Page 1

T Cl tA \ \ IC I> Cl V� I: I�

BACKPACK SPRAYER

OPTIONS & RTS NL

FIND OUR HOW TO GUIDE ON

You

wwyoutube. com/tomahawk-power

For Video Assembly Instructions

www.Youtube.com

assemble Tomahawk T

P25

PS25

Page 2

TPS25

www.tomahawk-power.com

Start by assembling sprayer wands

2

1

QUICK HOW-TO GUIDE

Washers

1

2

3

3

2 stroke oil only

• Mix 30:1 2-Stroke Engine Oil to Gas mixture and pour it in the tank.

4

6

5

Place washers inside brass connectors

∙Double check that all connections

are correct and stable.

∙Place washers inside brass

connectors & screw onto the machine.

Fuel-injecting pump

Prime 3 – 5 times

• Slowly pour pesticide liquid

into the chemical tank

-Do not add fuel while the

engine is hot or running

-Avoid filling the tank all

the way to the top

-Do not spill fuel on the

machine

-Keep away flammable

objects

-Do not add oil near fire

sources

4

5

6

UP

• Place choke into its

closed position

RUN

STOP

S T A R T

• Pull the recoil starter a couple of

times until engine is running

• Maintain the engine running

on idle for 3-5 minutes

• Begin spraying

DOWN

• Move choke to the open

position

-Smoking near the machine

is strictly prohibited

-Do not add fuel or operate

inside an enclosed area

For questions call:

(866) 577-4476

Page 3

Warning to Users

1. The gasoline engi 09.oN htiw ,1:03 fo oitar a ta leuf dexim esu tsum en

gasoline to two-stroke automobile oil.

2. Keep engine at a low speed 3-5 minutes after start and before stop.

3. Using your sprayer at a high engine speed without liquid spray or dust is prohibited

and may damage your sprayer engine.

4. When adding fuel, stop the engine and keep away from open flames.

5. In order to avoid electric shock, do not touch the cap of the spark plug or wiring

while the engine is on.

6. The surface of the muffler and the cylinder are very hot. Refrain from touching while

hot. Children should be kept away from the engine.

2

Page 4

Table of Contents

2. Main Application …………………………………………………….….………….....….……6

3. Main Features ………………………………………………………….………….….….…….6

4. Main Parts ....................................................……………………………………...……… 6

5. Operating Instructions …...............…………………………………….……...........……….7

6. Safe Operation….……….…………………………………………………….……………….9

7. Troubleshooting ………………………………………………….……….….…….................9

8. Maintenance and Storage ....……………………………………..….…….........................10

9. Quick How-to-Guide .......................................................................................................12

