TBH-1400N

Rotary hammer drill

Bohrhammer

Users manual

Bedienungsanleitung

Art. No. HDM6014

02 Ferm

10

4

1

2

3

5

6

7

9

11

2

1

3

Fig.A / Abb.A

Fig.B / Abb.B

Fig.C / Abb.C

Ferm 03

8

10

Fig.E / Abb.E

Regelschalter Drehzahl Umschaltung Betriebsart

1

2

3

Fig.D / Abb.D

ON

OFF

11

Fig.F / Abb.F

04 Ferm

ROTARY HAMMER DRILL

The numbers in the following text correspond with the pictures at page 2 - 3.

Read this manual carefully, before using the machine. Ensure that you know

how the machine works, and how it should be operated. Maintain the machine

in accordance with the instructions, and make certain that the machine

functions correctly. Store this manual and other enclosed documentation with

the machine.

Intended use

The FBH-1400N is intended for drilling holes in masonry such as brick, concrete and

similar materials. Furthermore, the machine can be used as a demolition hammer in

combination with the SDS cold chisels provided. The machine is on no account intended

for other purposes.

Please inspect the machine and accessories for transit damage.

Contents

1. Machine information

2. Safety instructions

3. Operating

4. Maintenance

1. MACHINE INFORMATION

Technical specifications

Voltage 230 V

Frequency 50 Hz

Power rating 1400 W

Rotational speed, not loaded 0-680/min

Impact rate 0-3600/min

Max. bit diameter

Concrete Ø 30 mm

Steel Ø 16 mm

Wood Ø 40 mm

Weight 6.5 kg

Hammer station:

Lpa (sound pressure level) 89 dB(A)

Lwa (sound power level) 105 dB(A)

Vibration main handle 9.58m/s

2

Hammer/drill station

Lpa (sound pressure level) 93 dB(A)

Lwa (sound power level) 107 dB(A)

Vibration main handle 11.38m/s

2

GB

Ferm 05

Product information

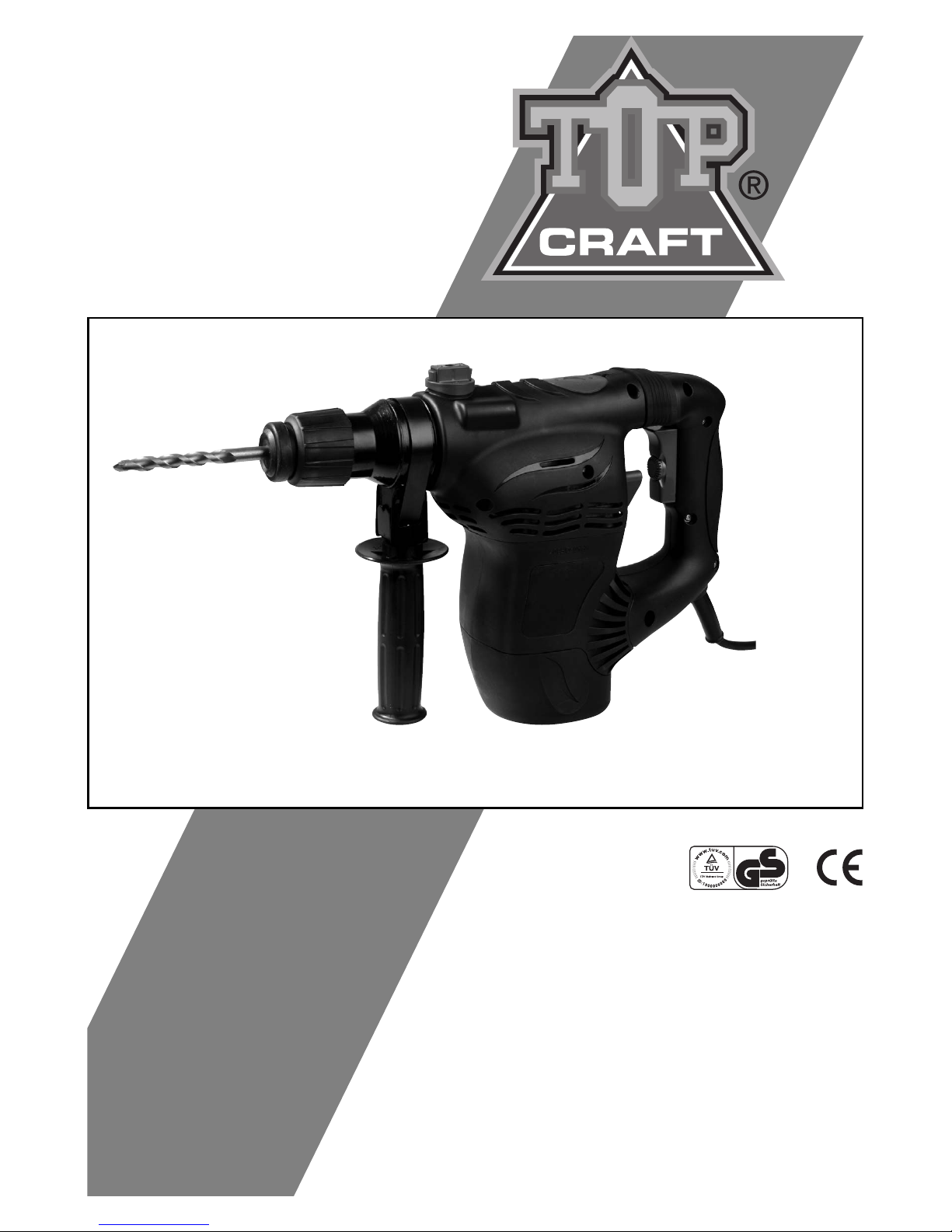

Fig. A + E

1. Function selection switch 1

2. On/Off switch

3. Main handle

4. Function selection switch 2

5. Electric cord

6. Auxiliary handle

7. Depth gauge

8. Dust catcher

9. Drill

10. Locking sleeve

11. Grease cap

Contents of packing

1 Rotary Hammer Drill

2 SDS chisels

3 SDS drills

1 SDS chuck + adapter + key

1 Depth gauge

1 Dust catcher

1 Cup with grease

1 Users manual

1 Warranty card

2. SAFETY INSTRUCTIONS

In this operator's guide the following symbols are used:

Read instructions carefully

In accordance with essential applicable safety standards of European

directives

Class II machine – Double insulation – You don’t need any earthed plug.

Denotes risk of personal injury, loss of life or damage to the tool in case of

non-observance of the instructions in this manual.

