Page 1

Page 2

Page 3

Table of Contents

1.

Safety Information

1.1

Safety Precautions

Operating Safety

1.2

1.3

Operator Safety while using Internal Combustion Engines

1.4

Service Safety

1.5

Label Locations

1.6

Safety Labels

1.5 Operating Labels

2.

Operation

2.1

Application

2.2

Structure

2.3

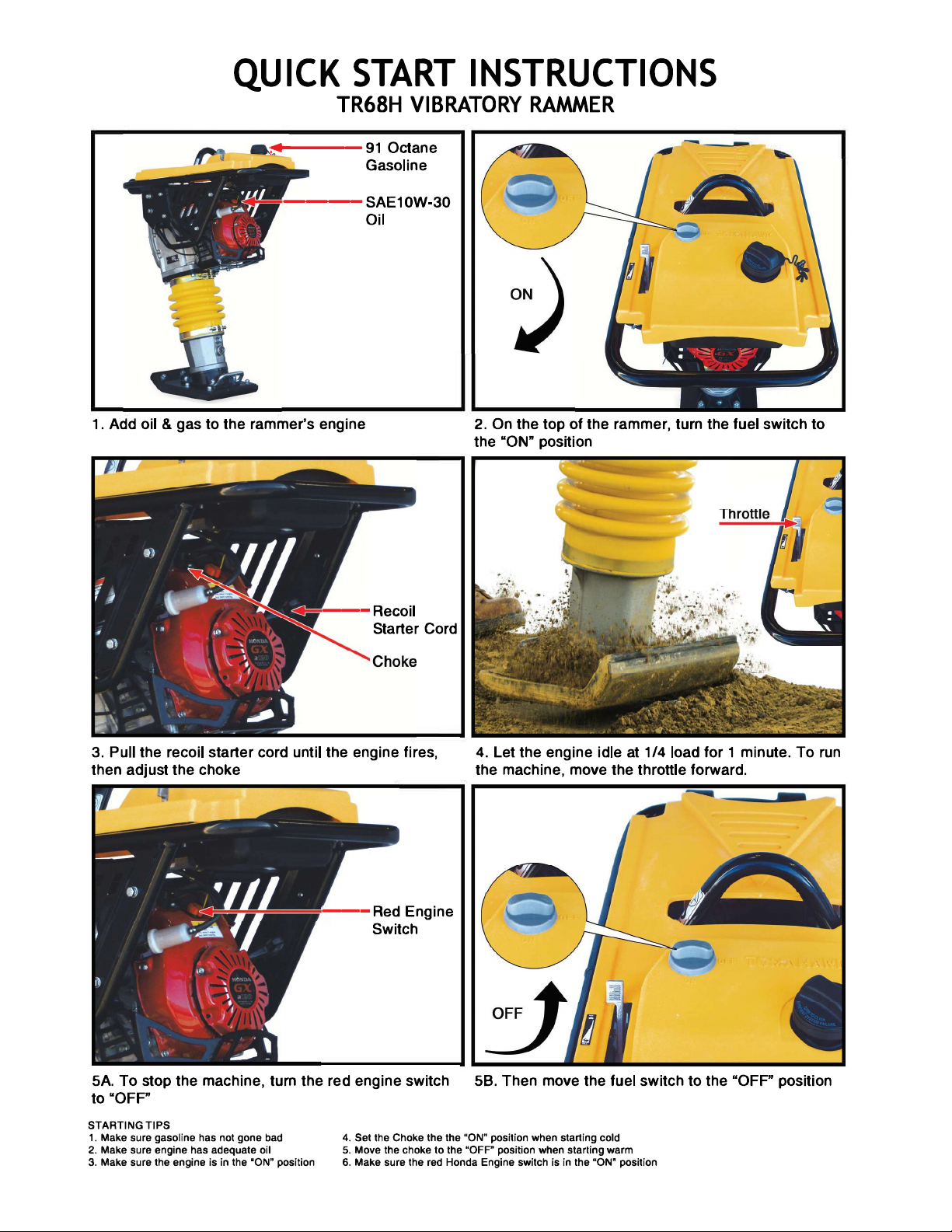

Before Starting

2.4

To Start

2.5

Operation

--------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------

------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------

------------------------------------------------------------------------

------------------------------------------------------------------------------

---------------------------------------------------------------------------------

----------------------------------------------------------------------------------

----------------------------

3

3

4

6

7

11

11

12

12

5

8

10

11

11

2.6

To Stop

3.