3

Page 5

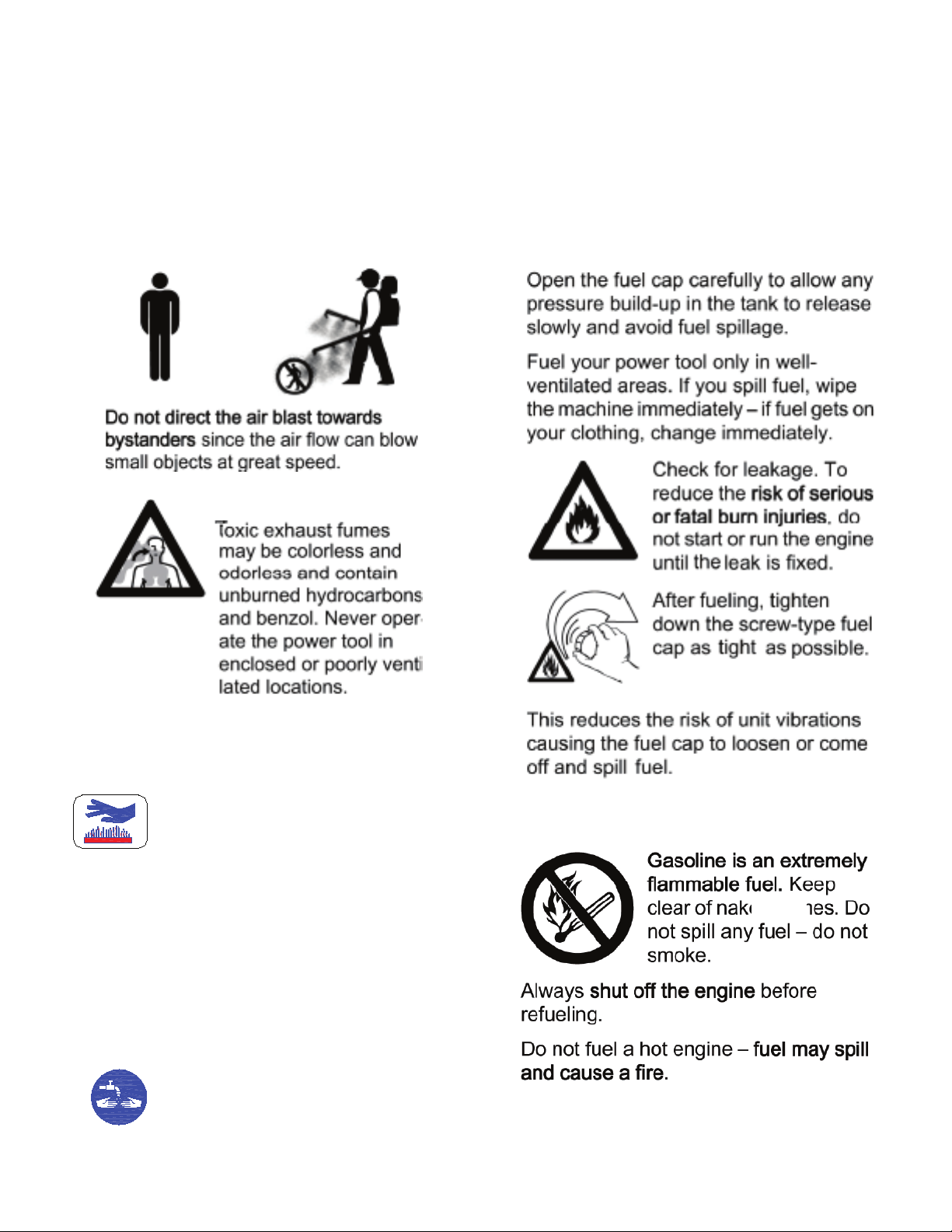

SAFETY PRECAUTION

•Wear glasses and gauze mask to

The use of the machine may be

hazardous. The impeller rotating

in the volute case may cause harm

if you try to touch it. It is important

that you read & fully understand the

following safety precautions and

warning.

Do not lend or rent your sprayer-

du s ter with o u t t h e O w n er ’s

Manual . Be sure that any one

using your sprayer-duster reads

and understands the information

contained in this manual.

Safe use of the Tomahawk Power Sprayer:

1.The operator

The operator must be in good physical

condition and mental health.

The operator must not use the machine if:

(1)

(2) Under the legal age.

(3) Has just exercised or has

not had enough sleep.

(4) Has no knowledge of the machine

Under the influence of a mind altering

substance.

protect your eyes and face to protect

against dust and pesticide.

•Wear closed-toed protective

shoes.

•Gloves must be worn to avoid

contact with pesticide .

•Clothing covering arms and legs

must be worn to avoid contact

with pesticide.

3. Using the Tomahawk Power

Backpack Sprayer Starting the engine

(1) Set the throttle handle to the stop

position before starting the engine, otherwise

chemical will be sprayed when starting engine.

(2) Be sure no one stands in front of

nozzle, ev en though t h e handl e is set,

to stop, residual materials in pipe will blow out.

