Page 1

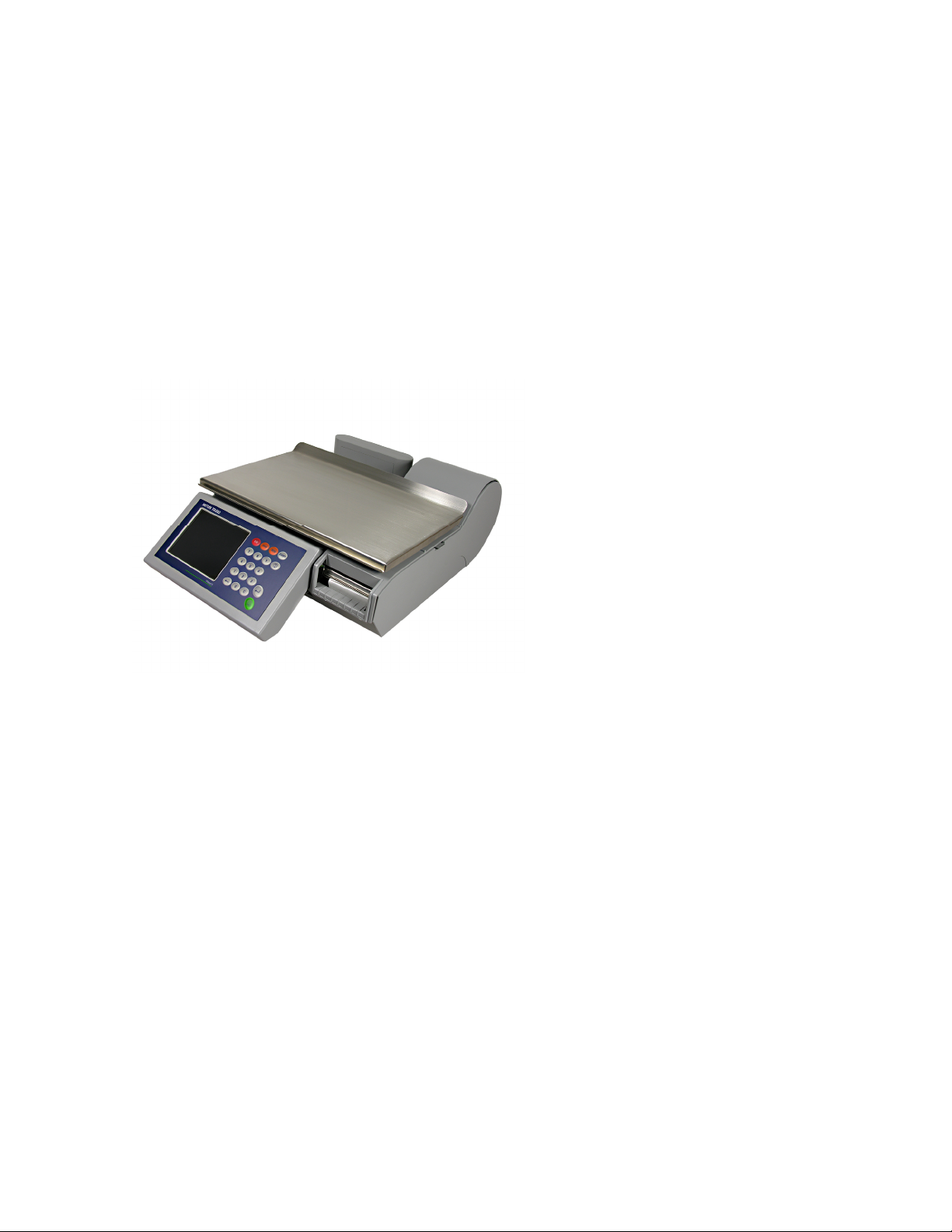

Impact S

Compact Scale

User’s Guide

®

64065336 R01

Page 2

©Mettler-Toledo, Inc. 2009

No part of this manual may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose without the

express written permission of Mettler-Toledo, Inc.

U.S. Government Restricted Rights: This documentation is furnished with Restricted Rights.

Page 3

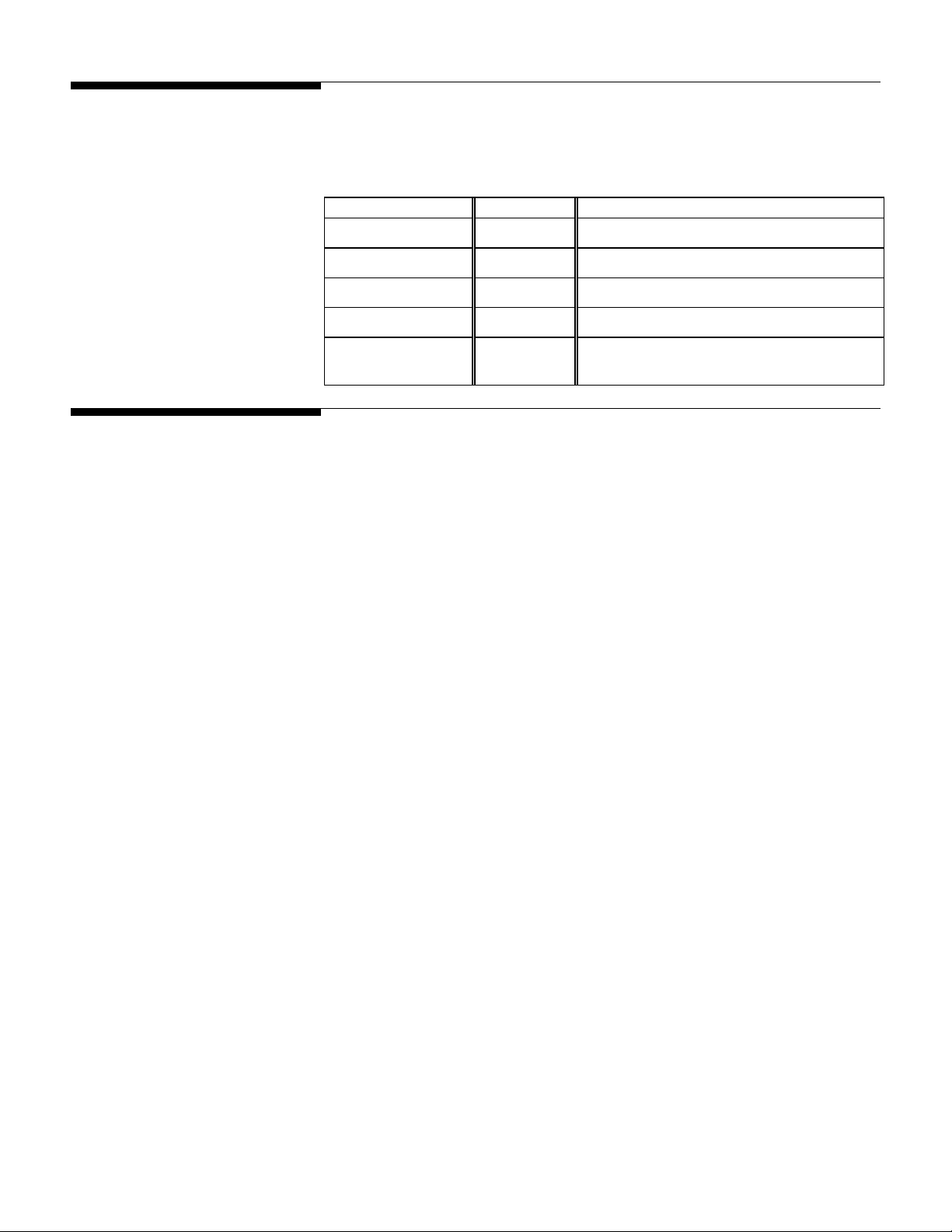

Publication Revision

History

Trademarks

Part Number Date Revisions

64065336 P01

64065336 P02

64065336 P03

64065336 R00

64065336 R01

METTLER TOLEDO® and Impact S® are registered trademarks of Mettler-Toledo, Inc.,

Columbus, OH, USA.

12/08 New manual

01/09 New GUI added throughout

03/09 Final revision 1 complete

05/09 Chapter 4 modified, Chapter 6 tables reworked

12/10 Formatting, text style changes, corrected

capacity specs in Chap 1.

Page 4

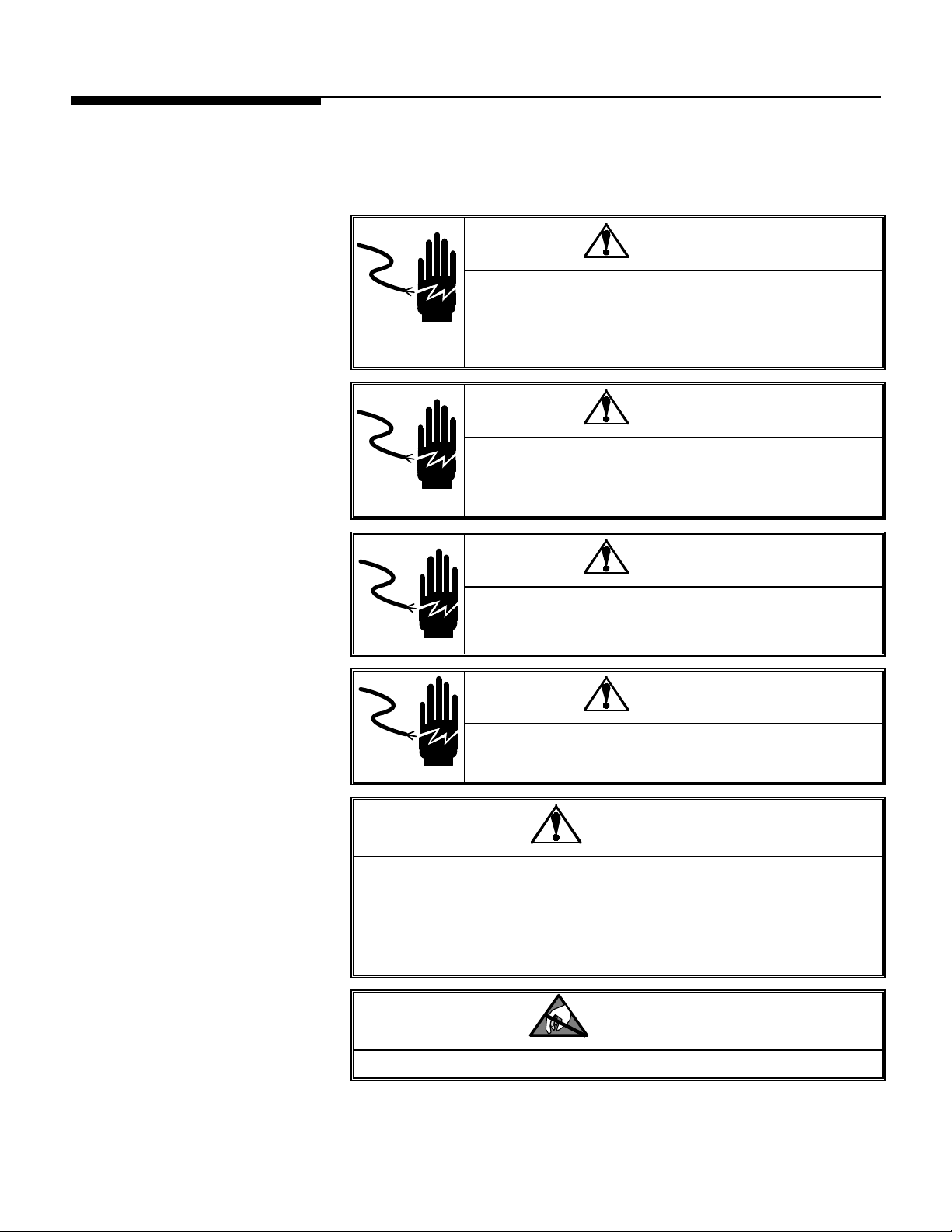

PRECAUTIONS

READ this manual BEFORE

operating or servicing this

equipment.

FOLLOW these instructions

carefully.

SAVE this manual for future

reference.

DO NOT allow untrained

personnel to operate, clean,

inspect, maintain, service, or

tamper with this equipment.

ALWAYS DISCONNECT this

equipment from the power

source before cleaning or

performing maintenance.

CALL METTLER TOLEDO

parts, information, and service.

METTLER TOLEDO

right to make refinements or

changes without notice.

®

for

®

reserves the

WARNING

ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THIS

EQUIPMENT. EXERCISE CARE WHEN MAKING CHECKS, TESTS AND

ADJUSTMENTS THAT MUST BE MADE WITH POWER ON. FAILING

TO OBSERVE THESE PRECAUTIONS CAN RESULT IN BODILY HARM

AND/OR PROPERTY DAMAGE.

WARNING

POWER OUTLETS MUST BE EASILY ACCESSIBLE AND LOCATED NO

FURTHER THAN THE LENGTH OF THE POWER CORD SUPPLIED

WITH THE PRODUCT. FAILURE TO DO SO COULD RESULT IN

PERSONNEL INJURY AND/OR PROPERTY DAMAGE.

WARNING

FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT

TO PROPERLY GROUNDED OUTLET ONLY. DO NOT REMOVE THE

GROUND PRONG.

WARNING

DISCONNECT & LOCK OUT ALL POWER TO THIS UNIT BEFORE

REMOVING THE FUSE OR SERVICING.

CAUTION

BEFORE CONNECTING OR DISCONNECTING ANY INTERNAL ELECTRONIC

COMPONENTS OR INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT,

ALWAYS REMOVE POWER AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY

CONNECTIONS OR DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE

PRECAUTIONS COULD RESULT IN DAMAGE TO, OR DESTRUCTION OF THE EQUIPMENT

OR BODILY HARM.

CAUTION

OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE DEVICES.

Page 5

CONTENTS

1 Introduction.................................................................................................... 1-1

General ..............................................................................................................................1-1

Specifications .....................................................................................................................1-2

Power Switch ......................................................................................................................1-3

Network Connection ............................................................................................................1-3

Leveling the Scale...............................................................................................................1-4

2 Operating Instructions..................................................................................... 2-1

Machine Configuration ........................................................................................................2-1

Keypad ...............................................................................................................................2-1

Operator Main Screen..........................................................................................................2-2

Customer Display Screen.....................................................................................................2-3

PLU Pricing Modes ..............................................................................................................2-4

By-Weight PLU....................................................................................................................... 2-4

By-Count PLU ........................................................................................................................ 2-4

Standard Pack PLU................................................................................................................. 2-4

PLU Screens .......................................................................................................................2-5

PLU Screen Details ................................................................................................................. 2-6

Calling Up PLUs ..................................................................................................................2-8

Printing Labels....................................................................................................................2-9

By Weight PLU....................................................................................................................... 2-9

By Count PLU ......................................................................................................................2-10

Standard Pack PLU...............................................................................................................2-10

Temporary Overrides .........................................................................................................2-11

Memory Mode...................................................................................................................2-12

3 Configuration ................................................................................................. 3-1

Introduction ........................................................................................................................3-1

Database ............................................................................................................................

