Page 1

INSTRUCTION MANUAL

For more information contact Synergy Positioning Systems or

visit the Synergy Positioning Systems website at www.synergypositioning.co.nz

All branches: Phone 0800 867 266 Email: info@synergypositioning.co.nz

PIPE LASER

TP-L5 SERIES

TP-L5GV

TP-L5G

TP-L5BG

TP-L5AV

TP-L5A

TP-L5B

32956 90092

Page 2

Page 3

HOW TO READ THIS MANUAL

Thank you for selecting the TOPCON instrument.

• Please read this instruction manual carefully before using this instrument.

• Verify that all equipment is included.

“ STANDARD SYSTEM COMPONENTS” (p. iii)

• The specifications and general appearance of the instrument are subject to change without

prior notice and without obligation by Topcon Corporation and may differ from those appearing

in this manual.

• Some of the diagrams shown in this manual may be simplified for easier understanding.

Symbols

The following conventions are used in this manual.

:

Indicates precautions and important items which should be read before

operations.

:

Indicates the chapter title to refer to for additional information.

:

Indicates supplementary explanation.

i

Page 4

HOW TO READ THIS MANUAL

Notes regarding manual style

• Except where stated, "TP-L5" means TP-L5GV/G/BG/AV/A/B in this manual.

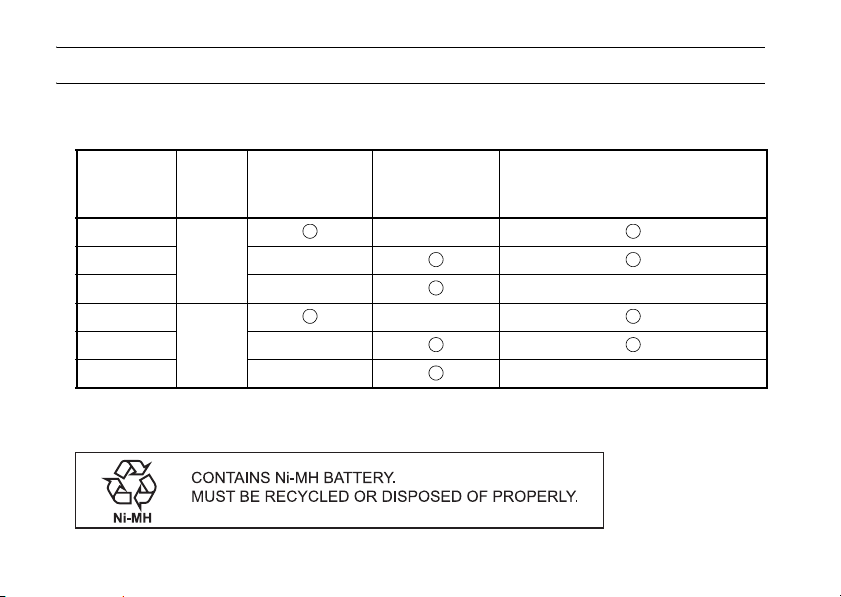

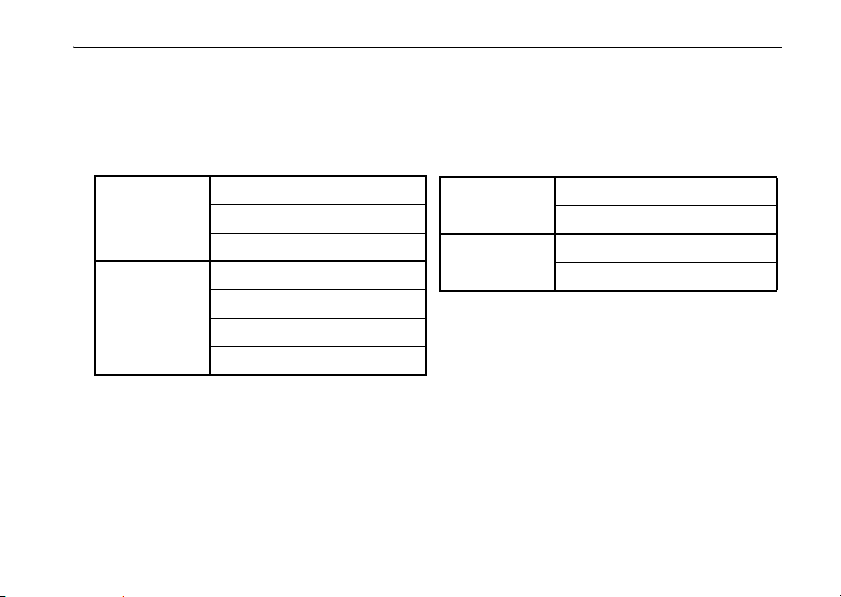

• The specifications by the model are as follows.

Auto alignment

(TP-L5GV/G/AV/A only)" (p. 39)

Red

Upper/Lower

Laser

---

--- ---

---

--- ---

Model Laser

TP-L5GV

TP-L5G

TP-L5BG

TP-L5AV

TP-L5A

TP-L5B

• All company and product names featured in this manual are trademarks or registered

trademarks of each respective organization.

Green

Centerline

LED

---

---

" Automatic alignment with the target

ii

Page 5

STANDARD SYSTEM COMPONENTS

1) Pipe Laser TP-L5..................................... 1pc.

2) Remote controller RC-200 ....................... 1pc.

3) Battery BT-53Q (rechargeable battery) ... 1pc.

4) AC/DC Converter AD-13 ......................... 1pc.

5) Battery adapter BA-2 ............................... 1pc.

6) Self-centering Feet

ø150mm .................................................. 4pcs.

ø200mm .................................................. 4pcs.

ø250mm .................................................. 4pcs.

ø300mm .................................................. 4pcs.

7) Single point foot ....................................... 1pc.

8) Target....................................................... 1set

9) AAA Manganese battery

*1)

...................... 4pcs.

10) Carrying case .......................................... 1pc.

11) Instruction manual ................................... 1vol.

• Please make sure that all of above items are in the box when you unpack.

*1) Batteries included in the package are to confirm the initial operation.

Please replace the batteries provided with new batteries (alkaline) as soon as possible.

iii

Page 6

CONTENTS

1. PRECAUTIONS FOR SAFE OPERATION ............................................................................ 1

2. PRECAUTIONS ..................................................................................................................... 7

3. LASER SAFETY INFORMATION ........................................................................................ 13

4. PRODUCT OUTLINE ........................................................................................................... 16

4.1 Parts and Functions of the Instrument .......................................................................... 16

Control panel............................................................................................................. 18

Key Operation (When the instrument is locked) ....................................................... 21

Indicators .................................................................................................................. 22

5. USING THE BATTERY ........................................................................................................ 25

5.1 Battery BT-53Q (Rechargeable battery) ....................................................................... 25

Removing the battery................................................................................................ 25

Battery charging........................................................................................................ 26

5.2 Battery Holder DB-53 (Dry battery holder) *Optional accessory................................... 29

Removing the battery................................................................................................ 29

Replacing the dry cell batteries................................................................................. 29

5.3 PC-17 (Power cable for 12vDC) *Optional accessory .................................................. 30

6. BASIC OPERATION ............................................................................................................ 31

6.1 Setting up the Instrument.............................................................................................. 31

6.2 Grade setting procedure ............................................................................................... 32

Direct entry of grade value ........................................................................................ 32

Set grade value by moving laser............................................................................... 35

iv

Page 7

CONTENTS

6.3 Setting Laser Line ......................................................................................................... 36

Automatic Centering.................................................................................................. 38

Automatic alignment with the target (TP-L5GV/G/AV/A only) ................................... 39

6.4 Changing the laser beam mode .................................................................................... 42

7. STANDARD ACCESSORIES............................................................................................... 43

7.1 Self-centering Feet........................................................................................................ 43

7.2 Single Point Foot........................................................................................................... 44

7.3 Remote Controller (RC-200) ......................................................................................... 45

Replacing battery for Remote Control, RC-200 ........................................................ 49

7.4 Target ........................................................................................................................... 50

8. CHANGING OPERATING PARAMETERS .......................................................................... 51

8.1 Operating Parameters................................................................................................... 51

8.2 How To Change Operating Parameters........................................................................ 53

8.3 How to Input (Change) Security Code .......................................................................... 55

8.4 How to change Company Name ................................................................................... 60

9. CHECKS AND ADJUSTMENTS .......................................................................................... 66

9.1 Procedure To Check and Adjust Laser Calibration ....................................................... 66

Checking Calibration ................................................................................................. 66

Adjusting Calibration ................................................................................................. 67

9.2 Checking of Upper/Lower Laser (TP-L5GV/AV only).................................................... 70

v

Page 8

CONTENTS

10. ERROR DISPLAYS.............................................................................................................. 71

11. TROUBLESHOOTING ......................................................................................................... 72

12. OPTIONAL ACCESSORIES ................................................................................................ 77

13. SPECIFICATIONS ...............................................................................................................78

14. REGULATIONS.................................................................................................................... 81

vi

Page 9

1. PRECAUTIONS FOR SAFE OPERATION

For the safe use of the product and prevention of injury to operators and other persons as well

as prevention of property damage, items which should be observed are indicated by an

exclamation point within a triangle used with WARNING and CAUTION statements in this

instruction manual.

