Page 1

Reversible Plate Compactor

TPC400Z

Operator’sManual

Page 2

Foreword

1 Foreword

Thank you very much for purchasing your new mac hine from Tomahawk

Manual contains information and procedures for the safe operation and maintenance of your

new machine. In concern about your own safety and to prevent potential hazards & accidents,

kindly read this manual carefully and familiarize yourself with

operating procedures.

For an extensive maintenance and repair work, we are advising you to contact our

Tomahawk Power Customer Service Team. Such work should be carried out by Tomahawk

service or authorized specialists.

Power

The safety of the operator was the primary concern of Tomahawk

machine was designed. Either, improper use or incorrect maintenance can pose a risk. To

attain the best efficiency and trouble free operation of your Tomahawk

Please follow the operating procedures and maintenance schedules in accordance with the

instructions in this operator's manual. For your future references, Kindly note the serial

number printed in the name plate of your machine.

It’s not advised to operate the machine with defected parts and defective machine parts must be

replaced immediately. Please contact your Tomahawk Power representative if you have

any questions concerning operation or maintenance.

safety information, warnings and

Power. This Operator’s

Power Equipments when this

Power machine,

Operator’sManual 2

Page 3

Page 4

Table of Contents

1. Technical Data 18

2. Description 23

2.1 Dimensions ..................................................................................................20

2.2 Max. admissible inclination ..........................................................................20

2.3 Description of function .................................................................................21

3. Transport to work site /Recommendations on compaction 23

3.1 Transport to work site ..................................................................................23

3.2 Recommendations on compaction ..............................................................24

4. Operation 25

4.1 Starting ........................................................................................................25

4.2 Mechanical oil pressure control ...................................................................26

4.3 Forward and reverse motion ........................................................................27

4.4 Switching off ................................................................................................27

4.5 Compaction without extension plates ..........................................................27

4.6 Additional notes on starting at very low temperatures! ................................28

5. Maintenance 29

5.1 Maintenance schedule ...............................................................................29

5.2 Engine oil ...................................................................................................30

5.3 Hydraulic control ........................................................................................31

5.4 Exciter ........................................................................................................32

5.5 Exciter V-belt ..............................................................................................33

Operator’sManual 4

Page 5

6. Faults 34

6.1 Forward speed too low ...............................................................................34

6.2 Reverse speed too low ...............................................................................34

6.3 No reverse motion ......................................................................................34

6.4 Loss of hydraulic oil ....................................................................................35

6.5 Engine does not start .................................................................................35

Operator’sManual 5

Page 6

Safety Information’s

2.1 Principle

State of the art

This machine has been designed and manufactured in accordance to the recognized safety

standards and ergonomics factors. Nevertheless, when used improperly, dangers to the

operator’s life and limb of the operator or to third persons or damage to the machine or other

machine parts cannot be excluded.

Proper use

The machine must only be used for the following purposes:

• Compaction of soils.

• Compaction of asphalt.

• Shaking in of paving stones.

The machine may not be used for the following purposes:

• Compaction of intensely cohesive soils.

• Compaction of frozen soils.

• Compaction of hard, non-compactable soils.

• Compaction of soils those are not capable of bearing a load. Its proper use also includes

the observance of all instructions contained in this operator's manual as well as complying

with the required service and maintenance instructions.

Any other way of machine use is regarded as improper. Any damage occurs from improper use

will void the warranty and the liability on behalf of the manufacturer. The operator assumes full

responsibility.

Structural modifications

Without the written permission of the manufacturer, never attempt to modify the machine parts. In

doing so, it will endanger your safety and the safety of other people. In addition, this will void the

warranty and the liability on behalf of the manufacturer.

Especially the following are cases of structural modifications:

• Opening the machine and the removal of permanent components from

Tomahawk Power.

• Installing new components which are not from Tomahawk Power Equipments and not

equivalent to the specification of original parts

• Installation of accessories which are not from Tomahawk Power Equipments and not

s

pecified in this operator’s

It is no problem to install spare parts as specified by Tomahawk Power.

It is no problem to install accessories

t

produc

manual.

range of your machine. Please refer to the installation regulations in this operator's

manual

those are belongs to the Tomahawk Power Equipments

.

Operator’sManual 6

Page 7

Requirements for operation

The ability to operate the machine safely requires:

• Proper transport, storage and setup.

• Careful operation.

• Careful service and maintenance.

Operation

• Operate the machine only as intended and only when in proper working condition.

• Operate the machine in a safety-conscious manner with all safety devices attached

and enabled. Do not modify or disable any safety devices.

• Before starting operation, check that all control and safety devices are functioning

properly.

• Never operate the machine in a potentially explosive environment.

Supervision

Never leave the machine running unattended!