PLUs..................................................................................................................................... 3-3

Extra Text .............................................................................................................................. 3-3

Nutrifacts............................................................................................................................... 3-4

COOL.................................................................................................................................... 3-5

Accumulators......................................................................................................................... 3-5

Clear..................................................................................................................................... 3-7

Reports ................................................................................................................................. 3-7

Action Code Text ....................................................................................................................3-8

Grade ...................................................................................................................................3-8

Group ................................................................................................................................... 3-9

Preset...............................................................................................................................

Select Page .........................................................................................................................3-11

Edit Page Name ................................................................................................................... 3-11

Swap Pages ........................................................................................................................ 3-12

Delete Pages .......................................................................................................................3-12

Program Preset .................................................................................................................... 3-12

Edit Preset Name.................................................................................................................. 3-14

Swap Preset ........................................................................................................................3-14

Delete Preset........................................................................................................................ 3-15

3-2

3-10

Page 6

Reaction.............................................................................................................................. 3-15

Edit Group Name.................................................................................................................. 3-15

Swap Groups....................................................................................................................... 3-15

Delete Groups......................................................................................................................3-15

Quick Edits........................................................................................................................3-16

Labels ..............................................................................................................................3-18

Assign Styles ....................................................................................................................... 3-18

Print Test Label .................................................................................................................... 3-19

Verify Labels........................................................................................................................3-19

Unit Setup.........................................................................................................................3-20

Time and Date ..................................................................................................................... 3-21

Language............................................................................................................................ 3-22

Backup/Restore.................................................................................................................... 3-23

Department.......................................................................................................................... 3-24

Scale Settings ...................................................................................................................... 3-25

Communication ...................................................................................................................3-29

Screen Calibration ................................................................................................................ 3-33

Set Home Screen.................................................................................................................. 3-34

Technician........................................................................................................................... 3-35

Printer Setup.....................................................................................................................3-39

Label Group......................................................................................................................... 3-40

Print Speed.......................................................................................................................... 3-40

Calibrate Gap Sensor, Calibrate Label Taken & Measure Label ................................................... 3-41

Type, Graphic format, Auto Size & Label Taken ........................................................................ 3-41

Label Length, Gap Length, Image Offset & Eject Length ............................................................. 3-41

Security............................................................................................................................3-42

Users.................................................................................................................................. 3-43

Security............................................................................................................................... 3-43

System Status ...................................................................................................................3-44

System Information............................................................................................................... 3-44

Log View............................................................................................................................. 3-45

Log Level ............................................................................................................................3-46

Marquee...........................................................................................................................3-47

Setup and Import Image........................................................................................................ 3-47

4 Labels............................................................................................................ 4-1

Loading Labels

Label Requirements.............................................................................................................4-4

Label Paper ...........................................................................................................................4-4

Label Stripping....................................................................................................................... 4-5

Finished Label Roll Requirements............................................................................................. 4-5

Finished Label and Roll Dimensional Requirements.................................................................... 4-7

Preprinted Labels

Special Shaped Labels ......................................................................................................4-10

Optical Densities...............................................................................................................4

Black Stripe Optical Density ................................................................................................... 4-11

....................................................................................................................4-1

................................................................................................................4-9

-10

5 Maintenance .................................................................................................. 5-1

Unit Cleaning......................................................................................................................

Printer Cleaning..................................................................................................................5-2

5-1

6 Appendix ....................................................................................................... 6-1

Page 7

Geo Index ...........................................................................................................................6-1

Country Currency Defaults

...................................................................................................6-3

Country Time Defaults .........................................................................................................6-4

Misc. Country Defaults

........................................................................................................6-5

`

Page 8

For your notes

Page 9

4

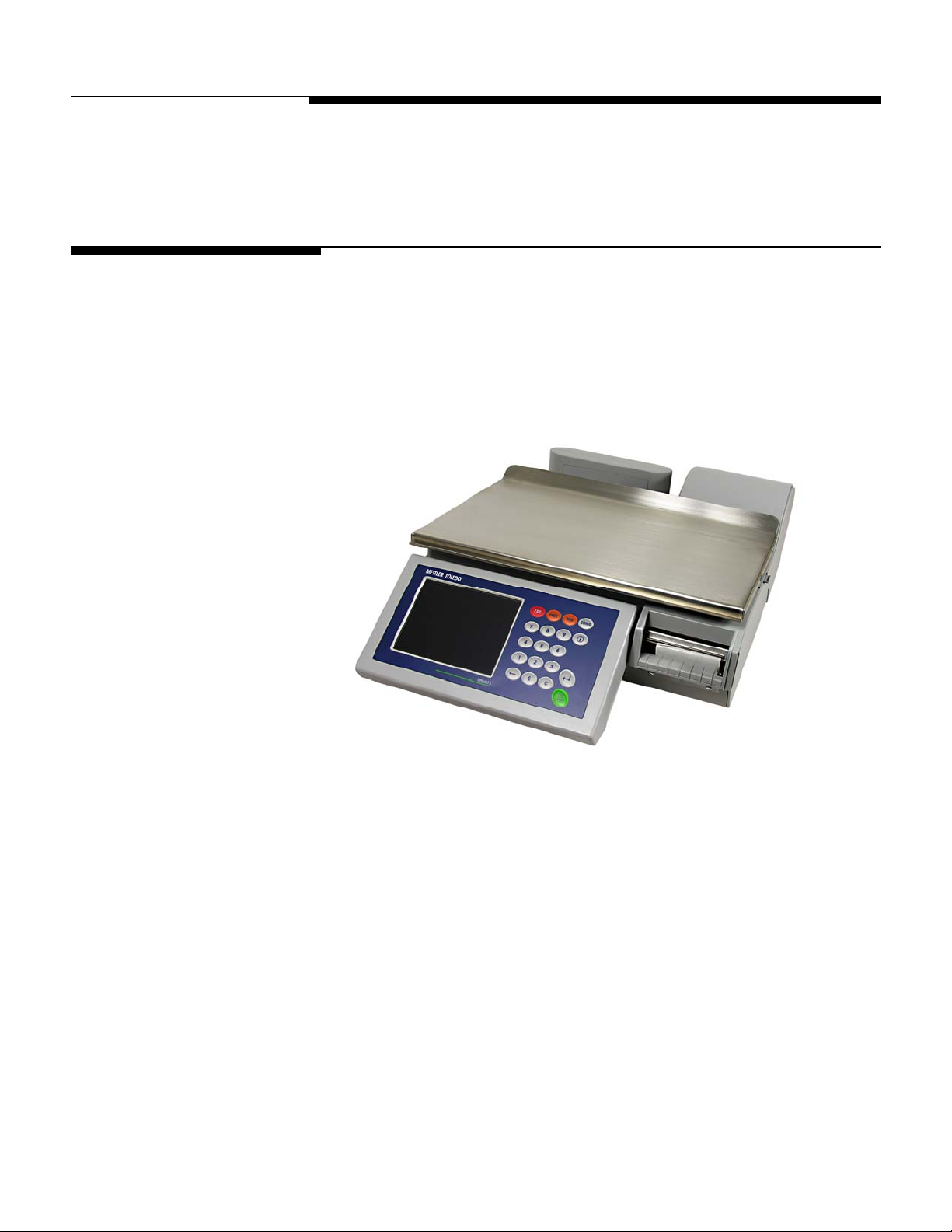

1 Introduction

General

Thank you for purchasing an Impact S® scale. Because Mettler Toledo designed the

Impact series for your current and future requirements, the Impact S

variety of operations and easily adapts to changing process and data requirements.

This flexibility protects your investment and helps you keep pace with rapidly changing

production and customer demands.

Chapter 1: Introduction

General

®

can handle a

METTLER TOLEDO

interface. All scales contain a built-in thermal label printer which is designed for quick

and easy roll changes. Also the Impact S

®

’s Impact S® scale offers very easy programming with a user friendly

®

provides touchscreen preset keys for easy

PLU look-up and a straightforward keypad for optimum operator control.

The Impact S

Impact S

and the highest impact in added value promotion, merchandizing, and cross-selling to

a consumer, the Impact S

®

is a low profile counter scale which provides unlimited connectivity. The

®

has an internal loadcell and customer rear display. Allowing easy readability

®

will change the way you do business!

1-1

Page 10

METTLER TOLEDO Impact S® User's Guide

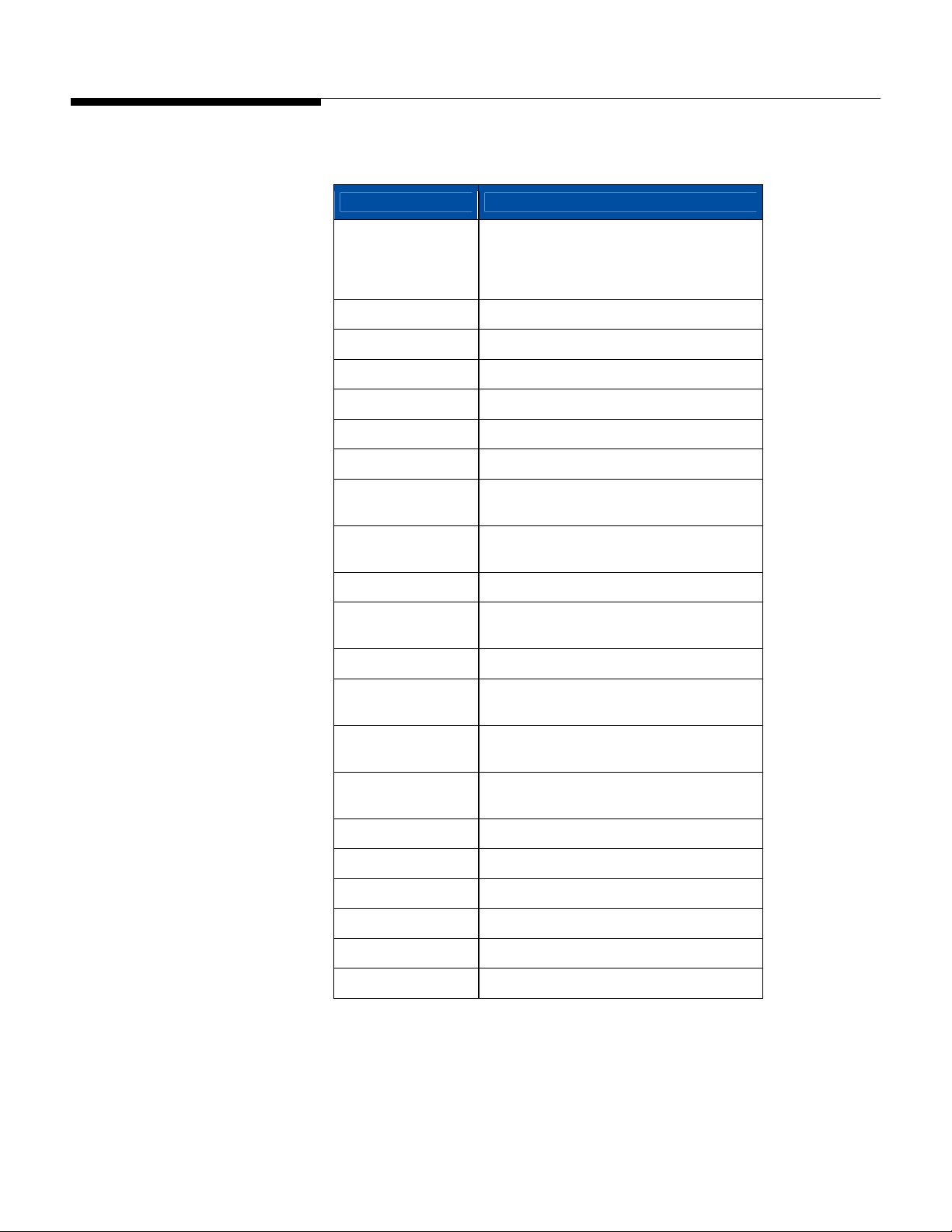

Specifications

Specifications

Description Specifications – Impact S

30 x 0.01 lb

Capacity x Division

Weighing Modes lb , kg, (single and dual interval)

Dimensions H: 5.875”, W: 15.35”, D: 17.5”

Platter Dimension W: 15.25” x D: 9.25” (10.0” counting lip)

Weight of Unit 23.5 lb (10.7 kg)

Shipping Weight 30.0 lb (13.7 kg)

Base Construction Plastic upper shell with cast-metal bottom

15 x 0.005 kg

6/15 x 0.002/0.005 kg

15/30 x 0.005/0.01 lb

Operator Display

Operator Keyboard /

Touchscreen

Customer Display Monochrome 240 x 240 LCD

Printer

Power 100-240 VAC, 50/60 Hz, 0.5A

Operating Temperature

Storage Temperature

Network Interface

Processor XSCALE

Memory Minimum 64 Megabyte SDRAM

Mass Storage Minimum 512 MB Compact Flash

Available Serial port External load cell

5.7” backlit Monochrome QVGA display with

tactile keypad

4 wire resistive Touchscreen

3” (72 mm paper, 80mm path),

up to 5”/sec, thermal - 6” roll capacity

0º C to 40º C, humidity

5% to 95% non condensing

-20º C to 70º C with humidity from

5% to 95% non -condensing

Ethernet 802-3 10/100

RF optional 802.11B/G

1-2

RJ13 External load cell power

USB Port For mouse, keyboard, USB flash drive, etc.