The definitions of the indications are listed below. Be sure you understand them before reading

the manual’s main text.

Definition of Indication

WARNING

CAUTION

This symbol indicates items for which caution (hazard warnings inclusive) is urged.

Specific details are printed in or near the symbol.

This symbol indicates items which are prohibited. Specific details are printed in or

near the symbol.

This symbol indicates items which must always be performed. Specific details are

printed in or near the symbol.

Ignoring this indication and making an operation error could possibly

result in death or serious injury to the operator.

Ignoring this indication and making an operation error could possibly

result in personal injury or property damage.

1

Page 10

General

1. PRECAUTIONS FOR SAFE OPERATION

Warning

Do not use the unit in areas exposed to high amounts of dust or ash, in areas where

there is inadequate ventilation, or near combustible materials. An explosion could

occur.

Do not perform disassembly or rebuilding. Fire, electric shock, burns or hazardous

radiation exposure could result.

Do not use under thunderous weather conditions. This unit is conductive and if

struck by lightning, death or injury could result.

Handle with care when using near high voltage cables or transformers. This unit is

conductive and contact could result in electric shock.

When securing the instrument in the carrying case make sure that all catches,

including the side catches, are closed. Failure to do so could result in the

instrument falling out while being carried, causing injury.

2

Page 11

Caution

Do not use the carrying case as a footstool. The case is slippery and unstable so a

person could slip and fall off it.

Do not place the instrument in a case with a damaged case or belt. The case or

instrument could be dropped and cause injury.

Do not wield or throw the plumb bob. A person could be injured if struck.

Power Supply

Warning

Do not short circuit. Heat or ignition could result.

Do not place articles such as clothing on the battery charger while charging

batteries. Sparks could be induced, leading to fire.

Do not use voltage other than the specified power supply voltage. Fire or electrical

shock could result.

1. PRECAUTIONS FOR SAFE OPERATION

3

Page 12

1. PRECAUTIONS FOR SAFE OPERATION

Do not use batteries other than those designated. An explosion could occur, or

abnormal heat generated, leading to fire.

Do not use damaged power cords, plugs or loose outlets. Fire or electric shock

could result.

Do not use power cords other than those designated. Fire could result.

Use only the specified battery charger to recharge batteries. Other chargers may

be of different voltage rating or polarity, causing sparking which could lead to fire or

burns.

Do not use the battery or charger for any other equipment or purpose. Fire or burns

caused by ignition could result.

Do not heat or throw batteries or chargers into fire. An explosion could occur,

resulting in injury.

To prevent shorting of the battery in storage, apply insulating tape or equivalent to

the terminals. Otherwise shorting could occur, resulting in fire or burns.

4

Page 13

Tripod

1. PRECAUTIONS FOR SAFE OPERATION

Do not use batteries or the battery charger if wet. Resultant shorting could lead to

fire or burns.

Do not connect or disconnect power supply plugs with wet hands. Electric shock

could result.

Caution

Do not touch liquid leaking from batteries. Harmful chemicals could cause burns or

blisters.

Caution

When mounting the instrument to the tripod, tighten the centering screw securely.

Failure to tighten the screw properly could result in the instrument falling off the

tripod, causing injury.

Tighten securely the leg fixing screws of the tripod on which the instrument is

mounted. Failure to tighten the screws could result in the tripod collapsing, causing

injury.

5

Page 14

1. PRECAUTIONS FOR SAFE OPERATION

Do not carry the tripod with the tripod shoes pointed at other persons. A person

could be injured if struck by the tripod shoes.

Keep hands and feet away from the tripod shoes when fixing the tripod in the

ground. A hand or foot stab wound could result.

Tighten the leg fixing screws securely before carrying the tripod. Failure to tighten

the screws could lead to the tripod legs extending, causing injury.

6

Page 15

2. PRECAUTIONS

Before starting work or operation, be sure to check that the instrument is functioning correctly

with normal performance.

Charging Battery

• Be sure to charge the battery within the charging temperature range.

Charging temperature range: 10 to 35

Warranty policy for Battery

• Battery is an expendable item. The decline in retained capacity depending on the repeated

charging/discharging cycle is out of warranty.

Vibration and Impact Protection

• When transporting the instrument, provide protection to minimize risk of severe vibration or

impact. Severe vibration or impacts may affect beam accuracy.

Sudden changes of temperature

• A sudden change in temperature may cause water condensation on the glass used for the

laser emission part. In such a case, let the instrument stand for a while to allow it to adjust to

the temperature prior to actual use.

°C

7

Page 16

2. PRECAUTIONS

Storage precautions

• When storing the instrument, keep it in a place not exposed to direct sunlight and at the

temperature range from -30

• Do not store the wet instrument in the carrying case. If any part of the instrument is wet,

thoroughly wipe off with soft cloth and leave it dry before storing in the carrying case.

to 60°C.

Battery

• The battery is not charged when the instrument is shipped. Make sure to charge it fully before

use.

• If the battery is over-discharged, it may make re-charging impossible or shorten the running

time. Store the battery when it is fully charged.

• Even if the instrument is not used for a long period, charge the battery at least once per 3 to

6 months to maintain the performance of the battery.

• If the battery's running time shortens after using it for a certain period, contact your local

dealer.

• When using an external power supply, it should be rated between 9 and 20 volts DC.

8

Page 17

2. PRECAUTIONS

Measurement

This instrument is designed for survey and survey related uses (that is, surveying coordinates,

distance, angles and depths, and recording such measurements). This product should never be

used:

• Without the user thoroughly understanding this manual.

• After disabling safety systems or altering the product.

• With unauthorized accessories.

• Without proper safeguards at the survey site.

• Contrary to applicable laws, rules, and regulations.

Maintenance

• Wipe off moisture completely if the instrument gets wet during survey work.

• Wipe away stain or dirt with soft cloth after dusting.

• Clean storage case using cloth moistened with neutral detergent or water. Do not use ether,

benzene, thinner or other solvents.

• To clean the instrument or the carrying case, lightly moisten a soft cloth in a mild detergent

solution. Wring out excess water until the cloth is slightly damp, then carefully wipe the surface

of the unit. Do not use any alkaline cleaning solutions, alcohol, or any other organic solvents

on the instrument or display.

• When removing the instrument from the carrying case, never pull it out by force. The empty

carrying case should be closed to protect it from moisture.

• Check the tripod for loose fit and loose screws.

• Check the instrument for proper adjustment periodically to maintain the instrument accuracy.

9

Page 18

2. PRECAUTIONS

Other precautions

• Protect the instrument from heavy shocks or vibration.

• When setting up the instrument, position it so the bubble in the digital level vial on the display

is in the center position.

• When you remove the instrument from the carrying case, be sure to open the cover of the

case after laying the case down, right side up.

• Consult your local dealer before using the instrument under special conditions such as long

periods of continuous use or high levels of humidity. In general, special conditions are treated

as being outside the scope of the product warranty.

• Physical reflection and refraction may occur under hot weather conditions or in a small pipe

diameter due to its temperature or moisture conditions, which could interfere with the

precision or available range of the instrument. To minimize the effect of these conditions

please take the following precautions.

1)Place the pipe hot side (heated by sunlight etc.) down.

2)Do not apply an excessive amount of "pipe adhesive" to the pipe joints.

3)Immediately back fill the trench as pipe work is finished.

If it is difficult to follow the instructions noted above, please use a blower (commerciallyavailable) or place the instrument on the pipe before performing the operation.

User

• Wear the required protectors (safety shoes, helmet, etc.) when operating.

10

Page 19

2. PRECAUTIONS

Exporting this product (Relating EAR)

• This product is equipped with the parts/units, and contains software/technology, which are

subject to the EAR (Export Administration Regulations). Depending on countries you wish to

export or bring the product to, a US export license may be required. In such a case, it is your

responsibility to obtain the license. The countries requiring the license as of May 2013 are

shown below. Please consult the Export Administration Regulations as they are subject to

change.

North Korea

Iran

Syria

Sudan

Cuba

URL for the EAR of the US: http://www.bis.doc.gov/policiesandregulations/ear/index.htm

Exceptions from Responsibility

• The user of this product is expected to follow all operating instructions and make periodic

checks of the product’s performance.

• The manufacturer, or its representatives, assumes no responsibility for results of a faulty or

intentional usage or misuse including any direct, indirect, consequential damage, and loss of

profits.

11

Page 20

2. PRECAUTIONS

• The manufacturer, or its representatives, assumes no responsibility for consequential

damage, and loss of profits by any disaster, (an earthquake, storms, floods etc.). A fire,

accident, or an act of a third party and/or a usage any other usual conditions.

• The manufacturer, or its representatives, assumes no responsibility for any damage, and loss

of profits due to a change of data, loss of data, an interruption of business etc., caused by

using the product or an unusable product.

• The manufacturer, or its representatives, assumes no responsibility for any damage, and loss

of profits caused by usage except for explained in the user manual.

• The manufacturer, or its representatives, assumes no responsibility for damage caused by

wrong movement, or action due to connecting with other products.

