Page 1

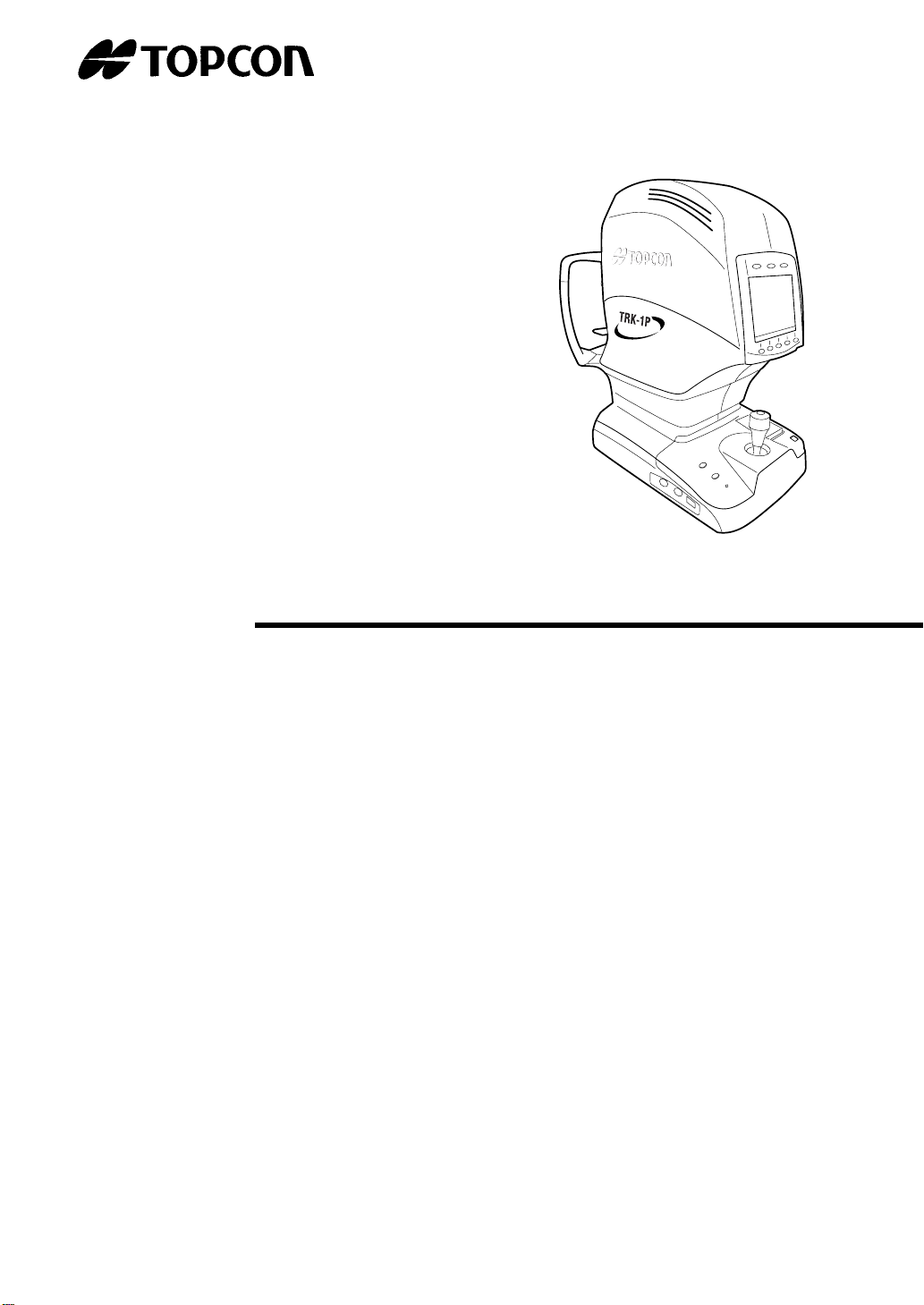

INSTRUCTION MANUAL

AUTO KERATO-REFRACTO-TONOMETER

TRK-1P

Page 2

INTRODUCTION

Thank you for purchasing the TOPCON Auto Kerato-refracto-tonometer TRK-1P.

This instrument has the following features:

• Exact measurement of refraction power, corneal curvature, intraocular pressure and

central corneal thickness by simple operations

• Softer air blow in measuring intraocular pressure

•

Auto alignment and auto start functions enabling quick measurement under best conditions

This text outlines the Auto Kerato-refracto-tonometer TRK-1P and describes basic operations, troubleshooting, checking, maintenance and cleaning.

To encourage the safe, efficient use of this instrument, carefully read "Displays for Safe

Use" and "Safety Precautions."

Also, keep this Instruction Manual in a convenient location for your future reference.

PRECAUTIONS

• This is a precision instrument, install/store it in a place with the following conditio ns: temperature (10 to 40

direct exposure to sunlight.

• To ensure smooth operation, install the in strument on a leveled st and free of vibrations. Also , do

not place any objects on the instrument.

• Before using the instrument, connect all cables correctly.

• Use the specified source voltage.

• When not in use, turn off the power and put the measuring win d ow lens ca p an d du st cove r on .

• To ensure the correct reading, do not mar the measuring window with finger prints, dust, etc.

Also, do not touch the measuring nozzle except during cleaning.

°C), humidity (30 to 75%) and atmospheric pressure (700 to 1060hPa). Avoid

[WARNING]

When operating the instrument, be not touch the patient's eye or nose.

[WARNING]

To prevent corneal damage, do not measure a patient with corneal disease or corneal surgery.

To prevent corneal damage, do not measure a patient's wearing a contact lens.

This symbol is applicable for EU member countries only.

To avoid potential negative consequences for the environment and possibly human

health, this instrument should be disposed of (i) for EU member countries - in

accordance with WEEE (Directive on Waste Electrical and Electronic Equipment),

or (ii) for all other countries, in accordance with local disposal and recycling laws.

1

Page 3

CAUTIONS ON USE

BASIC NOTES

Do not open the cover. For repair, ask our service engineer (to avoid electric shocks).

Keep the instrument in a dry place.

Do not open the cover. For repair, contact your authorized Topcon distributor.

When changing the fuse, turn off the power, and disconnect the power cable. Use the rated

fuse.

DISPOSAL

When disposing of the instrument, observe ordinances of the jurisdiction on disposal and

recycling.

WORKING ENVIRONMENT

Temperature: 10 to 40°C

Humidity: 30 to 75% (no dewing)

Atmospheric pressure:700 to 1060hPa

STORAGE, USAGE PERIOD AND OTHERS

1. INSTALLATION CONDITIONS (WITHOUT PACKAGE)

Temperature: 10 to 40°C

Humidity: 30 to 75% (no dewing)

Atmospheric pressure:700 to 1060hPa

2. STORAGE CONDITIONS

(1) Keep the instrument in a dry place free of dust, salt, sulfur, chemicals or gases.

(2) Keep the instrument in a place free of the effects of atmospheric pressure, temperature,

moisture, draft, sunshine, dust, salt and sulfur.

(3) Avoid storing the instrument on inclined surfaces and avoid shock and vibrations during

transport.

(4) Avoid places storing chemicals and generating gases.

3. NORMAL LIFE SPAN OF THE INSTRUMENT

Eight (8) years from delivery providing regular maintenance is performed (TOPCON data)

TRANSPORT AND STORAGE CONDITIONS (with package)

Temperature: -20°C to 50°C

Humidity: 10 to 95%

MAINTENANCE AND CHECKS

1.Regularly maintain and check the equipment and parts.

2.When resuming the use after a long storage time, verify that the instrument operates correctly and safely.

3.To ensure the correct reading, do not mar the measuring window with finger prints, dust,

etc.

4. If the measuring window is soiled, clean it following the "CLEANING THE MEASURING

WINDOW GLASS" instructions on page 156.

2

Page 4

DISPLAYS FOR SAFE USE

In order to encourage the safe use of the machine and prevent any danger to the operator and

others or damage to properties, important warnings are placed on the product and inserted in the

instruction manual.

We suggest that everyone understand the meaning of the following displays and icons before

reading the "Safety Precautions" and the main text.

DISPLAY MEANING

Ignoring or disregarding this display may lead to

WARNING

CAUTION

• Injury refers to cuts, bruises, sprains, fractures, burn, electric shock, etc.

• Physical damage refers to extensive damage to buildings or equipment and furniture.

ICON MEANING

death or serious injury.

Ignoring or disregarding this display may lead to

personal injury or physical damage.

This icon indicates Prohibition.

Specific content is expressed with words and/or an

illustration near the icon.

This indicates Mandatory Action.

Specific content is expressed with words and/or an

illustration near the icon.

This indicates Caution.

Specific content is expressed with words and/or an

illustration near the icon.

3

Page 5

SAFETY PRECAUTIONS

WARNING

Icon Description Page

To prevent corneal damage, do not measure a patient with corneal

disease or corneal surgery.

To prevent corneal damage, do not m easure a patient's wearing a

contact lens.

Tell the patient to remove the contact lens.

Do not open the cover. For repair, contact your authorized Topcon

distributor.

Keep the instrument in a dry place.

To avoid fire and electric shocks, keep the instrument in a dry

place.

To avoid fire and electric shocks in case of tumbling, do not place a

cup or vessel containing water/fluid near the instrument.

To avoid electric shocks, do not insert metal objects into the instrument body through the vent holes or gaps.

When changing the fuse, turn off the power, and disconnect the

power cord. Use the rated fuse.

To av oid fire and electric shocks by short circuiting, be sure to connect the instrument into a grounded outlet.

—

113

8

162

—

—

—

8

160

34

In case an abnormal condition such as smoke occurs, immediately

switch OFF the power and unplug the power cable. Contact your

dealer for repair.

WARNING : Handling the cord on this product or cords associated with accessories sold with

this product, will expose you to lead, a chemical known to the State of California to cause birth

detects or other reproductive harm. Wash hands after handling

This Product Contains Mercury in the backlighting of the LCD display. Prior to disposal remove

of otherwise ensure that this is dispose d of in accordance with Lo cal, State and Federal Laws.

This information is applicable in U.S.A only.

This Product Contains a CR Lithium Battery which contains Perchlorate Material-special handling may apply.

See http://www.dt s c.ca.gov/hazardouswaste/perchlorate/

Note; This is applicable to California. U.S.A only.

—

4

Page 6

CAUTION

Icon Description Page

8

To avoid injury in changing the measurement mode, do not place

fingers into the measuring opening.

* Inform the patient accordingly

90

96

109

To avoid injury, when moving the chinrest up/down, keep fingers

away from moving parts.

To avoid injury, do not install the instrument on a slope or on an

unstable place.

To avoid electrical shock, do not handle the power plug with wet fingers.

To avoid failure or potential injury, do not open the printer cover

while the printer is in operation.

To avoid potential injury in case of malfunction, including a paper

jam, be sure to shut off the power before attempting to repair it.

Never insert your fingers under the chinrest.

* Inform the patient of this, too.

Careless insertion of fingers may cause injury by pinching.

Do not use or apply any spray-type cleaner near the instrument.

If the cleaner remains inside the measuring nozzle, the patient's

eye may be injured during measurement.

8

33

34

86

159

86

159

98

113

161

When operating the instrument, be careful not to touch the p atient' s

eye or nose.

When moving the instrument, be sure to hold it at the base with two

persons. Carrying by one person may cause harm to his back or

injury by falling parts. Also, holding areas other than the base may

cause injury, as well as damage to the instrument.

8

33

5

Page 7

CAUTION

Icon Description Page

When setting an instrument on an instrument table, pay attention

not to injure the patient's fingers between the instrument and the

table.

33

To avoid potential injury, do not touch the printer body while the

printer is in operation or when replacing the printer paper.

Before starting measurement, be sure to confirm the measuring

screen (to avoid making the ocular pressure measurement to the

patient's eye wearing a contact lens.)

Before measuring, check if there is any foreign matter on and

around the measuring nozzle.

If any, it may enter and damage the patient's eye during the measurement.

Before measuring, set the safety stop to prevent the measuring

window glass from hitting the patient's eye.

Set it respectively for the right and left eyes.

Set the safety stop from the side face of the instrument.

Setting operations from other positions, where checking of the eye

position is not easy, may cause injury.

Clean the measuring window glas s, meas ur ing nozz le and the w indow glass inside the measuring nozzle using ethanol.

Other chemicals may cause damage to the patient's eye during

measurement.

86

159

101

106

119

126

110

114

114

156

157

6

This instrument has been tested (with 100/120/230V) and found to

comply with IEC60601-1-2: Ed.2.1: 2004.

This instrument may emit a radio frequency energy (within the standard) and cause an adverse effect on the devices located nearby.

When such effect is confirmed by the ON/OFF operation, a proper

treatment as to change the direction, use another outlet, etc. is recommended. If the problem remains unsolv ed , call yo ur deal er.

—

Page 8

USAGE AND MAINTENANCE

PURPOSE

This Auto kerato-refracto-tonometer "TRK-1P" is a precision electrical instrument for

medical use which must be used under instructions of a doctor.

USER MAINTENANCE

To maintain the safety and performance of the instrument, never attempt to do maintenance

on your own. Ask our service engineer for repair except for the items specified here which can

be maintained by the user. For details, follow the instructions.

CHANGING THE FUSE

The primary fuses for the main body may be changed by a non-trained service techn ician.

For details, refer to "REPLACING THE FUSE" on page 160.

CLEANING THE MEASURING WINDOW

The measuring window glass may be cleaned. For details, refer to "CLEANING THE MEASURING WINDOW GLASS" on page 156.

CLEANING THE MEASURING NOZZLE AND WINDOW INSIDE THE MEASURING NOZZLE

Regarding the measuring nozzle and the window glass surface inside the measuring nozzle,

cleaning is allowed.

For detail see "CLEANING THE NOZZLE AND CHAMBER GLASS INSIDE THE MEASURING NOZZLE"on page 157.

ESCAPE CLAUSE

• TOPCON shall not take any responsibility for damage due to fire, earthquakes, actions by a

third party or other accidents, or the negligence and misuse of the user and use under

unusual conditions.

• TOPCON shall not take any responsibility for damage derived from inability to use this

equipment, such as loss of business profits and suspension of business.

• TOPCON shall not take any responsibility for damage caused by operations other than

those described in this Instruction Manual.

• Diagnosis shall be made on the responsibility of the doctors, and TOPCON shall not take

any responsibility for the result of such diagnosis.