Spray Operation

Operation during cool weather with little

(1)

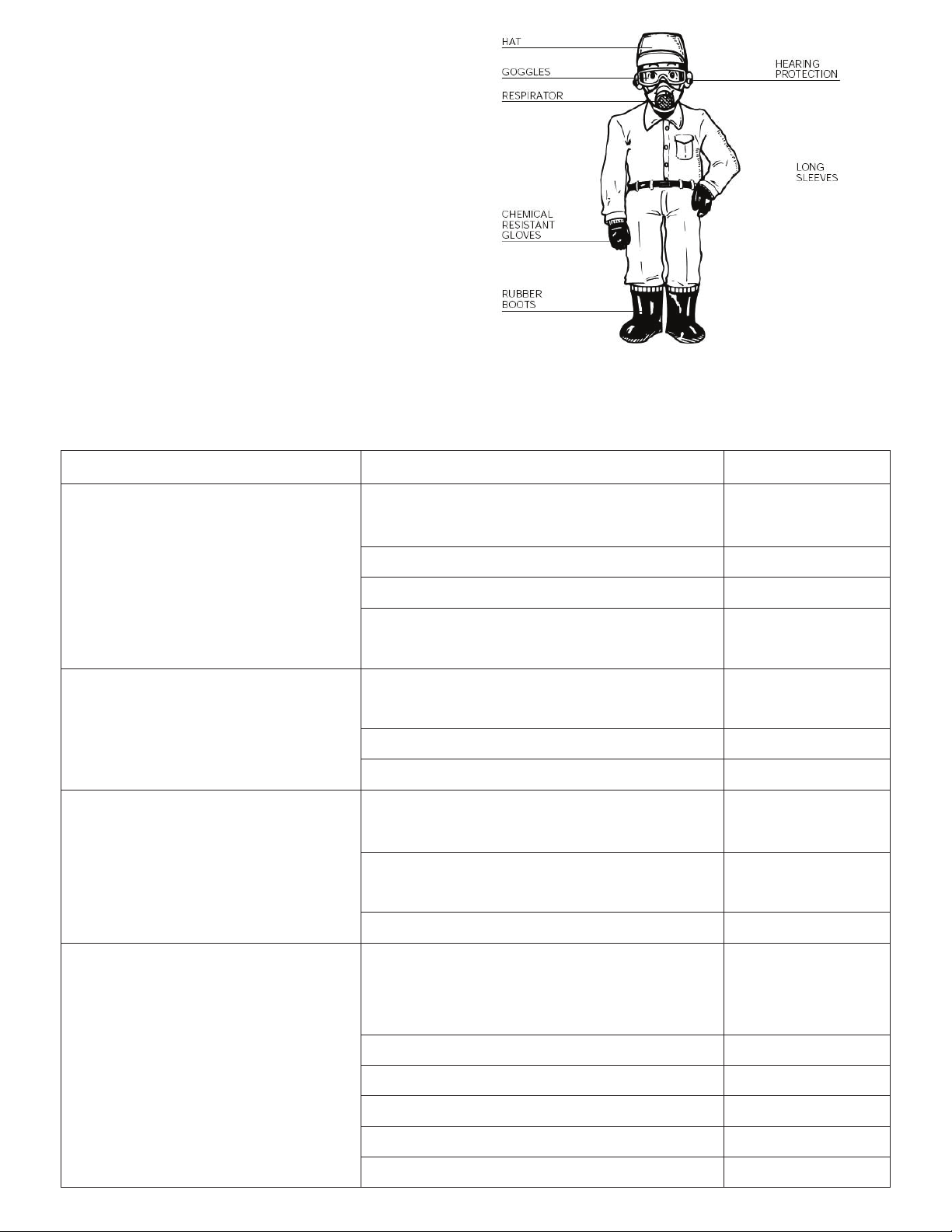

2.Proper Clothing

To reduce the risk of injury, the operator

should wear proper protective apparel.

•Carefully read this manual before

using this product.

•Wear ear mufflers to protect your

hearing.

wind is recommended. For example,

in the early morning or in the late afternoon.