12

Page 21

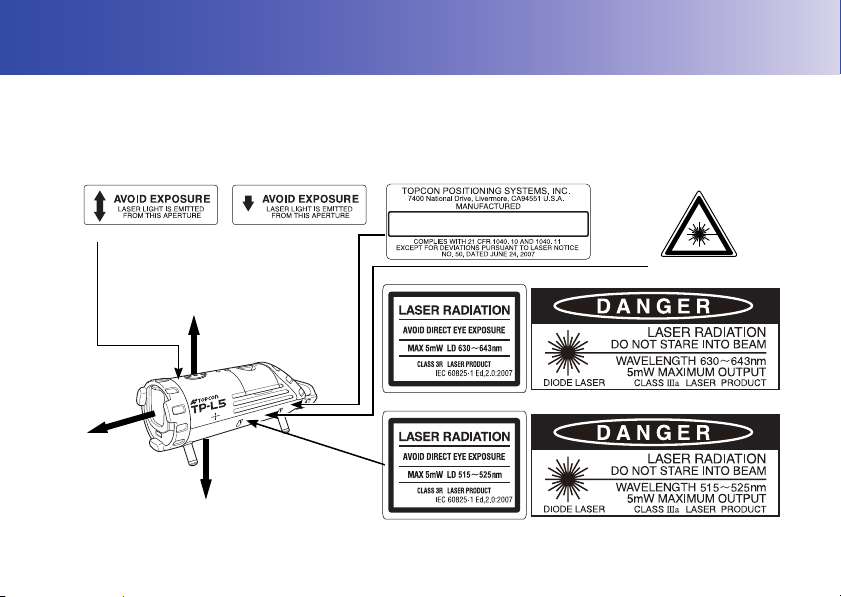

3. LASER SAFETY INFORMATION

Laser beam emitted from here

(TP-L5GV/AV model only)

TP-L5GV/G/BG

TP-L5AV/A/B

Laser beam

emitted from here

Laser beam emitted from here

(TP-L5GV/AV model only)

Warning Label

TP-L5GV/AV

TP-L5G/BG/A/B

The TP-L5 is classified as a class 3R Laser Product according to IEC Standard Publication 60825-1

Ed.2.0: 2007 and United States Government Code of Federal Regulation FDA CDRH 21CFR Part

1040.10 and 1040.11 (Complies with FDA performance standards for laser products except for

deviations pursuant to Laser Notice No.50, dated June 24, 2007.)

13

Page 22

3. LASER SAFETY INFORMATION

Warning

• Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

• Never intentionally point the laser beam at another person. The laser beam is injurious

to the eyes and skin. If an eye injury is caused by exposure to the laser beam, seek

immediate medical attention from a licensed ophthalmologist.

• The laser beam is emitted when the power is turned ON. Before turning the power on,

make sure that persons are not located in the path of the laser beam.

• Secure the instrument in a fixed position before it is used. If it is necessary to hold the

instrument by hand, make sure that persons are not located in the area before the laser

is emitted.

• Do not look directly into the laser beam. Doing so could cause permanent eye damage.

• Do not stare at the laser beam. Doing so could cause permanent eye damage.

• Never look at the laser beam through a telescope, binoculars or other optical

instruments. Doing so could cause permanent eye damage.

Caution

• Perform checks at start of work and periodic checks and adjustments with the laser beam

emitted under normal conditions.

14

Page 23

3. LASER SAFETY INFORMATION

• When the instrument is not being used, turn off the power.

• When disposing of the instrument, destroy the battery connector so that the laser beam

cannot be emitted.

• Avoid setting the instrument at heights at which the path of the laser may strike

pedestrians or drivers at head height. Operate the instrument with due caution to avoid

injuries that may be caused by the laser beam unintentionally striking a person in the eye.

• Do not emit the laserbeam at eye level.

• Never point the laser beam at mirrors, windows or surfaces that are highly reflective. The

reflected laser beam could cause serious injury

• Only those who have received training as per the following items shall use this product.

• Read this manual for usage procedures for this product.

• Hazardous protection procedures (read "LASER SAFETY INFORMATION")

• Requisite protective gear (read "LASER SAFETY INFORMATION")

• Accident reporting procedures (stipulate procedures beforehand for transporting

the injured and contacting physicians in case there are laser-induced injuries).

• Persons working within the range of the laser beam are advised to wear eye protection

which corresponds to the laser wavelength of the instrument being used.

• Areas in which the laser is used should be posted with a standard laser warning sign.

• Sight targets so that the laser beam does not stray from them.

15

Page 24

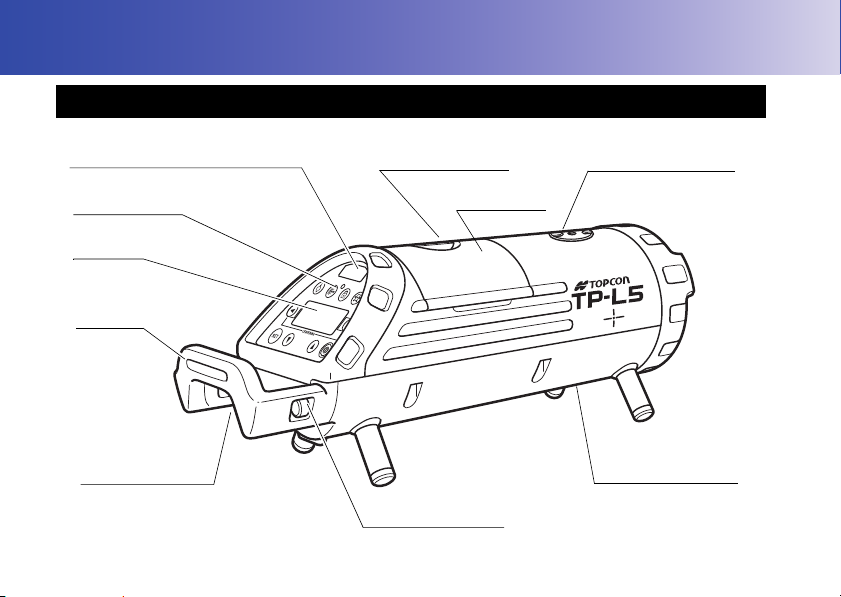

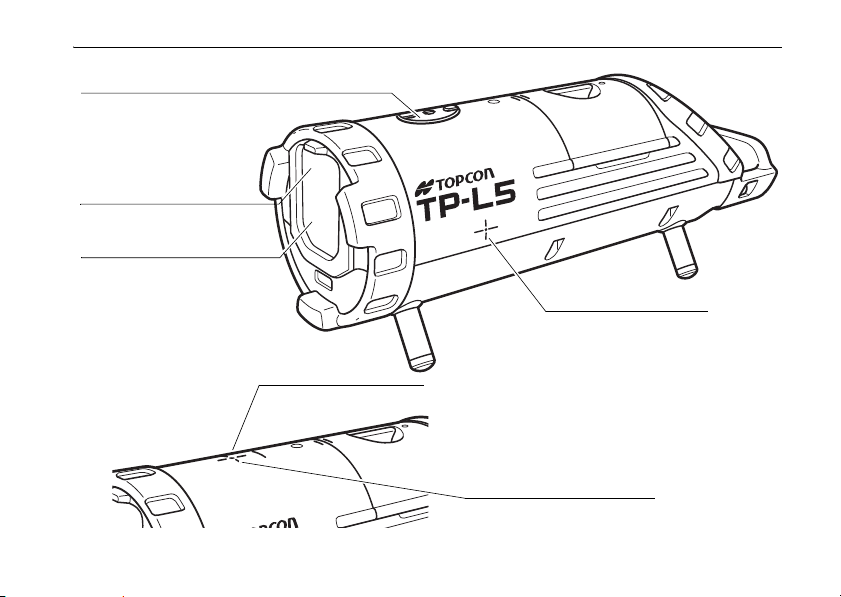

4. PRODUCT OUTLINE

Display

Operating keys

Handle

Remote control receiving window

Battery knob

Handle fixing screw

Power supply

connector

(with cap)

Battery

Upper laser emitting

window

(TP-L5GV/AV only)

Lower laser emitting

window

(TP-L5GV/AV only)

4.1 Parts and Functions of the Instrument

16

Page 25

Laser beam window

Laser beam emitted

from here

Grade axis mark

Laser grade starting point

Remote control receiving

window

Centerline LED

(TP-L5G/BG/A/B only)

Starting point of the laser line

Laser centerline mark

(TP-L5G/BG/A/B only)

Upper laser blocking hatch (TP-L5GV/AV only)

