Page 1

PARTS LIST

These are the parts included in this kit.

ITEMS REQUIRED

These are the materials required to assemble and install the

cockpit kit as shown in these instructions:

❏ Instrument panel ❏ Thin CA

❏ Hobby knife with #11 blade ❏ Medium CA

❏ 1/16" [1.6mm] Drill ❏ 1/8" [3.2mm] Drill

❏ Sandpaper assor tment ❏ Small paint brushes

❏ (20) #2 x 3/8" [9.5mm] Screws ❏ Paint

❏ 1/4" x 1/4" x 27" [6 x 6 x 700mm]

Basswood or hard balsa stick

❏ 1/4" x 1/2" x 16" [6 x 13 x 410mm] Balsa stick

❏ Hobbico curved-tip, plastic-cutting scissors (HCAR0667)

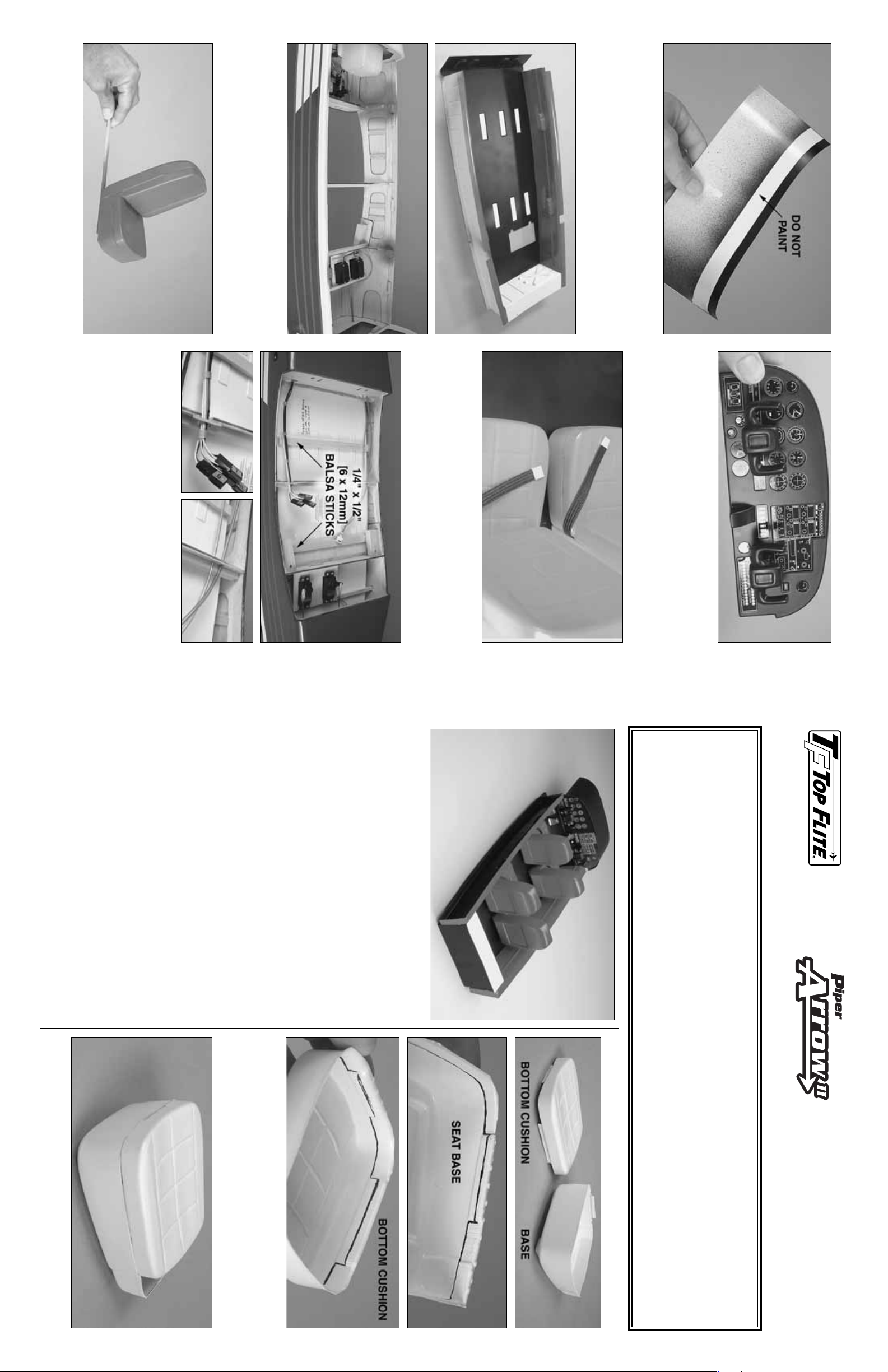

MAKE THE SEA TS

❏ 1. Cut out one of the seat bases and one of the bottom

cushions. True the edges by sanding with medium-grit

sandpaper and a bar sander. Note: The molded-in cutlines

have been dra wn with an ink pen for illustration in the photo.

❏ 2. Use thin or medium CA to glue the bottom cushion to

the seat base.

❏ Elastic band

(for seat belts)

❏ Decal

❏ (2) 1/8" x 1-1/4"

[3 x 32mm] dowel

❏ Right and left

cockpit sides

❏ Instrument panel

❏ Floor

❏ Valence panel

❏ Cabin back

❏ (4) Seat base

❏ (4) Bottom cushion

❏ (4) Seat back

❏ (4) Back cushion

❏ (2) Steering Yokes

❏ (3) Small pin

❏ (3) Large pin

SCALE COCKPIT KIT – ASSEMBLY INSTRUCTIONS

Copyright © 2004Printed in USA – ARO6CIP01 for TOPQ8414

PAINT THE COCKPIT KIT

❏ 1. Use a strip of masking tape to cover the inside of the

valence panel 3/8" [9.5mm] from the aft edge so it will not

get painted—this will allow for secure gluing to the

instrument panel.P aint the outside and inside of the valence

panel. Flat black is suggested.

❏ 2. Use masking tape to cover the indentations in the cockpit

floor where the seats will be glued down, then paint the cockpit

floor and sides. Also paint the formers in the fuselage that will

not be totally concealed by the cockpit sides.

❏ 3. Paint the seats. Use a drop of medium CA to

temporarily tack glue a balsa stick to each seat bottom.Hold