Maintenance

Regular maintenance work is required in order for the machine to operate properly

and reliably over time. Failure to perform adequate maintenance reduces the working

efficiency of your machine

• Strictly observe the prescribed maintenance schedules.

• Never run the machine if it requires maintenance or repairs.

Malfunctions

If you detect a malfunction, you must shut down and secure the machine immediately.

Eliminate the malfunctions that impair safety immediately

Have damaged or defective components replaced immediately

For further information, refer to chapter Troubleshooting.

Spare parts, accessories

Uses only spare parts as prescribed from Tomahawk Power Equipments or such

that

are equivalent to the original parts in design and quality. Only use accessories

from Tomahawk Power. Non-compliance will exempt the manufacturer from all

liability.

Operator’sManual 7

Page 8

Operator's manual

Always keep the operator's manual near the machine or near the worksite for quick

reference.

If you have misplaced the operator's manual or require an additional copy, contact

your Tomahawk Power Equipments representative or download the operator's

manual from the Internet (www.Tomahawk-Power.com).

Always handover this opera

the machine.

Country-specific regulations

Observe the country-specific regulations, standards and guidelines in reference to

accident prevention and environmental safety, for example those pertaining to

hazardous materials and wearing protective gear.

Complement the operator's manual with additional instructions taking into account the

operational, regulatory, national or generally applicable safety guidelines.

Operator's controls

Always keep

grease.

Operating elements such as ON/OFF switch, gas handles etc. may not be locked,

manipulated or changed without authorization from Tomahawk Power Equipments.

the operator's controls of the machine dry, clean and free of oil or

Cleaning

Always keep the machine clean and be sure to clean it each time you have finished

using it.

tor's manual to other operators or to the future owner of

Do not use gasoline or solvents. Danger of explosion! Do not use high pressure

washers. Permeating water can damage the machine.

When electrical equipment is present, this can pose a serious injury risk from electric

shocks.

Checking for signs of damage

Inspect the machine when it is switched off for any signs of damage at least once per

work shift.

Do not operate the machine if there is visible damage or defects.

Have any damage or defects eliminated immediately.

Operator’sManual 8

Page 9

2.2 Qualification of the operating personnel

Operator qualifications

Only trained personnel are permitted to start and operate the machine. The following rules also

apply:

• You are at least 18 years of age.

•

You are physically and mentally fi

• You have received instruction on how to independently operate the machine.

• You have received instruction in the proper use of the machine.

• You are familiar with required safety devices.

• You are authorized to start machines and systems in accordance with the standards

governing safety.

• Your company or the operator has assigned you to work independently with this machine.

Incorrect operation

Incorrect operation or misuse by untrained personnel can endanger the health and safety

of the operator or third persons and also cause machine and material damage.

Operating company responsibilities

The operating company must make the operator's manual available to the operator and ensure

that the operator has read and understood it.

Work recommendations

Please observe the recommendations below:

• Work only if you are in a good physical conditi

• Work attentively, particularly as you finish.

• Do not operate the machine when you are tired.

Carry out all work calmly, circumspectly

•

• Never operate the machine under the influence of alcohol, drugs or medication. This can

impair your vision, reactions and your judgment.

• Work in a manner that does not endanger others.

• Ensure that no persons or animals are within the danger zone.

t.

on.

and carefully.

Operator’sManual 9

Page 10

2.3 Protective gear

Work clothing

Clothing should be appropriate, i.e. should be close-fitting but not restrict your movement.

When on construction sites, do not wear long hair loosely, loose clothing or jewelry

including rings. These objects can easily get caught or be drawn in by moving machine

parts.

Only wear clothing made of material that is not easily flammable.

Personal protective gear

Wear personal protective gear to avoid injuries or health hazards:

• Non-skid, hard-toed shoes.

• Work gloves made of durable material.

• Overalls made of durable material.

• Hard hat.

• Ear protection.

Ear protection

This machine generates noise that exc

(individual rating level). It may therefore be necessary to wear ear protection. You can

find the exact value in the chapter Technical Data.

When wearing ear protection while working, you must pay attention and exercise

caution because you’re hearing is limited, e.g. in case someone screams or a signal tone

sounds. Tomahawk Power recommends that you always wear ear protection.

eeds the country-specific permissible noise levels

2.4 Transport

Switching off the machine

Before you transport the machine, it must be switched off, and the engine must be given

sufficient time to cool down.

Center pole in transport position

Before commencing transport, move the center pole to the transport position. Let the

center pole latch into its lock.

Observing hazardous materials regulations

Observe the national safety guidelines and the hazardous materials regulations that apply

to the respective means of transportation.

Operator’sManual 10

Page 11

Lifting

When lifting the machine, observe the following instructions:

Loading the machine

Transport vehicle

• Designate a skilled person to guide you for the lifting procedure.

• You must be able to see or hear this person.