Maintenance

3.1

Periodic Maintenance Schedule

3.2

Transporting

Spark Plug

3.3

3.4

Air Cleaner

Storage ----------------------------------------------------------------------------------------

3.5

3.6

Troubleshooting

4.

Technical Data

Warranty

Maintenance Record

-----------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------

--------------------------------------------------------------

----------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------- 17

----------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------

----------------------------------------------------------------------------

13

14

14

15

15

16

16

19

20

21

3

Page 4

This manual provides information and procedures to safely operate and maintain this

model. For your own safety and protection from injury, carefully read, understand and

observe the safety instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this manual or need an

additional copy, please contact Tomahawk Power. This machine is built with user safety

in mind; however, it can present hazards if improperly operated and serviced. Follow

operating instructions carefully. If you have questions

about operating or servicing this

equipment, please contact Tomahawk Power.

The information contained in this manual is based on machines in production at the

time of publication. Tomahawk Power reserves the right to change any portion of this

information without notice. No part of this publication may be reproduced in any form or

by any means, electronic or mechanical, including photocopying, without express

ten permission from Tomahawk Power.

writ

Any type of reproduction or distribution not authorized by Tomahawk Power rep-

resents an infringement of valid copyrights and will be prosecuted. We expressly reserve

theright to make technical modifications, even without due notice, which aim at

improving our machines or their safety standards.

SAFETY INFORMATION

1.

1.1

Safety Precautions

This manual contains DANGER, WARNING, CAUTION, and NOTE callouts which must be

followed to reduce the possibility of personal injury, damage to the equipment, or

improper service.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation which, if not avoided, will

DANGER

result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

WARNING

CAUTION indicates a potentially hazardous situation which, if not avoided, may

CAUTION

result in minor or moderate injury.

4

Page 5

CAUTION: Used without the safety alert symbol, CAUTION indicates a potentially

hazard

1.2

ous situation which, if not avoided, may result in property damage.

Operating Safety

Familiarity and proper training are required for the safe operation of this equipment.

Equipment operated improperly or by untrained personnel can be dangerous! Read the

operating instructions and familiarize yourself with the location and proper use of all

instruments and controls. Inexperienced operators should receive instruction from

someone familiar with the equipment before being allowed to operate the rammer.

-NEVER operate rammer in applications for which it is not intended.

-NEVER allow improperly trained personnel to operate rammer.

-NEVER touch hot muffler, engine cylinders, or cooling fins.

-NEVER use accessories or attachments for the rammer, which are not recommended by

TOMAHAWK POWER. Damage to the rammer and/or injury to user may occur.

-NEVER leave a running machine unattended.

-NEVER run machine indoors or in an enclosed area such as a deep trench unless

adequate ventilation is provided. Exhaust gas from the engine contains poisonous

carbon monoxide gas; exposure to carbon monoxide can cause loss of consciousness

and may

lead to death.

-NEVER tamper with or disable the function of operating controls.

-NEVER use choke to stop the engine.

-NEVER operate the machine in areas where explosions may occur.

-ALWAYS remove or disconnect engine spark plug before servicing rammer, to avoid

accidental start-up.

-ALWAYS read, understand, and follow procedures in the Operation Manual before

attempting to operate equipment.

-ALWAYS be sure that all other persons are at a safe distance away from the rammer. Stop

the machine if people step into the working area of the machine.

-ALWAYS be sure the operator is familiar with proper safety precautions and operation

techniques before using rammer.

-ALWAYS wear protective clothing when operating rammer. Wear goggles or safety glass-

es, hearing protection, and safety shoes.

-ALWAYS keep hands, feet, and loose clothing away from the moving parts of rammer.

5

Page 6

-ALWAYS use common sense and caution when operating rammer.

-ALWAYS be sure rammer will not tip over, roll slide, or fall when not being operated.

-ALWAYS turn engine OFF when rammer is not being operated.

