Page 1

WARNING

!

T

o re

duce th

e risk of injury, all ope

r

ators and maintenance personnel must read and understand these

instructions before operating, changing accessories, or performing maintenance on this power

equipment. All possible situations cannot be covered in these instructions. Care must be

exercised by everyone using, maintaining, or working near this equipment.

Operation and Instruction Manual

MODEL: TSCAR-8H

GAS CONCRETE SCARIFIER

(Honda Gasoline Engine)

Page 2

Contents of TSCAR-8H Manual

2

2

2

3

3

3

4

4

5

5

5

6

7

7

8

Safety Instructions

Assembly

Product Assembly

Stop Switch

Edger Installation

Edger Removal

Cutter Cage Removal and Cutter

Change Starting Procedures

Stopping the Engine

Maintenance

Bearing Replacement Procedures

Troubleshooting Guide

Specifications

Transportation

Warranty

Maintenance Record

8

2

Page 3

Safety Instructions

A. Only authorized, experienced or properly trained individuals should operate this equipment.

B. Operating personnel should be equipped with proper safety protection.

C. Rotating and moving parts will cause injury if contacted. Ensure guards and safety devices are in

place before this machine is operated. Make sure engine is shut down and spark plug is

disconnected before servicing your SURFACE PREPAPATION UNIT. Never leave a machine

unattended when it is running.

D. Be careful to avoid contact with the muffler when the engine is hot as it may cause severe burns.

E. When using a DUST CONTROL UNIT avoid hose contact with the TSCAR-8H muffler as the muffler

may burn a hole in the hose.

F. Do not operate the machine in an explosive atmosphere, near combustible materials or where gas

fumes may not be properly dispersed. Repair any fuel leaks. Remove accumulated dust frequently

from air filter system.

G. Do not run the air motor without sufficient oil in the lubricating system. Lubricant levels should be

checked regularly on gas and air powered units. Refer to manufacturer’s manual for amounts.

H. Before starting your unit, always raise the cutter cage assembly using the hand knob adjustment, so

that the cutters do not contact the surface.

Assembly

Your SURFACE PREPARATION UNIT has been shipped partially assembled with the exception of

the handle assembly. The gas powered units require only filling with fuel and a brief check of lubricant

levels in preparation for operation. Engine crankcase is not pre-serviced with oil at factory; levels

should be checked.

Handle Assembly

A. To attach the handle, first remove the pin from the handle assembly. Align the lift plate and re-insert

the top pin. Place flat washer on pin. Insert spring clip through hole in pin. Feed threaded bolt end of

cable through hole on lift plates.

B. Tighten cable by attaching nut.

C. Remove the four bolts and lockwashers from the machine housing. Match up the holes on the handle

assembly and the machine housing and insert the bolts and the washers. Tighten bolts corner to

corner. Before final tightening, place the machine on a flat surface to ensure that all wheels contact

the surface.

3

Page 4

Stop Switch

On gas powered models feed the attached stop wire under the bridge and through the circular hole on

the machine housing, from below the engine, up to attached terminal on the engine. Secure it to terminal

by clamping with a pair of pliers.

Edger Installation

1. Make sure that the power source is disconnected; disconnect spark plug and turn off fuel supply on

gas unit.

2. Tilt machine onto handle (if your unit is equipped with a Honda GX engine, unit must be tilted forward

or cylinders will be flooded with oil).

3. Remove cutter cage and retainer shaft (see cutter cage removal).

4. Facing underside of machine, slide dummy shaft through outboard bearing on left side (if engine is a

Honda GX this will be on the right side of the housing).

5. Slide retainer shaft through edger cage. The roll pin in the shaft head should fit into the slot on the

end plate of the cage.

6. Slide retainer shaft through the outboard bearing and the dummy shaft.

7. Using socket or wrench tighten the retainer shaft by turning counter clockwise.

8. Install edger housing using the three bolts supplied.

9. Note: Edger operation is not to be performed with main TSCAR-8H cage in place.

Edger Removal

1. Make sure the power source is disconnected; disconnect spark plug and turn off fuel supply on gas

unit.

2. Tilt machine onto handle (if your unit is equipped with a Honda GX engine, unit must be tilted forward

or cylinders will be flooded with oil).

