Page 1

www.topconpositioning.com

X30 • X25

Console

Athene Spreader Control

Operator’s Manual

Page 2

Page 3

Athene Spreader Controller

Operator Manual

Part Number: 1014197-01

Rev Number: 1.0

For use with Software Version 3.22

© Copyright Topcon Precision Agriculture

June 2016

All contents in this manual are copyrighted by Topcon. All rights reserved. The information

contained herein may not be used, accessed, copied, stored, displayed, sold, modified, published or

distributed, or otherwise reproduced without express written consent from Topcon.

www.topconpa.com

Page 4

Page 5

i

Preface

This manual provides information about operating and maintaining this Topcon

Precision Agriculture product. Correct use and servicing is important for safe and

reliable operation of the product.

It is very important that you take the time to read this manual before using the

product.

Information in this manual is current at the time of publication. A system may vary

slightly. The manufacturer reserves the right to redesign and change the system as

necessary without notification.

Terms and Conditions

Note:Please read these Terms and Conditions carefully.

General

APPLICATION - You accept these Terms and Conditions by purchasing the product from

Topcon Precision Agriculture (TPA) or from one of TPA’s product dealers.

COPYRIGHT - All information contained in this manual is the intellectual property of, and

copyrighted material of TPA. All rights are reserved. You may not use, access, copy, store,

display, create derivative works of, sell, modify, publish, distribute, or allow any third parties

access to, any graphics, content, information or data in this manual without TPA’s express written

consent and may only use such information for the care and operation of your product. The

information and data in this manual are a valuable asset of TPA and are developed by the

expenditure of considerable work, time and money, and are the result of original selection,

coordination and arrangement by TPA.

TRADEMARKS – ZYNX, PROSTEER, EAGLE, KEE Technologies, Topcon, Topcon

Positioning Systems and Topcon Precision Agriculture are trademarks or registered trademarks of

the Topcon Group of companies. Microsoft and Windows are trademarks or registered trademarks

in the United States and/or other countries of Microsoft Corporation. Product and company names

mentioned herein may be trademarks of their respective owners.

WEBSITE AND OTHER STATEMENTS - No statement contained at the website of TPA or

any other Topcon Group company or in any other advertisements or TPA literature or made by an

employee or independent contractor of TPA modifies these Terms and Conditions.

IMPORTANT: SAFETY - Improper use of the product can lead to death or injury to persons,

damage to property and/or malfunction of the product. The product should only be repaired by

authorized TPA service centers. You should closely review the safety warnings and directions as

to the proper use of the product in this manual and at all times comply with the same.

Limited Warranty

ELECTRONIC AND MECHANICAL COMPONENTS -TPA warrants that the electronic

components manufactured by TPA shall be free of defects in materials and workmanship for a

period of one year from the original date of shipment to the dealer. TPA warrants that all valves,

hoses, cables and mechanical parts manufactured by TPA shall be free of defects in materials and

workmanship for a period of 90 days from the date of purchase.

Page 6

ii

RETURN AND REPAIR - During the respective warranty periods, any of the above items

found defective may be shipped to TPA for repair. TPA will promptly repair or replace the

defective item at no charge, and ship it back to you. You must pay the shipping and handling

charges in respect of the same. Calibration of components, labor and travel expenses incurred

for in-field removal and replacement of components are not covered in this warranty policy. The

foregoing warranty shall NOT apply to damage or defects resulting from:

(i) disaster, accident or abuse

(ii) normal wear and tear

(iii) improper use and/or maintenance

(iv) unauthorized modifications of the product; and/or

(v) use of the product in combination with other products not supplied or specified by TPA.

Software accompanying any product is licensed for use in connection with the product and not

sold. Use of software that is provided with a separate end user license agreement (“EULA”)

will be subject to the terms and conditions, including those relating to limited warranty, of the

applicable EULA, notwithstanding anything in these Terms and Conditions to the contrary.

WARRANTY DISCLAIMER -OTHER THAN FOR THE ABOVE WARRANTIES,

WARRANTIES PROVIDED IN AN APPLICABLE WARRANTY CARD,

APPENDIX OR END USER LICENSE AGREEMENT, THIS MANUAL, THE

PRODUCT AND RELATED SOFTWARE ARE PROVIDE ‘AS-IS’. THERE ARE

NO OTHER WARRANTIES AND TO THE EXTENT ALLOWED BY LAW TPA

EXCLUDES ALL IMPLIED TERMS, CONDITIONS AND WARRANTIES IN

RESPECT OF THE MANUAL AND THE PRODUCT (INCLUDING ANY IMPLIED

WARRANTY OR MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

USE OR PURPOSE). TPA IS NOT RESPONSIBLE FOR THE OPERATION OF

GNSS SATELLITES AND/OR AVAILABILITY, CONTINUITY, ACCURACY, OR

INTEGRITY OF GNSS SATELLITE SIGNALS.

LIABILITY LIMIT AND INDEMNITY - TPA and its dealers, agents and representatives

shall not be liable for technical or editorial errors or omissions contained herein or for special,

indirect, economic, incidental or consequential damages resulting from the furnishing,

performance or use of this material, the product or its accompanying software (including where

TPA has been advised of the possibility of such damage). Such disclaimed damages include but

are not limited to loss of time, loss or destruction of data, loss of profit, savings or revenue or

loss of or damage to the product. You shall defend, indemnify and hold TPA harmless from and

against any claims, actions, suits, damages, losses, liabilities and costs (including attorneys’ fees)

arising from, or relating to (a) your operation use, or maintenance of the product and/or software

other than as provided for in this manual or the applicable end user license agreement; and (b)

your negligence or wrongful act or omission in respect of the product.

In any event, TPA’s liability to you or any other person for any claim, loss or damage (in

contract, tort or on any other basis) will be limited (in TPA’s option) to either (a) the

replacement or repair of the product, or (b) payment of the cost of replacing or repairing the

product.

Page 7

iii

Other

These Terms and Conditions may be amended, modified, superseded or cancelled, at any time by

TPA. These Terms and Conditions will be governed by, and construed in accordance with:

n the laws of South Australia if the product is sold and supplied to you in Australia (in which

case the courts of South Australia or the Federal Court of Australia (Adelaide Registry) have

exclusive jurisdiction in respect of any claim or dispute) or

n the laws of the State of California if the product is sold and supplied to you outside of Australia

n the provisions of the United Nations Convention on Contracts for the International Sale of

Goods shall not apply to these Terms and Conditions.

All information, illustrations, and applications contained herein are based on the latest available

information at the time of publication. TPA reserves the right to make product changes at any time

without notice.

If any part of these Terms and Conditions would be unenforceable, the provision must be read

down to the extent necessary to avoid that result, and if the provision cannot be read down to that

extent, it must be severed without affecting the validity and enforceability of the remainder of these

Terms and Conditions.

Service Information

Service assistance can be provided by contacting your local TPA Authorized Dealer.

Communications Regulation Information

FCC Compliance Statement (USA)

This equipment has been tested and found to comply with the limits for a

Class ‘A’ digital device, pursuant to Part 15 of the FCC Rules. Operation

of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the

interference at the user's expense.

FCC Compliance Statement (Canada)

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulation.

CE EMC Statement (European Community)

Warning:This is a class ‘A’ product. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

‘C’ Tick EMC Statement (Australia & New Zealand)

This product meets the applicable requirements of the Australia and New

Zealand EMC Framework.

Page 8

iv

Type Approval and Safety Regulations

Type approval may be required in some countries to license the use of transmitters

on certain band frequencies. Check with local authorities and your dealer.

Unauthorized modification of the equipment may void that approval, the warranty

and the license to use the equipment.

The receiver contains an internal radio-modem. This can potentially send signals.

Regulations vary between countries, so check with the dealer and local regulators

for information on licensed and unlicensed frequencies. Some may involve

subscriptions.

Radio and Television Interference

This computer equipment generates, uses, and can radiate radio-frequency energy.

If it is not installed and used correctly in strict accordance with TOPCON

Precision Agriculture instructions, it may cause interference with radio

communication.

You can check if interference is being caused by this equipment by turning the

Topcon equipment off to see if the interference stops. If the equipment is causing

interference to a radio or other electronic device, try:

l Turning the radio antenna until the interference stops

l Moving the equipment to either side of the radio or other electronic device

l Moving the equipment farther away from the radio or other electronic device

l Connecting the equipment to another circuit that is not linked to the radio.

To reduce potential interference operate the equipment at the lowest gain level that

will allow successful communication.

If necessary contact your nearest Topcon Precision Agriculture dealer for

assistance.

Note:Changes or modifications to this product not authorized by TOPCON

Precision Agriculture could void the EMC compliance and negate authority to

operate the product.

