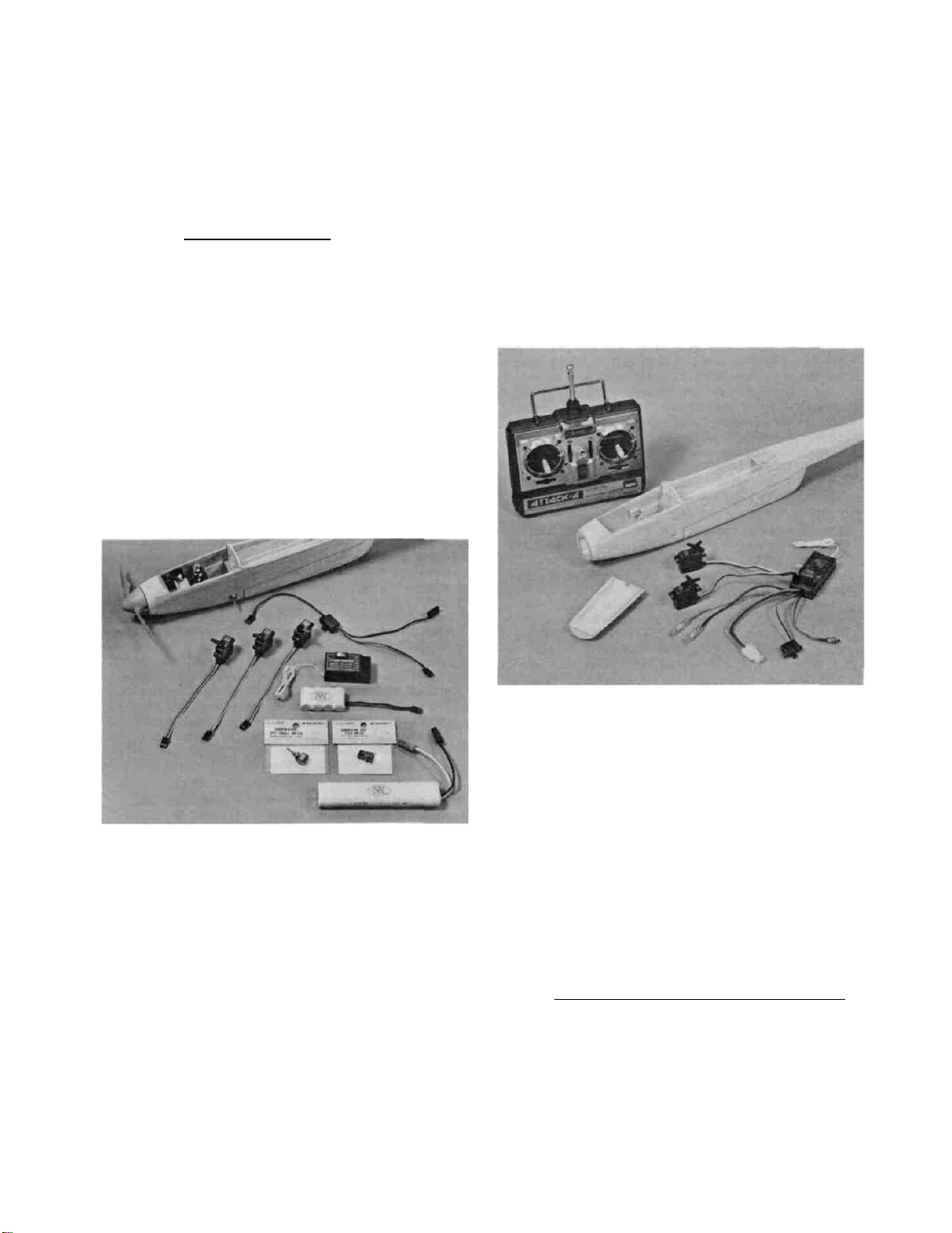

III. RADIO SYSTEMS

Our prototype PHASOARS have been tested and flown

using two radio types from different manufacturers.

The first of these radio systems is the one

depicted on the plans. The system consists of a

standard-sized 6-channel receiver (AIRTRONICS

#92262), three micro-servos (AIRTRONICS #94501) and

a standard-sized, internally-mounted switch harness

(AIRTRONICS

system by a 4-cell SR 300 mAh battery pack, fitted

with an AIRTRONICS connector. The servos have been

fitted with the 4-arm servo output arms, with three

of these arms cut-off and the remaining arm trimmed

as shown on the plans.

These three servos drive the rudder, stabilator and

the ON/OFF micro motor switch.

#97001).

Power

is

supplied to

this

fully-proportional, motor controller. Secondly,

the receiver and servos are powered by the motor

battery pack, thus, eliminating the need for a

separate, on-board battery supply for these

components! This means that there is no need for

a micro-switch, the wood mounts, the hardware to

mount these parts and no need for the arming switch

because the FUTABA system has all of these

components built-in. This system is available with

FUTABA's #S-133 servo included. The S-133 servo

has almost the same dimensions as the AIRTRONICS

#501 servo, thus no adjustment to the plans in the

servo area is required. Lastly, this system

includes FUTABA's Attack-4 transmitter which is

equipped with servo-reversing.

The radio system just described is very acceptable

in terms of weight and reliability!

The transmitters we've used in conjunction with the

above system were the AIRTRONICS Championship

Series 6-channel and the AIRTRONICS SR Series 4channel. Both of these worked well. whatever

system you choose, we suggest that the minimum

requirement is servo-reversing ability.

The second radio system that we've used is made by

FUTABA. This radio system has sophisticated

features that work well in the PHASOAR. First,

when using this system, your servo count goes from

three to two. because the receiver also houses a

FUTABA's System #4NBL 133MN 72 designates the radio

which

will

mentioned.

provide

For comparison, the airborne weight of the FUTABA

system is 3.25 ounces. The AIRTRONICS system

described earlier, with the micro-switch, mounts,

hardware and arming switch weighs or 5.93 ounces.

The difference amounts to 2.68 ounces, or nearly a

10% loss of weight for the model which uses the

FUTABA system!

There are other systems that would also work in the

PHASOAR.

Have whichever radio system selected available for

sizing and fitting purposes during construction.

all

of the

components

IV. MOTOR AND PROPELLER CHOICES

The PHASOAR has been designed and engineered to be

powered by the ASTRO FLIGHT 035 Cobalt motor, using

direct drive. This motor is relatively small,

light-weight (about 130 grams), very powerful for

3

just

Page 4

its size and quite easy to mount/install. It

swings a 7-3 or 7-4 propeller and accepts a wide

variety of battery packs.