Use only suitable and certified hoisting gear, lifting tackle and load-bearing equipment wi

•

sufficie

• Only use the attachment points described in the operator's manual.

• Attach the machine securely to the hoisting gear.

• Ensure that no one is nearby or under the machine.

• Do not climb onto the machine.

• Loading ramps must be able to bear the load and be in a stable position.

• Make sure that no one can be endangered if the machine slips away or tips over or if

machine parts suddenly move upward or downward.

• Put the operating controls and moving parts in their transport position.

• Secure the machine with load-securing straps so that it cannot tip over, fall down or slide

away. Only use the attachment points described in the operator's manual.

Use

tie-down lugs.

nt lifting capacitie

only suitable transport vehicles with sufficient load-carrying capacity and suitable

s.

th

Transporting the machine

Secure the machine on the transport device against tilting, falling or slipping. Only use the

lashing points listed in the operating instructions. Also observe the country-specific

regulations, standards and guidelines.

Restarting

Machines, machine parts, accessories or tools that were detached for transport purposes

must be re-mounted and fastened before restarting. Only operate in accordance with the

operating instructions.

2.5 Operating safety

Explosive environment

Never operate the machine in a potentially explosive environment.

Work environment

Familiarize yourself with your work environment before you start work. This includes e.g.

the following items:

• Obstacles in the work and traffic area

• Load-bearing capacity of the ground.

• The measures needed to cordon off the construction site from public traffic in particular.

• The measures needed to secure walls and ceilings.

• Options available in the event of an accident.

.

Operator’sManual 11

Page 12

Safety

Starting the machine

Vertical stability

Proper operator position

Leaving the danger area

in the work area

When working with the machine especially pay attention to the following points:

• Electric lines or pipes in

• Gas lines or water lines in the work area.

Observe the safety information and warning notices located on the machine and in the

operator's manual.

Never attempt to start a machine that requires maintenance or repairs.

Start the machine as directed in the operator's manual.

Always ensure that th

away.

Do not leave the proper operator position while operating the machine.

The proper operator position is behind the center pole of the machine.

Injury may be caused by moving machines or flying materials.

Ensure that other persons observe a minimum safety distance of 2 m from the machine.

work area.

e machine is vertically stable and cannot tip over, roll or slide

Caution with movable parts

our h

Keep y

Parts of your body being pulled in or crushed can cause serious injuries.

Switching off the machine

Swit

h off the engine in the following situations:

c

• Before breaks.

• If you are not using the machine.

Store the machine in such a way that it cannot tilt, fall or slip.

Storage location

After operation, allow the machine to cool and then store it in a sealed-off, clean and dry

location protected against frost and inaccessible to children.

Not using starter sprays

Highly flammable starter sprays pose a fire hazard.

Do not use any starter sprays.

Starter sprays are highly flammable and can cause backfiring and engine damage

ands, feet and loose clothing away from moving or rotating machine parts.

Operator’sManual 12

Page 13

Vibrat

ions

When manually operated machines are intensively used, long-term damage caused by

vibrations cannot be precluded.

Observe the relevant legal instructions and guidelines to minimize vibration stress.

Details on vibration stress associated with the machine can be found in the chapter

Technical Data.

2.6 Safety

Integrated driving mechanism

Belt guard

Danger of falling over

Load-carrying capacity of the ground

Avoiding crushing

during the operation of vibratory plates

Machines with integrated driving mechanism must not be set down or stored on the

transport device. The driving mechanism is only intended for transport.

Never operate the machine without a belt guard.

Exposed belts and belt pulleys are dangerous and can cause serious injuries if they pull in

any part of your body or if parts are ejected.

Operate the machine so

and steps.

Keep in mind that the load-carrying capacity of the earth to be compressed or bed can be

greatly reduced by the effects of vibration, for example near slopes.

When operating the machine,

the machine and an obstacle. Always look in the direction of travel!

that it cannot tip over or fall down from bordered areas, edges

pay particular attention to avoid being squeezed between

Compacting on slopes

The following points must be observed if you plan to compact inclined surfaces (slopes,

escarpments):

• Always stand above the machine on a sl

• Start at the bottom of a slope (slopes that can be easily managed in an upward

direction can be safely traveled in a downward direction also).

• Never stand in a position where the machine could possibly fall. A slipping or tipping

machine can cause serious injuries.

Not exceeding the maximum tilt position

• Do not exceed the maximum tilt position (see chapter Technical Data).

• Only operate the machine at maximum tilt for short periods of time.

If you exceed the maximum tilt, the engine lubrication system will fail and thus inevitably

damage important engine parts.

Operator’sManual 13

ope.

Page 14

Check the effects of vibration

Compacting work in the vicinity of buildings can lead to structural damage. For this reason

you must always check the possible effects of vibrations on surrounding buildings in the

run-up to work.