This product was tested for EMC compliance using Topcon Precision Agriculture

peripheral devices, shielded cables and connectors. It is important to use Topcon

Precision Agriculture devices between system components to reduce the possibility

of interference with other devices

General Safety

DANGER: It is essential that the following information and the

product specific safety information is read and understood.

Most incidents arising during operation, maintenance and repair are caused by a

failure to observe basic safety rules or precautions. Always be alert to potential

hazards and hazardous situations.

Page 9

v

Always follow the instructions that accompany a Warning or Caution. The

information these provide aims to minimize risk of injury and/or damage to property.

In particular follow instructions presented as Safety Messages.

Safety Messages and Warnings

The safety symbol is used with the relevant word: DANGER, WARNING or

CAUTION.

Messages marked in this way recommend safety precautions and practices. LEARN

and apply them.

DANGER: Indicates an imminently hazardous situation that, if not

avoided, could result in DEATH OR VERY SERIOUS INJURY.

WARNING: Indicates a potentially hazardous situation that, if not

avoided, could result in DEATH OR SERIOUS INJURY.

CAUTION: Indicates a potentially hazardous situation that, if not

avoided, may result in MINOR INJURY.

Safety Signs

WARNING: DO NOT remove or obscure safety signs. Replace any

safety signs that are not readable or are missing. Replacement signs are

available from your dealer in the event of loss or damage.

If a used vehicle has been purchased, make sure all safety signs are in the correct

location and can be read. Replace any safety signs that cannot be read or are missing.

Replacement safety signs are available from your dealer.

Operator Safety

WARNING: It is YOUR responsibility to read and understand the safety

sections in this book before operating this vehicle. Remember that YOU

are the key to safety.

Good safety practices not only protect you, but also the people around you. Study

this manual as part of your safety program. This safety information only relates to

Topcon equipment and does not replace other usual safe work practices.

WARNING: Ensure power is removed from the Topcon equipment prior

to maintenance or repair of the vehicle or implements.

WARNING: Ensure appropriate precautions are taken prior to handling any hazardous substances. Always read the Material Safety Data

Sheet prior to commencing work.

Page 10

vi

WARNING: In some of the illustrations or photos used in this manual,

panels or guards may have been removed for demonstration purposes.

Never operate the vehicle with any panels or guards removed. If the

removal of panels or guards is necessary to make a repair, these

MUST be replaced before operation.

WARNING: Always check that any suspended vehicle attachments are

lowered to the ground before beginning repair or maintenance work

on a vehicle.

WARNING: Vehicle and implement parts can become hot during operation and may be under pressure. Refer to vehicle manuals.

WARNING: Wear appropriate protective clothing for the task being

undertaken and conditions.

WARNING: Do not operate equipment around explosive equipment or

supplies.

WARNING: Topcon is committed to good environmental performance

and minimizes the use of any potentially harmful substances in its

products. However, it is always advisable not to handle damaged electronic equipment. This Topcon product may contain a sealed lithium

battery. Always dispose of any electronic equipment thoughtfully and

responsibly.

Exposure to Radio Frequency

Exposure to energy from radio frequencies is an important safety issue. Keep a

distance of at least 20 cm (7.8 inches) between people and any radiating antenna.

Keep a distance of at least 20 cm between transmitting antennas.

WARNING: Products using cellular modem or an RTK base station

can transmit radio frequency energy. Check with your dealer.

This device is designed to operate with TPA approved antennas. Discuss with your

dealer.

Preparation for Operation

l Read and understand this manual and learn all of the controls before you use

the equipment.

l Keep the manual with the equipment.

l If the equipment is moved to another vehicle, move the manual as well.

l Read the manual for the vehicle with which the equipment will be used and

check that the vehicle has the correct equipment required by local regulations.

Page 11

vii

l Make sure you understand the speed, brakes, steering, stability, and load

characteristics of the vehicle before you start.

l Check all controls in an area clear of people and obstacles before starting work.

l Identify possible hazards.

WARNING: Topcon equipment must not be used by an operator

affected by alcohol or drugs. Seek medical advice if using prescription or

over-the-counter medication.

Disclaimer

Topcon accepts no responsibility or liability for damages to property, personal

injuries, or death resulting from the misuse or abuse of any of its products.

Further, Topcon accepts no responsibility for the use of Topcon equipment or the

GNSS signal for any purpose other than the intended purpose.

Topcon cannot guarantee the accuracy, integrity, continuity, or availability of the

GNSS signal.

The operator must ensure that the equipment is correctly turned off when not in use.

Before operating any vehicle equipped with Topcon products, read and understand

the following product specific safety precautions.

Important Safety Information

Operator Alertness and Responsibility

The console helps the operator to steer the vehicle, but the operator remains in charge

and must be alert and in complete control of the vehicle at all times. The operator is

ultimately responsible for safe operation of this equipment.

It is essential that safety requirements are met when operating the console and any of

its components. All operators and other relevant personnel must be advised of safety

requirements.

Electrical Safety

WARNING: Incorrectly connected power can cause severe injury and

damage to people or the equipment.

When working with electrical components, you must do the following:

l Make sure the negative terminal of the battery is disconnected before doing any

welding on the vehicle.

l Check that all power cables to system components are connected to the correct

polarity as marked. Please refer to the vehicle manual for safety information.

l Check that equipment is grounded in accordance with installation instructions.

Page 12

viii

Operation and Risk of Obstacles

The following list is not exhaustive or limited. To use the console for assisted

steering along a defined wayline, the operator must ensure that it is used:

l Away from people and obstacles

l Away from high voltage power lines or other overhead obstructions (identify

any clearance problems before activating the console)

l On private property without public access

l Within cleared fields

l Off public roads or access ways.

Note that:

l The operator needs to know the vehicle’s position and the field conditions at

all times.

l The operator will need to respond if the GNSS satellite or differential

correction signal is lost momentarily.

l The console cannot detect obstacles (people, livestock or other).

l Only use the console in areas that are clear of obstacles and keep a proper

distance.

l Steering needs to be disengaged for manual control if an obstacle appears in

the path or the vehicle moves away from the wayline.

On/Off and Manual Control

WARNING: Ensure the steering switch is Off to prevent unintentional

engagement of the assisted steering. When repairing or maintaining

the vehicle/implement, ensure the vehicle CANNOT be moved. Disengage steering, apply brakes and remove keys.

The operator must ensure that the steering switch is Off (all LED indicators are

off) when assisted steering is not being used.

The operator must disengage assisted steering and use manual control if an

obstacle is in the line of travel or moves into the line of travel, or if the vehicle

steers away from the desired wayline.

To disengage assisted steering:

l Turn the steering wheel a few degrees OR

l Select the Disengage Auto Steering button on the console AND/OR

l If using an external steering switch, disengage using the switch if the above

actions do not disengage assisted steering.

Vehicle Shut Down Safety

Before leaving the vehicle, disengage assisted steering, disengage external steering

switch if this is being used, and remove the key from the key switch.

Page 13

ix

Using a Reference (Base) Station

WARNING: Do not move a reference station while in operation. Moving

an operating reference station can interfere with the controlled steering

of a system using the reference station. This could result in personal

injury or damage to property.

Operators and other affected personnel must be advised of the following safety

precautions.

l Do not erect the reference station under or within the vicinity of high voltage

power lines.

l When using the portable reference station, make sure that the tripod is securely

mounted.

To Get the Best Out of the Product

Back up data regularly. The console has large, but limited storage capacity. Use the

Diagnostics Mini-view to view capacity available. A warning screen displays if

storage is reaching its limit.

Be aware of file format compatibility. Discuss compatible formats with the dealer.

Topcon Agricultural Products are hardy and designed to work in tough conditions.

However, if equipment is unused for a length of time, store away from water and

direct heat sources.

Alert Symbols

In this manual two alert symbols are used:

Note:This offers additional information.

WARNING: A warning signal appears on safety signs and in this

manual to show that this information is very important to your safety.

LEARN these and APPLY them.