7

Page 9

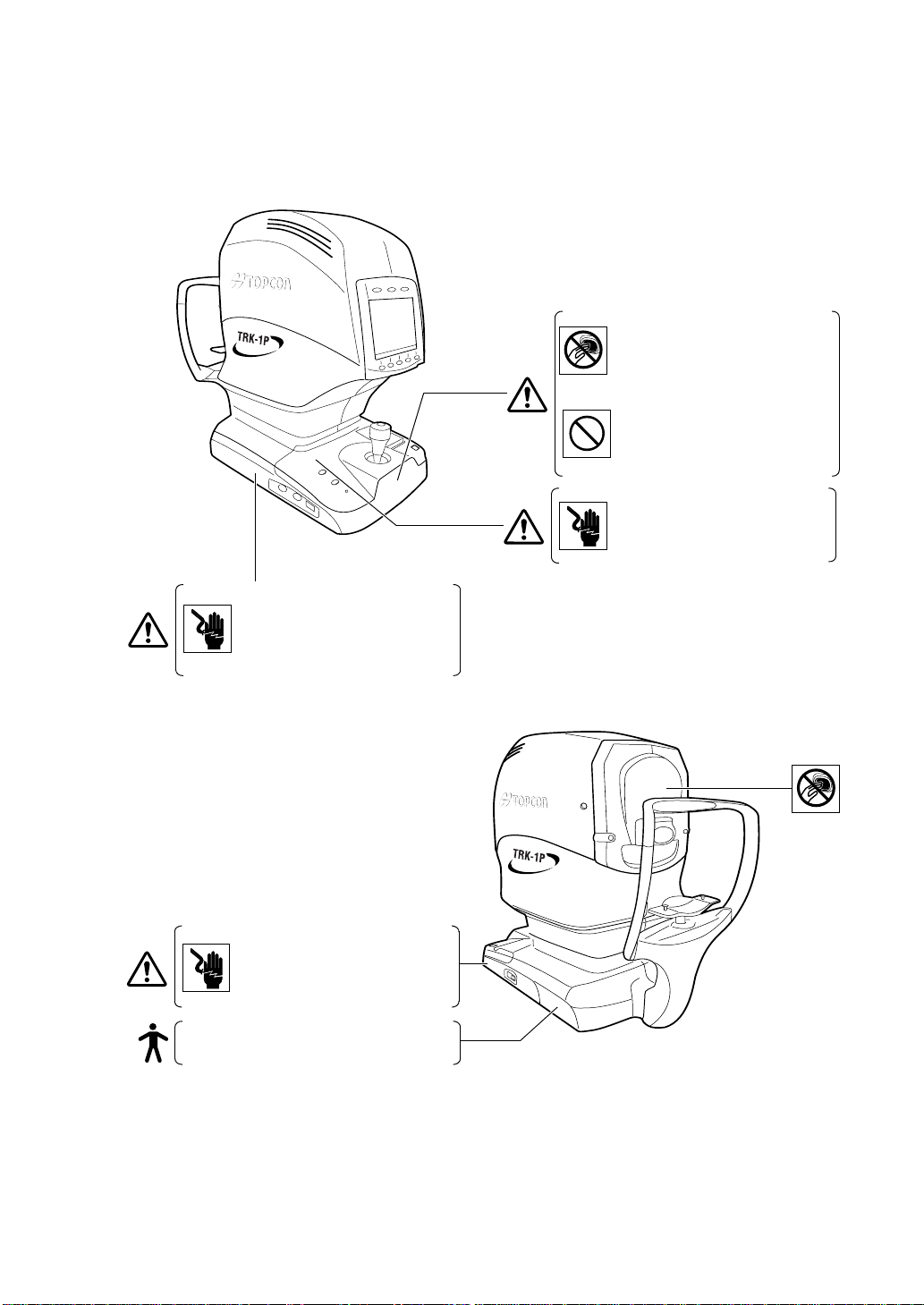

WARNING INDICATIONS AND POSITIONS

To ensure the safety, this machine provides warning displays.

Use the instrument correctly by observing the display instructions. If any of the following display labels are missing, contact your TOPCON dealer at the address listed on the back cover.

• Do not open the cover. For repair,

WAR NI NG

contact your authorized Topcon distributor.

Keep the instrument in a dry place.

• T o avoid inju ry in chang ing the mea surement mode, do not place fingers into the measuring opening.

* Inform the patient accordingly.

• When operating the instrument, be

careful not to touch the patient's eye

or nose.

CAUTION

• To avoid injury, when moving the

chinrest up/down, keep fingers away

from moving parts.

CAUTION

8

• When changing the fuse, turn off the

WARNING

power, and disconect the power

cord. Use the rated fuse.

Degree of protection against electric shock:

TYPE B EQUIPMENT

Page 10

CONTENT

INTRODUCTION ...................................................................................................1

DISPLAYS FOR SAFE USE..................................................................................3

SAFETY PRECAUTIONS......................................................................................4

USAGE AND MAINTENANCE ..............................................................................7

ESCAPE CLAUSE.................................................................................................7

WARNING INDICATIONS AND POSITIONS ........................................................8

COMPONENTS

COMPONENT NAMES.......... ... ... ... .... .................................................................12

COMPOSITION OF PARTS WHICH CONTACT THE HUMAN BODY........ ...... .12

CONTROL PANEL COMPONENTS (REF/KRT MODE).....................................13

CONTROL PANEL COMPONENTS (TONO/PACHO MODE) ............................16

MONITOR SCREEN COMPONENTS (REF/KRT MODE) ..................................19

MONITOR SCREEN COMPONENTS (TONO/PACHO MODE)..........................22

OTHER SCREEN DISPLAYS..............................................................................25

PRINTER OUTPUT .............................................................................................27

STANDARD ACCESSORIES....................................................... .......................32

PREPARATIONS

INSTALLING THE INSTRUMENT.......................................................................33

CONNECTING THE POWER CABLE...... ... ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... .......34

CONNECTING EXTERNAL I/O TERMINALS .....................................................35

FUNCTION SETTINGS BY MEANS OF MENU.......................................................36

LIST OF MENUS................................ ... ... ... ... .... ... ... ...........................................36

INITIAL SETTING.............. .... ... ...........................................................................38

PREPARATION FOR INITIAL SETTING ......................................................38

RETURNING TO THE MEASUREMENT SCREEN......................................38

INITIAL SETTING..........................................................................................39

SETTING PRINTOUT....................................................................................49

ON-LINE SETTING (DATA COMMUNITATION)...........................................61

MENU SETTING..................................................................................................67

PREPARATION FOR MENU SETTING........................................................67

DISPLAYING THE MENU SCREEN .............................................................67

RETURNING TO THE MEASUREMENT SCREEN......................................68

MENU SCREEN UNDER FULLY AUTOMATIC MEASUREMENT MODE... 68

SETTING MENU (R/K)..................................................................................69

SEETING MENU (T/P) ..................................................................................81

SETTING THE PRINTER PAPER.......................................................................86

RESETTING FROM POWER SAVE STATUS ....................................................88

OPERATING THE CONTROL LEVER................................................................88

9

Page 11

BASIC OPERATIONS

CHANGING THE MEASUREMENT MODE .............................................................90

MEASUREMENT MODE............. ... .... ... ... ... ... .... .................................................90

TYPE OF MEASUREMENT TO BE DONE UNDER REF/KRT

MEASUREMENT MODE............. ... .... ... ... ... ... .... .................................................92

TYPE OF MEASUREMENT TO BE DONE UNDER TONO/PACHO

MEASUREMENT MODE............. ... .... ... ... ... ... .... .................................................93

CHOOSING THE EYE TO BE MEASURED........................................................94

WHEN MEASURING THE REFRACTORY POWER AND CORNEAL

CURVATURE RADIUS OF THE EYE.......................................................................96

PREPARATION BEFORE MEASUREMENT (REF/KRT MODE) . .......................96

TURN ON THE POWER ...............................................................................96

POSITIONING THE PATIENT............................................................ .... .......98

ADJUSTING MONITOR'S ANGLE................................................................99

MEASUREMENT UNDER AUTO MODE (REF/KRT MODE)............................100

MEASUREMENT UNDER MANUAL MODE (REF/KRT MODE).......................105

DISPLAYING MEASUREMENT VALUES (REF/KRT MODE) ..........................107

DELETING MEASUREMENT VALUES (REF/KRT MODE)..............................108

WHEN MEASURING THE OCULAR PRESSURE AND CORNEA

THICKNESS OF THE EYE.....................................................................................109

PREPARATIONS BEFORE MEASUREMENT (TONO/PACHO MODE) ..........109

TURN ON THE POWER .............................................................................109

CHECKING THE MEASURING NOZZLE ...................................................110

AIR CHECK.................................................................................................111

POSITIONING THE PATIENT............................................................ .... .....113

ADJUSTING MONITOR'S ANGLE..............................................................114

SETTING THE SAFETY STOP...................................................................114

MEASUREMENT UNDER AUTO MODE (TONO/PACHO MODE)...................117

MEASUREMENT UNDER MANUAL MODE (TONO/PACHO MODE)..............124

MEASURING THE CORNEA THICKNESS (TONO/PACHO MODE) ...............130

DISPLAYING MEASUREMENT VALUES (TONO/PACHO MODE)... ...... .... ... ..131

DELETING MEASUREMENT VALUES (TONO/PACHO MODE) .....................132

IN A CASE LIKE THIS ...........................................................................................133

TO STOP MEASUREMENT..............................................................................133

TO MEASURE THE RIGHT/LEFT EYE ONLY..................................................134

THE LIMIT ICON APPEARS AND THE MEASUREMENT IS NOT POSSIBLE

THE NOZZLE LIMIT APPEARS AND THE MEASUREMENT IS NOT POSSIBLE

ALIGNMENT DOES NOT START .....................................................................138

......136

....137

10

Page 12

INDIVIDUAL OPERATIONS

CHANGING THE NUMBER OF MEASUREMENTS .........................................141

DISPLAYING ALL MEASUREMENT DATA ......................................................142

PRINTING MEASUREMENT VALUES .............................................................146

MEASURING THE CORNEA DIAMETER.........................................................148

MEASURING THE HARD CONTACT LENS.....................................................154

INPUT/OUTPUT USING RS-232C.................................................................. ..155

MAINTENANCE AND CHECKING

DAILY MEAINTENANCE...................................................................................156

CHECKING THE MEASURING ACCURACY..............................................156

CLEANING THE INSTRUMENT .................................................................156

CLEANING THE MEASURING WINDOW GLASS......................................156

CLEANING THE NOZZLE AND CHAMBER GLASS INSIDE

THE MEASURING NOZZLE ..................................................... ... ... ............157

ADJUSTING THE MONITOR SCREEN......................................................158

PRINTER PAPER JAM ...............................................................................159

REPLACING THE FUSE.............................................................................160

SPECIAL NOTE OF CLEANING.......................................................................161

CLEANING THE OUTER COVER AND MONITOR SCREEN ....................161

CLEANING THE COMPONENTS TOUCHING THE PATIENT...................161

ITEMS OF SPECIALIST MAINTENANCE...................................................161

BEFORE REQUESTING SERVICE

AIR CHECK.................................... ...................................................................162

CHECKING OPERATIONS ...............................................................................162

REFERENCES

MESSAGE LIST ................................................................................................163

OPTIONAL ACCESSORIES..............................................................................164

ORDERING CONSUMABLE SUPPLIES .. ... ... .... ... ... ... .... ... ... ... .... .....................165

SHAPE OF PLUG..............................................................................................165

RS232C COMMUNICATION SPECIFICATIONS..............................................167

SPECIFICATIONS

SPECIFICATION AND PERFORMANCE..........................................................168

DIMENSIONS AND WEIGHT............................................................................169

INTENDED USE................................................................................................169

OPERATION PRINCIPLES ...............................................................................169

ELECTRIC RATING .............................................................. ... .... ... ..................169

ELECTROMAGNETIC COMPATIBILITY ..........................................................170

EQUIPMENT CLASSIFICATION.......................................................................174

DISPOSAL OF PRODUCT................................................................................174

11

Page 13

COMPONENTS

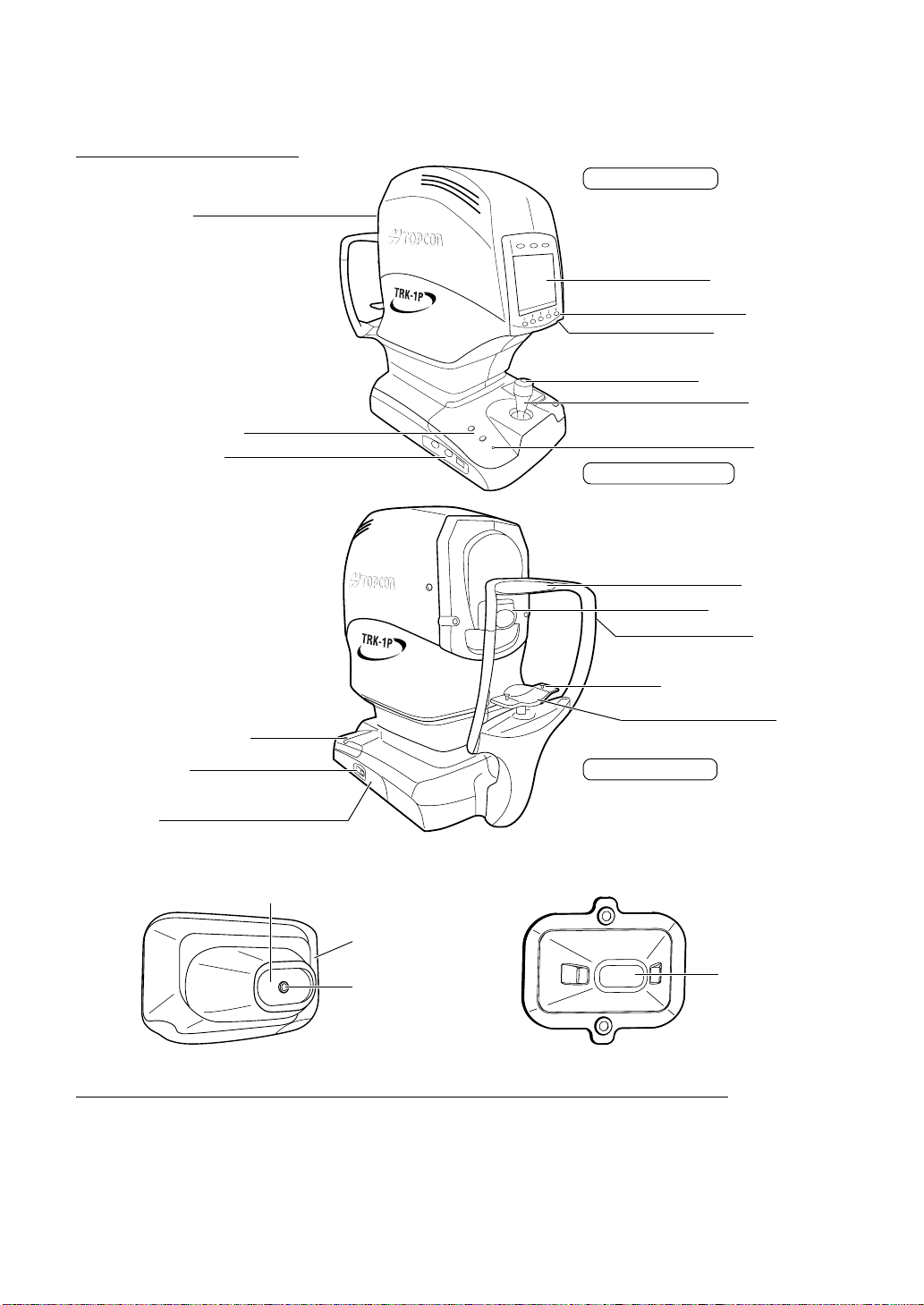

COMPONENT NAMES

Measuring head

Main body Section

Color LCD monitor

Control panel

Brightness control

Measurement switch

Control lever

Chinrest up/down button

External I/O terminal

Printer cover open button

POWER switch

Inlet cover

Measuring window at TONO/PACHO mode

Measuring window

Measuring opening

Power lamp

Power supply Section

Forehead rest

Measuring opening

Height mark

Chinrest tissue stopper pin

Chinrest

Chinrest Section

Measuring nozzle

COMPOSITION OF PARTS WHICH CONTACT THE HUMAN BODY

Forehead rest : Silicone rubber

Chinrest : Acrylonitrile butadiene styrene resin

12

COMPONENTS

Measuring window

lens cap

Page 14

CONTROL PANEL COMPONENTS (REF/KRT MODE)

(1) R/L (2) Mode (3) Print

R/K

(4) Function button

(1) R/L button: Switches between right and left eyes. Sets continuous measurement

of both eyes, measurement of the right eye only and measurement of

the left eye only.

