Page 1

ASSEMBLY AND USE

INSTRUCTION BOOKLET

Congratulations on choosing the Top Flite Smart Stripe, the professional way to cut MonoKote

®

stripes for trimming film-covered models. Once you assemble and use the Smart Stripe for the first

time, you'll wonder how you ever got along without one. With a little practice, you'll be cutting trim

stripes as narrow as 1/32" with precision and consistency unattainable with a straightedge and

hobby knife.

The Smart Stripe can be mounted on your workbench for use, then slid off the attachment

screws in seconds if space is limited. Bench mounting is particularly useful when loading the roller,

as you can pull the film tight with one hand as you wind it on with the other.

Colors can be quickly changed by preparing several rollers (sold separately) with your favorite

shades, or loading more than one color on the roller supplied with your Smart Stripe.

The best part of using MonoKote stripes instead of the sticky-back variety is the satisfaction of

knowing your trim scheme won't come off after a few flights. Not only will you have a durable finish,

but you’ll also have forty-seven MonoKote colors from which to choose, and an unlimited range of

stripe widths.

Top Flite Model Mfg.

3002 N. Apollo Dr., Suite 1

Champaign, IL 61822

Technical Assistance – Call (217) 398-8970, ext. 5

© Copyright 2008 STRPP01 V 1.1

Page 2

2

ASSEMBLE THE

SMART

STRIPE

TOOLS REQUIRED

Screwdrivers – Phillips and a small flat blade type

7/16" Wrench or 4-way prop wrench (Great Planes

#GPMP2000)

Common pliers

6" draftsman's triangle or carpenter's square

Flat file

Bar soap or paraffin wax

Paper towels

Electric drill (Optional)

PARTS LIST

NOTE: Some parts will be found under the

cardboard insert.

QTY. PART # DESCRIPTION

1 STRP001 BASE

2 STRP002 UPRIGHT

1 STRP003 LEFT BLADE HOLDER

1 STRP004 RIGHT BLADE HOLDER

1 NYLON107 THREADED INSERT

1 HRDWD023 WOOD ROLLER

1 METAL068 DEAD PIN

1 SCRW106 1/4-20 ROLLER KNOB

1 SCRW105 1/4-32 x 8" THREADED SHAFT

1 KNOB001 KNOB FOR THREADED SHAFT

2 SCRW107 4-40 X 3/4" SCREW W/KNOB

2 SCRW102 6-32 X 1/4" SCREW W/KNOB

1 BLADE08 #11 BLADE

2 NUTS002 4-40 HEX NUT

1 NYLON108 1/4" UNTHREADED NYLON

HEX NUT

4 SCRW047 #6 X 1/2" SHEET METAL

SCREW

2 WSHR005 #4 FLAT WASHER

1 SCRW030 1/4-20 X 1" HEX HEAD BOLT

1 STRPP01 INSTRUCTIONS

1 STRPD01 DECAL

A WORD ABOUT SAFETY

Used properly, the Smart Stripe is a safe and

dependable tool. However, like a hobby knife, you are

dealing with a very sharp, exposed blade. The best

way to avoid being cut is to remove the blade when

loading the roller or any time you're not using it. We

also suggest covering the blade point with a small

balsa block when removing the stripes from the

roller. Keep the Smart Stripe out of children's reach

at all times.

ASSEMBLE THE BLADE HOLDER

NOTE: An exploded view diagram is provided in the

center of this booklet for reference while assembling

your Smart Stripe.

1. Slide a #4 flat washer onto each of the two

4-40 x 3/4" blade holder screws, then insert the

screws through the right half of the blade holder.

2. Install the left half of the blade holder onto

the screws.

3. Insert a #11 blade between the blade holders to see

how it is supposed to fit, then remove the blade. Please

be careful–the blade is sharp, sharp, sharp!

4. Join the blade holder halves together. First insert

two 4-40 hex nuts into their retainers on the left half

of the blade holder.Then finger tighten the two blade

holder screws.

5. Slide the threaded insert through the hole at the

back (square) end of the blade holder.

6. Start the 6-32 x 1/4" blade holder alignment

screws into the holes at the back of the blade holder,

but don't tighten them.