Page 14

x

Table of contents

Chapter 1 – Introduction 1

Chapter 2 – Implement Setup 3

2.1. Enabling ISOBUS 4

2.2. Setting up a new implement 7

2.3. Setting implement geometry 9

2.4. Setting up section control 11

2.4.1. Enabling section control 11

2.4.2. Setting timing 11

2.4.3. Setting up the section switch 12

2.5. Setting up master switch and speed 13

Chapter 3 – Athene Setup 15

3.1. Switching between setup and operation screen 15

3.2. Opening the Athene UT window 16

3.3. Athene primary screens 18

3.3.1. Main screen 18

3.3.1. Spreader settings screen 23

3.3.1. Totals screen 27

3.4. Setting up units 28

3.5. Load cell configuration 29

3.5.1. Load cell calibration 31

3.6. Setting up working width 32

3.7. Setting up pre-start 33

3.7.1. Operating pre-start 34

3.8. Setting up boundary reduction 35

3.8.1. Operating boundary reduction 36

3.9. Setting up products 37

3.10. Setting up alarms 39

3.11. Setting up forward speed 40

3.11.1. SSF Autocal 40

3.11.2. Simulated speed 41

3.12. Adding product / tare 42

3.12.1. With load cells 42

3.12.2. Without load cells 42

Page 15

xi

Chapter 4 – Calibration 45

4.1. Product calibration modes 45

4.1.1. Dynamic mode 45

4.2. Performing calibration (with or without load cells) 47

4.2.1. Product flow factor – check calibration routine 49

4.3. Nudge calibration 52

4.4. Static mode calibration 53

4.5. Valve calibration 54

Chapter 5 – Operation 57

5.1. Opening auto section control 57

5.2. Using the master switch 59

5.3. Variable rate control 60

5.3.1. If using VRC maps 60

Chapter 6 – Updating Athene Software 65

Chapter 7 – Index 67

Page 16

xii

Page 17

1

Chapter 1 – Introduction

The Athene spreader controller is an ISOBUS UT-compliant

monitoring and application control system for self-propelled / trailed

belt spreaders spreading lime / granular materials. Forward speed

measurement and cutout sensing enables full proportional control, to

maintain (within limits) a set application irrespective of changes in

forward speed.

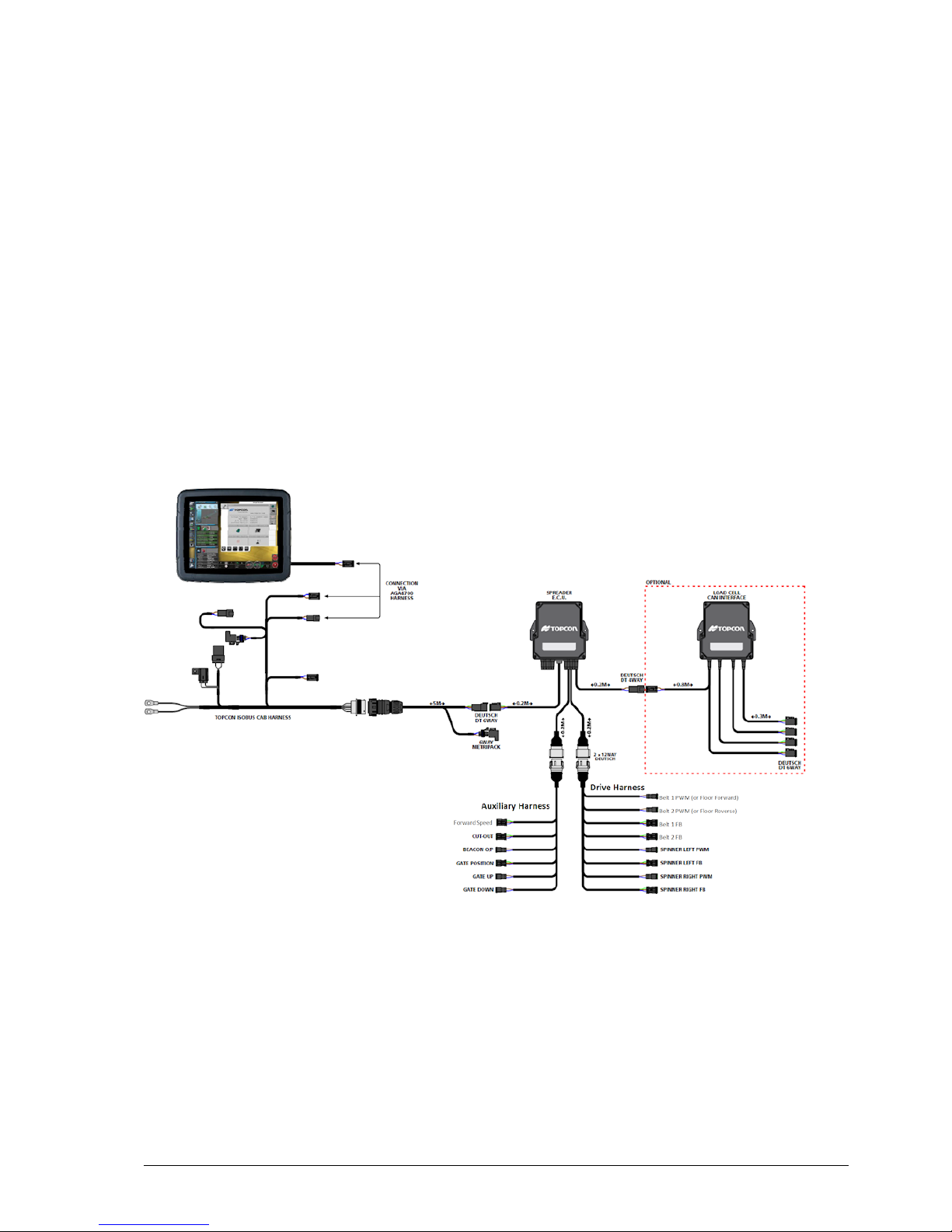

Shown is a typical retrofitted system (that is independent from the

tractor ISOBUS). Some installations will have minor variations, but

the key components are the Console, Spreader ECU, Loadcell ECU

and load cells.

Forward speed sensing may be performed via a GPS VTG message,

or optionally by a magnetic sensor measuring wheel or propshaft

rotation (fitted to the tractor / self-propelled spreader or trailed

spreader). There is no physical master cutout switch. The master

on/off switch is ‘virtual’ (a softkey on the Athene operation screen).

The system may be fitted with or without load cells.

Page 18

2

Machines without load cells: The system relies on volumetric

calculation from the known gate height and width, and a known

product density (or selecting the product from a pre-defined list). It

works best for relatively free-flowing material of consistent density.

Machines with load cells: Load cells enable fully-automatic,

continuous calibration. They are advantageous for controlling the rate

of material with more variable density. By constantly measuring the

weight of product in the spreader, the floor (belt) speed is

continuously adjusted to achieve the correct target application rate.

The system quickly reacts to changes in product characteristics or

spreading conditions without having to adjust or re-calibrate the

machine.

Other spreader functions, such as spinner speed, can also be

monitored, with warnings being triggered if they are not operating

correctly.

Page 19

3

Chapter 2 – Implement Setup

This chapter explains how to setup and configure the console for use

with the Spreader Controller features.

Note: When the system is new, the following Setup screen displays.