-ALWAYS guide the rammer in such a way that the operator is not squeezed between the

rammer and solid objects. Special care is required when working on uneven ground or

when compacting coarse material. Make sure to stand firmly when operating the machine under such conditions.

-ALWAYS operate the rammer in such a way that there is no danger of it turning over or

falling in, when working near the edges of breaks, pits, slopes, trenches and platforms.

Operator Safety while using Internal Combustion Engines

1.3

-DO NOT smoke when refueling the engine or operating the machine.

-DO NOT refuel a hot or running engine.

-DO NOT refuel the engine near an open flame.

-DO NOT smoke while operating the rammer.

-DO NOT operate the rammer near open flames.

-ALWAYS refill fuel tank in a well-ventilated area.

-ALWAYS replace fuel tank cap after refueling.

-ALWAYS check fuel lines, fuel cap, and fuel tank for leaks and cracks before starting

engine. Do not run this machine if fuel leaks are present, or fuel cap or fuel lines are

loose.

-If fuel is spilled during refueling, wipe it off from the engine immediately and discard

the rag in a safe place. Do not operate the unit if fuel or oil leaks remain.

-NEVER operate any gas powered equipment in a poorly ventilated or enclosed area.

-NEVER perform any work on the unit while it is running. Before working on it, stop the

engine and disconnect the spark plug wire to prevent accidental starting.

-Avoid prolonged breathing of exhaust gases.

-Avoid contact with hot exhaust systems and engine parts.

-Allow engine to cool before performing any repairs or service.

-ALWAYS transport and handle fuel only when contained in approved safety containers.

-ALWAYS keep the area around the muffler free of debris such as leaves, paper, cartons,

etc. A hot muffler could ignite the debris and start a fire.

6

Page 7

1.4

Service Safety

Poorly maintained equipment can become a safety hazard! In order for the equipment to

operate safely and properly over a long period of time, periodic maintenance and

occa

sional repairs are necessary.

-DO NOT attempt to clean or service rammer while it is running.

-DO NOT operate rammer with safety devices or guards removed or that are not in

work

ing order.

-DO NOT operate rammer without air cleaner.

-DO NOT remove air cleaner paper component, or air filter cover while

operating

rammer.

-DO NOT alter engine speeds. Run engine only at speeds specified in Technical Data

Section.

-ALWAYS replace safety devices and guards adhere to repairs and maintenance.

-ALWAYS keep area around muffler free of debris in order to reduce to chance of an

acci

dental fire.

-ALWAYS do Periodic Maintenance as recommended in Operation Manual.

-ALWAYS clean debris from engine cooling fins.

-ALWAYS replace worn or damaged components with spare parts designed and

recom

mended by TOMAHAWK POWER for servicing this rammer.