This can reduce the evaporation and drift of

chemicals and improve spraying efficiency.

(2) Operator should face his/her back to wind.

(3) If your mouth or eyes are spattered

with chemicals, wash them with clean water

and go to see a doctor immediately.

(4) If the operator has a headache or

dizziness, stop working at once and go to

see a doctor immediately.

4

Page 6

(5) For the operator’s safety, dusting / spraying

must be carried out strictly according to the

Fueling

Keep the fuel tank far away from the

instruction of the chemicals and agricultural

requirements.

(6) If you want to stop the engine while

dusting, the throttle handle must be set to stop.

Warning

flames or sparks. Do not smoke

near fuel. When the machine is

running, do not add more fuel to

the fuel tank.

During operation, the muffler or

catalytic muffler and surrounding

cov er m ay b ecom e extremely

hot. Avoid contact durin g and

immediatel y a f t e r operation.

raelc aera tsuahxe peek syawlA

of flammable debris. Allow the

engine and muffler to completely

c o o l b efo r e p e rf o rmi n g a n y

maintenance activities.

After working, wash your hands

and clean all of clot hing. NOTE:

Residual pesticide can stain what

you touch.

while operating.

5

Page 7

Name

L×W×H (in) 18 × 13 × 25

Net Weight (lbs) 19.8

Chemical Tank Capacity (gal) 6.6

Water Absorption Volume (gal) 1.45

Working Pressure (MPa)

Mating Power 1E31F

Fuel Type

Way of ignition

Way of starting

Way of stopping

2. Main Application

This Tomahawk Power Backpack Sprayer is

the ideal portable tool for prevention of diseases

and for plant protection. It is mainly used in

prevention and cure of diseases and pests

of plants such as cotton, rice, wheat,

fruit trees, corn, greens, vines, etc.It can also

be used fo r residential and commercial pest

control, city sanitation, and greenhouses.

3. Main Features

3.1 This machine uses a gear structure to

decrease speed, so it is very durable.

3.2 The main part is the plunger pump

The structure is

allows for easy maintenance.

3.3 This machine has high pressure, great

flow and high efficiency, so the spraying of the

simple and compact, so it

0 ~ 2.5

Gasoline/Oil Mixture

CDI

Recoil starting

Shutting throttle fully

30:

1

4. Main Structur e

This machine consists mainly of:

4.1 Engine. It is the source of power

for the machine. It is connected to

the plunger pump through a decelerating device and connected to the

frame by a bottom support.

4.2 Plunger Pump. It is the heart of

the machine. It is connected to the

engine and to the frame.

4.3 Frame. It supports the machine.

4.4 Chemical Tank. It is used for

holding chemical liquid.

4.5 Spraying Parts. Consists of

plastic tube assembly, handle, valve,

straight spraying tube assembly and

long spraying nozzle.

4.6 Accessories. A single nozzle

conical gun and a heavy duty foundation

gun are available. Must purchase

separately.

chemicals is highly efficient.

6

Page 8

5.Operating Instructions

5.1 Preparation before start

5.1.1 Connecting spraying parts. Before starting, verify all the connections are working.

1

.Long Spraying Nozzle

2.Washer

3.Straight Spraying Tube

Never fill the fuel tank to the very top.

Never add fuel to the tank in a closed non-ventilated area.

Do not add fuel to this unit close to a open fire or sparks.

Be sure to wipe off spilled fuel before attempting to start the engine.

Do not attempt to refuel a hot engine.

.2 Start

5

5.2.1 Adding fuel. This gasoline engine is a single-cylinder, two stroke. The engine uses a fuel

mixture of No. 90 gasoline and two-strole oil. The gasoline oil mixture ratio is of 30:1 (gasoline : oil)

5.2.2 Push the fuel-injecting pump continuously until the pump is visibly is full.

5.1.2 Check that all the connections are correct and stable.

5.1.3 For long term storage, oil sealed must be removed first. To remove: Take off the spark plug,

use the lift thumb to stop the spark plug hole and pull the starter to remove oil.