Page 11

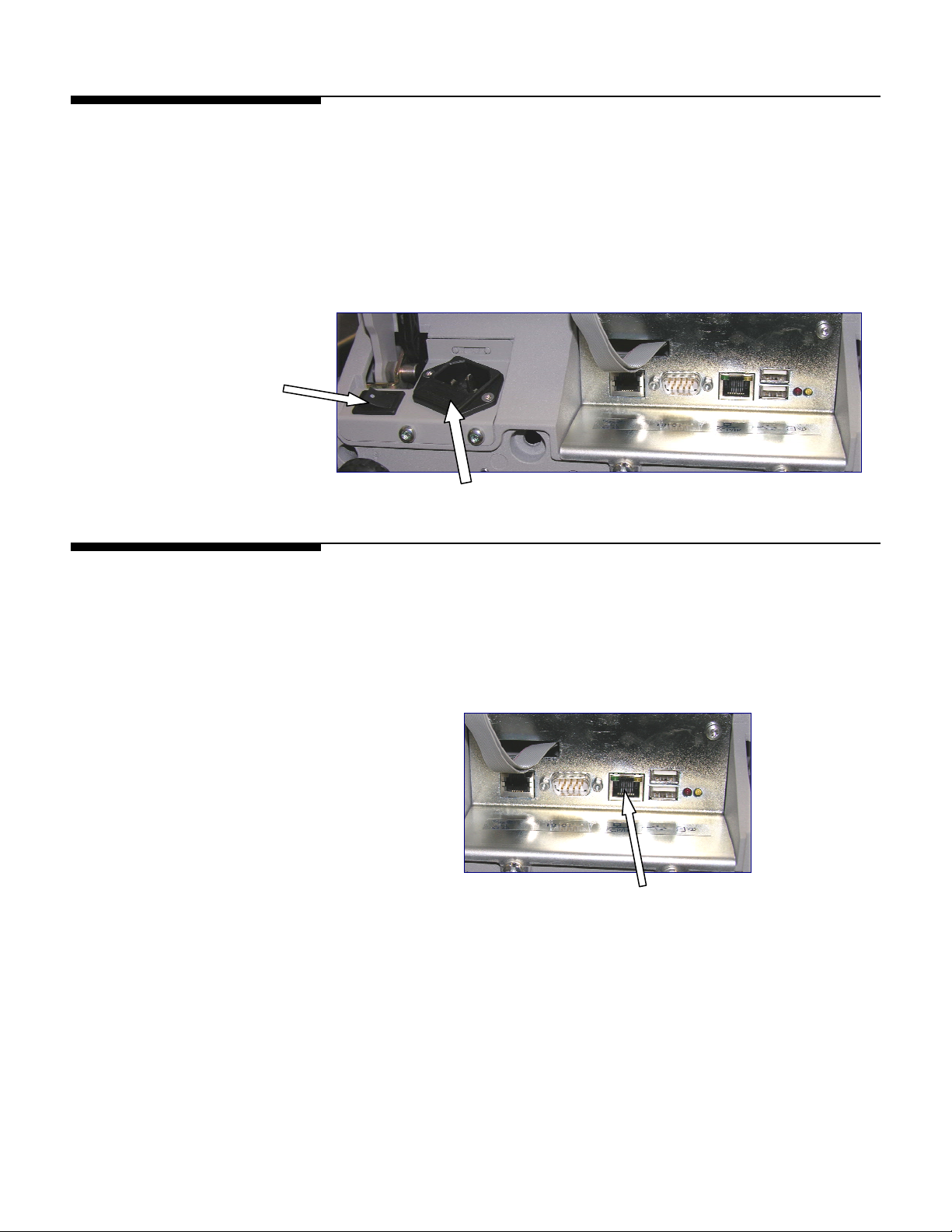

Power Switch

Power Switch

Chapter 1: Introduction

Power Switch

The power switch and power cord jack are located under the touchscreen on the left

front of the scale.

Press on the switch to turn the scale power to ON and again to turn the scale off (it is

a momentary switch, so don’t be alarmed when it doesn’t stay depressed – it’s not

supposed to). Always exit any editing screens before pressing the switch to turn power

OFF.

Always turn the scale off before cleaning.

Network Connection

Power Cord Jack

The Impact S® can connect to your Ethernet network using a cable or using a wireless

radio. If you use a wired network connection and experience connection problems,

make sure your Ethernet cable is connected and seated securely in the jack, located

under the touchscreen at the front of the scale.

Ethernet port

If you are using a wireless radio, it is built into the scale under an access panel situated

below the platter and spider on the left-hand side.

If the scale has a wireless card installed, do not connect an external Ethernet cable to

the Ethernet port. The wireless card will plug in to that slot instead.

1-3

Page 12

METTLER TOLEDO Impact S® User's Guide

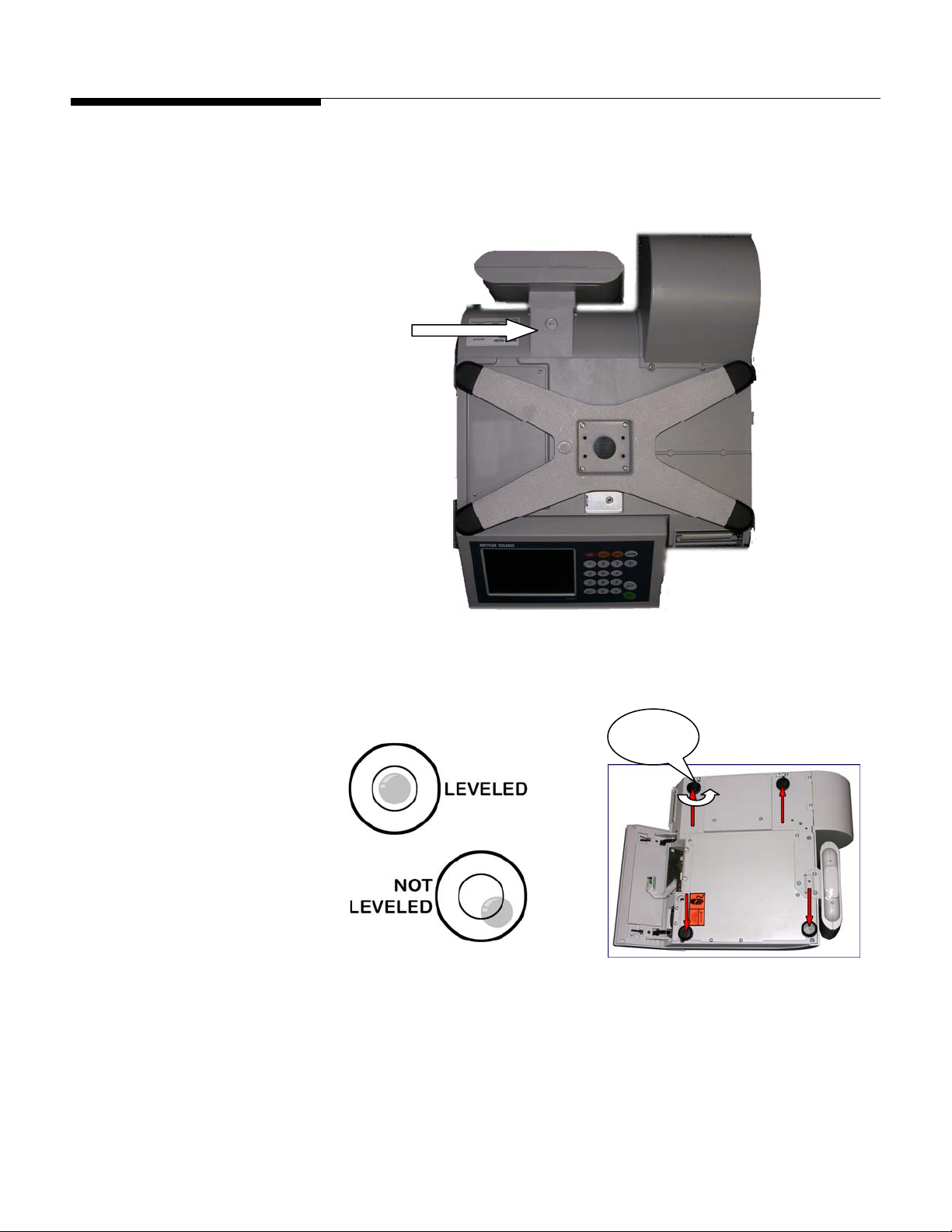

Leveling the Scale

Leveling the Scale

The Impact S

®

scale must be level and installed on a stable counter. The level indicator

is located behind the customer display, as shown below.

Level

Indicator

Level Indicator Location

The bubble in the indicator must be centered inside the circle. If the bubble is outside of

the circle on the indicator, use the four leveling feet to level the scale.

Leveling

Feet

The level indicator consists of

a bubble and two circles.

Center the bubble and the

scale will be level.

Rotate leveling feet clockwise

or counterclockwise to

determine a level platter.

1-4

Page 13

2 0BOperating Instructions

Machine Configuration

The main operator screen of the Impact S® consists of a keypad and display screen.

Chapter 2: Operating Instructions

Machine Configuration

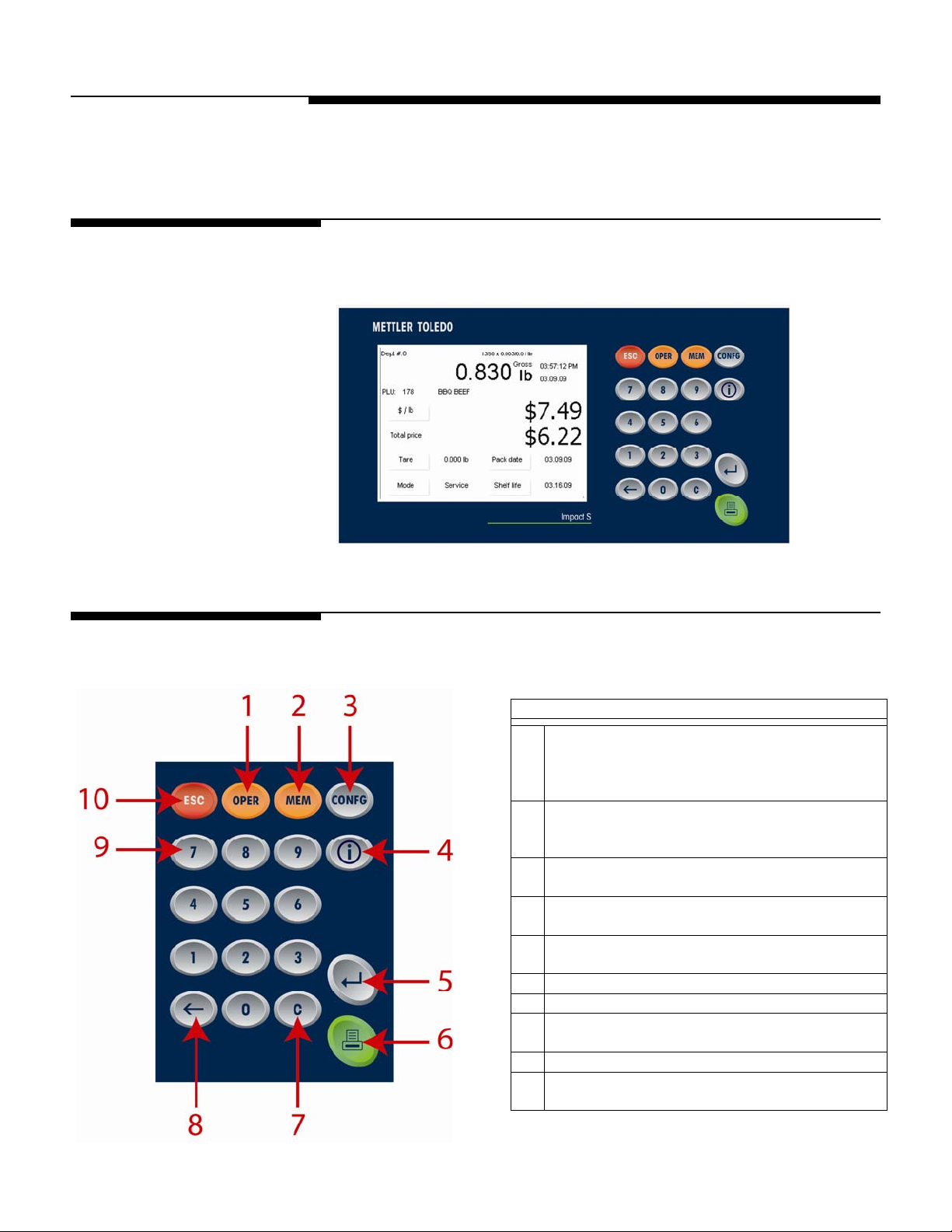

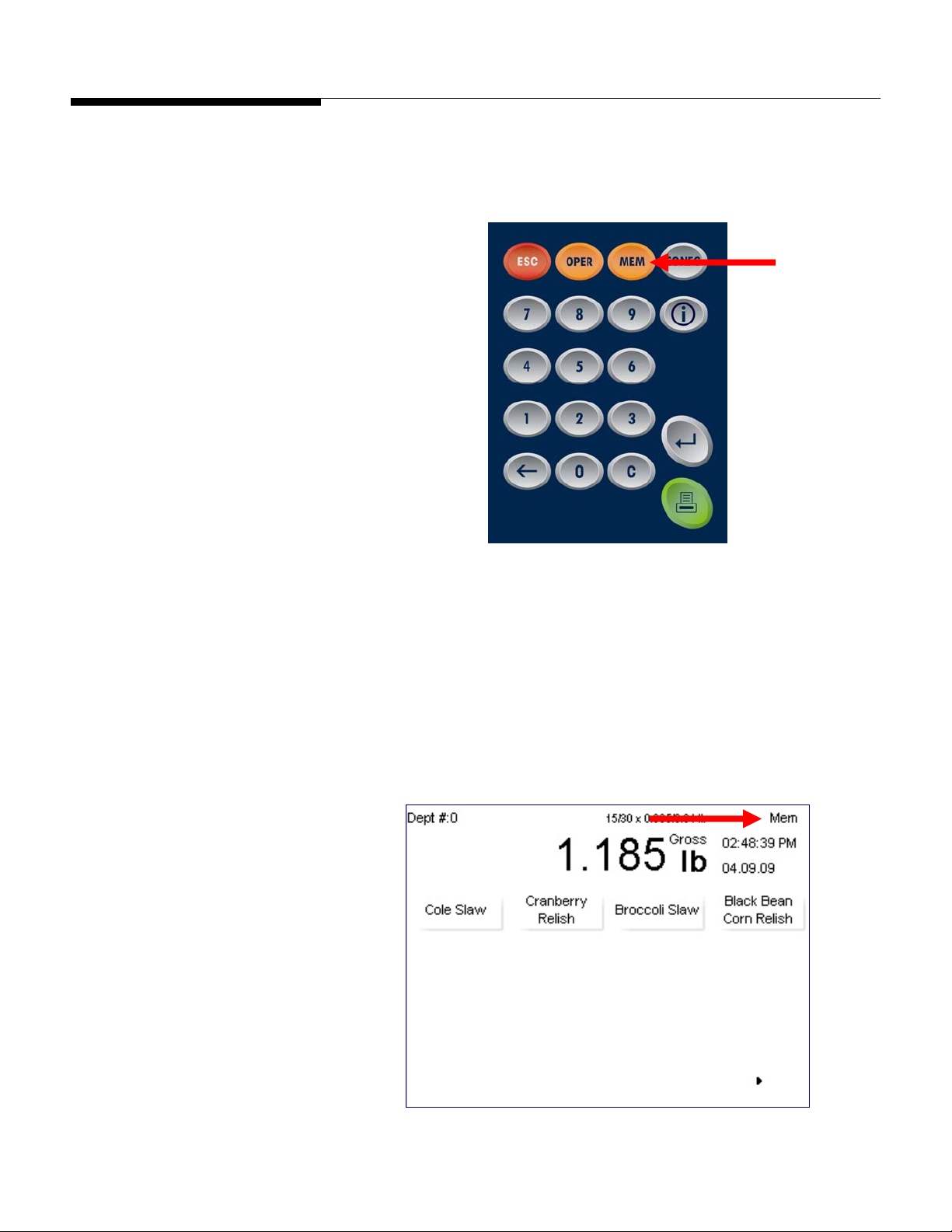

Keypad

The operator display screen will change based on what transaction is taking place.

1

OPER – Operator Key. Provides an operator menu

from the home screen for overrides. Also allows

edits to be made to the PLU by the Operator for the

current transaction ONLY.

2

MEM – Memory Mode Key. Places a transaction in

Memory Mode which collects multiple transactions

and prints them on one label.