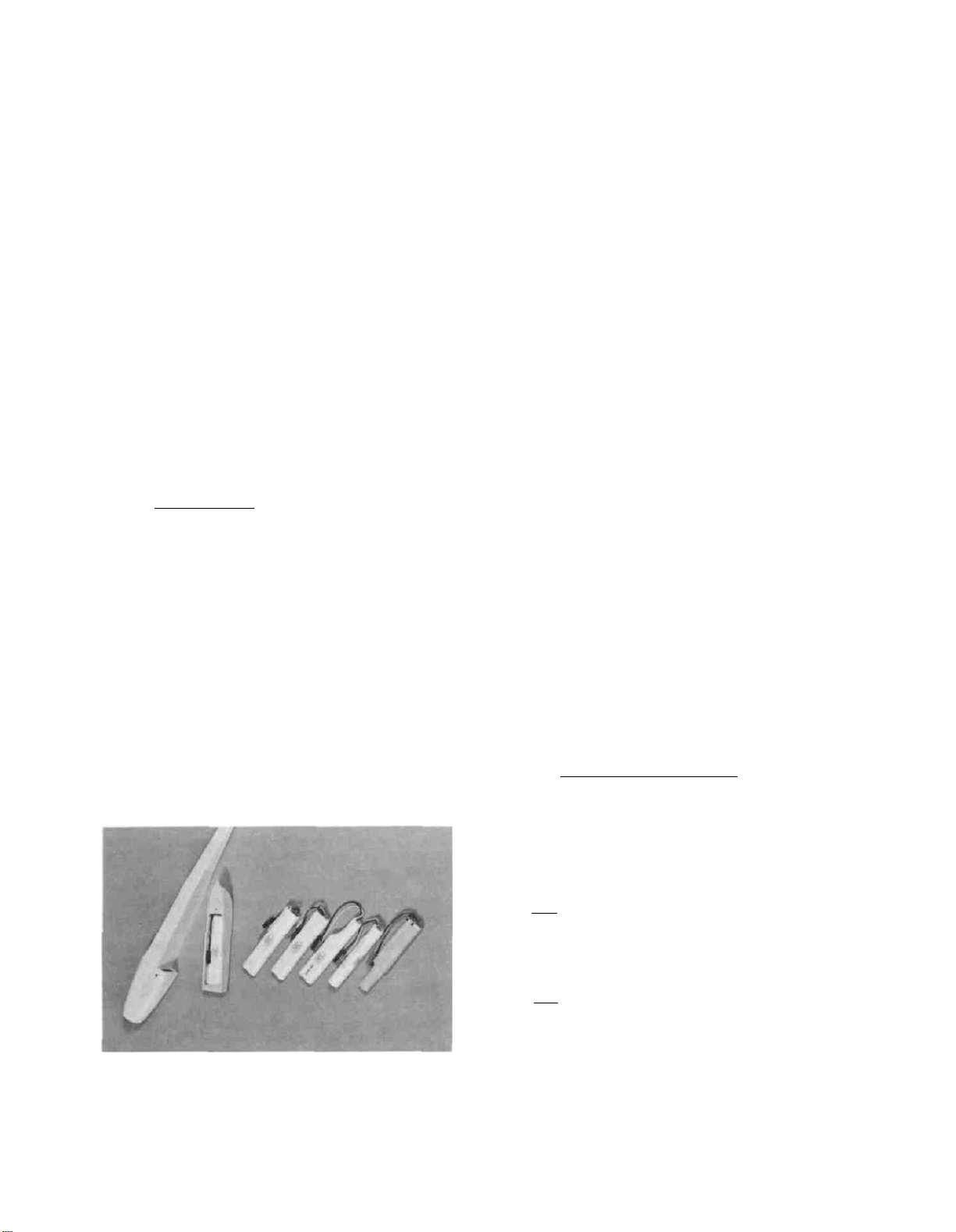

The photograph shows the five (5) battery-pack

types and capacities that we've used to power the

PHASOAR.

There are other motors that will fit into the

PHASOAR's nose, e.g.. the KYOSHO LEMANS 360, the

MABUCHI RS-380SH, and the ASTRO FLIGHT 020 Cobalt,

etc. We must, however, forewarn that these motors

are not going to yield the kind of high-performance

climb-to-altitude that the PHASOAR has been

designed for. Decide now which motor you want to

use

because

during construction.

The propeller choice always tends to be a function

of experience in flying the model. Therefore,

propeller sizes and diameters can and should be

"played with" to determine which one works best.

Our first recommendation is to seriously consider

a folding propeller. Since the PHASOAR is. in nonpowered flight, a sailplane, it derives a certain

amount of efficiency by being quite aerodynamically

"clean." while fixed-blade propellers work well,

the folding units tested performed better after

cutting power.

you

will

be

fitting

it

to the fuselage

V. BATTERIES

Your PHASOAR's battery pod has been designed to

carry six (6) AA-sized batteries, or four, possibly

five (if configured appropriately), "Sub C" type

batteries. The capacities of these two battery

types can and do vary and it is important for you

to know at least some of the differences. It is

also important to know that the current drain, when

using the ASTRO FLIGHT 035 Cobalt motor. Is higher

than that of a ferrite-type "can motor." Because

of this, it is appropriate to provide your model

with the best possible set of batteries, both in

terms of capacity and certainly in terms of weight.

Why worry about weight? The single heaviest, FIXED

WEIGHT item that your PHASOAR must carry aloft is

the battery pack. This weight directly influences

the wing loading of the model which dictates how

the model behaves when the power is OFF.

First, on the left in the pod, is the SR 1250 mAh

"Magnum" 6-cell pack. Moving from left to right in

the row of five packs, is another SR 1250 "Magnum"

pack. The next pack shown is the SR 1000 pack,

then the SR 1000 pack in a 5-cell format. Next is

the 4-cell, Sub-C SR 1000 pack, and at the far

right is a 5-cell pack made-up from Sanyo 800

cells. The weights for these units (all with

connectors) are as follows:

These numbers are revealing, especially when tied

into the capacities (potential amount of power) of

each of the packs and their effects on the model's

wing loading. All five of these packs have been

used in testing the PHASOAR and all five have

worked well. The best all-around battery pack has

been the SR 1250 (mAh) 6-cell pack, since it

provides the amount of power that the 035 Cobalt

thrives on. At the same time, it has an acceptable

weight for thermal hunting with the PHASOAR's wing

area (335 sq. inches) and resultant wing loading

(with this pack in place) of 11 ounces/sq. ft.

using the AIRTRONICS equipment or 10 ounces/sq. ft.

when using the FUTABA system.

To get the most out of your PHASOAR, in terms of

flying time, consider obtaining three (3) battery

packs. In this way you can be flying almost

constantly because one pack will be in the model,

one pack will be cooling and the third will be on

charge. With only a single flight pack you could

conceivably have to wait 35 to 40 minutes between

flights.. Be sure to follow manufacturer's

recommendations for recharging the batteries.

SR 1250 6-cell "Magnum" pack. . 7.43 oz.

SR

1000

6-cell

pack

SR

1000

5-cell

SR 1000 4-cell Sub-C pack . . . 6.09 oz.

Sanyo

800

(mAh)

pack

5-cell

......

......

pack . .

7.60

oz.

6.43

oz.

6.52.oz.

VI. BATTERY CHARGERS

There are a great many chargers available for recharging Nickel-Cadmium batteries (Ni-Cads); too

many to test them all. We have had success with

the two we use and, therefore, recommend these to

you knowing that many others may work out just as

well.

For fast charging (15 to 20 minutes) the LEISURE

#107 AC/DC model works well and can be either used

on your auto's 12-volt battery or plugged into a

110 volt wall socket. Great for quick charges at

the flying field.

For slow charging ACE R/C's DUAL-METERED VARICHARGER (#34K32) is available in both kit form and

pre-assembled. It allows two battery packs to be

charged simultaneously. Super when you have the

time at home to top-off the charge in each pack.

4

Page 5

VII. WING CONSTRUCTION

Be sure and protect your plans by covering them

with backing from a roll of MonoKote or a material

such as clear food wrapping. Take a minute to

study the plans and understand them. We suggest

building a right and left wing panel, starting with

the inboard sections, we'll start with the left

wing first.

1. From the 1/16" x 3" x 30" sheeting

provided, cut, fit and locate over the

plans, the bottom leading edge sheet (use

a long straight edge to develop the correct

width and to true-up the edges). From the

1/8" x 3/16" spruce spar stock provided,

measure and cut the required 15" length for

the bottom spar, set this aside . Now cut

and locate over the plans, the 1/4" x 1"

length of shaped trailing edge stock. Next

cut and glue the bottom center section

sheeting in place to the trailing edge

stock and the forward bottom wing sheet.

Cut, fit and glue in place the six bottom

1/16" x 3/16" cap strips from the stock

provided. Using one of the die-cut W-2

wing ribs as a location guide, the bottom

spruce spar (cut earlier) can now be glued

in place. Lastly, note in the cross

sections that the leading edge of the

bottom wing sheeting needs to be lifted up

and supported in order to match the bottom

contours of the wing ribs, forward of the

spar. This is best done with a length of

trailing edge stock.

2. Note the "tick" marks just in front of and

just behind the wing panel drawings. These

correspond to the rib locations. Use a

straight edge and a soft lead pencil to

mark the rib locations directly on the

leading edge and center section sheeting.

