Topcon System 350, System 350 X30 Operator's Manual

www.topconpa.com

Spreader Controller

System 350

X30 Console

Operator’s Manual

X30 Spreader Controller

Operator’s Manual

Part Number: AGA4950-EN

Rev Number: 1.0

.1

For use with Software Version 3.12.12

© Copyright Topcon Precision Agriculture

August 2012

All contents in this manual are copyrighted by Topcon. All rights reserved. The information

contained herein may not be used, accessed, copied, stored, displayed, sold, modified, published

or distributed, or otherwise reproduced without express written consent from Topcon.

www.topconpa.com

X30 Spreader Controller

0-1

Preface

This manual provides information about operating and

maintaining this Topcon Precision Agriculture product. Correct

use and servicing is important for safe and reliable operation of

the product.

It is very important that you take the time to read this manual

before using the product.

Information in this manual is current at the time of publication. A

system may vary slightly. The manufacturer reserves the right to

redesign and change the system as necessary without notification.

Alert Symbols

In this manual two alert symbols are used.

This offers additional information.

Warning: A warning signal appears on safety

signs and in this manual to show that this

information is very important to your safety.

LEARN these and APPLY them.

X30 Spreader Controller

0-2

Terms and Conditions

Please read these Terms and Conditions carefully.

General

APPLICATION

- You accept these

Terms and Conditions by purchasing

the product from Topcon Precision

Agriculture (TPA) or from one

TPA’s product dealers.

COPYRIGHT

- All information

contained in this manual is the

intellectual property of, and

copyrighted material of TPA. All

rights are reserved. You may not use,

access, copy, store, display, create

derivative works of, sell, modify,

publish, distribute, or allow any third

parties access to, any graphics,

content, information or data in this

manual without TPA’s express

written consent and may only use

such information for the care and

operation of your product. The

information and data in this manual

are a valuable asset of TPA and are

developed by the expenditure of

considerable work, time and money,

and are the result of original

selection, coordination and

arrangement by TPA.

TRADEMARKS

– ZYNX,

PROSTEER, EAGLE, KEE

Technologies, Topcon, Topcon

Positioning Systems and Topcon

Precision Agriculture are trademarks

or registered trademarks of the

Topcon Group of companies.

Microsoft and Windows are

trademarks or registered trademarks

in the United States and/or other

countries of Microsoft Corporation.

Product and company names

mentioned herein may be trademarks

of their respective owners.

WEBSITE AND OTHER

STATEMENTS

- No statement

contained at the website of TPA or

any other Topcon Group company or

in any other advertisements or TPA

literature or made by an employee or

independent contractor of TPA

modifies these Terms and

Conditions.

IMPORTANT: SAFETY

- Improper

use of the product can lead to death

or injury to persons, damage to

property and/or malfunction of the

product. The product should only be

repaired by authorized TPA service

centers. You should closely review

the safety warnings and directions as

to the proper use of the product in

this manual and at all times comply

with the same.

Limited Warranty

ELECTRONIC AND

MECHANICAL COMPONENTS

-

TPA warrants that the electronic

components manufactured by TPA

shall be free of defects in materials

and workmanship for a period of one

year from the original date of

shipment to the dealer. TPA

X30 Spreader Controller

0-3

warrants that all valves, hoses, cables

and mechanical parts manufactured

by TPA shall be free of defects in

materials and workmanship for a

period of one year from the date of

purchase.

RETURN AND REPAIR - During

the respective warranty periods, any

of the above items found defective

may be shipped to TPA for repair.

TPA will promptly repair or replace

the defective item at no charge, and

ship it back to you. You must pay the

shipping and handling charges in

respect of the same. Calibration of

components, labor and travel

expenses incurred for in-field

removal and replacement of

components are not covered in this

warranty policy. The foregoing

warranty shall NOT apply to damage

or defects resulting from:

(i) disaster, accident or abuse

(ii) normal wear and tear

(iii) improper use and/or

maintenance

(iv) unauthorized modifications of

the product; and/or

(v) use of the product in

combination with other products

not supplied or specified by

TPA.

Software accompanying any product

is licensed for use in connection with

the product and not sold. Use of

software that is provided with a

separate end user license agreement

(“EULA”) will be subject to the

terms and conditions, including those

relating to limited warranty, of the

applicable EULA, notwithstanding

anything in these Terms and

Conditions to the contrary.

WARRANTY DISCLAIMER -

OTHER THAN FOR THE ABOVE

WARRANTIES, WARRANTIES

PROVIDED IN AN APPLICABLE

WARRANTY CARD, APPENDIX

OR END USER LICENSE

AGREEMENT, THIS MANUAL,

THE PRODUCT AND RELATED

SOFTWARE ARE PROVIDE ‘ASIS’. THERE ARE NO OTHER

WARRANTIES AND TO THE

EXTENT ALLOWED BY LAW TPA

EXCLUDES ALL IMPLIED

TERMS, CONDITIONS AND

WARRANTIES IN RESPECT OF

THE MANUAL AND THE

PRODUCT (INCLUDING ANY

IMPLIED WARRANTY OR

MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR

USE OR PURPOSE). TPA IS NOT

RESPONSIBLE FOR THE

OPERATION OF GNSS

SATELLITES AND/OR

AVAILABILITY, CONTINUITY,

ACCURACY, OR INTEGRITY OF

GNSS SATELLITE SIGNALS.

LIABILITY LIMIT AND

INDEMNITY - TPA and its dealers,

agents and representatives shall not

be liable for technical or editorial

errors or omissions contained herein

or for special, indirect, economic,

incidental or consequential damages

resulting from the furnishing,

performance or use of this material,

the product or its accompanying

software (including where TPA has

been advised of the possibility of

such damage). Such disclaimed

damages include but are not limited

to loss of time, loss or destruction of

data, loss of profit, savings or

revenue or loss of or damage to the

product. You shall defend,

indemnify and hold TPA harmless

from and against any claims, actions,

suits, damages, losses, liabilities and

X30 Spreader Controller

0-4

costs (including attorneys’ fees)

arising from, or relating to (a) your

operation use, or maintenance of the

product and/or software other than as

provided for in this manual or the

applicable end user license

agreement; and (b) your negligence

or wrongful act or omission in

respect of the product.