3

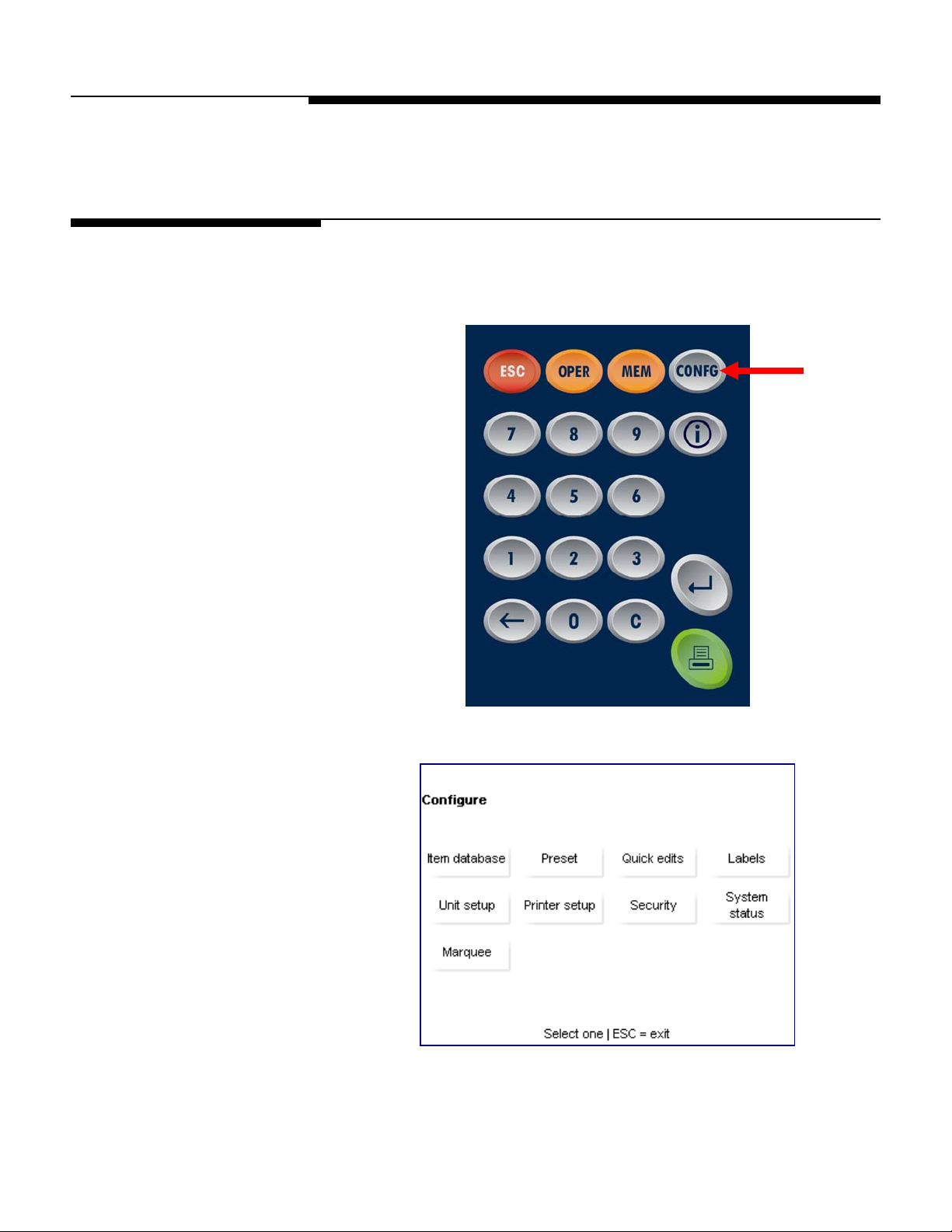

CONFG – Configuration key. Access to the

Configuration screen allowing scale setup.

4

Help key (i). Activates the help system specific to

the displayed screen (if applicable).

5

Enter Key. Accepts changes and returns to the

previous screen.

6

Print Key. Prints the label (if applicable)

7

C – Clear Key. Clears all data in the entry field.

8

Backspace Key. Used to erase digit to the left of the

cursor.

9

Number Keypad. Used to enter PLU and other data.

10

ESC – Escape Key. Quits and returns to the previous

screen without saving changes

Keypad Components

2-1

Page 14

METTLER TOLEDO Impact S® User's Guide

2

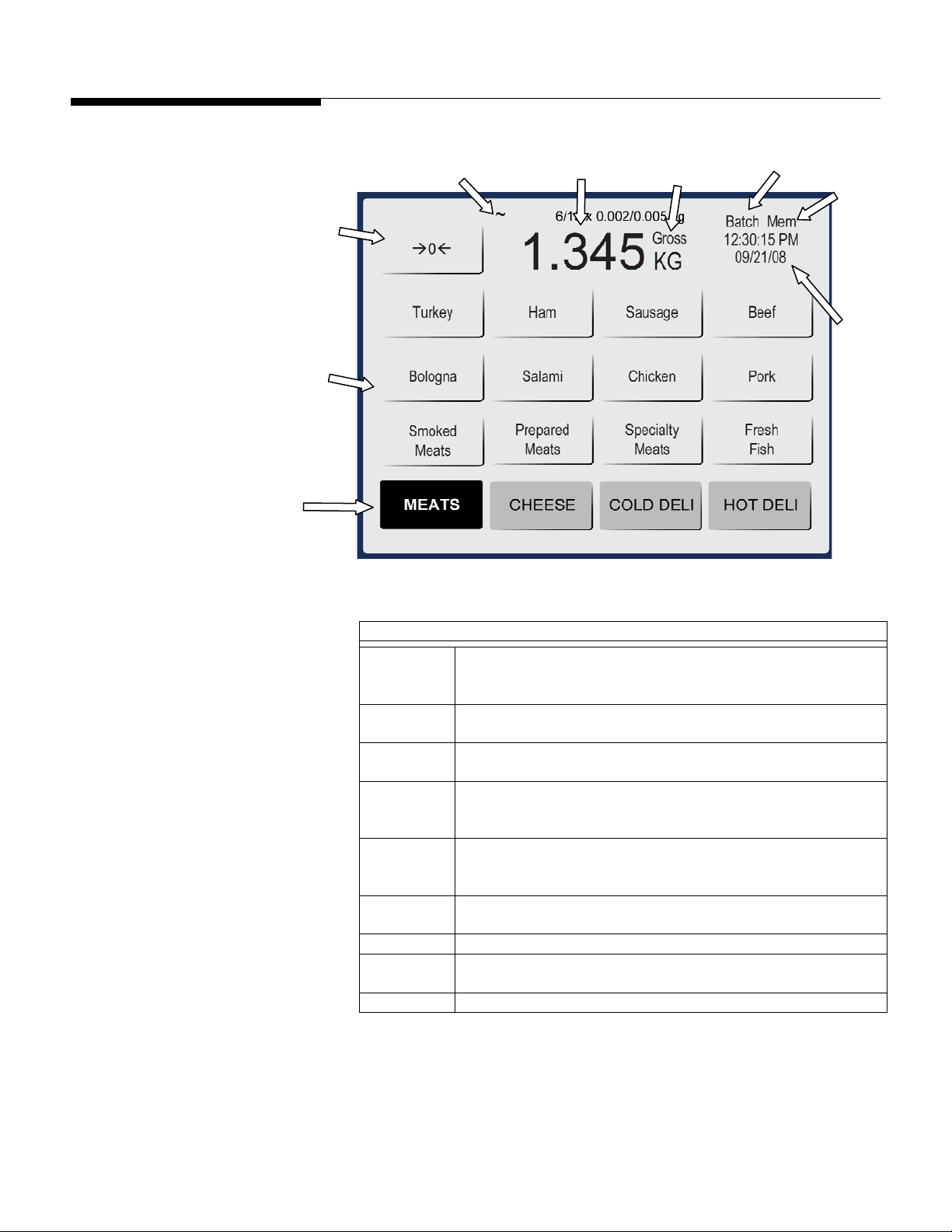

Operator Main Screen

Operator Main Screen

NOTE: the operator display is

a touchscreen. Simply press

the keys displayed on the

screen. But please, only use

fingertips to press on the keys.

DO NOT use any sharp

objects on the touchscreen.

This could cause permanent

damage to the touchscreen.

9

8

7

1

3

4

5

6

1

2

3

4

5

6

7

8

9

Motion/No motion. This symbol indicates that the weight on

the scale is fluctuating; when no symbol appears the weight on

the scale is stable.

Weight Display shows the current weight on the scale as well as

the unit of measure (kg/lb).

Net/Gross when NET displays, it indicates a tare weight has been

taken.

Batch is used to print multiple labels in one batch. When in this

mode, if any transactions are in queue, the word ‘Batch’ will

appear.

Memory (MEM) is used to store transactions for use in printing a

receipt-type label. When transactions are in memory, the word

MEM will appear.

Date and Time. Shows current date and time. The display format

can be set from Configuration.

Preset Page Buttons. Select the preset Page you wish to use.

Preset Keys. Used for one-touch calling of PLU records or, if the

key is linked to another page, touching will display that page.

Touch to Zero. Zeros out the scale.

Operator Main Screen Components

2-2

Page 15

Customer Display

Screen

Chapter 2: Operating Instructions

Customer Display Screen

The Customer Display can show different display screens based on the operation mode

the scale is in. The different options are By Weight PLU, By Count PLU, Standard Pack

PLU, Weight Displayed/Weight at Zero/No PLU and Weight at Zero/No PLU with a

marquee message.

Customer Display – By Count PLU display

2-3

Page 16

METTLER TOLEDO Impact S® User's Guide

PLU Pricing Modes

PLU Pricing Modes

11BBy-Weight PLU

PLU is an abbreviation for Price Look Up. The PLU is a reference number assigned to a

product's record including fields such as the description, price, tare, etc.

Different PLU's will have different pricing modes. Meat is normally sold "By Weight" by

the pound or kilogram. Many bakery products are sold "By Count". Other products may

be sold in a standard package that all weigh the same (or assumes all weight is the

same or a minimum value). The different pricing modes are as follows –

Examples of products sold By Weight are meats, cheese, poultry, and produce. ByWeight items can be priced in three ways:

Priced "Per Pound/kilo" - Typically weighed items are priced per pound. The weight

multiplied by the unit price equals the total price of the product.

Priced "Per Fraction of a Pound/100g" (fractional) - The item may also be priced

by the fraction of the pound (where legal and desired). Pricing per 1/4 pound and

per 1/2 pound are available. Kilos are not interchangeable for pounds in this

mode.

12BBy-Count PLU

13BStandard Pack PLU

"Pounds/kilos for price" - The PLU may be sold with a pounds-for-price (rather

than price per pound). For example, “2 pounds for $1.00” rather than

“$0.50/pound.”

Examples of items sold by the count are cookies, donuts, rolls, bread, etc. Example: 4

Apples for $0.69. The By-Count PLU allows the operator to use the scale to print labels.

Pricing is entered as a certain quantity of items for a set price. If the total weight for the

items is needed, a weight field can be configured on the label to print the weight of the

items in addition to the By-Count information.

Examples of items sold by Standard Pack include whole chickens, sheet cakes, bread,

etc. The Standard Pack PLU is similar to By-Count and also allows the operator to print

labels. These labels indicate the net weight and total price of the item. These types of

items all weigh the same (or are assumed to weigh the same or of a minimum value).

2-4

Page 17

PLU Screens

Chapter 2: Operating Instructions

PLU Screens

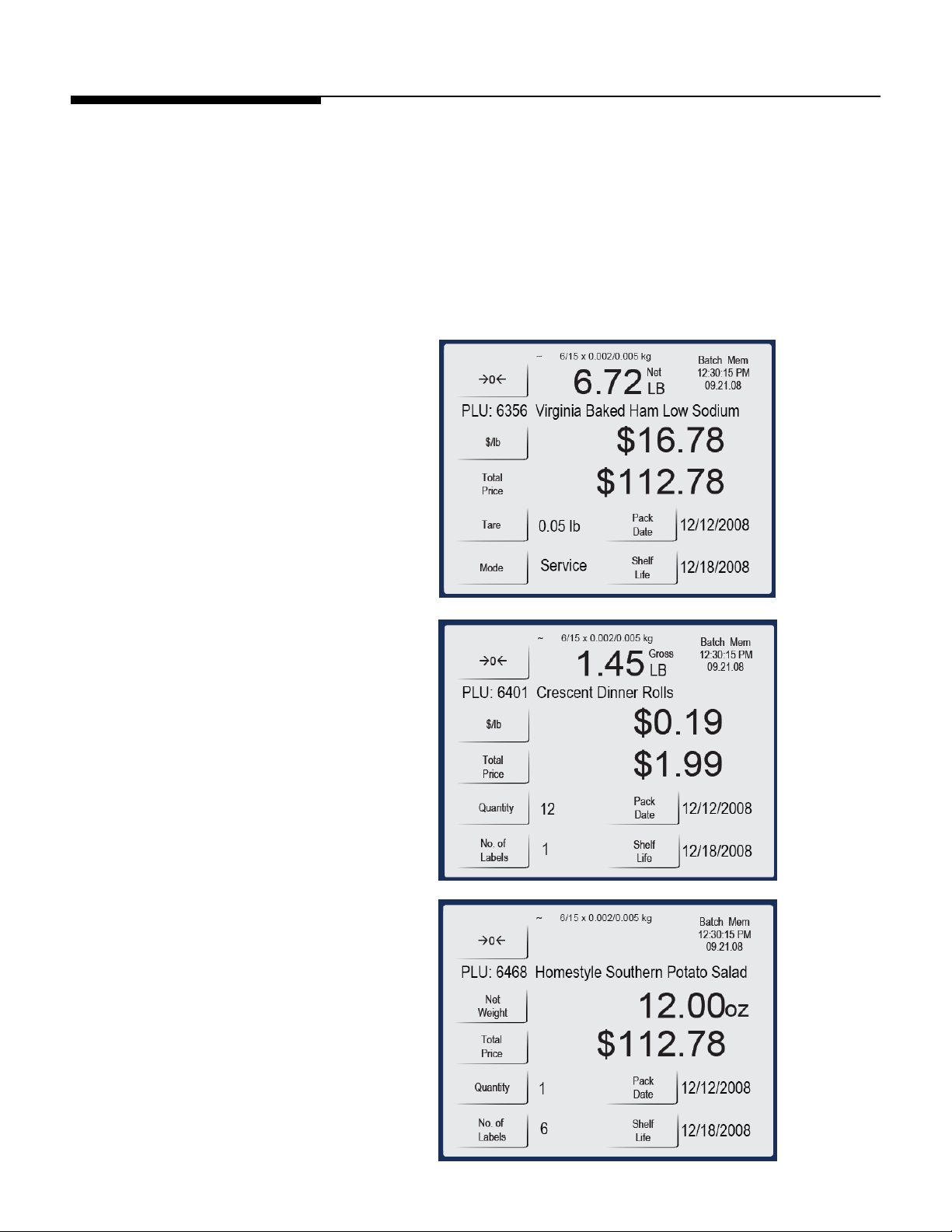

The PLU screen will vary based on the type of PLU that is being displayed: By Weight,

By Count or Standard Pack.