(2) Mode button: Switches between REF/KRT mode and TONO/PACHO mode.

The Mode is selected:

Fully automatic measurement mode (REF/KRT mode changes to

TONO/PACHO mode continuously), REF/KRT mode and TONO/

PACHO mode.

Turns on in orange under REF/KRT mode and in greenish-blue

under TONO/PACHO mode.

(3) Print button: Prints out measurement results. When there is no measurement

value, this feeds printer paper by continuous pressing.

When the result is stored, the switch green.

(4) Function button: Sets functions under REF/KRT mode.

Functions are displayed as PAGES (PAGE 1, PAGE 2, PAGE 3) on

the screen.

13

COMPONENTS

Page 15

PAGE 1

After turning power on, the initial status of PAGE is as follows.

(6) Alignment button (8) IOL button

(5) Measurement mode button (7) Target image button (9) PAGE selecting button

(5) Measurement mode button:

Switches between measurement modes of REF/KRT mode. Pressing the Function button enables you to select R/K (REF/KRT continu ous measurement), REF (REF measurement) or KRT (KRT

measurement).

: REF/KRT continuous measurement

: REF measurement

: KRT measurement

(6) Alignment button: Switches between auto measurement and manual measurement.

: Auto measurement

: Manual measurement

(7) Target image button: Allows observation of the saved image on the monitor screen.

During the REF/KRT continuous measurement (R/K mode), you can

observe the target image by switching between REF and KRT

modes.

On the TARGET IMAGE DISPLAY screen, press th e

MEASUREMENT MODE button

ment, pressing the will change the right/left data.

To return to the MEASUREMENT screen, press the

MEASUREMENT switch

.

(8) IOL button: When errors are frequent in measuring an IOL-inser ted eye, pressing

the button may allow the measurement.

R/L button

. During the right/left measure-

(9) PAGE selecting button:

14

COMPONENTS

: Turned ON when errors are frequent.

IOL mark is displayed on the measuring screen if "ON" is

selected. (See page 19)

: Turned OFF during a normal measurement.

Changes the PAGE screen to another.

Page 16

PAGE 2

PAGE selecting button

If the is pressed on PAGE 1, the status of PAGE changes as follows.

If the button is pressed again, PAGE 3 is changed.

(11) Cornea diameter button (13) R/K menu button

(10) Fixation target button (12) Clear button (14) PAGE selecting button

(10) Fixation target button:

Varies the brightness of fixation target.

: Darkens the fixation target.

: The brightness of fixation target to normal.

When Hi is selected, the fixation lamp mark appears on

the MEASUREMENT screen. (See page 19)

(1 1) Cornea diameter button:Used to measure the cornea diameter.

The measurement can be made by using actual image or static

image, and the status of button icon changes accordingly.

: Measuring actual image

: Measuring static image

For setting of the actual and static image, refer to "CHANGING THE

METHOD OF CORNEA DIAMETER MEASUREMENT" on page 44.

For measuring details, refer to "MEASURING THE CORNEA DIAMETER" on page 148.

This icon is not displayed in REF (REF single measurement).

(12) Clear button: Deletes measurement data.

(13) R/K menu button: Displays the MENU screen of REF/KRT mode.

(See "SETTING MENU (R/K)" on page 69)

(14) PAGE selecting button:Changes the PAGE screen to another.

PAGE 3

PAGE selecting button

If the is pressed on PAGE 2, the status of PAGE changes as follows.

If the button is pressed again, PAGE 1 is returned.

(15) All data button (16) Page selecting button

(15) All data button: Displays all measurement data on the screen. (See page 142)

(16) PAGE selecting button:

Changes the PAGE screen to another.

15

COMPONENTS

Page 17

CONTROL PANEL COMPONENTS (TONO/PACHO MODE)

(1) R/L (2) Mode (3) Print

(4) Function button

(1) R/L button: Switches between the righ t and left eyes. Sets continuou s measure-

ment of both eyes, measurement of the right eye only and measure-

ment of the left eye only.

(2) Mode button: Switches between REF/KRT mode and TONO/PACHO mode.

The Mode is selected:

Fully automatic measurement mode (REF/KRT mode changes to

TONO/PACHO mode continuously), REF/KRT mode and TONO/

PACHO mode.

Turns on in orange under REF/KRT mode and in greenish-blue

under TONO/PACHO mode.

(3) Print button: Prints out measurement results. When there is no measurement

value, this feeds printer paper by continuous pressing.

When the result is stored, the switch green.

(4) Function button: Sets functions under TONO/PACHO mode.

Functions are displayed as PAGES (PAGE 1, PAGE 2, PAGE 3) on

the screen.

16

COMPONENTS

Page 18

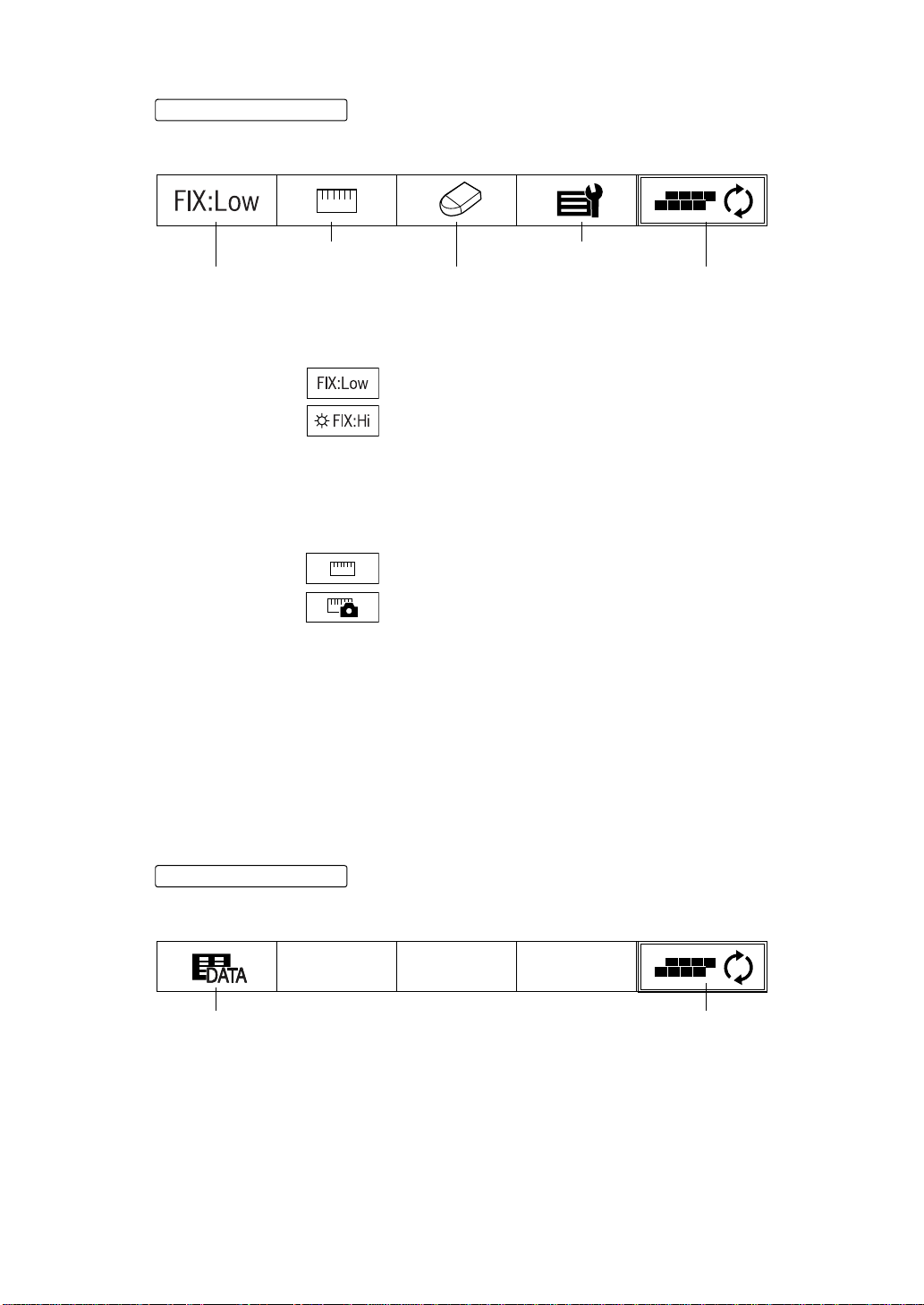

PAGE 1

After turning power on, the initial status of PAGE is as follows.

(6) Alignment button (8) Safety stop button

(5) Measurement mode button (7) Count change button (9) PAGE selecting button

(5) Measurement mode button:

Switches the measurement mod es of the ocular pressure measur e-

ment and the cornea thickness measurement.

Pressing the Function button enables you to select T/P (ocular pres-

sure measurement/cornea thickness continuous measurement),

TONO (ocular pressure measurement) or PACHO (cornea thickness

measurement).

30

If is selected by in Page 2:

: Ocular pressure measurement/cornea thickness

continuous measurement

: Ocular pressure measurement

: Cornea thickness measurement

30/60 button

60

If is selected by in PAGE 2:

: Ocular pressure measurement/cornea thickness

continuous measurement

: Ocular pressure measurement

: Cornea thickness measurement

(6) Alignment button: Switches between auto measurement and manual measurement.

: Auto measurement

: Manual measurement

(7) Count change button:In the AUTO measurement, the number of measurements can be

selected between "single measurement" and "the previously set

number of measurements".

: Single measurement

: Previously set number of measurements

This is not displayed under MANUAL mode.

When the measurement mode is changed by the

, is returned.

(8) Safety stop button: Used for position setting to keep the measuring window glass from

the patient's eye during the measurement. For details, see page 113.

(9) PAGE selecting button:Changes the PAGE screen to another.

MEASUREMENT MODE button

30/60 button

17

COMPONENTS

Page 19

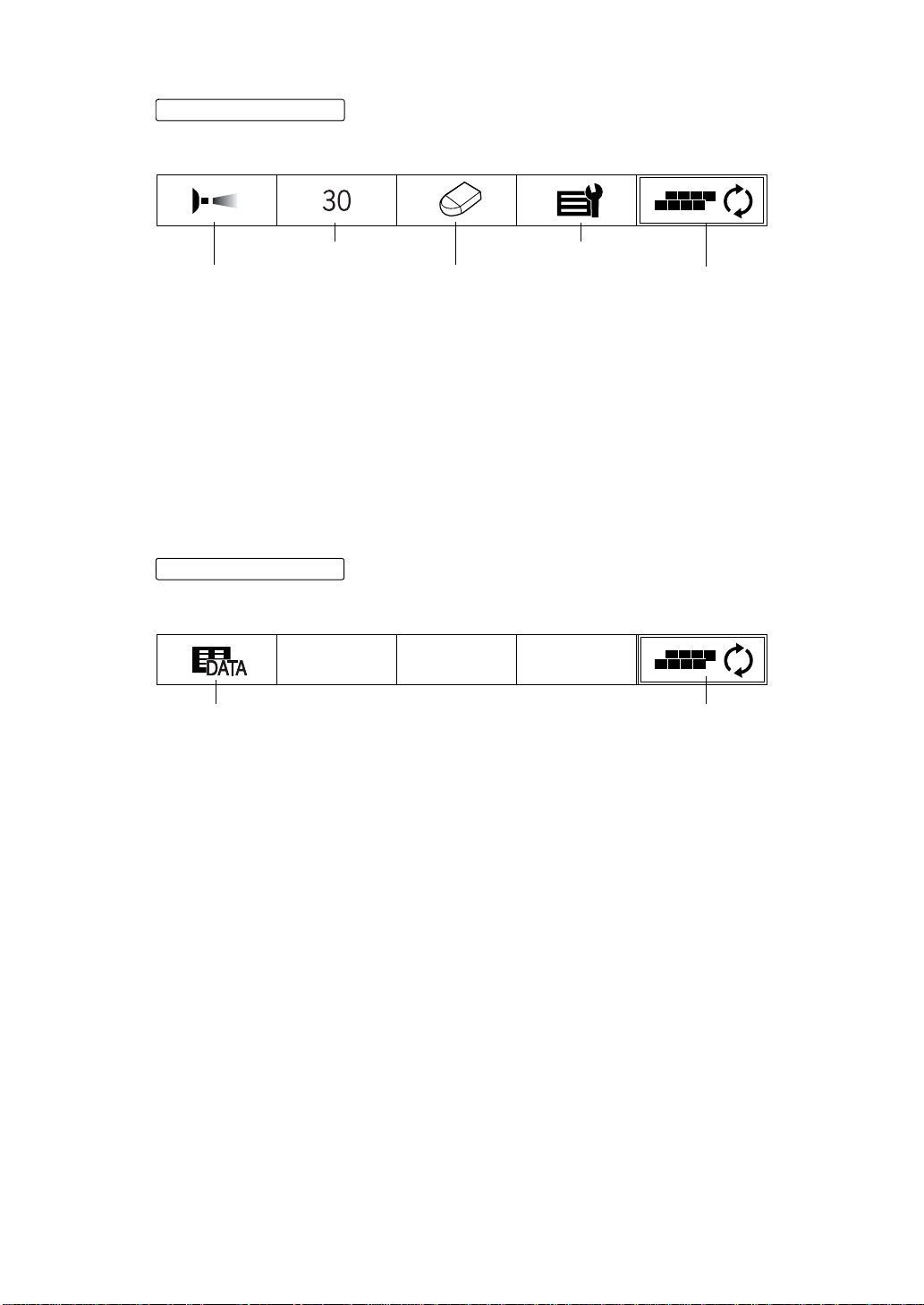

PAGE 2

PAGE selecting button

If the is pressed on PAGE 1, the status of PAGE changes as follows.

If the button is pressed again, PAGE 3 is returned.

(11) 30/60 button (13) T/P menu button

(12) Clear button(10) Air check button

(14) PAGE selecting button

(10) Air check button: Checks correct operations of the measurement system inside the

instrument. For detail, see page 111.

(11) 30/60 button: Switches between 0-30 range and 0-60 range. This is not displayed

under PACHO mode.

(12) Clear button: Deletes measurement data.

(13) T/P menu button: Displays the MENU screen of TONO/PACHO mode.

(See "SEETING MENU (T/P)" on page 81)

(14) PAGE selecting button:

Changes the PAGE screen to another.

PAGE 3

PAGE selecting button

If the is pressed on PAGE 2, the status of PAGE changes as follows.

If the button is pressed again, PAGE 1 is returned.

(15) All data button (16) PAGE selecting button

(15) All data button: Displays all measurement data on the screen. (See page 142)

(16) PAGE selecting button:

Changes the PAGE screen to another.