Page 20

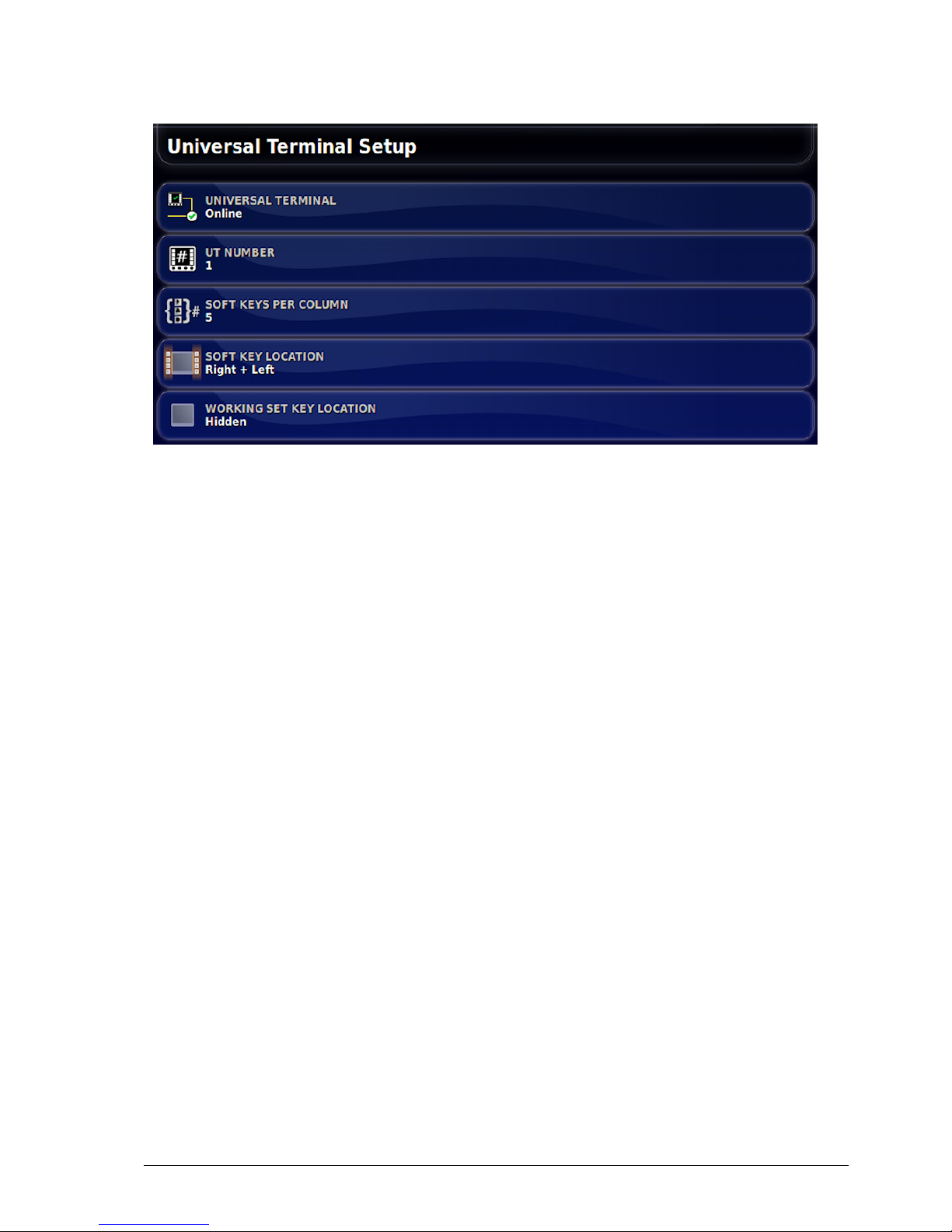

2.1. Enabling ISOBUS

4

2.1. Enabling ISOBUS

Enables the ISOBUS Universal Terminal server that allows interaction

with the Athene ISOBUS compliant ECU.

To enable ISOBUS / Universal Terminal:

1.

Select System / Features / Console .

2. Select FILE SERVER and select Enabled.

3. Select UNIVERSAL TERMINAL and select Enabled.

4.

Select System / ISOBUS / UT .

The Universal Terminal setup page is displayed.

Page 21

Chapter 2 – Implement Setup

5

l Universal terminal: Controls whether the UT server is actively

receiving connections from other devices.

This may be useful if there are multiple UTs on the bus and

multiple UTs claim to be the primary UT (in which case the UT

will go offline automatically and require the UT Number to be

changed before it will go online again), or to temporarily deactivate

the UT on the console.

l UT number: Sets the UT number for the console. If there are

multiple UTs on the bus, use this setting to assign a unique number

to this UT to avoid conflicts. The UT with number 1 will be the

default UT. If the UT client doesn’t appear on the correct UT you

may need to reconfigure its UT number appropriately. If there is a

conflict, the following message will appear:

'The UT Number of this UT conflicts with another UT on the bus,

and this UT has been disabled. Please make sure that this UT has a

unique UT Number.'

l Soft keys per column: Sets the number of available softkeys on the

UT interface on the Operation screen. Note: This should be set to 5

(or 6 if the option to select 5 is not available).

l Soft key location: Sets the location of the softkeys on the UT

interface and the number of columns (1 or 2). Note: Right + Left

should be selected.

Page 22

2.1. Enabling ISOBUS

6

l Working set key location: Sets the visibility and location of the

keys that switch the interface between ECUs (if more than one

ISOBUS compliant ECU is connected). Note: This should be set

to Hidden.

Page 23

Chapter 2 – Implement Setup

7

2.2. Setting up a new implement

Creates a new implement profile for the attached implement.

Note: Existing implement files can be imported from a USB. Refer to

the Guidance and Auto Steering manual.

To create a new implement:

1.

On the Setup screen, select Implement / New .

l Custom: Create a new implement profile.

l Factory: Select an implement template from a pre-defined list.

2. If the required implement is not available in the Factory templates,

select Custom.

3. Use the arrows to select the implement Type and confirm.

rigid

pivoted (tow behind)

Page 24

2.2. Setting up a new implement

8

front mount

double pivoted (tow between)

A message displays stating that the console will restart once the

implement has been created.

A default name for the implement is displayed.

Note: It is highly recommended that items are named in a

thoughtful and structured way to allow easy use in future seasons.

4. To change the default name, select IMPLEMENT NAME and

enter the new name, then confirm.

The New Implement Setup wizard displays.

5. Select IMPLEMENT CONTROL, select Section Control and

Rate Control, confirm and select next..

6. Select ECU TYPE, select ISOBUS, confirm and select next.

7. Select IMPLEMENT FUNCTION, select Spreader, confirm and

select next.

8. Select ECUASSIGNMENT, select SM-1 and select next, then

to confirm.

The ECUSetup screen is displayed.

9. The ECU name SM-1 should be displayed in the table. If not,

press REFRESH ECU SETTINGS to trigger the ECU to

communicate with the console.

Page 25

Chapter 2 – Implement Setup

9

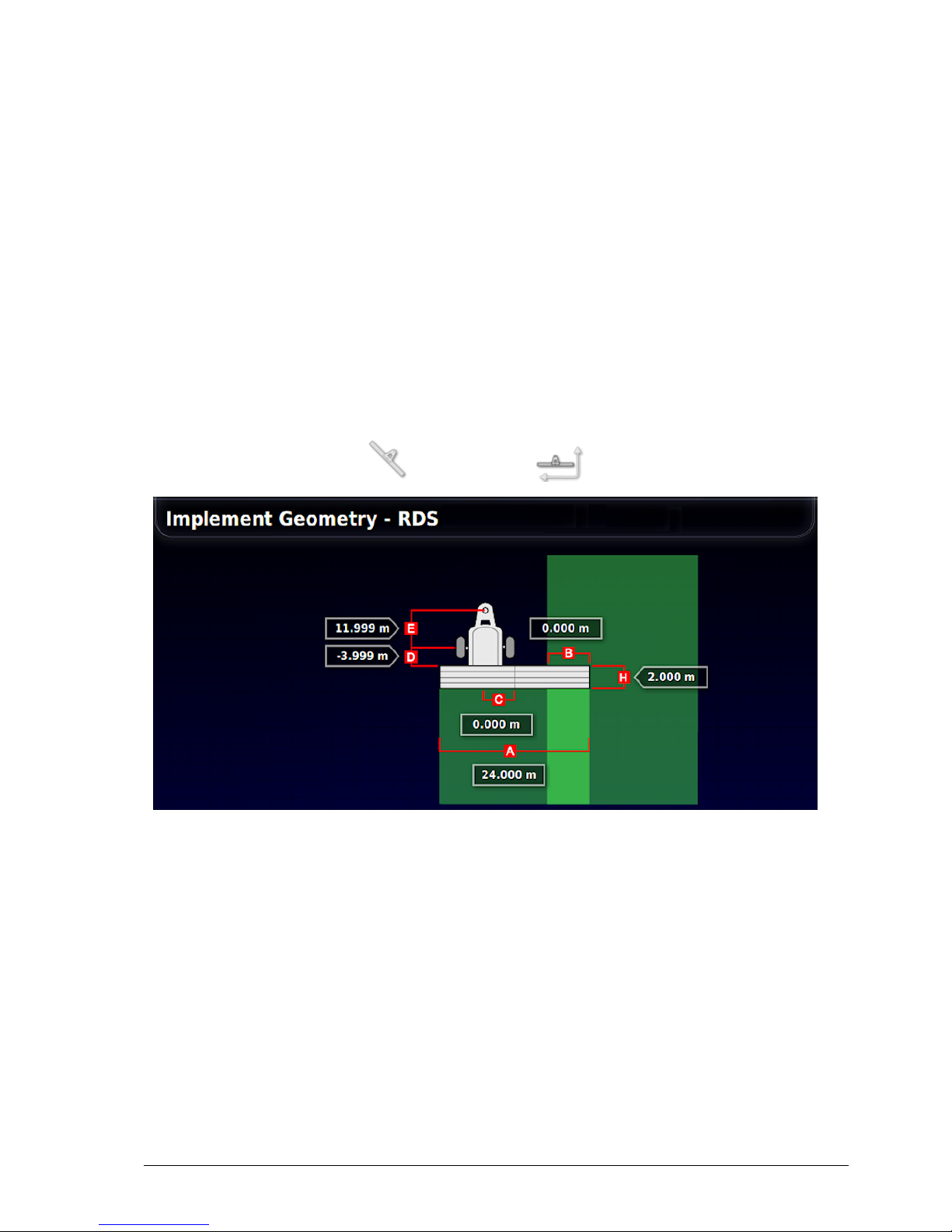

2.3. Setting implement geometry

Sets the implement measurements so that guidance can work accurately.

Note: Measure the implement dimensions as accurately as possible.