On the PLU screen, if a value field has a border it can be changed for that transaction.

Override the values by touching the box and selecting/entering new values. Note: this is

only a temporary override for this transaction only and the values will revert to the

original the next time the PLU is called.

If the field has no border the value cannot be changed, as determined by Setup

Configuration.

By Weight

By Count

Standard Pack

2-5

Page 18

METTLER TOLEDO Impact S® User's Guide

8

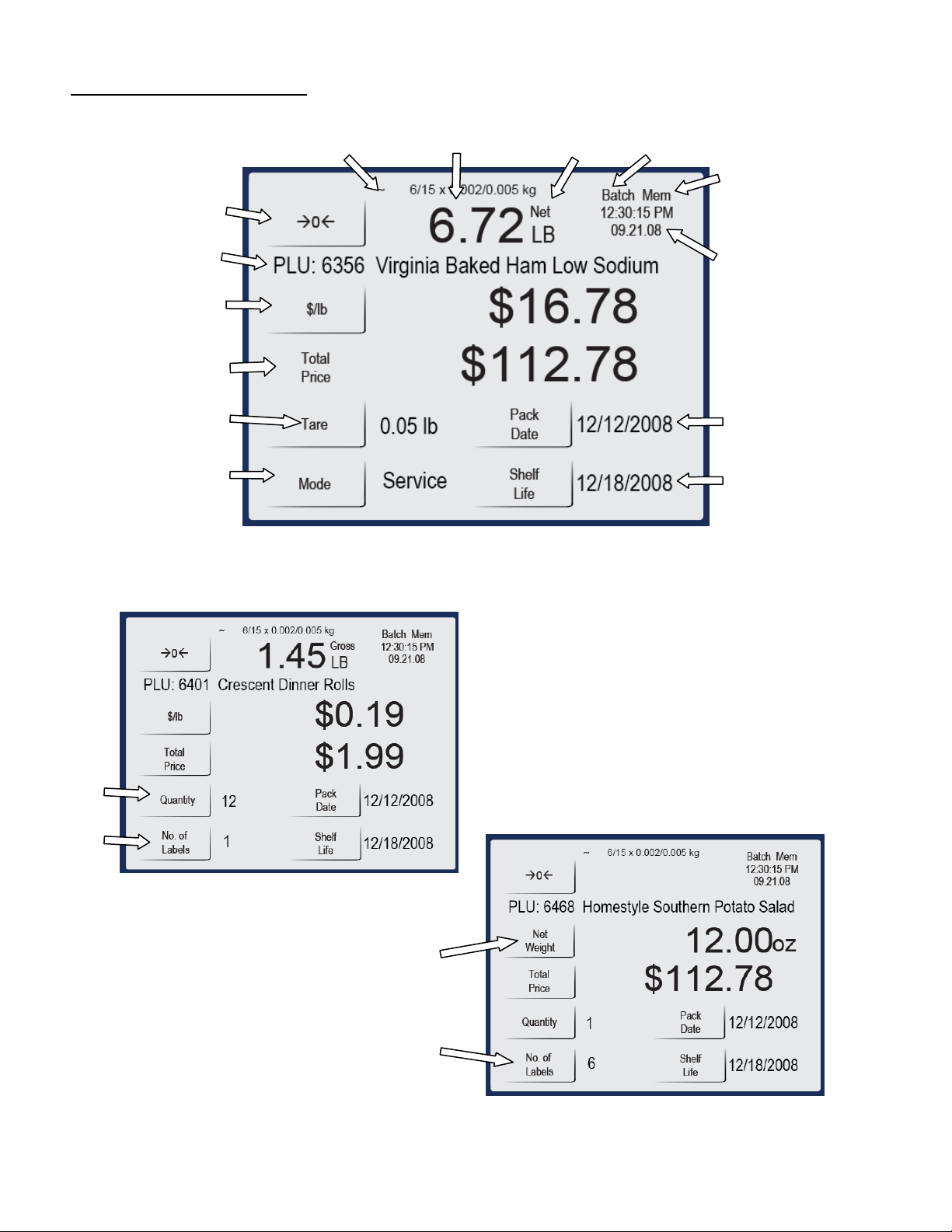

PLU Screens

14BPLU Screen Details

1

2

3

4

14

13

5

6

12

11

10 7

9

PLU By-Count

PLU By-Weight

NOTE: you can find the corresponding chart on

the following page.

15

16

PLU Standard Pack

17

16

2-6

Page 19

Chapter 2: Operating Instructions

PLU Screens

1

Motion/No motion. When this symbol appears the weight on the scale is fluctuating; when no

symbol appears the weight on the scale is stable.

2

Weight Display shows the current weight on the scale as well as the unit of measure (kg/lb). This

is used to calculate the Total Price.

3

Net/Gross when NET displays, it indicates a tare weight has been taken.

4

Batch is used to print multiple labels in one batch When in Batch mode with transactions in queue,

the word Batch will appear.

5

Memory (Mem) is used to store transactions for use in printing a receipt-type label. When

transactions are in memory, Mem will appear.

6

Date and Time. Shows current date and time. The display format is set by the configuration.

7

Pack Date displays the current date.

8

Shelf Life displays the date programmed into the PLU. The item should NOT be consumed or sold

beyond this date.

9

Mode states the mode of Operation: Service, or PrePack.

10

Tare displays the tare value assigned to the PLU transaction.

11

Total Price of the item. If the item is sold by weight, this is the unit price multiplied by the weight of

the item. The Total Price is never operator accessible.

12

Unit Price is programmed into the PLU record. If allowed, touch to override. This is used to calculate

the Total Price.

13 PLU number and description.

14

Touch to Zero. Zeros out the scale.

15

Quantity shows how many is in the PLU’s count.

16

Number of Labels displays how many labels will be printed.

17

Net Weight the weight of actual goods, excluding packing materials. The scale will automatically

determine Kg or Lb or Count depending on the PLU item type.

PLU Screen Components

2-7

Page 20

METTLER TOLEDO Impact S® User's Guide

Calling Up PLUs

Calling Up PLUs

When the Impact S® is in Service Mode, the operator screen will display the active

department’s Preset Pages and Preset PLUs.

Note: “Service Mode” is normally the default on the PLU Edit screen. After the product

has been weighed, a label has been printed, and the item has been removed from the

scale, the PLU will clear and the scale will return to the home screen, ready for the next

item.

To begin a transaction, place the item on the weighing tray (can be done after a PLU is

called up).

Call up the PLU (Price Look Up) Record. To do this, find the Preset PLU related to the

product, it may be a By Weight, By Count or Standard Pack item(s). You may also

directly enter the PLU number in order to bring a particular PLU’s data to the screen.

Note: Remember some PLU buttons can link into another page of related items, so you

may need to drill down to find your item’s PLU. Or check that the scale is displaying the

right Preset Page or category for desired PLU. These Preset Page buttons are along the

bottom of the screen and represent PLUs grouped into categories or departments. The

current Preset Page shows a black button, along the bottom. Switch Preset Pages by

touching the desired button.

Once you locate the PLU button touch it to get a detailed PLU screen. The screen will

vary slightly in appearance depending on whether it is By Weight, By Count or Standard

Pack.

Depending on how the PLU has been set up you may be able to edit some of the values

for this current selection. If allowed change items such as Shelf Life, Tare, etc by using a

Temporary Override (see this chapter’s Temporary Override section for details).

2-8

Page 21

Printing Labels

15BBy Weight PLU

Chapter 2: Operating Instructions

Printing Labels

Once the By Weight PLU has been called up, make any needed changes, and then

press the Print button on the keypad to print a label.

Take the label and remove the item from the scale to complete the transaction.

NOTE: the By Weight screen may also look different based on if the scale is set up for

weighing units in kilograms (kg) or in pounds (lb). Regardless of weighing standard,

the By Weight the label printing process is the same.

2-9

Page 22

METTLER TOLEDO Impact S® User's Guide

Printing Labels

16BBy Count PLU

Once the By Count PLU has been called up, make any needed changes, and then press

the Print button on the keypad to print a label.

Note: if the count is different than what is programmed into the PLU record, press the

Quantity box, change the quantity of the item using the keypad and press Enter, and

then press the Print key to print the label.

17BStandard Pack PLU

Take the label and remove the item from the scale to complete the transaction.

When a Standard Pack PLU has been called up, make any needed changes, enter the

number of labels needed, and then press the Print button on the keypad to print the

label(s).

Note: if the count is different than what is programmed into the PLU record, press the

Quantity box, change the quantity of the item using the keypad and press Enter, and

then press the Print key to print the label.

2-10

Take the label and remove the item from the scale to complete the transaction.

Page 23

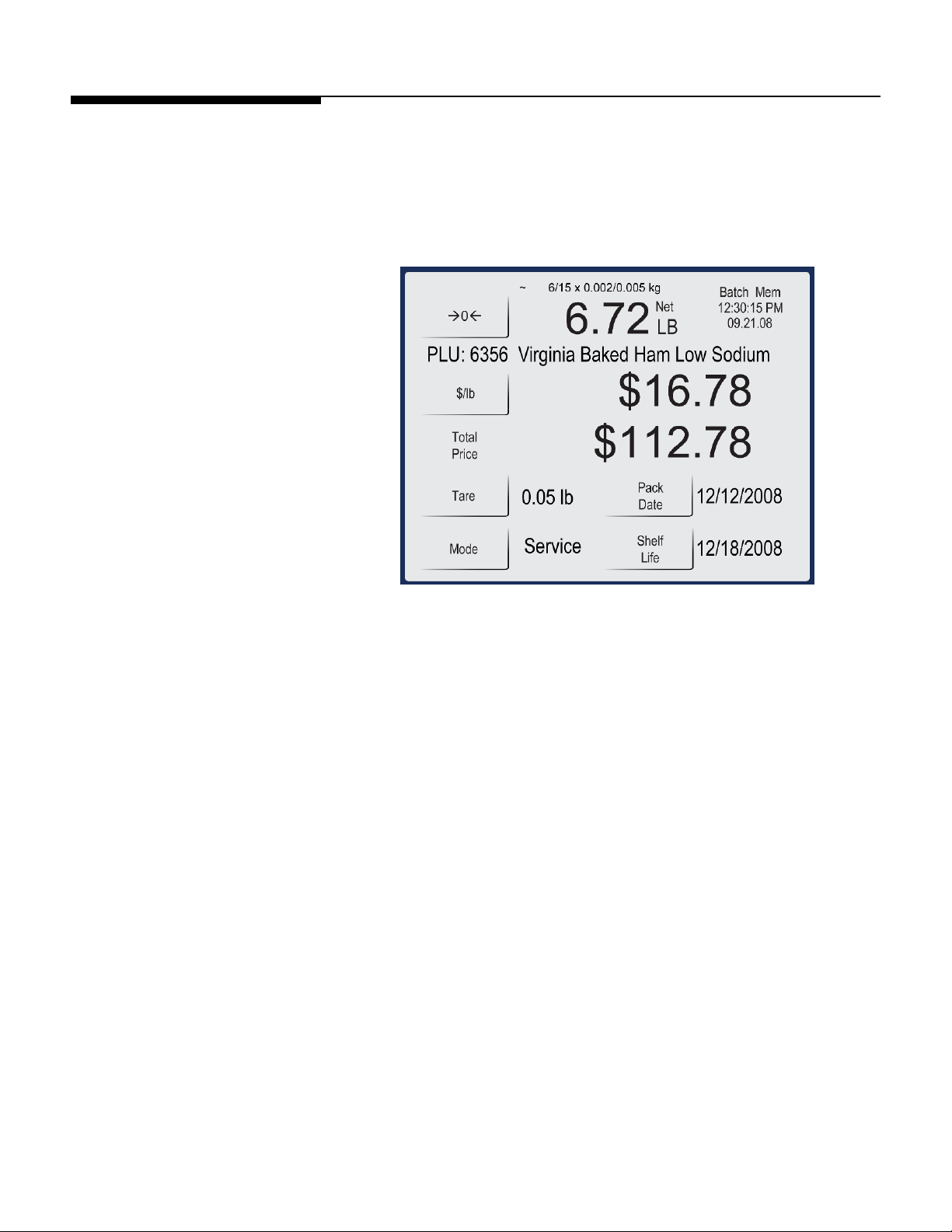

Temporary Overrides

Chapter 2: Operating Instructions

Temporary Overrides

Temporary Overrides are certain values can be adjusted for the current transaction only

from within the PLU screen. The changes are temporary and will not be retained in the

original PLU.

If a value can be changed a button will appear around the value. This indicates that the

value can be changed during a transaction.

In the PLU screen above, the Unit Price ($/lb), Tare, Mode, Pack Date, and Shelf Life,

have buttons, indicating they can be changed. The Total Price field does not have a

button and cannot be changed. There is also a button graphic around the Touch to Zero

field, but that does not indicate a changeable field, but rather an interactive one.

To change a value, touch the field. Then depending on the field: enter a numeric value

in the pop-up window using the keypad, toggling to a different within the selected field,

or if there are multiple choices, a new screen will appear and a selection can be made

from that screen.

As always, additional overrides can be found by pressing the OPER button on the

keypad.

2-11

Page 24

METTLER TOLEDO Impact S® User's Guide

Memory Mode

Memory Mode

When the user processes a Memory Mode transaction, he presses the MEM key instead

of the Print key. This will store the transaction data into Memory Mode and return the

user to the Home screen.

If a PLU is added to MEMORY that already exists in MEMORY, it is treated as a separate

entry. This means that it is possible to have multiple transactions associated with the

same PLU.

Making use of items stored via Memory function is simple. Begin with the scale at the

home screen and press the MEM key to bring up a dedicated MEM array. The user will

find Subtotal, Remove Item and Clear MEM keys available.

In order to make use of data, the user will need to press the Subtotal key. From there,

they will select their MEM entry and press Print when ready.

NOTE: When a PLU is added to MEMORY, the word MEM will display on the main

screen alerting the operator to the presence of data in the MEMORY queue.

2-12

Page 25

3 Configuration

Introduction

Setup for the Impact S® is controlled from the Configure screen. This is accessed by

pressing the gray CONFG button on the Operator keypad.

Chapter 3: Configuration

Introduction

From here the Item Database, Preset, Quick Edits, Labels, Unit Setup, Printer Setup,

Security, System Status and Marquee settings can be accessed and modified.