Indicates electrical shock hazard.

Immediately unplug the plug from the mains electricity in the case that the cord

gets damaged and during maintenance

GB

06 Ferm

Wear a dust mask

Wear ear and eye protection

Faulty and/or discarded electrical or electronic apparatus have to be collected

at the appropriate recycling locations.

General safety instructions

Warning! Read all instructions. Failure to follow all instructions listed below may result in

electric shock, fire and/or serious injury. The term “power tool” in all of the warnings listed

below refers to your mains operated (corded) power tool or battery operated (cordless) power

tool. Save these instructions!

1) Work area

a. Keep work area clean and well lit. Cluttered and dark areas invite accidents.

b. Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gasses or dust. Power tools create sparks which may ignite the

dust of fumes.

c. Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

2) Electrical safety

a. Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

any adapter plugs which earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b. Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e. When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

Always

use tool in conjunction with a residual circuit breaker device.

3) Personal safety

a. Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury.

b. Use safety equipment. Always wear eye protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

GB

Ferm 07

c. Avoid accidental starting. Ensure the switch is in the off position before plugging in.

Carrying power tools with your finger on the switch or plugging in power tools that

have the switch on invites accidents.

d. Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

e. Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

g. If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of these devices can reduce dust

related hazards.

h. Use clamps or a vice to hold work. It’s safer than using your hand and it frees both

hands to operate tool.

4) Power tool use and care

a. Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce the risk

of starting the power tool accidentally.

d. Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect the power tools operation. If damaged,

have the power tool repaired before use. Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool, taking

into account the working conditions and the work to be performed. Use of the power

tool for operations different from intended could result in hazardous situation.

h. Damaged switches must be replaced at a customer service repair centre. Do not use

power tools that cannot be switched on and off.

i. Do not leave power tools unattended while they are switched on. Always switch off

the tool and wait until it has come to a full standstill before leaving.

j. If the mains cable has been damaged, it must be replaced with a special mains cable.

These can be obtained from the manufacturer or the manufacturer's customer service

department. The mains cable may only be replaced by the manufacturer, the

manufacturer's customer service department or equally qualified persons.

GB

08 Ferm

5) Service

a. Please use a qualified expert who uses original replacement parts to repair your power tool.

This will ensure proper functioning of the power tool.

b. Caution! The use of any accessories or additional tools other than those recommended in

this manual may lead to an increased risk of injury. Only use original replacement parts.

Specific safety instructions

• Wear ear protectors. Exposure to noise can cause hearing loss.

• Use auxiliary handles supplied with the tool. Loss of control can cause personal injury

For use of this machine/tool:

• Inspect the surface to be drilled for hidden electrical wiring, gas pipes or other

obstacles (for example, using a metal detector).

• Check the following points:

• Does the appliance’s voltage correspond with the mains power supply voltage?

• Are power cords, insulation and plug in good order: sound, not loose or

damaged?

• Is there a good, firm connection at the mains socket?

• Does the drill show any sign of abnormal running, overheating or excessive

sparking?

• Whenever any of the problems mentioned above appear, immediately cease

using the machine and have it repaired by an expert.

Electrical safety

Always check that the mains voltage is the same as on the type plate of the

machine.

The machine is double insulated; therefore, no earth connection is required.

Replacement of power cords or plugs

Immediately dispose of old cords and plugs once they have been replaced. It is

dangerous to plug a loose power cord into a mains power socket.

Use of extension leads

Only ever use approved extension leads that are suitable for the power rating of the

machine. The minimum core thickness is 1.5 mm

2

. Whenever using a reel extension lead,

always fully unroll the lead.

3. OPERATING

Hammer drills require very little operator pressure. Excessive pressure on the

tool can lead to unnecessary overheating of the motor, and burning of the

driven tool.