3. Using a 15/16” socket or wrench, turn head of shaft clockwise to loosen.

4. While turning the shaft outwards, cage will move towards the outer edge as well. Free cage from

locking pins on shaft by pushing cage back towards main housing. Turn shaft out and remove.

4

Page 5

Cutter Cage Removal and Cutter Change

A. To remove the cutter cage from the machine:

1. Make sure that the power source is disconnected. With gas models turn off fuel supply to engine and

disconnect spark plug.

2. Tilt machine onto the handle. (If your unit is equipped with a Honda GX engine, unit must be tilted

forward to change cutter or cylinders will be flooded with oil. This will prevent starting).

3. Facing the underside of the machine housing place a bar between the cutter rods to jam cage.

4. Insert a drift pin into the hole on the main shaft and pull towards you until loose (if equipped with a

Honda GX engine, drift pin will be pushed away from you to loosen main shaft). Remove drift pin and

turn shaft out by hand. Remove shaft.

Changing Cutters/Shafts

Once the cage has been removed use Allen Key and open end wrench, remove screws from cover plate

and remove from cage. With drift pin, tap rods (or, if changing cutters on edger cage) from the drive side

until free of cage. Replace cutters or shafts as required. Replace cover plate. To re-install cutter cage in

machine, reverse procedure for removal. Ensure that shaft is tight.

Removing cage for Hand Held Models

Remove thumbscrews from cover plate, remove cover. Using chuck wrench insert in slot of matching

spline of drive unit to hold cage assembly. Insert pin wrench in matching holes of cage assembly.

Holding both wrenches at the same time, turn pin wrench counter clockwise until cage is free.

Changing Cutters-Hand-Held Unit

Remove cage shaft plate by removing screws. Using drift pin, tap out rods until free of cage. Replace

cutters or shafts as required. Reposition rods and cover plate and re-install cage in unit by reversing

procedure for removal.

Starting Procedure

Gas Operated

Important: Set the machine in an upright position and adjust the cutter cage to maximum height by

turning the height adjustment knob to its farthest position. (This will ensure clearance for the rotating

cage).

Open the fuel valve on gas tank. Place throttle lever at fast idle position. Set the choke to closed position.

Start engine, open choke to prevent flooding. Move throttle control to open or run position when engine is

warmed up. Increase throttle control to maximum operating position (3600r.p.m.), close choke. Stop

engine after two (2) minutes. Re-start engine.

5

Page 6

To Stop Engines

With machine in upright position, adjust the cutter cage to maximum height by turning the height

adjustment knob to its farthest position. (This ensures clearance for the rotating cage).

GAS UNIT- Stop engine by

depressing kill switch button located at top of handle.

Maintenance

The machine is generally run in very dusty conditions. Engine life will be extended by maintaining a

clean engine and using a DUST CONTROL UNIT or SHOP-VAC. Keep the air filter clean at all times.

Wash the element in a non-oil based solvent. Squeeze out any residue and allow filter to dry before

re-installing in the air cleaner.

Lubrication: Use proper engine oil as recommended by manufacturer. Deep engine oil clean, change

as required. Maintain crankcase levels as recommended in engine manual.

Spark plug: Check and clean spark plugs regularly. A fouled or dirty spark plug causes difficulty

in starting and poor engine performance; set spark plug gap to recommended clearance in engine

manual.

Drive Shaft: Keep a coating of grease on the drive shaft and threads for easy installation or removal

and longer bushing life.

Spot Checks: Perform as required. Machine should be inspected with ignition in “off” position or

power cord disconnected. Do not perform inspections while machine is running.

● Check all fasteners for tightness- machine is subject to vibration.

● Check “V” belt for wear; adjust or replace as required.

● Check that wheels are clean and rotating freely.

● Check that inside of housing is clean; remove any build-up as required.

● Check that pulleys are aligned properly to ensure that “V” belt is running true (i.e. not at an angle).

Bearing Replacement Procedures

Important: disengage power supply. Do not attempt replacement while machine is operable

Sealed Bearing Replacement – Outboard Side: Remove drive shaft and cutter cage assembly as per

cutter change procedure. Remove snap ring and bearing shield from inside housing. Loosen and

remove bearing block flange by removing screws and lockwashers. Using a soft drift, drive out bearing

sleeve. Remove old bearing and clean parts which will be re-used. Carefully press new bearings into

flange. Clean and install bearing cover plate taking care to seat the plate flush. Re-install bearing sleeve.