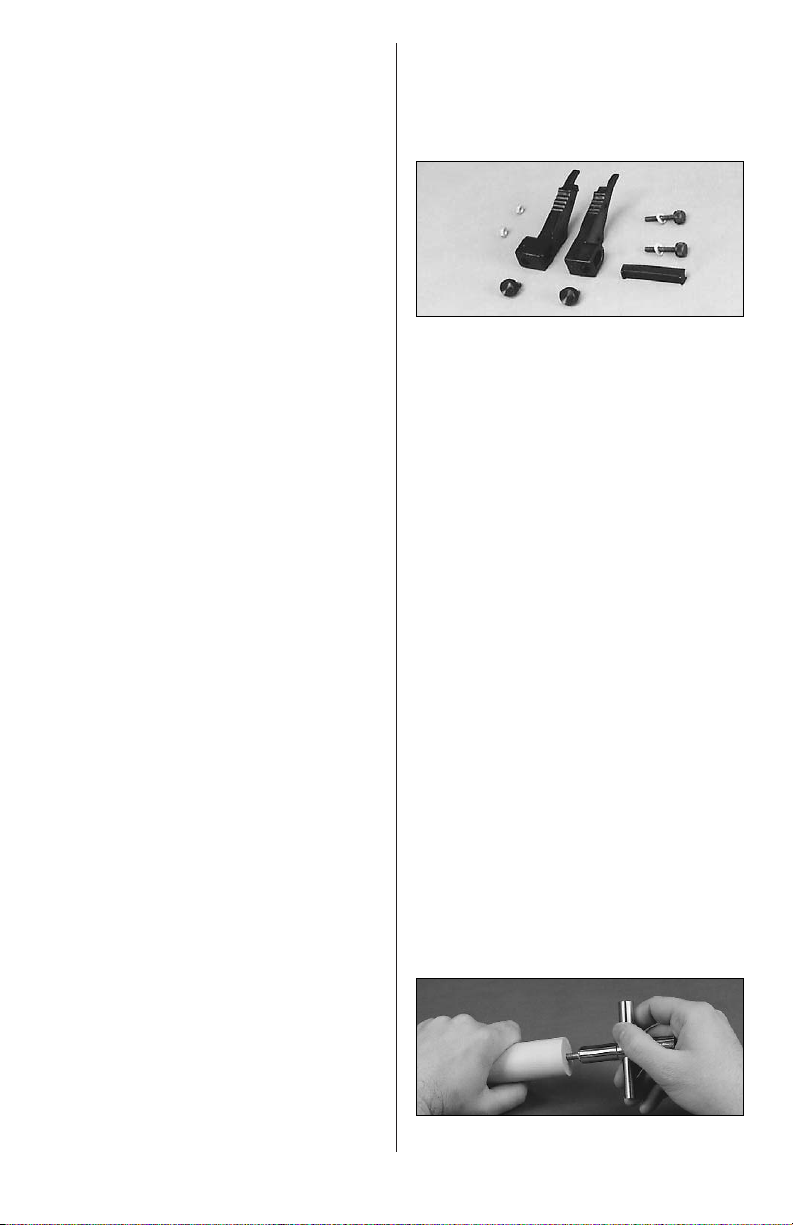

PREPARE THE ROLLER

1. Insert the dead pin into the holes in both ends of

the hardwood roller to determine which hole the

dead pin can be most easily inserted into and

removed from. Make threads in the hole at the

opposite end of the roller as explained in the

following steps.

2. Use the 1/4-20 x 1" hex head bolt to make

threads in the end of the hardwood roller determined

Page 3

3

in step #1. A four-way prop wrench works well for

this operation. Twist the bolt all the way into the roller

until the head contacts the wood, or strong

resistance is felt, then remove it.

3. Rub some bar soap or paraffin wax as a lubricant

onto the shaft threads of the 1/4-20 roller knob, then

screw the knob in and out of the threaded hole to

distribute the lubricant. Do not use excessive force

when performing this operation to avoid breaking the

knob or stripping the threads. If the threads tighten

up, remove the screw and add more lubricant. You

want this screw to be very easy to install and

remove.

FINAL ASSEMBLY

NOTE: The following steps describe assembling the

Smart Stripe for right-hand operation. If you are

left-handed, simply switch the position of the knobs,

hex nut and dead pin from one side to the other.

1. Now is an excellent time to decide where you

would like to mount your Smart Stripe. It need not be

mounted permanently, but it will help to have it

mounted when loading the roller. Position the base

where you will mount it, then use a pencil to mark

the mounting screw locations on your workbench.

2. Remove the backing from the pressure sensitive

decal and apply it to the recessed area in the base

as shown on the box cover.