GB

Ferm 09

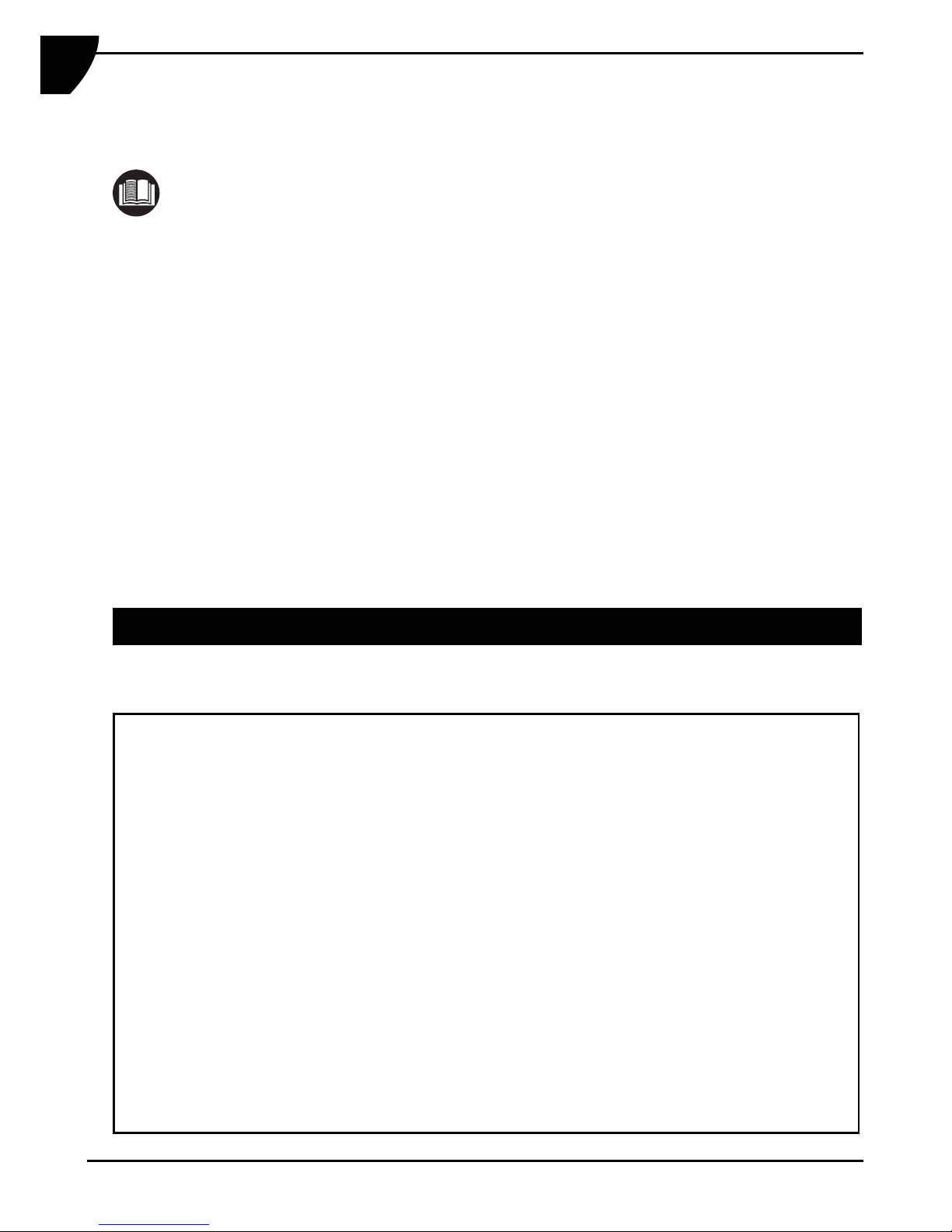

Auxiliary handgrip

The auxiliary handgrip can be rotated 360º around the drill head, enabling safe and

comfortable operation, for both left and right-handed users.

• Loosen the handgrip by turning it anticlockwise.

• Rotate the handgrip to the desire position.

• Retighten the handgrip in the new position.

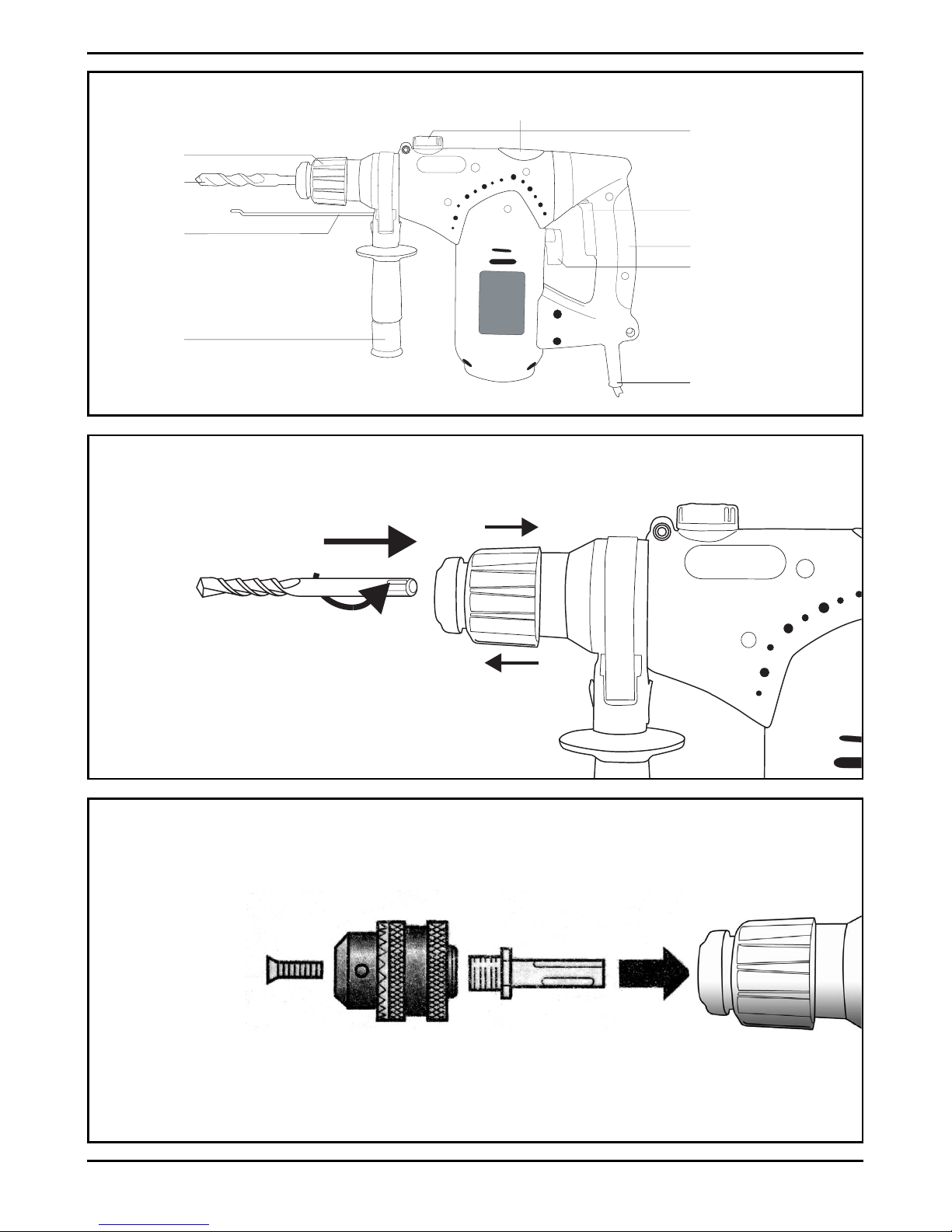

Exchanging and removing drill bits

Fig. A + B

Before exchanging bits, first remove the power plug from the wall socket.

Inspect bits regularly during use. Blunt bits should be re-sharpened or

replaced.

• Lightly oil the bit shaft before inserting it into the chuck.

• Slide the locking sleeve (11, Fig. A) to the rear, and insert the bit into the chuck

opening.

• Beware that the rubber disc stays in outer position (space between disc and locking

sleeve)

• Ensure that the keyway in the bit is seated properly in the chuck, by carefully turning

the bit until it clicks into place. Release the locking sleeve.

• To remove the bit, slide and hold the locking sleeve to the rear.

Chuck + adapter

Fig. C

• Use the enclosed chuck for drilling with common drills. Install chuck as indicated in

the picture.

Setting depth gauge

Fig. A

• Loosen the handgrip by turning it anticlockwise.

• Insert the depth gauge ruler through the hole in the auxiliary handgrip.

• Slide the ruler to the desired depth.

• Retighten the screw firmly.