In any event, TPA’s liability to you

or any other person for any claim,

loss or damage (in contract, tort or

on any other basis) will be limited

(in TPA’s option) to either (a) the

replacement or repair of the product,

or (b) payment of the cost of

replacing or repairing the product.

Other

These Terms and Conditions may be

amended, modified, superseded or

cancelled, at any time by TPA.

These Terms and Conditions will be

governed by, and construed in

accordance with:

- the laws of South Australia if the

product is sold and supplied to

you in Australia (in which case

the courts of South Australia or

the Federal Court of Australia

(Adelaide Registry) have

exclusive jurisdiction in respect

of any claim or dispute) or

- the laws of the State of California

if the product is sold and supplied

to you outside of Australia

- the provisions of the United

Nations Convention on Contracts

for the International Sale of

Goods shall not apply to these

Terms and Conditions.

All information, illustrations, and

applications contained herein are

based on the latest available

information at the time of

publication. TPA reserves the right

to make product changes at any time

without notice.

If any part of these Terms and

Conditions would be unenforceable,

the provision must be read down to

the extent necessary to avoid that

result, and if the provision cannot be

read down to that extent, it must be

severed without affecting the validity

and enforceability of the remainder

of these Terms and Conditions.

Service Information

Service assistance can be provided

by contacting your local TPA

Authorized Dealer.

X30 Spreader Controller

0-5

Communications Regulation Information

FCC Compliance Statement (USA)

This equipment has been tested and found to comply with

the limits for a Class ‘A’ digital device, pursuant to Part

15 of the FCC Rules. Operation of this equipment in a

residential area is likely to cause harmful interference in

which case the user will be required to correct the

interference at the user's expense.

FCC Compliance Statement (Canada)

This Class A digital apparatus meets all requirements of

the Canadian Interference-Causing Equipment

Regulation.

CE EMC Statement (European Community)

Warning: This is a class ‘A’ product. In a domestic

environment this product may cause radio interference in

which case the user may be required to take adequate

measures.

‘C’ Tick EMC Statement (Australia & New Zealand)

This product meets the applicable requirements of the

Australia and New Zealand EMC Framework.

Type Approval and Safety Regulations

Type approval may be required in some countries to license the

use of transmitters on certain band frequencies. Check with local

authorities and your dealer. Unauthorized modification of the

equipment may void that approval, the warranty and the license to

use the equipment.

The receiver contains internal radio-modem. This can potentially

send signals. Regulations vary between countries, so check with

the dealer and local regulators for information on licensed and

unlicensed frequencies. Some may involve subscriptions.

X30 Spreader Controller

0-6

Radio and Television Interference

This computer equipment generates, uses, and can radiate radiofrequency energy. If it is not installed and used correctly in strict

accordance with Topcon Precision Agriculture instructions, it

may cause interference with radio communication.

You can check if interference is being caused by this equipment

by turning the Topcon equipment off to see if the interference

stops. If the equipment is causing interference to a radio or other

electronic device, try:

Turning the radio antenna until the interference stops

Moving the equipment to either side of the radio or other

electronic device

Moving the equipment farther away from the radio or other

electronic device

Connecting the equipment to another circuit that is not linked

to the radio.

To reduce potential interference, operate the equipment at the

lowest gain level that will allow successful communication.

If necessary contact your nearest Topcon Precision Agriculture

dealer for assistance.

Changes or modifications to this product not authorized by

Topcon Precision Agriculture could void the EMC

compliance and negate authority to operate the product.

This product was tested for EMC compliance using Topcon

Precision Agriculture peripheral devices, shielded cables

and connectors. It is important to use Topcon Precision

Agriculture devices between system components to reduce

the possibility of interference with other devices.

X30 Spreader Controller

0-7

General Safety

DANGER: It is essential that the following

information and the product specific safety

information is read and understood.

Most incidents arising during operation, maintenance and repair

are caused by a failure to observe basic safety rules or

precautions. Always be alert to potential hazards and hazardous

situations.

Always follow the instructions that accompany a Warning or

Caution. The information these provide aims to minimize risk of

injury and/or damage to property.

In particular follow instructions presented as Safety Messages.

Safety Messages and Warnings

The safety symbol is used with the relevant word: DANGER,

WARNING or CAUTION.

Messages marked in this way recommend safety precautions and

practices. LEARN and apply them.

DANGER: Indicates an imminently hazardous

situation that, if not avoided, could result in DEATH

OR VERY SERIOUS INJURY.

WARNING: Indicates a potentially hazardous

situation that, if not avoided, could result in DEATH

OR SERIOUS INJURY.

CAUTION: Indicates a potentially hazardous

situation that, if not avoided, may result in MINOR

INJURY.

X30 Spreader Controller

0-8

Safety Signs

WARNING: DO NOT remove or obscure safety signs.

Replace any safety signs that are not readable or are

missing. Replacement signs are available from your

dealer in the event of loss or damage.

If a used vehicle has been purchased, make sure all safety signs

are in the correct location and can be read. Replace any safety

signs that cannot be read or are missing. Replacement safety signs

are available from your dealer.

Operator Safety

WARNING: It is YOUR responsibility to read and

understand the safety sections in this book before

operating this vehicle. Remember that YOU are the

key to safety.

Good safety practices not only protect you, but also the people

around you. Study this manual as part of your safety program.

This safety information only relates to Topcon equipment and

does not replace other usual safe work practices.

WARNING: In some of the illustrations or photos

used in this manual, panels or guards may have

been removed for demonstration purposes. Never

operate the vehicle with any panels or guards

removed. If the removal of panels or guards is

necessary to make a repair, these MUST be replaced

before operation.

Warning: Always check that any suspended vehicle

attachments are lowered to the ground before

beginning repair or maintenance work on a vehicle.