The first wing rib to be installed is the

first W-2 rib, inboard from the polyhedral

break (the inboard end of polyhedral brace

W-10 will butt against this rib when it is

installed). Continuing to work inboard,

toward the center, install the next three

U-2 ribs. From their die-cut sheets,

remove ply dihedral braces W-8 and W-9 and

polyhedral braces w-10 (balsa). The two

remaining inboard w-2 ribs must now be cut

to compensate for the installation of the

W-8 and W-9 dihedral braces; use these

braces as a thickness guide and trim the

ribs as shown on the plans. Finally, root

rib W-1 must also be trimmed into two

pieces to fit in front of and behind the

dihedral braces. Once this is done,

holding W-8 in place again as a guide, glue

all of the remaining forward rib ends in

place to the bottom leading edge sheeting;

remove W-8 from the structure. Using W-9

as a guide, glue all remaining rear rib

ends in place and remove W-9 from the

structure. The remaining outboard W-2 rib

must be trimmed in a similar manner. Using

the same procedure as described, trim this

rib into a front and rear piece and glue in

place using W-10 as a spacer; remove W-10

from the structure.

3. Cut. fit and glue the 1/4" sq. leading edge

in place.

4. Carefully remove this structure from your

work surface. Use a sanding block to

lightly sand the outboard edges (the

polyhedral break) smooth. Place the

structure back on the plans and block up

the center 2-1/2." Using the same

construction as described earlier, the

outer wing panel is now built directly over

the plans and directly to the inner panel.

Take pains to bevel the trailing edge butt

joint for a good fit. Be sure to install

w-10 first before the front and rear

segments of U-2, followed by W-3, W-4, etc.

5. With all of the ribs in place, cut, fit and

glue the top spruce spar in place from W-7

to the W-2 at the polyhedral break. From

your parts bag, locate the bundle of ten

vertical grain shear webs. Carefully trim

one of these to fit between W-3 and W-2 and

against the spars and W-10 with the top

flush with the top of the spar. Once

satisfied, glue this web in place.

6. As shown on the plans, the 1/4" sq. leading

edge must now be sanded down to match the

top contours of the ribs. The razor plane

then sanding block work great here. Once

satisfied, cut, fit and glue in place the

top 1/16" leading edge sheeting (note that

this top sheeting is placed slightly

forward on the top spar thus creating a bit

of a "shelf"). Lastly, cut, fit and glue

in place all of the top 1/16" x 3/16" cap

strips with the exception of the one which

will cover the W-2 ribs at the polyhedral

break. Remove the left wing panel from

your work surface. Use your sanding block

to smooth the outboard face of W-7 in

preparation for the wing tip. Inspect the

bottom polyhedral joint and lightly sand as

needed.

7. The right wing structure is now built using

the same procedures just described.

8. Next, the right and left wing halves will

be joined together. Preparation for this

requires that the two inboard ends of the

wing halves be sanded smooth and beveled

to create a good, straight fit. Do this

now. Pin or weight one of the wing halves

(let's use the left) flat to your work

surface. Next, make sure the rib curve in

the bottom leading edge sheeting is

5

Page 6

supported with a length of trailing edge

Stock. With everything secure, trial-fit

the right wing half in place with its

polyhedral break supported 2-5/8" off of

the work surface. The resulting butt joint

should be as flush fitting as possible and

the leading and trailing edges of both

inner panels should be straight; take your

time here and ensure that the fit is the

best you can produce, with all parts

lining-up correctly. Once satisfied, apply

a thin, even coat of glue (5-minute epoxy)

to the inboard end of the right wing panel

and carefully fit it to the pinned down

left panel, again making sure the right

panel is raised 2-5/8" at the polyhedral

break. Carefully wipe off any oozing

adhesive. Now, fit W-8 dihedral brace in

place, trimming if needed for a good fit.

Glue w-8 in place. Cut, fit and glue the

left panel's spruce spar in place. Rear

dihedral brace w-9 can now be glued in

place.

below, cut a few scraps of 1/8" balsa to

fill in the leading edge of the wing tip

and glue these in place. From the

remaining 1/16" balsa sheet provided in

your kit, cut. fit and glue in place the

wing tip braces as shown on the plans. On

our prototypes we added these braces top

and bottom.

9. With the left wing still down flat to your

work surface, locate the vertical grain

shear webs (1/16" balsa). Cut, fit and

glue these in place between the remaining

w-2 ribs. out to the polyhedral break.

10. Remove the joined wing structure from the

bench. Pin or weight the right panel in

place to the bench and glue the remaining

top spruce spar in place followed by the

remaining vertical grain shear webs.

11. As you did with the wingtip panels,

carefully shave and sand the inner panel's

leading edges to conform with the top

contours of the wing ribs. Use your

sanding block to lightly sand any high

points on the panel's top surfaces. When

done. the inner panels are ready to sheet.

Pin or weight one side or the other in

place on your work surface. Cut, fit and

glue the leading edge sheeting in place

(again leaving a bit of a "shelf" at the

rear edge of the top spar). Cut, fit and

glue the center section sheeting in place

using the patterns shown on the plans.

Finally, install all of the remaining 1/16"

x 3/16" cap strips out to and including the

polyhedral break. Repeat this procedure

on the opposite wing panel.

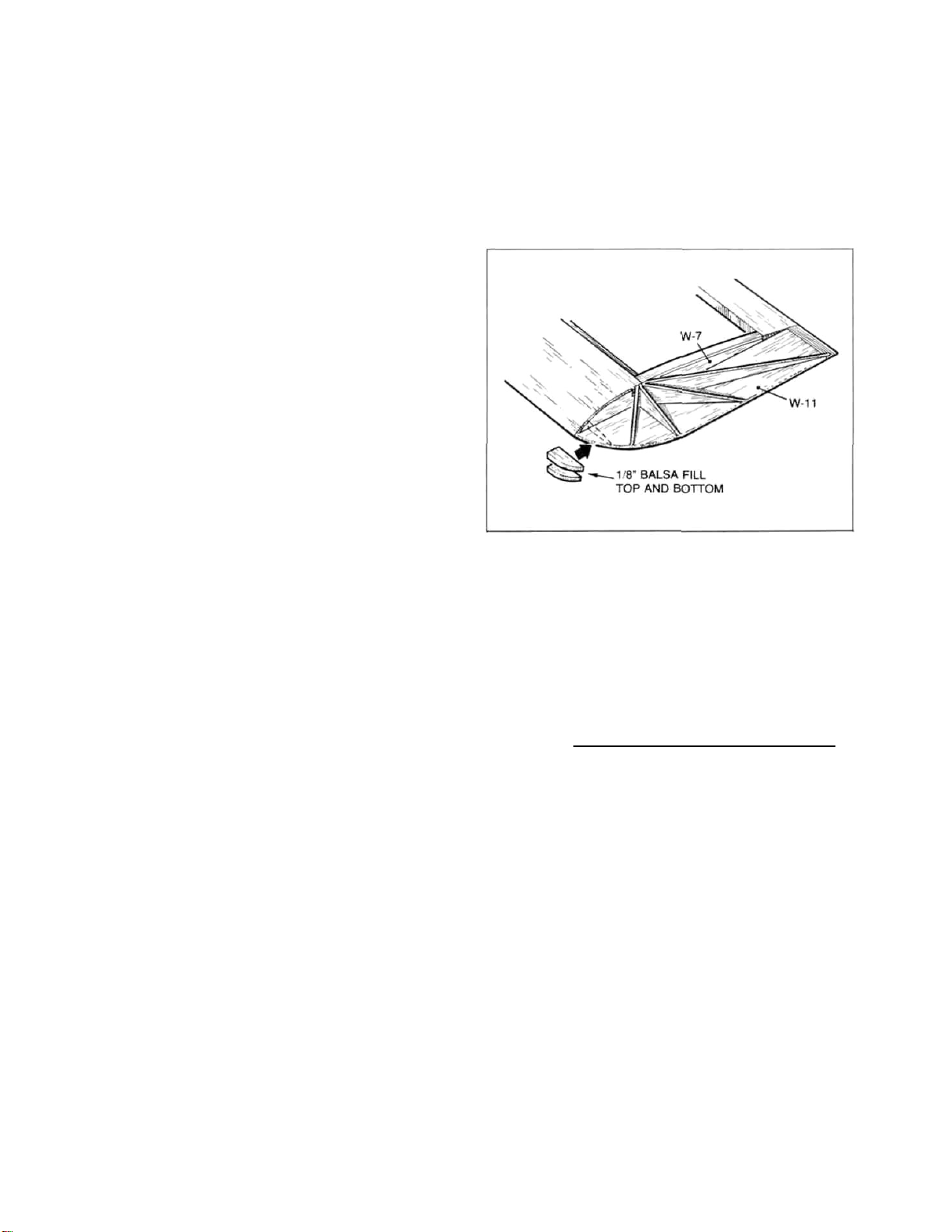

12. Locate and remove wing tip parts W-11 from

their die-cut sheets. Sand their inner

edges lightly to render them flat and

straight. Note the tip reinforcement

option shown on the plans. This addition

of a length of 1/8" x 3/16" spar stock

really "beefs-up" an area prone to stress

in an accident. Glue the W-11 wing tips in

place as shown on the plans ("End View of

Wing tip" left panel). Also as shown

The completed wing structure should be carefully

sanded to final shape including the leading edges.