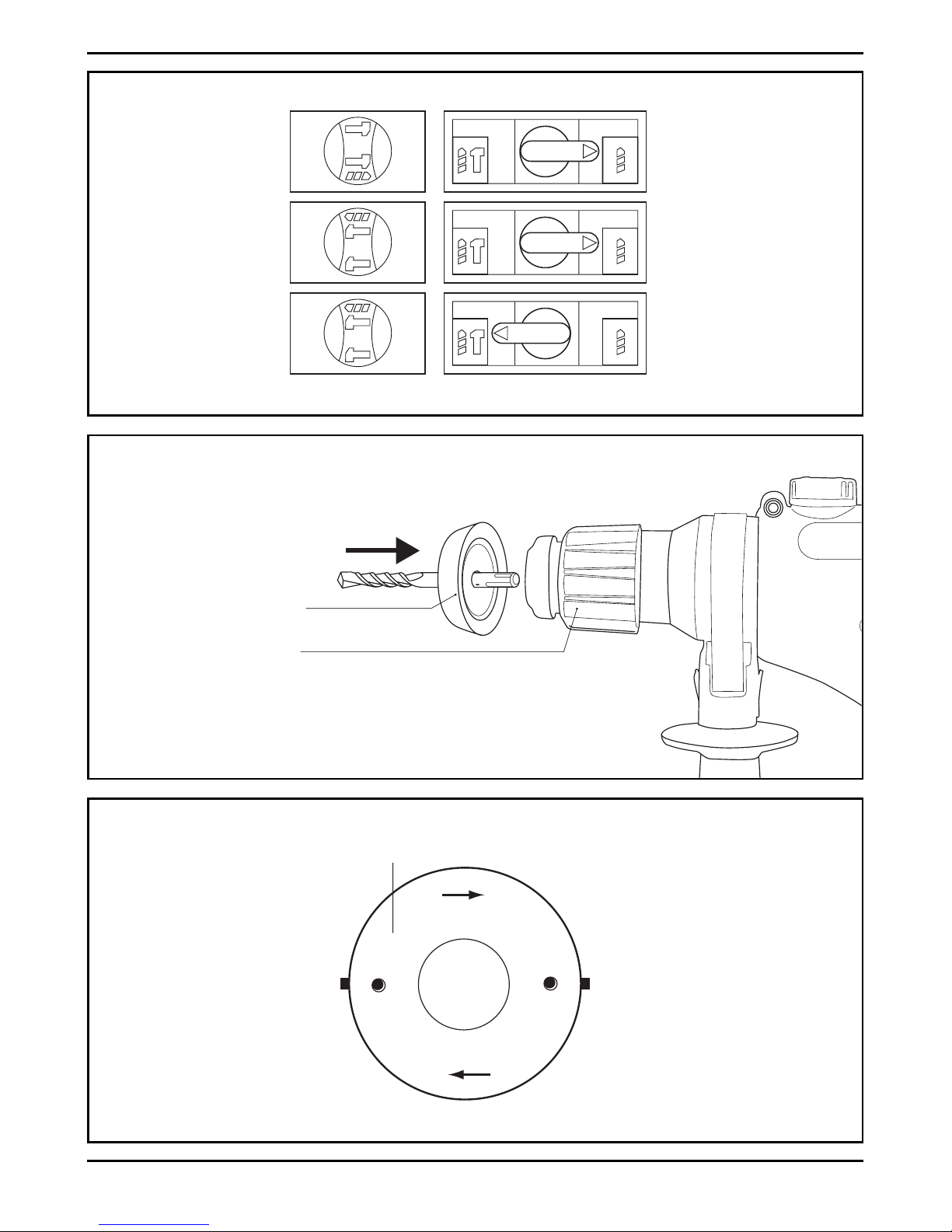

Function selection switch

Fig. D

The correct position of the selection switch for each machine function is given in the

diagram on page 3.

1 = Demolition hammer/chisel

2 = Rotary hammer drill

3 = Drilling

GB

10 Ferm

Switching On/Off

• To start the drill, squeeze the On/Off switch.

• To stop the drill, release the on/off switch.

Installing dust catcher

Fig.E

The dust catcher prevents large amounts of drilling dust entering the machine when

drilling into ceilings.

• Remove the drill bit.

• Slide the dust catcher over the shaft of the drill bit.

• Place the drill bit with catcher in the drill chuck.

• Always replace a damaged dust catcher immediately.

4. MAINTENANCE

Take care that the machine is not connected to power whenever maintenance

work on the mechanical parts is taking place.

Machines are designed to function problem-free for a long period with a minimum of

maintenance. Through regular cleaning and correct treatment, you help assure a long

working life for your machine.

Defects

The machine should be regularly inspected for the following possible defects, and

repaired if necessary.

• Damage to power cord

• Broken On/Off switch assembly.

• Short circuiting.

• Damaged moving parts.

Trouble shooting

• When switched on, the

motor does not turn.

• Failure in power supply.

• Poor contact in the

On/Off switch.

• Mains voltage too low.

• Damaged motor.

• Carbon brushes worn.

• Check the power supply.

• Repair or replace the

On/Off switch assembly.

• Extension lead too long,

or too light.

• Have your machine

repaired by an expert.

• Replace the carbon

brushes

GB

Ferm 11

Cleaning

Clean the machine casings regularly with a soft cloth, preferably after each use. Make

sure that the ventilation openings are free of dust and dirt. Remove very persistent dirt

using a soft cloth moistened with soapsuds. Do not use any solvents such as gasoline,

alcohol, ammonia, etc. Chemicals such as these will damage the synthetic components.

Lubrication

Fig.F

• Regularly grease the hammer drill shaft.

• Regularly check the grease-level inside the machine:

• Remove the grease cap (11) on top of the machine (Off)

• Remove also the second cap (with 4 notches)

• Now you can see the rotating parts inside the machine: there should be grease

on the moving parts.

• If necessary put some grease into the hole.

• Place the cap onto the hole and tighten it again.

• Mount the grease cap again (On)

Faults

Should a fault occur, e.g. after wear of a part, please contact the service address on the

warranty card. In the back of this manual you find an exploded view showing the parts

that can be ordered.

Environment

To prevent damage during transport, the appliance is delivered in a solid packaging which

consists largely of reusable material. Therefore please make use of options for recycling

the packaging.

• Motor generates

excessive noise, and

runs too slowly or not at

all.

• Overheating in the

transmission case.

• Heavy sparking from the

motor.

• Motor is overloaded due

to excessive pressure or

drilling depth.

• Damaged motor.

• Supply voltage too low.

• Carbon brushes worn.

• Overloading of machine,

or blunt drill bit

• Reduced voltage.

• Inspect the carbon

brushes for wear.

• Reduce the pressure or

drilling depth, reduce

power.

• Have your machine

repaired by an expert.

• Adjust the supply

voltage.

• Replace the carbon

brushes

• Reduce the loading, or

hone the drill bit.