The recommended tolerance is +/- 5 cm.

When an ISOBUS implement is connected, some of the geometry items

are provided by the implement and cannot be altered in the console user

interface. Any changes to these must be made in the Athene ISOBUS

UT control screen (see Setting up working width, page 32).

To set the implement geometry:

1.

Select Implement / Geometry .

2. Select an implement dimension. The name of the dimension

appears in the title bar.

Dimensions requested vary according to the type of implement

selected.

3. Add or adjust dimensions where needed and confirm.

Measurements used are as follows:

l Swath Width: Measures the working width of the implement (that

is, the width of the area that is treated during one pass of the

implement).

Page 26

2.3. Setting implement geometry

10

l Working Length: Length from the start to the finish of the

working area of the boom. Together with swath width, it defines

the ‘Working Area’, which is the region that product is applied

over for that boom.

l Overlap: Measures the width of the overlap between two adjacent

passes.

l Implement Offset: Measures the distance between the hitch point

and the wheels of the implement.

l Implement Wheels Offset: Measures the distance between the

wheels and the working area of the implement.

l Inline Offset: Measures the off-center offset of the implement

relative to the hitch point. Enter a positive number if the

implement is shifted to the right and a negative number if it is

shifted to the left.

l Trailer Offset: Measures the distance between the trailer hitch

point and the trailer wheels.

l Trailer Wheels Offset: Measures the distance between the

implement hitch point and the trailer wheels.

Page 27

Chapter 2 – Implement Setup

11

2.4. Setting up section control

Follow these steps to set up section control for the implement.

2.4.1. Enabling section control

To use Auto Section Control, this must be enabled.

1.

Select System / Features / Implement and set

AUTO SECTION CONTROL to Enabled.

2. If using VRC prescription maps, select VARIABLE RATE

CONTROL, choose Enabled and confirm.

3. Repeat for each feature you wish to enable or disable.

2.4.2. Setting timing

These settings set the response times for the sections when switched on

or off. It is important to accurately calculate the response times to avoid

overlaps or gaps in product application.

To calculate the response times:

1. Ensure the implement is ready to begin product application and that

the product calibration has been performed (refer to Calibration,

page 45).

Page 28

2.4. Setting up section control

12

2. Use a stop watch to time the delay between switching a section on

and the application of product. This is the ONTIME.

3. When the section is switched off, time the delay between

switching it off and the product ceasing to flow. This is the OFF

TIME.

To set the response times:

1.

Select Implement / Section Control / Timing .

2. Select ON TIME to set how many seconds delay there is between

switching a section on and the application of product, then

confirm.

3. Repeat for OFF TIME and confirm. This will set how many

seconds delay there is between switching a section off and

stopping product flow.

2.4.3. Setting up the section switch

The section switch option is not functional when using spreader

implements.

Page 29

Chapter 2 – Implement Setup

13

2.5. Setting up master switch and speed

1.

Select Implement / Master Switch .

2. Set MASTER SWITCH to Virtual.

3.

Select Implement / Speed .

4. Set ISO GROUND SPEED to Disabled.

5. Set GPS NMEA2000 to Enabled.

Page 30

2.5. Setting up master switch and speed

14

Page 31

15

Chapter 3 – Athene Setup

3.1. Switching between setup and operation

screen

The console has two main screens; the Setup screen and the Operation

screen.

Use the highlighted buttons to switch between the screens.

Page 32

3.2. Opening the Athene UT window

16

3.2. Opening the Athene UT window

To view the Athene UT window:

1. Select the Athene UT icon on the left of the operation screen.

2. Expand the mini-view by selecting the arrow in the top right

corner, or by swiping left to right across the mini-view (ending

the swipe to the right of the mini-view screen).

3. To open the Athene UT window in full screen, select the UT

maximise button.

Page 33

Chapter 3 – Athene Setup

17

Page 34

3.3. Athene primary screens

18

3.3. Athene primary screens

Athene has three primary screens: Main, Totals and Spreader Settings.

1.

Press to cycle between the primary screens.

Note: The appearance of the screens will vary depending on the

selections made on the ISOBUS UT setup screen. Refer to Enabling

ISOBUS, page 4.

3.3.1. Main screen

The main screen displays job information. The buttons and

information displayed varies depending which settings are selected /

enabled.

Main screen buttons

Pre-start. Starts the floor (belt) moving when there is no

forward speed to ensure good coverage at the beginning of a

run (see Setting up pre-start, page 33).

Master on / off. Note: This does not simultaneously activate /

deactivate coverage as indicated on the guidance screen.

Coverage is independently activated / deactivated using the

console master switch / .

Rate control mode.

Full automatic mode proportional to forward speed. The

Page 35

Chapter 3 – Athene Setup

19

target rate is entered on the main screen. The floor (belt) speed

is automatically adjusted to maintain the correct rate based on

the forward speed and working width.

The floor speed is manually controlled using and

. This mode is commonly used to run the floor belt while

the spreader is stationary (for example; to empty remaining

contents).

Set the target application rate. Vary application

rate (± % increments).

Boundary reduction. The left-hand spinner RPM can be

slowed down to reduce the spread width when traversing the

field boundary (see Setting up boundary reduction, page 35).

Page 36

3.3. Athene primary screens

20

Main screen fields

1

Forward speed.

2

Calibration mode (see Product calibration modes, page 45).

3

Product remaining (actual weight measurement from load

cells for dynamic calibration, a theoretical calculation

otherwise).

4

Live, current application rate.

5

Target application rate.

6

Working width (see Setting up working width, page 32).

7

Job information. Touch to toggle between job information

and spinner speed control (see Variable screen display, page

21).

8

Spinner speed.

9

Work status. Red crosses are shown when the spreader is not

operating.

10

Touch to toggle the bottom left of the display between gate

height and auxiliary function. This button is only present if

additional hydraulic functions have been enabled via Factory

menu / Machine Options / Gate Control and Aux

Page 37

Chapter 3 – Athene Setup

21

Function. Default is OFF (see Variable screen display, page

21).

11

Gate height.

12

Belt speed (% of max).

Variable screen display

The bottom left area of the screen can toggle between job information

and spinner speed by pressing the right button, and gate height and

auxiliary function by pressing the left button.

Job information

Displays the area, weight and time for the current job.

Spinner speed

Page 38

3.3. Athene primary screens

22

Manual / auto spinner speed control. Press to toggle between

AUTO and MAN mode. In AUTO mode, press to set the spinner

speed. Spinners will automatically run at the set speed. In manual

mode, they can be adjusted on-the-go. Note: Please refer to the

machinery manufacturer's manual to establish the correct spinner

RPM for the product / desired spread width.

Gate height

Displays the gate height control option. Use the plus and minus

buttons to adjust the height.

Auxiliary function

Displays the auxiliary hydraulic function. Use the arrow buttons to

activate the function.

Page 39

Chapter 3 – Athene Setup

23

3.3.1. Spreader settings screen

Technician, factory and diagnostics menu should not need to be used

during normal use.

Technician menu. Requires a password for access. See below for

details.

Factory menu. Requires a password for access.

Diagnostics menu. Requires a password for access. See below for

details.

Return to main menu.

Product setup. See Setting up products, page 37.

Alarm setup. See Setting up alarms, page 39.

Cycle between primary screens.

Page 40

3.3. Athene primary screens

24

Select calibration mode (see page 45), add weight / tare

(see page 42).

Set full working width. See Setting up working width,

page 32.

Used to test the machine in the factory or if there is a

problem with the normal forward speed signal. See

Simulated speed, page 41.

Start floor moving while spreader is stationary. See

Setting up pre-start, page 33.

Configure units (see page 28) and forward speed

options (see page 40).

Reduce spinner RPM on boundary. See Setting up

boundary reduction, page 35.

Press to return to the previous screen or to confirm an

entry.

Technician menu

The Technician menu provides the following settings.

Display options:

l Speed smoothing:Damping of forward speed displayed. Higher

number gives more damping.

l Rate lock on %: If the actual rate is within this % of the target,

then the target rate will be displayed on the main screen.

l Rate smoothing: Damping of application rate display. Higher

number gives more damping.

l Off target alarm: If the actual rate is outside this % of the target

then the 'Over/Under Application' alarm is shown.

Page 41

Chapter 3 – Athene Setup

25

l Average weight: Sets whether the average weight is visible on the

INFO screen.

l Info weight: Selects whether the INFO page is based on theorical

weight (rotations of floor) or the weight reduction from the load

cells.