At this point your PHASOAR's wing structure is

nearly complete. Later, after the FUSELAGE

ASSEMBLY, we will insert the forward 3/16" dia. x

1-1/2" hold-down dowel, drill the center section

trailing edge for the hold-down screw and add the

front and rear balsa wing/fuselage fairings.

VIII. STABILATOR CONSTRUCTION

Studying the plans you'll note that the entire tail

group (stabilator, fin and rudder) for your PHASOAR

consists of flat "plate" structures, which have

die-cut "core" parts and die-cut "cap" parts.

These structures are sanded to airfoil shape (shown

on plans) after assembly. Although these

structures are quite straight-forward in design, it

remains important that care be taken in cutting and

gluing the required parts together.

1. From the small parts bag, locate and remove

the single 3" length of 1/16" I.D. aluminum

tubing and two of the four 1/16" dia. x 11/2" lengths of music wire (M.W.).

Carefully measure and cut-off four(4) 5/8"

lengths of the aluminum tubing, using a

single-edge razor blade with a rolling

motion on a hard surface. Be sure to save

the remaining 1/2" length of this tubing

for later use.

6

Page 7

2. Locate and carefully remove the 3/32" die-

cut core parts S-1 (2 each) and S-2 (2

each), and the 1/16" cap parts S-3 (4

each). Make sure your stabilator plan is

covered with clear protective material and

position each of the S-1 parts in place weight or pin. Glue the S-2 parts in place

to each S-1, directly over the plans.

Remove the two resultant structures from

the plan and, holding them together,

lightly sand their outer edges to match

exactly.

3. In this step you are going to glue each of

the S-1/S-2 structures to a S-3 cap part,

a bottom left and right. Apply a thin

coating of glue to the bottom of each S1/S-2 structure, keeping it out of the

slots, and pin or weight in place over the

bottom S-3 cap. Once again, remove the two

resultant structures from your building

board, hold them together and light-sand

their outer edges flush with each other.

Re-position these parts back over the plans

and securely pin or weight in place.

4. Now test-fit each of the four (4) 5/8"

lengths of aluminum tubing in place into

the slots provided in the S-1/S-2 parts

with both of the 1/16" x 1-1/2" M.W. rods

in place. This is a good time to trim

anything that does not fit well. Refer to

drawing. Note that the two M.W. rods are

meant to be parallel with each other when

in place. Using 5-minute epoxy, glue each

tube in place into each slot in each S-1/S-

2/S-3 structure, being careful to keep glue

out of the tubes - allow to cure.

6. Cut, fit and glue the 1/4" x 3/8" balsa

trailing edges and tips in place - pin or

weight securely. From the 1/4" balsa stock

provided in your kit, cut, fit and glue the

two required tip corner gussets in place.

Again using the 1/4" balsa stock, cut, fit

and glue the leading edges in place.

7. Using the 3/32" x 1/4" balsa stock provided

in your kit, cut, fit and glue the diagonal

geodetic "ribs" in place, using the plans

as a guide. Take care here to create the

best joints that you can. Using the trim

lines shown on the right stab side, trim

the right stab tip as shown. Remove the

stabilator structures from your building

board. Holding the right stab half over

the left. trim the left stab half tip to

match the right, while still holding the

structures together, sand the rear, inboard

trailing edge "notches" per plan.

8. The stabilator halves should now be

complete and matched. Further, when joined

together with the 1/16" M.W. rods, they

should be flat in relationship with one

another. The last step is to sand these

halves to airfoil shape as shown on the

plan.

5. Apply a thin coat of glue to the bottoms

of the two remaining S-3 top caps and pin

or weight these in place directly over the

tops of the S-1/S-2 structures, carefully

lining-up the inboard edges. Remove the

two structures from your building board and

remove the two 1/16" dia. x 1-1/2" M.W.

rods and pin or weight directly over the

plans.

Note holes through geodetic ribs and root section

of stabs and a similar hole through bottom of

rudder and through top of TC-1's on fin. These are

"breather" holes for covering purposes. They allow

hot air to escape the structure, allowing MonoKote

to fully shrink.

IX. RUDDER CONSTRUCTION

1. Locate and carefully remove the two

7

required R-1 die-cut rudder cores from

their

sheets.

required 1/32" RC-1 rudder cap parts.

Start construction by gluing the two R-1

parts together, taking care to match their

outer edges with each other. Pin or weight

the

R-1/R-1

plans.

Do

the

structure

same

in

for

place

over the

the

two

Page 8

2. Cut, fit and glue the rudder's 3/16" sq.

balsa leading, top and trailing edge in

place. Glue one of the RC-1's in place

directly over the R-1/R-1 structure,

matching each edge. Locate and remove two

of the die-cut 1/32" x 3/16" x 8-1/2" fin

and rudder cap strips from their sheet. As

shown on the plans, the cross-hatched areas

at the leading edge and top of the rudder

are "capped" with this capstrip stock - do

this now. Remove the structure from the

plans and lightly sand the "capped" side

smooth. Place the structure back on your

work surface, opposite side up, and glue

the remaining RC-1 and capstrip stock in

place. Again, lightly sand this side of

the rudder smooth. Re-position the rudder

assembly in place over the plans - pin or

weight.

3. Using the 1/4" sq. balsa stock provided,

cut, fit and glue the two bottom, leading

and trailing edge corner gussets in place.

Using the 3/32" x 1/4" balsa provided, cut,

fit and glue the diagonal geodetic "ribs"

in place, using the plans as a guide.

Again take care to create the best joints

that you can.

4. Remove the rudder structure from your work

surface and use a sanding block to smooth

each of the four outer edges and the left

and right surface of each side. with the

exception of the addition of the 1/32" ply

rudder control horn and the 45-degree bevel

for hinging, the rudder is now complete and

can be sanded to the shape shown on the

plans. Set the structure aside for later

fitting to the fin.

X. FUSELAGE/FIN CONSTRUCTION

Note that the fuselage and fin, with the stabilator

drive, are constructed as a single unit.

1. Remove the two fuselage sides from their

die-cut sheet. Tape, pin or clamp them

together and use a sanding block to lightly

sand their edges, thus matching them

exactly. Remembering that a left and right

side is required, glue F-2 on the fuselage

sides as shown below on the assembly of

nose and forward fuselage drawing.

8

Page 9

2. Glue 1/4" triangular corner blocks, leaving

space for F-3 at forward edge of fuselage.

Using F-3 and F-4 for spacing, cut and glue

1/32" vertical-grain nose doublers.

Glue block in place to RIGHT T-1, just

below cutout. Insert cable into tube and

use a heat gun to bend tubing and cable to

fit within right fuse side. Once bend has

been made, glue tube to right fuse side up

to F-5 location about every inch.

3. Add 1/8" longerons and uprights per

sections E-E, F-F, and G-G.

4. Drill LEFT fuse side for rudder control

tube exit as shown, glue tube in place to

inside of left side all the way to F-5

(about every 1") - set aside.

5. Build basic fin frame directly over plans

using 3/16" x 3/16" outside frame stock.

Remove from plans; lightly sand flat.

Install antenna tube

(sections E-E and F-F).

8. Notch F-5 to accept rudder, elevator, and

antenna tubes. Notch F-4 to accept rudder

and elevator tubes.

9. Mark rear pivot hole location onto LEFT T1 side. Use a punch (nail, etc.) to open

this hole enough so that later sanding

won't remove it. Glue LEFT T-1 sheet in

place. Use the 1/32" x 3/16" stock to cap

the left side of the fin. Lightly sand

flat.

10. Lay the LEFT fuselage side over the RIGHT

fuselage side/fin assembly. Check fit.

