Page 1

V1.98 21/06/06

.

X20/X15/X10 Operators Manual

Spray Rate Control

A2677 V1.98 1.4

W133

Page 2

V1.98 21/06/06V1.98 21/06/06

.

Page 2

As with any computer operated equipment, software and/or hardware is in many cases changed and upgraded

over the life of the equipment.

KEE Technologies software engineers are constantly working on software enhancements which will provide you

with many additional benefits and features in the future.

The ZYNX System will keep on evolving! ...to ultimately improve your ‘bottom line’!

KEE Technologies personnel have records of all changes implemented to your system with the subsequent serial

number.

To keep this Operator’s manual “alive” and current with your equipment and software versions you

will need to administer and document the evolution of your ZYNX System in this manual.

In some cases we will provide you with software upgrades and additional/ replacement pages to add to this

manual. With major software upgrades we may provide you with a completely new manual for the

corresponding ZYNX Solution.

When talking to KEE Support staff, always have this manual with you, as we may ask you what version manual

you are currently looking at to ensure we all talk the same language. For this purpose all pages are coded as

follows.

Page number Date when written Software version

Below is space provided to keep records of any software and hardware upgrades you may have received.

Type of upgrade (software or hardware) Version Date Manual upgraded

09/06

09/06

V1.98

V1.98

21/06/06

21/06/06

ZYNX X20 Sprayer Software (ex factory)

ZYNX X15 Sprayer Software (ex factory)

A

B C

Page 3

Contents

Page 3

V1.98 21/06/06

V 1.86

IINNSSTTAALLLLAATTIIOONN

1.0

FFoorr AALLLL IInnssttaallllaattiioonnss aanndd SSeerrvviicciinngg ooff SSpprraayy EECCUU’’ss 1100

1.1 Installing the Spray ECU (All Models) 11

1.2 Installing Spray ECU 30S KEE Spray Controller Kits 13

1.2.1 Installing the Tractor Harness 13

1.2.2 Installing the Sprayer Harness 16

1.2.3 Installing the Valve Harness 20

1.3 Installing Spray ECU 30S kits to Existing KEE Controllers 25

1.4 Installing to Existing Raven Controllers 27

1.5 Connecting the Spray ECU to the Battery 30

SPRAYER SETUP OPTIONS

4.0 GPS 46

5.0 ECU 48

5.1 ECU (Spray ECU ONLY) 50

6.0 TANKS 52

6.1 REGULATOR VALVE SETTINGS 54

6.2 PROPORTIONAL VALVE SETTINGS 56

7.0 SECTIONS 58

8.0 SWITCHES 60

8.1 SWITCHES (SPRAY ECU 2 ONLY) 62

8.2 CUSTOM SECTION MAPPING 63

9.0 SENSORS 64

9.1 SENSORS (SPRAY ECU 2 ONLY) 66

10.0 SETUP 67

10.1 SETUP (SPRAY ECU2 ONLY) 69

10.2 WHEEL CALIBRATION 70

11.0 UNITS 71

12.0 ALARMS 72

12.1 ALARM DEFAULTS 74

13.0 PRESETS 75

14.0 SIMULATION 76

15.0 Other 77

16.0 SAVING THE SPRAYER CONFIGURATIONS 78

16.1 CHANGE SETTINGS TO THE CURRENT CONFIGURATION 79

Content Page No.

IInnttrroodduuccttiioonn 66

HHooww ttoo UU

ssee tthhiiss MMaannuuaall 77

GGEETTTTIINNGG SSTTAARRTTEEDD 3311

2.1 Starting the X15 Console 32

2.2 Starting the X20 Console 33

2.3 Registration and Sprayrate Control Software Version 34

2.4 Overview of Functions-

WWoorrkkiinngg SSccrreeeenn

35

2.5 Navigating Around the OPTIONS window 38

3.0 Configuration Setup 42

3.1 Adjust Audio Volume 42

3.2 Configuration 42

3.3 Factory Configuration 43

3.4 Quick Setup (For Factory Configurations) 44

3.5 Select the ‘Change/View Configuration’ button 44

Page 4

Page 4

V1.98 21/06/06

Contents

V1.98 21/06/06

V 1.86

17.1 Pressure Window 82

17.2 Calibrating the Pressure Sensor 83

17.3 Manual Entry of Pressure Calibration Factors (Spray ECU) 83

17.4 Flow Window 84

17.5 Speed Window 85

17.6 Area/Volume Window 86

17.7 Tank Setup 88

17.7.1 Fill The Tank 89

17.8 Calibrate The Flow Meter 90

17.8.1 Flow Calibration for Normal Valves 90

17.8.2 Flow Calibration for Balanced Valves 91

17.9 Enable Lockout Feature 92

17.9.1 Enable Lockout 92

17.9.2 Dis-able Lockout 92

17.10 Sprayer Switchbox 93

START SPRAYING

18.1 Simulate Spraying 95

18.2 Start Spraying 96

18.3 Using ZYNX Guidance with the Spray Controller 97

TESTING

19.1 Regulator Valve 100

19.2 ZYNX Switched Power 100

19.3 Dump Valve 101

19.4 KEE Sensors 101

19.5 ‘3 Wire Section Valves’ 102

19.6 PWM Regulator Valve 102

SYSTEM COMPONENTS AND SPECIFICATIONS

20.1 Sprayer Components- Part List 103

20.2 Specifications 104

20.2.1 ZYNX Console 104

20.2.2 KEE Sensors (Ground, Fan and Auxiliary Sensors) 104

20.2.3 Flow Sensors 104

20.2.4 Pressure Sensor 105

Content Page No.

SSEETTTTIINNGG UUPP TTHHEE SSPPRRAAYYEERR

Page 5

WIRING CONNECTION TABLES

21.1 Selecting the Right Controller 107

21.2 Wiring Connection Tables for Spray ECU Controllers 109

21.3 Spray ECU (with tails) 111

21.3.1 A1999 (Hagie) Connection Tables 112

21.3.2 A2006 (Raven) Connection Tables 114

21.4 Spray ECU 116

21.4.1 A2036 Spray ECU Connection Tables (060001-060014) 117

21.4.2 A2036 Spray ECU Connection Tables (060015- 060053) 120

21.5 Spray ECU (Raven) 123

21.5.1 A2445 KEE Spray ECU 3 Connection Tables (()50001- 050011) 124

21.5.2 A2445 KEE Spray ECU 3 Connection Tables (060001 -060037) 128

21.6 Spray 10SR 132

21.6.1 Spray ECU 10SR Wiring Connection Tables (060000-060040) 133

21.6.2 Spray ECU 10SR Wiring Connection Tables (060041- ) 137

21.7 Spray ECU 30S 141

21.7.1 Spray ECU 30S Wiring Connection Tables 142

21.8 Hardi 5500 Spray ECU 145

21.8.1 Hardi 5500 Spray ECU Connection Tables 146

21.9 KEE Sprayrate Interface 148

21.9.1 KEE Sprayrate Interface Wiring Connection Tables 149

WIRING SCHEMATICS OF KEE SPRAY ECU TRACTOR AND SPRAYER LOOMS 151-164

SERVICE BULLETINS

23.0 Pressure Relief Valve installation to Raven Fast Flow Valves 166

Contents

Page 5

V1.98 21/06/06

Page 6

Major Topic Heading

Introduction

Page 6

V1.98 21/06/06

Introduction

The Spray ECU is a new generation spray controller to used in conjunction with the NEW

X20 or ZYNX X15 consoles brought to you by KEE Technologies. The Console is the graphical

interface of the Spray ECU controller. The Spray ECU replaces the KEE Sprayrate Interface.

The Spray ECU can control up to 30 section valves (3 wire) and allows Automatic Section

Control (ASC) of the 30 section valves (the X15 Console can control up 15 sections under

ASC). The Spray ECU can control up 2 liquid tanks directly. If the Spray ECU is used in

conjunction with a Multi-Drive Electronic Control (MDECU) unit, it can control up to 3 liquid

injection tanks.

The Spray ECU can handle ‘Boom Sensing’ inputs therefore can be connected to existing

Remote switches. The Spray ECU also has a new feature called ‘Section Mapping’ which

allows one section switch to control a number of section valves. Therefore the existing KEE

Switchbox or Remote switches (usually 6 or 8 switches) can control all 30 section valves

when they are controlled manually. The ZYNX sprayer software sets up the section mapping

automatically. The ASC still controls all 30 section valves individually.

The Spray ECU can control Regulator or Proportional type control valves. The Spray ECU can

control ‘3 Wire’, ‘2 Wire’ (reverse polarity) or solenoid type section valves.

Page 7

How to use this Manual

Page 7

V1.98 21/06/06

HOW TO USE THIS MANUAL

All operators who have a Spray ECU installed must read the following page:

Section 1.0 ‘For all Installations and Servicing of Spray ECU’s’.

UUppggrraaddiinngg tthhee ZZYYNNXX SSpprraayy RRaattee CCoonnttrrooll SSooffttwwaarree

If the ‘Spray Rate Interface’ or ‘Spray ECU’ is already installed and you are using this book to

upgrade the ZYNX Sprayrate Control software to a later version, then go to straight to Section

3.0 ‘Configuration Setup’.

IInnssttaallllaattiioonn ooff tthhee SSpprraayy EECCUU

1. Read Section 1.0 ‘For all Installations and Servicing of Spray ECU’s’ before attempting

any installations

2. Section 1.1 has details about installing the Spray ECU controller, Power/Comms harness

and KEE Sprayer Switchbox.

3. Then select one of the following installations, depending on which Spray ECU kit

was purchased:

3a. Section 1.2: Installing a complete KEE Spray ECU 30S kit. This section explains how to

install the following: Tractor harness, Sprayer Harness, Valve Harness, wheel sensor kit,

flow sensor kit, connect to a regulating valve, electronic pressure sensor and connect to

a dump valve.

3b. Section 1.3: Installing a Spray ECU 30S kit to an existing KEE MK5 Spray controller or

KEE Spray Rate Interface.

3c. Section 1.4: Installing the 10SR Spray ECU to existing Raven 4xx, 6xx, 4400 and 4600

series controllers. The Spray ECU 10SR has been pinned to allow direct replacement of

some of the Raven 4xx, 6xx, 4400 and 4600 series controllers.

4. This section connects the Spray ECU to the battery. The hardware installation is

complete.

5. Once the Installation is complete then go to Section 2.0 ‘Getting Started’. Go to Section

2.1 if starting an X15 Console

OORR

to Section 2.2 if starting starting an X20 Console.

These sections explain starting the ZYNX Console. The manual from Section 2.3 onward

will be the same whether an X15/X10 Console or X20 Console is used. Section 2.3 checks

the spraying software is registered. This section gives an overview of the Sprayer

Working Screen and how to ‘Navigate Around the Screen’ during setting up the sprayer

software.

6. Section 3.0: ‘Configuration Setup’ explains how to load your KEE Spray kit or Sprayer

from the factory configurations files loaded on the ZYNX Console, if your sprayer is

listed. These configuration files contain most of the sprayer settings required to set up

your sprayer. If your sprayer is listed in the Factory Configurations then you can choose

to do the Quick Setup (Section 3.4)

OORR

manually follow the manual through all the

sprayer software setup options (Section 4 to 15) in the Software Setup Section.

7. (Section 4 through to 15): The Sprayer Software Setup section takes the operator

through the 11 pages of the OPTIONS window to setup the sprayer.

Page 8

How to use this Manual

8. Section 16: ‘Saving the Configurations’ section shows the operator how to save and

name the sprayer settings entered into the Sprayer Software Setup (Sections 4 to 15).

9. Section 17:’Setting up the Sprayer’ explains the Pressure, Flow, Speed, and

Area/Volume windows. This section explains how to ‘Fill the Tank’ and the Sprayer

Switchbox. This section also explains how to Calibrate the Pressure Sensor and Flow

sensor. Setting up is now complete the sprayer is ready for testing.

10. Section 18: ‘Start Spraying’ section explains how to test and simulate spraying using

water before any actual spraying takes place. The section then explains how to start

spraying, in either MANUAL or AUTOMATIC mode.

11. Section 19: The ‘Testing’ section explains how to test the Regulator Valve, test for

Switch power for the Spray ECU, test the dump valve, test KEE sensors, test for 3 wire

section valves and test PWM valves.

12. Section 21: The ‘Wiring Connection Tables’ section shows how to select between

‘Spray Rate Interface’ and ‘Spray ECU’ controllers when selecting in the software.

This section also contains the Wiring Connection tables for each of the connectors for

the different Spray ECU’s.

13. Section 22: This section contains the schematic wiring diagrams of the current the KEE

Spray ECU 30S Tractor and Sprayer harness’s available.

Page 8

V1.98 21/06/06

Page 9

Page 9

V1.98 21/06/06

Spray Rate Control

Installation

Page 10

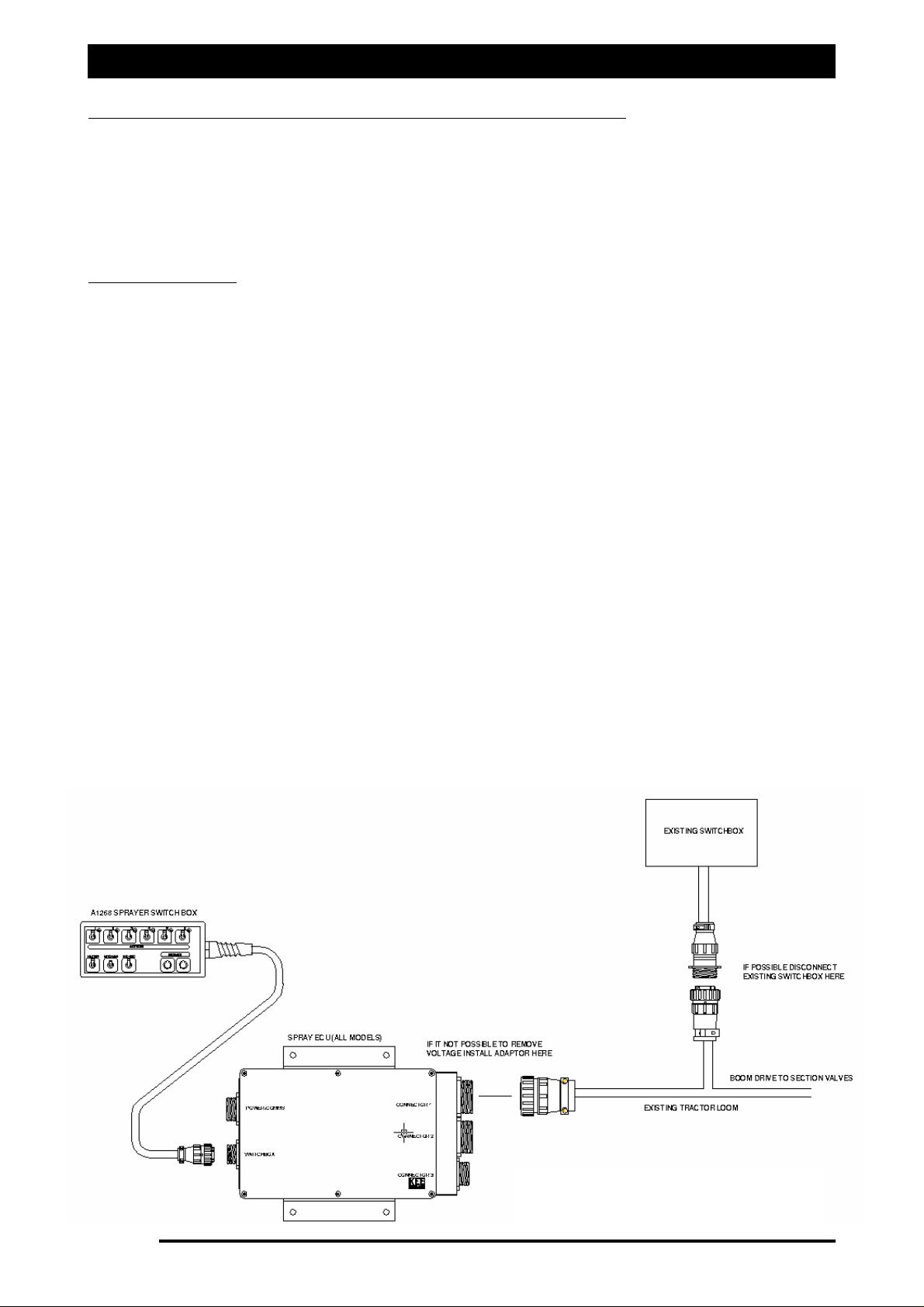

Warning when Installing Spray ECU Controller

1.0 FOR ALL INSTALLATIONS AND SERVICING OF SPRAY ECU'S

Damage will occur if any external power is applied to the Section Drive Outputs on the

Sprayer ECU. Follow this procedure to ensure that damage is avoided.

Disconnect both the ZYNX Console and Spray ECU controller from the battery before

charging, jump starting or welding on the vehicle and/or sprayer.

TTeessttiinngg PPrroocceedduurree::

Commence test by disconnecting the existing tractor harness from the existing controller.

AA.. IInnssttaallllaattiioonnss wwiitthh nnoo eexxiissttiinngg sswwiittcchhbbooxx ((SSwwiittcchheess oonn EExxiissttiinngg CCoonnttrroolllleerr))::

With ignition key on, check each Section Drive Output pin on the existing tractor harness for

voltage (refer manufacturer of existing tractor harness for pin detail). Locate where voltage

is supplied to determine if it can be removed without limiting existing functionality.