Loadcell correction:

l Correction span: Amount the calibration factor can change by after

each dynamic calibration.

l Min static weight: Weight of product that must be spread during a

static test.

l Dynamic time: How often a dynamic calibration is made.

l Dynamic weight: Weight of product that must be spread during

each dynamic calibration.

l Start delay: Delay at the start of each new load before dynamic

corrections are made.

l Steady weight: % change that is allowed each second before weight

reading is considered unstable.

l Headland delay: Delay when the machine is switched in to work

before dynamic corrections are made.

l Cal factor delay: Pause time between the previous dynamic

correction being made and the new correction starting.

l Dynamic fill weight: When the hopper weight increases by this

value it is considered re-filled.

l Correction span fast: Amount the calibration factor can change by

if weight is below 'Fast empty point'.

Overload log: A list showing each time the weight in the spreader went

over the maximum permissible load.

Diagnostics menu

The Diagnostics menu provides a method to view the following:

l Channels: Shows the current forward speed, target floor speed and

current floor speed.

Page 42

3.3. Athene primary screens

26

l LCI diagnostics: Voltage and weight from the load cell interface.

l Angle sensor: View the current machine angle.

l Dynamic calibration: View the actual weight vs. theory weight

during each dynamic calibration.

l Machine: View other miscellaneous input status.

There are no user settable options.

Page 43

Chapter 3 – Athene Setup

27

3.3.1. Totals screen

Records the grand total and part totals 1 and 2 of area, weight and the

number of loads.

Note: The Reset button is used to reset the selected total.

Page 44

3.4. Setting up units

28

3.4. Setting up units

The measurement system is set from the console setup menu,

however the units (e.g. kg/ha, tonnes/ha) are set from the Athene

setup menu.

1.

Select User / Region / Units .

2. Select the required UNITS (metric or imperial).

3. Exit the console setup menu and start the Athene application.

4.

From the Spreader Settings screen, select General Setup /

Sub Units.

5.

Select the required units and press to confirm.

Page 45

Chapter 3 – Athene Setup

29

3.5. Load cell configuration

1. To ensure the software is set to communicate with the load cell

interface, from the Spreader Settings screen select Factory /

Loadcell Interfaces.

2. If the machine is not fitted with load cells, set Function to NOT

USED.

3. If the machine is fitted with load cells, set Function to CAN

module 1.

To calculate the correct weight, the load cell interface contains an angle

sensor. The orientation of the load cell interface must be entered.

4.

Select Factory / Loadcell Interfaces / Angle Sensor.

5. Press the cycle button to rotate the icon of the ECU around the

spreader until it matches the orientation on which it is mounted.

Page 46

3.5. Load cell configuration

30

6. With the spreader parked on flat ground, press the TARE button

and this will zero the angle sensor.

7. To set the zero point for the load cell, with the spreader empty

select Factory / Loadcell Interfaces / Loadcell

Calibration.

8. When prompted ‘Is spreader empty?’ select YES and then select

again to confirm the spreader is empty. This sets the zero

point.

The load cell gain value must be set. This tells the software that a

load of xx kg causes an increase of 1 volt from the load cell interface.

9.

Place a known weight of product in the spreader. Note: This

process is more accurate if using a bigger known weight.

Page 47

Chapter 3 – Athene Setup

31

10.

Select Factory / Loadcell Interfaces / Loadcell Calibration.

11. When prompted ‘Is spreader empty?’ select NO and enter the actual

weight in the spreader.

3.5.1. Load cell calibration

Load cells may drift out of calibration after an initial period of 'bedding

in' on a new machine.

To recalibrate, repeat the procedure detailed above from step 6.

Page 48

3.6. Setting up working width

32

3.6. Setting up working width

This sets the full working width of the spreader.

Note: Please refer to the machinery operators manual to establish the

correct spinner RPM for the product / desired spread width.

1.

From the Spreader Settings screen, select Width .

2. Enter the implement working width. (The width of the area that is

treated during one pass of the implement.)

The Offsets are the dimensions from the GPS receiver location to

where the product is applied, as part of guidance setup. They do not

normally need to be changed.

Page 49

Chapter 3 – Athene Setup

33

3.7. Setting up pre-start

Pre-start is used to start the floor moving when there is no forward

speed. This ensures that there is good coverage at the start of each run,

and that irrespective of how the product has been loaded, the spreader

does not have to start moving until a suitable amount of product has

reached the spinners.

1.

From the Spreader Settings screen, select Pre-Start .

Pre-start mode

AUTO mode: Pre-start is automatically triggered when the spreader is

switched into work. This removes the need to push the button at the

start of each load.

MAN mode: Pre-start is activated manually by pressing on the

main screen.

Default = MAN

Pre-start time

The duration pre-start will run before stopping the floor if there is no

forward speed movement. This should be long enough to ensure that

product is being spread but also so that there is a smooth transition

between pre-start and starting to move forward. An average pre-start

time is 8-10 seconds.

Page 50

3.7. Setting up pre-start

34

Default = 8 sec

3.7.1. Operating pre-start

1.

Engage hydraulics and/or press on the main screen.

Product automatically moves towards spinners.

2. Once the spread pattern is observed, start to drive forward.

Page 51

Chapter 3 – Athene Setup

35

3.8. Setting up boundary reduction

The RPM of a selected spinner can be slowed down (using a hydraulic

diverter valve) to reduce the spread width when traversing the field

boundary.

Note: The boundary should be driven clockwise if the left spinner is

selected and anticlockwise if right spinner is selected.

1. From the Spreader Settings screen, select Spinner Reduction

.

The reduced speed is set as a proportion of the spinner speed. The

reduction must be established by trial and error to establish the desired

spread pattern.

If the Spinner Reduction option is not visible, enable spinner reduction

as follows:

1.

From the Main Menu select Factory / Machine Options.

2. Change Channel Selected to 2 and In Use to ON.

Page 52

3.8. Setting up boundary reduction

36

3.8.1. Operating boundary reduction

1.

Select the boundary reduction icon to activate.

The boundary reduction indicator displays in red below the

spreader image when operating.

The instrument will beep every 15 seconds to remind the operator

that this function is enabled.

Page 53

Chapter 3 – Athene Setup

37

3.9. Setting up products

The system can store 10 different products with customizable names.

1.

From the Spreader Settings screen, select Products .

2. Select the Product button and the left / right arrows to change the

selected product.

3. Select the product name to edit the name.

l Rate: The rate at which the product is applied.

l D Factor: The product density. Take note of the units when

entering this figure.

l Gate Height:The height of the opening that the product passes

through from the belt. The gate height and maximum forward speed

Page 54

3.9. Setting up products

38

are theoretically calculated as a result of the volumetric calibration

routine (see Calibration, page 45), or an approximate gate height

can be entered here if known.

l Flow Factor: This accounts for any product flow inconsistencies

that may come from pelletized (prilled) or low friction products.

It can be established either by carrying out a calibration nudge

after spreading a certain amount of product (see Nudge

calibration, page 52) or by following the check calibration routine

(see Product flow factor – check calibration routine, page 49).

Page 55

Chapter 3 – Athene Setup

39

3.10. Setting up alarms

1.

From the Spreader Settings screen, select Alarms .

2. Select the alarm field to enter the value beyond which the alarm

should sound.

The system can be set to show an alarm in the following conditions:

l RPM Lo / High:Spinners 1 and 2 RPM too slow / too fast.

l Low Level: Hopper level low.

l Beacon Weight: Hopper maximum load (activates a warning

beacon output if maximum weight exceeded). Only applicable if

load cells are fitted.

Note: Alarms are disabled when set to zero.

Page 56

3.11. Setting up forward speed

40

3.11. Setting up forward speed

1.

From the Spreader Settings screen, select General Setup /

Speed Factor.

There are four preset options for the forward speed signal:

l (0): Magnetic sensor (1 pulse per rev)

l (1): Magnetic sensor (2 pulses per rev)

l (2): Radar sensor (0.00778 metres per pulse)

l (3): GPS (NMEA VTG message)

With the exception of option (3), the factors can be manually edited if

required. However if options (0), (1) or (2) are selected, it is

recommended to perform an ‘Autocal’ routine.

3.11.1. SSF Autocal

The Speed Sensor Factor (SSF) is the distance traveled forward in the

time between two pulses from the forward speed sensor. In the case of

magnetic sensor options (1) and (2), this could be calculated based on

the nominal tire diameter or rolling distance and then entered

manually. However this does not take into account wheel slip,

compaction, or tire deformation under practical operating conditions.

1. Mark a set distance of 100 metres by suitable means. The surface

should be representative of the average field conditions (i.e. not a

paved surface).

2. Position the vehicle with the first marker level with a suitable

reference point on the vehicle.

3.

From the Spreader Settings screen, select General Setup /

SSF Auto Cal and then follow the screen instructions.

4. Stop the vehicle when the second marker lines up with the predetermined reference point on the vehicle and press to end the

Auto Cal procedure. The Speed Sensor Factor is automatically recalculated and stored in memory.