Sides should match. Glue LEFT fuse side

to RIGHT fuse side from 1" forward of the

fin, back to the end of the fuselage weight or pin and allow to dry.

11. Spread fuse sides and glue F-5 in place keep square (5-minute epoxy allows a bit

more positioning time. Glue F-4 in place;

keep square.

to right side

6. Glue RIGHT fin sheet part T-1 accurately

in place, as shown on fin drawing. Glue

rear 3/16" Sq. pivot block in place. Glue

RIGHT side 1/32" x 3/16" fin frame cap

stock in place; lightly sand flat. Glue

fin in place to RIGHT fuselage side, over

plans.

7. Solder drive fitting to cable end. Use

3/16" x 3/16" block to hold cable tube.

12. Glue rear 1/8" ply screw plate in place

against F-5 fuse sides and against bottoms

of F-2.

13. Epoxy F-3 in place.

14. Trial-fit motor, with the ASTRO FLIGHT

Cobalt 035, rotate motor as far as it will

go to the right (this minimizes the height

of the brush housings). Note that the

bottom brush housing will contact the

9

Page 10

bottom left triangular stock. Mark with a

pencil where this occurs and use a DREMEL

to relieve this area. Once the motor is in

place, drill two 1/8" diameter holes in F3 for mounting with two 4-40 x 1/2" screws.

Remove motor and screws - set aside.

Note: For a MABUCHI 380 motor, no

special rotating is required, but metric

mounting screws are needed (not supplied).

15. Using 1/16" balsa sheet stock, glue bottom

sheeting in place (cross-grain) from rear

of F-4 back to end of fuse sides.

16. Glue 1/8" pod screw plate in place between

1/8" fuse longerons and against rear of F-

5.

17. Tack glue die-cut P-4 ply pod base to

bottom of fuse sheeting with front edge

securely against F-4. Glue forward pod

former P-2 carefully to P-4 (Keep glue off

of F-4 and be sure to center P-2). Glue

triangular 1/4" stock to bottoms of P-1 pod

sides - be sure you make a LEFT and RIGHT

pod side!

18. As shown on the plans the pod is held in

place at the front with two 5/8" lengths

of 1/16" music wire. The two required

holes for their locating/mounting pins must

now be drilled through P-2 and F-4. Drill

1/16" holes. Insert the two 1/16" x 1-1/2"

music wire pins in place and glue securely

to the P-4 pod base and P-2 former.

1/2"x 2" x 12" length of balsa. Using a

sanding block, bevel-sand one end of the

block to fit against the forward face of

F-4, holding it in place at the top of the

fuselage.

23. The forward end of the radio hatch is now

cut at the angle shown on the plans. Once

the bevel cut has been made, use the

sanding block to lightly clean up each end

of the cut. Set aside the hatch part for

a moment. On the remaining length of block

measure forward from the bevel cut and cut

this piece off. This then becomes the

forward "lip" for the radio hatch. Use

tape to hold the radio hatch in place to

the top of the fuselage, against F-4.

Apply a small amount of glue to the bottom

of the forward block and glue it in place

to the top of the fuselage and nose block,

matching the bevel on the front of the

radio hatch block, thus insuring a nice fit

between these two blocks. Untape and

remove the radio hatch block. Locate and

remove the ply hatch "lip" from its die-cut

sheet. F-4 can now be glued to the

forward, bottom surface of the hatch block

with 3/16" of its forward end protruding,

thus providing a fit beneath the forward

block just installed and preventing

shifting from side-to-side. Install the

two 1/8" square hatch locators. Repeat

procedure for the bottom nose block. The

bottom block, not being removable, can now

be glued in place.

19. Now glue the P-1 pod sides in place to P2/P-4 making sure the P-1's match the

fuselage sides. Make certain to keep glue

off of fuse sides. See drawing below.

20. Glue 1/8" x 3/8" spruce/ply to bottom of

P-4 and butt up to P-3.

21. Fit and glue P-6 and pod tail blocks in

place. Drill cooling air outlet holes and

sand bottom of pod to accept P-5.

22. Now drill and tap pod screw plate with an

8-32 tap. Glue P-5 in place. Locate the

24. The next step is to assemble the nose

block. Glue the plywood spinner ring to

the 1/4"x 1-3/4" x 2" balsa nose block,

carefully centering it. After the block

has dried, remove center section by cutting

along center of spinner ring with a #11

blade. Sand the front of the fuselage per

section B-B to accept the nose block

assembly. Align the nose block with the

motor shaft and cement to F-3. The coolair intake hole can be drilled at this time

(see photo below).

10

Page 11

25. Now trial-fit your wing to the fuselage.

Make sure the wing is centered and that the

leading edge is up against F-4. Holding

these two structures together, observe the

fit between the bottom of the wing and the

wing saddle area. It may be necessary to

slightly bevel the tops of the fuselage

sides and F-1 doublers to get a snug fit;

do this now. Once satisfied with the

wing/fuselage fit, you're ready to make the

hold-down system. Again place the wing on

the fuselage and use weights to hold it

firmly in position. Make sure that the

wing is squarely in position on the

fuselage by taking wingtip-to-tailpost

measurements as shown in the figure below

("X" should equal "X").

the threads have been cut, give them a very

thin coat of instant CA glue and again run

the tap through them. This toughens the

threads in the plywood. Re-fit the wing to

the fuselage and screw it in place to again

check the fit. Note that about 7/8" of the

length of the nylon screw (1-1/2" supplied)

can be trimmed off.

26. Remember that 1/2" length of 1/16" I.D.

aluminum tubing that you saved back when

building the stabilator? Locate it now.

with a 3/32" drill bit, finish the hole

through the fin (the stab pivot hole). Cut

a 1/4" length of aluminum tubing, clean

each end with a #11 blade and carefully

insert it into the stab pivot hole just

cleared out; do not glue. Attach the

stabilator halves to the fin; just press in

place for now. what we're going to check

for now is alignment, we want to view the

airplane head-on at a bit of a distance.

Place it on a table, facing you, and backoff a few paces, sighting directly at the

front. Is the wing sitting properly on the

fuselage? Is the stabilator tilted in

relationship to the wing/fuselage or does

it line-up right? If everything else seems

to line-up, we can proceed to finish

sheeting the top, rear of the fuselage. If

it doesn't, we need to know which way to

twist the fin to make everything line-up

properly because once the top, rear

sheeting is installed, it "locks" the

fuselage firmly in place thus making any

such corrections extremely difficult, if

not impossible.

Locate the 3/16" dia. dowel from the parts

bag. A 3/16" dia. hole must now be drilled

through F-4 (see mark) and into the wing's

center w-1 ribs, to a depth of 1-7/8,"

measured from the front face of F-4. Mark

this depth on your drill bit with a strip

of tape. Once the hole is drilled, remove

the wing from the fuselage and trial-fit

the 3/16" dia. dowel in place. Use

sandpaper to slightly round the front edge

of the dowel. Now glue the dowel in place

in the wing (clean off any oozing glue).

Once dry, again fit the wing to the

fuselage and use weights to hold it in

place. The rear nylon screw hold-down

system is now made. Start by drilling a

hole, with a #29 drill bit, through the

wing's trailing edge and through the 1/8"

ply wing screw plate at a slightly forward

angle (see plans). Remove the wing from

the fuselage. Enlarge the hole in the

wing's trailing edge to allow the 8-32

nylon screw to slip through to the head.

Now using either an 8-32 tap or an 8-32

screw (metal), tap the threads into the

hole made in the ply wingscrew plate. Once

27. If the alignment appears to be OK, remove

the stabilator halves, leave the wing in

place, and carefully cut and glue the 1/16"

balsa sheet (applied cross-grain, as shown)

top, rear decking in place back to the

leading edge of the fin. However, if some

alignment is needed by having to pull the

top of the fin left or right, now is the

time to do it, before applying the top,

rear sheeting. This is how it's done. Set

the assembled airplane on a large, flat

table. Height the top of the wing center

section to hold it firmly in place. Again,

sighting directly at the front of the

model, determine which way the fin has to

be tilted. Pull off a long length of

masking tape and stick it to the top of the

fin. Pull against the tape until the fin

is in the right position and stick the

other end to the table, thus preventing the

fin from shifting. With it now properly

aligned, cut, fit and glue the top, rear

sheeting in place as earlier described.