You must take the following points into special consideration when evaluating the effects

of vibration:

• Vibration behavior, sensitivity and resonance frequency of surrounding buildings

• Distance of the buildings from the vibration site (= worksite).

• Condition of the soil.

You may need to carry out measurements to determine the vibration speed.

You must also comply with the relevant guidelines and regulations,

particularly DIN 4150-3.

The foundation must also have sufficient load-bearing capacity to withs

compaction energy. In case of doubt involve a soil mechanics specialist in the

evaluation. Tomahawk Power is not liable for any s

tructural damage.

2.7 Safety during the operation of combustion engines

Checking for signs of damage

Check the engine while switched off for leaks and cracks in the fuel line, tank and fuel cap

at least once per work shift. Do not operate the machine if there is visible damage or

defects. Have any damage or defects eliminated immediately.

.

tand the

Dangers during operation

Combustion engines can be dangerous, particularly during operation and when refueling.

Read and follow all safety instructions. Otherwise there is a risk of personal injury and/or

damage to property!

Do not start the engine near spilt fuel or if you smell fuel – this may cause an explosion!

• Remove the machine from such areas.

• Remove the spilt fuel immediately!

Not changing the engine speed

Do not change the preset engine speed, as this may cause engine damage.

Preventing fires

Open flames and smoking are strictly prohibited in the immediate vicinity of the machine.

Make sure that waste, such as paper, dry leaves or grasses do not accumulate around the

exhaust muffler. The waste materials may ignite.

Operator’sManual 14

Page 15

Safety precautions when refueling

Please observe the following safety-relevant instructions when refueling:

• Do not refuel near open flames.

• Do not smoke.

Turn off the engine before refueling and allow it to c

•

• Refuel in a well-ventilated environment.

• Wear fuel-proof protective gloves and, if there is the possibility of spraying, protective

goggles and clothing.

• Do not inhale fuel vapors.

• Avoid skin and eye contact with fuel.

• For refueling, use clean tools such as a hopper.

• Do not spill fuel, especially onto hot parts.

• Remove any spilt fuel immediately.

• Use the correct fuel grad

• Do not mix fuel with other liquids.

• Fill the tank only up to the maximum marking. If there is no Maximu

up the tank completely

fill

• Lock the fuel cap securely after refueling.

Operation in closed rooms

In closed or partially closed rooms such as tunnels, drifts or deep trenches, ensure

sufficient ventilation and extraction by, for example, providing a powerful exhaust air fan.

Danger of poisoning! Do not inhale exhaust fumes. They contain toxic carbon monoxide

that can lead to unconsciousness or death.

ool down.

e.

m marking, do not

.

Caution with hot parts

Do not touch any hot parts such as the engine block or exhaust muffler during operation or

directly afterwards. These parts can become very hot and cause severe burns.

Cleaning the engine

Clean the engine when it is cool to remove any dirt.

Do not use gasoline or solvents. Danger of explosion!

Notes on the EPA engine

Caution

Thi

Modifying the motor speed influences the EPA certification and emission. The motor may

only be set by a skilled technician.

For more detailed information, contact your nearest motor or Tomahawk Power

representative.

s machine is equipped with an EPA-certified engine.

Health hazard due to exhaust fumes

Warning

The engine's exhaust fumes contain chemicals which are known to the State of California

to cause cancer, congenital defects or other reproductive anomalies.

Operator’sManual 15

Page 16

2.8 Safety during the operation of hydraulic machines

Hydraulic oil

• Hydraulic oil is harmful to health.

• Wear safety glasses and safety gloves when handling hydraulic oil.

• Avoid direct skin contact with hydraulic oil. Remove hydraulic oil from the skin im-

mediately with soap and water.

• Make sure that no hydraulic oil comes gets in the eyes or on the body. See a physician immediately if hydraulic oil gets into the eyes or is swallowed.

• Do not eat and drink while handling hydraulic oil.

• Make sure to have extreme cleanliness. Contamination of the hydraulic oil with dirt or

water can cause premature wear or failure of the machine.

• Dispose of left over and spilled hydraulic oil according to the applicable regulations for

environmental protection.

2.9 Maintenance

Maintenance work

Service and maintenance work must only be carried out to the ex

operating instructions. All other procedures must be performed by your Tomahawk Power

representative.

For further information, refer to chapter Maintenance.

tent described in these

Switching off the engine

Before carrying out care or maintenance work, switch off the engine and allow itto cool

down. For gasoline powered engines, you must pull off the spark plug cap.

Disconnecting the battery

For machines with electric starter, you must disconnect the battery before working on the

electronic parts.

Using only a Tomahawk Power battery

Use only Tomahawk Power batteries to replace defective batteries, see chapter

Technical Data.

Only the Tomahawk Power battery is vibration resistant and thus suitable for the high

vibratory stresses.