Page 57

Chapter 3 – Athene Setup

41

Note: If you overrun the marker, do not reverse - repeat the Auto Cal

procedure from the beginning.

3.11.2. Simulated speed

If the speed sensor is not providing a signal, a simulated speed can be

set to continue operation.

1.

From the Spreader Settings screen, select Simulation Speed

/ Speed Factor.

2. Enter the desired speed and switch the simulation ON.

3.

Press to start the simulation.

Note: Actual forward speed must be matched to the simulated speed as

closely as possible. Otherwise the system will under-apply if you travel

too quickly, or over-apply if you travel too slowly.

Page 58

3.12. Adding product / tare

42

3.12. Adding product / tare

The main screen displays the current weight remaining in the hopper

(a theoretical calculation if volumetric calibration is in effect, or the

actual weight measurement from load cells for dynamic calibration).

The weight setup screen varies, depending on whether the system has

load cells fitted or not (see Load cell configuration, page 29).

3.12.1. With load cells

The hopper contents display refreshes automatically to show the

current weight as product is loaded.

The weight can be tared either when the hopper is empty, or if it

contains a known weight. To maintain correct angle compensation,

only perform the tare with the spreader on level ground.

1.

From the Spreader Settings screen, select Weight Setup /

Tare Calibration.

2. Follow the screen prompts.

3.12.2. Without load cells

1. Refill the hopper with the desired load.

2.

From the Spreader Settings screen, select Weight Setup /

Add Weight / Tare.

l Max: The full hopper weight. Confirm that MAX corresponds to

the hopper maximum capacity, and adjust if necessary. If loading

Page 59

Chapter 3 – Athene Setup

43

the hopper to capacity, then press OK to reset to full.

l Now: The current (theoretical) weight remaining in the hopper.

l To add: The weight required to replenish the hopper (MAX –

NOW). When this weight has been added to the hopper, press OK

to confirm it has been loaded. The TO ADD value is added to the

NOW total, and TO ADD is recalculated.

Page 60

3.12. Adding product / tare

44

Page 61

45

Chapter 4 – Calibration

4.1. Product calibration modes

If using load cells, there are two calibration modes:

l Dynamic: Constant, automatic re-calibration on-the-move.

l Static: Calibration over a set distance. This mode may be useful if

spreading at low application rates or if the product is not flowing

freely. See Static mode calibration, page 53.

To select the calibration mode:

1.

From the Spreader Settings screen, select Weight Setup /

Mode and use the left / right arrows to select the mode.

If the required mode is not available, ensure the software has been

configured for load cells (see Load cell configuration, page 29).

Note: Selecting MAN here is the equivalent to selecting MAN on

the main screen . The floor speed is then manually controlled

using + and – arrows and is not proportional to forward speed.

MAN mode is normally only used for emptying the spreader or

for checking that the valve and encoder are working correctly.

If not using load cells, during operation the product weight shown is

theoretical based on the floor (belt) speed and gate height. To perform

a calibration without load cells, see Performing calibration (with or

without load cells), page 47.

4.1.1. Dynamic mode

The system will normally be operated in Dynamic (DYN) calibration

mode. This method of calibration is particularly suited for products

with more variable density.

The weight of the product is constantly measured by the load cells.

The amount the actual weight has decreased is compared to the

theoretical weight decrease. The calibration factor is then adjusted to

speed up or slow down the floor (belt) speed accordingly. The

Page 62

4.1. Product calibration modes

46

operator should only have to enter the target rate and working width

and all other factors are adjusted in the background to ensure the

correct rate is applied.

As dynamic calibration is constantly self-correcting, the calibration

routine is there to assist in determining the appropriate gate height

and to calculate the forward speed range for applying a new product.

To perform a calibration in Dynamic mode, see Performing

calibration (with or without load cells), page 47.

Page 63

Chapter 4 – Calibration

47

4.2. Performing calibration (with or without

load cells)

This procedure is applicable if not using load cells and to Dynamic

mode if using load cells. See Static mode calibration, page 53 for

calibration in Static mode.

The calibration factor is called the ‘T’ factor. It is the volume of

product dispensed per revolution of the floor belt roller. It is calculated

as: gate height (mm) x gate width (mm) x belt travel per revolution of

the belt roller (mm).

The product density is then used to convert the volume to weight.

1. Select the required product (see Setting up products, page 37).

2.

From the Spreader Settings screen, select Weight Setup /

Calibration.

3. Follow the screen prompts to enter the:

l Required application rate

l Working width

l Density

l Average working speed

Based on the information entered, the software recommends a gate

height setting. This takes account of the minimum and maximum

RPM of the belt roller. The recommended gate height is based on

the roller rotating in the middle of its RPM range, so that it allows

maximum flexibility to forward speed.

Page 64

4.2. Performing calibration (with or without load cells)

48

4. Confirm the recommended gate height or enter a different gate

height if desired.

The operating speed range is displayed based on the above

calculations.

5. If you have not previously done so, select Check Calibration to

determine the 'flow factor' for the product (continue to the next

section). Note: This procedure is only applicable if load cells are

fitted.

Page 65

Chapter 4 – Calibration

49

6. Otherwise select Start Spreading to end the calibration sequence

and return to the main operating screen.

4.2.1. Product flow factor – check calibration routine

The flow factor accounts for any product flow inconsistencies that may

come from pelletized (prilled) or low friction products. To achieve

accuracy across a complete product range, each product should be tested

to enable the system to learn the flow characteristics of that material.

Note: This procedure is applicable if load cells are fitted, in Dynamic

or Static mode.

The flow factor can be established by:

l Following this routine, which involves running the floor for a set

time period, catching and then weighing the product that is

dispensed from the spreader, or

l Carrying out a calibration nudge after spreading a certain amount of

product (see Nudge calibration, page 52).

1.

From the Spreader Settings screen, select Weight Setup /

Calibration.

2. Follow the product calibration procedure through and then select

Check Calibration.

3. Enter the weight of product to be caught and weighed for the test.

Note: If catching the product to be weighed, it is advisable to select

enough product for a minimum of 5 Ha depending upon target rate.

Page 66

4.2. Performing calibration (with or without load cells)

50

The system will run the belt for that much product and can then

be calibrated once this has been weighed. The greater the volume

of product dispensed for calibration, the greater the accuracy.

4.

Press to switch the spreader on.

5.

Press to start the calibration. The belt will start running,

based on the Average Working Speed entered during the

calibration procedure.

The display then counts up the theory weight (the weight the

Athene has calculated based on the calibration factors entered in

step 3), and the live weight (the weight as measured by the load

cells).

The belt will automatically stop when the theory weight is

reached.

6.

Press to switch the spreader off.

7.

Press to continue.

8. If metering out a smaller weight that can be lifted by scales, enter

the weight that has been measured into the weight entry page. For

smaller weights, such as 40 kg, it is advised not to use the live

load cell weight for this calibration.

Page 67

Chapter 4 – Calibration

51

9. If dispensing a large volume of product (1000 kg) back in to a bulk

store, then enter the Live Kg that is shown from the load cells.

Note: To check application rate accuracy, dispense the TOTAL

amount of product that is shown in the hopper.

10.

Press to continue.

The flow factor is recalculated and displayed.

Note: Increasing the flow factor has the effect of slowing the belt

speed compared to the programmed density. Decreasing the flow

factor has the effect of increasing the belt speed compared to the

programmed density.

'Dispensed weight' = 'Theory weight'.

11.

Press to finish the calibration routine.

Page 68

4.3. Nudge calibration

52

4.3. Nudge calibration

Some discrepancy between the target weight and the actual weight

can occur, often due to variations in the actual density of the product

from the theoretical density programmed. The calibration factor can

be fine tuned to account for any discrepancy.

1.

From the Spreader Setting screen, select Weight Setup /

Nudge Calibration.

2.

Enter the Target Weight then press enter .

3.

Enter the Actual Weight applied and press enter again. The

% error is calculated and displayed.

4.

Press enter to make the correction.

Page 69

Chapter 4 – Calibration

53

4.4. Static mode calibration

The calibration factor is calculated by doing a 'Static Test' routine. This

factor remains the same throughout subsequent spreading until either

manually adjusted, or another static test is done. Static calibration

assumes that the product density will be consistent, therefore results

may not be as accurate as with dynamic calibration.

To perform a calibration in Static mode:

1.

From the Spreader Settings screen, select Weight Setup /

Static Test.

2.

While stationary, press enter to start the test.

The weight in the hopper is measured. The system then calculates

the distance that must be driven, based on application rate and

spread width set, until the hopper weight decreases to a pre-set

threshold.

3. Start spreading until prompted to stop.

4.