Take extreme care to maintain aligned installation. Do not press sleeve into position if misaligned. Mount

bearing block to side of housing but do not tighten. From inside housing install bearing shield and snap

ring. Center block on the housing taking care that shield does not bind on bearing sleeve. Tighten bolts

when bearing block is in a free spin position.

Bearing Replacement – Drive or “V” Belt side: Remove belt guard and “V” belt. Loosen set screws,

remove key and remove pulley. Remove bearing block assembly by removing screws and lockwashers.

Remove snap ring and slip ring. Using a soft drift, drive out spindle. Take care not to burr or flare spindle.

Remove cover plate and bearing. Carefully press new bearing into block, clean and install bearing cover

plate being certain the plate fits flush. Press drive spindle into block. Install slip ring and snap ring.

Center and install spindle assembly to housing. Re-install pulley and key. Ensure pulley butts flush

against shoulder or spindle. Note: When removing spindle or sleeve, care must be taken not to damage

or distort these parts a soft drift is recommended to prevent damage.

6

Page 7

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE SOLUTION

GAS UNIT

1. Engine won’t start ● no fuel

● engine switch off

● kill switch grounded

● gas in air filter or

carburetor

● refuel

● remove air filter cover, crank

engine

● refer to engine manual

COMMON PROBLEMS

1. Cutters wearing unevenly

2. Drive shaft backs out while

running

3. Machine jumps on floor

4. “V” belt wearing rapidly

5. Uneven cut

● cage too low

● wrong setup

● material buildup

● cutters too tight

● no grease on threads

● cage lowered too far

● R.P.M. too low

● pulley misaligned

● wrong belt

● belt rubbing on surface

● wear on I.D. of front wheels

● wear on front axle

● raise cage

● see applications guide

● clean or change cutters

● remove one or more cutters

● grease threads

● not tightened properly

● adjust height knob

● reset throttle

● adjust pulley

● replace

● adjust height of machine

● replace wheels

● replace axle

Storage

The following steps should be taken to prepare your TSCAR-8H gas unit for

extended storage:

a. Close shutoff valve.

b. Siphon excess fuel from storage tank.

c. Start engine and run until it stalls due to lack of fuel. This will consume all the fuel in the carburetor and

prevent formation of deposits due to evaporating fuel.

d. Remove spark plug and pour two ounces of SAE 30 or SAE 40 motor oil into cylinder. Slowly crank the

engine two or three times to distribute the oil throughout the cylinder. This will prevent rust during

storage. Replace spark plug. Store the unit in an upright position in a cool, dry, and well ventilated

area.

To start your engine after prolonged storage

a. Refuel

b. Open shutoff valve

c. Start engine. Any excess oil residue will quickly burn off without harming operation

7

Page 8

Specification

Motor / Weight / Working Width :

Working Size (L X W X H):

TSCAR-8H 65 x 19 x 13 in

Transportation

1. Always shut off engine when transporting machine.

2. Make sure lifting device has enough capacity to hold machine (see identification plate on machine

for weight).

3. Trolley wheel is used for short distance transportation.

8

Page 9

Warranty

TOMAHAWK POWER products are covered by warranty for a period of 365 days from

the date of purchase - against defects in material or workmanship provided that:

z The product concerned has been operated and maintained in accordance with the operating

instructions.

z Has not been damaged by accident, misuse or abuse.

z Has not been tampered with or repaired by any unauthorized person.

The owner is responsible for the cost of transportation to and from the authorized repairer and the unit is

at the owners risk while in transit to and from the repairer.

Impact damage is not covered under warranty. Clutches are not covered under any warranty.

Engines are officially guaranteed by engine manufacturer. Please refer to the annex for

engine warranty.

For questions, quotes, servicing and more - call TOMAHAWK POWER at 866-577-4476

Maintenance Record

PREVENTATIVE MAINTENANCE AND ROUTINE SERVICE PLAN

This Scarifying Machine has been assembled with care and will provide years of service. Preventative

maintenance and routine service are essential to the long life of your Scarifying Machine.

After reading

through this manual thoroughly, you will find that you can do some of the regular maintenance yourself.

However, when in need of parts or major service, be sure to see your dealer. For your convenience we

have provided this space to record relevant data about your Scarifying Machine.