Operator’sManual 16

Page 17

Working on the battery

Always take the following safety measures when working with the battery:

• No fire, sparks, or smoking while working with batteries.

• Batteries contain corrosive acid. Use acid-proof protective gloves and protective

goggles when working with batteries.

• Avoid short circuits due to improper connection or bypassing with tools.

• Disconnect the negative terminal first when disconnecting the battery.

• Connect the positive terminal first when connecting the battery.

• Re-fasten terminal covers after connecting the battery.

Assembling safety devices

If it was necessary to dismantle safety devices, they must be reassembled and checked

immediately after completing maintenance work.

Always tighten loosened screw connections, complying with prescribed starting torque.

Handling operating fluids safely

Observe the following points when handling operating fluids, e.g. fuels, oils, greases,

coolants etc.:

• Always wear personal safety clothing.

• Avoid skin and eye contact with operating fluids.

• Do not inhale or swallow operating fluids.

• In particular, avoid contact with hot operating fluids. Burn and scalding hazard.

• Dispose of replaced or spilled operating fluids according to the applicable regulations

for environmental protection.

• If operating fluids escape from the machine, cease operation of the machine and have

it repaired immediately by your Tomahawk Power representative.

Operator’sManual 17

Page 18

1. Technical Data

Technical Data

TPC400Z

Operating weigh t

kg:

Forward/reverse speed

m/min:

Surface compaction

perform

Power transmission

Exciter

Vibrations

Centrifugal force

Multi grade oil

Oil quantity

Drive motor

Piston displacement cm3: 445

ance

2/h:

m

From drive engine directly to exciter unit via automatic

cent

Hz:

kN:

Shell Omala Oil 100

l: 0.8

Air-colled single-cylinder 4 stroke diesel engine

410

26

912

rifugal and V-belts

70

11250 lbs per sq ft

Engine speed

Rated power (*)

Fuel Diesel

Fuel consumption

Tank capacity

Oil SAE 10W40

Oil quantity

-1: 2850 -3060

min

kW:

l/h:

l:

l: 1,2

7.5

1,8

5,0

Operator’sManual 18

Page 19

Hydraulic control

Hydraulic oil Shell Omala Oil 100

Technical Data

TPC400Z

Oil quantity

l: 0,4

Special lubricating grase

LPA: 95 dB(A)

The weighted effec-tive

acceleration value, determined

2: 3,6

according to EN ISO 5349

Uncertainty K

m/s

2 1,0

m/s

(*) In accor

dance with the installed useful outlet power according to Directive 2000/14/EG.