5.1.4 Check the spark of the spark plug. Normally the sparks should be blue.

5

.1.5 Check if the air filter is clean. A dirty air filter will influence the volume of incoming air that

may cause bad engine performance.

4.Valve

5.Handle

6.Plastic Tube

Figure 2

5.2.3 Move the fuel handle in the starting position (about one third of the whole scale).

See Figure 3.

5.2.4 Pull the starter lightly 3-5 times to push fuel into the cylinder. Then pull faster to start the

engine.

Note: After starting the engine, the recoil starter

should be retracted slowly. If the rope on the recoil

retracts fast, it may cause damage to the engine.

5.2.5 Next, move the choke slowly to full open position. Regulate the fuel handle to a proper position to

run at a low speed for 3-5 minutes.

5.2.6 New machines should not work at full open

position within the first 4 hours. The speed should

be controlled at 4000-5000 rpm.

Figure 3

5.3 Spraying

5.3.1 When adding chemical liquid, it should be poured slowly into the chemical tank. The liquid

must be poured through the filter in order to avoid undesired matter from entering into the liquid

tank, which could cause harm to the chemical tank or engine. After adding liquid, screw down the

chemical tank lid in order to avoid leakage.

5.3.2 Regulate the choke (see Figure 4) to the closed position to start and then move to the full

open position when the engine is hot.

7

Page 9

5.3.3 Important notes when spraying:

A) Swing the spraying tube with your hand after

turning on the handle valve. In order to avoid

chemical harm, it is strictly prohibited to spray

only in one place.

B) Operator should face the wind. The spraying

tube should form an approximate 15° angle.

C) During spraying, the spraying tube should be

swung continuously between the left and the right

to increase spraying range.

5.3.4 Pressure regulation. When the engine’s speed

is 5000-6000rpm, regulate the water pressure of

the plunger pump.

If it is necessary to regulate, please do this

procedure as per the instructions on Figure 5.

Figure 4

5.3.4 Spraying. Regulate the fuel handle to allow the

machine to run at about 6500r/min and turn on the

handle spraying valve to begin spraying.

5.3.5 Stopping. Move the stop switch to the STOP

position when the engine idles.

Figure 5

5.4 Avoid fire.

a) NEVER start a fire or smoke near the machine.

b) NEVER refuel the machine when it is hot or running.

c) NEVER pour fuel on the machine. If you do, clean it

immediately. After adding fuel, screw down the fuel tank

lid, then move the machine to a new place to start the engine.

Figure 6

5.5 Spraying operation.

a) Chemical spraying should be performed under cool weather with little wind. We recommend

spraying early in the morning or in the late afternoon. This will reduce evaporation and drift of

chemicals improving spray efficiency.

b) The operator must walk facing the wind.

c) If chemical touches the operator’s mouth or eyes, wash them immediately with clean water and

and then visit a doctor.

d) If the operator has a headache or feeling dizzy, he must stop working immediately and should

visit a doctor.

e) For the operator’s safety, spraying must be carried out strictly according to the instruction

of the chemicals being used.

8

Page 10

6.Safe Operation

6.1 Read the instruction manual carefully.

6.2 Protective gear:

a ) Wear a flanged cap

b ) Wear dirt/fog-proof goggles

) Wear a gauze mask

c

) Wear a coat guard

d

e ) Wear long sleeve gloves

f ) Wear boots

7.Troubles hooting

7.1 Engine troubleshooting guide

Problem Cause Remedy

Fails to start Fail to push the fuel-injecting pump Push continuously

Water mixed with fuel Replace the fuel

Deterioration or carbon deposit of spark plug Replace the plug

Bad contact between spark plug and lead

wire

It starts but cannot run at high speed The choke is not on the full open position Open to full