7

Page 8

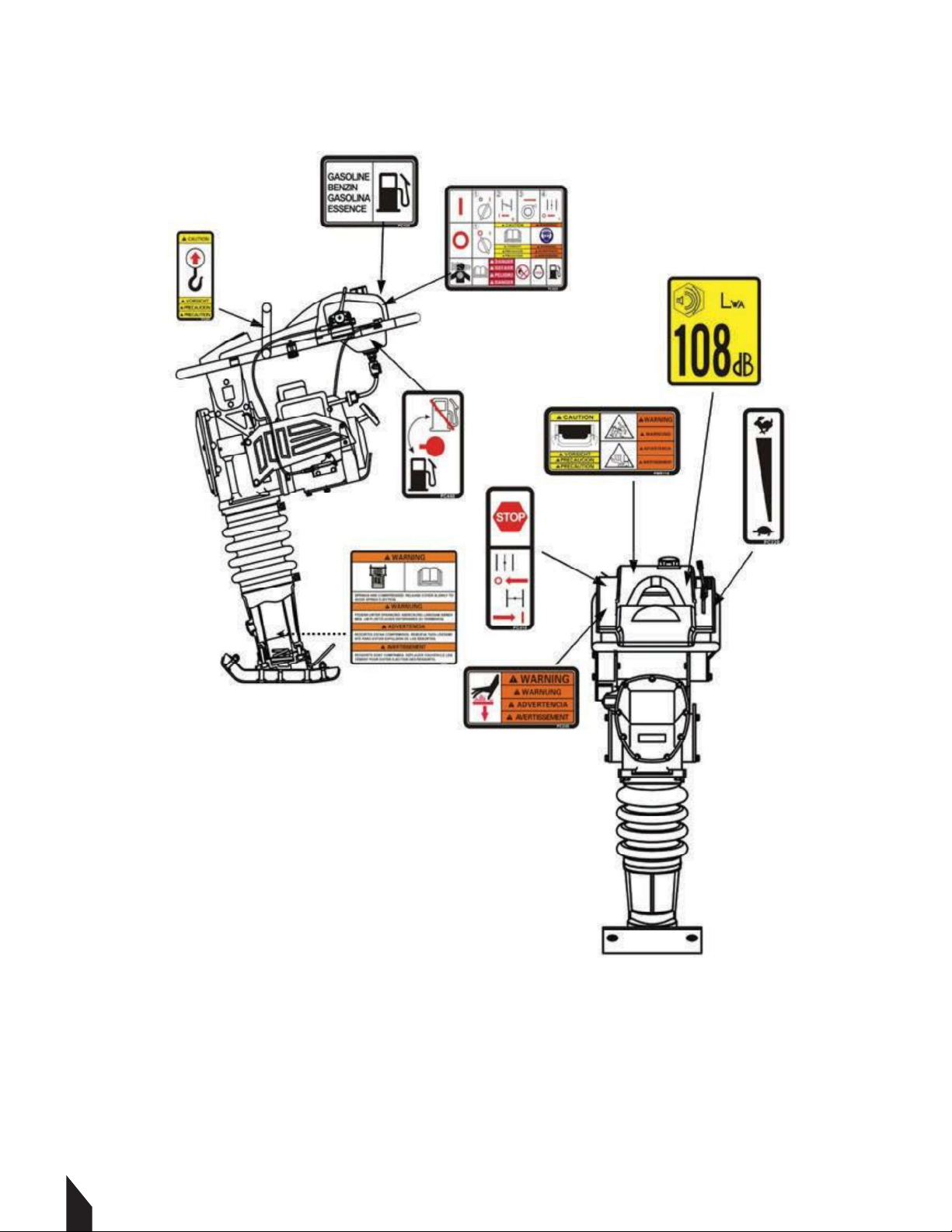

1.5

Label Locations

8

Page 9

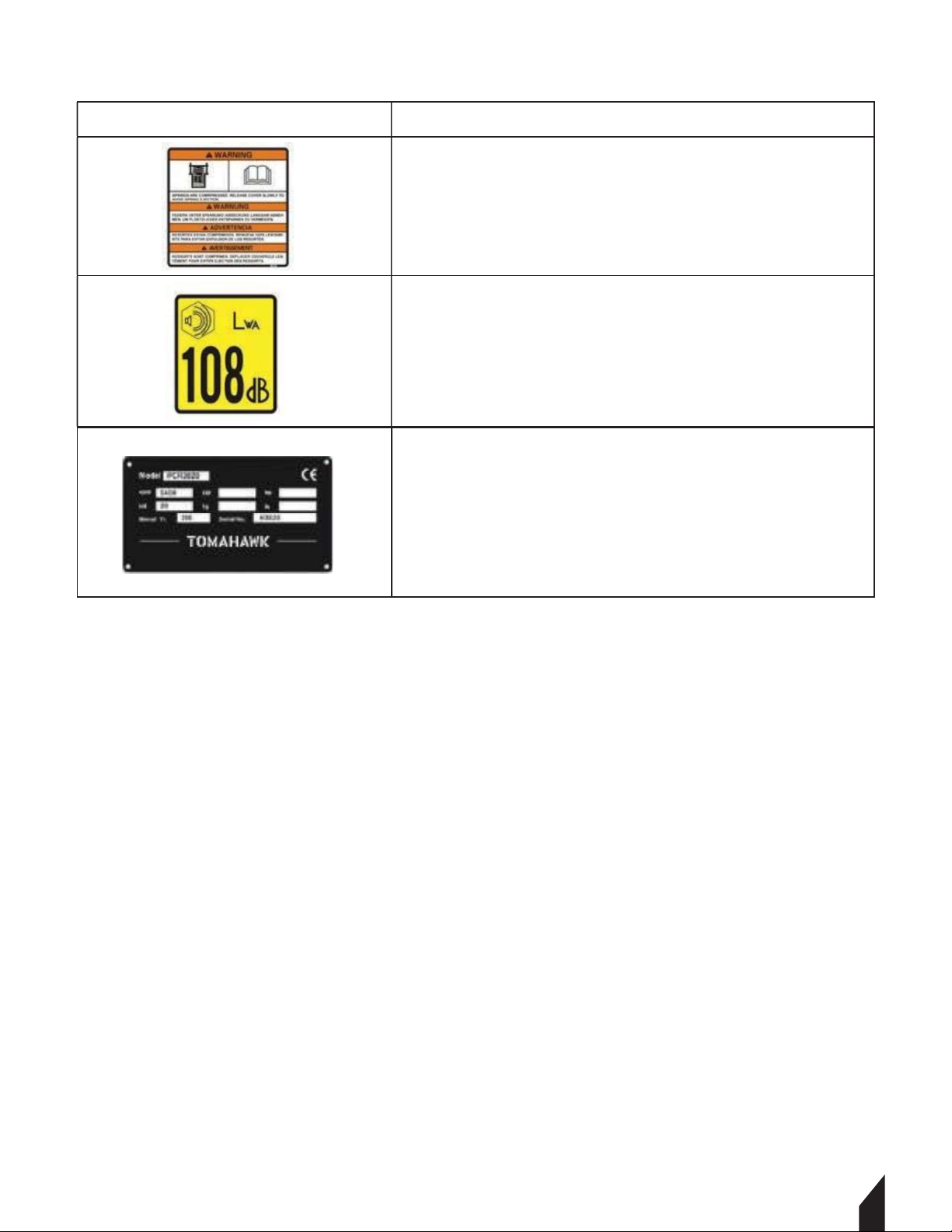

1.6

Safety Labels

Tomahawk & Jumping JX machines use international pictorial labels where

needed. These labels are

described below:

LABEL

MEANING

This label contains important safety and operating information.

If it becomes illegible, the cover must be replaced. Refer to the

Parts Manual for ordering information.

DANGER! Engines emit carbon monoxide; operate only in

well-ventilate area. Read the Operation Manual for machine

information. No sparks, flames, or burning objects should be

near the machine. Shut oG the engine before refueling. Use only

clean, filtered unleaded gasoline.

CAUTION!

Use only clean, filtered gasoline fuel.

CAUTION

Lihing point.

WARNING!

Hot surface!

CAUTION!

For optimal control, performance, and minimal hand/arm

vibration, grasp handle as shown.

9

Page 10

Page 11

LABEL

number

information

nameplate

MEANING

WARNING! Serious injury if struck by compressed spring or

cover. If the spring system cover is removed improperly, the

springs can eject.

Guaranteed sound power level in dB(A).

A nameplate listing the model number and serial

is attached to each unit. Please record the

found on this plate so it will be available if the