18

COMPONENTS

Page 20

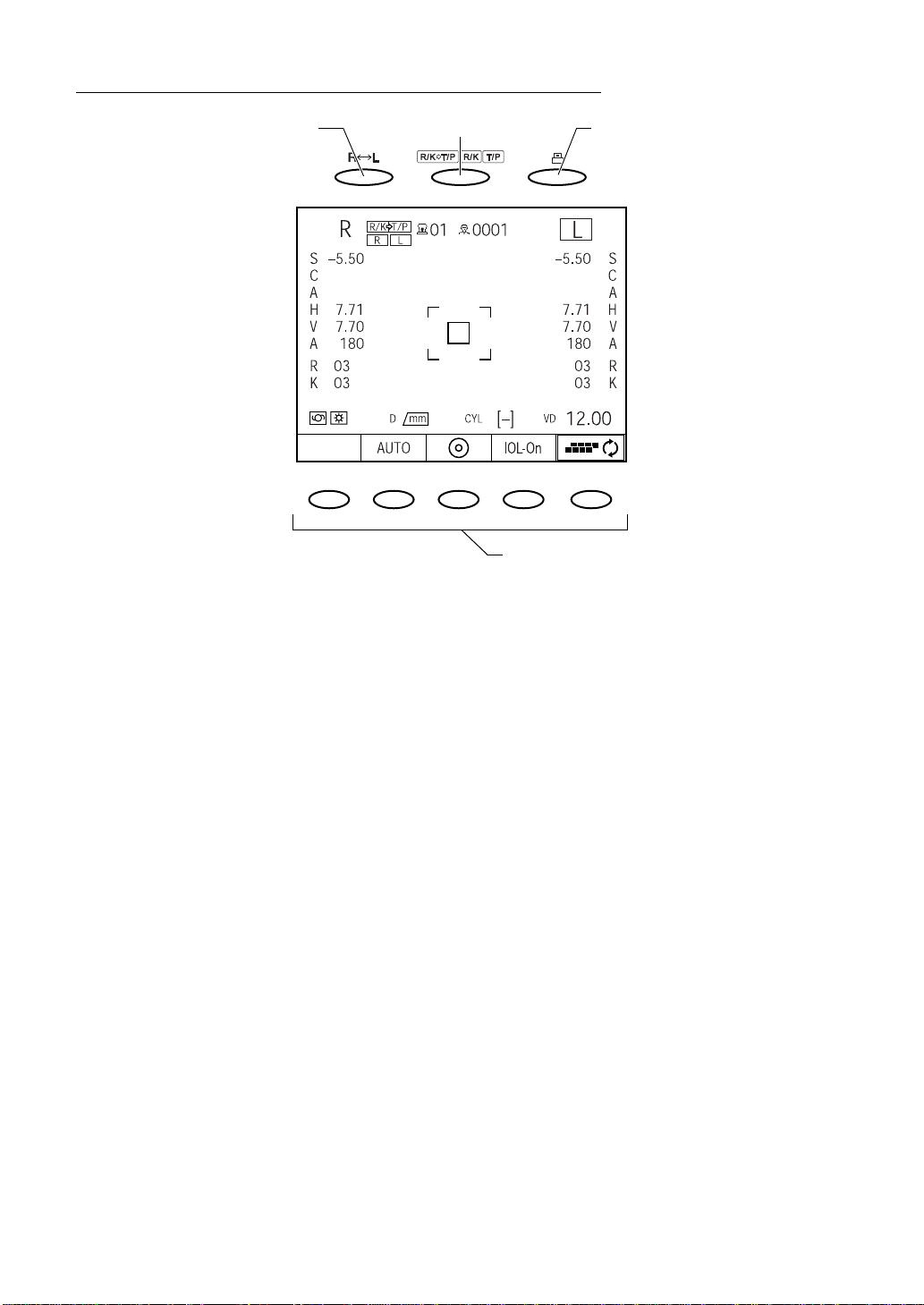

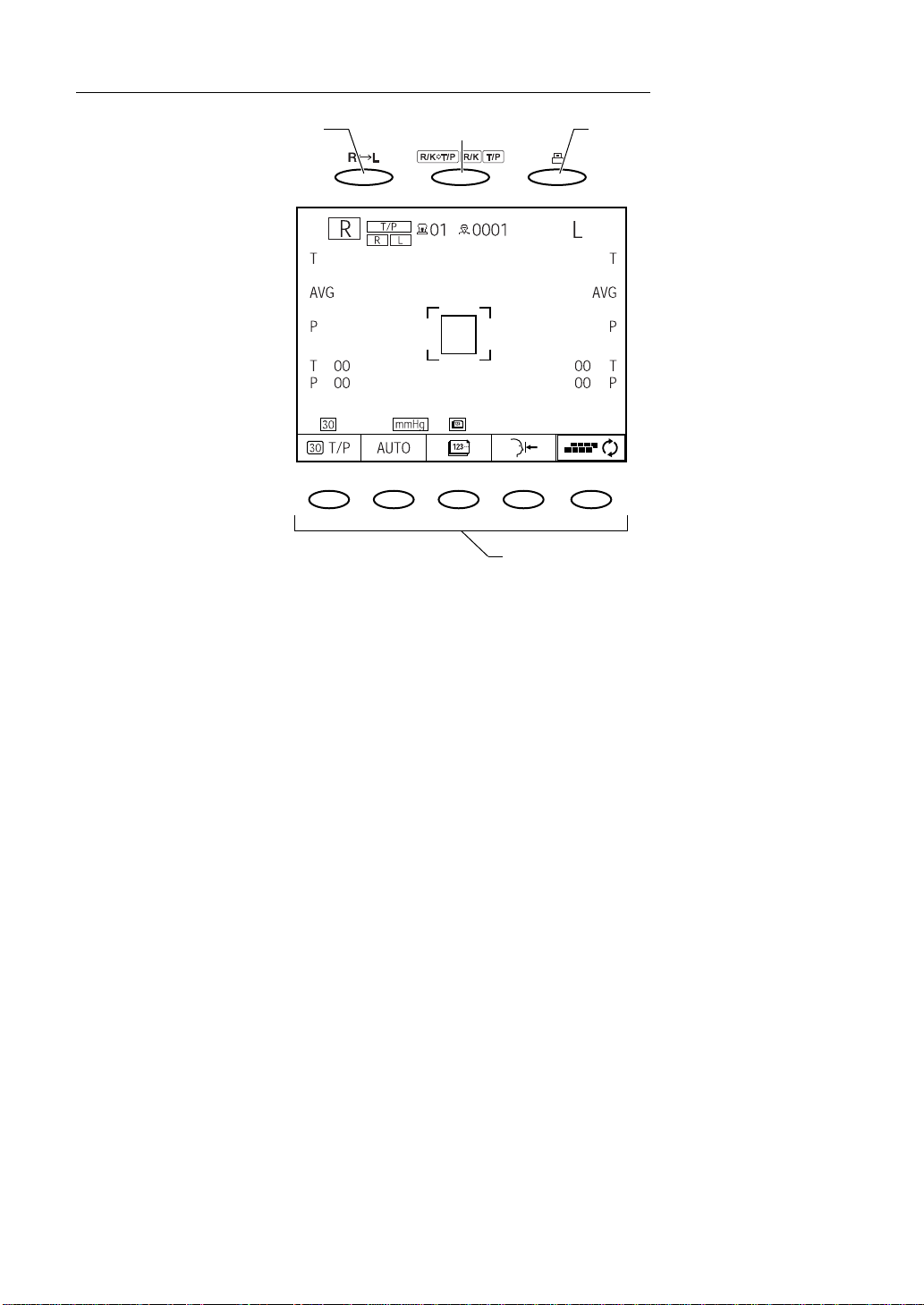

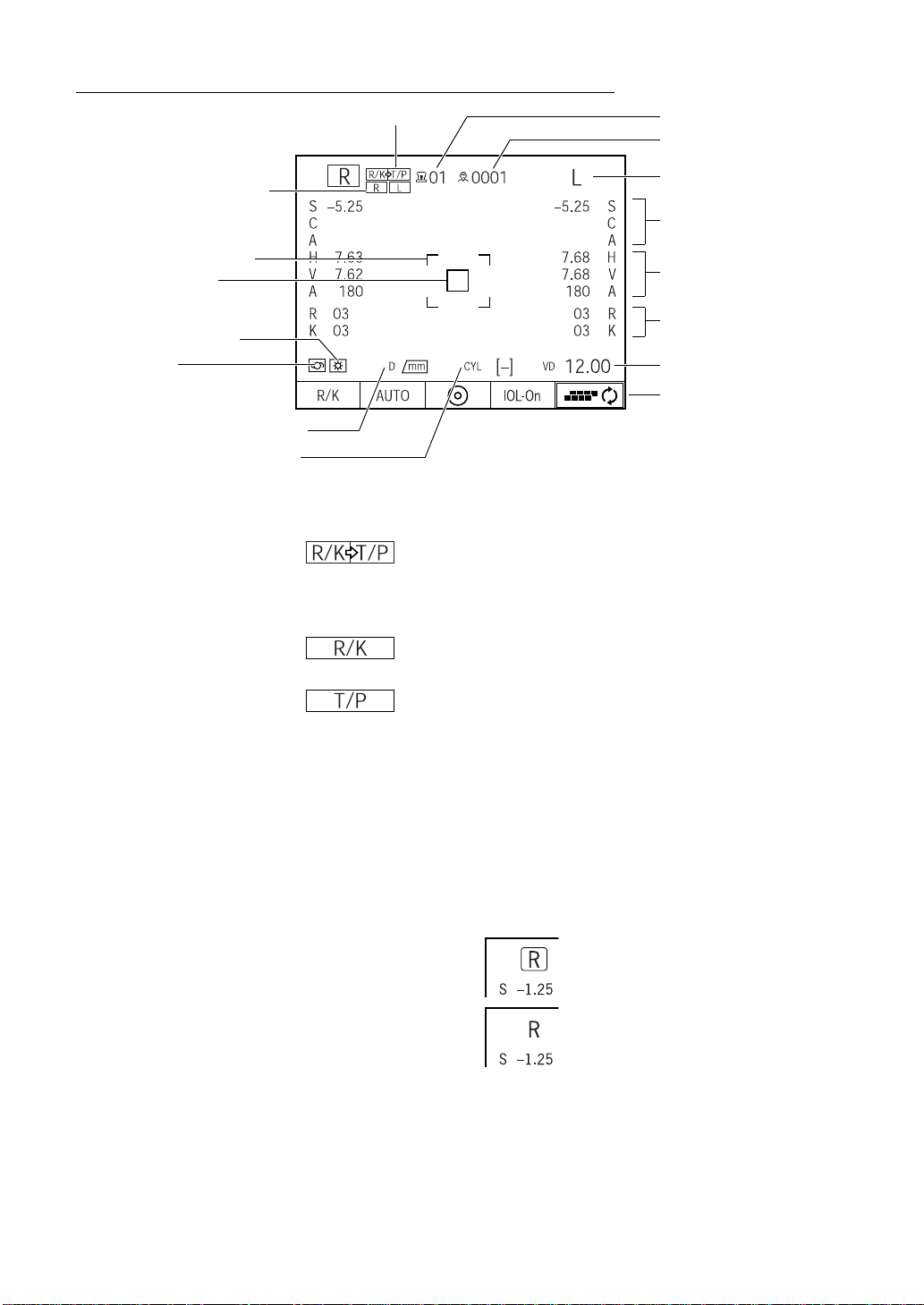

MONITOR SCREEN COMPONENTS (REF/KRT MODE)

(2) Instrument No.(1) Mode display

(3) Patient No.

(16) Selected measuring eye

mark

(12) Outer alignment mark

(13) Alignment mark

(15) Fixation lamp mark

(14) IOL mark

(9) Measurement result unit setting

(10) Set value of CYLINDER sign

(4) Right/left eye

(5) REF measurement value

(6) KRT measurement value

(7) Number of REF/KRT

measurements

(11) VD setting

(8) Function menu

(1) Mode display: Displays measurement mode of REF/KRT and TONO/PACHO.

: Fully automatic measurement mode.

Measurements in REF/KRT and TONO/PACHO are

continuously carried out.

Measuring begins in REF/KRT mode.

: REF/KRT mode. REF and KRT measurements are

available.

: TONO/PACHO mode. Ocular pressure and cornea

thickness measurements are available.

(2) Instrument No.: Displays the instrument No.

In the INITIAL MENU screen, setting and display/nondisplay can be

switched. (See page 43)

(3) Patient No.: Displays the patient No.

In the INITIAL MENU screen, setting and display/nondisplay can be

switched. Also, the patient No. received from an external device (bar-

code reader and the like) is displayed. (See page 42)

(4) Right/left eye: Displays the right/left eye of the patient.

The display in measurement is framed.

Measured :

The other measured :

19

COMPONENTS

Page 21

(5) REF measurement value:

Displays the REF measurement value.

Of measurement values, the latest data is displayed on the screen.

Figures only: When the measurement was done correct.

Figures with *: When the reliability of measurement is low.

ERROR: When the measurement was not done correctly.

(6) KRT measurement value:

Displays the KRT measurement value.

The latest measurement data is displayed on the screen.

In the INITIAL MENU screen, the display of HV (horizontal/vertical

direction) and R1R2 (major meridian direction) can be switched.

(See page 76)

(7) Number of REF/KRT measurements:

Displays the number of REF and KRT measurements.

(8) Function menu: Display the function button under REF/KRT mode.

For details, see "CONTROL PANEL COMPONENTS (REF/KRT

MODE)" on page 13.

(9) Measurement result unit setting:

Displays the unit of the result of KRT measurement (diopter or mm).

Diopter setting :

mm setting :

The setting can be changed in the INITIAL MENU screen. (See page

75)

(10) Set value of CYLINDER sign:

Displays the CYL set value.

The setting can be changed in the INITIAL MENU screen. (See page

77)

(11) VD setting: Displays the set value of vertex distance.

The setting can be changed in the INITIAL MENU screen. (See page

73)

(12) Outer alignment mark:

Used to get coarse alignment in aiming at the patient's eye.

(13) Alignment mark: Indicates the starting area of auto alignment.

(14) IOL mark: Displayed when the IOL button is ON.

(15) Fixation lamp mark:Displayed when the Fixation button is Hi.

(16) Selected measuring eye mark:

Selected patient's eye is shown.

R L

R R/K T/P

L R/K T/P

R L

After or is selected, automatically return to initial setting

(continuous measurement), if printing is carried out.

:Both eyes are measured continuously.

:Only the right eye is measured. When fully

automatic measurement mode is selected, only the right

eye is measured repeatedly.

:Only the left eye is measured. When fully auto-

matic measurement mode is selected, only the left eye is

measured repeatedly.

continuous measurement is set in initial settings.