Wrong ratio of fuel Replace

Water in fuel Replace the fuel

It runs but does not work efficiently The air filter is dirty Check and clean

Outlet of cylinder and muffler are dirty Remove the dirt

Piston, piston ring, cylinder have been worn Replace

Stops while running Fuel is out Add fuel

Check spark plug

position

The lead wire of plug is loose Check and replace

Plug covered with carbon Replace the plug

The filter is clogged Clean

Water in fuel Replace fuel

The air hole in the tank lid is clogged Clean

9

Page 11

7.2 Troubleshooting for spraying

Problem Cause Remedy

Liquid does not spray out Inlet valve and outlet valve blocked Replace or clean

Washer is damaged Replace

6004Z bearing is damaged Replace

Piston is damaged Replace

Low or no spraying pressure

Pressure is fine but spraying is low Piston is worn Replace

Not enough pressure

Not enough elastic force on regulating spring Replace

Corrosion resistant steel ball worn Replace

Pressure regulating valve seat worn Replace

Piston running distance is not enough Replace

Regulate

Inlet valve and outlet valve are worn Replace

Spraying parts are clogged Clean

Spraying mist is low The holes of spraying sheet are worn Replace

Spraying parts are clogged Clean

Warranty and Service

Tomahawk Power guarantees problem-free quality and will assume the costs for defect remediation by

replacing defective parts in the case of material or manufacturing defects that occur within the guarantee

period a the date of purchase. Please note that specific guarantee conditions apply in some countries. Ask your

sales person if you have any questions. As vendor of the products he is responsible for the guarantee. We

request your understanding that no guarantee can be assumed for damages due to the following: • Noncompliance with the operating instructions. • Neglecting required maintenance and repair work. • Damages

due to improper carburetor adjustment. • Normal wear and tear. • Obvious overload through persistently

exceeding the upper performance limits. • Using non-approved tools and cutting fixtures, Using non-approved

cutting bar and chain lengths in the case of chain saws. • The use of force, improper handling, misuse, or

accident. • Damages caused by overheating due to dirt build up on the ventilator casing. All guarantee work

must be carried out by a Tomahawk Power dealer.

Parts subject to wear and tear must be replaced, when required.

The following parts are subject to normal wear and are not covered by the manufacturer’s warranty:

• Air filter • Fuel filter • All rubber parts which come into contact with fuel •

Spark Plug • Starter

10

Page 12

9. Te ch n ic al M ai n te na nc e a nd

Long Term Storage

(1)Spraying units

a.Clean out any residual chemical mixture

in the chemical tank and all other

operation with clean water and and dry.

b.Clean the chemical tank inside and out

after spraying.

c.Loosen the chemical tank lid.

d.Let the machine run at a low speed 2-3

minutes after cleaning.

(2)Fuel system maintenance

a.Water or dirt in fuel is one of the main

cause of the engine trouble, clean the fuel

system regularly.

b.Residual fuel remaining in the fuel tank

and carburetor for an extended period will

clog the fuel system, causing the engine not

to work properly Fuel should be discharged.

if the machi

ne will not be in sure for a week.

parts after

Note:

The wor k including main t e nance,

cleaning and adjusting must be done

after stopping the machine.

Periodically ch eck the braces.

Without del ay, replace the worn out

braces.

(4)Long term storage

a.Clean the machine and apply antirust oil to

metal parts.

b.Remove the spark plug and pour 15~20g

of 2-stroke engine oil into the cylinde r

through the spark plug pole. Pull the starter

handle 4~5 times to distribute

the engine. Pull the handl

piston reaches the top of

it there, then install the spark plug.