lost or damaged.

9

Page 12

1.7

Operating Labels

labels are described below:

LABEL

MEANING

Start the engine:

Turn the engine switch to the ON position

Close the choke.

Pull the rewind starter.

Open the choke.

Stop the engine:

Turn the engine switch to OFF position.

Fuel valve:

Closed

Open

Engine stop button:

Press to stop engine.

Choke:

O: Open

I: Closed

NOTICE!

Throttle control lever:

Turtle = Idle or Slow

Rabbit = Full or Fast

10

Page 13

2.

Operation

Application

2.1

Rammers are designed to compact loose soils and gravel to prevent settling and to provide a firm, solid base for the placement of footings, concrete slabs, foundations, gas

piping works, water pipe works, and cable backfill works, etc.

Please do not use in the following cases as it may cause damage because

machine is unbalanced.

WARNING

-Pile foundation

-Hard soil excessively compacted over normal condition

-Steep bank and slopes

The Tamping Rammer is to be used for compacting cohesive clay, gravels, and patching

work on asphalt, etc.

Structure

2.2

Thetop end is made up of the engine, Clutch, Connecting Rod, Operating Handle, and

Fuel Tank that connects via Shock Absorbing Rubber to the body. The bottom end is

made up of Spring Cylinder (Sliding part), Foot Plate that ramps body, Foot and Bellows.