Press enter to measure the weight and calculate the new

calibration factor, which is then displayed.

5.

Press enter to confirm, and then ESC to return to the Main

menu.

Page 70

4.5. Valve calibration

54

4.5. Valve calibration

This procedure sets the minimum and maximum PWMto move the

spreader belt.

1.

From the Main Menu select Factory / Channels / Valve

Setup. The Belt Valve Setup screen summarizes the current valve

settings.

2. Select Valve Auto Cal, set the engine to normal operating rpm

and press to start the calibration procedure.

3. With Min Duty selected, by observing the Live Feedback rpm

value, adjust the belt until it is on the threshold of moving.

4.

Press to set the minimum PWM output.

Page 71

Chapter 4 – Calibration

55

5. With Max Duty selected, increase the belt speed to the maximum it

can go.

6.

Press to set the maximum PWM output.

The Belt Valve Setup screen displays a summary of the new

settings.

Page 72

4.5. Valve calibration

56

Page 73

57

Chapter 5 – Operation

5.1. Opening auto section control

Auto section control is available when an implement and ECU have

been set up and Auto Section Control has been enabled in the Setup

screen (System / Features / Implement ).

1.

Select Auto Section Control . The Auto Section Control

mini-view opens.

l Control mode: Use the slider or number keypad to set to avoid

overlap (0) or avoid gaps (100). If avoid overlap is chosen, there

may be some spaces where product is not applied. If avoid gaps is

Page 74

5.1. Opening auto section control

58

chosen, some overlap of application is likely near boundaries. The

default (50) is a compromise.

l Boundary limit: Sets which type of boundary limit will turn off

spraying when using auto section control.

Field Boundary and Headland are defined using the Field menu

on the Operation screen. Refer to the Guidance and Auto Steering

Operator Manual for more information on these.

Safety Zone reduces width of spreading by half a swath width

from the boundary to prevent over application.

l ASC on/off: Turn auto section control on/off.

Page 75

Chapter 5 – Operation

59

5.2. Using the master switch

When Virtual has been selected in the Setup screen (Implement /

Master Switch), the Spreader Master Switch on the Operation screen

turns the spreader system on. This switch does not work if External

ECU Sense is selected as the Master Switch.

The switch also indicates the readiness of the system:

Green

Spreader Controller is on and working. Select the master

switch to turn the spreader off.

White

Spreader Controller is ready to use. Select the master switch

to turn the spreader on.

Red

Spreader Controller is off and cannot be used. Select the

Master Switch to see possible causes of the problem. See the

example below.

Green indicates that the system is ready. Red indicates that the system is

not ready.Select to return to the main screen and complete the

necessary action.

The alarm bell button shows the number of active alarms.

Page 76

5.3. Variable rate control

60

5.3. Variable rate control

Before use, Variable Rate Control (VRC) must be set up with a

controller and must be enabled on the Setup screen (System /

Features / Implement ).

Select to enable or disable the VRC Map display on the

guidance screen.

5.3.1. If using VRC maps

There are three ways to perform VRC:

l Importing prescription maps (shapefiles and ISO XML files) into

created jobs using the VRC import wizard.

l Using real-time sensor data from nitrogen sensors mounted on the

tractor (for example: Topcon CropSpec).

l Using Task Data based prescription maps.

The following instructions describe the first two methods. If using

task data, refer to AGA4084 Guidance Manual.

Both shapefiles (.shp) and ISO XML files (.xml) may be imported

into created jobs. Note that only the prescription map portion of the

data is used if .xml files are imported.

1. Select a client / farm / field.

2. Create a new job.

3.

Select Job Menu / Configure Variable Rate Control

.

4. Select next at step 1 of the VRC Configuration wizard.

5. Select the rate source(s) for the VRC and select next. The possible

options are:

Page 77

Chapter 5 – Operation

61

l Shapefiles

l ISOXML

l CropSpec (if enabled)

Note that shapefiles and ISO XML cannot be used at the same time.

However CropSpec can be used in conjunction with shapefiles or

ISO XML

If Shapefiles or ISO XML are selected at step 2, all maps

previously imported to the current field are displayed so that

previously used maps can be recalled.

l If the desired maps are not already on the console, insert a USB

with prescription maps.

l

Select the USB icon at base of the screen . The window

background turns blue to indicate you are viewing the USB file

list.

l

Select the USB home icon to view the root of the USB file

structure. Files and folders on the USB root are displayed.

l Select a folder to open it. Find the required file and select it. It

will display as white and next is now enabled. Note that multiple

files may be selected.

Page 78

5.3. Variable rate control

62

l Select next.

6. If ISOXML was selected in step 2, select the task that you wish

to run. The file may have several tasks listed. Select the task that

matches the implement that is hooked up.

7. Select next.

Source and Attributes must now be assigned to channels.

l Channel: The tank or bin that is being controlled.

l Source: The source of the prescription map for that channel.

The list of files that were selected earlier on will appear here or

you can also select a live source like CropSpec or Yara.

l Attribute: One of the properties in the shape file or ISOXML

file or the sensor output from CropSpec. The same shape file

may have multiple attributes to define the rates for more than

one tank so this allows the operator to map the prescription to

the appropriate tank.

l Rescale: This column defaults to 1, which means that the

prescription defined in the source will be used directly.

However, depending on weather conditions, the operator may

choose to increase or decrease the rate of application. This

allows a uniform increase for all defined rates. For example, a

Page 79

Chapter 5 – Operation

63

rescale of 1.1 will apply 110 percent of the rate defined in the

source.

l Default: Defines the rate to use if the source doesn’t specify a rate

for that region of the paddock.

8. Select next.

9. On the final step, you must confirm the setup. This cannot be

changed for the job, so ensure it is correct before continuing. Select

Back to change the configuration or OK to confirm.

The map is displayed. If it does not display, ensure you are in close

proximity geographically to the map’s location.

Page 80

5.3. Variable rate control

64

Page 81

65

Chapter 6 – Updating Athene Software

1. Copy the folder named 'Apollo' onto the root directory of a USB

memory stick, and insert at the rear of the console.

2.

From the Main Menu select Factory / Software Info &

Reset and confirm.

ECU Object Pool and ECU Program Code show the version of

software that is currently installed. The new software number that

is found on the USB stick is shown at the top of the screen. In

this case CMS600-000rev83.

3. Press the top part of the display to display a drop-down menu

showing a list of software versions found on the USB. Ordinarily

there will only be one valid software version –

CMS600000revxx.

4.

Press to select.

5. Press the Update Software button to save the current settings to

the USB.

Once this has finished it will move onto ‘Loading Software',

followed by 'Loading Object Pool'.

6. Once this process has finished, the screen will appear white.

Without removing the USB, switch the console off and back on

Page 82

66

to trigger the new software to be reset.

7. When the console has restarted and the Athene UT screen is

available, select the Load Factors button to restore the previous

settings from the USB.

8. When ‘Loading Factors’ is complete, switch the console off and

back on for the restored settings to take effect.

Page 83

67

Chapter 7 – Index

alarms 39

angle sensor 29

ASC 57

auto section control 57

boundary reduction 35

calibration

check 49

modes 45

nudge 52

performing 47

valve 54

diagnostics menu 25

dynamic mode 45

forward speed 40

geometry 9

ground speed 13

implement

new 7

implement geometry 9

load cell

calibration 30

configure 29

main screen 18

master switch 13

using 59

nudge 52

operation screen 15

pre-start 33

product

adding 42

calibration 45

setup 37

section control 11

settings screen 23

setup screen 15

simulated speed 41

software update 65

speed factor 40

spinner reduction 35

SSF Autocal 40

static mode 53

tare 42

technician menu 24

totals screen 27

units setup 28

update software 65

valve calibration 54

variable rate control 60

VRC 60

working width 32

Page 84

68

Page 85

Page 86

Topcon Precision Agriculture

16900 West 118th Terrace

Olathe, KS 66061 USA

Phone: 866-486-7266

Topcon Positioning Systems, Inc.

7400 National Drive

Livermore CA 94551 USA

Phone: 925-245-8300

Fax: 925-245-8599

Topcon Precision Agriculture

14 Park Way

Mawson Lakes SA 5095 Australia

Phone: +61-8-8203-3300

Fax : +61-8-8203-3399

Topcon Precision Agriculture Europe

Avenida de la Industria 35

Tres Cantos 28760, Spain

Phone: +34-91-804-92-31

Fax: +34-91-803-14-15

Topcon Corporation

75-1 Hasunuma-cho, Itabashi-ku

Tokyo 174-8580 Japan

Phone: +81-3-5994-0671

Fax: +81-3-5994-0672

© 2016 Topcon Precision Agriculture All rights reserved

Specifications subject to change without notice

Loading...

Loading...