X30 Spreader Controller

0-9

Warning: Vehicle and implement parts can become

hot during operation and may be under pressure.

Refer to vehicle manuals.

Warning: Wear appropriate protective clothing for

the task being undertaken and conditions.

Warning: Do not operate equipment around

explosive equipment or supplies.

Warning: Topcon is committed to good

environmental performance and minimizes the use

of any potentially harmful substances in its products.

However, it is always advisable not to handle

damaged electronic equipment.

This Topcon product may contain a sealed lithium

battery.

Always dispose of any electronic equipment

thoughtfully and responsibly.

X30 Spreader Controller

0-10

Exposure to Radio Frequency

Exposure to energy from radio frequencies is an important safety

issue. Keep a distance of at least 20 cm (7.8 inches) between

people and any radiating antenna. Keep a distance of at least 20

cm between transmitting antennas.

Warning: Products using cellular modem or an

RTK base station can transmit radio frequency

energy. Check with your dealer.

This device is designed to operate with TPA approved antennas.

Discuss with your dealer.

Preparation for Operation

Read and understand this manual and learn all of the controls

before you use the equipment.

Keep the manual with the equipment.

If the equipment is moved to another vehicle, move the

manual as well.

Read the manual for the vehicle with which the equipment

will be used and check that the vehicle has the correct

equipment required by local regulations.

Make sure you understand the speed, brakes, steering,

stability, and load characteristics of the vehicle before you

start.

Check all controls in an area clear of people and obstacles

before starting work.

Identify possible hazards.

Warning: Topcon equipment must not be used by an

operator affected by alcohol or drugs. Seek medical

advice if using prescription or over-the-counter

X30 Spreader Controller

0-11

medication.

Disclaimer

Topcon accepts no responsibility or liability for damages to

property, personal injuries, or death resulting from the misuse or

abuse of any of its products.

Further, Topcon accepts no responsibility for the use of Topcon

equipment or the GNSS signal for any purpose other than the

intended purpose.

Topcon cannot guarantee the accuracy, integrity, continuity, or

availability of the GNSS signal.

The operator must ensure that the equipment is correctly turned

off when not in use.

Before operating any vehicle equipped with Topcon products,

read and understand the following product specific safety

precautions.

X30 Spreader Controller

0-12

X30 Important Safety Information

Operator Alertness and Responsibility

The X30 helps the operator to steer the vehicle, but the operator

remains in charge and must be alert and in complete control of the

vehicle at all times. The operator is ultimately responsible for safe

operation of this equipment.

It is essential that safety requirements are met when operating the

X30 and any of its components. All operators and other relevant

personnel must be advised of safety requirements.

Electrical Safety

Warning: Incorrectly connected power can cause

severe injury and damage to people or the

equipment.

When working with electrical components, you must do the

following:

Make sure the negative terminal of the battery is

disconnected before doing any welding on the vehicle.

Check that all power cables to system components are

connected to the correct polarity as marked. Please refer to

the vehicle manual for safety information.

Check that equipment is grounded in accordance with

installation instructions.

Operation and Risk of Obstacles

The following list is not exhaustive or limited. To use the X30 for

assisted steering along a defined wayline, the operator must

ensure that it is used:

Away from people and obstacles

X30 Spreader Controller

0-13

Away from high voltage power lines or other overhead

obstructions (identify any clearance problems before

activating the X30)

On private property without public access

Within cleared fields

Off public roads or access ways.

Note that:

The operator needs to know the vehicle’s position and the

field conditions at all times.

The operator will need to respond if the GNSS satellite or

differential correction signal is lost momentarily.

The X30 cannot detect obstacles (people, livestock or other).

Only use the X30 in areas that are clear of obstacles and keep

a proper distance.

Steering needs to be disengaged for manual control if an

obstacle appears in the path or the vehicle moves away from

the wayline.

On/Off and Manual Control

Warning: Ensure the steering switch is in the Off

position to prevent unintentional engagement of

the assisted steering. When repairing or

maintaining the vehicle/implement, ensure the

vehicle CANNOT be moved. Disengage steering,

apply brakes and remove keys.

The operator must ensure that the steering switch is in the Off

position (all LED indicators are off) when assisted steering is not

being used.

X30 Spreader Controller

0-14

The operator must disengage assisted steering and use manual

control if an obstacle is in the line of travel or moves into the line

of travel, or if the vehicle steers away from the desired wayline.

To disengage assisted steering:

Turn the steering wheel a few degrees OR

Select the Disengage Auto Steering button on the console

AND/OR

Move the steering switch to the OFF position if the above

actions do not disengage assisted steering.

Vehicle Shut Down Safety

Before leaving the vehicle, disengage assisted steering, turn the

steering switch to the OFF position, and remove the key from the

key switch.

Using a Reference (Base) Station

WARNING: Do not move a reference station

while in operation. Moving an operating reference

station can interfere with the controlled steering of

a system using the reference station. This could

result in personal injury or damage to property.

Operators and other affected personnel must be advised of the

following safety precautions.

Do not erect the reference station under or within the vicinity

of high voltage power lines.

When using the portable reference station, make sure that the

tripod is securely mounted.

X30 Spreader Controller

0-15

To Get the Best Out of the Product

Back up data regularly. The console has large, but limited storage

capacity. Use the Diagnostics Mini-view to view capacity

available. A warning screen displays if storage is reaching its

limit.

Be aware of file format compatibility. Discuss compatible formats

with the dealer.

Topcon Agricultural Products are hardy and designed to work in

tough conditions. However, should equipment be unused for a

length of time, store away from water and direct heat sources.