R L

20

COMPONENTS

Page 22

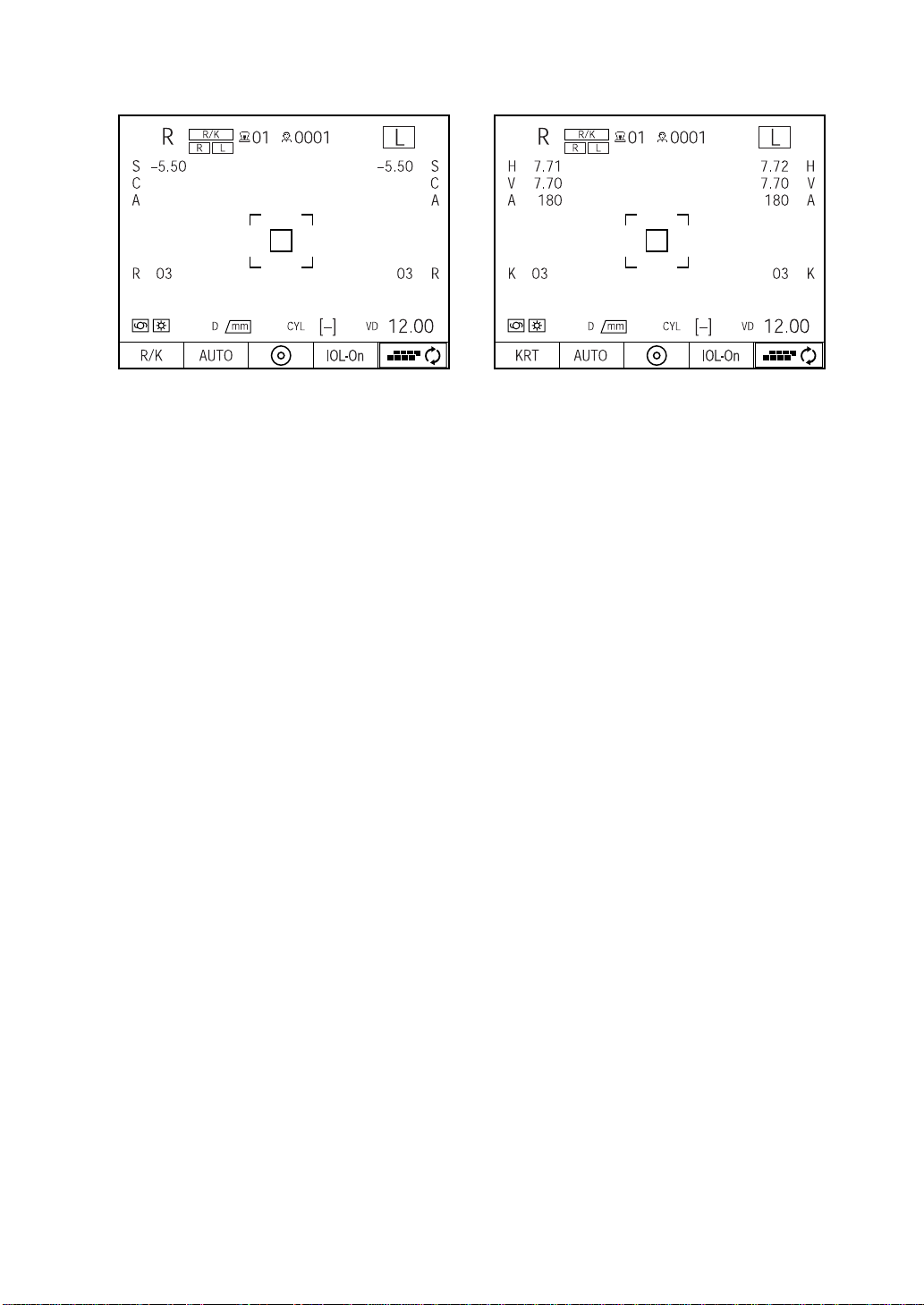

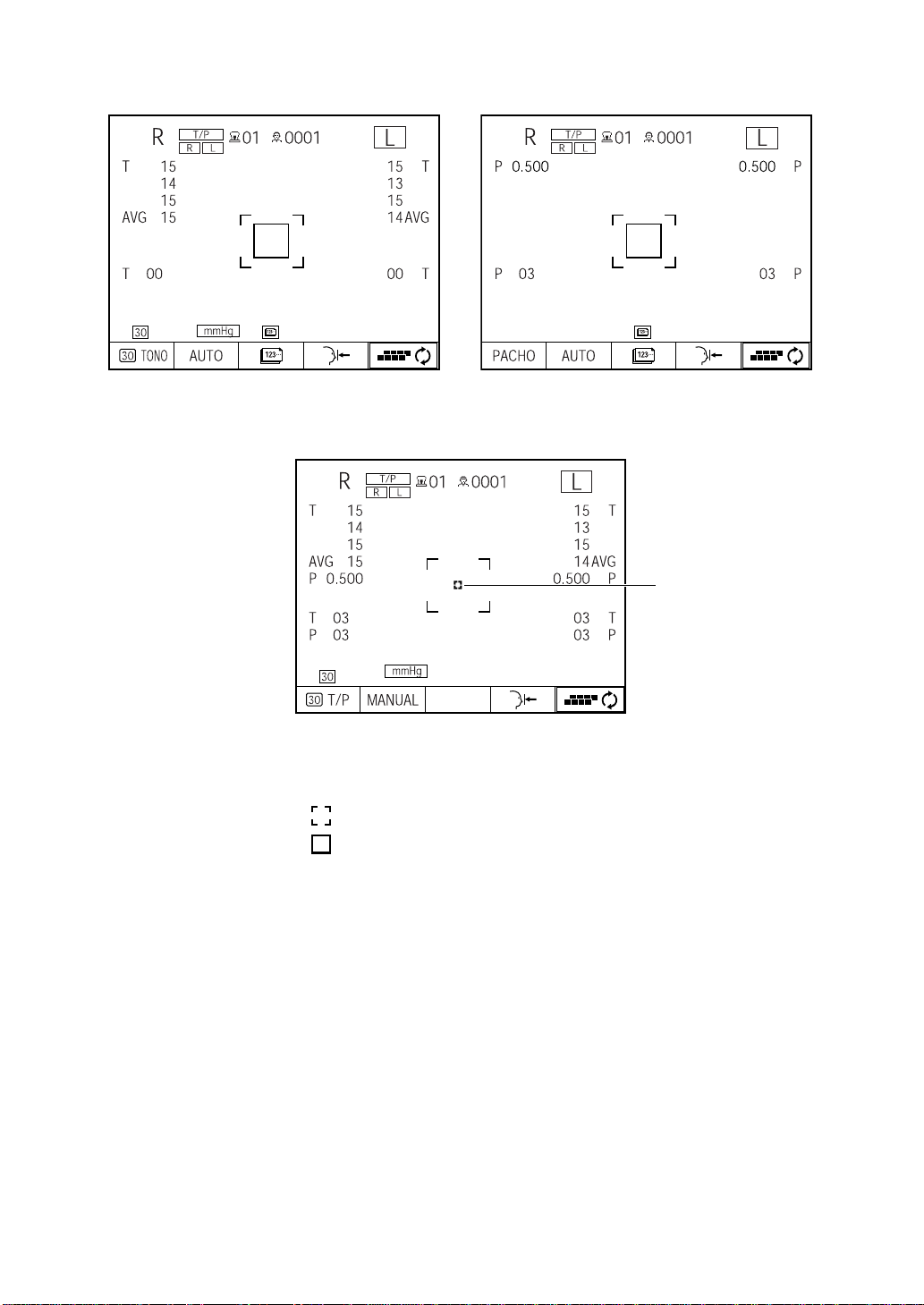

REF mode KRT mode

21

COMPONENTS

Page 23

MONITOR SCREEN COMPONENTS (TONO/PACHO MODE)

(2) Instrument No.(1) Mode display

(3) Patient No.

(15) Selected measuring eye

mark

(11) Alignment mark

(12) Outer alignment mark

(13) Measuring range mark

(14) Ocular Pressure

(Value unit) mark

(4) Right/left eye

(5)

TONO measurement value

(6) TONO average value

PACHO measurement value

(7)

(8)

Number of TONO/PACHO

measurements

(10) Number of

measurements mark

(9) Function menu

(1) Mode display: Displays measurement mode of REF/KRT and TONO/PACHO.

: Fully automatic measurement mode.

Measurements in REF/KRT and TONO/PACHO are

continuously carried out.

Measuring begins in REF/KRT mode.

: REF/KRT mode. REF and KRT measurements are

available.

: TONO/PACHO mode. Ocular pressure and cornea

thickness measurements are available.

(2) Instrument No.: Displays the instrument No.

In the INITIAL MENU screen, setting and display/nondisplay can be

switched. (See page 43)

(3) Patient No.: Displays the patient No.

In the INITIAL MENU screen, setting and display/nondisplay can be

switched. Also, the patient No. received from an external device (bar-

code reader and the like) is displayed. (See page 42)

(4) Right/left eye: Displays the right/left eye of the patient.

The display in measurement is framed.

22

COMPONENTS

Measured :

The other measured :

Page 24

(5) TONO measurement value:

Displays ocular pressure measurement values.

For one eye, three measurement values are displayed on the screen,

and thereafter the oldest measurement value is deleted.

White figures: When the measurement was done correct.

[ ]Yellow figures: When the reliability of measurement is low.

ERROR: When the measurement was not done correctly.

OVER: When the measurement range is exceeded.

(6) TONO average value:Displays the average value of ocular pressur e measurements. Inte-

ger/decimal representation of the average value can be selected on

the setting menu (see page 82).

(7) PACHO measurement value:

Displays the cornea thickness measurement value.

Only the latest measurement data is displayed in the screen.

(8) Number of TONO/PACHO measurements:

Displays the number of ocular pressure and cornea thickness mea-

surements.

(9) Function menu: Displays the function button under TONO/PACHO mode.

For details, see "CONTROL P ANEL COMPONENTS (TONO/PACHO

MODE)" on page 16.

(10) Count change mark:In the AUTO measurement, the number of measurements can be

selected between "single measurement" and "the previously set

number of measurements". For details, see "CHANGING THE NUM-

BER OF MEASUREMENTS" on page 141. This is not displayed

under MANUAL mode.

: Single measurement

: Previously set number of measurements

(11) Alignment mark: Indicates the starting area of auto alignment.

(12) Outer alignment mark: Used to get coarse alignment in aiming at the patient's eye.

(13) Measuring range mark:

The measuring range set by the 30/60 button is displayed. Th is is not

displayed under PACHO mode.

(14) Ocular Pressure (Value unit) Mark:

Indicates the unit of the measured ocular pressure value.

In the INITIAL MENU screen, the unit can be selected. (see p.48)

This is not displayed under PACHO mode.

(15) Selected measuring eye mark:

Selected patient's eye is shown.

R L

R R/K T/P

L R/K T/P

R L

After or is selected, automatically return to initial setting

(continuous measurement), if printing is carried out.

:Both eyes are measured continuously.

:Only the right eye is measured. When fully

automatic measurement mode is selected, only the right

eye is measured repeatedly.

:Only the left eye is measured. When fully auto-

matic measurement mode is selected, only the left eye is

measured repeatedly.

continuous measurement is set in initial settings.

R L

23

COMPONENTS

Page 25

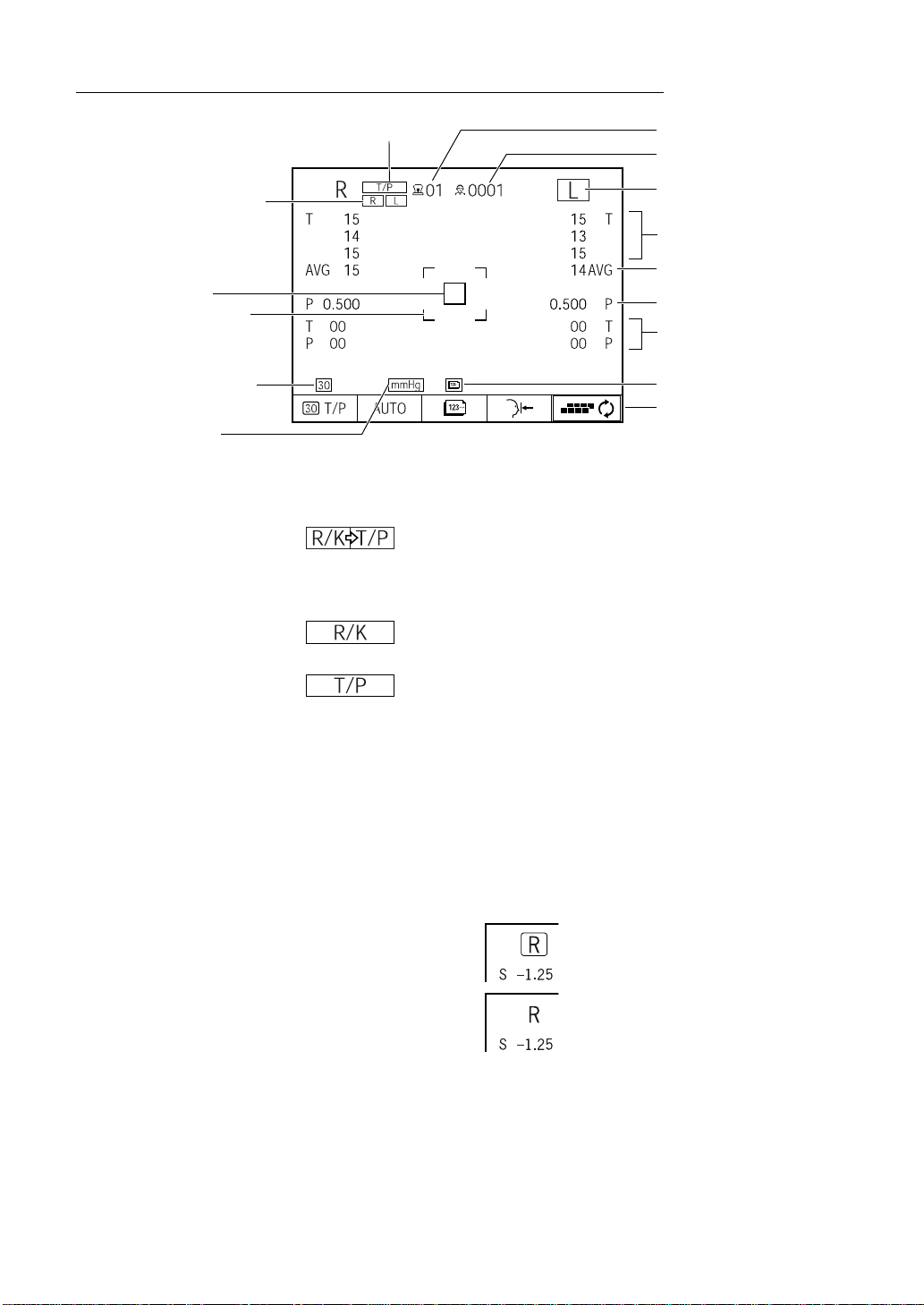

TONO mode PACHO mode

MEASUREMENT SCREEN UNDER MANUAL MODE

(16) Inner alignment mark:

Used to get alignment in aiming at the patient's eye in manual mode.

Change the mark according to the status of alignment.

: Alignment is insufficient.

: Alignment is sufficient in back/forth, left/right and up/down

directions (in the range where measuring is possible).

For details, see MEASUREMENT UNDER MANUAL MODE (TONO/

PACHO mode) on page 124.