the stick and rotate the seat while painting.

FINAL ASSEMBLY

❏ 1. Cut out and paint the control yokes.Drill 1/8" [3.2mm]

holes through the instrument panel for the dowels, then glue

in the dowels and glue on the yokes .Paint the dowels black.

❏ 2.Securely glue the instrument panel and the dash board

into the cabin top.

❏ 3.Use the included elastic material to make the seatbelts .

Wrap a piece of chrome MonoKote

®

trim sheet or foil around

the ends to simulate buckles.

❏ 4. Install the cockpit kit in the fuselage using the #2 screws.

❏ 5. Glue two 1/4" x 1/2" [6 x 12mm] balsa sticks to the

underside of the cockpit floor where shown.This will give the

floor a little more rigidity and hold it steady to reduce

vibration. Guide the ser vo wires and air lines past former 3

so they can be connected to the wires and lines coming

from the wing.

❏ 6.The large and small pins may be used as you prefer to

simulate any control knobs or sticks seen in photos you

have of the full size cockpit.

Thank you for purchasing the cockpit kit for the Top Flite

®

Piper Arrow II. Even though the cockpit kit is somewhat

concealed under the completed and painted cabin top, you will still be surprised and pleased by how much more realism

and “life” the completed cockpit kit will bring to your Arrow. The same as the airplane kit, the level of detail that can be

achieved is up to you. Simply painting and installing the cockpit kit will achieve a good scale effect. Or, you could go “all

out” and add as many details and features as you can see in a real Piper Arrow cockpit.

Caution: Do not paint the cockpit kit parts with Top Flite LustreKote

®

.The cockpit is vacuum-formed from styrene plastic

which will be deformed by LustreKote. We found that Testors enamel paint works well for this type of plastic.Testors is

not fuelproof, but this should not be a problem as the components of the cockpit should not come into contact with fuel.