3-1

Page 26

METTLER TOLEDO Impact S® User's Guide

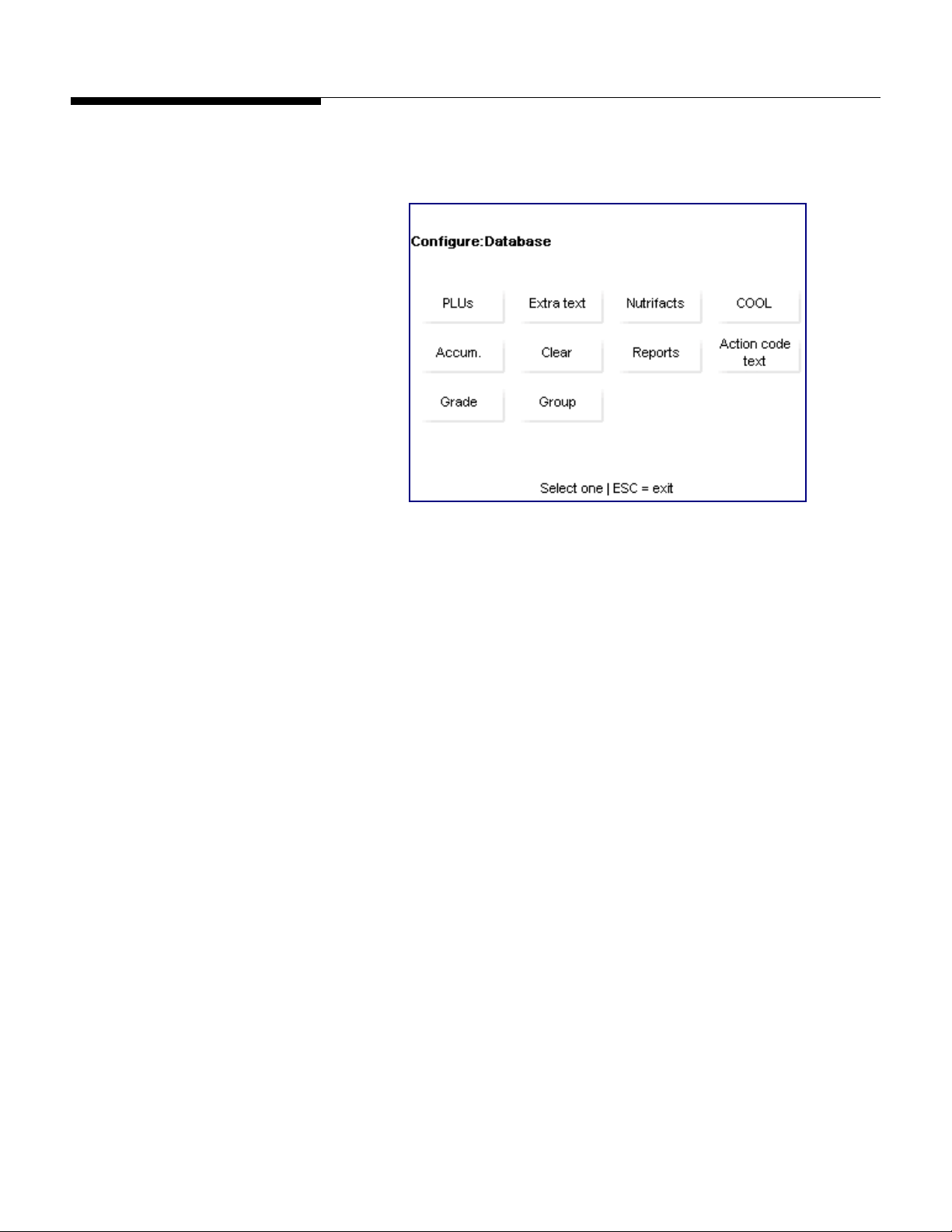

Database

There is extensive database support built into every Impact-S scale. The Database

menu allows for the viewing and editing of various item parameters.

This array of buttons allows the user to access data specific to the listed topics. Through

the use of this cascade, the operator may add, edit, view and delete many of the

parameters that differentiate PLUs as well as review the totals and transactions that have

occurred.

PLUs – this button takes the user to a very specific list of editable PLU features

Extra Text – used to view and edit the Extra Text displayed with a PLU

Nutrifacts – allows enabling/disabling of the embedded PLU nutrifacts

COOL – change, force or disable COOL data on a per-PLU basis

Accumulators – view and modify the accumulator lists

Clear – used to delete entries from various databanks

Reports – allows viewing of the various unit reports

Action Code Text – enable, disable, add or modify action text

Grade – used to edit or add grade information to PLU entries

Group – used to edit or add groups to the database

3-2

Page 27

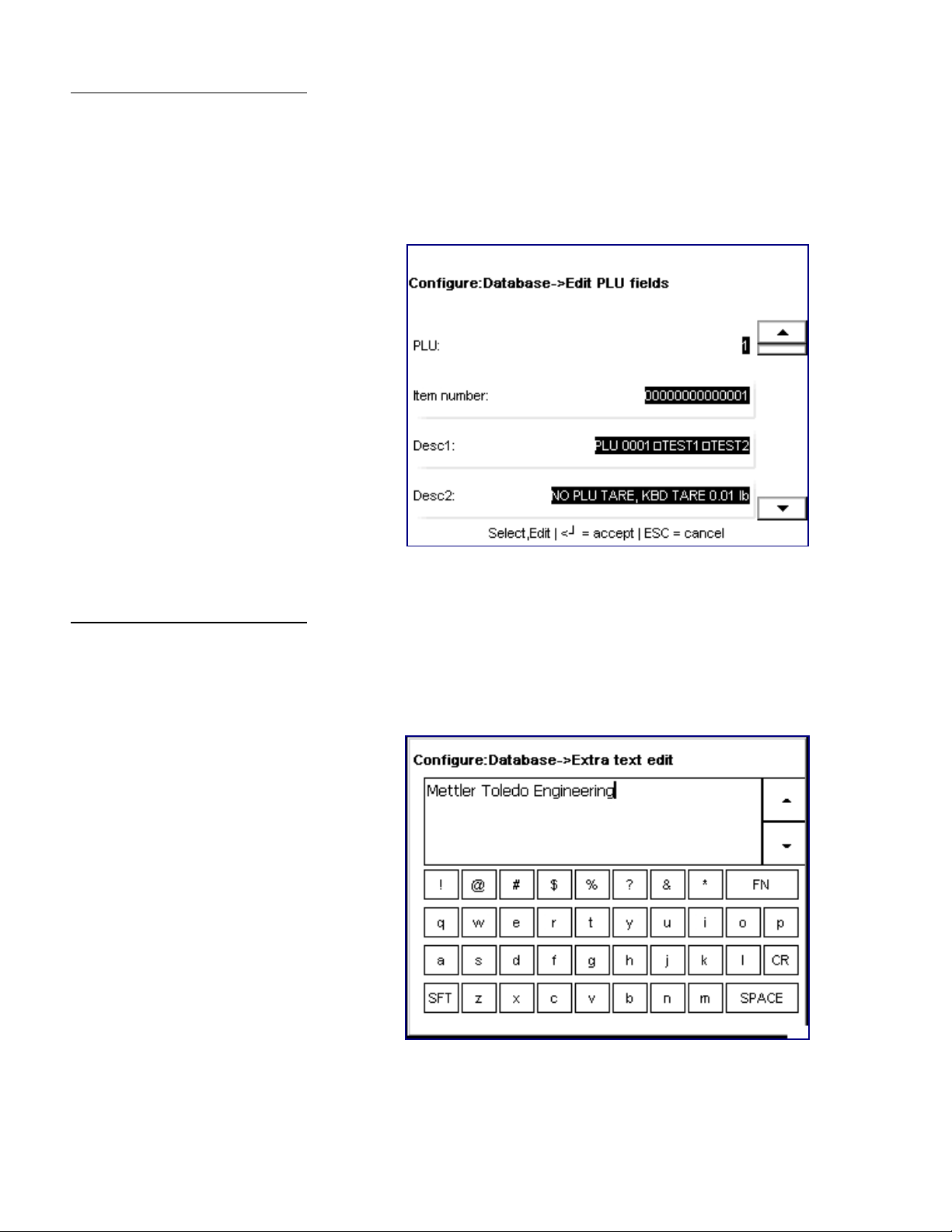

PLUs

Chapter 3: Configuration

Database

The PLUs tab is used to implement a more thorough edit of the less-common fields of a

particular PLU. The data is arranged in a scrollable list and can be modified simply by

touching the appropriate field and following the menu prompts. PLUs from any

department may be edited by choosing the desired department number at the DEPT.

NUMBER prompt.

Extra Text

Press Enter when satisfied with your changes.

The Extra Text function is rather straightforward, allowing the user to modify the

additional text displayed during a particular PLU transaction. There is a limit to the

number of characters that maybe displayed per line (selectable upon access).

Type out whatever product description you wish and hit Enter to return to the previous

screen. From there, you may further edit the text or return to the Database screen.

3-3

Page 28

METTLER TOLEDO Impact S® User's Guide

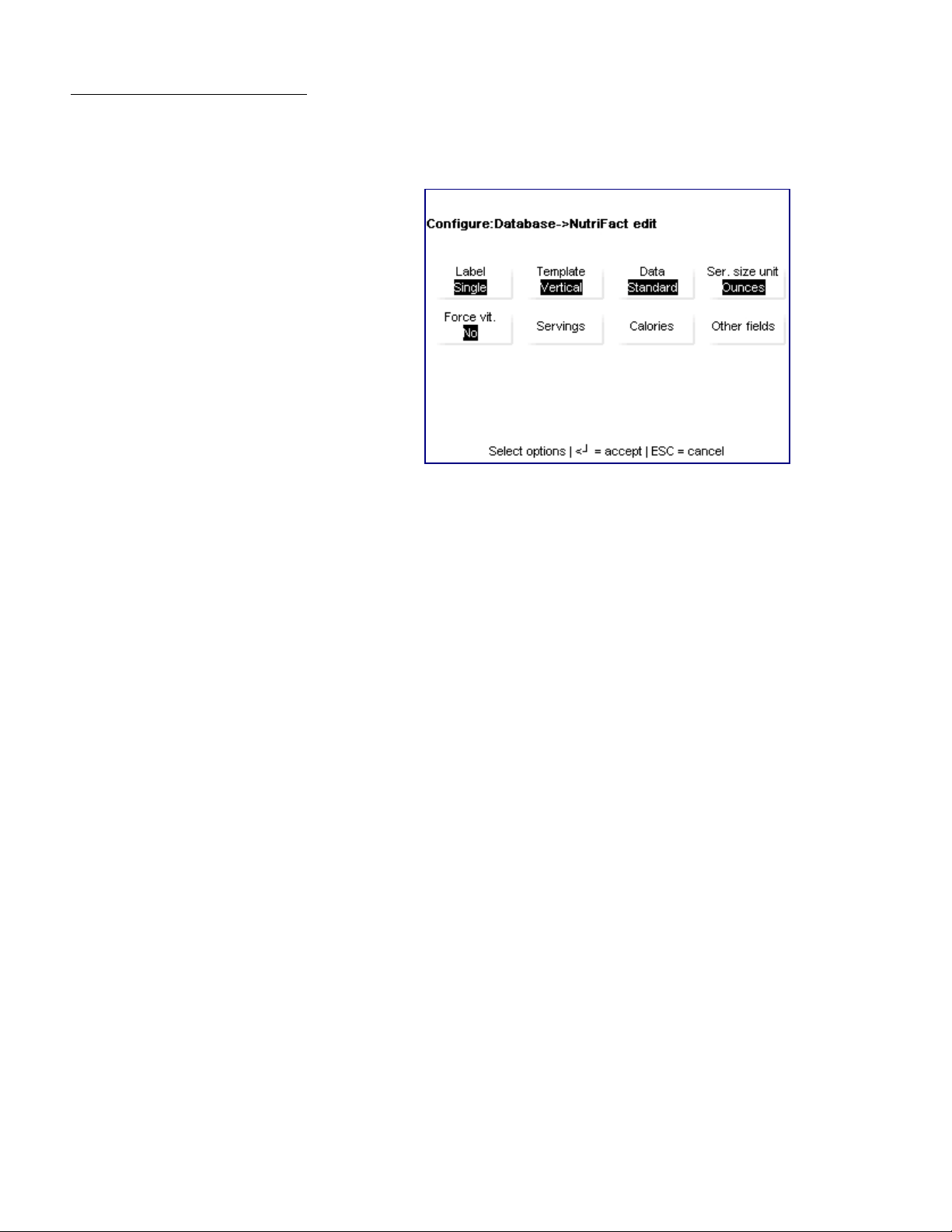

Nutrifacts

Selecting the Nutrifacts field will bring up a window that allows you to apply a Nutrifact

entry to a product by its database number.

If the number is not recognized you may select “add” on the next popup, or if you

simply wish to edit the Nutrifact entry, then you will be taken to this screen, where you

may further define your preferred data.

Label – allows the user to determine if the Nutrifact information will print on the main

label in its short-form or if it will print on a second label of its own. This menu also

allows the user to determine which of the two labels (if chosen) will be printed first.

Template – vertical, vertical simplified, tabular, tabular simplified, horizontal, etc.

These choices allow the user to orient the Nutrifacts in a particular direction so as to

make the best use of the label’s space. The simple modes only print the main box of a

Nutrifact entry, whereas the others will use all available label space to print data.

Data – this is where the user chooses between standard and simplified for the

Nutrifact information.

As always, touch the Enter key when finished making any changes.

3-4

Page 29

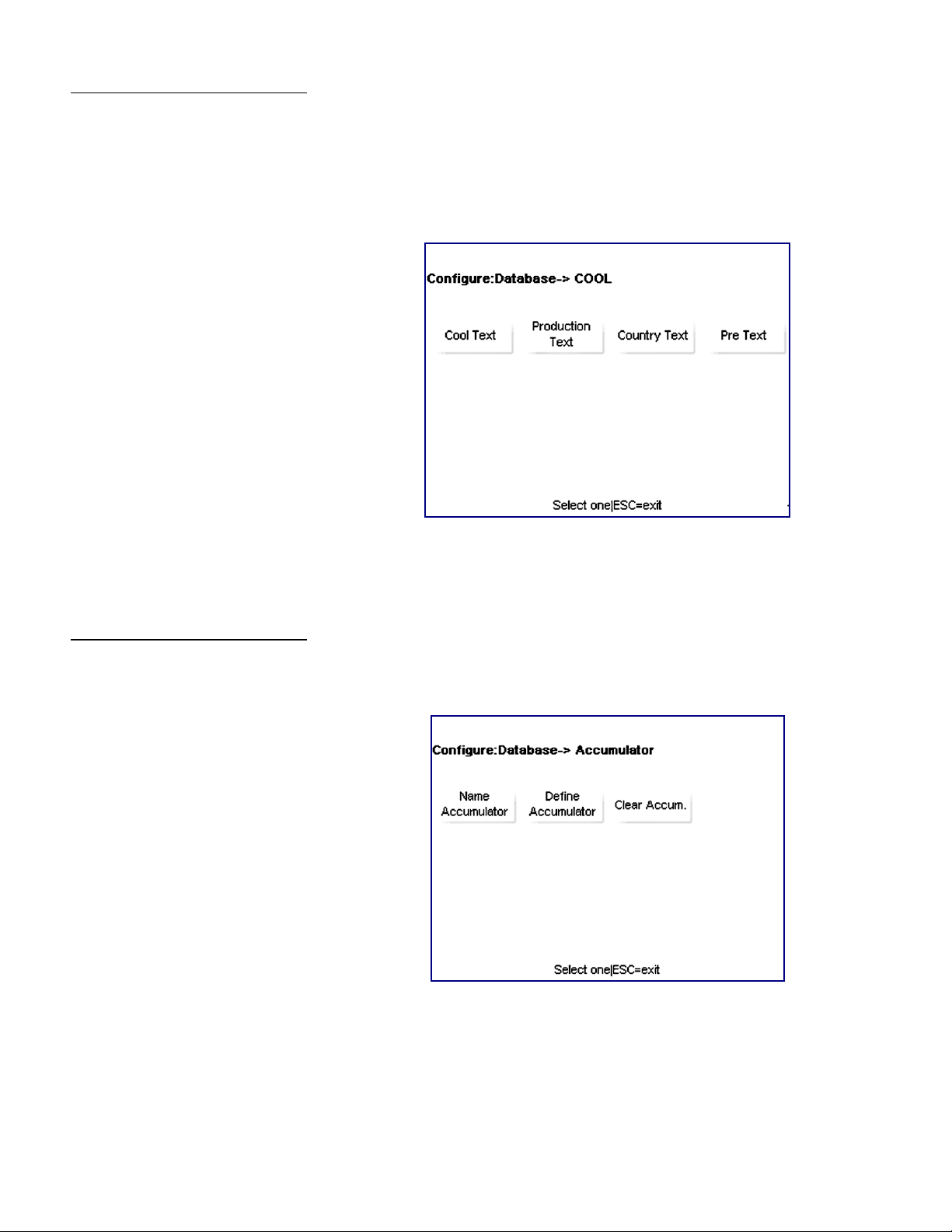

COOL

Chapter 3: Configuration

Database

The COOL section of the Database cascade allows the user to change or apply specific

COOL parameters to a PLU. Selection of these categories prompts you for a number that

corresponds to database entries. Should you forget the number – or if there isn’t a COOL

entry for the PLU you’re using – you may also add a new COOL entry or edit an existing

one by following the menu prompts.