X30 Spreader Controller

0-16

Table of Contents

Chapter 1 - Introduction .......................................................... 1-1

Chapter 2 - Implement Setup .................................................. 2-1

2.1 Setting up a New Implement ............................................................................... 2-2

2.2 Connecting to ECUs ............................................................................................ 2-5

2.3 Setting up the ECU ............................................................................................. 2-6

2.4 Setting up Implement Geometry ....................................................................... 2-13

2.5 Setting up Section Control ................................................................................ 2-15

2.5.1 Setting On Time and Off Time .................................................................. 2-15

2.5.2 Setting up the Switch Box ......................................................................... 2-17

2.6 Enabling Auto Section Control ......................................................................... 2-18

Chapter 3 - Spreader Controller Setup .................................. 3-1

3.1 Setting up Spreader Controller ............................................................................ 3-2

3.2 Setting up Actuator ............................................................................................. 3-4

3.3 Setting up Control Valve (Proportional) ............................................................. 3-9

3.4 Setting up Bin Control Valve (Regulator) ........................................................ 3-14

3.5 Setting up Spinners ........................................................................................... 3-19

3.6 Setting Spinner Control Valves ......................................................................... 3-23

3.7 Setting up the Wheel Sensor ............................................................................. 3-27

3.8 Setting Alarms ................................................................................................... 3-28

Chapter 4 - Operations ............................................................ 4-1

4.1 Using the Spreader Dashboard ............................................................................ 4-2

4.2 Opening Auto Section Control ............................................................................ 4-4

4.3 Opening Spreader Controller .............................................................................. 4-7

4.4 Choosing / Changing Bins and Rates .................................................................. 4-9

4.5 Choosing / Changing a Product and Rate ......................................................... 4-10

4.6 Monitoring Statistics ......................................................................................... 4-16

4.7 Choosing and Changing Sub Areas .................................................................. 4-17

4.8 Configuring and Calibrating ............................................................................. 4-19

4.9 Managing the Spinners ...................................................................................... 4-21

4.10 Using the Master Switch ................................................................................. 4-22

4.11 Using Map Views and Layers ......................................................................... 4-23

Chapter 5 - Variable Rate Control ......................................... 5-1

5.1 Loading VRC Map Files ..................................................................................... 5-2

5.2 Using Variable Rate Control ............................................................................... 5-8

5.3 Downloading VRC Map Files with AgJunction ............................................... 5-10

Appendix A – Start up Checklist

X30 Spreader Controller

1-1

Chapter 1 - Introduction

The X30 Spreader and Auto Section Controller is used with

the X30 Guidance and Auto Steering Console. Refer also to

the X30 Guidance and Auto Steering Operator's Manual.

The X30 Spreader Controller allows better control of the

amount of product being applied to a field. Once set up, it

will adjust the discharge rate according to vehicle speed and

the section being covered to maintain the preset application

rate. This provides more accurate use of a product over the

specified areas.

Auto Section Control minimizes wastage, turning parts of the

spreader on and off as the equipment passes through the

defined areas. The system will turn on when it detects an area

that has not been covered and it will turn off when it detects

areas that have already had product applied.

Section control is limited to the number of spinners being

controlled by the X30 Spreader Controller. In a two spinner

setup, there can be two sections (left and right). In a single

spinner setup, there is only one section which is the entire

working width of the spreader.

Regional information such as time and product

measurement units can be set by selecting User from the

Main Setup Menu

. Refer to the X30 Guidance and

Auto Steering Manual.

The console will ask you to confirm your selections:

Confirm the selection/action to continue.

Cancel the selection/action and return to previous screen.

X30 Spreader Controller

2-1

Chapter 2 - Implement Setup

This chapter explains how to setup and configure the X30

Console for use with the Spreader Controller features. The

Spreader Controller option is only available when the

Electronic Control Units (ECUs) have been set up.

To return to the X30 Main Setup screen from operations

screens, select .

Note that when the system is new, the following

X30

Main Setup

screen will appear.

2.1 Setting up a New Implement

2.2 Connecting to ECUs

2.3 Setting up the ECU

2.4 Setting up Implement Geometry

2.5 Setting up Section Control

2.6 Enabling Auto Section Control

Chapter 2 - Implement Setup 2.1 Setting up a New Implement

X30 Spreader Controller

2-2

2.1 Setting up a New Implement

Follow the steps below to create a new implement.

Implement information files can be imported from a USB.

Refer to the X30 Guidance and Auto Steering manual.