Before Starting

2.3

-This machine is of oil bath lubrication system.

-Check the oil level through a window at rear end of the foot. Replenish oil if oil is not

visible at the window. For lubrication, use automobile engine oil of SAE 10W-30.

-Fill the fuel tank with regular gasoline (unleaded). Simultaneously, check engine oil and

make it a habit to replenish on the earlier side. Low lubrication oil level may result in

engine seizure due to consumption during operation. Nevertheless, oil level should be

checked prior to start up without fail. For lubrication, use automobile engine oil of

10W-30 SE, SF or better grade. See Engine Operating Manual for further detail.

-Check every bolt, nut or screwed area for tightness.

These may have become loosened

due to vibrations from previous use.

-Remove dirt and dust. Particularly clean the vicinity of recoil starter and foot.

11

Page 14

2.4

To Start

Open the fuel shut-off valve by moving the fuel cock level to the open position.

1.

2.

Set the engine ON/OFF switch to the position.

3.

Grip the recoil starter handle and pull it until you feel slight resistance. Then pull

sharply and quickly. Return the recoil starter handle to the starter case before releasing.

4. Grip the recoil starter handle and pull it a little to feel slight resistance. Then pull

powerfully. To release the handle, do not release at the position where it has been

pulled to,

but release after returning closely to the starter case.

5. If the engine has started, return the choke lever slowly to the full-open position. Be

sure to perform a warm-up run for a period 3 to 5 minutes at low speed, while paying

careful attention to gas leakage or abnormal sound.

6. If it is difficult to start the engine by repeatedly pulling the starter rope, remove

ignition plug and check the sparking performance. If the plug is wet due to excessive

fuel intake or soiled, replace the coil or clean sufficiently. With the ignition plug

removed,

2.5

Operation

pull the recoil starter handle 2-3 times to discharge excessive gas.

1. Turn the choke lever to open the choke. Run the engine for 5 minutes at low speed to

warm the engine.

2. Move the throttle lever quickly to the position. DO NOT move the

throt

tle lever slowly as this may cause damage to the clutch or spring.

Make sure that the throttle lever is moved to the FULL OPEN position.

Operating the rammer at less than full speeds can result in damage to the

clutch springs or foot.

CAUTION

3. After starting the tamping action, adjust the jumping motion to suit the particular

soil condition by lightly controlling the throttle lever. When the engine speed falls

between the set values shown on the engine, your work can be carried out at the best

efficiency.

Increasing the engine speed unnecessarily does not cause the

compaction force to increase. On the contrary, a resultant resonance causes the

compaction force to decrease, damaging the machine.

4. Under cold weather, the oil in the machine may become viscous, causing the tamping

rammer to perform somewhat irregular movement. It is recommended to perform a

warm-up run while moving the throttle lever repeatedly between ON and OFF positions,

before beginning to work.

12

Page 15

5. Soil contacting surface of the foot is lined with heat-treated metal sheet for extra

strength. However, for compacting cobblestone, use the filling-up soil for example so

that the foot hits the soil uniformly.

6.

The tamping rammer has been designed to advance while jumping. For quicker

advance, erect the machine by pushing its handle down slightly so that flat surface of the

foot at its rear-end contacts the ground.

7. To stop the tamping action, move throttle lever quickly from the FULL OPEN to IDLE

position.

To Stop

2.6

2.6.1

Normal Shutdown

1. With the throttle lever closed from ON to OFF, run the engine for 3-5 minutes at low

speed, and after the temperature is lowered, turn the switch to the position.

2.

Close the fuel shut-off valve by moving the fuel cock lever to the CLOSED position.

2.6.2

Emergency Shutdown

Move the throttle lever quickly to the IDLE position, and turn the ON/OFF switch

to the OFF position.

13

Page 16

3.

or

months or

Maintenance

Periodic Maintenance Schedule

3.1

Check fuel level

Check oil level of machine

Check fuel line and fittings

for cracks or leaks.