• Adjust the supply

voltage.

GB

12 Ferm

Faulty and/or discarded electrical or electronic apparatus have to be collected

at the appropriate recycling locations.

Warranty

For the conditions of warranty, please refer to the separately provided warranty card.

CE DECLARATION OF CONFORMITY (GB)

We declare under our sole responsibility that this product,

TBH-1400N Rotary hammer drill

is in conformity with the following standards or standardized documents

EN60745-1: 2003 + A1, EN60745-2-6: 2003, EN55014-1, EN55014-2,

EN61000-3-2, EN61000-3-3

in accordance with the regulations.

98/37/EC, 2006/95/EC, 89/336/EEC, 2002/95/EC, 2002/96/EC

from 01-11-2006

ZWOLLE NL

J.A. Bakker - van Ingen J. Lodewijk

CEO Ferm BV Quality Manager Ferm Global

It is our policy to continuously improve our products and we therefore reserve the right to

change the product specification without prior notice.

Ferm BV • Lingenstraat 6 • 8028 PM Zwolle • The Netherlands

GB

Ferm 13

BOHRHAMMER

Die Nummern im nachfolgenden Text korrespondieren mit den Abbildungen auf

Seite 2 - 3.

Lesen Sie vor dem Gebrauch der Maschine diese Bedienungsanleitung

aufmerksam durch. Machen Sie sich unbedingt mit der Arbeitsweise der

Maschine und ihrer Bedienung vertraut. Warten Sie die Maschine gemäß der

Anweisungen und achten Sie darauf, dass die Maschine einwandfrei arbeitet.

Bewahren Sie die Bedienungsanleitung und andere zugehörige Unterlagen in

der Nähe der Maschine auf.

Verwendung

Der FBH-1400N eignet sich zum Bohren von Löchern in Mauerwerk aus Ziegel, Beton

und ähnlichen Materialien. Darüber hinaus kann die Maschine in Kombination mit den

mitgelieferten SDS-Meißeln auch als Meißelhammer verwendet werden. Die Maschine

wurde ausschließlich für diese Zwecke konzipiert.

Bitte überprüfen Sie Maschine und Zubehör auf mögliche Transportschäden.

Inhalt

1. Gerätedaten

2. Sicherheithinweise

3. Betrieb

4. Wartung

1. GERÄTEDATEN

Technische Daten

Spannung 230 V

Frequenz 50 Hz

Motorleistung 1400 W

Leerlaufdrehzahl 0-680U/min

Schlagzahl 0-3600/min

Max. Bohrerdurchmesser

Beton Ø 30 mm

Stahl Ø 16 mm

Holz Ø 40 mm

Gewicht 6.5 kg

Hammer-Funktion:

Lpa (Schalldruckpegel) 89 dB(A)

Lwa (Schallleistung) 105 dB(A)

Vibrationswert 9.58m/s

2

UK

D

NL

F

E

P

I

S

SF

N

DK

14 Ferm

Produktinformation

Abb. A + E

1. Funktionsschalter 1

2. Ein-/Aus-Schalter

3. Handgriff

4. Funktionsschalter 1

5. Netzkabel

6. Zusatzhandgriff

7. Bohrtiefenanschlag

8. Staubfänger

9. Bohrhammer

10. Verriegelung

11. Schmierdeckel

Packungsinhalt

1 Drehbohrhammer

2 SDS-Meißel

3 SDS-Bohrkronen

1 SDS-Bohrfutter + Adapter + Schlüssel

1 Tiefenanschlag

1 Staubfänger

1 Schmierfett

1 Benutzerhandbuch

1 Garantiekarte

2. SICHERHEITSHINWEISE

In dieser Bedienungsanleitung werden die folgenden Symbole verwendet:

Anweisungen sorgfältig lesen

Übereinstimmung mit den jeweils maßgeblichen EU-Sicherheitsrichtlinien

Gerät der Schutzklasse II – schutzisoliert – kein Schutzkontakt erforderlich

Lebens- und Verletzungsgefahr und Gefahr von Beschädigungen am Gerät bei

Nichteinhaltung der Sicherheitsvorschriften in dieser Anleitung.

Hammer/Bohr-Funktion

Lpa (Schalldruckpegel) 93 dB(A)

Lwa (Schallleistung) 107 dB(A)

Vibrationswert 11.38m/s

2

UK

D

NL

F

E

P

I

S

SF

N

DK

Ferm 15

Deutet das Vorhandensein elektrischer Spannung an.

Ziehen Sie, falls das Kabel beschädigt wird und auch während

Wartungsarbeiten,

sofort den Netzstecker.

Tragen Sie eine Staubschutzmaske

Schutzbrille und Gehörschutz tragen

Schadhafte und/oder alte elektrische oder elektronische Geräte müssen an

den dafür vorgesehenen Recycling-Stellen abgegeben werden.

Allgemeine Sicherhetshinweise

Achtung! Sämtliche Anweisungen sind zu lesen. Fehler bei der Einhaltung der

nachstehend aufgeführten Anweisungen können elektrischen Schlag, Brand und/oder

schwere Verletzungen verursachen. Der nachfolgend verwendete Begriff

„Elektrowerkzeug” bezieht sich auf netzbetriebene Elektrowerkzeuge (mit Netzkabel) und

auf akkubetriebene Elektrowerkzeuge (ohne Netzkabel). Bewahren Sie diese Hinweise

gut auf!

1) Arbeitsplatz

a. Halten Sie Ihren Arbeitsbereich sauber und aufgeräumt. Unordnung und

unbeleuchtete Arbeitsbereiche können zu Unfällen führen.

b. Arbeiten Sie mit dem Gerät nicht in explosionsgefährdeter Umgebung, in der sich

brennbare Flüssigkeiten, Gase oder Staub befinden. Elektrowerkzeuge erzeugen

Funken, die den Staub oder die Dämpfe entzünden können.

c. Halten Sie Kinder und andere Personen während der Benutzung des

Elektrowerkzeugs fern. Bei Ablenkung können Sie die Kontrolle über das Gerät

verlieren.