1 Select Implement and Select New.

Chapter 2 - Implement Setup 2.1 Setting up a New Implement

X30 Spreader Controller

2-3

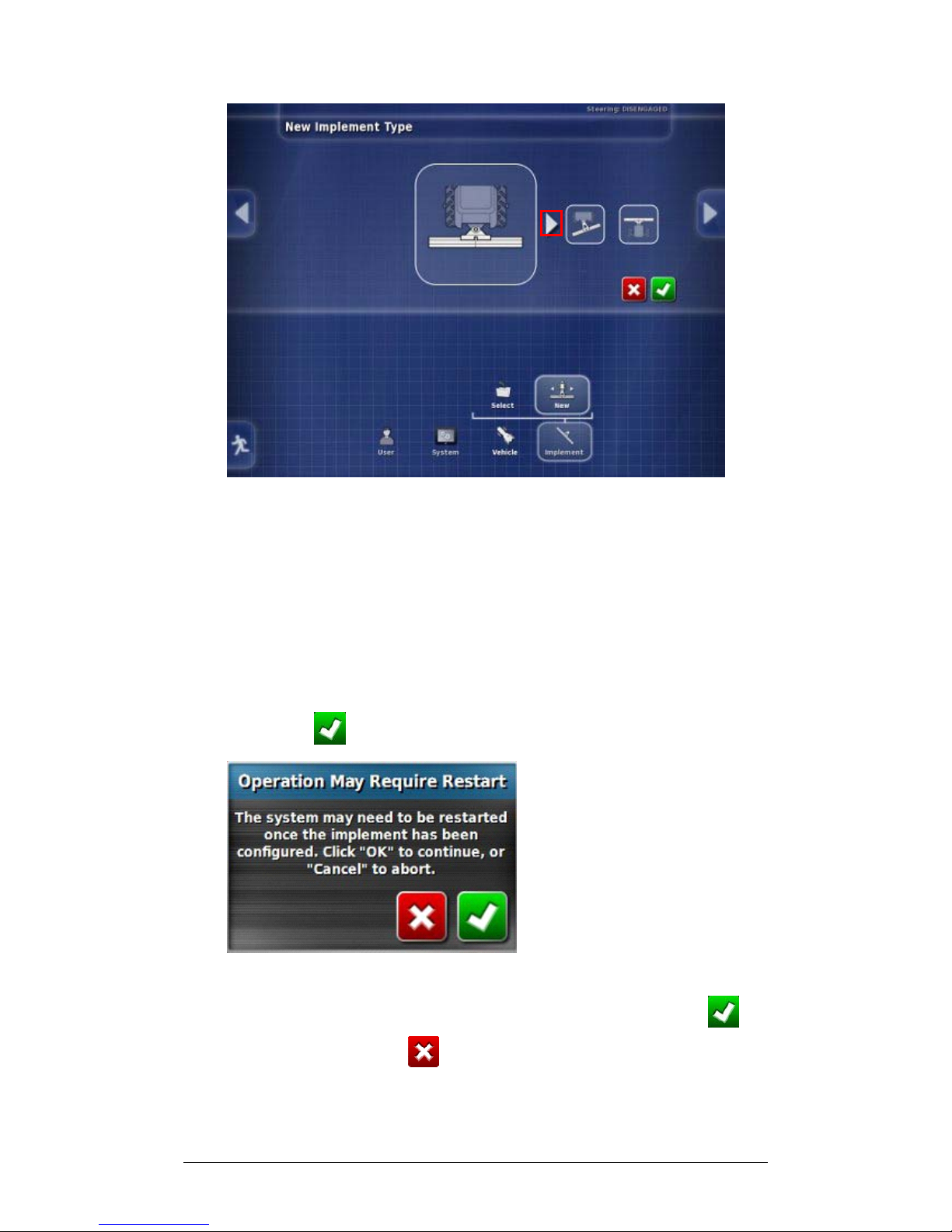

You may choose between:

Rigid

Front Mount

Pivoted (Tow behind)

Double Pivoted (Tow between).

2. Use the side arrows to choose an Implement Type and

Confirm .

3. The system will warn you that it may need to restart after

you have finished setting up the implement. Select to

continue (or select to cancel the action).

Chapter 2 - Implement Setup 2.1 Setting up a New Implement

X30 Spreader Controller

2-4

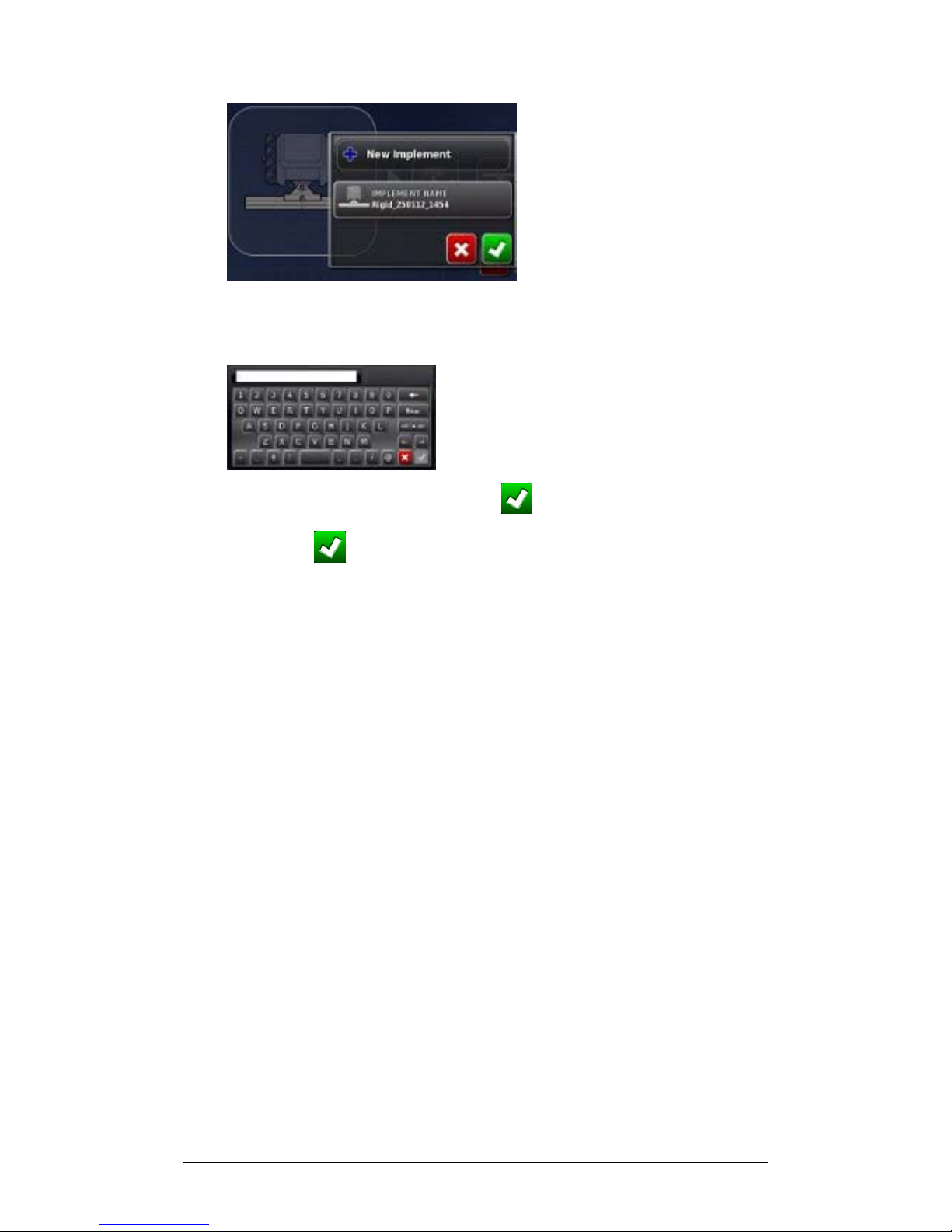

4. Select Implement Name if you wish to name your

implement.