Invoice Number: Type of Machine:

Date Purchased: Dealer Name:

Serial Number: Dealer Phone:

REPLACEMENT PARTS USED MAINTENANCE LOG

PART NO. DESCRIPTION QTY COST DATE DATE OPERATION

9

Page 10

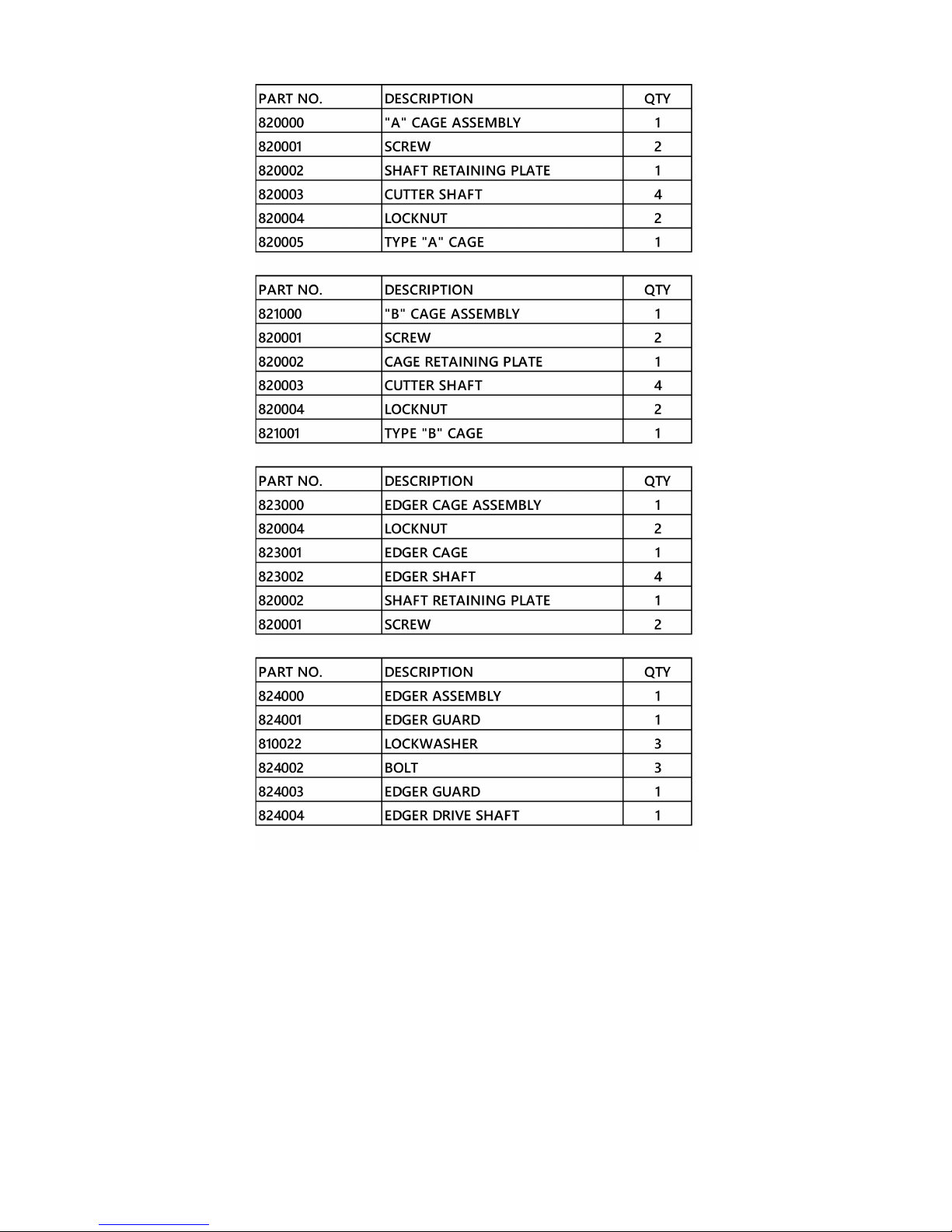

MODEL: TSCAR-8H

GAS CONCRETE SCARIFIER

(Honda Gasoline Engine)

SPARE PARTS MANUAL

Page 11

11

Page 12

12

Page 13

13

Page 14

14

Page 15

15

Loading...

Loading...