3. Attach the right and left uprights to the base with

four #6 x 1/2" sheet metal screws. Notice that the

right side is fixed and the left side is adjustable.

Tighten the left side screws just enough to hold the

upright in position, but still allow it to be moved.

4. Use the roller as a spacer to set the distance

between the front and rear uprights, then tighten the

screws on the adjustable side. Make sure the

uprights are parallel to one another.

5. File or grind a 3/16" wide flat spot 1/16" from

one end of the threaded steel shaft.

NOTE: The blade holder should be “broken in” by

screwing the threaded shaft through it several times.

Turning the threaded shaft with an electric drill works

well for this job.

6. Insert the threaded shaft into the hole nearest you

in the left hand upright. Verify that the threaded

insert is centered, with its tabs overlapping the sides

of the right and left blade holder, then thread the

shaft through the blade holder assembly. Keep

turning until 1-1/2" of thread protrudes out the

opposite side of the blade holder. Insert the threaded

shaft through the hole in the other upright.

7. Install the small knob on the threaded shaft on

the flat spot end. Install the 8-32 x 1/8" Set Screw

into the small Knob and tighten.

8. Wrap a thick cushion of paper towels around the

threaded shaft to protect the threads, then grip it

tightly with pliers. Use a 7/16" prop wrench to thread

the nylon hex nut on the end of the shaft as shown.

NOTE: This special hex nut is intentionally not

threaded. When fully seated, it will remain locked in

position. Thread the hex nut onto the shaft until it just

touches the upright, to remove any side-play.

9. Hold the roller between the uprights with the

threaded hole on the right. Slide the 1/4" dead pin

through the left upright into the unthreaded hole in

the roller. Insert the roller knob through the right

upright, then screw it into the roller until you feel a

little resistance.

10. Check your work. Does the roller turn freely

without side-play? Does the threaded rod work

smoothly, also without side-play?

1/16" 3/16" Threaded Shaft

Page 4

1 Base

2 Upright

3L Blade Holder – Left

3R Blade Holder – Right

4 Wood Roller

5 1/4" Dead Pin

6 1/4-20 Roller Knob

7 Threaded Steel Shaft

8 Shaft Knob

9 4-40 Screws W/Knob

10 #4 Washers

11 6-32 Screws W/Knob

12 4-40 Hex Nuts

13 Nylon Hex Nut

14 #6 x 1/2" Sheet Metal Screws

15 8-32 x 1/8" Set Screw

16 #11 Blade

17 Threaded Insert

See Inset at Right

Blade Holder Inset

10

16

9

17

11

12

14

1

2

15

8

5

7

2

13

6

4

14

3R

3L

Page 5

6

BLADE ALIGNMENT

IMPORTANT: The blade must be exactly

perpendicular to the roller or your stripes will not be

straight and even.

1. Install a #11 blade as shown above.

2. Raise the blade holder to a vertical position.

Check the angle between the centerline of the blade

holder and the base with a triangle – it should be 90

degrees. If needed, the blade holder can be tilted left

or right by adjusting the two screws on the back

edge. Don't overtighten the adjustment screws or

you will cause the blade holder to bind on the

threaded rod. When the angle is correct, gently

finger tighten the adjustment screws evenly on the

back of the blade holder to allow free movement

when the threaded rod is rotated. Re-check the angle.

MOUNTING THE SMART STRIPE

TO YOUR BENCH

We have found it much easier to load the roller when

the Smart Stripe is mounted to the workbench. When

cutting stripes, mounting is not necessary.

1. Decide where to mount your Smart Stripe, then

measure and mark two screw locations exactly

6-7/16" apart. You may have already marked these

locations on your workbench prior to assembly.

Center punch the hole locations, drill 1/8" pilot holes,

then screw a #8 x 5/8" sheet metal screw (not

included) part-way into your work bench at each

mark. Test fit the Smart Stripe by setting it on the

screws and sliding it back or forth to seat it. Adjust

the height of the screws until the base will just slide

under the screw heads and "click" into position.