If it is not possible to remove this voltage then you must install a Section Drive Output

Protection Adaptor. (A2812 for 37-pin on Connector 1 and A2813 for 16-pin on Connector 3)

If no voltage is found disconnect the vehicle's battery and continue with installation.

BB.. I

Innssttaallllaattiioonnss wwiitthh eexxiissttiinngg sswwiittcchhbbooxx ((IInncclluuddiinngg JJooyyssttiicckk CCoonnttrrooll))

Determine if it is possible to disconnect the existing switchbox without limiting existing

functionality (e.g. Boom Lift, Lower or Fold). If so, disconnect the switchbox, switch the

ignition key on and check each Section Drive Output pin on the existing tractor harness for

voltage (refer manufacturer of existing tractor harness for pin detail).

If it is not possible to remove this voltage then you must install a Section Drive Output

Protection Adaptor. (A2812 for 37-pin on Connector 1 and A2813 for 16-pin on Connector 3)

If no voltage is found disconnect the vehicle battery and continue with installation.

Disconnect the vehicle battery before proceeding with any installation or servicing of the

Spray ECU, Tractor, Sprayer or Valve Looms.

Page 10

V1.98 21/06/06

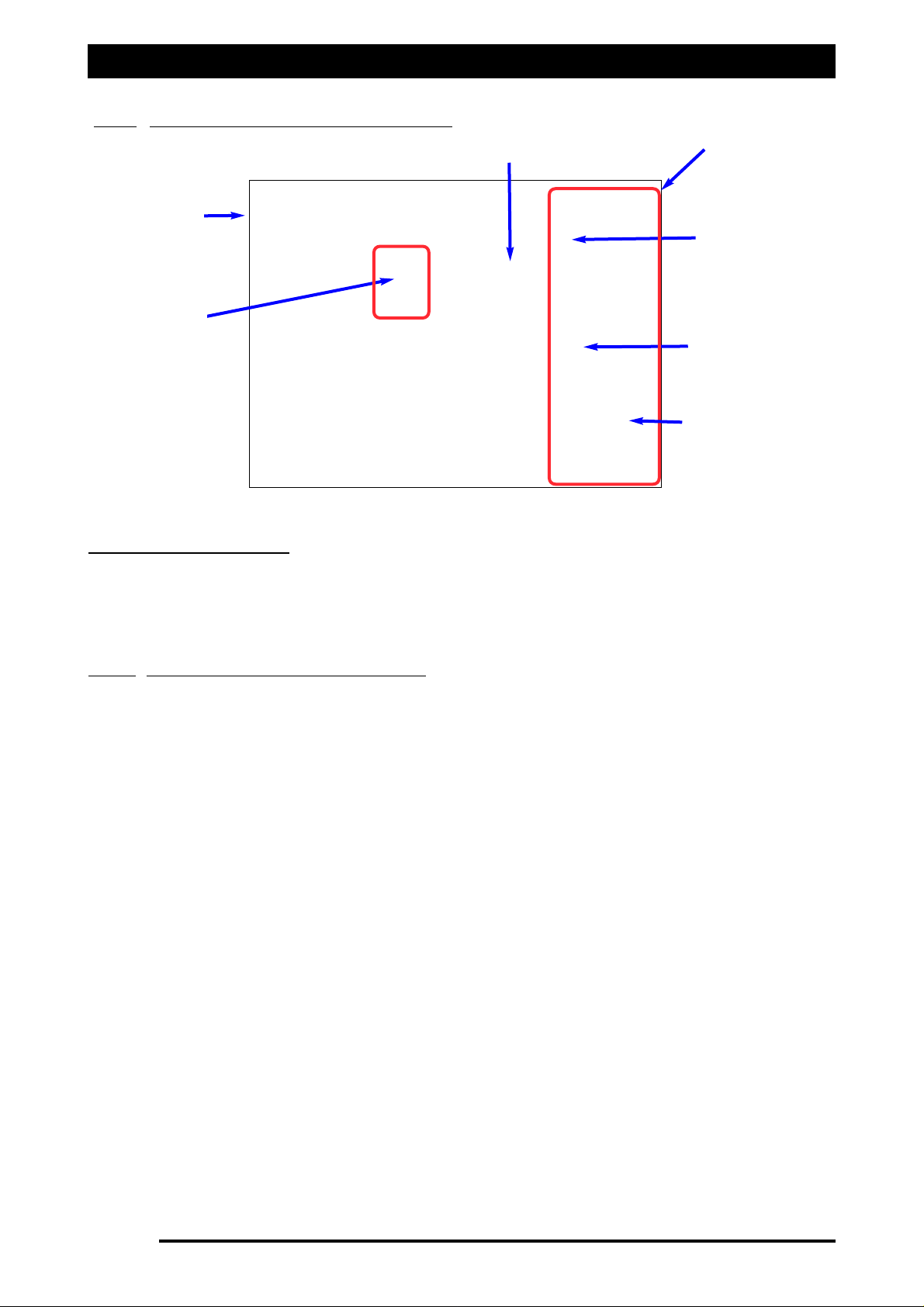

Figure 1: Connecting the

Spray ECU to existing Installations.

Page 11

Installing the Spray ECU

1.1 INSTALLING THE SPRAY ECU (ALL MODELS)

Step 1: Installing the Spray ECU 30S

1. Mount the Spray ECU (Electronic Control Unit) shown in Figure 2 in a suitable position

inside the cab ensuring that it and its connectors cannot be accidentally damaged by

moving objects, the Spray ECU can be mounted in any orientation. Figure 4 shows the

in-cabin assembly showing Spray ECU, Switch Box, Power Comms and Tractor Harness.

Please refer to the ZYNX Console (X15 or X20) manual for mounting the ZYNX Console.

Page 11

V1.98 21/06/06

NNoottee:: DDIISSCCOONNNNEECCTT TTHHEE VVEEHHIICCLLEE BBAATTTTEERRYY bbeeffoorree pprroocceeeeddiinngg wwiitthh aannyy iinnssttaallllaattiioonn oorr

sseerrvviicciinngg ooff tthhee SSpprraayy EECCUU 3300SS oorr TTrraaccttoorr hhaarrnneessss.. BBeeffoorree ccoommmmeenncciinngg aannyy i

innssttaallllaattiioonn oorr

sseerrvviicciinngg ooff tthhee SSpprraayyeerr HHaarrnneessss oorr VVaallvvee HHaarrnneessss,, mmaakkee ssuurree tth

hee TTrraaccttoorr HHaarrnneessss iiss

ddiissccoonnnneecctteedd ffrroomm tthhee SSpprraayyeerr hhaarrnneessss.. DDAAMMAAGGEE WWIILLLL OOCCCCUURR

iiff aannyy eexxtteerrnnaall ppoowweerr iiss

aapppplliieedd ttoo tthhee SSeeccttiioonn DDrriivvee OOuuttppuuttss oonn tthhee SSpprraayy

EECCUU..

AALLWWAAYYSS DDIISSCCOONNNNEECCTT TTHHEE VVEEHHIICCLLEE BBAATTTTEERRYY bbeeffoorree pprroocceeeeddiinngg wwiitthh aannyy wweellddiinngg,, j

juummpp

ssttaarrttiinngg oorr cchhaarrggiinngg oonn tthhee vveehhiiccllee oorr sspprraayyeerr..

2. Install the Power/Comms Harness. Route the red and black wires to a 12 volt battery.

DO NOT CONNECT TO BATTERY, UNTIL INSTALLATION IS COMPLETE.

Use the cable ties provided to secure the Power/Comms Harness away from hot and

moving parts and to avoid chaffing and wear.

3. Plug the ‘Switched Power’ connector that is located on the Power/Comms Harness, into

the ‘Switched Power’ connector on the ZYNX Power Cable. If this connection is already

utilized, connect it via the A1953 Power Splitter Harness. This connection ensures that

the Spray ECU is only powered up when the ZYNX Console is switched ON.

4. One end of the Power/Comms Harness has 'DB 9-Pin' Comms Cable connection.

Connect this cable to the next available COM Port at the back of the ZYNX Console.

5. Connect the other end of the Power/Comms Harness to the 16-pin connector marked

‘POWER/COMMS’ on the Spray ECU.

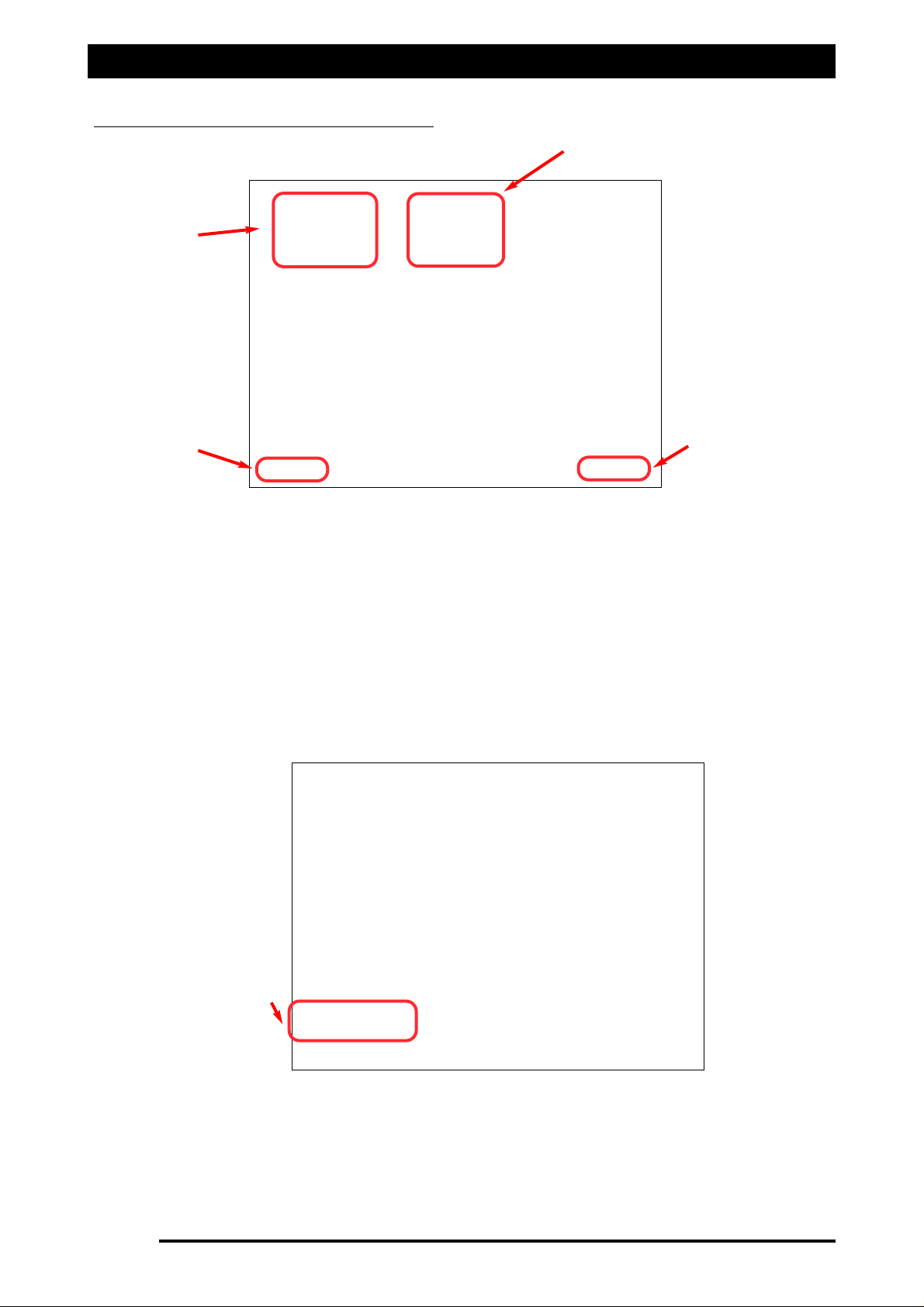

Figure 2: Spray ECU 30S

Figure 3: Sprayer Switchbox

Page 12

Installing the Spray ECU

6. Connect the Sprayer Switchbox, shown in Figure 3, to the '9-pin connector marked

SWITCHBOX on the Spray ECU. Then mount the Sprayer Switchbox using the doublesided tape supplied or other suitable means. Mount the Sprayer Switchbox in a

position which is easily accessible while spraying.

Note: The Sprayer Switchbox can be used so, one switch, switches one boom section

ON and OFF. If the sprayer has more than six boom sections then the ZYNX Sprayer

software can be setup so that one section switch, switches more than one boom section

ON and OFF. The operator can custom map the boom sections.

See Section 17.10 for details of the functions of the Sprayer switchbox.

7. For reference or troubleshooting at the back of this manual Section 21.7 shows the

pin out tables for each of the Spray ECU 30S Connector’s.

Page 12

V1.98 21/06/06

Page 13

Installation of Spray ECU 30S KEE Sprayer Kits

11..22 IInnssttaallllaattiioonn ooff SSpprraayy EECCUU 3300SS KKEEEE SSpprraayyeerr KKiittss

All KEE Sprayer kits come with their installation guide which is specific to each kit,

please use the specific installation guide which come with your KEE Sprayer kit. This

section is a general guide for an installation of all KEE Spray ECU 30S Sprayer kits.

This installation guide will take the installer through the following steps:

1.2.1 Installing the Tractor Harness

1.2.2 Installing the Sprayer Harness

1.2.3 Installing the Valve Harness

1.2.1 Installing the Tractor Harness

1. Connect the Tractor Harness to the 37-Pin connector marked CONNECTOR 1, on the

Spray ECU. Figure 4 shows the in-cabin assembly showing Spray ECU, Power/Comms

Harness, Switchbox and Tractor Harness.

2. Run the Tractor Harness from the Spray ECU to the drawbar or the back of the vehicle.

Ensure that the Tractor Harness is tied away from moving, hot or sharp objects. Do not

cut or splice the Tractor Harness, all excess cable should be strapped away to avoid

vibration and wear.

3. If the Tractor Harness has ‘2’ 37 pin connectors, then connect the ‘37’ pin connector

(male pins) marked ‘CONNECTOR 1’ to the plug marked ‘CONNECTOR 1’ on the Spray

ECU. Then connect the ‘37’ pin connector (female pins) marked ‘CONNECTOR 2’ to the

plug marked ‘CONNECTOR 2’ on the Spray ECU.

Note: As a general rule the ‘CONNECTOR 2’ plug is only required if:

a) The sprayer has more than 10 boom sections.

b) The sprayer has more than ‘2’ tanks.

c) The Spray ECU is connecting to external switches which control the boom

sections (boom sensing); for example boom section switches on a ‘T Bar’ or

‘Joy Stick’ or other ‘third party’ section switches.

4. Normally ‘CONNECTOR 3’ (16 pin) is only required if the sprayer requires extra

pressure inputs, tank level sensors and extra encoder inputs. See Wiring Connections

table for the Spray ECU 30S (A2643) controller for wiring pin-outs;( See Section 21.7).

5. The Tractor Harness has a 3-pin Weather Pack connector labeled Ground Speed, either

an A328 Shaft/Speed Sensor Kit or A449 Radar Sensor Interface Harness (not included

in this kit) can be connected to this connector. Typically the Radar Sensor Interface

Harness would be connected to the Tractor Harness Ground Speed connector. Only

one (1) speed connector must be used at any one time. Refer to 1.2.2 for installing

the Shaft/Speed Sensor Kit or Radar Sensor Interface Harness.