Operator’sManual 19

Page 20

Page 21

Description

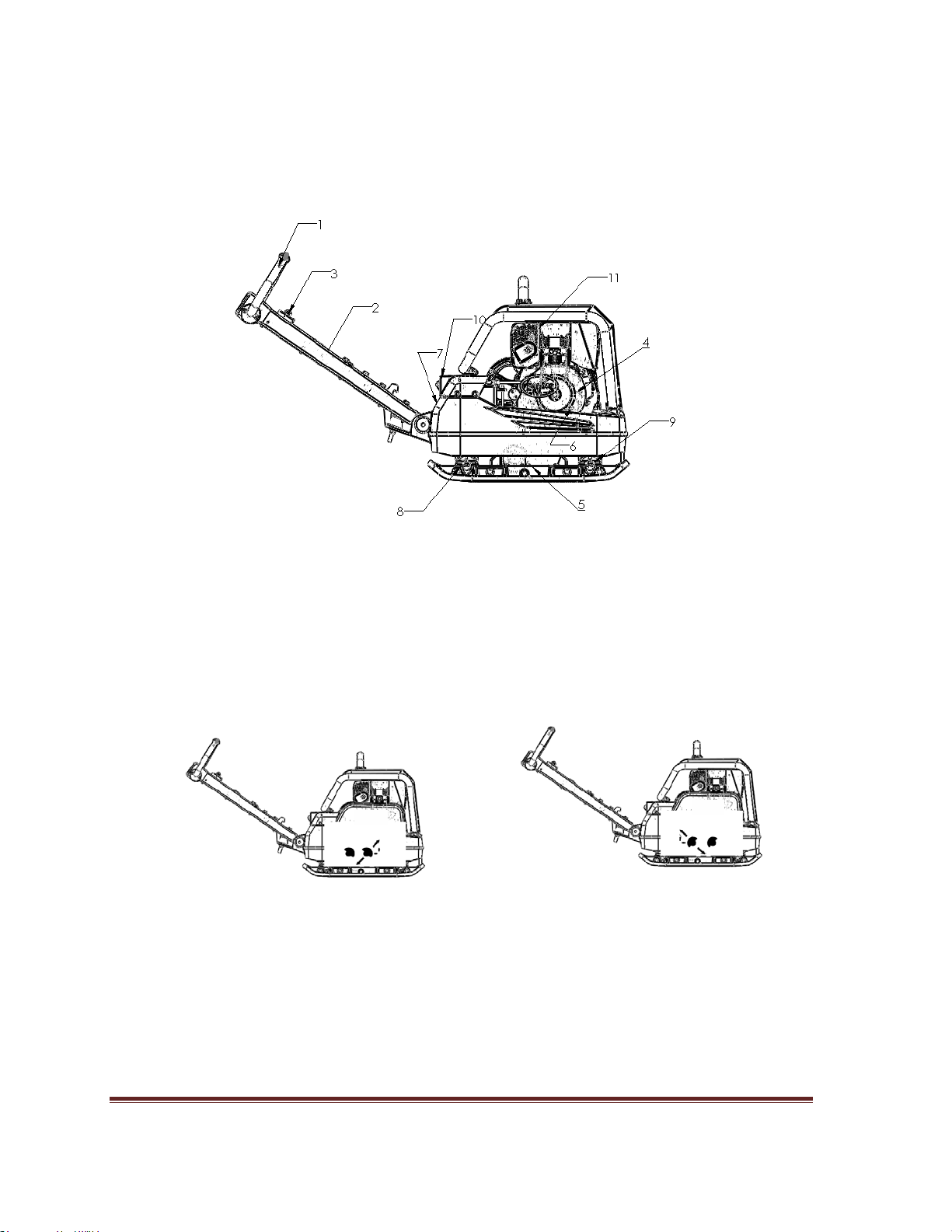

2.3 Description of function

.1

2.3

The vibration required for compaction is produced by the exciter (5) which is firmly joined

to the lower mass (8). This exciter (5) is designed as a central vibrator with aligned

vibrations. Such a principle permits the direction of vibration to be changed by turning the

eccentric weights. In this way an infinitely variable transition between vibration in forward

motion, at standstill and in reverse motion is possible. This process is hydraulically

controlled with the operating control handle (1) on the handle bar (2).

Forwards Reverse

2.3.2

transmitted by means of a friction connection through the centrifugal clutch (4) and the exciter Vbelt (6).

Operator’sManual 21

The drive engine (11) anchored to the upper mass (7) drives the exciter (5). The torque is

Page 22

2.3.3

2.3.4 The automatic V-belt pulley (13) combined with the centrifugal clutch

2.3.5 Moreover, the automatic V-belt pulley (13) automatically adapts to the V-belt flanks in

2.3.6 The speed of the drive engine (11) can be infinitely varied by remote control on the

The centrifugal clutch (4) interrupts flow of power to the exciter (5) at low engine speed

and thus permits perfect idling of the drive engine (11).

(4) Ensures optimum tension of the exciter V-belt (6) during operation and relief of the

tension of the exciter V-belt (6) when the machine is being relocated or transported.

line with the wear and thus makes the entire drive from the engine (11) to the exciter (5)

maintenance-free (see chapter Exciter V-belt).

throttle control lever (3). The upper (7) and lower (8) masses are connected to each

other by 4 vibration-damping rubber metal shock mounts (9). This damping system

prevents the very high frequencies from being transmitted to the upper mass (7). As a

result the function ability of the drive engine (11) is retained in spite of the high

compaction performance. The drive engine (11) works on the diesel principle; it is

started electrically by a pinion starter (10), draws in the combustion air through an air

filter, dry and is air-colled.

2.3.7 To facilitate the starting procedure (at very low temperatures, with hand start) the drive

engine (11) has an automatic decompression mechanism. It ensures that compression is

very low during the cranking operation but steadily increases after a few revolutions

when it then switches over to full compression.

Operator’sManual 22

Page 23

Transport to work site /Recommendations on

compaction

3. Transport to work site /Recommendations on compaction

3.1 Transport to work site

Conditions:

• To trans

bearing capacity of 500 kg.

• Always switch off engine before transporting the machine!

• Vertically set guide handle head and lock into place using the lock hook (41).

• Only attach suitable tackle at the central lifting point (40) provided. The central lifting point

is located exactly above the centre of gravity of the machine. The central lifting point can

be displaced rearwards (40), given an application in which the height of the machine is of

importance (torque wrench setting = 85 Nm).

Not

: Also observe the regulations in safety instructions.

e

port the vibration plate, only use suitable lifting equipment with a minimum load-

Operator’sManual 23

Page 24

3.2 Recommendations on compaction

3.2.1 Ground conditions

The maximum compaction depth depends on several factors relating to the ground

condition, such as moisture, grain distribution etc,

it is therefore not possible to specify exact values.