Page 2

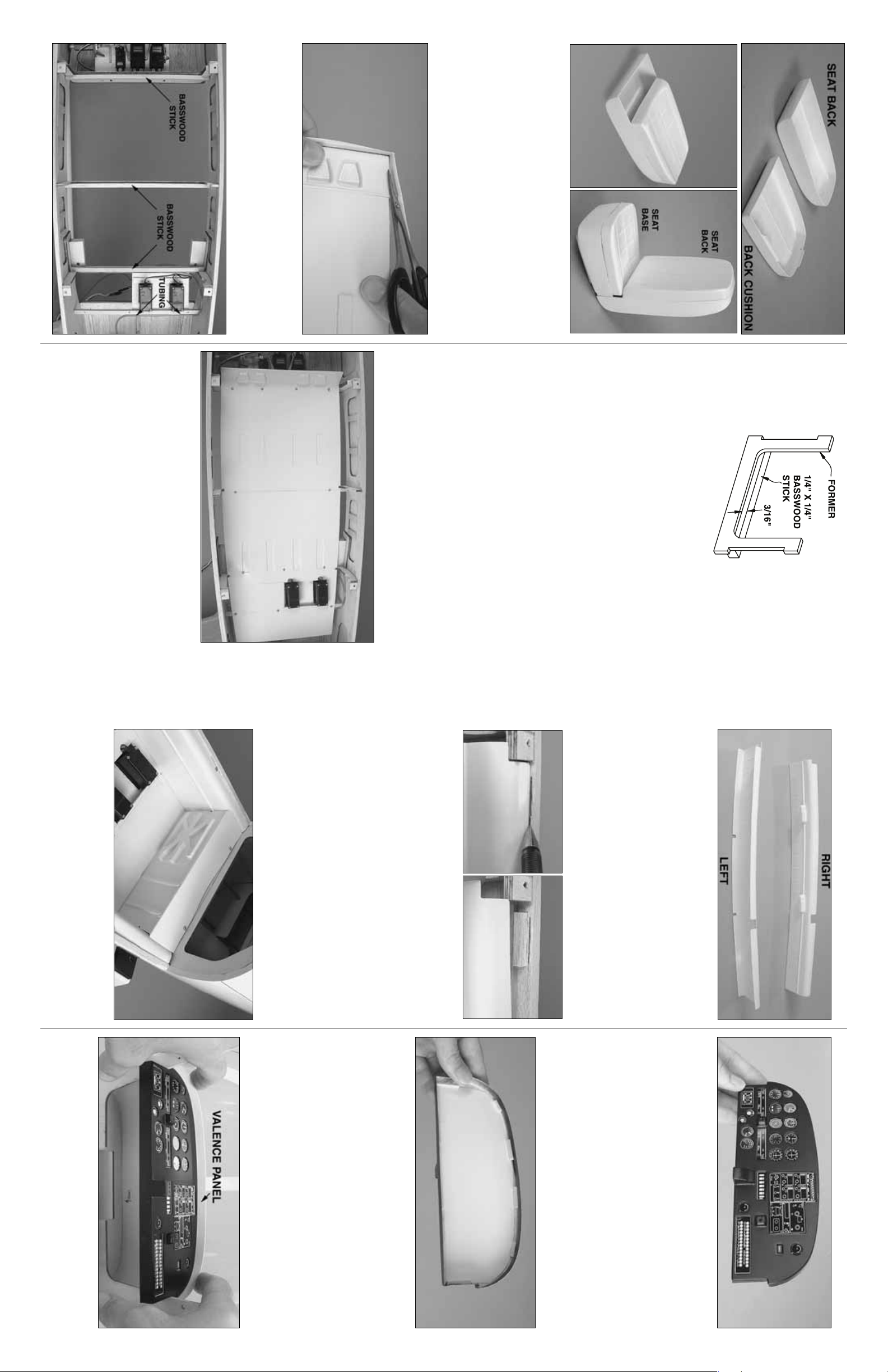

❏ 3. Cut out a seat back and a back cushion. Glue the two

pieces together.

❏ 4.Glue the completed seat back to the completed seat base.

❏ 5. Make three more seats the same way—hey, aren’t you

glad it’s not a 747?