Page 13

V1.98 21/06/06

Page 14

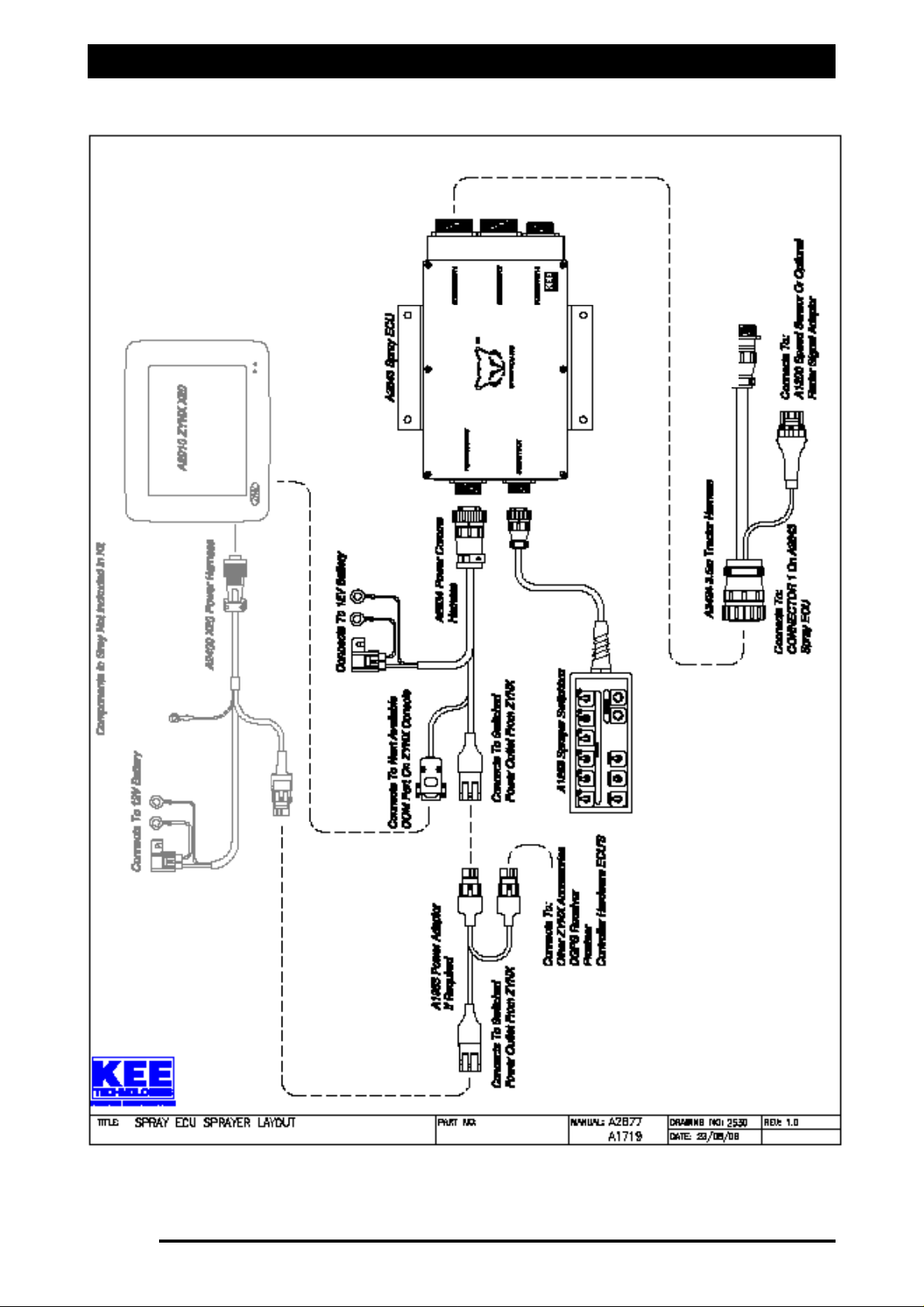

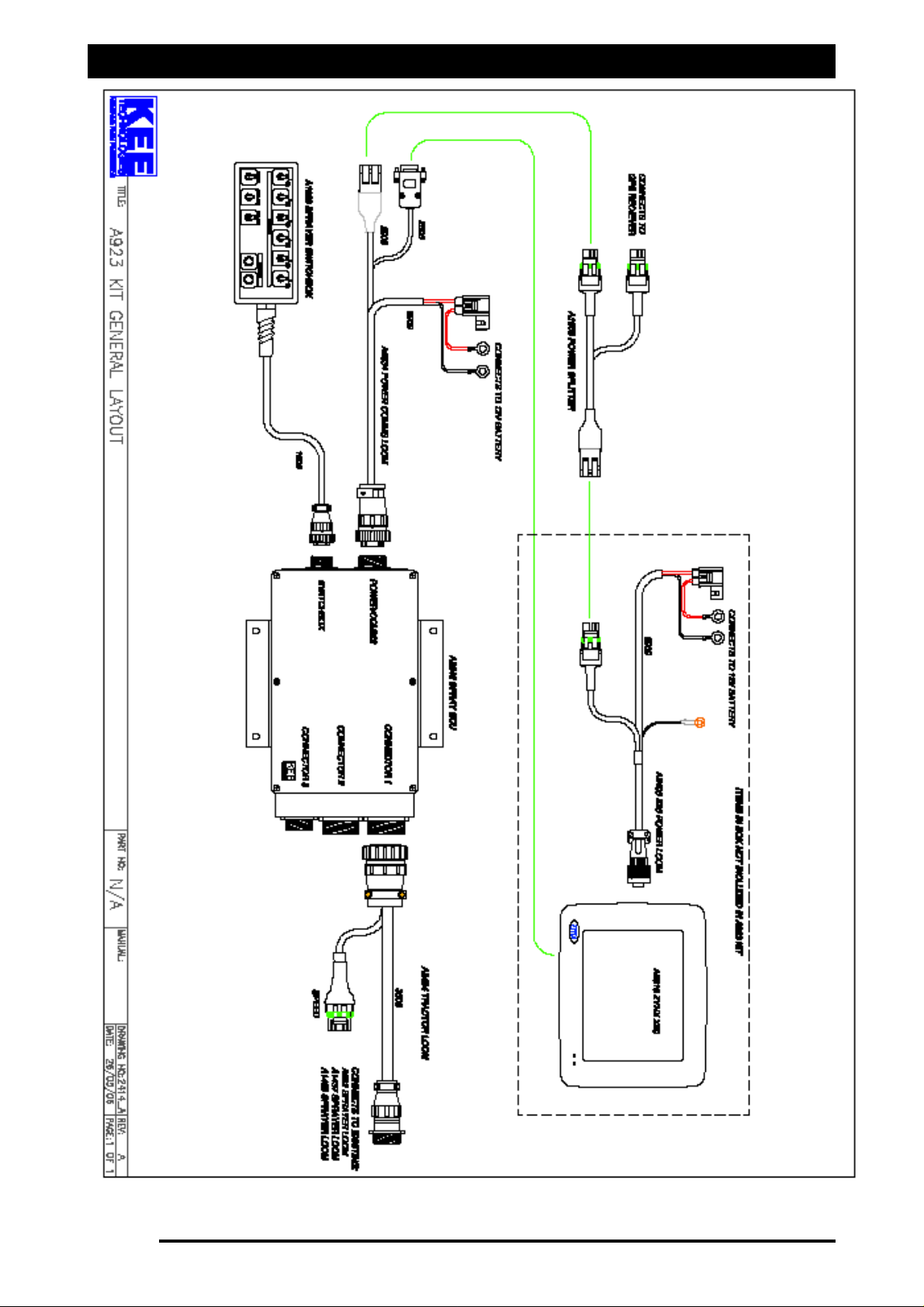

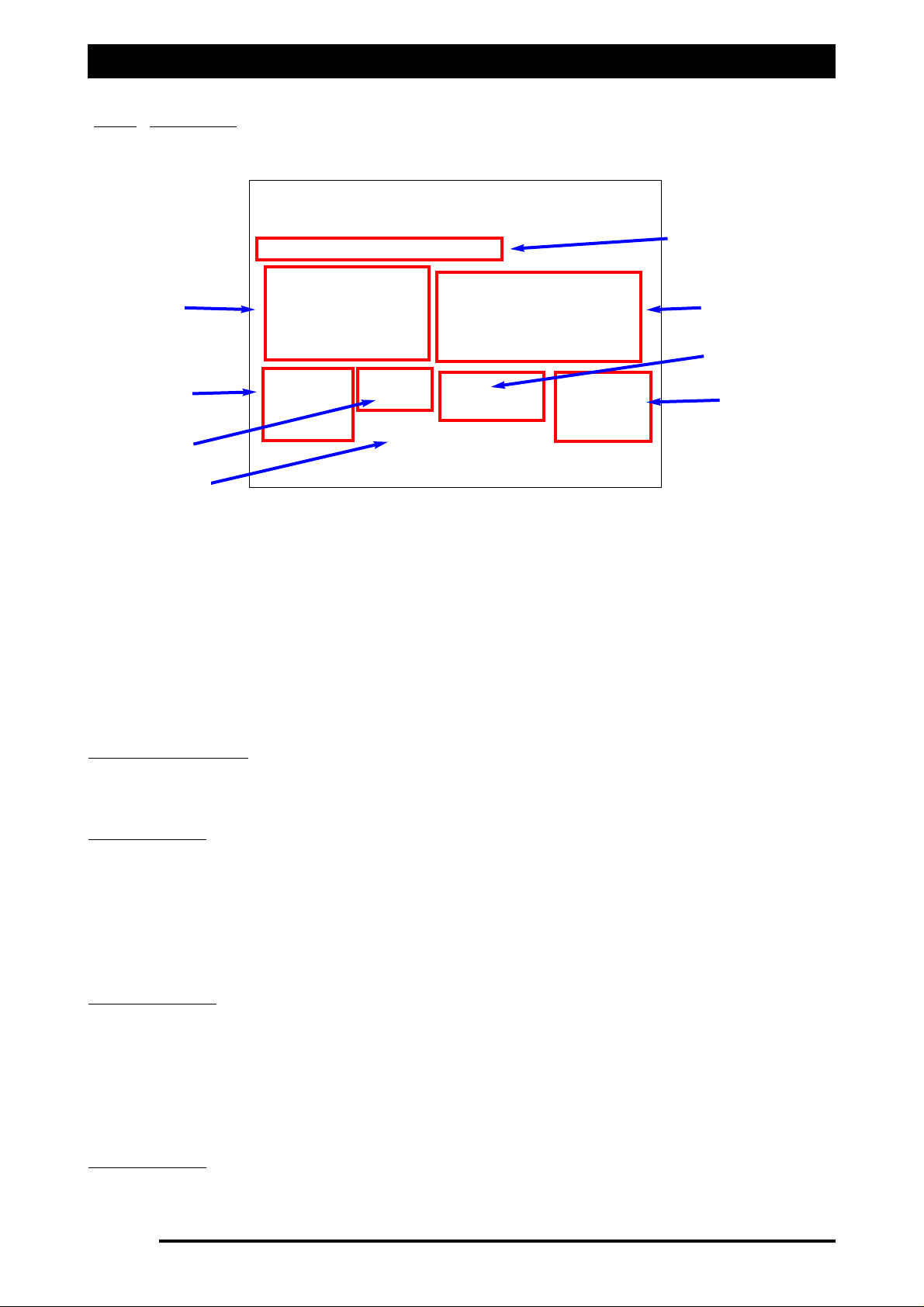

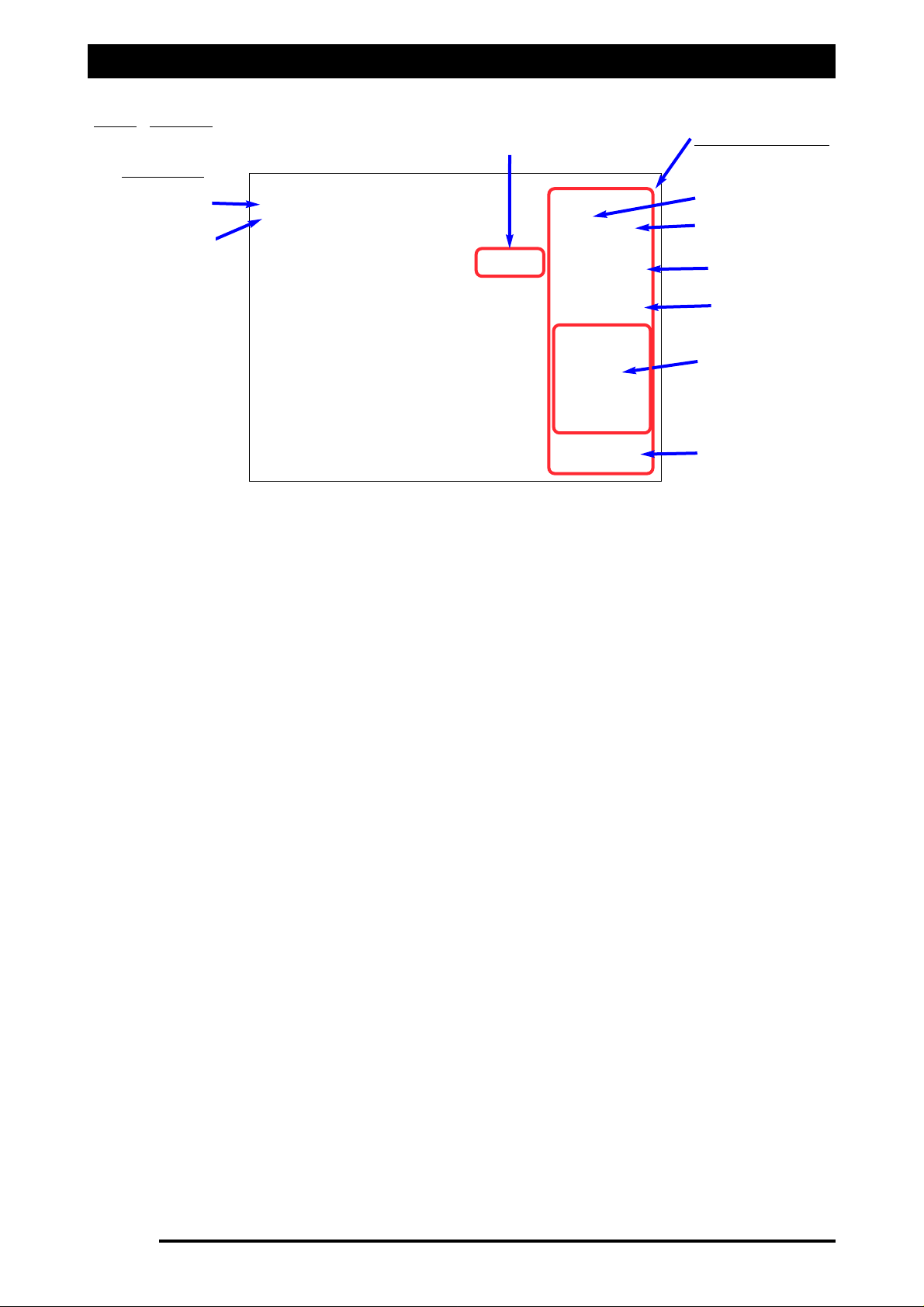

General System Layout for Spray ECU 30S KEE Controller Kits

Page 14

V1.98 21/06/06

Connects to Sprayer Harness

Figure 4: General Incab assembly

Page 15

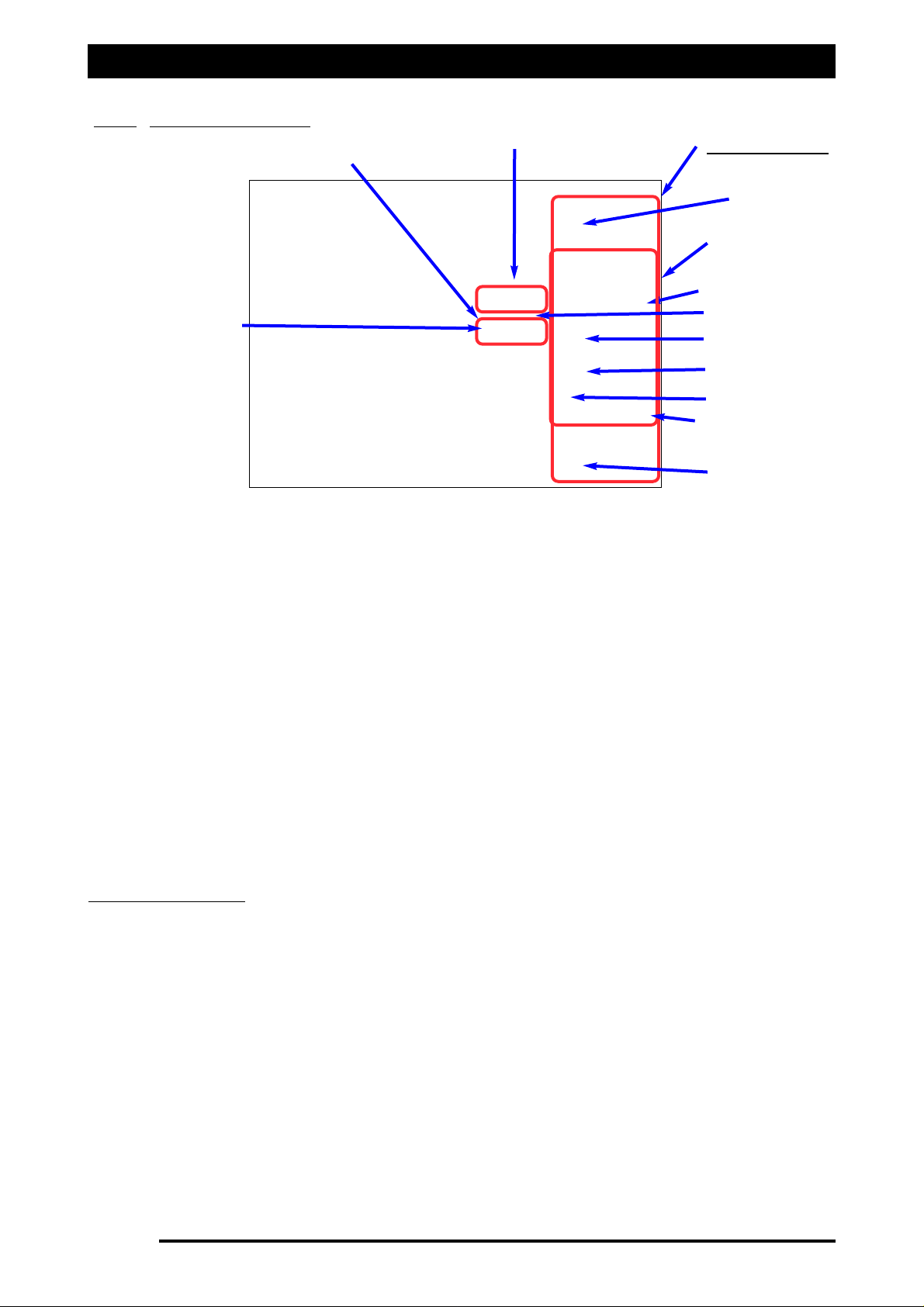

General System Layout for Spray ECU 30S KEE Controller Kits

Page 15

V1.98 21/06/06

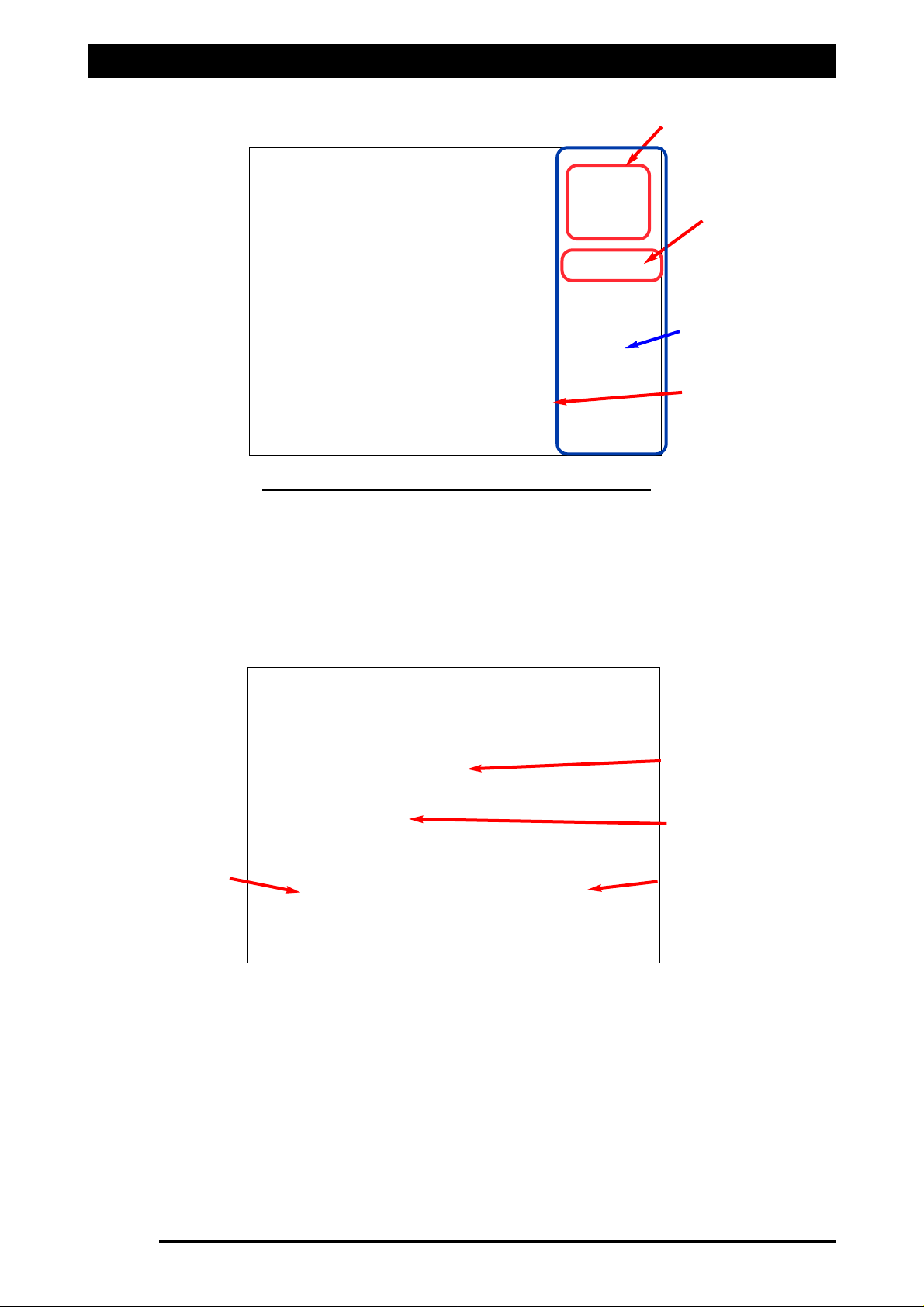

Tractor Harness

Dump Valve

Sprayer Loom

Figure 5: General Sprayer and Valve harness assembly

Page 16

Installation of Spray ECU 30S KEE Sprayer Kits

1.2.2 Installing the Sprayer Harness

1. The Sprayer Harness connects to the Tractor Harness at the back of the tractor or

vehicle via the connector and continues across the sprayer's chassis to the valve

set. Figure 5 shows the Sprayer Harness and Valve Harness Assembly.

2. Do not cut or splice the Sprayer Harness. Excess cable should be strapped away to

avoid vibration and wear.The typical Sprayer Harness has 5 connectors, they are

labeled as follows:

GGrroouunndd SSppeeeedd

- connects to the Shaft/Speed Sensor Kit which is supplied as part of this kit.

FFllooww MMeetteerr 11

- connects to a flow meter (not supplied).

PPrreessssuurree SSeennssoorr 11-

connects to the Pressure Sensor which is supplied as part of this kit.

RREEGG VVaallvvee 11-

connects to a regulator valve (not supplied).

VVaallvvee HHaarrnneessss-

connects to the Valve Harness which is supplied as part of this kit.

Note: The Sprayer Harness may have other connectors, refer to the Sprayer Installation kit that

came with your sprayer kit for more information. The Dump Valve connector may be located

on the Sprayer Harness. If the Valve Harness has an ‘Arag Interface box’ incorporated into the

Valve Harness, then the ‘Dump Valve’ connector will be located on the Valve Harness.

Troubleshooting Tip: For testing purposes on all 3-pin sensor connectors (Shaft/Speed Sensor

and Flow Meter) the voltage on each pin should be as follows: Pin A: +5 VDC Signal, Pin B:

Ground, Pin C: +12VDC Sensor Power. Refer to Figure 6 below:

Connecting to a Speed Sensor

This installation is used if connecting an A328 Shaft/Speed Sensor Kit (for ground speed) or

A449 Radar Sensor Interface Harness (not supplied) to the Ground Speed connector on either

the Tractor Harness or Sprayer Harness.

CCoonnnneecctt ttoo oonnllyy oonnee ((11)) ooff tthhee GGrroouunndd SSppeeeedd ccoonnnneeccttoorrss..

Select one of the following:

a) Installing the Shaft/Speed Sensor Kit to an un-driven wheel on either the Tractor

Harness or Sprayer Harness;

b) Installing the Shaft/Speed Sensor Kit to the Tail Shaft of a vehicle on either the Tractor

Harness or Sprayer Harness;

c) Use and existing radar speed sensor for ground speed.

Installation of the Shaft/Speed Sensor kit to an un-ddriven wheel for Ground Speed

1. The Shaft/Speed Sensor and Wheel Stud Magnets can be fitted to any un-driven ground

wheel, for example: front wheel of tractor or wheel on trailing sprayer. The magnet

activates the sensor as the wheel magnets sweep past. Refer to Figure 8.

Note: Use of a driven wheel for ground speed may be subject to "wheel slip" and may

not always reflect true ground speed.

Page 16

V1.98 21/06/06

Figure 6 : 3-Pin Weather Pack Sensor

Page 17

Installation of Spray ECU 30S KEE Sprayer Kits

2. Glue the magnets to the wheel studs with the side marked with a cross (+) facing the

Shaft/Speed Sensor. Use any silicone or epoxy type adhesive allowing adequate time

to set. Ensure that the magnets are spaced equally around the wheel to ensure

accurate speed update. To ensure adequate speed update place magnets onto ALL of

the available wheel studs. A Wheel Calibration Factor of no greater than 0.6m (24

inches) is required. Please note that the Hose Clamp and Magnetic Block are not used

in this case.

3. The Shaft/Speed Sensor must be rigidly mounted to an existing structure on the axle,

ideally in a protected position to face the magnet. The Mounting Bracket Assemblies

(slotted brackets and angle brackets with hose clamps) provided can be used to

construct a mounting bracket refer Figure 7 or you may fabricate your own mounting

bracket to suit the sprayer chassis.

IImmppoorrttaanntt:: TThheerree mmuusstt bbee NNOO mmoovveemmeenntt ooff tthhee sseennssoorr rreellaattiivvee ttoo tthhee mmaaggnne

ett..