Blocks the upper laser beam by rotating

17

4. PRODUCT OUTLINE

Page 26

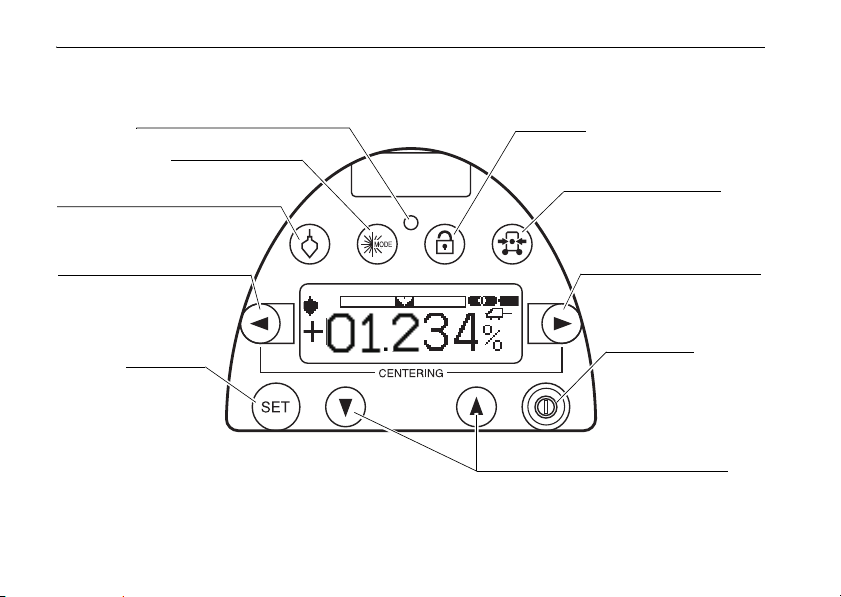

Control panel

Power key

Setting key

Laser righ t/ left key

(Line control/Digit shifting/

Auto centering)

Laser right/left key

(Line control/Digits shifting/

Auto centering)

Laser up/down key (Value setting)

Auto alignment key

Warning/Standby Indicator LED

Lock key

(TP-L5GV/G/AV/A only)

Centerline LED (TP-L5G/BG/A/B)/

LD

(TP-L5GV/AV) key

Beam mode key

4. PRODUCT OUTLINE

The illumination of the display will be ON for 30 seconds whenever anyone key is pressed.

18

Page 27

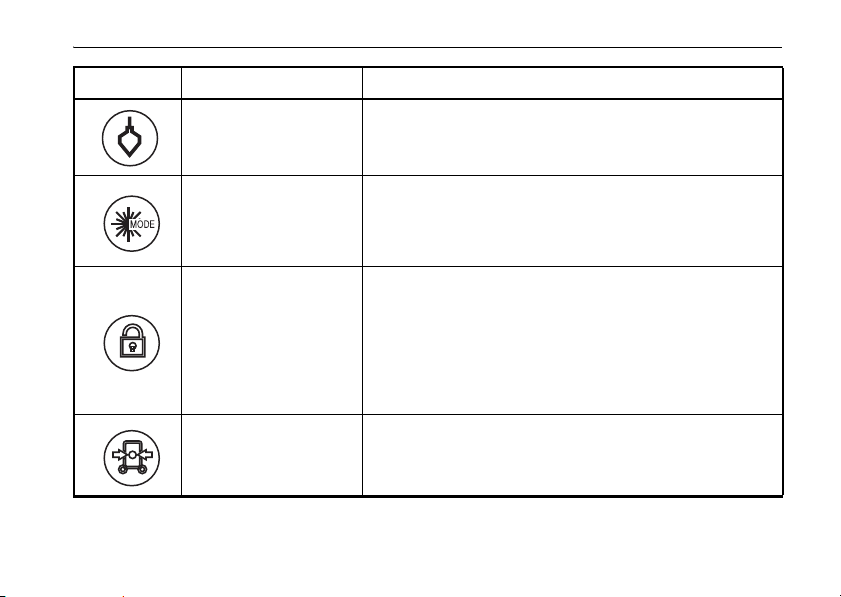

Key/LED Nomenclature Function

Centerline LED /

LD (GV/AV) key

Beam mode key

Turn the centerline LED/LD (GV/AV) ON or OFF by

pressing. (Auto shut off after 30 minutes.)

The mode of laser beam is switched alternately.

"On mode" / "Blinking mode" / "Energy mode (TP-L5GV/G/

BG only)"

“6.4 Changing the laser beam mode” (p.42)

Forbids the entry of the laser up/down key, the laser right/

left key, the setting key and the auto alignment key of the

Lock key

instrument and the remote control, as well as prevents the

setting value to be changed by incorrect operation.

Pressing again releases this function.

“Key Operation (When the instrument is locked)”

(p.21)

Auto alignment key

(TP-L5GV/G/AV/A)

The laser beam is aligned to the center of the target

automatically.

“Automatic alignment with the target (TP-L5GV/G/AV/

A only)” (p.39)

19

4. PRODUCT OUTLINE

Page 28

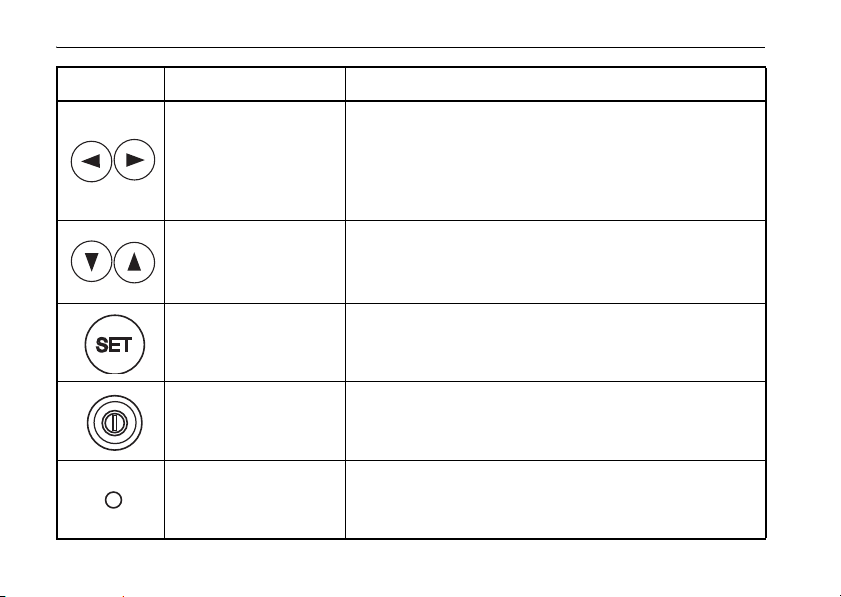

Key/LED Nomenclature Function

Press to move the laser beam to the right or to the left.

Active indicating digit shifts to the right or the left.

Laser right/left key

“6.3 Setting Laser Line” (p.36)

By pressing both keys at the same time, the laser beam

returns to the center automatically.

“Automatic Centering” (p.38)

Press to move the laser beam up or down.

Laser up/down key

Setting key Press to enter grade shown on display.

Power key Turn the instrument ON or OFF.

Positive and negative values are indicated in the display

for grade setting. By pressing both keys at the same time,

returns grade to 00.000% (0

‰).

4. PRODUCT OUTLINE

Warning /

Standby Indicator LED

Flashes to indicate warning or standby mode.

20

Page 29

4. PRODUCT OUTLINE

Operable keys

Centerline LED/LD key

Beam mode key

Power key

Inoperable keys

Auto alignment key

Laser up/down key

Laser right/left key

Setting key

TP-L5

RC-200

Operable keys

Laser ON/OFF switch

Laser beam mode key

Inoperable keys

Auto alignment key

Laser right/left key

Key Operation (When the instrument is locked)

When the instrument is locked, the operable/inoperable keys of the instrument and the remote

control are as follows.

• Press the lock key on the instrument to release the lock function.

21

Page 30

Indicators

Laser line indicator

Indicates the direction of the

laser line.

Centerline LED/LD (GV/AV) key

Digital level vial, rotate

instrument until centered

Battery warning indication

Remaining battery capacity is

shown in 3 steps.

Grade indication

Lock indicator

Indicates when the instrument

is locked.

Percent or Permil symbol

Laser mode indication

Auto leveling indication

(Flashing)

Flashes when the instrument is

auto leveled. After auto leveling

is finished, the display changes

laser mode.

By pressing the beam mode key,

the mode is switched alternately.

“6.4 Changing the laser beam

mode” (p.42)

Power remaining for

operation

Flashing

alternatory

Operating time is limited.

Recharging or alternate

power will be required soon.

Charging while using 12

volt DC external battery.

4. PRODUCT OUTLINE

22

Page 31

Level vial display indicates instrument rotation status

When the instrument is titled sideways or the unit is first turned on, the small

level vial indicator on the display enlarges to fill the entire display to aid the

user in accurate instrument setup.

“8. CHANGING OPERATING PARAMETERS” (p.51)

Warning indications

Rotation warning indication

The instrument is tilted too far to the right or left.

The laser beam will flash slowly.

Reposition the instrument to the direction indicated by arrow.

Always position the instrument so the bubble in the digital level vial is

centered.

Battery warning indication

Operation is impossible. The laser beam is not emitted then, and the

centerline LED does not turn on, too.

Charge the battery or replace with a fully charged battery.

Level warning indication

The instrument tilted beyond the auto-leveling range to the back or front.

The laser beam will flash slowly.

Reposition the instrument by tilting in the direction indicated by arrow.

4. PRODUCT OUTLINE

23

Page 32

Rotation direction detection error

Reposition the instrument horizontally.

WAIT

During laser position adjusting process

The display will appear during the adjustment of the laser after the startup of

the instrument. Operations can be performed just after "WAIT" disappears.

• If the battery is removed while the instrument is turned ON, this

display may be appeared the next time the instrument starts up.

• This display may be appeared when operating at especially high/low

temperature or starting up the instrument after the battery warning

indication "EMPTY" being displayed.

• While "WAIT" is displayed, the key operations are impossible.