Recommendation: In each case determine the maximum compaction depth with

compaction tests and soil samples

3.2.2 Compaction on slopes

The following points are to be observed when compacting on sloped surfaces (slopes,

embankments):

• Only approach gradients from the bottom (a gradient which can be easily overco

upwards,

•

The operator must never stand in the direct

•

The maximum gradient of 25

can also be compacted downwards without any risk

A tilt in excess of this angle could lead to a stopping of the engine due to the

automatic low oil shut-off system. A restarting of the engine can only take place after the

valve lever at the oil filter housing has been actuated once.

.

o

must not be exceeded.

ion of descent.

).

me

Right !

Operator’sManual 24

Wrong!

Page 25

Operation

4. Operation

4.1 S

4.1.1 Conditions:

4.1.2 Once these points have been observed, you can start the engine as follows:

tarting

Oil:

Check oil level with oil dipstick, if necessary top up with Shell Omala Oil 100 through oil

filler neck.

Fuel:

When pouring diesel fuel into the filler neck (15), maintain absolute cleanliness. Impurities

in the fuel can cause breakdowns in the injection system and premature clogging of the

fuel filter.

Air filter:

Clean air filter dry, dusty conditions.

Turn the throttle control lever (3) clockwise into full load posit

1.

Push decompression lever upwards

2.

Pull the crank cable outwards from the casi

3.

After having engaged the automatic decompression system to the st

4.

engine wi

fires up.

5.

Stand beside the engine (feet slightly apart), viewing in the forward directi

6.

Place one hand on the machine an crank with t

7.

Keeps a firm hold of the crank while cranking in order to avoid the risk of

8.

Turn crank slowly at first until crank engages and then increase cranking spe

9.

As soon as the engine is running, remove crank

10.

Turn throttle control lever (8) into idling position, allow engine to warm up for 7 minutes

idling speed.

ll require five full turns of the crank until the engine regains its compressio

.

ng.

he other hand.

(24).

ion.

op position, the

on.

sudden slippage.

n and

ed.

at

Note: D

Operator’sManual 25

o not activate automatic decompression lever while the engine is running.

Page 26

Wait until the engine stops before repeating the starting procedure.

NOTICEImproper use can damage the compression lever.

If the engine does not start, proceed as follows before attempting to start again:

Press the compression lever down fully and then pull it up

1.

Start the engine agai

2.

n.

.

4.2 Mechanical oil pressure control

It is necessary to reactivate the mechanical oil pressure control in the following cases:

• After the initial filling - first filling - of the fuel tank or if the tank has run dry.

• In the case of an automatic engine stop due to an inefficient engine oil

•

After freeing the engine when in presence of extremely low temperatures

1.

Fill up fuel ta

2.

Check engine oil le

3.

To activate depress hand lever for approx. 5 seconds

4.

Hold down pin during approx. 5 seconds in the case of encapsulated engine versions

5.

Simultaneously actuate hand lever a few times in the case of engines equipped with fuel

pumps

6.

.

Complete engine. Check to see that encapsulating elements seal correctl

nk.

vel.

.

supply.

.

y.

.

control.

Check oil level every 8 to 15 operating hours in spite of the mechanical oil pressure

Operator’sManual 26

Page 27

4.3 Forward and reverse motion

The engine speed can be infinitely varied on the throttle control lever.

The direction of travel is determinate with the shift lever (6).

Depending on the position of the shift lever (6), the vibration plate compacts in forward

direction, at standstill or in reverse direction.

The forward and reverse speeds can be varied by selecting intermediate positions of the

shift lever (6) or the machine can be employed for particularly intensive compaction at

standstill.

4.4 Switching off

Never switch off the engine with the automatic decompression (2) as this inevitably results

in damage to the valve drive and decompression mechanism.

Move the throttle control lever (8) to the stop.

4.5 Compaction without extension plates

If the vibration plates are used without extension plates, screw set of protective screws (8

pes) into the threaded boreholes situated in the lower mass, in order to avoid threads from

being damaged.

Operator’sManual 27

Page 28

4.6 Additional notes on starting at very low temperatures!

Never use starting sprays or similar - they are forbidden because they are dangerous.

Only use original Wacker crank.

If cranking, is too slow, the engine can start running in the opposite direction of

rotation.

In this case the air is drawn in through the exhaust and the exhaust gases excape

through the air filter. Risk of fire! Switch off engine and start it again.

Free the engine by turning it approximately 10 to 20 times with the

decompression lever in a central position. Then the engine is

decompressed, but not ready to start. This intermediate position is used to

turn the engine "free" when at very low temperatures. The turning

resistance becomes appreciably lower owing to the change in viscosity of

the oil film. At the same time you will hear that the nozzle of the fuel

injection system is injecting cleanly (rattling).

At very low temperatures (below -5

o

C), use the starting oil dosing device.

Note: Do not use more than 2 doses as otherwise there is a risk

of crank back-swing.

Operator’sManual 28

Page 29

5. Maintenance

Maintenance

5.1 M

Check all external screw connections for tight fit appox. 8 hours alfter first operation.