4. The Shaft/Speed Sensor to Wheel Stud Magnet distance needs to be 2 to 3 mm (1/16 to

1/8 inch). The Shaft/Speed Sensor must be mounted so that the Wheel Stud Magnets

pass the sensor evenly and squarely.

5. Protect the Shaft/Speed Sensor and wiring from damage if necessary by welding or

bolting a suitable plate over the. Damage to the front face of the Shaft/Speed Sensor

will stop the speed readout and prevent the controller from working.

6. If the Shaft/Speed Sensor is mounted on a steered wheel, then make sure the sensor

moves with the steering mechanism, to maintain constant clearance between the

magnets and the sensor when the wheel is turning from lock to lock.

7. Use the 3-pin Weather Pack Extension provided if required, connecting the Shaft/Speed

Sensor to either the Ground Speed connector on the Tractor Harness or Sprayer

Harness.

Page 17

V1.98 21/06/06

Figure 7 : Shaft/Sensor with Mounting Bracket

Figure 8 : Shaft/Speed Sensor on an

un-driven wheel installation

Page 18

Installation of Spray ECU 30S KEE Sprayer Kits

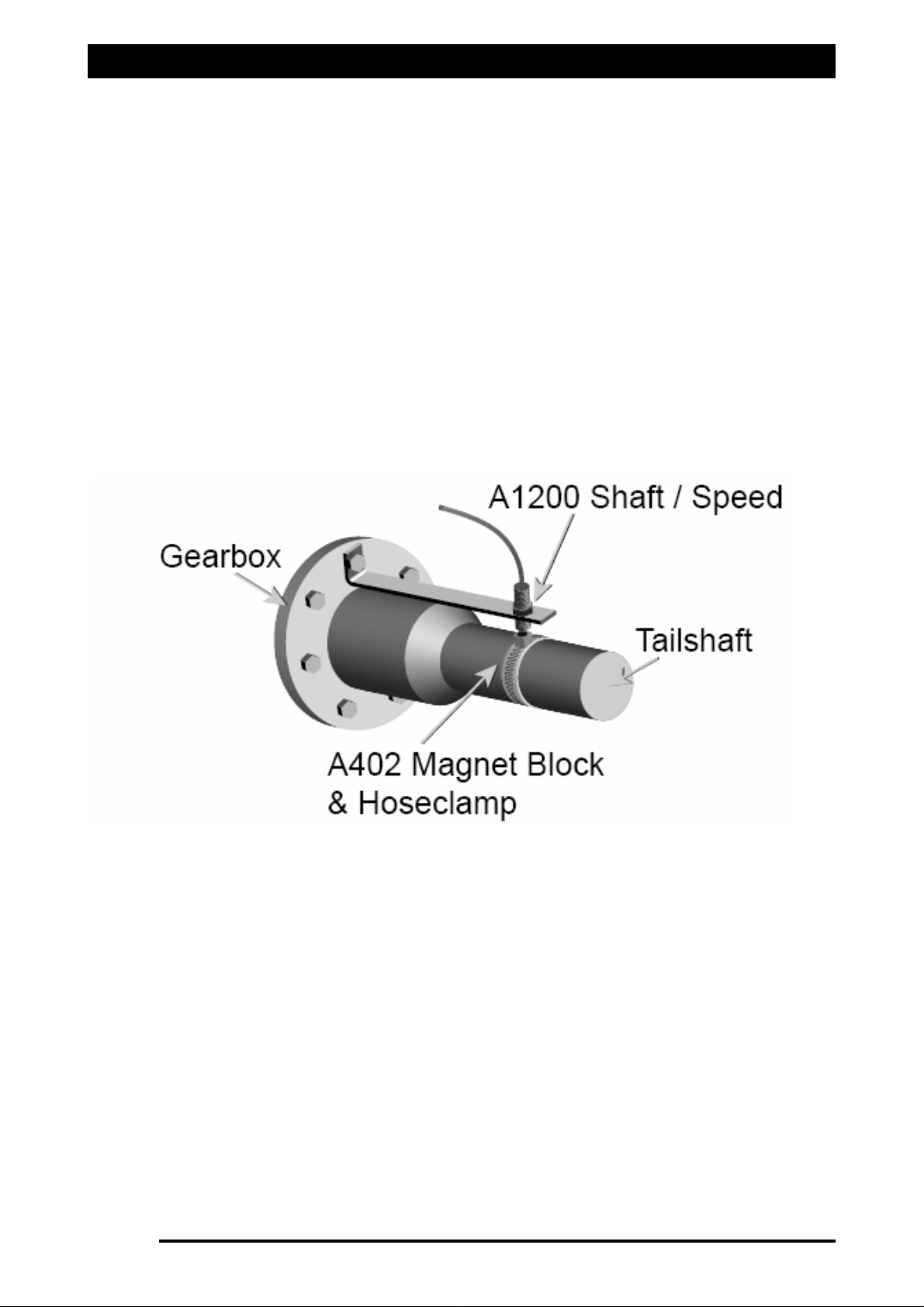

Installation of a Shaft/Speed Sensor kit to a tail shaft

1. On a tray mounted sprayer the Shaft/Speed Sensor Kit can used to read from the

vehicle tail-shaft. Refer to Figure 9. Using the Hose Clamp or other suitable means

securely mount the Magnet Block on the flange between the transmission housing and

the tail shaft. Note: Do not attach the Magnet Block directly to the tail shaft as its

position changes through its rotation. The Wheel Stud Magnets are not used in this

case.

2. Using an existing bolt on the transmission housing and the supplied Mounting Brackets

or other suitable means, securely mount the Shaft/Speed Sensor so it squarely faces the

Magnet Block with a clearance of 2 to 3mm (1/16 to 1/8 inch).

3. Ensure that the Shaft/Speed Sensor is firmly attached and protected so that it cannot

be damaged by wire or stones. If necessary cover the Shaft/Speed Sensor with a plate.

4. Use the 3-pin Weather Pack Extension provided if required, connecting the Shaft/Speed

Sensor to the Ground Speed connector on the Tractor Harness or Sprayer Harness.

Using an existing radar speed sensor for ground speed

1. An optional Radar Sensor Interface Harness (A449 - not provided as part of this kit but

may be ordered separately) allows direct connection to any existing radar speed sensor

on the tractor.

2. Connect the Radar Sensor Interface Harness to the Ground Speed connector on the

Sprayer Harness or Tractor Harness then connect this wire to the signal wire from the

radar sensor (not provided) to enable the Spray ECU to read the speed. Note: Check

the radar sensor manufacturer's manual before attempting connection. Use the

Extension Harness provided if required connecting the radar sensor to the Ground

Speed connector on either the Sprayer Harness or Tractor Harness.

Page 18

V1.98 21/06/06

Figure 9 : Shaft/Sensor Sensor installation a tail shaft

Page 19

Installation of Spray ECU 30S KEE Sprayer Kits

Connecting to Flow Meter

1. The flow meter (not supplied) is installed between the regulator valve and the section

valves. The flow meter will be installed so that it measures ONLY the quantity of liquid

being delivered to the spray line.

Note: There must be no return line to tank or pump after the flow meter.

2. Connect the flow meter 3-pin connector to the 3-pin connector marked Flow Meter 1

on the Sprayer Harness.

Note: The flow meter may require a connector change to attach to the 3-pin connector

marked Flow Meter 1 on the Sprayer Harness. Refer to the flow meter manufacturer's

specifications for correct pin allocation. Care should be taken when replacing these

connectors not to damage the Sprayer Harness or flow meter and connectors should

be fully circuit tested prior to installation.

3. Most flow meters have a label on the meter body that shows the flow meter

Calibration Factor in pulses/volume. For example: '645 ppl' (pulses per litre) or 2441

ppg (pulses per gallon). This value is the Calibration Factor and will be required to be

entered into the sprayer software setup. This means the flow meter sends 645 pulses

to the Spray ECU for every litre (or 2441 pulses for every gallon) of liquid that passes

through the flow meter.

4. For connection to a Raven flow meter: The value marked on the label represents

pulses/10 units of liquid. Divide this number by 10 for the correct value to enter as the

Calibration Factor into the Sprayer Software Setup.