the oil inside

e slowly until the

its travel and leave

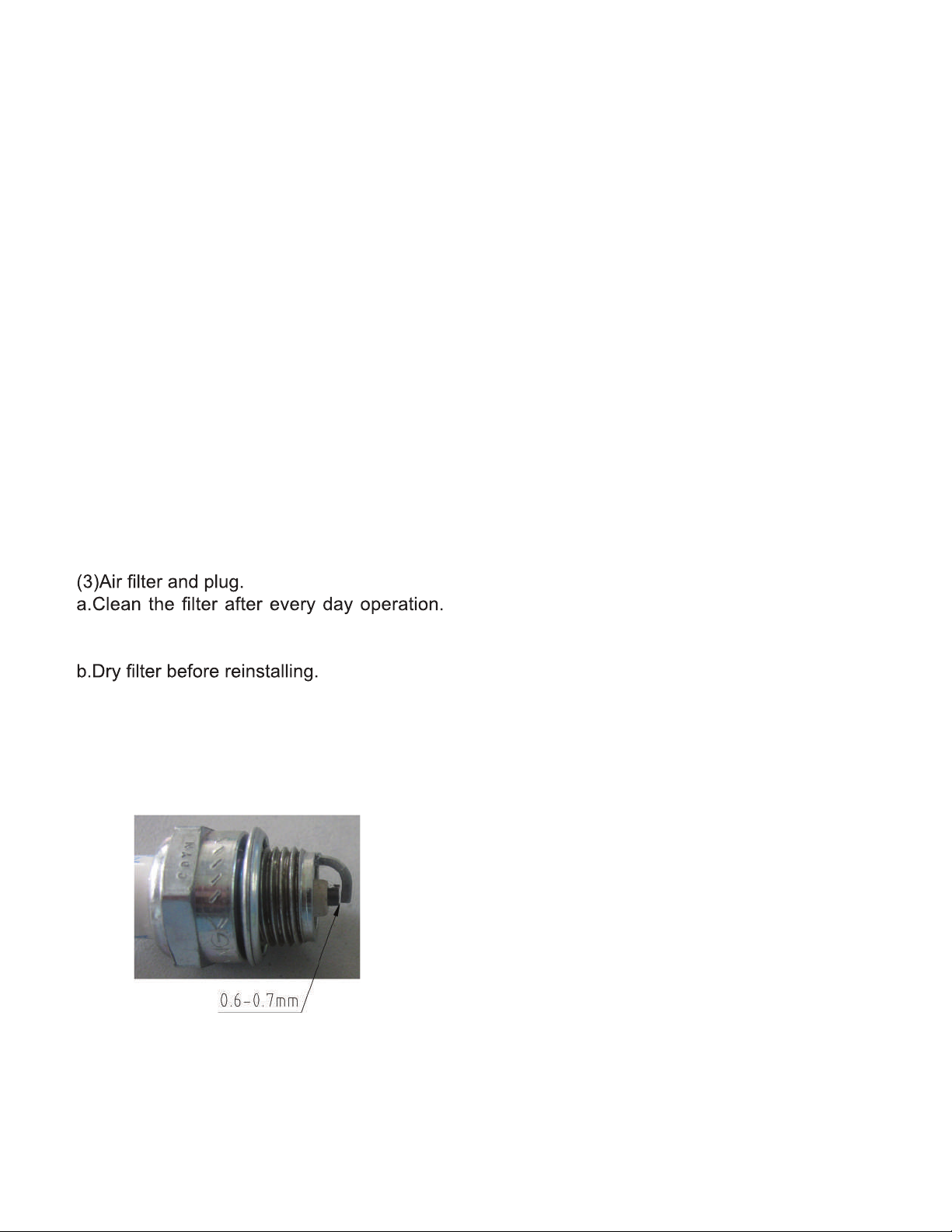

Dirt adhering to the filter reduces the engine

power.

c.Clean stains or carbon off the spark plug

and adjust spark gap to 0.6~0.7mm.

d.The plug model of this machine is 4106J,

as seen on Figure 13.

Do

not use other models.

c.Remove the chemical

inside and outside, then leave the lid loose.

d.Remove spray wands and clean them. Store

separately.

e.Discharge fuel in the

entirely.

f.Cover the machine w

and store it in a dry and clean place.

tank lid, and clean

tank and carburetor

ith a plastic dustcoa

t

Fig 13

11

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Loading...

Loading...