Component Maintenance work Maintenance interval

Drive engine First oil change and filter.

Valve clearance

Air filter

Drive engine Check oil level, if nec. top up oil.

Centre pole height

setting, transport lock

V-belt Check V-belt, if. nec. replace.

aintenance schedule

Cold engine: Check valve clearance, and adjust if

necessary. Inlet valve 0,1 mm - outlet valve 0,2

mm.

Check dry type air filter - clean or replace filter

cartridge if necessary (pay attention to the

maintenance indication).

Regrease. weekly

approx. 8 hours after

initial start-up

daily

Protective frame

Check attachment screws for tight fit.

Tow-bar head Check oil level, top up if necessary.

Oil change, change oil filter. Keep cooling fins

Drive engine

Exciter Oil change.

Valve clearance

Fuel filter Change filter. every 500 h

free of dirt, clean dry. Retighten all accessible

screw connections.

Cold engine: Check valve clearance, and adjust if

necessary. Inlet valve 0,1 mm - outlet valve 0,2

mm.

monthly

every 250 h

Operator’sManual 29

Page 30

5.2 Engine oil

5.2.1 Check oil level:

• Check

• If the oil level is too low, top up with Fuchs Titan Unic 10W40 MC though the filler neck.

5.2.2 Changing the oil:

1. Let engine warm up.

Loosen oil dr

2.

Loosen fastening screws and place bracket over used oil container.

3.

4. Remove oil drain screw and pour oil into container.

5. Screw oil drain screw back in and refasten bracket.

6. Pour in 1,0 l of oil through the filler neck (19).

oil level with oil dipstick (15).

ain screw.

Take notice: Please pay attention to the corresponding environmental laws when

disposing of used engine oil. We recommend you carry the oil in a container to a central collecting

point for used oils. Do not pour used engine oil into the garbage nor into the sewer system, waste

pipes or even on the ground.

Operator’sManual 30

Page 31

5.3 Hydraulic control

5.3.1 Check oil level:

1. Move handle bar (23) into working position of 45 degree

2. Move the Shock handle bar (22) to full reverse position

3. Open filler bore (21).

4. Oil level must be at mark, if necessary top up with hydraulic oil Shell Omala oil 100.

5. Close filler bore (21).

Operator’sManual 31

Page 32

5.4 Exciter

5.4.1 Check oil level:

1.

Tilt the vibration pl

2.

Open fill

3.

The oil level must reach the start of the thread of the filler bore

4.

If necessary, pour in Shell Omala oil 100 through filler bore (use funnel 0.

Close filler bore. (Tightening to

5.

5.4.2 Changi

1.

Open fill

2.

Tilt vibration plate and keep it tilted until the oil

Place vibration plate in horizontal positi

3.

4.

Pour in 0.8 l Shell Omala oil 100 throu

5.

Close filler bore. (Ti

Do not pour in too much oil!

ate for 10 degree.

er bore (25).

.

8 l).

rque 100 Nm)

ng the oil:

er bore (30).

has run out.

on.

gh the filler bore.

ghtening torque 100 Nm)

Take notice: Please pay attention to the corresponding environmental laws when disposing of

used engine oil. We recommend you carry the oil in a container to a central collecting point for

used oils. Do not pour used engine oil into the garbage nor into the sewer system, waste pipes or

even on the ground.

Operator’sManual 32

Page 33

5.5 Exciter V-belt

It is not necessary to retighten the V-belt owing to the use of the automatic centrifugal

clutch.

Should the V-belt width fall below 15,5 mm the V-belt must be replaced.

5.5.1 Changing the exciter V-belt:

Remove belt guard (5) by removing the Bolt on both side

1.

Undo screw (3

2.

Remove the centrifugal clutch (31) from the engine along with belt (32) and rotate th

3.

xciter pulley for the trouble free operation

e

Change exciter V-bel

4.

Assemble the components in reverse order; make sure that the Bolt tighteni

5.

ch had attained to full torque limit.

clut

Do not oil or grease clutch components (will damage the graphite bushes).

0).

t (32).

s

e

ng the

Operator’sManual 33

Page 34

Faults

6. Faults

6.1 Forward speed too low

Cause Remedy

To little hydraulic oil in the centre pole

head.

Air in hydraulic control. Bleed system.

6.2 Reverse speed too low

6.3 No reverse motion

Cause Remedy

Top up hydraulic oil.

Mechanical Fault

Operator’sManual 34

Contact Tomahawk Power Service

Dept

Page 35

6.4 Loss of hydraulic oil

Cause Remedy

Leaks, Hydraulic hose defective

6.5 Engine does not start

Cause Remedy

Leak of Lubric ating Oil

Contact Tomahawk Power Service

Dept

Fill up with oil and actuate value lever

at oil filter housing once

Operator’sManual 35

Loading...

Loading...