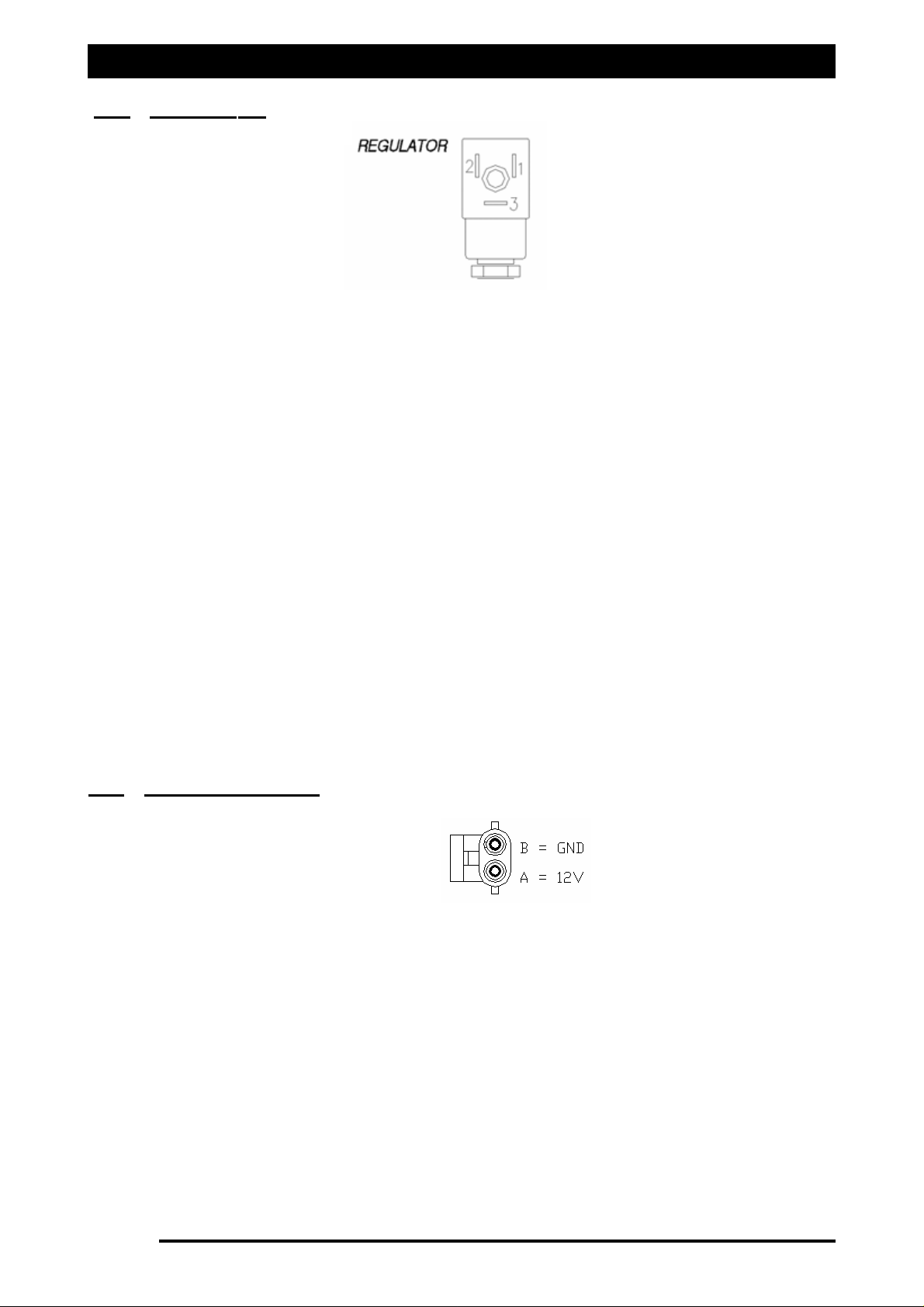

Connecting to the Regulator Valve

1. The regulator valve (not supplied) is a motorized flow control valve used to maintain

the product flow to the section valves. It will be situated between the pump and the

flow meter.

2. All bypass or agitation return lines that return to tank must be taken before the

regulating valve, so there is no return path after the regulating valve and the flow

sensor.

3. Using the Regulator Valve Adaptor Harness (A802) connect the regulator valve's 2-pin

connector to the 2-pin connector marked REG Valve 1 on the Sprayer Harness.

Note: The regulator valve may require a connector change to attach to the 2-pin

connector marked REG Valve 1 on the Sprayer Harness. Refer to the regulator valve

manufacturer's specifications for correct pin allocation. Care should be taken when

replacing these connectors not to damage the Sprayer Harness or regulator valve and

connectors should be fully circuit tested prior to installation.

4. When you test the sprayer with water you may find that the regulator valve works in

the opposite direction than is required. For example the pressure increases when it

should decrease. You can set the "Reverse Valve Direction" in the Sprayer Setup

software to remedy this.

Page 19

V1.98 21/06/06

Page 20

Major Topic Heading

Installation of Spray ECU 30S KEE Sprayer Kits

Pressure Sensor installation and connection

1. Mount the Pressure Sensor (A092) either upright or horizontal and support the brass

gauge saver. To properly measure Spray Line operating pressure the Pressure Sensor

must be positioned between the flow meter and the section valves. The supplied

Pressure Sensor is a 5 Bar (72 psi) pressure sensor.

2. Connect the Pressure Adaptor Harness (H1125) to the connector labeled Pressure Sensor 1

on the Sprayer Harness.

3. Undo the two (2) nuts on top of the Pressure Sensor.

4. Place the two ring terminals on the Pressure Adaptor Harness onto the terminals on the

Pressure Sensor. It doesn't matter which way around the terminals are attached to the

Pressure Sensor.

5. Once the ring terminals are placed on the Pressure Sensor terminals replace the two (2)

nuts and tighten the nuts securely.

1.2.3 Installing the Valve Harness

1. The Valve Harness continues from the connector on the Sprayer Harness and connects to

the Section and Dump Valves on the Sprayer.

2. The Valve Harness normally contains connectors for the section valves; either they are; ‘3

Wire section valves’, ‘2 Wire Section Valves’ or ‘solenoid valves’.

See below for an

explanation of the different types of section valves..

Note: If the Valve Harness has an Arag Interface box incorporated into the harness, then

the Dump Valve plug will be on the Valve Harness.

5. The typical Valve Harness has the following connectors, they are labeled as follows:

DDuummpp 11-

connects to the Dump Valve.

SSeeccttiioonn XX-

connects to the Section Valves. ‘X’ represents the section number.

SSpprraayyeerr HHaarrnneessss-

connects to the Sprayer Harness.

3. There are different Valve Harness depending on which type of section valves on fitted on

the sprayer.

Note: If the Valve looms need to be re-terminated because the connectors are different to

the section valves being connected to, then make sure the ‘Sprayer Harness’ is

disconnected from the ‘Tractor Harness’. Otherwise damage to the Spray ECU

wwiillll

occur if

the wires are shorted out during the installation.

4. Secure the Valve Harness away from moving, hot or sharp objects to avoid chaffing and

wear, using the cable ties provided.

6. Connect the Valve Harness to the Sprayer Harness.

Page 20

V1.98 21/06/06

Page 21

Installation of Spray ECU 30S KEE Sprayer Kits

Single Line Install

5. Connect the connectors marked Section X (‘X’ represents the section number) to the

correct section valves. Section 1 connects to the section valve on the far left. Section 2

connects to the next section valve and so forth until all the section valves are connected

to the Valve Harness.The section valve with the highest number will operate the

boom section on the far right. If there are too many connectors for the section valves,

then as a general rule use the connectors with the lowest numbers first.

6. Cable-tie the spare connectors to the Valve Harness.

Dual Line Install

7. Connect the connectors using the lowest numbers first that operate the primary spray

line (Line A). Starting with Section 1 to operate the section on the FAR LEFT of the

spray line, when facing forward finishing with the highest number section valve on

Line A to operate the FAR RIGHT.

8. Connect the connectors to the section valves which are going to operate the secondary

line (Line B). Starting the lowest number on the Line B to operate the FAR LEFT boom

section, finishing with the highest number boom section on the Line B to operate the

FAR RIGHT boom section.

Note: If the Valve Harness needs the connectors replaced to suit the valves connectors

then make sure the Sprayer Harness is disconnected from the Tractor Harness.

Otherwise damage to the Spray ECU will occur if the wires are shorted out during this

procedure.

Connecting to the Dump Valve

6. The dump valve (not supplied) must be located between the pump and the flow meter.

7. The dump valve is activated when all sections are switched OFF, or the Master Switch

is switched OFF, therefore all the flow is diverted back to the tank.

8. Connect the ARAG connector, labeled Dump 1 to the dump valve.

Note: During setting up of the sprayer the wires in the ARAG connector may have to

be swapped, if the dump valve is going in the wrong direction.

9. If the Dump Valve connector is on the Sprayer Harness, then an adaptor will be

required to connect the 4-Pin Weather Pack to the Dump Valve. Connect the correct

adaptor to the Dump Valve from the following adaptors:

a) A2266- if connecting to a 2-wire dump valve and 12v is applied to the dump

valve when the Master switch is OFF.

b) A2267- if connecting to a solenoid valve, with 6mm spade terminals and 12v

is applied to the dump valve when the Master switch is OFF.

c) A2268- if connecting to a 3-wire dump valve and 12v is applied to the dump

valve when the Master is OFF.

d) A2269- if connecting to 3-wire dump valve and 12v is applied to the dump

valve when the Master is ON.

Page 21

V1.98 21/06/06

Page 22

Installation of Spray ECU 30S KEE Sprayer Kits

9. Once all the ARAG connectors are in place, using a screwdriver tighten the screw at the

top of the ARAG connector to secure the connector to the section and dump valves.

10. Tidy any excess harness using cable ties.

11. To complete the installation go to Section 1.5 to connect the Spray ECU Power/Comms

harness to the battery.

Explanation of the Different types of Valves

22-wwiirree VVaallvvee ((RReevveerrssee PPoollaarriittyy))

Refers to an electric section, dump or regulator valve. The valve is driven by an electric motor

that is able to rotate in both directions. 2 wires are connected to this type of valve from the

controller. To rotate the motor 12v is applied to one of the wires whilst GND is applied to the

other. When opposite voltage is applied to the two wires the motor will rotate in the opposite

direction. Common terms for this system are Reverse Polarity or Bi-Directional.

33-wwiirree VVaallvvee

Refers to an electric section, dump or regulator valve. The valve is driven by an electric motor

that is able to rotate in both directions. Unlike the 2-wire valve, the 3-wire valve has inbuilt

changeover relays that change the motor direction depending on whether 12v or 0v is applied

to the signal wire.

Constant 12v and GND are required in addition to the signal wire.

SSoolleennooiidd VVaallvvee

Refers to electromagnetic coil type valves. They usually consist of a coil that when exposed to

voltage produces a magnetic field. The magnetic field draws a needle against a spring away

from it’s seat to allow liquid to flow.

GND and 12v signal is required for this type of valve.

Page 22

V1.98 21/06/06

Page 23

Major Topic Heading

Plumbing for Diaphragm Pumps for KEE Sprayer Kits

Plumbing for Diaphragm Pumps for KEE Sprayer Kits

Page 23

V1.98 21/06/06

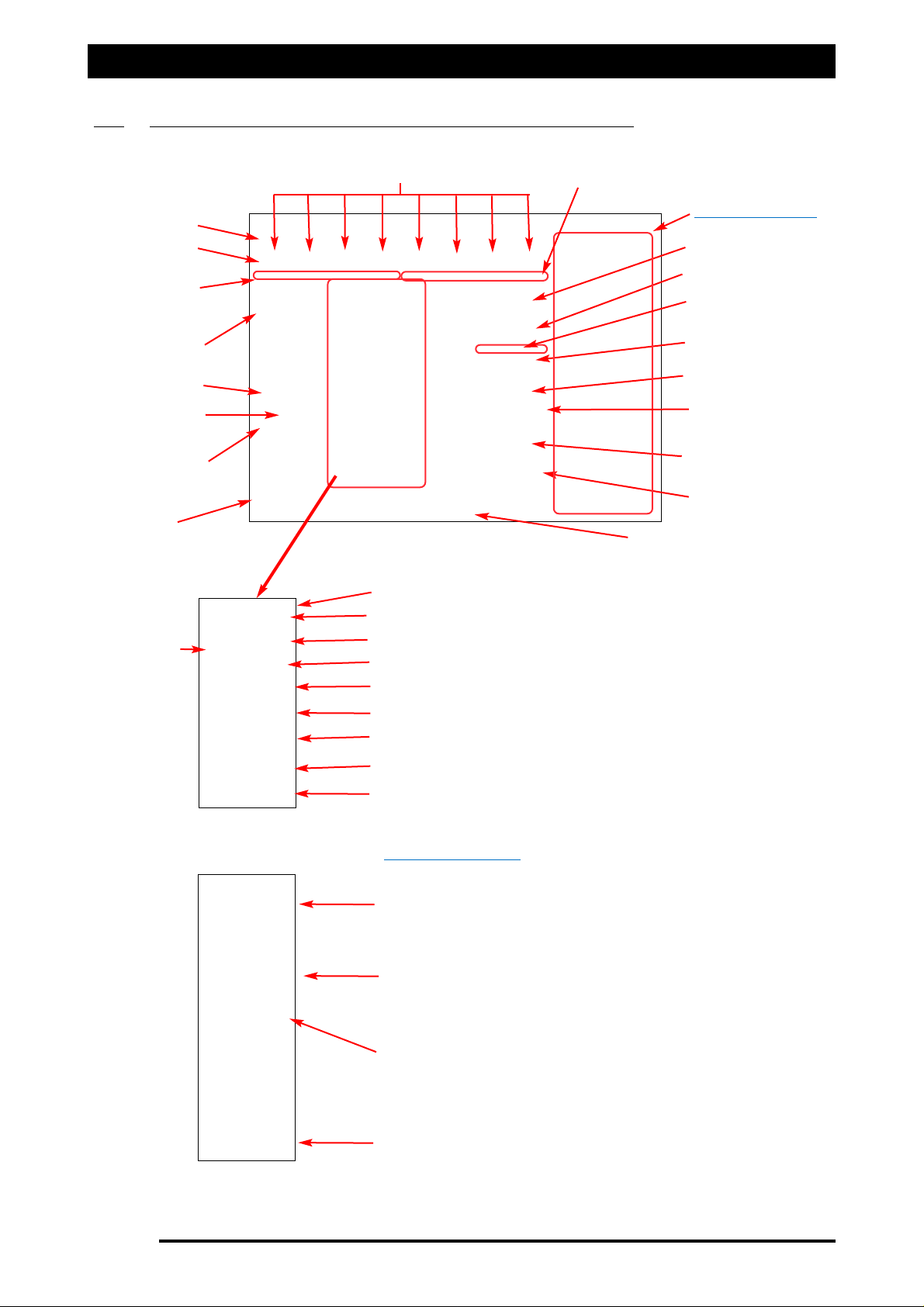

Figure 10: Plumbing Diaphragm Pumps for KEE Sprayer kits

Page 24

Plumbing for Centrifugal Pumps for KEE Sprayer Kits

Page 24

V1.98 21/06/06

Plumbing for Centrifugal Pumps for KEE Sprayer Kits

Figure 11: Plumbing for Centrifical Pumps for KEE Sprayer kits

Page 25

Installing Spray ECU 30S Kits to Existing KEE Controller

1.3 INSTALLING SPRAY ECU 30S KITS TO AN EXISTING KEE CONTROLLER

Note: Use this install guide if replacing an existing a KEE MK3, KEE MK5 sprayer console or KEE

Sprayrate Interface.

1. Before removing the existing Controller Run the Sprayer and record the minimum and

maximum pressure and flow rates attainable. Ensure that the system is functioning

correctly before removing the controller.

2. Record all of the cal factors and section width values. These can then be easily

transferred to the ZYNX after installation. It will also be a useful reference if replacing

the existing controller.

3. Remove the existing KEE Spray Controller console or KEE Sprayrate Interface.

4. Remove the existing Tractor harness.

5. Install the Tractor Adaptor harness that came with the Spray ECU kit. Connect the

Tractor Harness to ‘Connector 1’ on the Spray ECU. The Tractor Adaptor Harness

connects to the Spray ECU and takes the harness as far as the drawbar of the tractor or

vehicle, where a breakaway is attached so the vehicle can be easily detached from the

trailing sprayer. Lead the harness from the Spray ECU to the back of the vehicle. Care

should be taken running the tractor harness from the Spray ECU back cable tying where

possible. Do not cut or splice the harness, all excess cable should be strapped away to

avoid vibration and wear.

6. Securely mount the Breakaway connector above any hydraulic outlets to reduce the

risk if oil ingress to the connectors. (Do not expose the connectors to high pressure

water or oil)

7. Connect the Tractor Adaptor Harness to the existing Sprayer Harness.

8. Refer to the ZYNX Console’ manual for the installation procedures for installing the

ZYNX Console to the vehicle, if required.

9. To complete the installation go to Section 1.5 to connect the Spray ECU Power/Comms

harness to the battery.