USING YOUR

SMART

STRIPE

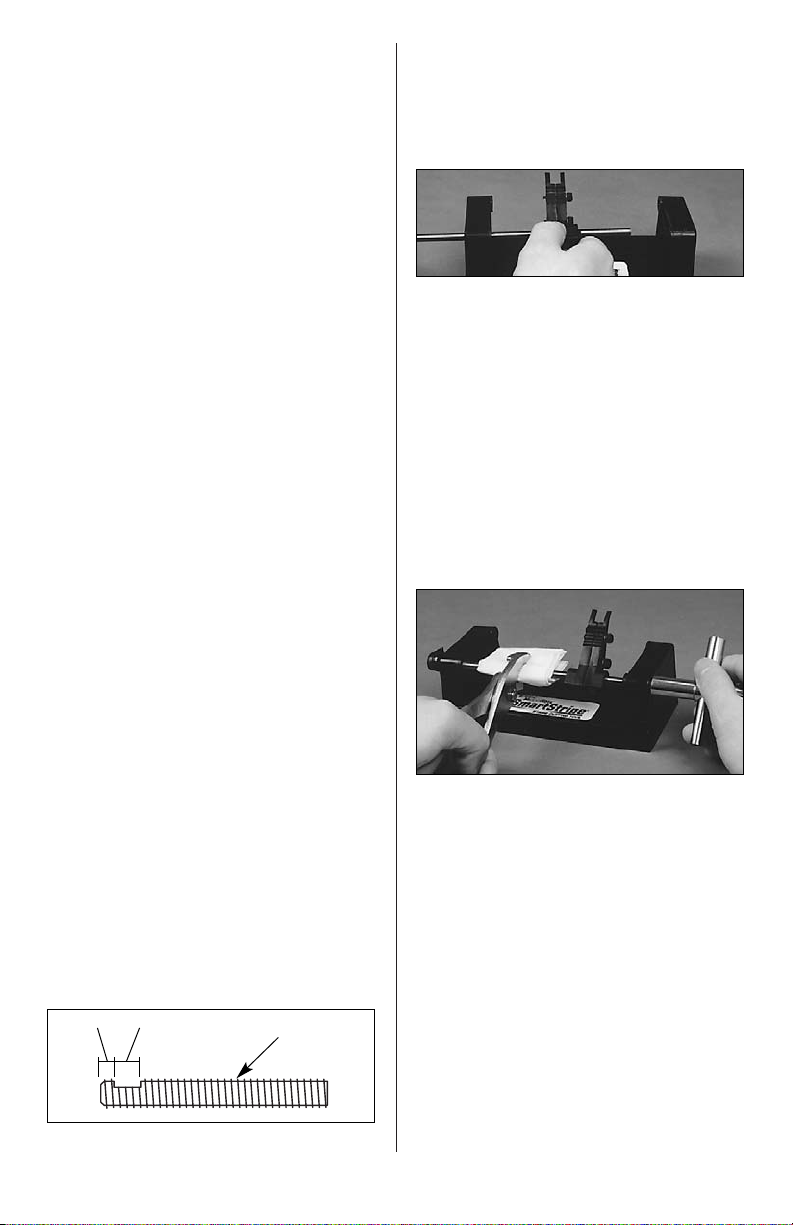

LOADING THE ROLLER

1. Cut a 4"-wide strip of MonoKote to whatever

length you require. A simple way to cut a 6' long strip

is to cut a 4" width off a full roll by using a finetoothed razor saw.

2. Place the MonoKote on your work bench in front

of you, with the loose end coming off the top and

pointing toward the roller. Position the MonoKote

strip about 1/16" from the left side of the roller. Use

cellophane tape across the entire width of the

MonoKote to fasten it to the top of the roller.

3. Hold the MonoKote roll firmly with your left hand

while winding it onto the roller with your right. Slowly

move the MonoKote across the roller about 1/32"

per rotation so that one edge will be staggered like

shingles toward the center of the roll. When you

reach the end of the roll, secure the MonoKote in

position with a strip of cellophane tape across the

entire width.

4. Wrap a strip of cellophane tape around the

MonoKote shingles, extending it over onto the roller.

This technique will prevent the MonoKote from

shifting sideways.

Wood Roller

Shingled MonoKote

Note: Drawing Not To Scale

Page 6

7

CUTTING STRIPES

1. Position the blade over the untaped end of the

MonoKote, about the same distance in as the width

of the shingles. Gently press down on the blade

holder while rotating the roller. Keep turning the

roller until the blade reaches the wood.

2. Remove the scrap MonoKote. Check that the cut

edge on the roller is straight and smooth. Move the

blade holder over 1/8" (4 revolutions of the knob)

and make a test stripe.