(16) Inner alignment mark

24

COMPONENTS

Page 26

OTHER SCREEN DISPLAYS

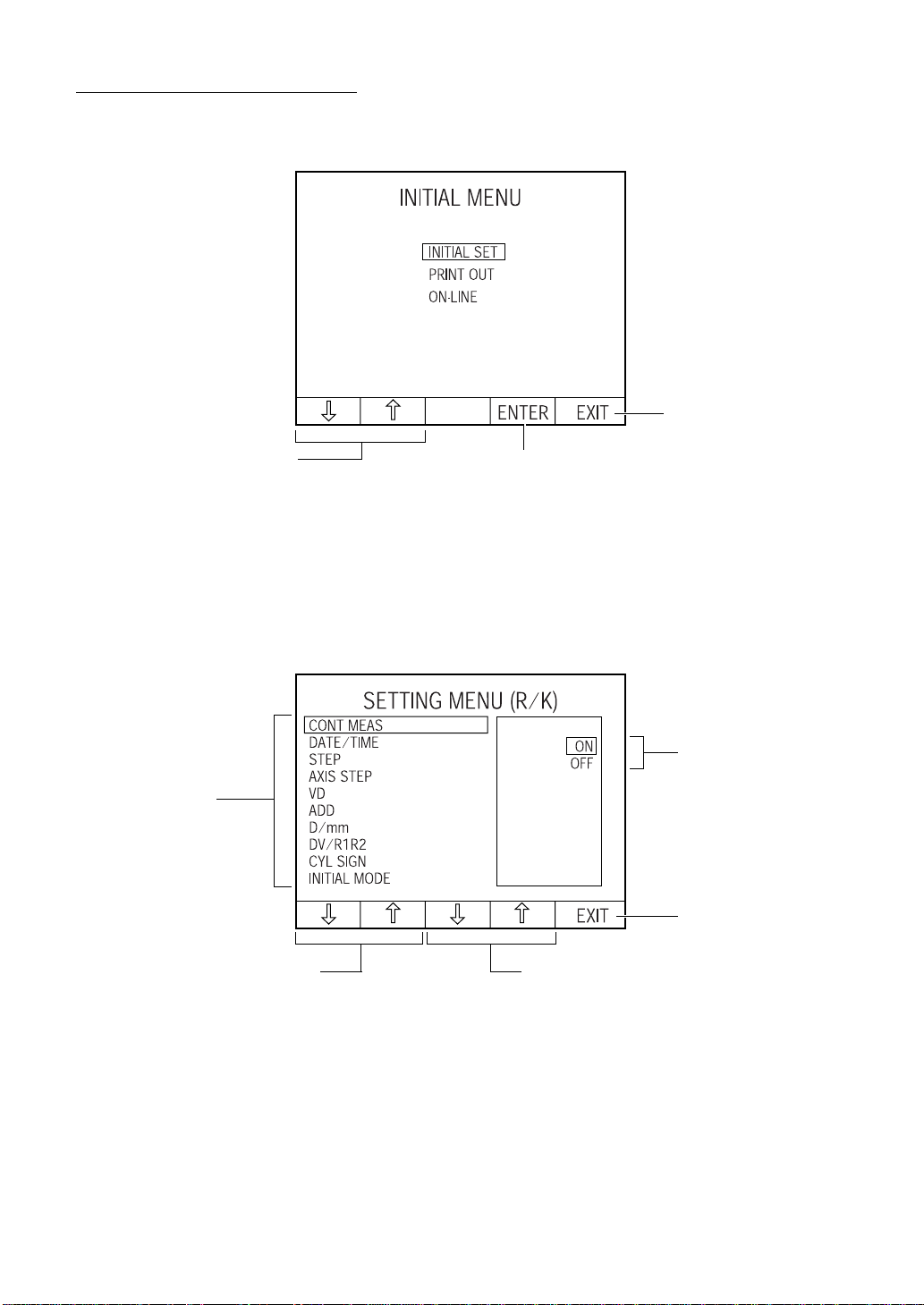

INITIAL SETTING SCREEN

(1) Set item change button (2) Execution button

(1) Set item change button: Move the cursor up/down and select the set item.

(2) Execution button: Execute the menu selected by the cursor.

(3) Menu end button: Quit the MENU screen and save the set content.

(3) Menu end button

MENU SETTING SCREEN (REF/KRT MODE)

(2) Set value

(1) Set item

(5) Menu end button

(4) Set value change button(3) Set item change button

(1) Set item: Displays settable menu items. (The cursor is yellow.)

(2) Set value: Displays the set content of set items and the cur rent settings.

The cursor is displayed on the content being set. (The cursor

is blue.)

(3) Set item change button: Move the yellow cursor up/down and select the set item.

(4) Set value change button: Move the blue cursor up/down and select the set value.

(5) Menu end button: Quit the MENU screen and save the set content.

25

COMPONENTS

Page 27

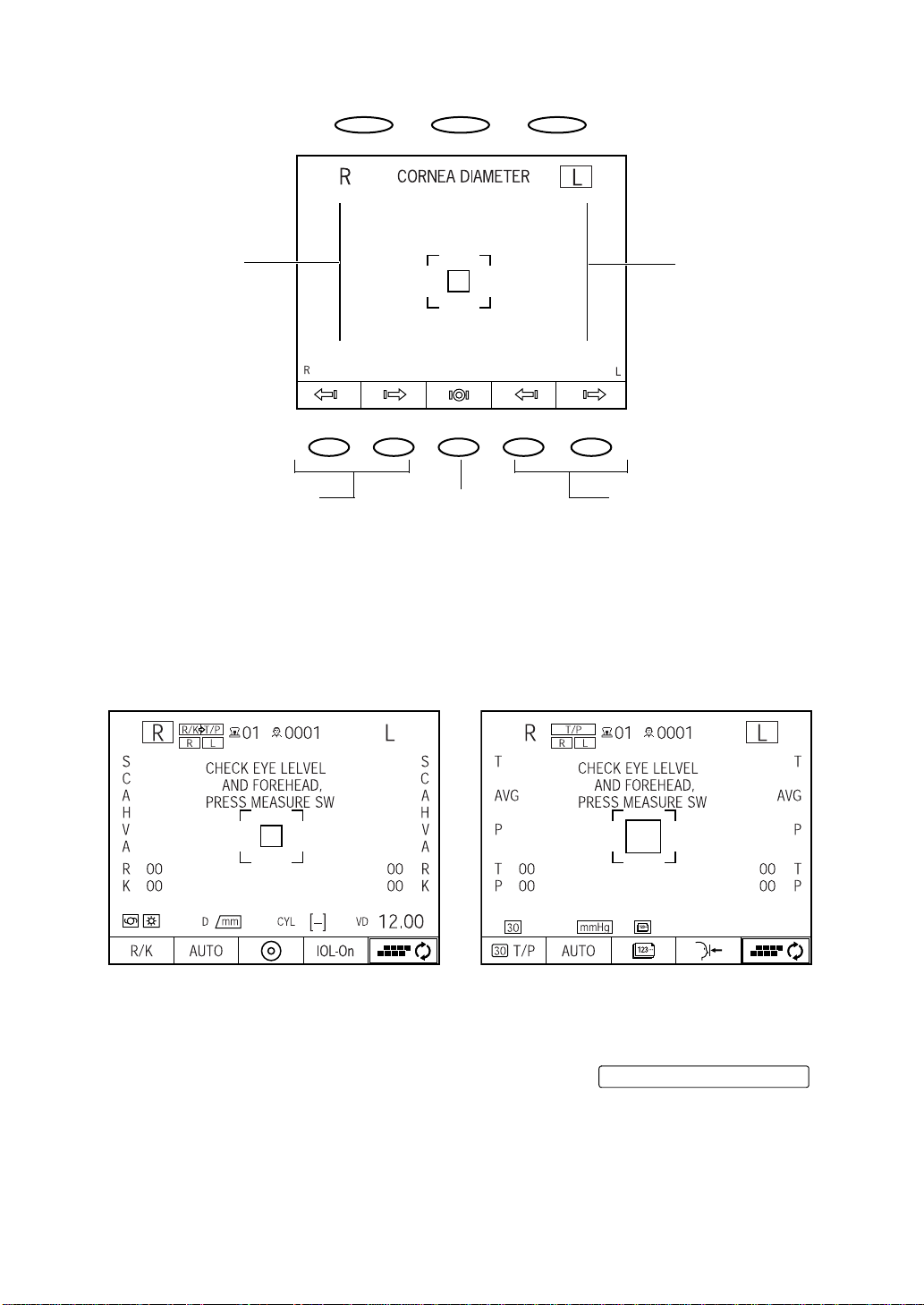

CORNEA DIAMETER MEASUREMENT SCREEN

(1) Left positioning bar

(3) Move left positioning bar button (4) Move right positioning bar button(5) Initial position button

(1) Left positioning bar: Set the left position of cornea diameter measurement.

(2) Right positioning bar: Set the right position of cornea diameter measurement.

(3) Move left positioning bar button: Move the left positioning bar right/left.

(4) Move right positioning bar button:Move the right positioning bar right/left.

(5) Initial position button: The bar returns to the initial position.

WAITING SCREEN

(2) Right positioning bar

REF/KRT mode TONO/PACHO mode

This screen appears after powering on, after printing out and after clearing data.

If the screen is displayed, no measurement is done.

In this case, following the screen message, pressing the will

enable measurement.

MEASUREMENT switch

26

COMPONENTS

Page 28

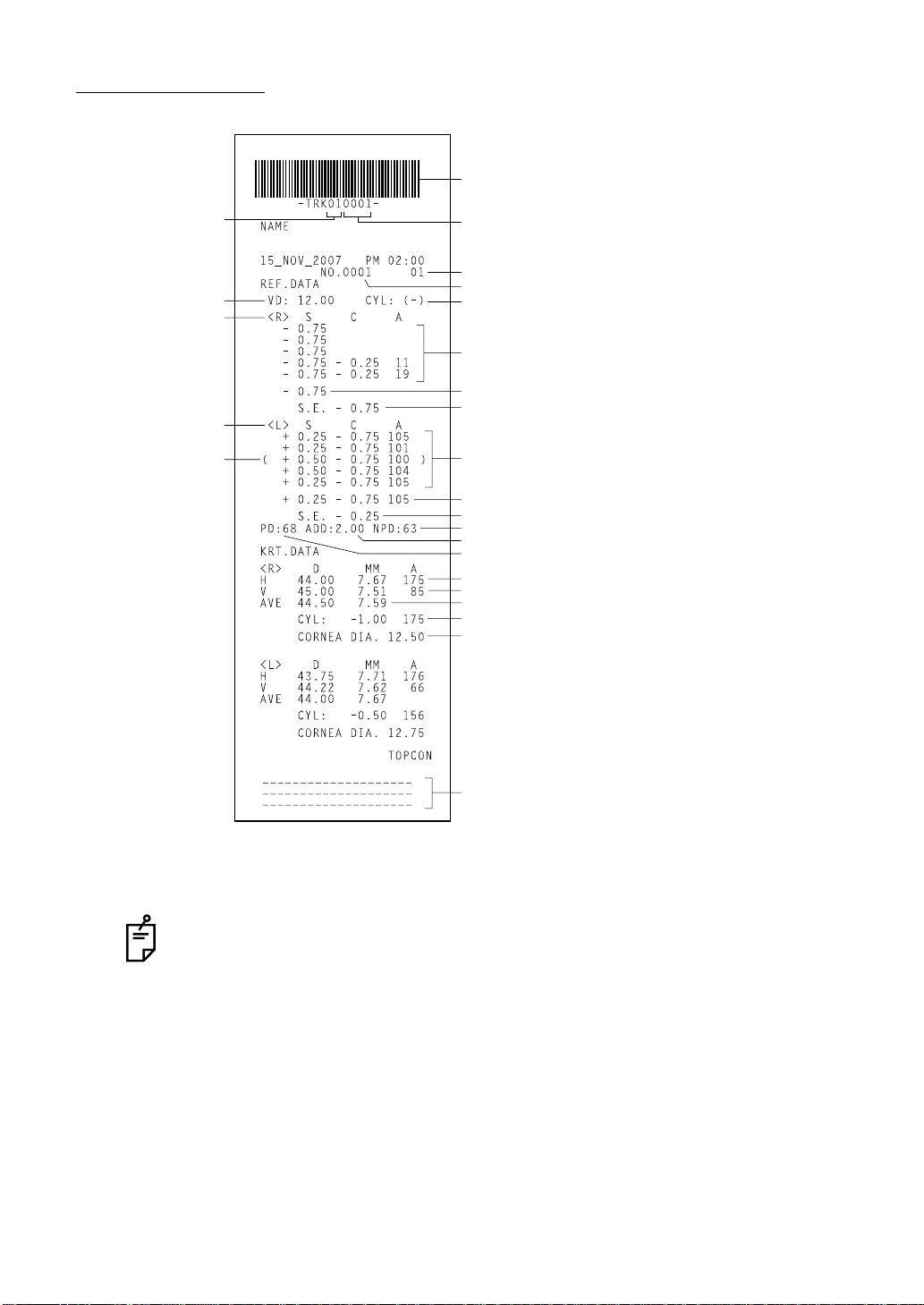

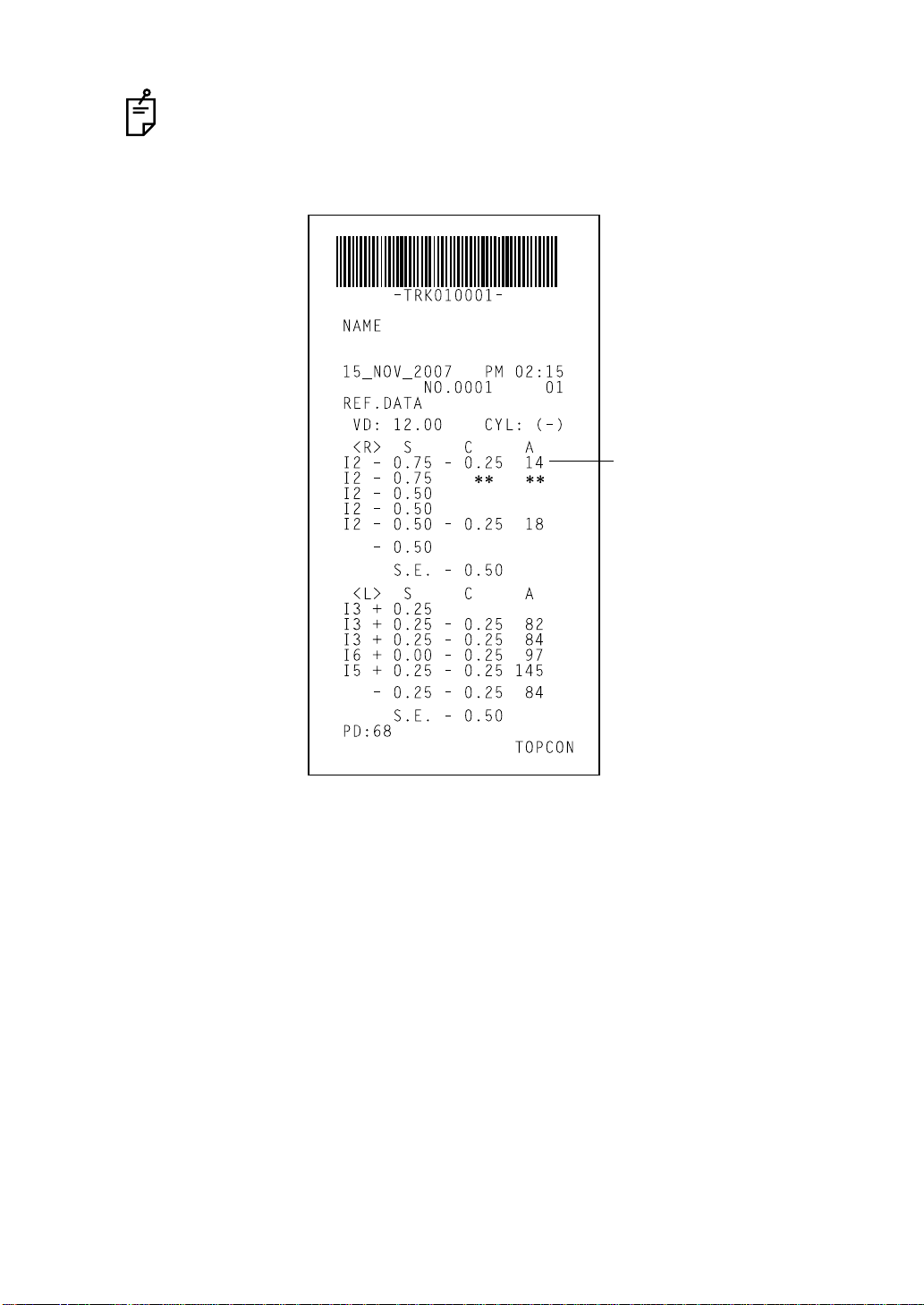

PRINTER OUTPUT

<R/K> MODE

Bar code

Instrument No.

VD (vertex distance)

Right eye measurements

Left eye measurements

The ( ) mark is added

when measurement

values are not fully

reliable.

Work ID No.

Instrument No.

Patient No.

Cylindrical power mark

Measurement Results of 5 right eye measurements

(recordable up to 10 measurements)

Typical value of right eye (The * mark is displayed when

3 or more measurements are done.)