Page 25

V1.98 21/06/06

Page 26

General Layout of fitting a Spray ECU 30S to an Existing KEE Spray Controller

Page 26

V1.98 21/06/06

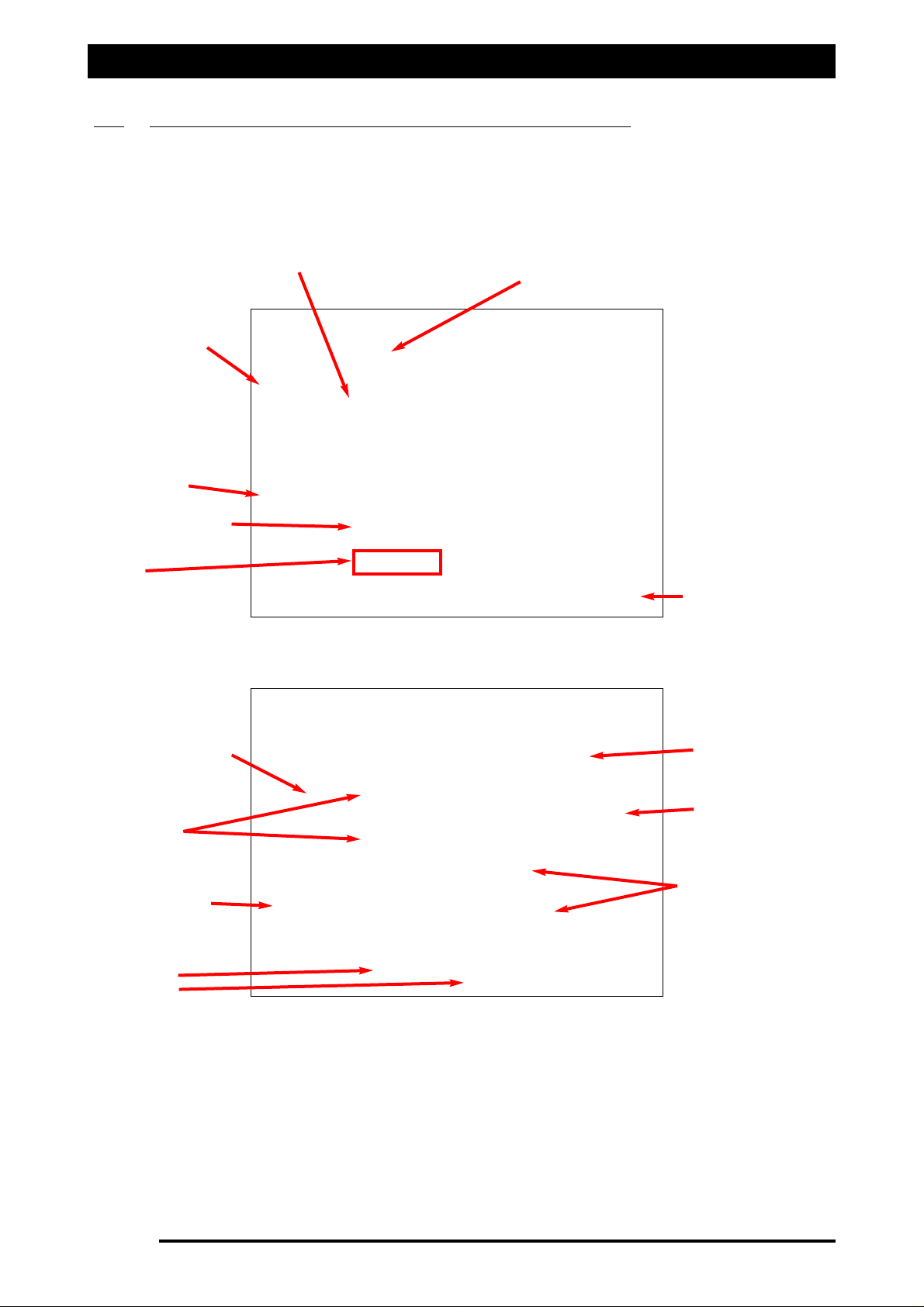

Figure 12: General Layout of Spray ECU connecting to existing KEE Sprayer Harness

Page 27

1.4 REPLACING EXISTING RAVEN CONTROLLER WITH A SPRAY ECU 10SR

OVERVIEW

The 10SR Spray ECU have been pinned to allow direct replacement of some of the Raven 4xx,

6xx, 4400 and 4600 series controllers.

Generally most 4xx, 6xx and 4400 series controllers with inbuilt section switches can be

replaced with no need for adaptors. Connector 1 is used for the 4400 series, Connector 2 for

4600 series and connector 3 for the 4xx and 6xx series controllers.

Direct PWM control is not possible with direct connection to the Spray ECU. Adaptor looms

will be required.

It is important to note that

nnoott

all Raven 37 and 16-pin connectors are pinned alike. Subtle

differences do occur in some looms so it is extremely important to confirm the pin locations

and functions are the same as the Spray ECU before connection as damage can occur. Locate

the Raven console harness part number (E.g.115-0159-xxx) and use the relevant Raven console

harness wiring diagram to help confirm the pin locations. If the pins and functionality are not

the same as the ECU do not connect to it. Contact your KEE dealer and confirm if an adaptor

for this application is available.

Note: that damage will occur if any external power is applied to the section drive outputs on

the Sprayer ECU. Follow this procedure before installing the ECU to ensure that damage is

avoided.

SWITCHES ON EXISTING CONTROLLER

1. With ignition key on, check each section drive output pin on the existing Raven

console harness for voltage (use DMM test procedure below). Locate where

voltage is supplied from to determine if it can be removed without limiting

existing functionality.

2. If it is not possible to remove this voltage then you must install a Section Drive

Output Protection Adaptor.

(A2812 for 37-pin on Connector 1 and A2813 for 16-pin on Connector 3)

ANY EXTERNAL SWITCHES SEPARATE TO EXISTING CONTROLLER

(E.g. Joystick and dash board switches)

Replacing 4xx, 6xx, 4400 and 4600 controllers that use external section switches is possible

however the following steps MUST first be confirmed prior to installing of the ECU.

1. Determine if it is possible to disconnect the existing switchbox without limiting

existing functionality (e.g. Boom Lift, Lower or Fold).

2. If yes, disconnect the switchbox, switch the ignition key on and check each Section

Drive Output pin on the existing Raven console harness for voltage. If no voltage is

present continue with installation.

3. If no, and voltage is present and cannot be removed then you must install a Section

Drive Output Protection Adaptor between the ECU and the existing tractor harness.

(A2812 for 37-pin on Connector 1 and A2813 for 16-pin on Connector 3)

4. With all of the section switches in the off position confirm that each section pin on the

Raven harness does NOT have continuity to Gnd. If Gnd exists on any of these pins with

the section switches in the off position, and the switchbox cannot be disconnected. DO

NOT proceed with installation.

5. If external switches must remain connected they must always be switched to the OFF

position or ASC will not function correctly.

Installing Spray ECU 3 and Spray ECU 10SR

Page 27

V1.98 21/06/06

Page 28

Installing Spray ECU 3 and Spray ECU 10SR

Digital Multimeter (DMM) Test Procedure

1. Testing voltage on section outputs on Raven Console Harness with switches on.

With DMM set to 20vdc insert Gnd probe into Gnd Pin (usually Pin 1) and Positive probe

into each section pin. Confirm yes or no to voltage present.

2. Testing for Gnd on section outputs on Raven Console Harness with switches off.

With the DMM set to ohms, insert Gnd probe into Gnd pin (usually Pin 1) and positive

probe into each section pin. Confirm yes or no to continuity.

Always disconnect the vehicle battery before proceeding with any installation or servicing of

the Spray ECU, Tractor, Sprayer or Valve Looms.

IInnssttaalllliinngg tthhee 1100SSRR SSpprraayy EECCUU

1. Before removing the existing controller run the sprayer and record the minimum and

maximum pressure and flow rates attainable. Ensure that the system is functioning

correctly before removing the controller.

2. Record all of the calibration factors and section width values. These can then be easily

transferred to the ZYNX after installation.

3. Remove the controller.

4. Refer to Section 1.1 for mounting the Spray ECU, Power/Comms Harness and Sprayer

switchbox

5. Connect the existing Raven Console harness to CONNECTOR 1 or 3 of the Spray ECU.

6. Connect existing Raven Gnd/Radar speed input to the ‘SPEED’ connector on the Spray

ECU.

7. Carefully run the power lead to the tractors battery ensuring it is tied away from

moving, hot or sharp objects.

8. To complete the installation go to Section 1.5 to connect the Spray ECU Power/Comms

harness to the battery.

Page 28

V1.98 21/06/06

Page 29

System Layout for Spray ECU connecting to an existing Raven console

Page 29

V1.98 21/06/06

Figure 13: General Layout of Spray ECU connecting to existing Raven Sprayer Harness

Page 30

Connecting the Spray ECU to the Battery

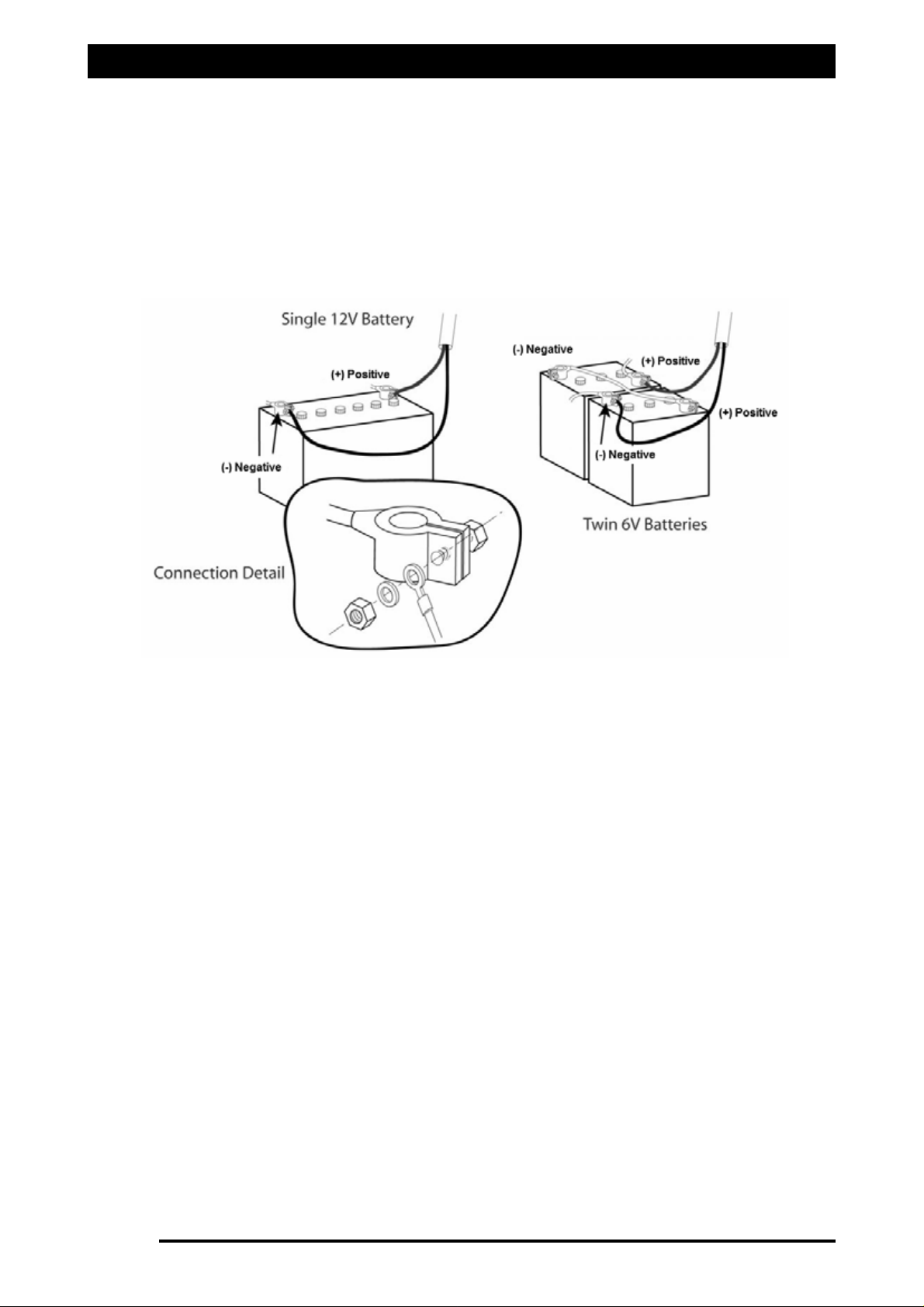

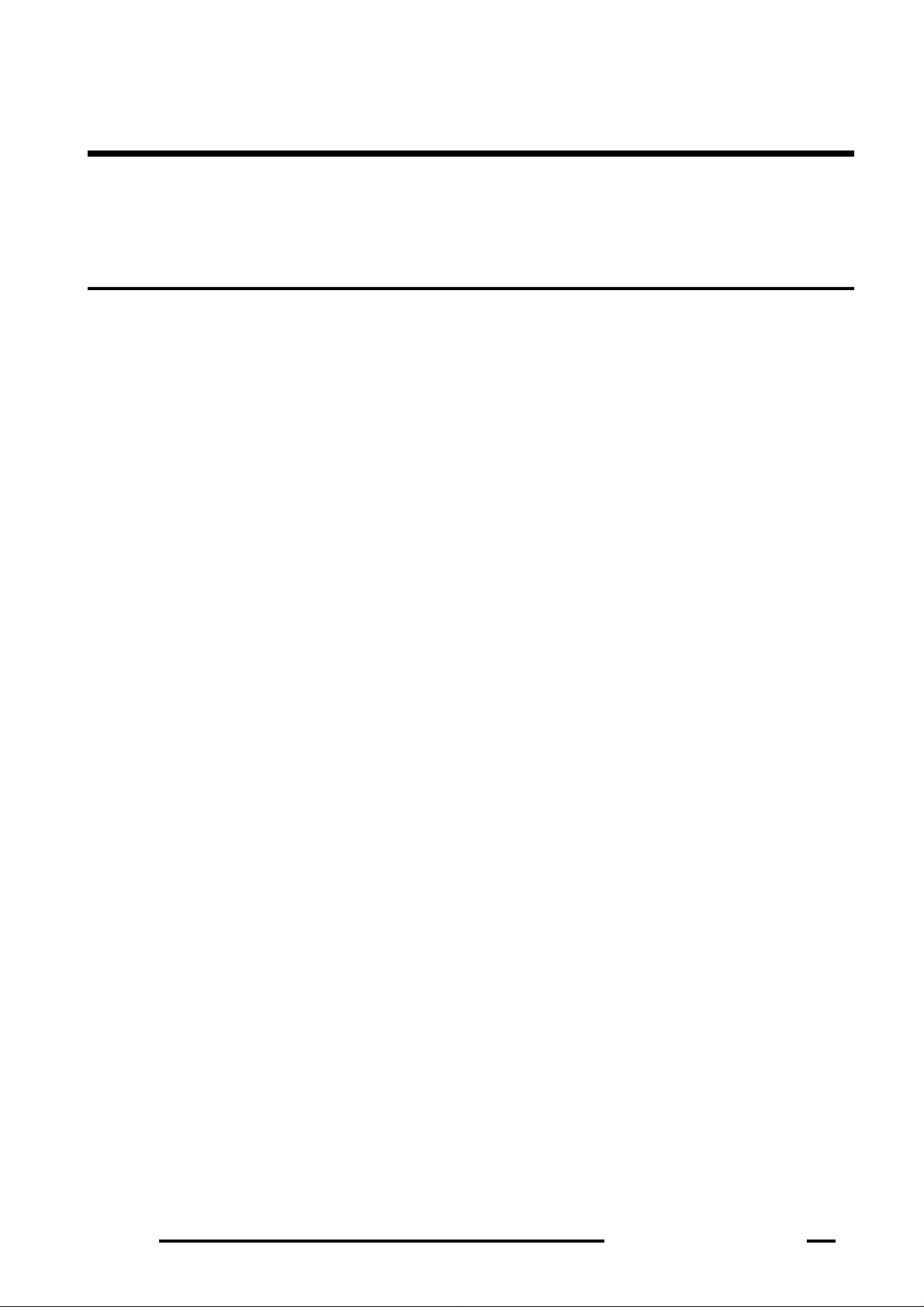

Step 5: Connecting the Spray ECU to the Battery

1. DO NOT attach the wires to the battery terminals until the installation of the Tractor

Harness, Sprayer Harness and Valve Harness has been completed.

2. Connect the Power/Comms Harness directly to 12 VDC battery terminals. Refer to

Figure 14.

FFoorr ttrraaccttoorrss tthhaatt uussee 2244 VVoolltt bbaatttteerriieess yyoouu MMUUSSTT uussee aa 1122 VVoolltt // 1155

AAmmpp ((mmiinniimmuumm)) iinnvveerrtteerr..

3. Do not connect the Power/Comms Harness to an alternator or starter motor as this may

cause interference or power fluctuations or surges and may damage your system.

4. Attached the Red wire to the POSITIVE (+) battery terminal. Attach the Black wire to

the NEGATIVE (-) battery terminal, when installation of the sprayer is completed.

5. DO NOT connect the Black wire to vehicle chassis unless an Isolation Switch is fitted to

the negative side of the battery.

6. Do not power other equipment from the power cable; other than KEE products.

7. Connection to the battery terminals must be kept clean and tight at all times.

8. The hardware installation of the Sprayer Hardware Kit is now complete.

9. Refer to the ‘Getting Started’ (Section 2.0) and ‘Software Setup’ (Section 3.0) sections

of this manual to complete the software setup for the Sprayer.