Tighten ramming shoe

hardware

Check and tighten

engine

cylinder screws

Check and tighten external

hardware

Clean engine cooling fins

Daily

before

starting

Afte

r

first 5

hours

Every

week or

25 hours

Every

month

100 hours

Every 3

300 hours

Clean and check spark plug

gap

Replace spark plug

Clean recoil starter

Change ramming system oil

Clean engine muffler and

exhaust port

* Change ramming system oil after first 50 hours of operation.

Note: If engine performance is poor, check, clean, and replace air filter elements as

needed.

14

Page 17

3.2

Transporting

Shutdown engine for transportation

1.

2. For transportation, tighten fuel tank cap securely and close fuel cock to prevent fuel

from spilling.

Drain fuel for transportation over long distances or poor roads.

3.

Secure machine firmly to prevent it from moving or tipping.

4.

The rammer should be transported in the same position as if it is placed on level

5.

ground. In case the rammer must be laid down for transportation, drain the fuel tank as

well as the carburetor and make sure that the oil plug is tightened securely, then tie the

rammer to the vehicle at points (a) and (b).

6. The rammer must be laid down so that the air filter faces up. After laying the

rammer

down, make sure that there is no leak from the fuel from cap (c).

7. Make sure lifting device has enough capacity to hold machine (see identification

plate

8.

on machine for weight). Use central lifting point (a) when lifting machine.

Use trolley kit (supplied as optional) for short distance transportation.

3.3

Spark Plug

Check and clean spark plugs regularly. A fouled, dirty spark plug may cause hard starting

and poor engine performance. Set spark plug gap to recommended clearance. Refer to

engine manual.

The muffler and engine cylinder become very hot during operation and

remain hot for a while after stopping the engine. Allow engine to cool

WARNING

before removing spark plug.

NOTICE: A loose spark plug can become very hot and may cause engine damage.

15

Page 18

3.4

Air Cleaner

A clean engine will extend engine life. Keep the air filter clean at all times. Clean the

air filter using the recommended solvent daily. See engine manual for proper

cleaning procedure. Let the filter dry before reinstalling.

NEVER use gasoline or other types of low flash point solvents for cleaning

the air cleaner. A fire or explosion could result.

3.5

WARNING

Storage

The rammer should be stored on level ground, after the engine and machine have

cooled

down. Be sure to secure the rammer as necessary to avoid it from falling down.

Ifthe rammer has to be laid down, tighten fuel tank cap and engine oil plug securely

andwait until the engine and machine are cooled down. After laying it down, make

sure that there is no fuel or oil leak (if fuel leaks, drain the tank).

3.5.1 Long-Term Storage

- Drain fuel from fuel tank, fuel line and carburetor.

-Remove spark plug and pour a few drops of motor oil into cylinder. Crank engine 3 to 4

times so that oil reaches all internal parts.

-Clean exterior with a cloth soaked in clean oil.

-Store unit covered with plastic sheet in moisture free and dust free location out of direct

sunlight.

16

Page 19

3.6

amplitude not uniform

Troubleshooting

3.6.1

Rammer Troubleshooting

SYMPTOM

Engine rotates but

or does not strike

POSSIBLE PROBLEM SOLUTION

Operating speed of throttle

lever is incorrectly set?

Oil in excess?

Clutch slips? Replace or adjust clutch.

Spring failure? Replace spiral spring.

Improper engine speed?

Set throttle lever to correct position.

Drain excess oil. Bring to correct level.

Adjust engine speed to correct

operating RPM setting.

17

Page 20

3.6.2

plug

will not ignite. (Power

tension

Short

circuit

due to deficient

available but spark plug

deposits?

Fuel is inadequate (water, dust)?

Flush

fuel system

and replace

with

fresh

Air filter

clogged?

Clean or replace air filter.

Tighten

cylinder

head

bolts

or

replace

Not enough

Engine Troubleshooting

SYMPTOM

Difficult to start, fuel is

available, but spark

available at high

code.)

Difficult to start, fuel is

will not ignite.(Power

NOT available at high

tension code.)

Fuel is available and

spark plug ignites

(compression normal).

POSSIBLE CAUSES SOLUTION

Ignition plug not properly connected?

Carbon deposit at ignition? Clean or replace ignition.

insulator?

Improper spark plug gap? Set spark plug gap to the correct gap.

Short circuit at stop switch?

Ignition coil defective. Replace ignition coil.