5. Enter the name and Confirm .

6. Confirm the new implement details to continue.

Chapter 2 - Implement Setup 2.2 Connecting to ECUs

X30 Spreader Controller

2-5

2.2 Connecting to ECUs

ECUs should be connected to the CAN2 connector on the

console’s termination harness. Start with all ECUs

disconnected from the CAN line and confirm that the harness

is connected to the console. Only one termination is

necessary, placed at the ECU farthest from the console.

Follow the steps below and, when prompted, connect the first

ECU to the CAN line. Only one ECU can be detected at a

time. Once each ECU is detected, connect the next ECU

when prompted.

The blue status indicator on the ASC-10 will flash three times

slowly, then three times quickly to indicate normal

operations.

Chapter 2 - Implement Setup 2.3 Setting up the ECU

X30 Spreader Controller

2-6

2.3 Setting up the ECU

This will involve configuring ECU type, control function and

bin. The number of ECUs depends on the number of bins,

belts and spinners in your setup.

Setup for the ECU will begin automatically as part of

creating a new implement.

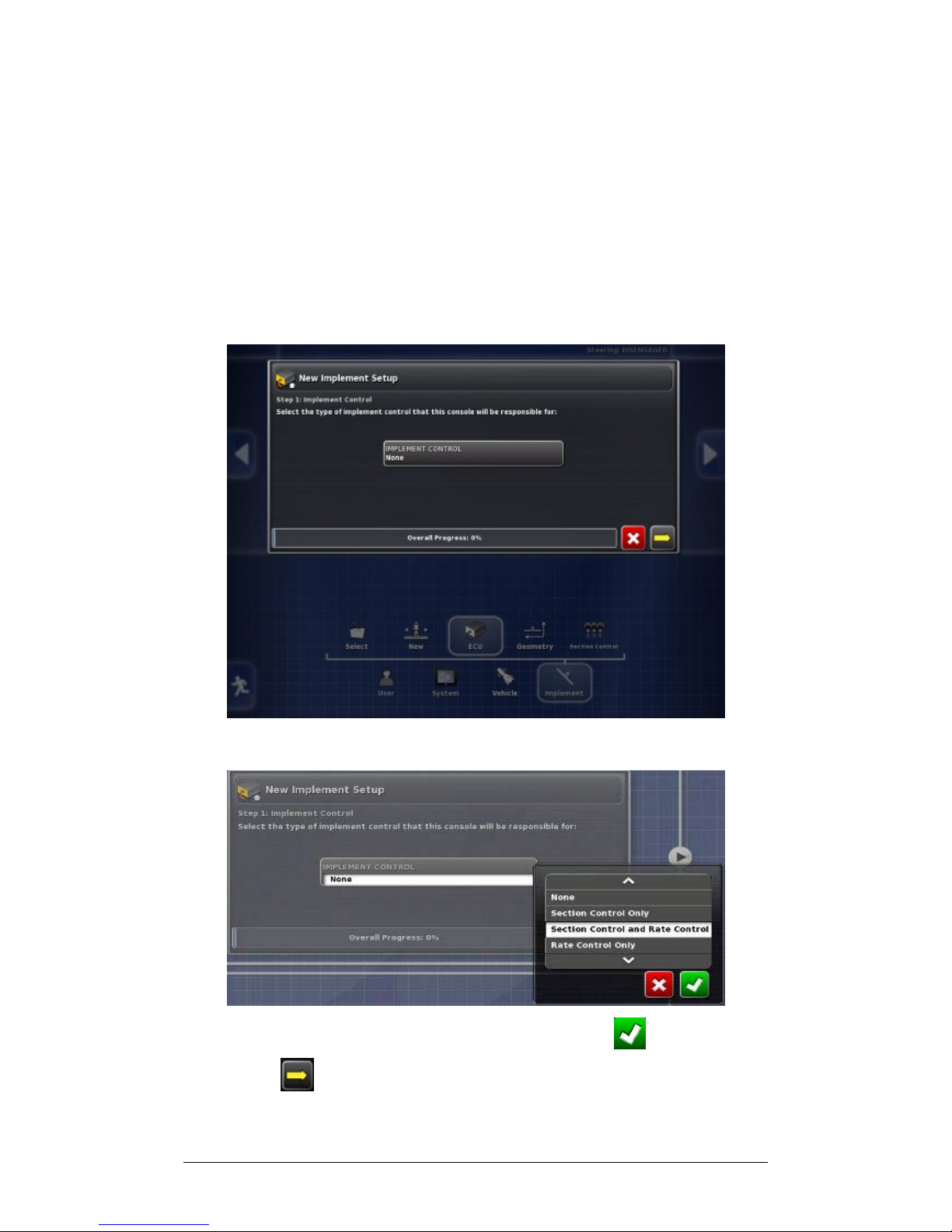

1. Select Implement Control.

2. Choose the control required and Confirm and select

Next .