Page 30

V1.98 21/06/06

Figure 14: Battery Configuration

Page 31

Page 31

Spray Rate Control

2.0 Getting Started

Page 32

Getting Started

Page 32

V1.98 21/06/06

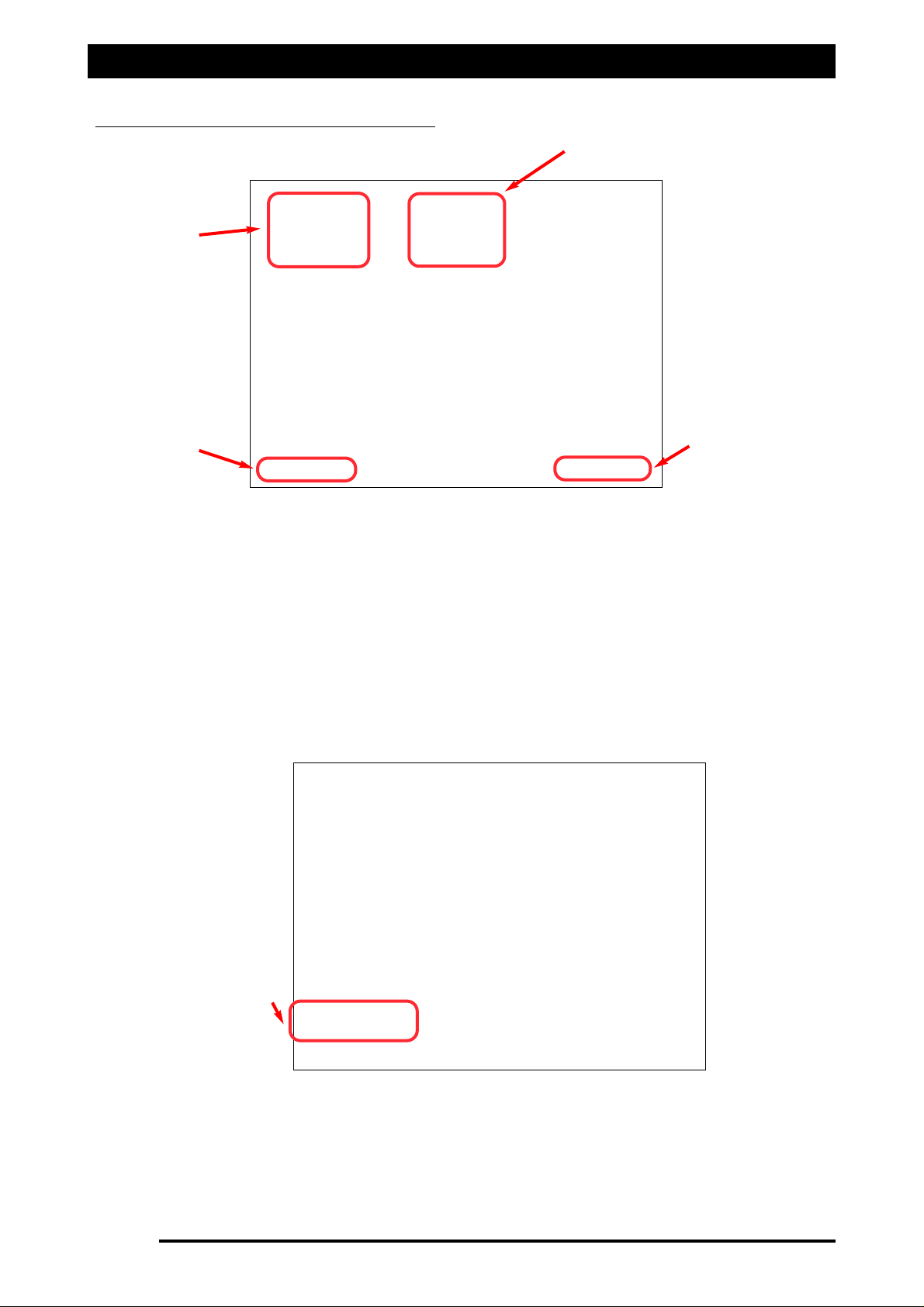

2.1 STARTING THE X15 CONSOLE

1) Switch the ZYNX X15 Console ON

2) Press the ‘

SSTTOOPP’’

button when the ‘ZYNX X15 Product Selection Screen’ is displayed.

3) Highlight the

SSPPRRAAYY CCOONNTTRROOLLLLEERR

. (If the ‘Sprayer Controller’ software is being used

on its own.

OR Highlight the

SSPPRRAAYY CCOONNTTRROOLLLLEERR

and

GGUUIIDDAANNCCEE

screens

..

NNoottee::

The Operators

manual assumes the

GGUUIIDDAANNCCEE

and

SSPPRRAAYY CCOONNTTRROOLLLLEERR

are being used together.

This can be done by simply touching the

SSPPRRAAYY CCOONNTTRROOLLLLEERR

and

GGUUIIDDAANNCCEE

screens.

4) Select the

‘‘SSTTAARRTT

’ button. The ‘ZYNX Spray Controller’ and ‘ZYNX Guidance’

software, will now be loaded. The ‘GUIDANCE’ screen will be displayed, shown below.

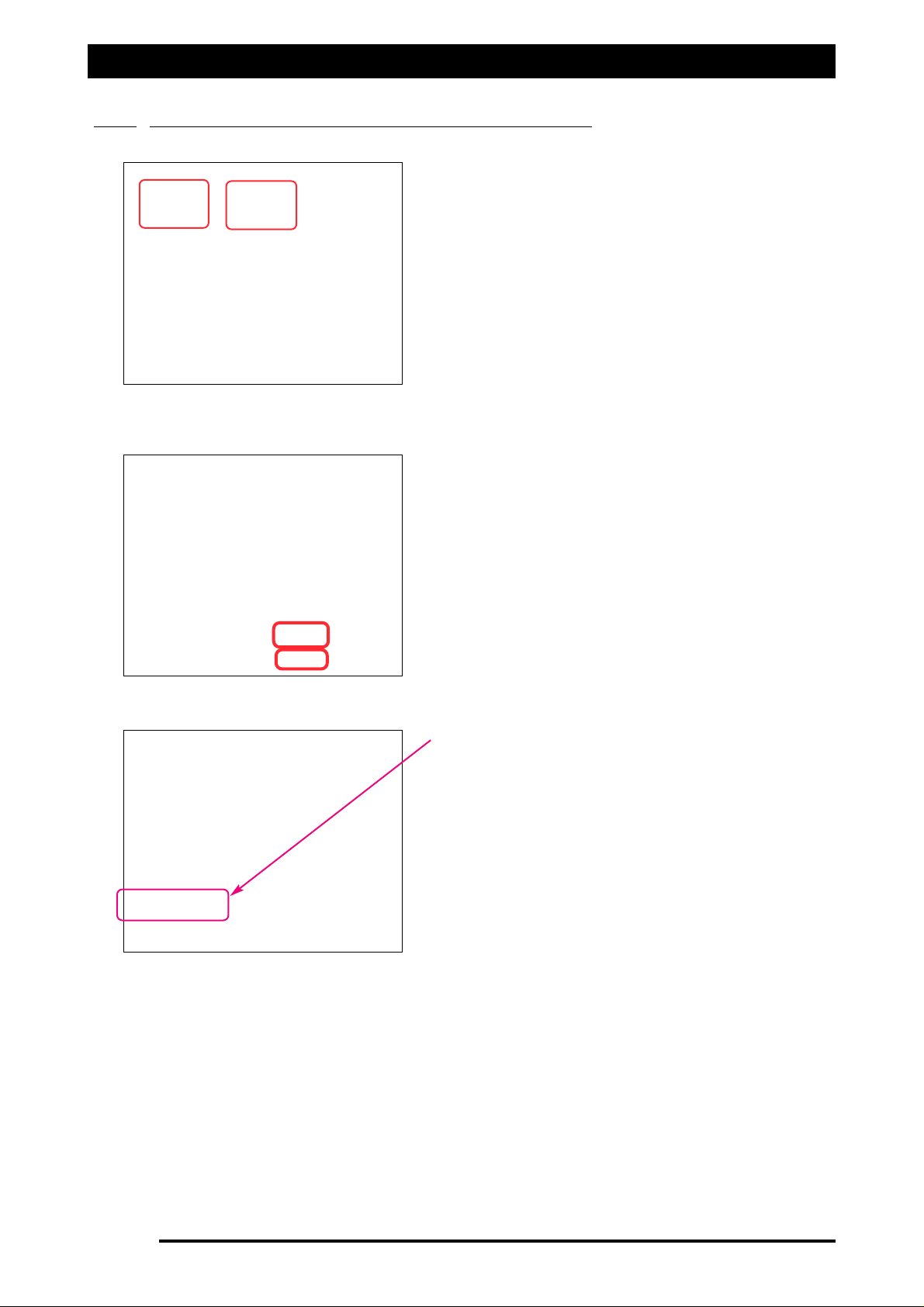

‘GUIDANCE’

screen

‘STOP’ button

‘SPRAY CONTROLLER

screen

‘START’ button

‘SPRAYER’ ICON

5) Select the ‘SPRAYER’ icon. The Sprayer ‘Working Screen’ will be displayed.

Note: If the ‘SPRAYER CONTROLLER’ was the only screen selected, then the Sprayer

‘Working Screen’ will be displayed instead of the above ‘GUIDANCE’ screen.

Figure 15: ZYNX Product Selection screen

Figure 16: ZYNX Guidance Screen showing Sprayer Icon

Page 33

Getting Started

2.2 STARTING THE X20 CONSOLE

1) Switch the ZYNX X20 Console ON

2) Press the ‘

SSTTOOPP’’

button when the ‘ZYNX X20 Product Selection Screen’ is displayed.

3) Highlight the

SSPPRRAAYY CCOONNTTRROOLLLLEERR

. (If the ‘Sprayer Controller’ software is being used

on its own.

OR Highlight the

SSPPRRAAYY CCOONNTTRROOLLLLEERR

and

GGUUIIDDAANNCCEE

screens

..

NNoottee::

The Operators

manual assumes the

GGUUIIDDAANNCCEE

and

SSPPRRAAYY CCOONNTTRROOLLLLEERR

are being used together.

This can be done by simply touching the

SSPPRRAAYY CCOONNTTRROOLLLLEERR

and

GGUUIIDDAANNCCEE

screens.

4) Select the

‘‘SSTTAARRTT

’ button. The ‘ZYNX Spray Controller’ and ‘ZYNX Guidance’

software, will now be loaded. The ‘GUIDANCE’ screen will be displayed, shown below.

Page 33

V1.98 21/06/06

‘GUIDANCE’

screen

‘STOP’ button

‘SPRAY CONTROLLER

screen

‘START’ button

‘SPRAYER’ ICON

5) Select the ‘SPRAYER’ icon. The Sprayer ‘Working Screen’ will be displayed.

Note: If the ‘SPRAYER CONTROLLER’ was the only screen selected, then the Sprayer

‘Working Screen’ will be displayed instead of the above ‘GUIDANCE’ screen.

Figure 15: ZYNX Product Selection screen

Figure 16: ZYNX Guidance Screen showing Sprayer Icon

Page 34

Major Topic Heading

Getting Started

22..33 RREEGGIISSTTRRAATTIIOONN AANNDD SSPPRRAAYY RRAATTEE CCOONNTTRROOLL SSOOFFTTWWAARREE VVEERRSSIIOONN

6) The ‘WORKING SCREEN’ will be displayed, with the ZYNX ‘Sprayer Menu’ on the

right-hand side.

7) Press the

ZZYYNNXX SSpprraayyeerr LLooggoo

Icon, an ‘About ZYNX Spray Rate Controller’ window will

be displayed, as displayed below.

Page 34

V1.98 21/06/06

FIGURE 17: ‘SPRAYER WORKING SCREEN’

ZYNX SPRAYER Logo

OPTIONS button

ZYNX ‘Sprayer Menu’

8) The ‘About ZYNX Sprayrate Rate Controller’ window displays:

a) The ZYNX Spray Rate Controller software version number, this version

number may be requested by a KEE Service person.

b) The Spray ECU version number will be displayed, when the ZYNX Console is

connected to the Spray ECU.

c) Displays whether the ZYNX Sprayer software is ‘Registered’ or ‘Unregistered’.

9) Select the ‘Register’ button if the ZYNX Sprayer software is ‘Unregistered’, then contact

your local KEE Dealer.

10) The ‘Enable Lockout’ button will explained in Section 17.9.

11) Select the ‘Close’ button, the ‘ZYNX Sprayer Working Screen’ will be displayed.

Software Version

Registration

‘Register’ Button

‘Close’ Button

Figure 18: ‘About ZYNX Spray Rate Controller’ window

MAIN MENU button

Page 35

Getting Started

2.4 OVERVIEW OF FUNCTIONS- WORKING SCREEN

Page 35

V1.98 21/06/06

Boom Sections (ON/OFF) - Up to 30 sections.

Sub total area

Ground speed

Sub-total of volume

or weight used

Automatic Control

Activates all data on the

right hand side of the

screen.

Returns to the

Main Menu Screen

Manual Control

Volume Readout

for each Tank

Pressure Readout

Switches

Hydraulic Pump

ON/OFF

Displays Product being applied.

Displays Volume left in Tank 1.

Displays Volume left in Tank 1 graphically.

Displays ‘Application Rate’ Units.

Current ‘Application Rate’.

Increase the Rate on the go.

Preset Rate 1.

Preset Rate 2.

Decrease the Rate on the go.

Displays Tank

Number

When ‘selected' a window appears displaying:

1- Software Version and date.

2- A ‘Button’ to Register the software.

3- A ‘Button’ to Enable or Disable the ‘Lockout’ function.

Select ‘OPTIONS’ button to a access the ‘OPTIONS’

window. The ‘OPTIONS’ window is where the sprayer

settings can be entered.

Select the ‘SHUTDOWN’ button; returns the operator

to the ‘Windows Desktop’ or ‘Shuts Down’ the ZYNX

Console.

Displays the ‘On Screen’ help.

Front boom

Back boom

Switches all boom sections ON or OFF

Spraying Indicators for Back Line

Spraying Indicators

for Front Line

Tank Indicator (displayed if

more than 1 tank is selected)

Main Menu Screen

Pump Speed Readout

‘Min. Flow’ or

Nozzle Min Flow

indicator

MAIN MENU SCREEN

Figure 19: Sprayer Working screen

Figure 20: Sprayer Working screen

Figure 21: Main Menu screen

Page 36

Getting Started

Overview of Functions- The ‘Working Screen’

BBoooomm SSeeccttiioonnss-

Displays the number of boom sections selected. A ‘Dual’ boom is shown,

showing the front and back lines; the top line representing the front line and the bottom line

displaying the back line. If ‘Single’ line is selected in OPTIONS/SPRAYER then only a single line

of sections would be displayed. The boom sections are numbered starting from the left hand

side of the spray line with the far left section valve being section valve ‘1’.

The boom sections can be switched ON/OFF either by touching the boom section on the

‘Working Screen’ or switching the boom sections switches ON/OFF on the ‘External Switch

Box’.

SSpprraayyiinngg IInnddiiccaattoorrss-

are displayed below the boom sections. On the ‘Working screen’

displayed on Page 9 there are 16 ‘Spraying Indicators’, because there are in total 16 section

valves (8 front section valves and 8 back section valves). The first eight ‘Spraying Indicators’ on

the left represent the boom sections on the front line, the next eight, on the right represents

the boom sections on the back line.

When a ‘Spraying Indicator’ is ‘grey’ means the boom section is NOT spraying.

When a ‘Spraying Indicator’ is ‘green’ means the boom section IS spraying.

When the boom sections are ‘grey’ in colour indicates the sections are switched OFF.

When the boom sections are ‘red’ in colour indicates the sections are switched ON but the

‘Low Speed Shutoff’ speed has not been reached.

When the boom sections are ‘green’ in colour indicates the boom section is switched ON, the

‘Low Speed Shutoff’ has been achieved and ready to start spraying.

When a boom section is ‘green’ and ‘Spraying Indicator’ is ‘grey’ indicates the boom section is

ready for spraying but the ‘Master’ is OFF.

When the ‘Master’ is switched ON, boom section is ‘green’ and ‘Spraying Indicator’ is ‘green’

then the boom section valve is spraying.

When using the Automatic Section Control (ASC) when the sections are switched OFF, under

ASC the boom sections turn ‘grey’ and the ‘Spray Indicators’ turn ‘grey’; when switched ON

under ASC both the boom sections and ‘Spray Indicators’ turn ‘green’.

AAUUTTOO-

button when selected (by selecting ‘Auto’ on the switch box or selecting the ‘AUTO’

button from the ‘Working Screen’), will become highlighted and a green indicator will be

shown on the ‘AUTO’ button. When ‘AUTO’ is selected the ZYNX Spray Controller is

automatically adjusting the flow according to speed and area.

MMAANNUUAALL-

button when selected (by selecting ‘Manual’ on the switch box or selecting the

‘MANUAL’ button from the ‘Working Screen’), will become highlighted and a green indicator

will be shown on the ‘MANUAL’ button.

SSyysstteemm PPrreessssuurree-

displays the system pressure if an electronic pressure sensor is installed and

selected in the OPTIONS/SPRAYER. The number in the top left hand corner indicates which

tank (1,2 or 3) the system pressure reading is from.

Selecting the ‘System Pressure’ button displays a ‘TANK PRESSURE’ screen on the right hand

side. See Section 14.1 for details.

VVoolluummee RReeaad

doouutt-

displays Volume per minute (for the front line) or Volume per nozzle (for

the front line nozzles), depending which was selected.

Selecting the ‘Volume Readout’ button displays a ‘FLOW’ screen on the right hand side. See

Section 14.4 for details.

Page 36

V1.98 21/06/06

Page 37

Major Topic Heading

‘‘PPUUMMPP iiss OONN’’-

button only appears when ‘Spray ECU’, ‘Prop. Valve’ and ‘Enable Pump Control

Button’ are

aallll

selected. When selected the button says ‘PUMP is ON’ and turns ‘green’, this

switches the hydraulic pump ON. When selected again the button says ‘PUMP is OFF’ and

turns ‘red’, this switches the hydraulic pump OFF.

GGrroouunndd SSppeeeedd-

Displays the actual ground speed whether from the wheel sensor on the

sprayer, tractor radar or GPS speed; depending what type was selected.

Selecting the ‘Ground Speed’ readout displays a ‘SPEED’ screen on the right hand side. See

Section 14.5 for details.