Muffler clogged with carbon

Mixed fuel quality is inadequate? Check fuel to oil mixture.

Check ignition system.

Replace insulators.

Check stop switch circuit. Replace stop

switch if defective.

Clean or replace muffler.

fuel.

Fuel is available and

spark plug ignites

(compression normal).

Operation not

satisfactory-

power available

(compression normal,

no misfiring)

Defective cylinder head gasket?

Cylinder worn?

Spark plug loose?

Air cleaner clogged?

Air in fuel line?

Fuel level in carburetor float

chamber improper?

Carbon deposit in cylinder?

head gasket.

Replace cylinder.

Tighten spark plug.

Clean or replace air cleaner.

Bleed (remove air) from fuel line.

Adjust carburetor float.

Clean or replace cylinder.

18

Page 21

SYMPTOM

Exhaust or muffler clogged with

Replace spark plug with correct type

clogs.

POSSIBLE CAUSES SOLUTION

Not enough power

available (compression

normal, no misfiring)

Engine overheats.

Rotational speed

fluctuates.

Recoil starter

malfunction.

Ignition coil defective?

Ignition plug shorts?

Fuel is inadequate (water, dust)? Flush fuel system and replace fuel.

Mixed fuel quality is inadequate?

Excessive carbon deposition in

combustion chamber?

carbon?

Spark plug heat value incorrect?

Governor adjustment improper?

Governor spring defective?

Fuel flow restricted?

Air taken in through suction line?

Debris in recoil starter track? Clean recoil starter assembly.

Spiral spring loose?

Flush fuel system and replace fuel.

Replace ignition wires, clean ignition.

Check fuel to oil mixture.

Clean or replace crankcase.

Clean or replace muffler.

spark plug.

Adjust governor to correct lever.

Clean or replace ignition.

Check entire fuel system for leaks or

Check suction line.

Replace spiral spring.

TECHNICAL DATA

4.

Model

Engine type

Engine speed operating RPM

Power (hp)

Weight (lb)

Impact force (kN)

Jumping stroke (in)

Fuel tank capacity (L)

Shoe size (in)

Ramming system lubrication

JX60H

Honda GX100

3800±100

3.0

150

12.8

1.6 - 3.4

0.81 US qt

14 x 11

0.8 L, CD10W-30

19

Page 22

Working Size(in):

Sound Specification (According to 2000/14/EC)

Measured sound power level

Guaranteed sound power level

Sound power level limit

Hand-Arm Vibration Specification (According to ISO 5394, EN 1033 and EN500-4):

6.8 m/s

2

105 dB (A)

106 dB (A)

108 dB (A)

WARRANTY

Tomahawk products are covered by a Warranty for a period of twelve (12) months from

the date of purchase against defects in material or workmanship provided that:

-The product concerned has been operated and maintained in accordance with the

ating instructions.

oper

-Has not been damaged by accident, misuse or abuse.

-Has not been tampered with or repaired by any unauthorized person.

The owner is responsible for the cost of transportation to and from the authorized

repairer and the unit is at the risk while in transit to and from the repairer.

20

Page 23

Impact damage is not covered under warranty. Clutches are not covered under any

warranty.

Engines are officially guaranteed by Honda.

MAINTENANCE RECORD

PREVENTATIVE MAINTENANCE AND ROUTINE SERVICE PLAN

Tomahawk TR68H Rammer has been assembled with care and will

provide years of

service. Preventative maintenance and routine service are essential to the long life of

your tamping rammer. Adhere reading through this manual thoroughly, you

that you can do some of the regular maintenance yourself. However, when in

will find

need of

parts or major service, be sure to see your dealer. For your convenience we have

provided this space to record relevant data about your tamping rammer.

Invoice Number:

Date Purchased:

Serial Number:

Type of Machine:

Dealer Name:

Dealer Phone:

REPLACEMENT PARTS USED MAINTENANCE LOG

PART NO. DESCRIPTION QTY COST DATE DATE OPERATION

21

Page 24

Tomahawk Power, LLC

San Diego, CA

Sales Support

(866) 577-4476

sales@tomahawk-power.com

Service and Registration

support@tomahawk-power.com

www.tomahawk-power.com

17

Loading...

Loading...