Chapter 2 - Implement Setup 2.3 Setting up the ECU

X30 Spreader Controller

2-7

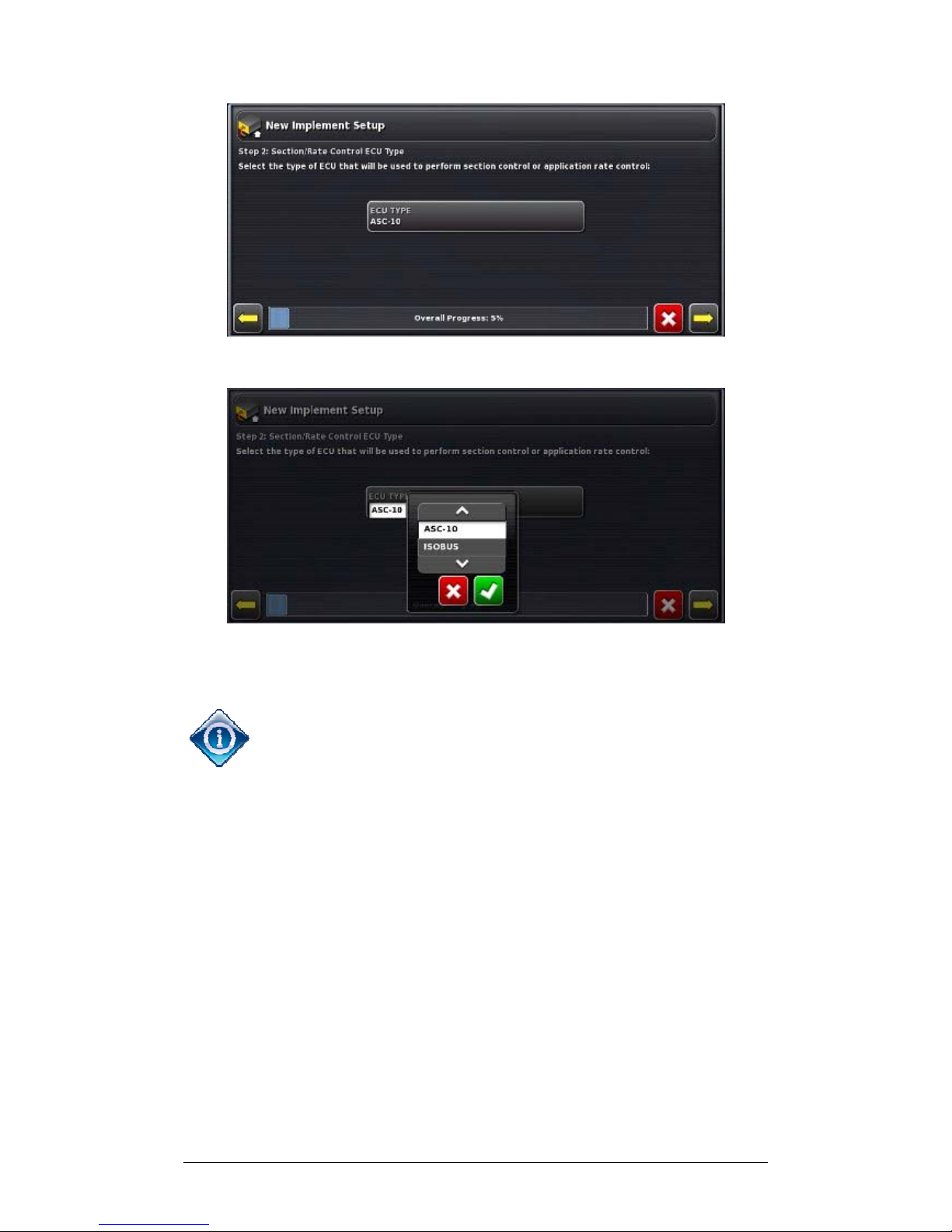

3. Select ECU Type.

4. Choose the type of ECU required, Confirm and select

Next.

Note that the Spreader Controller interface described in

Chapters 3 and 4 of this manual is only used to control

spreaders equipped with the Topcon ASC-10 ECUs.

If ISOBUS ECU is chosen, functionality will depend on

the ISOBUS unit connected. The ISOBUS ECU can be

operated through the Virtual Terminal feature of the X30

software. Please refer to the ISOBUS ECU documentation.

Minor variations in the following ECU setup options may

appear.