SSuubb TToottaall ((AArreeaa))-

readout displays the area sprayed for the sub area selected depending on

the units selected. The number in the top left hand side of the readout, is displaying the

current sub area number. There are 10 sub area numbers (0 -9).

Selecting the ‘Sub Area’ readout displays an ‘AREA’ screen on the right hand side. See Section

14.6 for details.

SSuubb TToottaall ((VVoolluummee UUsseedd))-

readout displays the volume (or weight) sprayed for the sub area

selected depending on the units selected. The number in the top left hand side of the

readout, is displaying the current sub area number. There are 10 sub area numbers (0 -9).

Selecting the ‘Sub Area’ readout displays a ‘AREA’ screen on the right hand side. See Section

11.6 for details.

TTaannkk IInnddiiccaattoorr-

Only appears when more than ‘1’ Tank is selected in OPTIONS/SPRAYER. This

allows the ‘Sub Total Area’ and ‘Sub Total Volume’ to be displayed for each tank. To change

which tank is displayed select either the ‘Sub Total Area’ readout or ‘Sub Total Volume’

readout, you will notice the ‘orange’ ‘Tank Indicator’ will change each time the readouts are

selected, this will then display the readouts for each tank.

PPuummpp SSppeeeedd RReeaaddoouutt-

This displays the actual pump speed. The Pump Speed readout is only

displayed if selected. See ‘Pump Options’ on the OPTIONS/ SETUP Page.

‘‘MMiinn.. FFllooww’’ oorr ‘‘MMiinn.. NNoozzzzllee FFllooww’’ iinnddiiccaat

toorr-

A ‘red’ indicator will be displayed in the ‘Volume’

readout when the minimum flow for the regulator valve is reached or the minimum flow for

the nozzles has been reached. Select the ‘Volume’ readout to see the reason the red indicator

is being displayed. This will be displayed on the right hand ‘Flow’ window.

Getting Started

Overview of Functions- The ‘Working Screen’

Page 37

V1.98 21/06/06

Page 38

Major Topic Heading

Navigating Around the Options Window

2.5 NAVIGATING AROUND THE OPTIONS WINDOW

Page 38

V1.98 21/06/06

Pages (tab)

Enabling Boxes

Enabling Boxes

Selection Options

Buttons

Inaccessible Options

DONE Button

From the ‘Working Screen’ select the ‘OPTIONS’ button, this will advance you to the ‘Options’

window. To explain the various options for navigating around the screen, the ‘Tanks’ and’

Sections’ pages will be used, as examples, as shown below

..

An explanation of the terms used

are explained on the following pages, this will help you select the right options for your

sprayer.

Calculator Icon

Up and Down Arrows

Previous and

Next Buttons

Title

Window

Display Window

Display Window

Figure 22: Options- Tanks page

Figure 23: Options- Sections page

Page 39

SSeelleeccttiinngg-

means selecting an item by ‘touching’ the screen with your finger (or mouse if

connected to the ZYNX Console). There are various ways of selecting the different options.

11-

To select a ‘Pr. Sense’ option, you would touch the screen either on the ‘white box’ or

where ‘Tank 1’ is written, when selecting a ‘tick’ will appear in the box.

22-

To select an option within the ‘Tank 1 Mode’ window, you would ‘touch’ the screen i.e

‘Liquid’, where the ‘Liquid’ is written, once selected a ‘black dot’ will be displayed next to

‘Liquid’.

33-

‘Buttons’ are areas on the page, rectangular in shape, with the option written within the

box or icon displayed. Examples of ‘Buttons’ on the page are: i.e ‘DONE’, ‘Settings’ ,

‘Calculator Icon’, ‘Previous’ and ‘Next’. To select the ‘Button’ touch the area within the outline

of the box, of the ‘Button’ required. Once the ‘Button’ is selected it usually opens another

‘window’; except for the ‘DONE’ button which closes the ‘Options’ window.

PPaaggeess-

Within the ‘Options’ window there are 12 Pages (or 11 Pages) , they are: ‘GPS (this

Page is only displayed if the Guidance or Variable Rate Control is selected with Spray Rate

Controller ’; ECU’; ‘Tanks’; ‘Sections’; ‘Switches’; ‘Sensors’; ‘Setup’; ‘Units’; ‘Alarms’; ‘Presets;

‘Sim. (Simulation)’ and ‘Other’.

The operators manual starts on the ‘GPS’ page and explains all the options on that page then,

moves in sequence by selecting the ‘Next’ button, from page ‘1’ through to ‘12’.

To select another page ‘touch’ the tab of the page required. Eg. To select the ‘Switches’ page,

then ‘touch’ the part of the screen where it says ‘Switches’, the ‘Switches’ page will be

displayed.

OR

Select the ‘Next’ button to advance to the next page, each time the button is selected it will

advance one page. The ‘Previous’ button goes back one page each time the button is

selected.

You may EXIT back to the ‘Working Screen’ from any page by selecting the ‘DONE’ button.

TTiittlleess aanndd WWiinnddoowwss-

Then each ‘Page’ is broken into areas called ‘windows’, these areas are

bordered by a thin grey line, each of these ‘windows’ has a ‘title’ which gives a description of

the options available in that window.

EEnnaabblliinngg BBooxxeess-

Are ‘options’ identified with square white boxes lying next to the written

option. Examples of Enabling Boxes are: ‘Pr. Sense’, ‘Tanks and ‘Valves’. The option is selected

when there is a ‘tick’ present in the white box. An ‘Enabling box’ can be selected or not

selected or you can select some or all of the options. In the example of ‘Pr. Sense’ if you have

a ‘Electronic Pressure Sensor’ connected to the system, then you would select the option by

placing a ‘tick’ in the box. If no ‘Electronic Pressure Sensor’ was connected to the system then

you would leave the box blank.

In the ‘Tanks’ window you have 3 options ‘Tank 1’, ‘Tank 2’ and ‘Tank 3’; you can select 1 or

2 of the options or all the options depending on your system setup, by placing a ‘tick’ next to

the options required.

Page 39

V1.98 21/06/06

Navigating Around the Options Window

Page 40

Navigating Around the Options Window

SSeelleeccttiioonn OOppttiioonnss-

Are options identified with white circles lying next to the written option.

Examples of ‘Selection Options’ are ‘Tank 1 Mode’, ‘Lines’, and ‘Controller’ windows. With

‘Selection Options’ for that window,

oonnee

and

oonnllyy oonnee

option can be selected. The option is

selected when a black ‘dot’ is placed in the circle next to it. At

lleeaasstt oonnee

of the options must

be selected. Example the ‘Lines’ window; in this window you can select either ‘Single’ or

‘Dual’; one of the options must to be selected. If ‘Single’ was already selected, but your system

was a ‘Dual’ line system, then you would select ‘Dual’ by touching the screen where ‘Dual’ is

written. A black ‘dot’ would be placed next to ‘Dual’ and the black ‘dot’ next to ‘Single’ would

disappear.

BBuuttttoonnss-

The rectangular ‘Buttons’ on the screen allow the operator to access extra options.

Examples of ‘Buttons’ are: ‘DONE’, ‘Settings’ , ‘Calculator Icon’ and ‘Enable Diagnostics’. When

the ‘Calculator Icon’ is selected, this displays screen keyboard for entering values into. The

‘DONE’ button closes the ‘Options’ window. The other buttons on the screen usually open up

other windows to allow the operator to select options.

UUpp aanndd DDoowwnn AArrrroowwss-

Next to some ‘Display Windows’ there are up and down arrows to alter

the current value, without using the ‘Calculator Icon’ button. Usually a ‘mouse’ is required to

use the up and down arrows.

The ‘UP’ arrow increases the value displayed in the ‘Display Window’.

The ‘DOWN’ arrow decreases the value displayed in the ‘Display Window’

IInnaaccc

ceessssiibbllee OOppttiioonnss-

When a ‘window’ is greyed out this means that ‘window’ is inaccessible.

In the example (see page 33) the ‘Controller 1’ window is greyed out because the ‘Controller’

selected on the ‘ECU’ page is not capable of controlling proportional valves, therefore the

‘window’ is locked on the ‘Regulator Valve’ option. When a different ‘Controller’ i.e ‘Spray

ECU 2’ is selected then the ‘Controller 1’ window will become accessible.

DDiissppllaayy WWiinnddooww-

Displays the current value, which is next to the option.

SSiimmuullaattiioonn mmooddee-

If ‘Simulation mode’ is displayed, in RED on the ECU page then ‘Simulation’

has been selected from the ‘Com Port’ window. This is useful if the X20 Console is being setup

and not connected to a Spray ECU. When in ‘Simulation mode’ it stops all alarms from being

displayed.

OOppttiioonnss WWiinnddooww-

The Options window cannot be resized. The Options window cannot be

minimised or maximised.

Page 40

V1.98 21/06/06

Page 41

Navigating Around the Screen

CCaallccuullaattoorr IIccoonn-

The ‘Calculator Icon’ button, when selected, allows the operator to enter a

value for the option for which is next to the ‘Calculator Icon’. The value next to the ‘Calculator

Icon’ displays the current value for that option. Example, in the ‘Sections’ window, the current

‘Number’ of sections is ‘8’, to change the number select the ‘Calculator Icon’ next to the

‘Number’. A ‘Screen Keyboard’ will appear (shown below), type in the number of sections

applicable to your sprayer, as the value is being typed in, the value will be displayed in the

‘

Calculator Window’. The ‘Title’ bar displays a description of the value being entered. Then

select ‘ENTER’ to save and close the ‘Screen Keyboard’. The new value will be displayed in the

‘Section Number’ display window.

TTiittllee-

Displays a description of the value being entered in the ‘

Calculator Window’

Calculator

WWiinnddooww

- displays what is typed in using the ‘Screen Keyboard’.

NNuummbbeerr bbuuttttoonnss ((00 ttoo 99))-

When the numbers are selected, they allow the value to be entered,

they are displayed in the ‘

Calculator Window’.

CCaallccuullaattoorr FFuunnccttiioonnss ((//,, xx,, -,, ++,, ==))-

use when required to perform simple calculations.

DDEELL-

The DEL button deletes one value at a time from the ‘

Calculator Window’, each time

the button is pressed.

CCLLEEAARR-

The CLEAR button clears

aallll

values from the ‘

Calculator Window’.

CCAANNCCEELL-

The CANCEL button closes the ‘Screen Keyboard’ without making changes.

EENNTTEERR-

The ENTER button saves the value entered and closes the ‘Screen Keyboard’ window.

Then displays the saved value in the ‘Display Window’.

Page 41

V1.98 21/06/06

Title

Calculator

Functions

Calculator

Window

Figure 24: Screen Keyboard

Page 42

Major Topic Heading

Configuration Setup

3.0 CONFIGURATION SETUP

1) Select OPTIONS from the ‘ZYNX SPRAYER’ MENU on the right hand of the screen.

A Configuration window will be displayed, as shown above.

Complete the installation of the Sprayer before setting up the ZYNX Sprayer software.

The OPTIONS window allows the step by step guide for setting up the ZYNX Sprayer

software.

33..11 AAUUDDIIOO VVOOLLUUMMEE

Allows the operator to set the desired audio level. The slide can be adjusted up or down

33..22 CCOONNFFIIGGUURRAATTIIOONN

The ‘Configuration’ page contains two windows:

1) ‘Change Current Configuration’.

2) ‘Load Configuration’.

The ‘Load Configuration’ window has 2 buttons ‘Factory Configuration’ and ‘User

Configuration’. The ‘Factory Configurations’ is a list of Sprayers models and KEE Sprayer kits,

the files contain all the sprayer settings for the particular sprayer or kit. The ‘Factory

Configurations’ files are pre-loaded with the new ZYNX Console or new Zynx Sprayer

software.

The ‘Factory Configurations’ files when selected are loaded in the OPTIONS window, this loads

all the settings for that particular sprayer model, into the OPTIONS window. The sprayer

settings can then be viewed by selecting the ‘Change/View Configuration’ button. The

changes made to the sprayer settings are then saved, the operator can then save the sprayer

settings; and name the sprayer as a configuration. The sprayer is then saved into the ‘User

Configuration’ list.

The ‘Factory Configurations’ cannot be changed or altered.

The ‘User Configurations’ sprayer list can be changed any time the sprayer settings are

changed, the operator will be prompted to overwrite the file or select a new file.

The operator can have all their different sprayers saved in the ‘User Configurations’ list. These

sprayers can be recalled at anytime.

The ‘Change/View Configuration’ button allows the operator to view the settings of the

current sprayer loaded from either the ‘Factory Configurations’ or ‘User Configurations’.

Page 42

V1.98 21/06/06

Audio Volume

Displays the

name of the

‘Current

Configuration’.

Note: No

configuration is

currently loaded.

Slide

Figure 25: Options- Configuration page

Page 43

Major Topic Heading

Configuration Setup

33..33 FFAACCTTOORRYY CCOONNFFIIGGUURRAATTIIOONN

The ‘Factory Configuration’ button allows selection of KEE Sprayer kits or Listed Sprayers

1) Select ‘Factory Configurations’ button. A ‘Select File’ window will be displayed, as

displayed below. Check to see whether your Sprayer or KEE Sprayer kit is listed here.

2) If your sprayer

iiss nnoott

listed then go to ‘Point 3’.

If your sprayer

iiss

listed then go to ‘Point 5’.

3) Select the ‘CANCEL’ button. This will close the ‘Select File’ window.

44)) TThheenn ggoo ttoo SSeeccttiioonn 33..55..

Page 43

V1.98 21/06/06

A2786-DL15S-ST

Showing the

highlighted

option

5) Select the sprayer by touching the name of the ‘Sprayer’, this will highlight the sprayer.

The above example is shown ‘A2786-DL15S-ST’ which is a KEE Sprayer kit.

6) Press the ‘SELECT’ button to load the sprayers configuration.

7) A window will appear confirming that the sprayer selected will be loaded.

Select the ‘YES’ button, to load the settings for the selected sprayer.

OR Select the ‘NO’ button to stop loading the selected sprayer.

If the Sprayer or Sprayer Kit was listed and selected then the Sprayer Configuration will be

loaded. The current Sprayer or Sprayer kit will be displayed, the ‘(Factory)’ after the Sprayer

name, as shown below, indicates the Sprayer was loaded from the ‘Factory Configurations’ list.

Showing current

Sprayer selected

FFiigguurree 2266:: HHiigghhlliigghhtteedd sspprraayyeerr

FFiigguurree 2277:: OOppttiioonnss- CCoonnffiigguurraattiioonn sshhoowwiinngg sspprraayyeerr kkiitt

Page 44

Major Topic Heading

Configuration Setup

33..44 QQUUIICCKK SSEETTUUPP

Once a Sprayer or Sprayer kit is selected then the most of the sprayer values and settings will

be loaded into the ZYNX Sprayer software OPTIONS and the operator will only have to enter

a few values to get started. For Example: Section Widths, select the type of Units (metric,

imperial etc), Flow Sensor Calibration factor, Wheel Calibration Factor, to be used etc.

a) The operator has the option of going the to ‘Section 3’ of the Software Setup and

working through the manual, which outlines all the sprayer options within the

software. Go to ‘Section 3’.

OR b) Going through the Quick Setup as listed below and entering in the sprayer settings

which are unique to the operators sprayer.

1) Select the ‘Change/View Configuration’ button. This will allow the operator to view

the settings of the sprayer that was loaded. The operator can start on the GPS page

and then use the ‘NEXT’ button to advance to the next page; or the (‘PREVIOUS’

button).

2) Select a COM Port the Spray ECU is connected to the back of the ZYNX Console.

See Section 2.0

3) Enter the Tank Capacity of the Spray. See Section 3.0.

4) The number of sections will be displayed in Section 4.0, change if different.

5) Check the number of Guidance sections used. See Section 4.0.

6) Enter in the swath width of the Spray boom, by entering in the Section widths of each

of the boom sections. See Section 4.0.

7) Enter in the number of nozzles of each boom section. See Section 4.0.

8) Enter in the Minimum Flow value of the nozzles fitted to the Spray Line, check nozzle

chart, See Section 4.0.

9) Enter in Flow Calibration factor for the Flow meter. See Section 6.0

10) Enter in the Flow Meters ‘Minimum Flow’ value, check Flow meters specifications.

See Section 6.0.

11) See Section 7.0 to enter in a Wheel Calibration.

12) See Section 8.0 to display the Units being used, change to suit preferences.

13) Go to Section 15.0 save to the changes to a ‘USER CONFIGURATION’.

33..55 SSeelleecctt tthhee ‘‘CChhaannggee//VViieeww CCoonnffiigguurraattiioonn’’ bbuuttttoonn

Select the ‘Change/View Configuration’ button. This will then advance the operator to the

OPTIONS SETUP window. This window contains 11 or 12 Pages.

These pages will guide the operator through setting up the sprayer for the first time. This

section of the operators manual explains each of the settings within each of the pages.

When the operator has finished on the first page then select the ‘NEXT button at the bottom

of each of the pages, then select ‘NEXT’ to advance to the next page.

If the operator needs to go back ‘1’ page then select the ‘Previous’ page; this will keep

advancing the operator back ‘1’ page.

Once the operator has entered all the information into each of the pages, then the sprayer

controller software is setup.

In Section 16 of the manual, it will explain how to save the configuration for your sprayer and

how to name the configuration.

The ‘User Configurations’ button will be explained in Section 16 and also how to save any