3. Remove and examine the test stripe. The edges

should be parallel and straight – if not, try another

cut using less pressure on the blade holder. After a

few practice cuts, you will develop a feel for how

much pressure is enough. With practice (and an

accurately aligned blade) you will be able to cut

1/32" wide panel line stripes with ease.

4. Remember, each revolution of the threaded shaft

knob moves the blade holder 1/32".

REVOLUTIONS STRIPE WIDTH

1 --------------1/32"

2 --------------1/16"

3 --------------3/32"

4----------------1/8"

6 --------------3/16"

8----------------1/4"

12----------------3/8"

16----------------1/2"

Use sharp blades.MonoKote will dull the edge

of a new blade after only a few cuts and, although it

will continue cutting, the stripe edges will be ragged

and the blade won't track straight.

Make sure the blade is fully inserted into the

blade holder,so only the tip of the blade contacts the

MonoKote when cutting.

More than one color of MonoKote can be loaded

at one time. Just stack a couple of colors, then roll them

on tightly. Also, narrower strips of different colors can

be loaded on the roller side-by-side.

Periodically check the fit of the uprights

against the roller. There should be no end-play.

If you get fine "hairs" when cutting narrow

stripes you are: (a) pressing too hard on the blade

holder, causing the blade to flex or (b) the blade is

out of alignment with the roller.

Use sharp blades, light pressure, and tightly

rolled MonoKote for consistently good stripes. A little

practice also helps.

STRIPE APPLICATION

Install a Top Flite Hot Sock™ on your sealing

iron. Set the iron for about one-third less heat than

you use for covering.

In most cases the MonoKote backing will come

off without any help. Position the stripe and tack it

down at one end. Gently pull the stripe taut, close to

the surface you are covering. For straight lines, tack

the stripe down at its other end point. Set the iron

down on the stripe at several points without sliding it

back and forth – just press down. Keep pressing the

stripe onto the surface until the entire length is in

position.

After applying all of the stripes to your model

as described, turn up the heat to your normal

covering setting and seal the stripes to the surface

with a gentle sliding motion, keeping the iron parallel

with the stripe.

When applying wide stripes, tack one end

down; then, while holding the stripe slightly off the

surface, iron it down starting at the tacked end. Keep

working the iron toward the open end. By so doing

you will be squeezing out the air bubbles as you

proceed. If you do get a few air bubbles, prick them

with a needle, then touch them with the iron to expel

the trapped air.

Page 7

Narrow stripes can be made to go around

curves. Stripes with widths of 1/8" or less work the

best. Heat the stripe with the tip of the iron as you

work it around the curve, a little at a time.

Clean off any color residue from around the

edges with Top Flite CA Debonder (TOPR1028) or

lacquer thinner. This should only be done if color

residue is visible. Don't apply debonder or thinner to

all stripes.

We hope you enjoy using your Smart Stripe as

much as we do in the Top Flite model shop. Before

you know it, you will be turning out professionallooking, low-maintenance trim schemes that will

generate lots of "oohs" and "ahs" at the flying field.

Top Flite®MonoKote®Hot Sock™Iron Cover

Very inexpensive and easy to use, the soft, 100%

cotton Hot Sock simply ties over your sealing iron’s

shoe to prevent it from scratching and hazing your

covering. Hot Sock also protects your sealing iron,

extending its working life. TOPR2175

Hobbico®#11 Knife Blades

The Top Flite Smart Stripe works best with a fresh,

sharp cutting blade. Made of hardened carbon steel,

Hobbico #11 blades are ground to a long-lasting,

razor-sharp edge. Each low-priced package contains

100 blades. Keep a supply on

hand! HCAR0311

Top Flite®MonoKote®Trim Seal Tool

Seal hinge gaps, wing saddles, inside corners and

intricate trim schemes with ease, using the ingenious

Trim Seal Tool. Features include high/low heat control

and adjustable shoe depth. Two tips and an aluminum

stand are also included.

TOPR2200

Top Flite®MonoKote®SmartCut™Trimming Tool

Specifically designed for trimming covering material

around a model airplane’s unique contours,

SmartCut helps even first-time finishers achieve

clean edges and virtually invisible seams. Two

standard #11 blades are included.

TOPR2400

Top Flite®Smart Stripe™Wooden Rollers

These optional wooden rollers, designed specifically

for the Smart Stripe, let you keep your favorite

MonoKote colors always wrapped and ready for

cutting into stripes. They're economical and easily

interchangeable on the cutting tool. TOPR2425

Loading...

Loading...