2) Elektrische Sicherheit

a. Der Anschlussstecker des Gerätes muss in die Steckdose passen. Der Netzstecker

darf in keiner Weise verändert werden. Verwenden Sie keine Adapterstecker

gemeinsam mit schutzgeerdeten Geräten. Unveränderte Netzstecker und passende

Steckdosen verringern das Risiko eines elektrischen Schlages.

b. Vermeiden Sie Körperkontakt mit geerdeten Oberflächen, wie von Rohren,

Heizungen, Herden und Kühlschränken. Es besteht ein erhöhtes Risiko durch

elektrischen Schlag, wenn Ihr Körper geerdet ist.

c. Halten Sie das Gerät von Regen oder Nässe fern. Das Eindringen von Wasser in ein

Elektrogerät erhöht das Risiko eines elektrischen Schlages.

d. Zweckentfremden Sie das Netzkabel nicht, um das Gerät zu tragen, aufzuhängen

oder um den Netzstecker aus der Steckdose zu ziehen.

UK

D

NL

F

E

P

I

S

SF

N

DK

16 Ferm

Halten Sie das Netzkabel fern von Hitze, Öl, scharfen Kanten oder sich bewegenden

Geräteteilen. Beschädigte oder verwickelte Netzkabel erhöhen das Risiko eines

elektrischen Schlages.

e. Wenn Sie mit einem Elektrowerkzeug im Freien arbeiten, verwenden Sie nur

Verlängerungskabel, die auch für den Außenbereich zugelassen sind. Die Anwendung

eines für den Außenbereich geeigneten Verlängerungskabels verringert das Risiko

eines elektrischen Schlages,

3) Sicherheit von Personen

a. Seien Sie aufmerksam. Achten Sie darauf, was Sie tun, und gehen Sie mit Vernunft

an die Arbeit mit einem Elektrowerkzeug. Benutzen Sie des Gerät nicht, wenn Sie

müde sind oder unter dem Einfluss von Drogen, Alkohol oder Medikamenten stehen.

Ein Moment der Unachtsamkeit beim Gebrauch des Gerätes kann zu ernsthaften

Verletzungen führen.

b. Tragen Sie persönliche Schutzausrüstung und immer eine Schutzbrille. Das Tragen

persönIicher Schutzausrüstung, wie Staubmaske, rutschfeste Sicherheitsschuhe,

Schutzhelm oder Gehörschutz, je nach Art und Einsatz des Elektrowerkzeuges,

verringert das Risiko von Verletzungen.

c. Vermeiden Sie eine unbeabsichtigte lnbetriebnahme. Vergewissern Sie sich, dass der

Schalter in der Position ,,AUS(0)” ist, bevor Sie den Netzstecker in die Steckdose

stecken. Wenn Sie beim Tragen des Geräts den Finger am Schalter haben oder das

Gerät eingeschaltet an die Stromversorgung anschließen, kann dies zu Unfällen

führen.

d. Entfernen Sie Einstellwerkzeuge oder Schraubenschlüssel, bevor Sie das Gerät

einschalten. Ein Werkzeug oder Schlüssel, der sich in einem drehenden Geräteteil

befindet, kann zu Verletzungen führen.

e. Überschätzen Sie sich nicht. Sorgen Sie für einen sicheren Stand und halten Sie

jederzeit das Gleichgewicht. Dadurch können Sie das Gerät in unerwarteten

Situationen besser kontrollieren.

f. Tragen Sie geeignete Kleidung. Tragen Sie keine weite Kleidung oder Schmuck.

Halten Sie Haare, Kleidung und Handschuhe fern von sich bewegenden Teilen.

Lockere Kleidung, Schmuck oder lange Haare können von sich bewegenden Teilen

erfasst werden.

g. Wenn Staubabsaug- und -auffangeinrichtungen montiert werden können,

vergewissern Sie sich, dass diese angeschlossen sind und richtig verwendet werden.

Das Verwenden dieser Einrichtungen verringert Gefährdungen durch Staub.

h. Sichern Sie das Werkstück. Ein mit Spannvorrichtungen oder Schraubstock

festgehaltenes Werkstück ist sicherer gehalten als mit Ihrer Hand.

4) Sorgfältiger Umgang und Gebrauch von Elektrowerkzeugen

a. Überlasten Sie das Gerät nicht. Verwenden Sie für lhre Arbeit das dafür bestimmte

Elektrowerkzeug. Mit dem passenden Elektrowerkzeug arbeiten Sie besser und

sicherer im angegebenen Leistungsbereich.

b. Benutzen Sie kein Elektrowerkzeug, dessen Schalter defekt ist. Ein Elektrowerkzeug,

das sich nicht mehr ein- oder ausschalten lässt, ist gefährlich und muss repariert

werden.

UK

D

NL

F

E

P

I

S

SF

N

DK

Ferm 17

c. Ziehen Sie den Netzstecker aus der Steckdose, bevor Sie Geräteeinstellungen

vornehmen, Zubehörteile wechseln oder das Gerät weglegen. Diese

Vorsichtsmaßnahme verhindert den unbeabsichtigten Start des Geräts.

d. Bewahren Sie unbenutzte Elektrowerkzeuge außerhalb der Reichweite von Kindern

auf. Lassen Sie Personen das Gerät nicht benutzen, die mit diesem nicht vertraut

sind oder diese Anweisungen nicht gelesen haben. Elektrowerkzeuge sind gefährlich,

wenn Sie von unerfahrenen Personen benutzt werden.

e. Pflegen Sie das Gerät mit Sorgfalt. Kontrollieren Sie, ob bewegliche Geräteteile

einwandfrei funktionieren und nicht klemmen, ob Teile gebrochen oder so beschädigt

sind, dass die Funktion des Gerätes beeinträchtigt ist. Lassen Sie beschädigte Teile

vor dem Einsatz des Gerätes reparieren. Viele Unfälle haben ihre Ursache in schlecht

gewarteten Elektrowerkzeugen.

f. Halten Sie Schneidwerkzeuge scharf und sauber. Sorgfältig gepflegte

Schneidwerkzeuge mit scharfen Schneidkanten verklemmen sich weniger und sind

leichter zu führen.

g. Verwenden Sie Elektrowerkzeug, Zubehör, Einsatzwerkzeuge usw. entsprechend

diesen Anweisungen und so, wie es für diesen speziellen Gerätetyp vorgeschrieben

ist. Berücksichtigen Sie dabei die Arbeitsbedingungen und die auszuführende

Tätigkeit. Der Gebrauch von Elektrowerkzeugen für andere als die vorgesehenen

Anwendungen kann zu gefährlichen Situationen führen.

h. Beschädigte Schalter müssen bei einer Kundendienstwerkstatt ersetzt werden.