The buttons in this array are pretty self-explanatory, with each directing you to the COOL

sector of the same name. Type where necessary, use the database-given numbers

when you’re able and hit Enter when finished.

Accumulators

The Accumulator array allows the user to view and modify the accumulator settings.

3-5

Page 30

METTLER TOLEDO Impact S® User's Guide

Name Accumulator – this function allows you to rename the existing accumulators or

add new ones to the existing list.

Select the accumulator you would like to rename by touching the screen with the tip of

your finger. Press Enter when satisfied with your changes.

Define Accumulator – if you would like to enable or disable the existing accumulators,

this is the menu cascade to which you need refer.

3-6

Pressing the individual fields toggles the accumulators between yes and no. Set as

necessary and press Enter when finished.

Clear Accumulator – used for deleting specific PLUs and other bits of data. Follow the

menu prompts to make changes.

Page 31

Clear

Chapter 3: Configuration

Database

As the name suggests, the Clear branch of the Database menu allows for deletion of

data. Simply touch the category you’d like to clear and follow the menu prompts to

eliminate data.

Should you want to delete only select PLUs or bits of data, you will be prompted for a

number. When complete, you may press ESC to return to the Database main screen.

Reports

Pressing the Reports button at the Database screen will bring the user to this array.

Depending on which report they would like to view, simply press the corresponding

button and follow the menus (Department, hours, date, etc.) until the desired report is

reached.

Totals by Group – allows the user to view the weight and value (among other

categories) totals for all PLUs in a particular group. Simply key in the group number and

wait for the unit to scan.

Totals by Department – Same as Totals by Group but with all the PLUs in a particular

department. Key in the department number and wait for the unit to scan.

Department Voids – enables a report to be viewed containing the weight totals, value

totals and modified value totals (among others) of anything that has been voided out

on the unit.

3-7

Page 32

METTLER TOLEDO Impact S® User's Guide

Action Code Text

The Action Code Text menu allows for three different functions:

1.) Create or edit a message to the operator via the operator screen

2.) Change the store address line on the printed label

3.) Implement specific marquee action code (taken from the image database)

Insert the associated number when the pop-up appears and edit as normal.

Grade

Press Enter when finished making changes.

The Grade function allows for editing of the various, numerical grade entries in the

embedded database. Make your numerical selection in the first pop-up window and

then choose whether to change (edit) or delete (clear) that grade entry (below

screenshot).

3-8

Upon selection of the Edit command, you will be taken to a keyboard screen wherein

you may enter a string of text defining the grade selection. The Grade definition is

limited to 23 characters. Press Enter when finished.

Page 33

Group

Chapter 3: Configuration

Database

The Group function in this section allows for the groups (assigned during PLU entry

creation or modification) to be defined beyond their numerals. The user need only type

in the group number to access a keypad wherein they may name said group whatever

they wish – beef, pork, fresh fish, etc.

Press Enter when satisfied.

3-9

Page 34

METTLER TOLEDO Impact S® User's Guide

Preset

The Preset button allows the user to characterize and change how the PLUs in a

vendor’s database are arrayed and accessed. The menu allows many customizations

from creating preset pages to defining groups of PLUs

Included in this cascade are the following buttons –

Select Page – allows the user to select from the preconfigured preset pages

Edit Page Name – modify the preset page’s name

Swap Pages – used to pull pages from other preset cascades into the currently active

preset array

Delete Pages – permanently remove a preset page from the database

Program Preset – create a new preset page

Edit Preset Name – modify a preset button’s name

Swap Presets – used to pull single presets from other preset cascades into the currently

active array

Delete Preset – permanently remove a preset from the current preset array

Reaction – toggle between EDIT and PRINT

Edit Group Name – modify a group’s name

Swap Groups – used to pull PLUs from other groups into the currently selected group

Delete Group –permanently delete group information for all PLUs identified in the

selected group

3-10

Page 35

Select Page

Chapter 3: Configuration

Preset

Pressing the Select Page button will bring up the following screen –

To select a preset page, simply touch the button that describes your desire and press the

ENTER button. The user will be taken back to the main preset configuration screen.

Edit Page Name

Pressing the Select Page button will bring up the following screen –

Simply type in a new name for the preset and press ENTER when satisfied.

3-11

Page 36

METTLER TOLEDO Impact S® User's Guide

Swap Pages

Delete Pages

Program Preset

Should a user desire to do so, he may swap pages of preset information back and forth

between the established presets. They begin by pressing the button for the first of the two

presets they would like to swap. Press ENTER. Next, select a second Preset from which

to swap. Press ENTER. Confirm and the swap will be done.

The user will find the previously desired page under the name and/or heading of the

originally selected preset.

Simply put, this menu allows a user to select and permanently delete a preset page (or

pages) from the database. Simply select which page to delete, press ENTER and

confirm in the popup window.

This button takes the user to a series of screens wherein they may develop preset pages

of their own. In the following examples, I’ll use the page TESTMANUAL throughout as

the created preset title. Keep in mind that you will only be able to edit Preset groups and

buttons that correspond to the page you select in the beginning of the process.

First, select the group wherein the preset will be found. Select a blank button to represent

the new Preset page and press ENTER.

3-12

Page 37

Chapter 3: Configuration

Name the new Preset button by pressing the EDIT BUTTON NAME button and using the

popup keypad. In this case, I named the Preset TESTMANUAL.

To populate the new Preset, press the PROGRAM PRESET button and key in the

department and desired PLU numbers.

Name the new PLU –

3-13

Page 38

METTLER TOLEDO Impact S® User's Guide

And it will appear in the cascade the next time you desire to modify or otherwise edit

that menu.

Repeat this to populate the Preset until satisfied.

Edit Preset Name

Swap Preset

This button allows a user to rename a Preset page or button. Simply select the page or

PLU button to change and press ENTER. The popup keypad will display, allowing you to

key in a new name. Save the choices by pressing YES at the window prompt.

Consult this menu to change the positions of existing Preset buttons or pages. Simply

press the button or page to be moved and follow the directions at the bottom of the

screen to change its position. Be sure to press Enter before exiting to save the progress.

3-14

Page 39

Delete Preset

Reaction

Edit Group Name

Chapter 3: Configuration

As the name suggests, this button takes you to the same grid as does the Edit Preset

Name button. Here, however, you may select a button (Page or PLU) and press the C

button to delete it from the system. Be sure that the PLU or Preset Page chosen is the

one that needs to be deleted, as there is no UNDO function to cover a mistake.

This button toggles between EDIT and PRINT and controls what the unit does after the

user presses a PLU. If EDIT is selected, the unit will pause on the transaction screen so

they user may make changes to the transaction before the label prints. If PRINT is

selected, the unit will print the label straightaway.

Simply touch the group name you would like to change and key in the new name on the

popup keypad. Press ENTER when finished.

Swap Groups

Delete Groups

Swapping groups takes you to a screen that looks identical to the EDIT GROUP NAME

menu. Swapping these buttons simply changes their place in the cascade, so follow the

instructions by pressing the button to be moved and then the location to move it. It

should immediately relocate itself.

Before you leave the page, it will ask you to verify the move. Press YES to finalize.

Simply touch the group button you would like to delete and follow the verification

prompts through to the item’s deletion.

3-15

Page 40

METTLER TOLEDO Impact S® User's Guide

Quick Edits

Quick Edits is a menu cascade that allows the user to specify a PLU number to work

with before making any changes. This locks all changing information into that originally

selected PLU, so the user can modify it to be exactly what they need.

After keying in a PLU number, this screen will appear. Select the category you would like

to begin with and press the ENTER key.

Each selection will bring up either a single large window –

3-16

Page 41

Chapter 3: Configuration

Quick Edits

Or a separate cascade to select from –

Each section is meant to be the quickest method of modifying the PLU for a particular

parameter. With the use of simple touches or the right-hand keypad, adjusting

numerical data or defining field types is both simple and very, very fast.

The user may FORCE data usage for a particular PLU by selecting the field they wish

and pressing the FORCE button on the popup prompt. This will require the particular

data (GROUP, USE-BY, etc.) to be displayed whenever the PLU is accessed (see

below).

When finished with the edits, press the ENTER key and you will be taken back to the

main configuration screen.

3-17

Page 42

METTLER TOLEDO Impact S® User's Guide

Labels

The Labels menu allows a user to assign standard or custom label formats/styles to the

printed stock.

Assign Styles

Label Group –takes you to an array of keys representing available label sizes

Assign Styles – allows the user to modify the preset label formats

Print Test Label – prints a label of the selected size and style

Verify Labels – prints a sequence of labels representing a series of PLUs

This array of buttons deals specifically with the label parameters of the Impact-S unit.

Use the scroll bar to see the remainder of the below-detailed list of selection options.

3-18

ByWeight – select to assign label styles for By-Weight transactions

PrePack – select to assign label styles for PrePack transactions

ByCount – select to assign label styles for By-Count transactions

StdPack – select to assign label styles for Standard Pack transactions

Page 43

Print Test Label

Chapter 3: Configuration

Labels

Receipt – select to assign label styles and specific formatting to the printing of receipts

Verify – select label format to apply to Verify Label printings

Totals – select label format to apply to Totals Labels

NF Label Format – select label format to apply to Nutrifact Labels (done at NF

programming)

This menu is used to view labels as they are printed on label stock. The user would

benefit from this procedure should they be interested in exactly how the labels they’ve

set up will look on different label stock sizes.

Verify Labels

Simply select the label stock measurement of the current roll and press Enter.

To use the Verify Labels menu, a user simply needs to define the range of PLUs they

wish to see printed (using the first two fields) or select a department (with the third field)

before hitting the Begin Printing button. Once this process begins, it can be stopped by

pressing the ESC key on the keypad.

3-19

Page 44

METTLER TOLEDO Impact S® User's Guide

Unit Setup

Pressing the Unit Setup button will take you to this button array –

This cascade of buttons includes many of the parameters that will be integral to the

proper scale parameter setup, viewing of the screens and setup of the preferred

navigation paths.

Time and Date – select to change or format the unit’s time and date settings

Language – select to change the display and printed languages

Backup/Restore – select to backup or restore current scale data

Department – select to define or edit the department choices

Scale Settings – select to change the various base-settings of the scale

Communication – select to alter the communication settings (peripheral, Ethernet,

network and component)

Screen Calibration – select to calibrate the touchscreen and screen preferences

Set Home Screen – select to change the screen to which the unit boots

Technician – select to access the password-protected Technician cascade

3-20

Page 45

Time and Date

Chapter 3: Configuration

Unit Setup

The Time and Date menu allows you to format or set the scale’s date and time. Press

the Enter key after making any changes to apply your preferences.

Time/Date Format – select to format the unit’s time and date settings. Here you may

select parameters including adjustment for time zones and seasonal daylight savings,

as well as apply the particular date and time orders (i.e. month/day/year or 11:00pm

versus 23:00).

3-21

Page 46

METTLER TOLEDO Impact S® User's Guide

Language

Set Time/Date – select to set the time and date to match your region.

This menu enables you to toggle the display and keyboard languages between English,

French and Spanish. Simply tap the field to cycle through the choices.

Press the Enter key when finished to save your choices.

3-22

Page 47

Backup/Restore

Chapter 3: Configuration

Unit Setup

The Backup/Restore feature enables the user to save his settings to an external device

(internal, external USB flash drive, etc.) in case of corruption to the scale database. This

same menu cascade allows you to restore a previous saved image – or image fragment

– from a local or external storage device.

The Export Log feature enables you to move log files to \service\log directory for export.

Copy makes it possible to backup data from the compact flash card on an external USB

device.

Backup – allows you to choose which data you would like to back up in an a-la-carte

fashion. Simply click a category and then click to toggle the desired file groups until you

have everything you need selected. Hit Enter when finished making your selections and

press Backup (move slider to the bottom) to begin the transfer process.

The Restore function allows you to select an existing file from a storage source with

which you may repair or overwrite your current data. Simply select the file and follow the

prompts.

Copy and Export Log work in the opposite way, allowing you to select your image

pieces or log files and copy them to a particular location via a Windows-style browser

view.

3-23

Page 48

METTLER TOLEDO Impact S® User's Guide

Department

Pressing the Department button from Unit Setup will offer up a prompt in which you

must type in the department number you would like to modify. After typing in a number,

you will be asked whether you want to Edit the entry or Clear an existing entry. Make

your choice or press Cancel to exit to the Configuration Home screen.

Department Edit – Touch the fields you would like to edit and make your changes.

When complete, press the Enter key to implement your preferences.

The address of the default department is printed on the label when the format specifies.

3-24

Page 49

Scale Settings

Chapter 3: Configuration

Unit Setup

Entering the Scale Settings menu allows the user to change many of the most basic

usability and functionality settings of the unit.

Scale Mode – use to modify the settings of different keys depending on whether the

scale is in service or PrePack mode.

Operator Permissions – set permissions for a unit operator

Supervisor Permissions – set permissions for the unit supervisor

Transaction Overrides – choose which fields are editable at the transaction screen

PLU Access Parameters – defines how particular PLUs can be accessed

Barcode Settings – choose the printed barcode format from a preexisting list

COOL – activate, disable or modify the country of origin labeling for the unit

Store Logo – select a graphical logo by-number from the unit database

Screen Saver – select a series of graphic images to display as a time-out screen saver.