Safety Lock

If the instrument is moved for any reason after the laser is OFF (standby

mode) using the remote controller, a safety lock will be in operation. This is

to insure operational accuracy. "SAFETY LOCK" will appear on the display

and the laser beam and the indicator LED will flash. To reset, turn power OFF

the instrument by the Power key on the control panel, check the instrument

position, and then turn ON the instrument again. While the safety lock is in

operation, power cannot be turned ON/OFF by the remote controller.

4. PRODUCT OUTLINE

24

Page 33

5. USING THE BATTERY

• The battery was not charged at the factory. Charge the battery fully before using the

instrument.

5.1 Battery BT-53Q (Rechargeable battery)

Removing the battery

• Before removing the battery, turn off the power to the instrument.

1 Turn the battery knob to "OPEN", lift and

remove the BT-53Q rechargeable battery.

25

Page 34

Battery charging

BT-53Q

Battery adapter BA-2

AC/DC converter AD-13

1

Insert the BA-2 battery adapter into the

BT-53Q rechargeable battery as shown.

2 Plug the AC/DC converter AD-13 into the

BA-2.

3 Insert the AC/DC converter power cord

into the appropriate AC outlet.

LED of the BT-53Q rechargeable battery

will light up red.

4 After charging is complete (Charging time:

Approx. 9 hours), unplug the BA-2 battery

adapter from the BT-53Q rechargeable

battery.

The LED will light up green.

5 Unplug the AC/DC converter power cord from the AC receptacle.

26

5. USING THE BATTERY

Page 35

5. USING THE BATTERY

• Charging while operating from DC12V external battery

This function is useful when operating from the BT-53Q rechargeable battery that is low and

needs charging. Using the instrument with 12vDC external battery in ambient temperature

[10 to 35°C (50 to 95°F)], the rechargeable battery can be recharged while the instrument is

in use.

Optional accessory power cable (PC-17) is necessary to use the instrument with 12vDC

external battery. “5.3 PC-17 (Power cable for 12vDC) *Optional accessory” (p.30)

Connect 12vDC external battery and turn the instrument ON, the BT-53Q will charge

automatically. The charging indicator LED on top of the BT-53Q will indicate charging status.

• The LED on the battery indicates charging status as follows:

Red ON : Charging

Green ON : Charging completed.

Green flashing : Internal error of BT-53Q rechargeable battery

Red flashing : BT-53Q rechargeable battery protection feature* is working automatically.

The instrument can be used in this case.

*Automatic protection feature:

In case of overcharge or high or low ambient temperatures that exceeds charging

temperature range, charging will be stopped or changed to protect battery.

27

Page 36

5. USING THE BATTERY

• If the 12vDC external battery is disconnected while working, the power source will

automatically switch to the BT-53Q rechargeable battery.

• Be sure to charge the battery within the charging temperature range (10 to 35°C).

• Do not perform charging with others except the AC/DC converter AD-13.

• For l.onger battery life, conform to the suggested charging time to the extent possible.

• The battery source will discharge when stored and should be checked before using with

instrument.

• Do not recharge the battery when fully charged. Doing so will lower battery performance.

• For long-term storage, the battery should be charged at least once per 3 to 6 months and store

in a place at 30°C or below. If you allow the battery to become completely discharged, it will

have an effect on future charging.

• Batteries generate power using a chemical reaction and as a result have a limited lifetime.

Even when in storage and not used for long periods, battery capacity deteriorates with the

passage of time. This may result in the operating time of the battery shortening despite having

been charged correctly. In this event, a new battery is required.

28

Page 37

5. USING THE BATTERY

DB-53

5.2 Battery Holder DB-53 (Dry battery holder) *Optional accessory

Removing the battery

1

Turn the battery knob to "OPEN", lift and remove the

battery holder DB-53.

Replacing the dry cell batteries

1

Open battery holder DB-53 by turning the lid knob to

"OPEN".

2 Remove the old batteries and replace with new

batteries (4xD size dry cell batteries) matching [+]

and [-] as shown in the figure. Close the battery

cover by turning the knob to "LOCK".

3 Insert the battery holder into the instrument. Secure by turning the knob to "LOCK".

• Replace all 4 batteries with new ones at the same time.

• Insert the batteries in the battery box according to the appointed direction.

• Do not mix used and new batteries, and do not mix different types of batteries together.

29

Page 38

5. USING THE BATTERY

PC-17

Power cable for 12vDC

Red clip to positive terminal

12 volt DC battery

Black clip to negative

terminal

5.3 PC-17 (Power cable for 12vDC) *Optional accessory

• Stop the engine while using automobile battery.

• Be sure to connect the red clip to positive terminal and black clip to negative terminal of the

battery when using the Power source cable for 12 volt DC. (Electric current consumption:

Max. 3A)

• Always turn OFF the instrument before removing on-board battery or external power cable.

30

Page 39

6. BASIC OPERATION

+10% (+100)‰

Inclination of the instrument

Setting grade

-10% (-100)‰

6.1 Setting up the Instrument

1 Always position the instrument so the bubble in the digital level vial is centered.

• The laser might move from side to side in order to adjust the position of laser beam after

the instrument is turned ON (See WAIT display on p.24). The instrument is not operable

during this adjusting process (for about 30 seconds).

The instrument has a self-leveling range of ±10%. To assure proper self-leveling the

instrument must be positioned to within 10% of the grade entered.

• A warning indication will appear depending on the instrument's installed condition.

"Warning indications" (p.23 to 24)

31

Page 40

6.2 Grade setting procedure

or

Direct entry of grade value

(Example) Setting grade of -12.345% (Format ± AB.CDE%)

• Input range: -15.000 to 40.000% (-150.00 to 400.00‰)

• Setting grade is not possible when the instrument is locked.

Procedure Key operation Display

1 Press [SET] key.

The previous data will be shown, and ±

mark is highlighted.

2 Press [ ] or [ ] key to change the sign

to -.

6. BASIC OPERATION

32

Page 41

3 Press [ ] key to shift to digit A.

or

or

・

・

・

・

・

Disit A is highlighted.

4 Press [ ] or [ ] key to change value to

"1".

5 Press [ ] key to shift to digit B.

Disit B is highlighted.

6 Press [ ] or [ ] key to change value to

"2".

7 Repeat previous steps to change values

of digit C to "3", digit D to "4" and digit E

to "5".

6. BASIC OPERATION

33

Page 42

6. BASIC OPERATION

8 Press [SET] key.

After entering, the instrument starts

repositioning the laser to the grade. The

auto leveling indication blinks during the

grade setting process. The laser beam

blinks at the same time.

• The grade value displayed on the screen will be set automatically if no value is entered within

15 seconds.

34

Page 43

6. BASIC OPERATION

The grade display will increase or decrease according

to the direction of the laser.

Pressing the [ ] or [ ] key, the laser beam moves up or down.

Set grade value by moving laser

Grade value can be set directly by moving laser up or down.

Be sure that the lock is disengaged before operating.

• 0 setting

Pressing the [ ] and [ ] key at the same time, the display and the laser will return to

00.000% (0‰).

35

Page 44

6. BASIC OPERATION

This display indicates that the laser

line is positioned at the right end of the

adjustment range. The laser line will

not travel to the right even if the laser

right/left key is held down. In addition,

the laser will blink to alert the user of

this condition. It is always a good idea

to pre-position the laser to the center

of its adjusting range prior to setup.

This display indicates that the laser

line is positioned at the left end of the

adjustment range. The laser line will

not travel to the left even if the laser

right/left key is held down. In addition,

the laser will blink to alert the user of

this condition. It is always a good idea

to pre-position the laser to the center

of its adjusting range prior to setup.

LASER LINE INDICATOR

6.3 Setting Laser Line

Use the laser right/left key on the instrument display panel or the RC-200 remote control to move

the horizontal laser position to the left or right required.

The maximum adjusting range is 9 m (29.5 ft.) at a distance of 30 m (100ft.)

The speed of the line travel is variable. When the key is first pressed, the speed will be slow.

By pressing the key continuously, the speed of line travel will increase.

The relative position of the laser beam is shown on the display as indicated below.

• Setting Laser Line is not possible when the instrument is locked.

36

Page 45

Maximum line adjust range

6. BASIC OPERATION

37

Page 46

6. BASIC OPERATION

Press the [ ] and [ ] key at the same time.

Laser line indication

Automatic Centering

Press both laser right and left keys at the same time. The laser will return to the center of the

line adjustment range automatically.

・ Automatic centering is not possible when the instrument is locked.

38

Page 47

6. BASIC OPERATION

Detection strips

Laser receiving side

Automatic alignment key

Automatic alignment with the target (TP-L5GV/G/AV/A only)

When the alignment is placed on centerline so it is in the alignment path of the beam, the laser

will search the horizontal center of the target and automatically align the beam to it. Set the

alignment target as follows and press the automatic alignment key on the instrument or the RC200 remote control. The instrument starts automatic alignment and the following display is

shown.

• This function is helpful for second day set ups.

・ Automatic alignment is not possible when the instrument is locked.

39

Page 48

Target

Set the target so the detection strips face the front of the

instrument.

• Large atmospheric motions could shorten the range of use of

automatic alignment. To prevent atmospheric motions from

occurring, limit the working range within the shade or use a

blower (commercially-available) for working.