Benutzen Sie keine Elektrowerkzeuge, bei denen sich der Schalter nicht ein- und

ausschalten lässt.

i. Elektrowerkzeuge nicht unbeaufsichtigt laufen lassen. Gerät immer ausschalten und

erst verlassen, wenn das Gerät völlig zum Stillstand gekommen ist.

j. Wenn die Anschlussleitung beschädigt wird, muss diese durch einde besondere

Anschlussleitung ersetzt werden. Diese erhalten Sie beim Hersteller oder seinem

Kundendienst. Das Auswechseln der Anschlussleitung darf nur den Hersteller, seinen

Kundendienst oder ähnlich qualifizierte Personen durchgeführt werden.

5) Service

a. Lassen Sie Ihr Elektrowerkzeug von einer qualifizierten Fachkraft unter Verwendung von

Originalersatzteilen reparieren. Dadurch wird die sichere Funktionsweise des

Elektrowerkzeuges gewährleistet.

b. Achtung! Der Gebrauch anderer als in dieser Bedienungsanleitung empfohlener

Zubehörteile oder Zusatzgeräte kann eine Verletzungsgefahr bedeuten. Verwenden Sie nur

Originalersatzteile.

Zusätzliche Sicherheitshinweise

• Tragen Sie Gehörschutz. Die Lärmbelastung kann zu Gehörschäden führen.

• Verwenden Sie die im Lieferumfang enthaltenen Zusatzgriffe. Durch Kontrollverlust

kann es zu Verletzungen kommen.

Für den Gebrauch dieses Elektrowerkzeuges:

• Kontrollieren Sie die zu bohrende Stelle auf versteckte Elektrokabel, Gasleitungen

oder andere Hindernisse (z. B. mit einem Metalldetektor).

• Überprüfen Sie folgendes:

• Entspricht die Spannung des Gerätes der Netzspannung?

D

18 Ferm

• Sind Netzkabel, Isolation und Netzstecker in einwandfreiem Zustand:

unbeschädigt, nicht lose oder defekt?

• Ist die Wandsteckdose in Ordnung?

• Läuft der Bohrhammer unrund, ist er überhitzt oder erzeugt übermäßige Funken?

• Sollte eines der genannten Probleme auftreten, unterbrechen Sie sofort die Arbeit

und lassen Sie die Maschine von einem Fachmann reparieren.

Elektrische Sicherheit

Kontrollieren Sie immer, ob die Netzspannung mit der auf dem Typenschild

angegebenen Spannung übereinstimmt.

Die Maschine ist schutzisoliert; Erdung ist somit nicht erforderlich.

Austausch von Netzkabel oder Netzstecker

Entsorgen Sie alte Kabel oder Stecker sofort, sobald diese durch neue ersetzt wurden. Es

ist gefährlich, ein Netzkabel mit lockerem Stecker in die Steckdose zu stecken.

Verwendung von Verlängerungskabeln

Benutzen Sie ausschließlich Verlängerungskabel, die für die Maschinenleistung ausgelegt

sind. Der Mindestaderquerschnitt muss 1,5 mm

2

betragen. Bei Verwendung einer

Kabeltrommel muss das Kabel immer vollständig abgerollt werden.

3. BETRIEB

Beim Betrieb eines Bohrhammers muss durch den Bediener nur sehr wenig

Druck ausgeübt werden. Übermäßiger Druck auf das Werkzeug kann zur

Überhitzung des Motors und Verbrennen des verwendeten Werkzeuges

führen.

Zusatzhandgriff

Der Zusatzhandgriff kann 360º um den Bohrkopf gedreht werden, was ein sicheres und

bequemes Arbeiten für Links- und Rechtshänder ermöglicht.

• Lösen Sie den Handgriff durch Drehen gegen den Uhrzeigersinn.

• Drehen Sie den Handgriff in die gewünschte Position.

• Ziehen Sie den Handgriff in der neuen Position wieder fest.

Bohrer austauschen und entfernen

Abb. A + B

Ziehen Sie zunächst den Netzstecker aus der Steckdose, bevor Sie Bohrer

austauschen.

D

Ferm 19

Kontrollieren Sie während des Gebrauchs regelmäßig die Bohrer. Stumpfe

Bohrer müssen geschärft oder ausgetauscht werden.

• Ölen Sie den Bohrerschaft leicht ein, bevor Sie ihn in das Bohrfutter einsetzen.

• Schieben Sie die Arretierhülse (11, Abb. A) zurück und setzen Sie den Bohrer in die

• Bitte achten Sie darauf, dass die Gummischeibe außen bleibt (zwischen Scheibe und

Verriegelungshülse).

• Bohrfutteröffnung ein. Stellen Sie sicher, dass die Keilnut des Bohrers richtig im

Bohrfutter sitzt, indem Sie den Bohrer vorsichtig drehen, bis dieser einrastet. Lassen

Sie die Arretierhülse los.

• Um den Bohrer zu entfernen, schieben Sie die Arretierhülse nach hinten und halten

sie in dieser Position fest.

Bohrfutter + Adapter

Abb. C

Verwenden Sie das beigefügte Bohrfutter für Bohrungen mit gewöhnlichen Bohrkronen.

Bringen Sie das Bohrfutter wie in der Abbildung gezeigt an.

Tiefenanschlag einstellen

Abb. A

• Lösen Sie den Handgriff durch Drehen gegen den Uhrzeigersinn.

• Schieben Sie den Tiefenanschlag (Lineal) durch die Öffnung des Zusatzhandgriffs.

• Stellen Sie das Lineal auf die gewünschte Tiefe ein.

• Ziehen Sie die Schraube gut fest.

Funktionsumschalter

Abb. D

Die richtige Position des Umschalters für die Maschinenfunktionen entnehmen Sie bitte

der Abbildung auf Seite 3.

1 = Meißelhammer/Meißel

2 = Bohrhammer

3 = Bohren

Ein-/Ausschalten

• Um die Bohrmaschine einzuschalten, betätigen Sie den Ein-/Aus-Schalter.

• Zum Ausschalten, lassen Sie den Ein-/Aus-Schalter los.

Montieren der Staubkappe

Abb.E

Die Staubkappe verhindert, dass Staub beim Bohren in Zimmerdecken in das Gerät

gelangt.

• Entfernen Sie den Bohrer.

• Schieben Sie die Staubkappe über den Bohrerschaft.

• Setzen Sie den Bohrer mit der Staubkappe in das Bohrfutter ein.

• Wechseln Sie eine beschädigte Staubkappe immer sofort aus.

D

20 Ferm

4. WARTUNG

Achten Sie darauf, dass die Maschine nicht an das Stromnetz angeschlossen

ist, wenn Wartungsarbeiten an den mechanischen Teilen durchgeführt werden.