Let the sheeting dry before removing the

masking tape from the fin and you'll find

that the fin is now properly aligned.

Remove the wing and stabilator halves from

11

Page 12

the fuselage. Use your sanding block to

now sand the top, rear sheeting and the

forward radio hatch and nose block piece

flush with the fuselage sides. You can

also now sand the top forward hatch and

nose-block contours to shape as shown in

the plans, no need to round corners yet.

28. From your parts bag, locate the 1/4" shaped

fin/fuselage fairing. Use your sanding

block to adjust the angles if needed and

glue in place. As shown, this is now

trimmed to fair the fin leading edge into

the top, rear of the fuselage.

handled this by sticking a length of

masking tape lengthwise about 3/16" above

this joint, on T-1. Then we carefully

sanded down the fuselage side(s) to as

close to T-1 as possible (the masking tape

was there to protect T-1 in case we got too

close). Then with the tape still in place.

we used filler to "fair-in" this joint,

feathering the material carefully. When

the filler was dry, the tape was removed

and we used very light sandpaper to finish

feathering the joint.

29. Finally, push the 1/4" length of aluminum

tubing that's in the rear pivot hole about

halfway out, apply just a bit of adhesive

to its outer surface (5-minute epoxy or

slow-cure CA) and push it back in place in

the fin.

30. with the exception of contouring and final

sanding, your fuselage should be complete.

XI. FINAL ASSEMBLY

It's often been said that the difference between a

good model and a great one is sandpaper and the

willingness and ability to use it. This point in

construction can literally make or break the

performance and the look of your model. Since the

PHASOAR is an obvious candidate for use of

MonoKote, keep in mind that the surface preparation

of the wood will dictate the finished, covered look

of your model. Referenced use of "filler" in the

following text. refers to products such as

MicroFill, Model Magic Filler, or something

similar. These products dry quickly, are very

light, and MonoKote goes over them nicely.

Let's start with the fuselage, since the other

components should, by now, be sanded and about

ready to use.

1. Note the lower left corner of Cross Section

F-F on the plans. This demonstrates about

the correct amount of radius that can and

should be sanded into the fuselage bottom.

As this sanding radius moves aft, toward

the fin post, and the fuselage diminishes

in width, the result will be a pleasant

looking oval shape. Next, sand the radio

hatch and nose sections. Use a rougher

grit of paper at first, followed by the

finer #220 to do the job nicely. The last

section to tackle is the top, rear of the

fuselage - back and including the fin

fairing and fin leading edge. Take every

effort needed to sand this structure to the

point that it looks and feels like one

piece. You will note that where the T-1

fin sides meet the fuselage sides, there is

a disparity in wood thickness resulting in

a kind of "tip." On our prototypes we

2. Use your sanding block to sand the trailing

edge of the fin flat and straight.

3. The last step in preparing the fuselage for

covering is to sand the fin/rudder

combination together, as a single unit.

Start by using masking tape to accurately

position the rudder to the fin. Now use

your sanding block to accurately match the

side view shape of the rudder to the

fin/fuselage. Once that's done, remove one

of the pieces of tape from one side only

and lay the structure down on a flat

surface - taped side down. Use your

sanding block to now sand the rudder's

cross-section shape into the fin/fuselage,

but only about halfway. Add another piece

of tape to the now sanded side, flip the

structure over, remove the tape and repeat

the sanding operation. After a couple of

passes on each side, you should be about

where you want to be; a fin with a true

leading edge and a rudder with a true

trailing edge and everything in between

accurately matched. The leading edge of

the rudder can now be beveled as shown on

the plans, thus facilitating left and right

movement when hinged with MonoKote.

Once this is done, locate and remove the

1/32" ply rudder horn from its die-cut

12

Page 13

sheet. Once again tape the rudder to the

fin, right side only. Use a sharp #11

blade to now cut a 1/32" wide slot in the

rudder's leading edge, at the bottom, on a

plane corresponding to the rudder tube's

exit point on the fuselage. Once the slot

is made to your satisfaction, trial-fit the

horn in place and trim as needed to get a

proper fit. Do not glue the horn in place

until after the model is covered.

4. Assemble the wing to the fuselage and cinch

it down with the wing screw. In this step

we want to rough-cut and fit the forward

and rear wing/fuselage fairings to the

wing's center section. The remaining

length of radio hatch block balsa will be

used for this. First either carve or use

a Dremel tool to route out the bottom

mating surface of each of these blocks; cut

and fit. Bevel the rear block to match the

fuselage (viewed from the side) and then

use your #11 blade to carve out a space for

F-12 when the block is held in place.

Also, the head of the screw will indent the

bottom of this block and therefore give you

the location to drill a 1/4" dia. hole to

allow the screw head to seat against F-12.

Once you're satisfied with how the two

blocks fit onto the wing and to the

fuselage, concentrate on the top view. The

forward should be sanded to a sort of halfround shape, carrying through the shape of

the hatch block. The rear block gently

curves in to the center line of the wing to

a point about 1-1/2" from the trailing

edge. Glue the blocks in place to the top

of the wing while the wing is still

attached to the fuselage. Protect the wing

sheeting around the edges of these blocks

with masking tape; sand to a final shape.

Use filler to fillet the blocks to the

wing. Lightly sand, and you're finished.

Remove the wing from the fuselage.

5. Use a sharp razor blade to remove the

finished radio hatch block. With the

battery/servo compartment now open, install

your servo mounting rails. Note on the

plans that we've used the remainder of the

1/8" x 3/16" spruce spar stock for these.

You may wish to use ply. Install these

rails in the approximate positions shown on

the plans, with the servo's output arms

lined-up with the rudder and elevator tube

ends protruding through F-4. with servos

in place, cut the 1/4" x 3/8" x 4" spruce

micro switch mount to fit as illustrated

on the drawing. Drill and attach the two

1/4" x 1/4" x 3/8" maple blocks to the

mount with #2 x 3/8 wood screws. Next

drill two holes in the mount for the micro

switch, and mount with two 2-56 x 1/2"

screws and nuts. Set the assembly in

position as shown on the drawing. When

proper contact is made with switch and

servo arm, glue in place. Once satisfied,

servos can be removed.

6. Before covering take a few minutes to

"ventilate" the various structures; wing,

fin (above T-1's), stab halves and the

rudder. Ventilating these components

allows the heated air (formed when

covering) to escape the various sealed

compartments (between rib bays, etc.)

rather than expanding and "ballooning" the

covering.

7. For the wing, use a 3/32" dia. drill bit,

hand-held, to drill one hole through each

rib, in the center, just behind the spar

location. Do this from W-7, at the tip.

all the way through the inner-most W-2 rib,

beneath the center section sheeting. Using

the same bit, drill a hole through the

bottom sheeting, just behind the spars on

each side of the W-1's.

8. Use a 1/16" dia. drill bit, again handheld, to now do the same thing to the fin

(and also through the 3/16" sq. brace

between the tops of the T-1's), rudder and

stab halves. On the rudder, drill a small

exit hole on the very bottom, behind the

horn location. On the stab halves, drill

the exit holes through the rear diagonal

3/16" sq. piece.

9. Final-check entire airplane for any flaws

or problems. If you find any, fix them

now.

10. Since the stabilator halves slip in place

using two 1/16" dia. steel pins, there is

a need to be able to retain them. This can

be done a couple of ways. The first is to

simply allow the pins to rust by leaving

them outdoors for a night or two. This

makes them press-fit into the stab half

tubes. Another way is to use a low-tack

adhesive (3-M #77 Spray Cement) to coat the

wires, thus making them a bit "sticky." In

any event, don't permanently glue these in

place since eventually the need will arise

for disassembling the stabilator halves

from the fin.

13

Page 14

XII. MOTOR/SWITCHES/BATTERY

WIRING

CAUTION

FAILURE TO READ, UNDERSTAND, AND THEN FOLLOW THESE

INSTRUCTIONS CAN RESULT IN SERIOUS PERSONAL AND/OR

PROPERTY DAMAGE TO YOU OR OTHERS!

WHEN OPERATING THE MOTOR:

* ALWAYS wear eye protection!

* KEEP safely away from others!