• When using the RC-200 remote control at close range during

auto alignment mode, the laser may be subject to stop outside

the target. Press the automatic alignment key to start automatic

alignment again.

6. BASIC OPERATION

40

Page 49

Display

WAIT

6. BASIC OPERATION

The display shows auto leveling is in process.

After auto leveling is completed, automatic alignment starts.

The display shows auto alignment is in process.

Each step shows alignment progress.

Automatic alignment in progress

Automatic alignment will finish soon.

Alignment is completed.

Confirm the laser beam on the target. If necessary, use the laser

right/left key or the remote control RC-200 and align the laser

precisely.

Alignment target is lost during auto alignment mode. Reset the

instrument and press the automatic alignment key again.

41

Page 50

6. BASIC OPERATION

Press the beam mode key.

ON mode

TP-L5AV/A/B

TP-L5GV/G/BG

Blinking mode

Energy-saving

mode

Display

Display

Blinking mode

ON mode

6.4 Changing the laser beam mode

Two laser beam modes are available, ON and Blinking.

A third mode, Energy-saving, is available on green laser beam models.

By pressing the beam mode key, the beam mode will change alternatively.

42

Page 51

150mm / 6"

200mm / 8"

250mm / 10"

300mm / 12"

Single point foot

7. STANDARD ACCESSORIES

7.1 Self-centering Feet

Four sets of centering feet are provided with the TP-L5. The feet provided with TP-L5 will center

the laser beam inside the following diameters of pipe:

150mm (6"), 200mm (8"), 250mm (10") and 300mm (12")

They can also be used to set laser on top of the pipe or on a flat surface.

43

Page 52

7. STANDARD ACCESSORIES

7.2 Single Point Foot

Use the single pointed foot when the TP-L5 is unstable due to setting up on rough surfaces.

It is possible to use two self-centering feet for 200 mm (8") diameter with the single point foot

when the surface is level.

44

Page 53

7. STANDARD ACCESSORIES

Signal aperture

Automatic alignment mode key

Automatic centering

Laser right/left key

Laser beam mode key

Signal lamp

Laser right/left key

Laser ON/OFF switch

Press both keys at the same time

When red LED is blinking, the signal is

transmitting

Controls laser ON/OFF for

the instrument

7.3 Remote Controller (RC-200)

The RC-200 allows you to remotely control most function of the TP-L5 as shown below.

The RC-200 is convenient for aligning the beam while using a transit, or for saving power by

temporarily putting the unit in standby mode using the ON/OFF switch.

45

Page 54

7. STANDARD ACCESSORIES

• Operating range by remote control:

Approx.200 m (656 ft.) (Though the pipe from a forward position)

Approx.25 m (82 ft.) (From above panel)

• The laser ON/OFF switch controls the laser beam only, not for the instrument. To turn power

OFF to the instrument, be sure to switch OFF the instrument after operation is finished. When

the laser is turned off by the laser ON/OFF switch, "STANDBY" is indicated on the display and

the laser flashes once for five seconds (standby mode).

• To turn the laser beam ON again after the laser is turned off by the remote control, wait for 2

seconds or more and then press the laser ON/OFF switch for 2 seconds or more.

• Large atmospheric motions could shorten the operating range by the remote control.

To prevent atmospheric motions from occurring, limit the working range within the shade or

use a blower (commercially-available) for working.

46

Page 55

7. STANDARD ACCESSORIES

Laser line will travel in the opposite

direction of the laser right/left key

when using the remote control from

a forward position.

Remote control receiving window

Laser line will travel in

the direction of the laser

right/left key when using

the remote control from

above or behind the

panel position.

Remote control receiving window

(Laser beam can be received from above

panel.)

• When using the remote controller, direct the signal aperture to the remote control receiving

window on front of the TP-L5.

47

Page 56

RC-200

ON

OFF

LASER BEAM

RC-200

ON

OFF

LASER BEAM

RC-200

RC-200

Manhole

Signal aperture

Remote control receiving window

Remote control

receiving window

Signal aperture

7. STANDARD ACCESSORIES

48

Page 57

7. STANDARD ACCESSORIES

Replacing battery for Remote Control, RC-200

1

Lift the battery cover on the back of the remote

controller RC-200 is lifted up slightly by pressing

toward the direction of the mark . When the

lid lifts up, take it out.

2 Replace the 4 old AAA alkaline batteries with

new ones.

3 Click to close the lid by pressing on it.

• Replace all 4 batteries with new ones at the same time.

• Insert the batteries in the battery box according to the appointed direction.

• Do not mix used and new batteries, and do not mix different types of batteries together.

49

Page 58

7. STANDARD ACCESSORIES

Targe t ( s )

Fixing screw

Level vial

Targe t ( L )

Target holder

Laser receiving side

Detection strips

(TP-L5GV/G/AV/A only)

When laser beam strikes

the detection strips in

auto alignment mode,

the laser beam starts

alignment.

7.4 Target

Select the size of target assembly appropriate for the pipe diameter.

50

Page 59

8. CHANGING OPERATING PARAMETERS

DISP1 ON/ [OFF]

DISP2 [ON] /OFF

8.1 Operating Parameters

The standard (default) setting for several operating parameters of the TP-L5 can be changed by

the user. This table below lists the operating parameters that can be changed, the stand default

setting and optional settings for each one.

Functions Parameter

ON/OFF of

enlarged display

of the level vial

indicator

R-TILT DISPLAY

(level vial indicator)

Options

[default]

Description

DISP 1: default OFF

When this parameter is set to ON, the level

vial indicator is enlarged when the

instrument is off and the power key is first

pressed.The power key must be pressed

again to turn instrument on.

DISP 2: default ON

The level vial indicator enlarges to fill the

display anytime the TP-L5 is tilted.The

display returns to normal when the

instrument is properly positioned or when

any other control key is pressed.

51

Page 60

8. CHANGING OPERATING PARAMETERS

--- / [30]

% / ‰

ON / [OFF]

ON/OFF of the

centerline LED/

upper and lower

lasers' automatic

cut-off (automatic

power off)

Switch the unit

of the grade

values displayed

(% /

ON/OFF of

Security Mode

Input / Change

the Security Code

Change the

Company Name

‰)

V-LED/

V-LD (GV /AV)

--- : Automatic cut-off is disabled. LED/LD

remains on whenever after being

turned on by user.

30 : Default setting. Centerline LED/LD

automatically cuts off 30 minutes after

it has been turned on by user.

p.19

UNIT

S CODE Activates security code function. Default is

% : Default setting. Grade is displayed to

the nearest thousandths of a percent

(+01.235%)

‰ : Grade is displayed as per mill

[+01.235% (percent) equals +012.35

(per mill)]

OFF. Changing to ON requires the entry of a

4-digit security to turn on instrument.

CHANGE

S CODE

CHANGE NAME

(no preset code)

(TOPCON preset)

Allows user to input any 4-digit security

code after S CODE is set to ON.

Allows user to enter name that will display

during powerup. Default name is TOPCON.

52

Page 61

8.2 How To Change Operating Parameters

+

Power ON

PARAMETERS

V-LD - - - [ 30 ]

[R-TILT DISPLAY ]

*1

PARAMETERS

DISP2 [ ON] OFF

DISP1 ON [ OFF ]

PARAMETERS

DISP2 [ ON] OFF

DISP1 [ ON] OFF

EXAMPLE

Change R-TILT DISPLAY, DISP1 from OFF to ON and disable the V-LED/LD (TP-L5GV/AV)

automatic cut-off.

1 Press Power ON key while pressing

and holding the Lock key.

The R-TILT DISPLAY is the first

parameter setting.

2 Press SET key to select R-TILT

DISPLAY.

3 The DISP1 parameter highlights to

show it is active. Press [ ] key to

select [ON] for DISP1.

8. CHANGING OPERATING PARAMETERS

Procedure Key operation Display

53

Page 62

4 Press SET key to accept new setting.

PARAMETERS

R-TILT DISPLAY

V-LD - - - [ 30 ]

PARAMETERS

R-TILT DISPLAY

V-LD - - - [ 30 ]

5 Press [ ] key to select [---].

6 Press SET key to accept new setting.

Display will change to operating

mode. The unit will now operate with

the new parameter settings (level vial

indicator enlarged on power-up and

centerline LED always on).

*1 "V-LED" is indicated when the TP-L5G/BG/A/B is used.

8. CHANGING OPERATING PARAMETERS

54

Page 63

8.3 How to Input (Change) Security Code

+

Power ON

PARAMETERS

V-LD - - - [ 30 ]

[R-TILT DISPLAY ]

*2

PARAMETERS

S CODE ON [OFF]

[CHANGE S CODE ]

To prevent unauthorized use of the TP-L5 a four-digit security can be set. The following table

describes how to activate the security mode (S CODE) and select a four-digit code.

When Security mode is set, it is necessary to input the code every time power is turned on (in

Normal mode, Selecting mode and Checking & Adjusting mode).

• Memorize the security code and file it in a safe place. It is not possible to operate the TP-L5

without entering the code.

1 Press Power ON key while pressing

and holding the Lock key.

(text in [brackets] indicates present

setting)

2 Select "CHANGE S CODE" (If first

time to set code, "INPUT S CODE" is

indicated.) by pressing the [ ] key

four times.