Maschinen sind so konzipiert, dass sie lange Zeit bei minimalem Wartungsaufwand

problemlos funktionieren. Durch regelmäßiges Reinigen und sachgerechte Behandlung

verlängern Sie die Lebensdauer Ihrer Maschine.

Beschädigungen

Die Maschine sollte regelmäßig auf die nachfolgenden möglichen Beschädigungen

überprüft und ggf. repariert werden.

• Beschädigungen am Netzkabel

• Defekt des Ein/Aus-Schalters

• Kurzschlüsse

• Beschädigungen an beweglichen Teilen.

Störungsbeseitigung

• Der Motor läuft nicht,

obwohl die Maschine

eingeschaltet ist.

• Motor erzeugt laute

Geräusche und läuft zu

langsam oder gar nicht.

• Keine

Spannungsversorgung.

• Wackelkontakt im

Ein/Aus-Schalter

.

• Zu niedrige

Netzspannung.

• Motorschaden.

• Abgenutzte

Kohlebürsten.

• Motor durch zu starken

Druck oder zu große

Bohrtiefe überlastet.

• Motorschaden.

• Zu niedrige

Netzspannung.

• Abgenutzte

Kohlebürsten.

• Überprüfen Sie die

Spannungsversorgung.

• Reparieren oder

ersetzen Sie den

Schalter.

• Verlängerungskabel zu

lang oder

unterdimensioniert.

• Lassen Sie Ihre

Maschine von einem

Fachmann reparieren.

• Lassen Sie die

Kohlebürsten ersetzen.

• Verringern Sie den

Druck oder die

Bohrtiefe, reduzieren

Sie die Leistung.

• Lassen Sie Ihre

Maschine von einem

Fachmann reparieren.

• Netzspannung

regulieren.

• Ersetzen Sie die

Kohlebürsten.

D

Ferm 21

Reinigung

Reinigen Sie das Maschinengehäuse regelmäßig mit einem weichen Tuch, vorzugsweise

nach jedem Gebrauch. Achten Sie darauf, dass die Lüftungsschlitze staub- und

schmutzfrei sind. Verwenden Sie bei hartnäckigem Schmutz ein weiches mit Seifenwasser

angefeuchtetes Tuch. Verwenden Sie keine Reinigungsmittel wie Benzin, Alkohol,

Ammoniak, usw. Diese Substanzen greifen die Kunststoffteile an.

Schmierung

Abb. F

• Schmieren Sie das Bohrfutter des Bohrhammers regelmäßig.

• Der Schmiermittelstand in der Maschine muss regelmäßig überprüft werden:

• Entfernen Sie den Schmierdeckel (11) oben auf der Maschine (Off).

• Entfernen Sie auch den zweiten Deckel (mit 4 Nasen).

• Jetzt sind die rotierenden Teile im Maschineninneren sichtbar. Die bewegten Teile

sollten mit Fett bedeckt sein.

• Geben Sie wenn erforderlich etwas Fett in die Schmieröffnung.

• Setzen Sie den Deckel wieder auf die Öffnung und drehen Sie ihn fest.

• Bringen Sie den Schmierdeckel wieder an (On).

Fehler

Sollte beispielsweise nach Abnutzung eines Teils ein Fehler auftreten, dann setzen Sie

sich bitte mit der auf der Garantiekarte angegebenen Serviceadresse in Verbindung. Im

hinteren Teil dieser Anleitung befindet sich eine ausführliche Übersicht über die Teile, die

bestellt werden können.

Umwelt

Um Transportschäden zu verhindern, wird die Maschine in einer soliden Verpackung

geliefert. Die Verpackung besteht weitgehend aus verwertbarem Material.

Benutzen Sie also die Möglichkeit zum Recyclen der

Verpackung.

Schadhafte und/oder alte elektrische oder elektronische Geräte müssen an

den dafür vorgesehenen Recycling-Stellen abgegeben werden.

Garantie

Lesen Sie die Garantiebedingungen auf der separat beigefügten Garantiekarte.

• Überhitzung des

Getriebegehäuses.

• Starkes Funkensprühen

des Motors.

• Maschine überlastet

oder Bohrer stumpf.

• Verringerte

Netzspannung.

• Prüfen Sie, ob die

Kohlebürsten abgenutzt

sind.

• Verringern Sie die

Belastung und schleifen

Sie den Bohrer.

• Netzspannung

regulieren.

D

22 Ferm

CE KONFORMITÄTSERKLÄRUNG (D)

Wir erklären in alleiniger Verantwortung, daß dieses Produkt,

TBH-1400N Bohrhammer

mit den folgenden Normen oder normativen Dokumenten übereinstimmt:

EN60745-1: 2003 + A1, EN60745-2-6: 2003, EN55014-1, EN55014-2,

EN61000-3-2, EN61000-3-3

gemäß den Bestimmungen der Richtlinien:

98/37/EC, 2006/95/EC, 89/336/EEC, 2002/95/EC, 2002/96/EC

ab 01-11-2006

ZWOLLE NL

J.A. Bakker - van Ingen J. Lodewijk

CEO Ferm BV Quality Manager Ferm Global

Unsere Firmenpolitik ist auf ständige Verbesserung unserer Produkte ausgerichtet und wir

behalten uns das Recht vor, die Produktspezifikation ohne vorherige Benachrichtigung zu

ändern.

Ferm BV • Lingenstraat 6 • 8028 PM Zwolle • Niederlande

D

Ferm 23

24 Ferm

Ferm 25

26 Ferm

Spare parts list

No. Description Position

700171 Depth gauge 24

700172 Side handle 25 till 29

700393 Locking sleeve (set) 76 till 78

806001 Bearing 6001 ZZ 81

700394 Rotor 82

700395 Stator 89

700396 Carbon brush (set) 95

700397 Switch 107

800608 Bearing 608 ZZ 116

Ersatzteilliste

No. Bezeichnung Position

700171 Tiefenanschlag 24

700172 Seitenhandgriff 25 bis 29

700393 Verriegelung (Satz) 76 bis 78

806001 Kugellager 6001 ZZ 81

700394 Rotor 82

700395 Stator 89

700396 Kohlebürsten(Satz) 95

700397 Schalter 107

800608 Kugellager 608 ZZ 116

Ferm 27

Exploded view / Explosionszeichnung

www.ferm.com GB-D-0703-28

GB Subject to change

D Änderungen vorbehalten

Loading...

Loading...