Scale Mode

The Scale Mode menu allows the user to specify both in which mode the scale will

operate and how the unit will deal with label-printing on a per-mode basis. Choose

between Service and Prepack modes and then set the appropriate print activities from

the corresponding menus. Press ENTER when finished.

3-25

Page 50

METTLER TOLEDO Impact S® User's Guide

Operator Permissions

The Operator Permissions menu allows items like Memory, different Total tracking,

Voids and formatting abilities to be enabled or disabled. Press the object with your

finger to toggle the fields to the right of the name.

Make your choices and press Enter.

Supervisor Permissions

Similar to the Operator Permissions menu, the Supervisor Permissions cascade

allows another supervisor (normal operators are denied access to this menu) or

technician to modify the fields and menus available to the unit supervisors. Toggle the

choices by pressing the appropriate line and press ENTER when satisfied.

Transaction Overrides

This menu allows a user to specify which fields will be modifiable within the transaction

process. Each field is set up with a YES/NO toggle that can be changed at the operator’s

whim. Press ENTER when finished making changes.

3-26

Page 51

Chapter 3: Configuration

Unit Setup

PLU Access Parameters

With this menu a user can toggle different PLU/item identification methods that may not

normally be used. Parameters such as timeouts, item number calling, merchandising

and world modes can also be enabled or disabled from this menu.

Press ENTER when finished.

Barcode Settings

This menu allows the user to select from several (total number depends on region)

barcode styles on a per-transaction-type basis. They are preprogrammed into the unit

database and, thus, a simple touch is all that’s required to change from one to another.

Using Windataback, it is also possible to create custom barcodes and import them into

the Impact S operating system for use on your networked scales.

Press ENTER when finished.

3-27

Page 52

METTLER TOLEDO Impact S® User's Guide

COOL

The COOL Options menu enables the various aspects of COOL (country of origin

labeling) for printing on labels. This is where you go to set whether or not embedded

COOL data is required or can be overridden, and if the tracking function will show up.

Touch to toggle, press Enter when satisfied with your setup.

Store Logo

Enables the user to type in the number of a store graphic already embedded in the unit

database. This necessitates knowledge of the graphic numbering, so be sure to check

them before making any changes.

Press ENTER to select.

Screen Saver

Allows the user to select the parameters that dictate when the screen saver will switch

on as well as the particular graphics that will be displayed in a slideshow-style viewing.

3-28

Page 53

Communication

Chapter 3: Configuration

Unit Setup

The Communications function allows the user freedom over many of the networking

parameters that enable the unit to network with other scales and devices.

The buttons in this array are designed for easy navigation of the discrete sections.

Simply touch and go.

Network Communications – adjust and view network settings

WiFi Communications – if the unit is equipped with a wireless transceiver, this button

takes you to its configuration menu

VPN Setup – possible addition to future software versions. Not currently implemented.

FTP – possible addition to future software versions. Not currently implemented.

Email (SMTP) – allows for the addition and editing of email contacts and messages

(not currently implemented)

Network Communications

Network Communications is a cascade that allows the user to adjust and view the

different network parameters currently implemented.

3-29

Page 54

METTLER TOLEDO Impact S® User's Guide

TCP/IP – within this cascade, the user may change the name and IP addresses of the

networked unit. This is also where you may enable or disable DHCP (the default setting

is Disabled).

Network Parameters – if you desire to change the parameters of the network’s

connectivity (like the Time Sync Server or Host Communications Port), use the

Network Parameters cascade.

3-30

Page 55

Chapter 3: Configuration

Unit Setup

Network Status – used to check the online status of other scales or devices on the

network. Press the Test Ping button with your finger, key in an IP address and press

Enter. A window will display with the results of the test.

WiFi Communications

You would use this cascade to modify the password and network settings for your unit’s

wireless controller, should it be so equipped.

The Mode and Rate fields are read-only, based on the radio option installed. Encryption

Mode toggles between standard methods as supported by the HW. Hit Enter to save

changes.

3-31

Page 56

METTLER TOLEDO Impact S® User's Guide

Wireless Network Configuration – works much the same as the broader category of

the same name, bringing up a cascade titled WEP Configuration that allows you to

adjust settings related to the unit’s selected wireless functionality. Encryption options

include none, WEP, WPA and WPA2.

Press Enter when finished making changes.

3-32

This functionality is expected to be unlocked in future versions of the system software.

Currently, there is no support for it.

Page 57

Screen Calibration

Chapter 3: Configuration

Unit Setup

It’s a good idea to calibrate the touchscreen once in a while to maintain precision in

your unit’s operation. There is a built-in timeout in case the function is accidentally

selected. When the timer counts to zero, the scale will return to the Configure main

screen.

Touch the center of the circular graphics as they appear, waiting until they shrink to a

small point and you are prompted to let them go. For added precision, you may want to

use the tip of a stylus.

When finished, you will be presented with the option of moving your finger around to

ensure realistic tracking of the on-screen pointer. Press Accept to complete calibration.

3-33

Page 58

METTLER TOLEDO Impact S® User's Guide

Set Home Screen

This menu allows the user to determine which screen will come up when the unit is first

booted. Any of the preset pages can be chosen, so long as the operator pressed Enter

after making his or her selection.

3-34

Page 59

Technician

NOTE: the Technician section

screens cannot be edited, but

are shown for review only.

Chapter 3: Configuration

Unit Setup

The password protected Technician cascade allows for various calibrations of the unit

and backup of the system data, as well as resetting of the unit.

This first window allows access to the password and user-ID input window.

This is the Technician Main screen

Load Cell Calibration – calibrate the unit’s load cell

Geo Calibration – adjust scale parameters in consideration of local gravity and time

Weight Management – adjust how weight is handled and displayed on your unit

Reset Unit – reset the various database sections to their original states

Backup/Restore – create an image of the current unit or replace the current image with

another. Able to use outside sources such as flash drives, CDs and direct networking

Price Management – specify currency, increments, separators and rounding

Service Log – view the service log

Serial Communication – view and/or adjust the specifics of unit serial communication

DB Maintenance – adjust parameters for database auto-maintenance

3-35

Page 60

METTLER TOLEDO Impact S® User's Guide

Weight Management

There are a few simple options contained within the Weight Management array. This is

where you will go to adjust the Tare limit, set particular Weight Options – such as

minimum print thresholds, weight separator symbols, price-by settings, etc. – and see

the Expanded Weight of an item, should pricing require.

Tare – This button allows you to change the weight limit of the tare function via a valueinput. Simply type in a number and press Enter when finished.

Minimum Print – Allows the user to key in a numeral denoting the minimum weight

required for the scale to print a label. 20, in the above example, stands for 0.20 lbs.

Weight Separator – Choose between “dot” and “comma” for the separation of large

integers.

Weight Options – This cascade includes options for specific pricing and weight

commands such as Price-By quarter/half pound, Pounds for, 100g and kg modes.

They are toggled as any other touchscreen menu bar, so simply tap lightly to cycle

through YES and NO until you have the configuration you desire.

3-36

Touch Enter when finished.

Page 61

Chapter 3: Configuration

Unit Setup

Expanded Weight – for anything that requires a very-specific weight measurement, this

button allows four-decimal places to be displayed. This is not a legal for trade display.

The unit will revert back to the legal display when this screen is exited.

Reset Unit

This menu is used to reset the various databases within the Impact-S unit.

Simply touch the database you would like to return to its original configuration and

follow the popup instructions (press OK or Cancel). Be mindful of the fact that this reset

cannot be reversed. It is suggested that the unit administrator makes a copy of the

current unit image before any of the databases are modified.

3-37

Page 62

METTLER TOLEDO Impact S® User's Guide

Price Management

This screen allows the user to adjust parameters such as the currency and how it is

displayed. Touching the individual areas will toggle the values or bring up a brick of

selectable options the user may choose from. The Rounding command allows the user

to adjust at what digit the unit will round a value.

Service Log

The Service Log button takes the user to a screen that, appropriately, displays the

entirety of the unit’s service log (as updated by the Technicians). Press ESC when

finished viewing.

3-38

Page 63

Printer Setup

Chapter 3: Configuration

Printer Setup

The Printer Setup menu is accessed from the main configuration screen and looks like

this –

This array of buttons deals specifically with the label parameters and printer sensor

calibration of the Impact S unit.

Label Group – press to select from a list of available label sizes

Print Speed – press to select from a list of print speeds

Calibrate Gap Sensor – press button to calibrate sensor. Multiple labels will print

Calibrate Take Label Sensor – press button to calibrate sensor. Multiple labels will

print

Label Delivery – toggle between “Stripped” and “Unstripped”

Graphic Format – this selection is for continuous label stock, toggle.

Auto Size – toggle between “Enabled” and “Disabled”. Enabling auto size matches a

label group to the current label stock after the unit measures it upon printing.

Label taken – toggle between “Enabled” and “Disabled”

Label Length – select to type in specific label lengths. Measure Label will override.

Gap length – select to type in specific gap lengths. Calibrate Gap Sensor will override.

Image Offset – select to type in specific offset to start label from top

Eject Length – select to type in specific eject length of label when complete

Measure Label – press to have the unit measure the existing label stock. Multiple labels

will print

Press Enter to accept changes to any fields.

3-39

Page 64

METTLER TOLEDO Impact S® User's Guide

Label Group

Selecting Label Group takes you to an array of keys representing available labels. Make

your choice by touching the desired field and press Enter to accept.

Print Speed

The Print Speed menu represents the possible speeds at which the unit can produce

labels. Make your selection and touch Enter to accept.

3-40

Page 65

Calibrate Gap Sensor, Calibrate Label Taken & Measure Label

Type, Graphic format, Auto Size & Label Taken

Chapter 3: Configuration

Printer Setup

These three functions are similar in that they discharge labels from the printer in order to

calibrate various printing parameters. Any time you change the label size or style, be sure to

calibrate both sensors and allow the photoeyes to measure the label stock by hitting the

appropriate keys.

The labels will likely collect on the lip of the printer discharge slot, making for easy removal

and disposal.

These four buttons are touch-toggled by the user to select between two choices each:

Type – changes between [stripped] and [unstripped] label delivery

Graphic Format – allows for flexibility in the printing of graphics on a per-label basis via

modification of the continuous label stock toggle.

Label Length, Gap Length, Image Offset & Eject Length

Auto Size – enables the auto setup of the “Label Size” selection after a label is measured

Label Taken – enables or disables the label taken sensor. Important for batch-processing of

labels.

It is necessary that the user press Enter when finished making changes to these toggles, else

his preferences will default to the unit standard.

These four parameters are directly user-editable. This cascade is used mainly to adjust the

printer for labels that fall beyond the parameters of normal label stock. The Image Offset

adjustment may need to be used to better print graphics or large amounts of text on normal

labels as well.

Label Length – allows the user to make dimensional provisions for labels that are not

categorized in the Label Size menu. Auto-updated or overwritten by Measure Label.

Gap length – specifies the gap, in millimeters, between two labels.

Image Offset – allows the user to fine-tune the start of the label text and graphics on the label

stock.

Eject Length – alongside label and gap length measurements, Eject Length tells the printer

how far to feed the stock so stripped labels are easily retrieved from the exit without falling to

the floor. Also insures all printed material is shown after tear-off of continuous.

Make sure to press the Enter key when finished making your selections.

3-41

Page 66

METTLER TOLEDO Impact S® User's Guide

Security

The Impact-S has various integrated security protocols that can be quickly modified by a

user with the proper clearances. Through the use of the Security cascade, new users

with different permissions may be added to the system.

The user will be presented with a login prompt to enter the menu.

It is STRONGLY recommended that the password and user ID be changed by the

technician servicing this scale. Contact your local Mettler Toledo service organization if

you would like to set up on-scale security features.

Most of the functionality of the Security menu exists within the first of the two buttons.

After making any changes, remember to press the Enter key to save.

Users – visit this button to add or edit the specifics of various user profiles. There are

four levels of user than can be defined:

1.) Operator – has access to transaction screens only. No permission to access

setup menu when security is enabled

2.) Supervisor – has access to transactions and item database setup menus.

No permission to access weights and measures significant parameters.

3.) Manager – has access to all supervisor-class screens/menus as well as

scale setup menus.

4.) Technician – has access to all screens, including full setup and calibration

menus.

Security – this field is a toggle that switches between “Enabled” and “Disabled” for the

scale. Only Managers and Technicians can change this state.

Users may take advantage of/edit/create at any level of the system that is equal to or

lower than their own. For example, a Technician can modify anything a Manager,

Supervisor or normal Operator can, but a Supervisor may only modify his own set of

screens and any of the Operator screens.

3-42

Page 67

Users

Chapter 3: Configuration

Security

The information made accessible by pressing the Users button constitutes more than

95% of the Security cascade, so familiarizing yourself with it is suggested. The basic

layout looks like this:

The pop-up menu is rather self-explanatory, with the Add, Modify and Delete functions

operating exactly as you’d expect them to. If you need to input a new employee or

scale-user into the system, press the Add button to bring up the following menu –

Once here, you will need to input an ID number, a user name and a password number.

These should be unique fields so as not to confuse anyone. Finally, you will select the

access level – operator, technician or supervisor – and hit Enter when finished.

1.) Operators have no access to setup menus (no password required, obviously)

2.) Supervisors cannot create/edit a technician’s permissions – just other supervisors and

operators. Password protected (passwords must be between 2 and 9 characters long)

3.) Managers can create/edit permissions for all but Technicians. Password protected.

4.) Technicians can alter anyone’s permissions. Password protected.

Security

The Security button is a simple toggle that activates and deactivates the security

parameters set in the Users cascade. To allow full access by all users, toggle this field

to Disabled.

3-43

Page 68

METTLER TOLEDO Impact S® User's Guide

System Status

The System Status menu is particularly useful for determining version information,

setting the comprehensiveness of the Log function and viewing the existing logged data.

System Information – brings up a list of current system versions and addresses

System Information

View Log – array gives user access to the various log lists

Log Level – allows user to choose between “Low,” “Mid” and “High” in regards to how

comprehensive the log function is

The System Information window is a read-only screen that displays various versions

and addresses for the unit.

3-44

As the screenshot shows, things like PLU, ET and NF record quantity are stored here

alongside user-editable (within other menus) content such as scale names and IP

addresses.

Page 69

Log View

Chapter 3: Configuration

System Status

This section allows the viewing of logged data. Touch your selection – Event or Error –

edit the filter parameters and press Display Log.

View Event Log – this menu displays a comprehensive list of the actions taken to

modify the parameters of the scale. Everything from on-and-off times to when specific

PLU display modes were modified can be listed here, assuming you have the Log Level

set high enough. This scrollable list can be limited by date or specific event type.

View Error Log – this menu displays any and all errors that have occurred within the

timeframe you choose.

3-45

Page 70

METTLER TOLEDO Impact S® User's Guide