8. CHANGING OPERATING PARAMETERS

Procedure Key operation Display

*1

4 times

55

Page 64

3 Press SET key.

CODE [_ _ _ _] SET

SECURITY

56789

ENTER

01234

or

or

CODE [_ _ _ _] SET

SECURITY

56789

ENTER

01234

CODE [ 7_ _ _ ] SET

SECURITY

56789

ENTER

01234

CODE

SECURITY

56789

ENTER

01234

[ 7777 ] SET

or

or

CODE

SECURITY

56789

ENTER

01234

[ 7777 ] SET

*3

4 Select a numeric character by

pressing the [ ], [ ], [ ], [ ] keys.

Example: 7

5 Press SET key.

6 Repeat steps 4 and 5 to set

remaining three code numbers.

Example: 7777

*4

7 Select "SET" by pressing the [ ],

[], [], [] keys.

8. CHANGING OPERATING PARAMETERS

56

Page 65

8 Press SET key.

SET

SECURITY CODE

PARAMETERS

S CODE [ ON] OFF

[CHANGE S CODE]

SET

The display returns to menu.

9 Press SET key.

*1 When security mode is ON, the security code must be input to operate.

*2 "V-LED" is indicated when the TP-L5G/BG/A/B is used.

8. CHANGING OPERATING PARAMETERS

57

Page 66

8. CHANGING OPERATING PARAMETERS

+

Power ON

PARAMETERS

V-LD - - - [ 30 ]

[R-TILT DISPLAY ]

*1

3 times

PARAMETERS

S CODE ON [ OFF ]

UNIT [ % ] ‰

or

PARAMETERS

S CODE [ ON] OFF

UNIT [ % ] ‰

*3 When security code has been entered, but security mode is OFF, input of current security

code is necessary to change security code.

*4

After all four digits are chosen and the SET key is pressed, each digit will highlight in

sequence. While it is higlighting, it is possible to change the number in case of error.

ON/OFF of Security Mode

Procedure Key operation Display

1 Press Power ON key while pressing

and holding the Lock key. (see *1 on

p.57)

(text in [brackets] indicates present

2 Select "S CODE" by pressing the [ ]

key three times.

3 Select ON or OFF by pressing the

[] or [] keys.

58

Page 67

4 Press SET key.

CODE [_ _ _ _] SET

SECURITY

56789

CHECK

01234

or

or

CODE

SECURITY

56789

CHECK

01234

ACCEPTED

SECURITY CODE

8. CHANGING OPERATING PARAMETERS

5 Enter the security code which was

previously set. (see *3 on p.58)

6 Select "SET" by pressing the [ ],

[], [], [] keys.

7 Press SET key.

The instrument returns to normal

mode.

Enter Code

59

Page 68

8. CHANGING OPERATING PARAMETERS

+

Power ON

PARAMETERS

V-LD - - - [ 30 ]

[R-TILT DISPLAY ]

*2

5 times

PARAMETERS

[CHANGE NAME]

[CHANGE S CODE]

8.4 How to change Company Name

The company name displayed during power-up can be changed.

The following characters can be used:

Numeric digits 0 to 9; capital letters A to Z; period; comma; apostrophe; space; opened and

closed parenthesis.

Maximum of 32 characters can be input (2 lines of 16 characters each).

Procedure Key operation Display

1 Press Power ON key while pressing

and holding the Lock key.

(text in [brackets] indicates present

setting)

2 Press the down arrow key five [ ]

times to scroll to CHANGE NAME.

*1

60

Page 69

3 Press SET key.

COMPANY NAME

ENTER

NEW NAME

or

=

or

=

_ _ _ _ _ _ _ _ _ _ _ _ _ _

4 Select a character string by pressing

the [ ] or [ ] keys.

5 Select a character in the character

string by pressing the [ ] or [ ]

keys.

Example; LASER(1)

8. CHANGING OPERATING PARAMETERS

*3

61

Page 70

6 Press SET key.

_

_ _ _ _ _ _ _ _ _ _ _ _ _ _

or

_

_ _ _ _ _ _ _ _ _ _ _ _ _ _

SET

COMPANY NAME

PARAMETERS

[CHANGE S CODE]

S CODE

ON [OFF]

8. CHANGING OPERATING PARAMETERS

7 Repeat procedures 4 and 6 until

complete.

*4

8 Select "SET" by pressing the [ ] or

[] keys.

9 Press SET key.

The display returns to menu.

62

Page 71

8. CHANGING OPERATING PARAMETERS

SET

10 Press SET key.

The instrument returns to normal

mode.

*1 When security mode is ON, the security code must be input to operate.

*2 "V-LED" is indicated when the TP-L5G/BG/A/B is used.

*3 When security code has been entered, but security mode is OFF, input of current security

code is necessary to change security code.

*4 Follow the steps below if it's necessary to correct a character during input.

63

Page 72

How to correct a character

or

_ _ _ _ _ _ _ _ _ _ _ _ _ _

LASOR(1) _ _ _ _ _ _ _

=

.

.

.

.

.

_ _ _ _ _ _ _ _ _ _ _ _ _ _

LASOR(1) _ _ _ _ _ _ _

=

_

_ _ _ _ _ _ _ _ _ _ _ _ _ _

LASOR(1) _ _ _ _ _ _ _

=

_

or

_ _ _ _ _ _ _ _ _ _ _ _ _ _

LASOR(1) _ _ _ _ _ _ _ _

ABCDEFGHIJ ←→ SET

_

Procedure Key operation Display

1 Select the left or right arrow by

pressing the [ ] or [ ] keys.

2 Press [SET] key.

The underline (cursor) moves to left

or right by pressing the SET key.

3 Select a character string by

pressing the

[ ] or [ ] keys.

8. CHANGING OPERATING PARAMETERS

64

Page 73

4 Select a character in the character

or

_ _ _ _ _ _ _ _ _ _ _ _ _ _

LASOR(1) _ _ _ _ _ _ _ _

ABCDEFGHIJ ←→ SET

_

_ _ _ _ _ _ _ _ _ _ _ _ _ _

LASER(1) _ _ _ _ _ _ _ _

ABCDEFGHIJ ←→ SET

_

string by pressing the [ ] or [ ]

keys.

5 Press SET key.

Repeat steps

characters.

8. CHANGING OPERATING PARAMETERS

1 and 5 to correct other

65

Page 74

9. CHECKS AND ADJUSTMENTS

+00.000%

9.1 Procedure To Check and Adjust Laser Calibration

Checking Calibration

1

Make sure grade is set to 00.000% (0‰).

2 Locate control points directly beneath the laser beam 1m (3.3 ft) in front of the TP-L5 and

60m (197ft.) from the first control point (see illustration above).

3 Set up a transit or level midway between the 1st and 2nd control points.

66

Page 75

9. CHECKS AND ADJUSTMENTS

Power OFF

+

4 Take elevation readings at both control points using the laser beam and the transit or level.

If the distance between the readings at each point (x1 and x2) are the same, the unit does

not need adjustment. If x1 and x2 are not the same, the unit requires adjustment as follows.

Adjusting Calibration

Procedure Key operation Display

1 When checking is finished, turn the

power OFF.

2 Press Power ON key while pressing

and holding the SET key.

"0 SET" is displayed.

67

Page 76

3 Press SET key.

I N I T

LEVELING

or

"INIT" is displayed, and then

"LEVELING" is displayed.

4 Adjust the height of laser beam x1

and X2 measurements are equal (use

[] or [] key).

• The display will be changed to

"LEVELING" again if the instrument

is moved. In this case, wait until the

display changes to "LEVEL" and

readjust the instrument.

9. CHECKS AND ADJUSTMENTS

LEVEL

68

Page 77

9. CHECKS AND ADJUSTMENTS

WAIT

END

5 Press SET key after completing the

adjustment.

"WAIT" is displayed.

6 When +00000 appears on the display,

press the SET key again.

Repeat checking procedure above to

confirm accurate calibration.

• If the adjustment range is exceeded, "E72" (error) will be displayed in step 5. Repeat

checking and adjusting procedure. If the error continues, contact your local dealer.

69

Page 78

9. CHECKS AND ADJUSTMENTS

Target

Vertical

direction

Manhole

Control point

Laser

Laser

GapGap

9.2 Checking of Upper/Lower Laser (TP-L5GV/AV only)

1 Set up the instrument on a single

control point using the downward

laser plummet.

2 Set up a target approximately 3m

(10ft.) above the instrument.

3 Move the target above the manhole

unit the upper laser is aligned to the

center of the target.

4 Rotate the instrument 180° without

changing lower laser line position.

If the upper laser emitting position

does not change more than 4mm, the

unit is within specification.

• If the unit is out by more than 4mm (0.014’), please contact your local dealer.

70

Page 79

10. ERROR DISPLAYS

If an error is displayed, follow the procedures shown below.

Error Code Contents Countermeasure

E-02

E-03

Abnormal operation of internal measuring

system.

Switch OFF the power, then ON

again. Excessive vibration around

the laser may cause this error.

Eliminate vibration.

E-04

E-05

E-72

E-99

The angle is not measured properly.

The laser's positioning is not adjusted

properly.

Indicates excessive tilt of the laser

instrument during calibration checking or

adjusting.

Abnormal operation of internal memory

system detected.

Contact your local dealer.