* ALWAYS make sure the propeller is securely

attached to the motor drive shaft!

* REMEMBER to always use the arming switch

correctly!

fuse. A fused electrical system offers some real

safety to its overall operation. Should the motor

stall, as in the case of the propeller being

stopped due to striking an object, the battery pack

will surge its current output and blow the fuse,

thus preventing motor and/or battery pack damage or

burn out.

HIRING

These instructions concern the required wiring when

using the ASTRO FLIGHT 035 Cobalt motor. The

components of this system (as shown below) are:

* WARNING:

Children should never be allowed

to operate this equipment without

adult supervision!

CAUTION: POTENTIAL BATTERY HAZARD!

The Ni-Cad battery packs used to power the PHASOAR

store a great deal of electrical energy. Always be

extremely careful to avoid shorting out these

batteries. This can lead to a fire, cause burns to

you and others and/or, at the very least, ruin the

battery pack.

CAUTION: PROPELLER HAZARD!

The suggested motor/battery/propeller components in

these instructions result in an extremely powerful

system. The arming switch system should be

properly notated to provide ON/OFF information.

When switched ON, the motor, instantly reaches

maximum RPM's and the spinning propeller becomes a

hazard to you and others, treat this system with

respect! It is very important that you understand

all of these precautions and take steps to prevent

accidental switching-on of the system. Always

unplug and remove the motor battery pack when

storing the model or working on it. Always store

the model away from small children or anyone else

unfamiliar with its correct and safe operation.

REMEMBER: Install and connect the motor battery

pack ONLY when the arming switch is in the OFF

position and the micro switch is inactive.

IN ANY OTHER SITUATION, always disconnect and

remove the battery pack, especially when working on

the model and transporting or storing it.

FUSES

In the following instructions there is a straight-

forward wiring diagram which also includes a

notation concerning the location of a 15 to 20 amp

* 10-1/2" of Red (positive, +) hi-flcx, hi-

strand count wire (we've used both R06ART

and SR wire with good results).

* 12-1/2" of Black (negative, -) wire.

* Micro switch (Subminiature SPDT Lever

Switch) made by ARCHER and sold through

RADIO SHACK stores - Catalog No. 275-016.

* Arming switch (Subminiature SPST Toggle

Switch) made by ARCHER and a RADIO SHACK

item - Catalog No. 275-612.

* 1 Package of SERMOS R/C CONNECTORS

(contains four connectors, 2 red and 2

black).

* Soldering Iron or Gun (about 42 watts).

* Flux and solder.

* Small 15-20 amp fuse with solderable

holder.

14

Page 15

1. The ASTRO FLIGHT 035 cobalt motor comes

already pre-wired with a Tamiya-type

connector and an RF choke soldered in

place. Start by un-soldering the black

wire from its post connector, leaving the

RF choke joint still in place.

Referring to the diagram above, cut a 4-

1/2" Length of hi-flex wire and use a razor

to remove about 1/4" of the sheathing from

one end. Bend the solder tab straight out

from the post on the motor. Now solder the

wire to the tab with the length of the wire

pointed forward, towards the front of the

motor. Bend the solder tab back down

again. Cut this wire in half, remove the

sheathing from each end and solder the

fuse/holder in place. The remaining end

of this length of wire is now soldered, in

place to the center solder tab on the micro

switch, with the wire in place straight

down, in relationship to the switch.

2. The remaining length of black (-) wire

(should be 8") is now prepared by first

removing 1/4" of the sheathing from each

end. Now solder the SERMOS connector clip

to one end and insert and snap the black

connector in place. The other end of the

wire is now soldered in place (wire

pointing straight down from the switch) to

the far left solder tab of the micro

switch. This completes the negative side

wiring.

each solder joint, making sure they are

each secure. Applying a small amount of

silicon adhesive to each of these joints

further avoids any shorting.

4. The wiring system and switch array should

now be tested. Assuming that your battery

pack has been equipped with SERMOS

connectors, connect the pack to their

appropriate leads. Hold the motor firmly

in your hand (WITHOUT A PROP IN PLACE) and

"blip" the micro switch with the arming

switch in the ON position. If nothing

happens (highly unlikely), your battery

pack is either totally dead (discharged) or

you have a cold solder joint somewhere.

Now is the time to again check all of these

connections to ensure proper operation

every time, on demand.

XIII. COVERING

In every aspect of these instructions thus far,

we've stressed the importance of paying attention

to weight. At this point in the construction of

your PHASOAR, you should have an amazingly light

model. In keeping with this attention to weight,

it is extremely important that you cover your

PHASOAR with MonoKote. MonoKote will provide your

PHASOAR with comparatively little weight gain, an

incredibly brilliant finish and most importantly-airframe strength!

Realistically, one 6' roll of MonoKote, properly

cut-up and applied would do the job, providing you

would settle for a mono-chromatic color scheme.

However, you may consider a multi-colored scheme

that is at once visible in the air and looks great

in the pit area, too! Now is the time to choose

your favorite MonoKote color combination.

MonoKote is easiest to apply and work with when you

have the appropriate tools at hand to do the job.

3. Now un-solder the remaining red wire on the

motor's solder tab, again leaving the RF

choke connection in place. Cut a 5" length

of red hi-flex wire and remove 1/4" of the

sheathing from each end. Solder one end of

this wire to the motor's solder tab with

the length of the wire pointing forward

toward the front of the motor. Bend the

tab back down. Solder the remaining end of

this wire to the "ON" solder tab of the

arming switch. The remaining length of red

wire (should be 5-1/2") is now prepared by

again removing 1/4" of sheathing from each

end. Solder one end into the SERMOS

connector clip and insert and snap the

connector (in this case red) in place. The

remaining end of the red wire is now

soldered in place to the "OFF" solder tab

of the arming switch. Clean and inspect

15

Page 16

Shown in the photo above is a collection of Top

Flite tools, the Hot Sock iron shoe cover (a

"must" for a great finish), MonoKote

Cleaner/Polish, a selection of MonoKote, razor

blades (single edge), a hobby knife with a #11

blade and a metal straight-edge (min. 36" long).

The best practice is to cover each of the

aircraft's components separately. In the case of

the PHASOAR, this means the wing, the fuselage, the

battery pod, the stabilator halves and the rudder.

After covering, carefully clear-out any of the

required holes, slots, etc., that may have been

covered up, i.e., rudder horn slot. stabilator

drive ovals, pivot holes, antenna tube exit, and

rudder cable drive exit, etc.

From

your

parts

bag,

locate the 1-1/2" long,

0.038

I.D. brass tubing. This material will be cut up to

provide solder connections between the drive cables

and the soft wire paper clip connectors.

Drill a 1/32" dia. hole through the rudder horn to

accept the paper clip drive wire. Cut off about

1/4" of the brass tubing connector material and

clean out each of it with your #11 blade to accept

the cable and paper clip ends. Cut off the

required length of paper clip wire (see plans) to

make the connection to the rudder horn and bend one

end into a "Z" bend. Slip the brass connector

halfway onto the drive cable end and the paper clip

wire into the other end of this connector. Sweat

solder the three pieces together, using a minimum

of solder. Slip the opposite end of this drive

cable into the rudder tube and feed its length

through the fuselage and into the servo compartment

- don't cut off the excess cable yet. Attach the

rudder horn to the "Z" bend and carefully glue the

horn into the slot previously provided.

The connections made at the servo ends of the

stabilator and rudder drive cables are done in the

same manner as described above. However, the paper

clip connectors are to be bent with a "V" bend as

shown, thus providing some centering adjustments

for flight trim.

On our prototype PHASOAR"s we used a small brush

and some flat black paint (aircraft dope is fine

here) to paint the inside of the air entry hole in

the nose and the hole in the rear of the battery

pod. This is not necessary, but looks quite nice.

The rudder can now be hinged to the fin using the

method shown on the plans. This hinge system

provides an extremely efficient rudder action in

flight by virtue of the fact that it is gapless.

Properly done, these hinges are all but invisible

and lend greatly to the overall "one-piece" look of

the finished model. Do not install the rudder horn

in place yet. This will be done in the RADIO

INSTALLATION section of these instructions.

With your covering job now complete, make it really

shine by giving it a glistening cleaning job with

a few shots of MonoKote Cleaner Polish! About all

that's left to do is to add your AMA numbers.