Chapter 2 - Implement Setup 2.3 Setting up the ECU

X30 Spreader Controller

2-8

5. Select Implement Function.

6. Choose Spreader, Confirm and select Next.

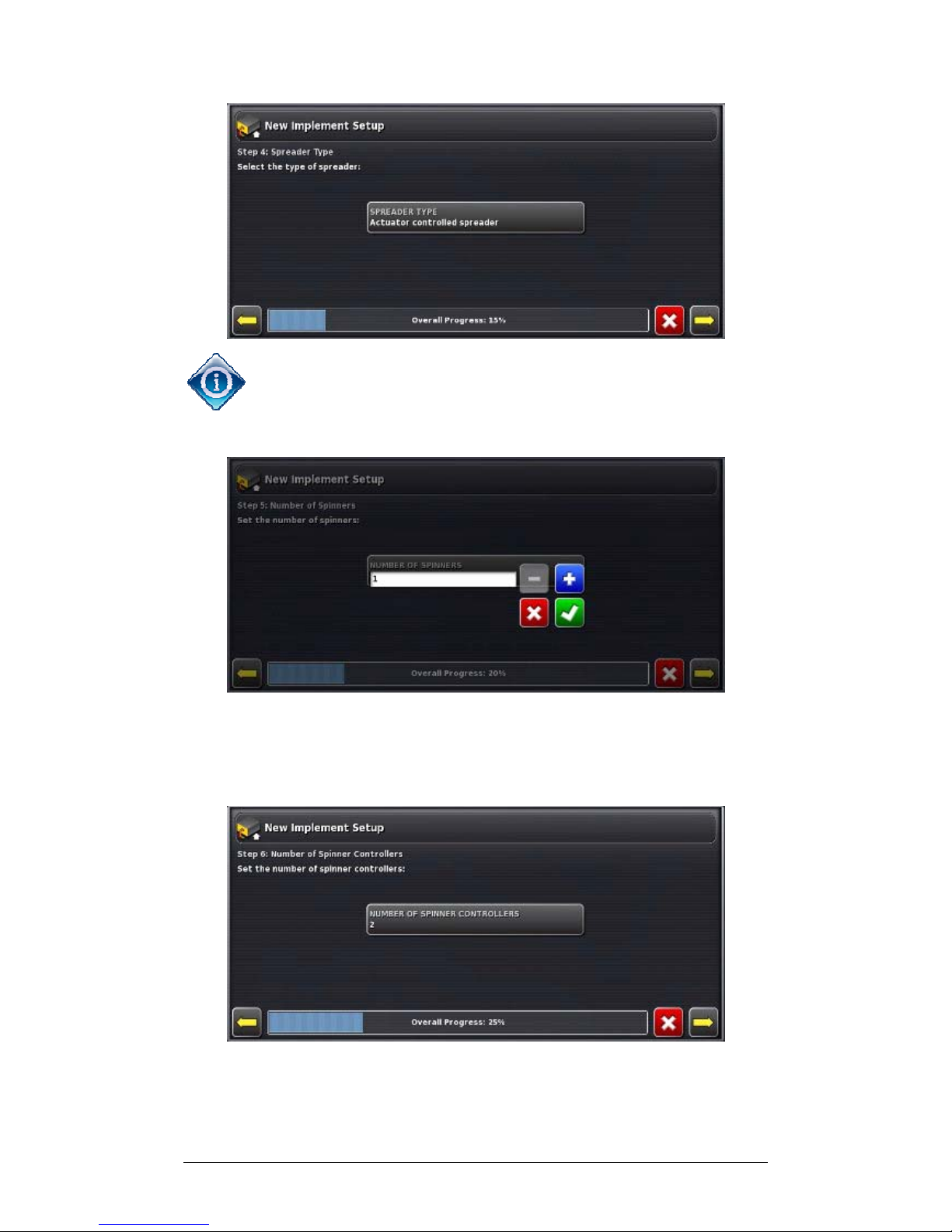

7. Select the type of Spreader, Confirm and select Next.

Chapter 2 - Implement Setup 2.3 Setting up the ECU

X30 Spreader Controller

2-9

The choice of Actuator controlled or Belt Driven spreader

will affect the options offered and the number of steps

shown on the screens. Follow the screen prompts.

8. Select Number of Spinners. Use plus or minus to choose

the number of spinners, Confirm and select Next. If only

one spinner is set, go to Step 10.

9. If more than one spinner has been set the following

screen will display.

Chapter 2 - Implement Setup 2.3 Setting up the ECU

X30 Spreader Controller

2-10

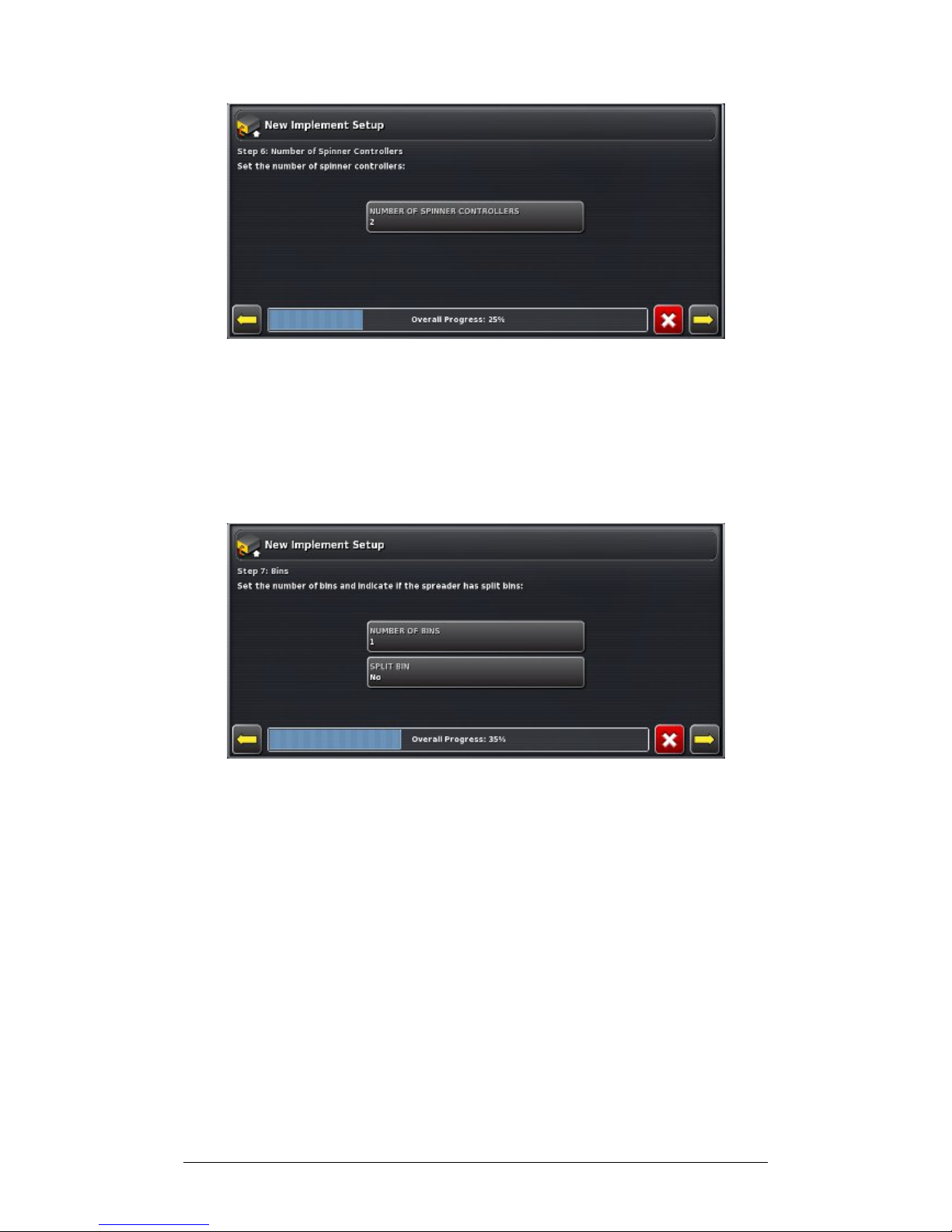

9a. Select Number of Spinner Controllers. Use plus or minus

to enter the number of spinner controllers, Confirm and

select Next.

9b. Select Number of Spinner Monitors, and use plus or

minus to enter the number, Confirm and select Next.

10. Select Number of Bins.

Loading...

Loading...