SPHERICAL EQUIVALENT of right eye

Measurement Results of 5 left eye measurements

(recordable up to 10 measurements)

Typical value of left eye

SPHERICAL EQUIVALENT of left eye

Near vision PD value

ADD (ordinary additional power)

Pupil distance (PD value)

Measured value of horizontal corneal curvature

Measured value of vertical corneal curvature

Average value

Corneal astigmatic power

Cornea diameter

Message column

(If the message is entered, it will be displayed in any mode.)

(Example) REF data “ALL”, KRT data “AVE”

The near-vision PD value is calculated based on the general addition number.

COMPONENTS

27

Page 29

When measurement is done under the IOL mode, a reliability factor is printed out

following the I mark.

The reliability factor is formed with integers 1 to 9 in increasing order of reliability.

Additionally, if the reliability is high enough, the reliability factor is not shown in the

printout.

The I mark is displayed at IOL

mode.

If the reliability is low and values

of C and A cannot be determined,

** marks are given to pertaining

columns.

28

COMPONENTS

Page 30

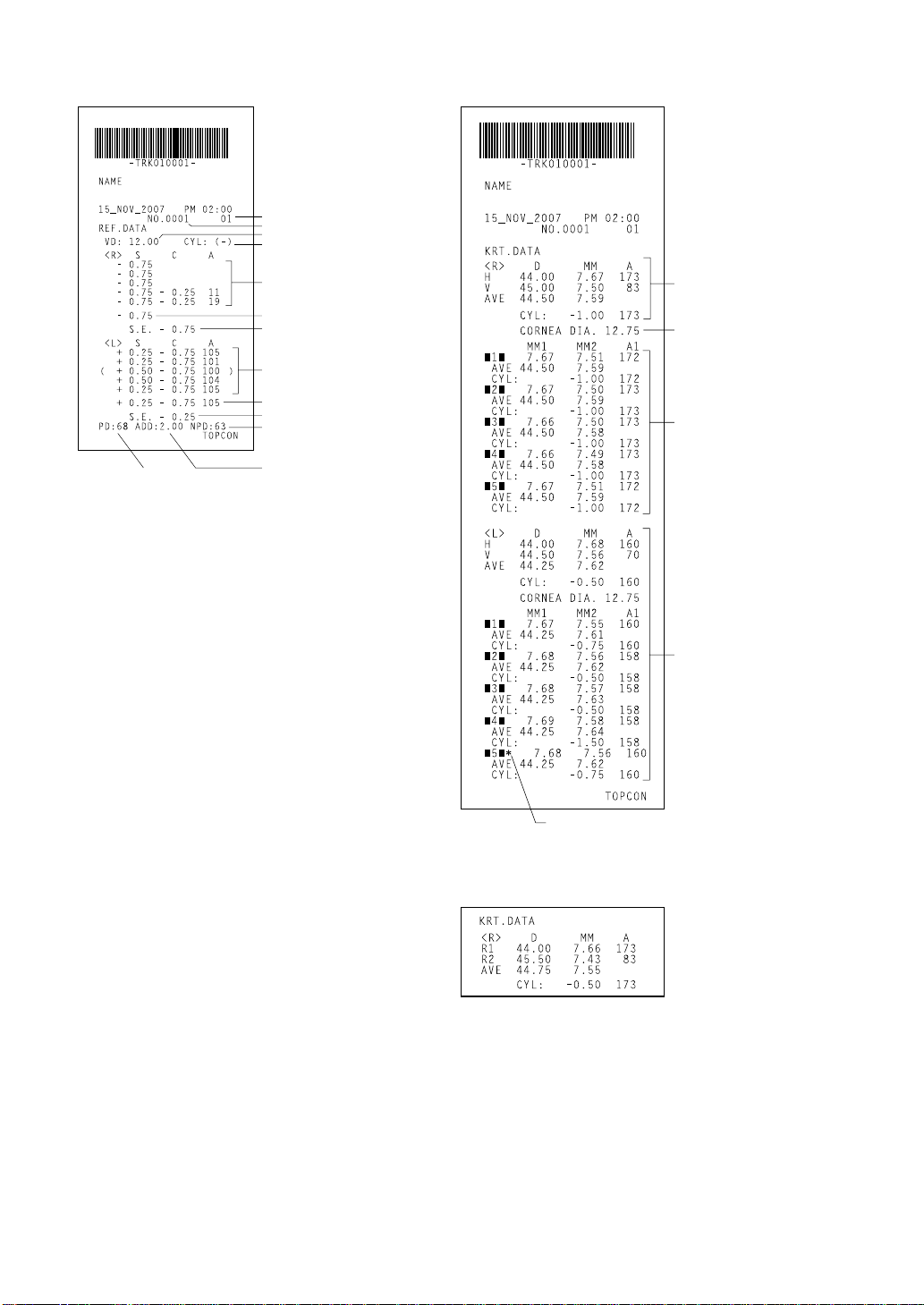

<REF> MODE <KRT> MODE

Instrument No.

Patient No.

VD (vertex distance)

Cylindrical power mark

Results of 5 refractory power measurements of right eye (recordable

up to 10 measurements)

Typical value of right eye

Typical value of right eye

SPHERICAL EQUIVAL ENT

of right eye

Results of 5 refractory power mea-

surements of left eye (recordable

up to 10 measurements)

Typical value of left eye

SPHERICAL EQUIVALENT of left eye

Near vision PD value

Pupil distance

(PD value)

ADD(ordinary additional power)

Typical measured value

of right eye corneal

curvature

Measured value of right

eye cornea (mm)

Results of 5 right eye corneal curvature measurements of right eye,

average value and astigmatic power of cornea

(recordable up to 10 measurements each for right /

left eye)

Reliability mark

(displayed only when reliability is low)

<R/K> <KRT> MODE

(Kerato data is printed as below

when H/V is set to R1/R2.)

Measured value of left eye

29

COMPONENTS

Page 31

<T/P> MODE

Bar code

Instrument No.

Measured of intraocular

pressure values

Measured value of central

corneal thickness

Work ID No.

Instrument No.

Patient No.

Measured intraocular pressure values

Average intraocular pressure values

Measured value of central corneal

thickness

Average value of central corneal

thickness

Printed example on setting the display unit of intraocular pressure measurement

values at hPa.

30

COMPONENTS

Measurement value at the unit of mmHg

Measurement value at the unit of hPa

Page 32

<TONO> MODE <PACHO> MODE

Measured intraocular

pressure values

Average intraocular

pressure values

Measured value of

central corneal

thickness

Average value of

central corneal

thickness

Printed example on setting the display unit of intraocular pressure measurement

values at hPA on TONO mode.

31

COMPONENTS

Page 33

STANDARD ACCESSORIES

The following are standard accessories. Make sure that all these items are included (quantity).

Power cable (1) Chinrest tissue pin (2)

Printer paper (2) Silicon cloth (1)

Chinrest tissue (1) Dust cover (1)

Fuse (2) Instruction manual, unpacking and assembling

(1 each)

Accessory case (1) Model eye (1)

Hexagon wrench (1) Window glass cleaning procedure (1)

Blower (1) Cotton applicator for nozzle cleaning (1)

Measuring window lens cap (1)

32

COMPONENTS

Page 34

PREPARATIONS

INSTALLING THE INSTRUMENT

When moving the instrument, be sure to hold it at the base with

two persons. Carrying by one person may cause harm to his

CAUTION

CAUTION

back or injury by falling parts. Also, holding areas other than

the base may cause injury, as well as damage to the instrument.

When setting an instrument on an instrument table, pay attention not to injure the patient's fingers between the instrument

and the table.

CAUTION

To avoid injury, do not install the instrument on a slope or on an

unstable place.

1 Hold the instrument body firmly at the specified positions and place it on the automatic

instrument table.

For the automatic instrument table, see "OPTIONAL ACCESSORIES" on page 164.

Holding positions Holding the instrument

2 Place the instrument horizontally, with care not to trample cables.

33

PREPARATIONS

Page 35

CONNECTING THE POWER CABLE

WARNING

CAUTION

To avoid fire and electric shocks by short circuiting, be sure to

connect the instrument into a grounded outlet.

To avoid electrical shock, do not handle the power plug with

wet fingers.

1 Make sure the instrument is OFF.

2 Remove the inlet cover.

Make sure you can see the mark "O"

(it shows power is OFF).

3 Connect the power cable to the instrument body.

34

PREPARATIONS

Page 36

4 Then put the inlet cover.

5 Plug the power cable into the 3-pin AC outlet with grounding.

CONNECTING EXTERNAL I/O TERMINALS

Use the external device complying with IEC60950/IEC60950-1 or UL60950/

UL60950-1.

DATA OUTPUT

This instrument can be connected to another device, including a personal computer via the

RS232C or USB terminal.

1 Connect the cable to the RS232C OUT terminal of the instrument.

2 Connect the other cable end to the PC and other extern al device.

RS232C IN terminal

RS232C OUT terminal

USB OUT terminal can be connected to Series B plug.

When connecting cable, be sure to use the cable with correct shape of plug.

DATA INPUT

This instrument can be connected to another device, including a barcode reader via the

RS232C terminal.

USB OUT terminal

1 Connect the cable to the RS232C IN terminal of the instrument.

2 Connect the other cable end to the external device.

For inquiries about the RS232C, call your dealer or TOPCON at the address

printed on the back cover of this manual.

35

PREPARATIONS

Page 37

FUNCTION SETTINGS BY MEANS OF MENU

LIST OF MENUS

MAIN MENU SUB MENU MENU ITEMS SETTING ITEMS Page

INITIAL

SETTING

INITIAL

SETTING

SETTING

PRINTOUT

BUZZER Setting the buzzer sound 39

INIT AUTO Setting the start mode after turning the

power on

AUTO PRINT Auto print after finishing auto measure-

ment

PRINT SWITCH Selecting print button functions 41

SERIAL No. RESET Setting the power resetting the patient

No.

SERIAL No. INPUT Setting the patient No. 42

SERIAL No. DISPLAY Displaying the patient No. 42

INSTRUMENT No. INPUT Setting the instrument No. 43

INSTRUMENT No. DISPLAY Displaying the instrument No. 43

DIOPTER SHIFT Shifting the refractory power 44

C.D MEMORY Changing the method of cornea diameter

measurement

MEASURING MODE Setting the measurement mode after

powering on

POWER ON MODE Setting the measurement mode under R/

K and T/P mode after power-on

POSITION SET Setting the waiting position after mea-

surement

POWER SAVE TIME Setting the power save time 47

AUTO MEASURE COUNT Setting the number of continuous mea-

surements

UNIT SELECT Setting the display unit of ocular pressure

measurement values

VD PRINT Printing VD values 49

CYL PRINT Printing the CYLINDER sign 50

REF PRINT FORM Changing the printout format of refraction

measurement values

S.E DATA Printing the SPHERICAL EQUIVALENT

(s.e. data)

GRAPHIC PRINT Printing the REFRACTION 51

PD PRINT Printing PD values 52

CL PRINT Printing COMPUTERIZED LENSME-

TER data

CREDIBILITY NUM Printing the credibility number 53

ADD PRINT Printing the addition number 53

KRT PRINT FORM Changing the printout format of cornea

measurement values

40

40

41

44

45

46

46

47

48

50

51

52

54

36

PREPARATIONS

Page 38

MAIN MENU SUB MENU MENU ITEMS SETTING ITEMS Page

(INITIAL

SETTING)

MENU

SETTING

(SETTING

PRINTOUT)

ON-LINE

SETTING

R/K CONT.MEAS. Setting cont. Meas. (continuous mea-

T/P DATE/TIME Setting the date and time 81

KRT AVE PRINT Printing th e average value of cornea

shape measurements

KRT DATA ORDER Changing the PRINTING SEQUENCE

cornea shape measurement values

KRT CYL PRINT Printing corneal astigmatism and AXIS 55

PRINT R/L Changing the PRINTING SEQUENCE 56

BAR CODE PRINT Printing the barcode 56

NAME PRINT Printing names 57

DATE PRINT Printing the date 57

DATE PRINT FORM Changing the printout format of date dis-

play

SERIAL No. PRINT Printing the patient No. 58

INSTRUMENT No. PRINT Printing the instrument No. 59

TOPCON PRINT Printing the TOPCON mark 59

PRINT DATA Setting for printing the measurement

result

OUTPUT DATA TYPE Selecting the output data format 62

DATA FORM Setting the communication format 63

DATA OUTPUT PORT Selecting the output port 65

BAUD-RATE Setting the speed of RS-232C communi-

cation

CL INPUT Computer the lensmeter data receiving

format

surement)

DATE/TIME Setting the date and time 70

STEP Setting step 71

AXIS STEP Setting axis step 72

VD Setting VD 73

ADD Setting the addition number 74

D/mm Setting D/mm 75

HV/R1R2 Setting HV/R1R2 76

CYL SIGN Setting CYLINDER sign 77

INITIAL MODE Setting the measurement mode under

REF/KRT mode

MESSAGE INPUT Setting message input 79

AVERAGE MODE Setting the average value of ocular pres-

sure measurements

INITIAL MODE Setting the measurement mode under

TONO/PACHO mode

MESSAGE INPUT Setting message input 84

54

55

58

60

65

66

69

78

82

83

37

PREPARATIONS

Page 39

INITIAL SETTING

In the initial setting, patient No., instrument No., refractory power shift, data input/output,

printer output, etc. can be set.

PREPARATION FOR INITIAL SETTING

1 Make sure the power cable is connected.

For connection, see "CONNECTING THE POWER CABLE" on page 34.

2 While pressing the of the control panel, press on the .

Continue to press the till the buzzer sounds. The POWER lamp lights

and the INITIAL MENU screen is displayed.

MENU button

MENU button

Menu button

POWER switch

RETURNING TO THE MEASUREMENT SCREEN

1 Press .

EXIT

2 Initialization starts, and the START UP screen is displayed.

38

PREPARATIONS

Page 40

INITIAL SETTING

In the INITIAL SET screen, buzzer sound, start mode, pa tient No., refracto ry power shif t, monitor display of typical value, method of corneal diameter measurement, etc. can be changed.

1 In the "INITIAL MENU screen," make sure that the cursor is on "INITIAL SET," and then

press . The monitor screen is changed to the "INITIAL SET screen."

ENTER

To exit from this screen

• Press .

• Close the "INITIAL SET screen" and return to the "INITIAL MENU screen".

To return to the previous item in the screen:

• Press the Set item change button .

EXIT

SETTING THE BUZZER SOUND

The buzzer sound can be turned ON/OFF. Before shipment, it is set to "ON" (buzzer sound).

1 In the "INITIAL MENU screen," select "INITIAL SET" and get the "INITIAL SET screen."

2 Press the Set value change button or and select "ON" (buzzer sound) or

"OFF" (no buzzer sound) of "BUZZER."

3 Setting is done by pressing the Set item change button , and the cursor goes to the

next item.

39

PREPARATIONS

Page 41

SETTING THE START MODE AFTER TURNING THE POWER ON

The start mode after powering on can be changed. Before shipment, it is set to "AUTO" (auto

measurement after powering on).

1 In the "INITIAL MENU screen," select "INITIAL SET" and get the "INITIAL SET screen."

2 Press the Set item change button and bring the cursor to "INIT AUTO."

3 Press the Set value change button or and select "AUTO" (auto measurement

after powering on) or "MANUAL"(manual measurement after powering on).

4 Press the Set item change button ; the setting is done and the cursor moves to the

next item.

AUTO PRINT AFTER FINISHING AUTO MEASUREMENT

After finishing the measurement of right and left eyes under auto measurement, the result can

automatically be printed. Before shipment, it is set to "ON" (auto print).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "AUTO PRINT."