REMEMBER that these have to be 1" or taller and

must appear on the RIGHT wing panel, we have used

both Super MonoKote and MonoKote Trim Sheets for

this job to make it easy and good-looking.

XIV. RADIO INSTALLATION

Before

installing

run in the right directions. If you have servo

reversing capability, this is a simple task.

Install

the

provided earlier.

servos

your

in

servos,

the

fuselage

make

sure that they

on

the

rails

Install the receiver next. To get the antenna

through the fuselage and out the hole previously

drilled for this purpose, "fish" a length of heavy

thread through the antenna exit hole and into the

receiver area. Then use a bit of CA glue to attach

the end of the antenna to the end of the thread and

pull the thread back out of the antenna hole. along

with the antenna.

The battery pack should now be installed, as shown

on the plans, and held in place with double-backed

tape. The ON/OFF switch can also be held in with

double-backed tape. With everything in place, turn

the system ON and test for correct movement and

centering. Adjust as needed.

The "CG" (Center of Gravity) shown on the plans is

exactly where we've flown our prototypes. Balance

your model at this point. Interestingly, our

prototypes did not require any lead at all to

arrive at the CG shown.

XV.

THE FLYING SITE

FLYING

Where there is no established local flying site, a

large, grassy field can be an ideal area. This

field should be free of trees, poles, large

obstructions and. especially, high-tension

electrical lines. Always fly far removed from

houses, populated areas or busy streets. An area

approximately two to four times the size of a

16

Page 17

regulation football field should provide you with

plenty of room, especially when attempting your

first few landings!

As we mentioned in the introduction, there is

simply no substitute for an experienced R/C pilot

to check-out, trim and test-fly your model! This

almost always is a guarantee of success. Remember,

if you have no experience you NEED an instructor!

Just as you did in the test-gliding phase, hold the

model high over your head, level or nose slightly

down, pointing to that imaginary point 100' ahead

of you and directly into the wind. With the

transmitter in your other hand, move the throttle

stick up to the ON position and trot or run

forward. When it feels right, smoothly throw the

model forward, wings level, toward that imaginary

point. Immediately take the transmitter in both

hands for control.

PRIOR TO POWERED FLIGHT

First, test-glide your model at least a couple of

times.

With the "throttle" stick and also the arming

switch in their OFF positions, turn the transmitter

ON. Now turn the model's airborne radio ON. Test

the controls with the transmitter, once again, to

be absolutely sure the controls are moving in the

proper direction!

Stand facing into the wind, if any (it's best if

there is none), hold the model high above your head

in a LEVEL position, with the transmitter in your

other hand. Trot or run forward to build up

"flight speed." When it feels right, briskly throw

the model directly forward (level) at an imaginary

point about 100' in front of you. In other words.

DO NOT pitch the model into the air in a nose up

condition! The model should glide smartly toward

that imaginary point without any tendency to veer

left or right. If it is turning, correct with

SMALL amounts of transmitter input to the opposite

side of the turn. If the model wants to pitch up,

correct quickly with SMALL amounts of DOWN elevator

input and if the model pitches down, correct

quickly with SMALL amounts of UP elevator input.

Just prior to touch-down, a SMALL amount of UP

elevator input can be used to "flare-out" to a

smooth landing. Continue this process until you

can consistently achieve the required flat, smooth

glide. Take your time here to get comfortable with

this phase of your model's regime because

ultimately the glide will constitute the bulk of

its flying time.

Typically, the PHASOAR will quickly get into

and

start an aggressive

momentary SMALL inputs of DOWN elevator to control.

Keep the model climbing out, into the wind and away

from you until it is about 400' away. At this

point, the model will be quite high and you can

start a slow 180 degree turn back toward you, still

allowing the model to climb out. Before it gets

back to you, do another 180 degree turn. Repeat

this process until comfortable altitude is reached

(with our prototypes, uncomfortable altitude...too

high...was reached in less than 55 seconds). Move

the throttle stick to the down or OFF position and

let the model transition into glide mode. This

first flight is for experience purposes only and

not dedicated thermal hunting so don't be concerned

about

looking

totally comfortable doing so.

With the PHASOAR now in un-powered glide,

familiarize yourself with each of the controls.

REMEMBER: This design is a powered sailplane, not

a pattern ship. Save the aerobatics for a

different design! Check for stall characteristics,

both upwind and downwind, by simply establishing a

heading and slowly pulling back on the elevator

stick. What should happen is nothing more exciting

than a nose-high attitude, followed by a nose-down

pitch with almost immediate recovery. If the model

wants to fall off briskly to one side or the other

(a

"tip stall"), you are going to want to impart a

little "washout" to each outboard wing panel when

you get home. Do this by twisting the wingtip to

raise

the

and then reshrink the MonoKote to maintain the new

position.

for

trailing

lift

edge

climb

that

right

now.

slightly

will

unless

(1/16

only

you're

to

1/8"),

"step"

need

POWERED FLIGHT

This is it! The pay-off for the work done thus

far! Just as you did before in the test-gliding

phase, activate the required switches in this

order:

1. Transmitter switch ON with throttle stick

down in the OFF position.

2. Make sure arming switch is OFF.

3. Turn airborne radio system ON.

4. NOW turn arming switch ON.

Again, test the FLIGHT CONTROLS of your model with

transmitter input to each. Holding the model away

from you (and others) move the throttle stick up

briefly to test the motor and then turn it off.

As your model gets down to 100-200' of altitude,

turn it into the wind and move the throttle stick

up to the ON position and power your way back up to

comfortable altitude and again shut down the motor.

LANDING

Land the PHASOAR by letting it glide smoothly

forward (very little, if any, elevator inputs) in

a pre-determined and large rectangular pattern

which terminates with the model pointing directly

into the wind, passing safely in front of you at an

altitude of 8' to 10.' At this point, the model is

heading away from you with the bulk of the field

ahead of it. Keep the wings level and slightly

"flare" the model (apply a touch of UP elevator)

17

Page 18

just before touchdown. Wind conditions can

profoundly influence flying and landing

characteristics. It is strongly suggested that you

do not fly this model in any wind above 5 mph until

you are totally comfortable in controlling it! The

PHASOAR has performed well in very stiff breezes

BUT only in the hands of very experienced and

competent R/C pilots. DO NOT EXCEED YOUR

EXPERIENCE AND/OR LIMITATIONS!

Take it easy and have fun!

XVI. KIT SPECIFICATIONS

The final specs on our prototypes turned out as

follows:

Wingspan

Wing

Weight

Aspect

........

Area.

.......

.........

Ratio

......

56

1/4"

335

sq.

24

to 27 oz.

9.9 : 1

in.

Overall Length ..... 32"

18

Page 19

BILL OF MATERIALS

TOP FLITE MODELS

PHASOAR 035

Kit Part

No.

RC-38- 1

59

RC-38-21

22

23

24

25

2

3

4

5

6

7

8

Computer

No.

390005

312019

312010

312020

312021

710114

312023

312024

511063

312030

390006

710115

710116

312022

312028

312029

Description Kit

Wood

D/C

D/C

D/C

D/C

D/C

D/C

D/C

Balsa Sheets

Balsa Sheet

Bundle #1 of 2

of

2

Balsa

Balsa

Balsa

Balsa

Plywood

Balsa

Balsa

Fuse sides

Wing

ribs

Fuse/Wing/Pod

Fin/Rudder

Fuse/Pod/Wing

Stab Caps

Fuse (F-2)

Wing/Fuse

Fuse Nose

Wood Bundle #2 of 2

Contains assorted balsa and spruce,

braided cable and plastic tubes.

All are rolled inside the plan sheet,

Separate Wood parts

D/C Plywood

D/C Plywood

Shaped Balsa

Shaped Balsa

Shaped Balsa

Fuse Former

Motor Mount

Pod Blocks

Fuse Nose

Hatch/Bottom Fuse

Qty/

1

2

2

1

1

1

2

1

5

1

RC-38-20

RC-38-41

380004

150026

150027

Poly Bag #1 of 1

Miscellaneous small wood parts.

Also, screws, nuts, tubing, and wire

Plan sheet

RC-38 Instruction Manual

19

Loading...

Loading...