INST ALL THE FLOOR

❏ 1. Use curved-tip plastic-cutting scissors to cut out the

cockpit floor. After cutting, the floor should be a flat sheet

with no lip around the edges.True the edges of the cockpit

floor by sanding.

❏ 2. Glue three 1/4" x 1/4" [6 x 6mm] basswood sticks (not

supplied) across the cross member portion of formers F3,

F4 and F5 as shown.Note that the top edge of each stick is

3/16" [5mm] above the top edge of each cross member.

❏ 3. Glue pieces of leftover 3/16" [5mm] pushrod tubing to

the aft edge of the aft servo rail to guide the air line coming

from the air tank.

❏ 4. As indicated in the instruction manual for the Arrow

airplane kit, cut notches in formers F3, 4 and 5 for the servo

wires and the air lines. Also round the top of former F4 to

accommodate the cockpit sides.

❏ 5. Bend the cockpit floor upward at the molded in scribe

line, but use care not to break it off.Reinforce both sides of

the seam with thin CA.

❏ 6. Test fit the cockpit floor into the fuselage. Cut the floor

where necessary to accommodate the formers and servos.

When in position, the front of the floor should be even with

the front of former F3.Drill 1/16" [1.6mm] holes through floor

and the 1/4" x 1/4" [6 x 6mm] sticks you glued to the f ormers

for fastening the cockpit floor with screws. Also drill holes in

aft servo rail. Install a #2 x 3/8" [9.5mm] screw into each

hole as you go.Some holes will have to be drilled from the

bottom of the sticks and up through the floor. Avoid drilling

holes where the screws will interfere with the cockpit sides

or seats.

INSTALL THE SIDES AND BACK

❏ 1. Cut out the left and right cockpit sides. True the

edges with a bar sander.

❏ 2. Test fit one, then the other cockpit side into the

fuselage.Widen the notches as necessary to accommodate

any formers or the canopy mounting blocks. The bottom

edges of the cockpit sides should rest on the cockpit floor.

❏ 3. Once any necessary adjustments have been made to

get the cockpit sides to fit, use thin CA to glue both sides to

the floor.

❏ 4. Use a ballpoint pen to mark the right main fuselage

stringer in three locations along the front, back and middle

of the top of the cockpit side.

❏ 5. Glue three 1/4" x 1/4" x 1" [6 x 6 x 25mm] hardwood

sticks to the stringer 1/64" [.5mm] below each line.

Note: The top of the cockpit sides must rest approximately

3/32" [2.4mm] below the top edge of the fuselage main

stringers. This will provide clearance between the screw

heads and the canopy frame.

❏ 6.Repeat the previous two steps for the left side of the coc kpit.

❏ 7. Drill 1/16" [1.6mm] holes through the top of the cockpit

sides into the hardwood sticks. Temporarily mount the

cockpit sides with six #2 x 3/8" [9.5mm] screws.

❏ 8. Cut out the cabin back. Test fit, then glue the aft edge

of the cockpit floor to the top of the lip on the bottom of the

cabin back. The same as was done for the sides, glue

hardwood sticks to former F6, then drill two more holes and

temporarily screw the back into position.

FIT THE INSTRUMENT P ANEL

❏ 1. Cut out the instrument panel—there should be an

approximately 1/8" [3mm] lip all the way around.

❏ 2. Attach the instrumentation decals using one of the

following two methods:

A) Paint the instrument panel, then cut out each instrument

from the decal sheet and stick it to the front of the panel.

B) Use a hobby knife and a rotary tool to cut all of the

instruments from the panel. Tr ue any straight edges with

a small hobby file. True circular holes with a piece of

sandpaper wrapped around a dowel or a brass tube.

Paint the instrument panel. After the paint dries, attach

the decal sheet, intact, to a plastic sheet. Cut out the

sheet, then glue it to the back of the instrument panel.

Use small balsa sticks to securely hold the sheet to the

back of the panel.

❏ 3. Cut out the valence panel. Test fit the valence panel

and the instrument panel inside the cabin top. Make

adjustments for a good fit, but do not glue it into the cabin

top until instructed to do so.

2 3

Loading...

Loading...