Switch OFF the power, then ON

again.

Switch OFF the power, then ON

again.

Set the instrument level then

repeat checking and adjusting

calibration procedure.

Switch OFF the power, then ON

again.

• If error code remains after trying countermeasures above, please contact your Topcon dealer.

71

Page 80

11. TROUBLESHOOTING

Check to see the instrument referring to the error list or the following troubleshooting list when you

notice the failure of the instrument.

If the instrument can't be recovered or the failure isn't written in the following list, please contact your

local dealer.

Conditions Causes Countermeasures

Laser beam does not

emit

Laser beam blinks 1) When Level Warning Indicator

1) Battery level is low.

2) Improper connection to an

external power source (such as a

12 volt DC battery).

3)The laser is turned off because the

laser ON/OFF switch of the

remote controller is pushed.

blinks, the instrument is tilted

beyond the self-leveling range

(laser blinks slowly).

2) Any shock or vibration to the unit

produces unstable condition

causing beam to blink.

72

1) Recharge or replace the

batteries with new ones.

2) Make sure connection is secure

and attached to correct

terminals.

3) Push the laser ON/OFF switch

of the remote controller, then the

laser is turned on.

1) Reposition the instrument until

the level warning indicator

disappears.

2) Eliminate the source of

disturbance to the unit.

Page 81

11. TROUBLESHOOTING

Conditions Causes Countermeasures

Laser beam emits

but grade setting is

not possible

Laser beam emits

but line setting is not

possible.

Remote control does

not function.

1) The instrument is in lock mode.

2) The value entered is out of the

grade range.

3) When Level Warning Indicator

blinks, the instrument is tilted

beyond the self-leveling range

(laser blinks slowly).

4) Battery level is low.

1) The instrument is in lock mode.

2) The laser beam has reached the

limit of line adjusting range.

1) The instrument is in lock mode.

2) The battery power of remote

control is low.

1) Press the lock key on the

instrument to release the lock

function.

2) Grade entry must be in the

range of 15 to 40%.

3) Reposition the instrument until

the level warning indicator

disappears.

4) Recharge or replace the

batteries with new ones.

1) Press the lock key on the

instrument to release the lock

function.

2) Center the line adjustment and

aim instrument so laser is

roughly aimed at target.

1) Press the lock key on the

instrument to release the lock

function.

2) Replace the batteries.

73

Page 82

11. TROUBLESHOOTING

Conditions Causes Countermeasures

The laser beam is

unstable.

The laser position

shifts over time

passed.

1) The laser beam is refracted due to

temperature differences within the

pipe.

2) The laser beam is refracting and

reflecting due to fog and/or mist.

1) The pipe may be sinking.

2) The target is not securely held.

1) When the pipe is laid, the trench

must be backfilled immediately

to help maintain temperature

stability.

2) Use a blower (commerciallyavailable) to move air through

the pipe to blend the air and

remove mist or fog.

• Cover the pipe to prevent heat

build up inside the pipe.

• Clear the mist or fog.

1) Confirm the pipe grade setting

using a level.

2) Secure the target within its

holder.

74

Page 83

11. TROUBLESHOOTING

Conditions Causes Countermeasures

The grade setting

value of the TP-L5

and the measured

grade value are not

equal.

1) Incorrect grade value was entered.

2) The bubble on the bubble tube

display of the instrument or the

bubble on the target was not

adjusted correctly.

3) The laser beam is refracted due to

temperature differences within the

pipe.

1) Confirm the input value (

and reset.

2) Adjust the laser and/or target so

the bubble is centered.

3) When the pipe is laid, the trench

must be backfilled immediately

to help maintain temperature

stability.

Use a blower (commerciallyavailable) to move air through

the pipe to keep temperature

75

‰ or %)

Page 84

11. TROUBLESHOOTING

Conditions Causes Countermeasures

The charging lamp of

the internal battery

BT-53Q is blinking

slowly when

connected to the DC12V external battery.

(Error blinking)

1) The charging temperature is out of

range.

2) The battery BT-53Q is completely

discharged.

1) Recharging should take place in

the temperature range of 10 to

35

°C (50 to 95°F).

2) Continue the charging for 30

minutes.

• If the lamp changes to red light

up mode, the battery is normal.

• If the lamp continues green

blinking, battery is faulty and

must be replaced. Always

properly dispose old battery.

76

Page 85

12. OPTIONAL ACCESSORIES

• AC/DC Converter AD-13

• Power cable for 12VDC PC-17

• Dry battery holder DB-53

• Drop manhole kit model 6

• Single pointed foot model 2

• Trivet stand model 3

• Trivet handle model 2

• Carrying case for trivet stand kit model 2

• Tripod adapter model 3

• Scope model 2

• Target (Large)

• Over the top target

• Optional accessories which are sold separately may be subject to change or be discontinued

without notice.

Contact your local dealer for the details.

77

Page 86

13. SPECIFICATIONS

TP-L5

Light source : Visible laser diode

Wave length : 520nm (TP-L5GV/G/BG, green)

635nm (TP-L5AV/A/B, red)

Laser power output : 4.5mW

Laser class : Class 3R

Laser diameter : ø12mm

Line control width : Approx. 17°

Grade readout : -15 to 40%(-150 to 400‰)

Minimum setting of grade : 0.001% (0.01

Grade setting method : Absolute encoder

Auto leveling range

Slope direction : ±10%

Axis direction : Approx. ±4°

Horizontal accuracy : ±10 arc seconds

Automatic alignment distance : 5 to 150m (TP-L5GV/G/AV/A)

Maximum line adjust range (p. 37)

‰)

78

Page 87

13. SPECIFICATIONS

Upper/Lower Laser (TP-L5GV/AV only)

Light source : Visible laser diode

Wave length : 655nm

Laser power output : 0.9mW (maximum)

Compensating range : Grade setting direction Approx. ±4°

Rotating direction Approx. ±2°

Vertical accuracy (Rolling direction) :

Upper ±1.5

Lower ±3.5'

Power source : Ni-MH battery BT-53Q

Working duration at 20°C (68°F)

TP-L5GV/G/BG

BT-53Q : about 40 hours

DB-53 (optional accessory)

: about 55 hours

TP-L5AV/A/B

BT-53Q : about 55 hours

DB-53 (optional accessory)

: about 80 hours

'

(Using alkaline manganese dry batteries)

(Using alkaline manganese dry batteries)

• Battery using time will vary depending on environmental conditions and operations

done with TP-L5 series.

79

Page 88

13. SPECIFICATIONS

External power source : 9 to 20V

Charging time per battery : about 9 hours

(Charging can take longer than the times stated above when

Charging temperature range : 10 to 35°C

Operating temperature range : -20 to 50°C (-4 to 122 °F)

Storage temperature range : -30 to 60°C (-22 to 140 °F)

Water resistance : IPX8 (IEC 60529:2001)

Size : 122mmX330mm (without handle)

Weight : about 3.8kg (with BT-53Q)

temperatures are either especially high or low.)

125mmX374mm (with rear handle)

Remote controller Model RC-200

Operating distance : Though the pipe from a forward position, about 200m (656ft.)

From above panel, about 25m (82ft.)

Functions : Line control, Laser beam ON/OFF, Laser beam mode,

Automatic alignment mode, Line centering

Power supply : Four AAA size dry batteries

Operating time : about 8 months

(Using alkaline manganese dry batteries)

80

Page 89

14. REGULATIONS

Region/

Country

Directives/

Regulations

U.S.A. FCC-Class A

Labels/Declarations

FCC Compliance

WARNING:

Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user's authority to operate the

equipment.

NOTE:

This equipment has been tested and found to comply with the limits for a

Class A digital device pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Declaration of Conformity

Model Number: TP-L5

Trade Name: TOPCON CORPORATION

81

Page 90

14. REGULATIONS

Manufacture

Name: TOPCON CORPORATION

Address: 75-1, Hasunuma-cho, Itabashi-ku, Tokyo, 174-8580

Country: JAPAN

JAPAN

U.S.A. Representative

Responsible party: TOPCON POSITIONING SYSTEMS,INC.

Address: 7400 National Drive Livermore, CA94551, U.S.A

Telephone number: 925-245-8300

California,

U.S.A.

Proposition65

82

Page 91

14. REGULATIONS

Region/

Country

California,

and NY,

U.S.A.

Directives/

Regulations

Recycling

Batteries

Labels/Declarations

83

Page 92

Canada ICES-Class A

14. REGULATIONS

This Class A digital apparatus meets all requirements of Canadian InterferenceCausing Equipment Regulations.

Cet appareil numérique de la Class A respecte toutes les exigences du Reglement

sur le matériel brouilleur du Canada.

This class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme a la norme NMB-003 du

Canada.

84

Page 93

14. REGULATIONS

Region/

Country

EU EMC:Class A

Directives/

Regulations

Labels/Declarations

85

Page 94

14. REGULATIONS

Region/

Country

EU WEEE Directive

EU

Directives/

Regulations

EU Battery

Directive

Labels/Declarations

86

Page 95

Page 96

©2015 TOPCON CORPORATION

http://www.topcon.co.jp

GLOBAL GATEWAY http://global.topcon.com/

Please see the attached address list or the following website for contact addresses.

ALL RIGHTS RESERVED

Loading...

Loading...