3 Press the Set value change button or and select "ON" (auto printout) or "OFF"

(no auto print).

4 Press the Set item change button ; the cursor moves to the next item.

40

PREPARATIONS

Page 42

SELECTING PRINT BUTTON FUNCTIONS

The Print button function can be changed. Before shipment, it is set to "ON" (print).

1 In the "INITIAL MENU screen," select "INITIAL SET" and get the "INITIAL SET screen."

2 Press the Set item change button and bring the cursor to "PRINT SWITCH."

3 Press the Set value change button or and select "ON" (print) or "OFF" (do not

print).

4 Press the Set item change button ; the cursor moves to the next item.

SETTING THE POWER RESETTING THE PATIENT No.

The patient No. can be reset by powering on. Before shipment, it is set to "OFF" (do not reset).

1 In the "INITIAL MENU screen," select "INITIAL SET" and get the "INITIAL SET screen."

2 Press the Set item change button and bring the cursor to "SERIAL No. RESET."

3 Press the Set value change button or and select "ON" (reset) or "OFF" (do not

reset).

4 Press the Set item change button ; the cursor moves to the next item.

41

PREPARATIONS

Page 43

SETTING THE PATIENT No.

The patient No. can be set between 0 and 9999. Before shipment, it is set to "0001."

1 In the "INITIAL MENU screen," select " INITIAL SET" and get the " INITIAL MENU

screen."

2 Press the Set item change button and bring the cursor to "SERIAL No. INPUT."

3 Press the Set value change button to decrease the value, or to increase.

4 Press the Set item change button ; the cursor moves to the next item.

Press the , and the cursor moves to the next

PATIANT No.'s digit to input.

DISPLAYING THE PATIENT No.

The patient No. can be displayed in the monitor screen. Before shipment, it is set to "ON."

MEASUREMENT switch

1 In the "INITIAL MENU screen," select "INITIAL SET" and get the "INITIAL MENU screen."

2 Press the Set item change button and bring the cursor to "SERIAL No. DISPLAY."

3 Press the Set value change button or and select "ON" (display) or "OF F" (do

not display).

4 Press the Set item change button ; the cursor moves to the next item.

42

PREPARATIONS

Page 44

SETTING THE INSTRUMENT No.

The instrument No. can be set between 0 and 99. Before shipment, it is set to "01."

1 In the "INITIAL MENU screen," select "INITIAL SET" and get the "INITIAL MENU screen."

2 Press the Set item change button and bring the cursor to "INSTRUMENT No.

INPUT."

3 Press the Set value change button to decrease the value, or to increase.

4 Press the Set item change button ; the cursor moves to the next item.

Press the , and the cursor moves to the next INSTRUMENT No.'s digit to input.

DISPLAYING THE INSTRUMENT No.

The instrument No. can be displayed on the monitor screen. Before shipment, it is set to

"OFF" (do not display).

MEASUREMENT switch

1 In the "INITIAL MENU screen," select "INITIAL SET" and get the "INITIAL MENU screen."

2 Press the Set item change button and bring the cursor to "INSTRUMENT No. DIS-

PLAY."

3 Press the Set value change button or and select "ON" (display) or "OF F" (do

not display).

4 Press the Set item change button ; the cursor moves to the next item.

43

PREPARATIONS

Page 45

SHIFTING THE REFRACTORY POWER

The refractory power (S value) can be shifted. Before shipment, it is set to "+0.375."

1 In the "INITIAL MENU screen," select "INITIAL SET" and get the "INITIAL SET" screen.

2 Press the Set item change button and bring the cursor to " DPTR SHIFT."

3 Press the Set value change button to increase the value, or to decrease.

The value can be set between -1.000D and 1.000D with 0.125D steps.

4 Press the Set item change button ; the cursor moves to the next item.

CHANGING THE METHOD OF CORNEA DIAMETER MEASUREMENT

The method of cornea diameter measurement can be selected between using an actual

image or a static image. Before shipment, it is set to "OFF" (measurement using actual

image).

1 In the "INITIAL MENU screen," select "INITIAL SET" and get the "INITIAL MENU screen."

2 Press the Set item change button and bring the cursor to "C.D MEMORY."

3 Press the Set value change button or and select "ON" (measurement using

static image) or "OFF" (measurement using actual image) .

4 Press Set item change button ; the cursor moves to the next item.

44

PREPARATIONS

Page 46

SETTING THE MEASUREMENT MODE AFTER POWERING ON

It is possible to set the measurement mode after powering on. Factory setting, it is set to "R/KT/P" (REF/KRT, TONO/PACHO continuous measurement).

1 Select "INITIAL SET" of the INITIAL MENU screen and get the INITIAL SET screen.

2 Press of the Set item change button and bring the cursor to " MEASURING MODE."

3 Press or of the Set value change button and select the desired measurement

mode.

"R/K-T/P" : REF/KRT, TONO/PACHO continuous measurement mode

"R/K" :REF/KRT measurement mode

"T/P" :TONO/PACHO measurement mode

4 Press the Set item change button to move the cursor to the next item.

When R/K-T/P is set, measurement starts from the REF/KRT mode .

45

PREPARATIONS

Page 47

SETTING THE MEASUREMENT MODE UNDER R/K AND T/P MODE AFTER POWER-ON

For both the REF/KRT and TONO/PACHO mode, it is possible to set the meas ur ement mo de

after powering on. Factory setting, it is set to "INIT" (initial setting state).

1 Select "INITIAL SET" of the INITIAL MENU screen and get the INITIAL SET screen.

2 Press of the Set item change button and bring the cursor to "POWER ON MODE."

3 Press or of the Set value change button and select "INIT" (initial setting state)

or "PREV" (state set before previous power-off).

4 Press the Set item change button to move the cursor to the next item.

SETTING THE WAITING POSITION AFTER MEASUREMENT

It is possible to set the waiting position of th e main body after finishing each measurement.

Factory setting, it is set to "R" (right eye measuring initial position)

1 Select "INITIAL SET" of the INITIAL MENU screen and get the INITIAL SET screen.

2 Press of the Set item change button and bring the cursor to "POSITION SET."

3 Press or of the Set value change button and select the desired measurement

mode:

"R" : Waiting at the right eye measuring initial position

"L" : Waiting at the left eye measuring initial position

"FINISH" : Waiting at the position of the measured eye and pulled toward the operator

4 Press the Set item change button to move the cursor to the next item.

46

PREPARATIONS

Page 48

SETTING THE POWER SAVE TIME

A time for the power save function can be selected. For shipment, 10min. is set.

1 Select "INITIAL SET" of the INITIAL MENU screen and get the INITIAL SET screen.

2 Press of the Set item change button and bring the cursor to "POWER SAVE TIME."

3 Press the Set value change button or and select "OFF", "5", "10", "20", "30",

or "60".

4 Press the Set item change button ; the cursor moves to the next item.

If "OFF" is selected, no power saving function works.

SETTING THE NUMBER OF CONTINUOUS MEASUREMENTS

Under AUTO mode, the number of continuous measurements can be set for each of REF/

KRT, TONO and PACHO. Before shipment, it is set to 3.

1 Select "INITIAL SET" of the INITIAL MENU screen and get the INITIAL SET screen.

2 Press of the Set item change button and bring the cursor to "AUTO MEASURE

COUNT."

3 Press the of the control lever and bring the cursor to the

desired mode.

MEASUREMENT switch

4 Press the Set value change button or and set the count.

47

PREPARATIONS

Page 49

5 Press the Set item change button ; the cursor moves to the next item.

The count can be set between 1 and 10.

The same count is set for REF and KRT.

If different counts are set for TONO and PACHO when the measurement mode is

set at T/P, measurement repeats respectively as specified.

SETTING THE DISPLAY UNIT OF OCULAR PRESSURE MEASUREMENT VALUES

The unit of ocular pressure measurement values displayed on the monitor screen can be

selected from mmHg, digit, hPa or Torr. Before shipment, it is set to "mmHg."

1 Select "INITIAL SET" of the INITIAL MENU screen and get the INITIAL SET screen.

2 Press the Set item change button and bring the cursor to "UNIT SELECT." The dis-

play unit of ocular pressure measurement values is displayed on the right, and the set uni t

is highlighted.

3 Press the Set value change button or and bring the cursor to the desired unit

of display unit of ocular pressure measurement values:

mmHg : The display unit of measurement values is set to mmHg.

digit : The display unit of measurement values is set to digit.

hPa : The display unit of measurement values is set to hPa.

Torr : The display unit of measurement values is set to Torr.

4 Press of the Set item change button and move the cursor to the next item.

48

PREPARATIONS

Page 50

SETTING PRINTOUT

In the PRINT OUT screen, printout format, printing equivalent spherical power, printing computer lensmeter data, and printing barcode, sequence of print out, etc. can be changed.

1 In the "INITIAL MENU screen," press and move the cursor to "PRINT OUT."

2 Press , and the monitor screen is changed to the "PRINT OUT screen."

PRINTING VD VALUES

VD values can be printed out. Before shipment, the setting is "ON" (print VD values).

ENTER

To quit the operation

• Press .

• Close the "PRINT OUT screen" and return to the "INITIAL MENU screen."

To return to the previous item in the screen:

• Press the Set item change button .

EXIT

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the " PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "VD PRINT."

3 Press the Set value change button or and select "ON" (print VD values) or

"OFF" (do not print VD values).

4 Press the Set item change button ; the cursor moves to the next item.

49

PREPARATIONS

Page 51

PRINTING THE CYLINDER SIGN

The CYLINDER sign can be printed out. Before shipment it is set to "ON" (print CYLINDER

sign).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the " PRINT OUT" screen.

2 Press the Set item change button and bring the cursor to "CYL PRINT."

3 Press the Set value change button or and select "ON" (print CYLINDER sign)

or "OFF" (do not print CYLINDER sign).

4 Press the Set item change button ; the cursor moves to the next item.

CHANGING THE PRINTOUT FORMAT OF REFRACTION MEASUREMENT VALUES

The printout format of refractory power can be changed. Before shipment it is set to "ALL"

(print all data).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "REF PRINT FORM."

3 Press the Set value change button or and select "ALL" (print all data) or "AVE"

(print date, settings and typical refraction value only).

4 Press the Set item change button ; the cursor moves to the next item.

50

PREPARATIONS

Page 52

PRINTING THE SPHERICAL EQUIVALENT (S.E. DATA)

The SPHERICAL EQUIVALENT can be printed out. Before shipment, it is set to "ON" (print

equivalent spherical power).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "S.E. DATA."

3 Press the Set value change button or and select "ON" (print S.E. data) or

"OFF" (do not print S.E. DATA).

4 Press the Set item change button ; the cursor moves to the next item.

PRINTING THE REFRACTION

You can print out the pattern showing the refractive state of the measured eye.

Before shipment, it is set to "OFF"(do not print out refractive state).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "GRAPHIC PRINT."

3 Press the Set value change button or and select "ON" (print out refractive

state) or "OFF" (do not print refractive state).

4 Press the Set item change button ; the cursor moves to the next item.

51

PREPARATIONS

Page 53

PRINTING PD VALUES

PD values can be printed out. Before shipment it is set to "ON" (print PD values).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "PD PRINT."

3 Press the Set value change button or and select "ON" (print PD values) or

"OFF" (do not print PD values).

4 Press the Set item change button ; the cursor moves to the next item.

PRINTING COMPUTERIZED LENSMETER DATA

COMPUTERIZED LENSMETER data can be printed out. Before shipment, it is set to "OFF"

(do not print COMPUTERIZED LENSMETER data).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "CL PRINT."

3 Press the Set value change button or and select "ON" (print COM PUTER-

IZED LENSMETER data) or "OFF" (do not print COMPUTERIZED LENSMETER data).

4 Press the Set item change button ; the cursor moves to the next item.

52

PREPARATIONS

Page 54

PRINTING THE CREDIBILITY NUMBER

The credibility number of measurement data can be printed out. Before shipment, it is set to

"OFF" (do not print credibility number).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "CREDIBILITY NUM."

3 Press the Set value change button or and select "ON" (print credibility num-

ber) or "OFF" (do not print credibility number).

4 Press the Set item change button ; the cursor moves to the next item.

PRINTING THE ADDITION NUMBER

The addition number can be printed out. Before shipment, it is set to "OFF" (do not print addition number).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "ADD PRINT."

3 Press the Set value change button or and select "ON" (print addition number)

or "OFF" (do not print addition number).

4 Press the Set item change button ; the cursor moves to the next item.

53

PREPARATIONS

Page 55

CHANGING THE PRINTOUT FORMAT OF CORNEA MEASUREMENT VALUES

The printout format of cornea measurement values can be changed. Before shipment it is set

to "ALL" (print all data).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "KRT PRINT FORM."

3 Press the Set value change button or and select "ALL" (print all data) or "AVE"

(print typical values only).

4 Press the Set item change button ; the cursor moves to the next item.

PRINTING THE AVERAGE VALUE OF KERATOMETRY MEASUREMENTS

The average value of KERATOMETRY measurements can be printed out. Before shipment it

is set to "ON" (print average value).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "KRT AVE PRINT."

3 Press the Set value change button or and select "ON" (print average values),

or "OFF" (do not print average value).

4 Press the Set item change button ; the cursor moves to the next item.

54

PREPARATIONS

Page 56

CHANGING THE PRINTING SEQUENCE KERATOMETRY MEASUREMENT VALUES

The sequence of displaying the cornea refractory power and curvature in the printout can be

changed. Before shipment, the setting is "D/MM" (print diopter value first)

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "KRT DATA ORDER."

3 Press the Set value change button or and select "D/MM" (print diopter value

first), or "MM/D" (print mm value first).

4 Press the Set item change button ; the cursor moves to the next item.

PRINTING CORNEAL ASTIGMATISM AND AXIS

The corneal astigmatism and AXIS can be printed out. Before shipment it is set to "ON" (print

corneal astigmatism and AXIS).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "KRT CYL PRINT."

3 Press the Set value change button or and select "ON" (print corneal astigma-

tism and AXIS), or "OFF" (do not print corneal astigmatism and AXIS).

4 Press the Set item change button ; the cursor moves to the next item.

55

PREPARATIONS

Page 57

CHANGING THE PRINTING SEQUENCE

The sequence of display in the printout can be changed. Before shipment, it is set to "DATA"

(print REF and KRT values separately).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "PRINT R/L."

3 Press the Set value change button or and select "DATA"(print REF and KRT

values separately), or "R/L" (print right and left eyes in order irrespective of REF/KRT).

4 Press the Set item change button ; the cursor moves to the next item.

PRINTING THE BARCODE

The barcode can be printed out. Before shipment, it is set to "OFF" (do not print barcode).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and move the cursor to "BARCODE PRINT."

3 Press the Set value change button or and select "ON" (print barcode) or

"OFF" (do not print barcode).

4 Press the Set item change button ; the cursor moves to the next item.

56

PREPARATIONS

Page 58

PRINTING NAMES

The name list can be printed out. Before shipment it is set to "ON" (print names).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "NAME PRINT."

3 Press the Set value change button or and select "ON" (print names), or "OFF"

(do not print names).

4 Press the Set item change button ; the cursor moves to the next item.

PRINTING THE DATE

The date can be printed out. Before shipment it is set to "ON" (print date).

1 In the "INITIAL MENU screen," select "PRINT OUT" and get the "PRINT OUT screen."

2 Press the Set item change button and bring the cursor to "DATE PRINT."

3 Press the Set value change button or and select "ON" (print date), or "OFF"

(do not print date).

4 Press the Set item change button ; the cursor moves to the next item.

When the built-in clock battery is used up, the date is not printed and "DATE" is

printed. For questions about the replacement of the built-in battery, call your dealer