Page 1

8572

DigiTOL®

PARTS

COUNTING

SCALE

Technical

Manual

and

Parts

Catalog

Page 2

TM008572 I01

Page 3

INTRODUCTION

This publication is provided solely as a guide for individuals who have received Toledo

Technical Training in servicing the Toledo product.

Information regarding Toledo Scale technical training may be obtained by writing to:

Toledo Scale

Training Center

P.O. Box 1705

Columbus OH 43216

(614) 438-4400

FCC NOTE

This equipment has been tested and found to comply with the limits of the United States of

America FCC rules for a Class A digital device, pursuant to Part 15 of the FCC Rules and

the Radio Interference Regulations of the Canadian Department of Communications.

These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

IMPORTANT

It is most important that the correct part number is used when ordering. Part orders are

machine processed, using only the part number and quantity as shown on the order.

Orders are not edited to determine if the part number and description agree.

TOLEDO SCALE RESERVES THE RIGHT TO MAKE

REFINEMENTS OR CHANGES WITHOUT PRIOR NOTICE

Page 4

Page 5

PRECAUTIONS

•

•

•

•

this manual before operating or

READ

servicing this equipment.

ALWAYS REMOVE POWER

seconds

disconnecting any internal harnesses.

Failure to observe these precautions may

result in damage to, or destruction of the equipment.

ALWAYS

DO NOT

scale base to the equipment with power

connected or damage will result.

BEFORE

take proper precautions when handling static sensitive devices.

connect or disconnect a load cell

and wait at least 30

connecting or

WARNING

DISCONNECT A LL P OW E R

TO THIS UNIT BEFORE

REMOVING THE FUSE

OR SERVICING.

WARNING

ONLY PERMIT QUALIFIED PERSONNEL TO

SERVICE THIS EQUIPMENT. EXERCISE CARE

WHEN MAKING CHECKS, TESTS, AND

ADJUSTMENTS THAT MUST BE MADE

WITH POWER ON.

•

•

•

•

this manual for future reference.

SAVE

DO NOT

tamper with this equipment.

ALWAYS DISCONNECT

power source before servicing.

CALL

information, and service.

allow untrained personnel to operate, clean, inspect, maintain, service, or

this equipment from the

METTLER TOLEDO for parts,

CA UTION

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE DEVICES

Page 6

Table of Contents

1. GENERAL DESCRIPTION

1.1. STANDARD FEATURES..................................................................................................................................... 1

1.2 OPTIONAL FEATURES...................................................................................................................................... 1

1.3. STATEMENT OF PERFORMANCE................................................................................................................... 2

1.4. ACCURACY CONSIDERATIONS....................................................................................................................... 2

2. SYSTEM DESCRIPTION

2.1. INTERNAL FUNCTIONS..................................................................................................................................... 3

2.2. OPTIONAL KITS.................................................................................................................................................. 3

2.2.1. Bar Code.................................................................................................................................................... 3

2.2.2. Remote Scale Input.................................................................................................................................... 3

2.2.3. Battery Power Operation ........................................................................................................................... 4

3. SPECIFICATIONS

3.1. ELECTRICAL....................................................................................................................................................... 5

3.1.1. Power Requirements ................................................................................................................................. 5

3.1.2. Conducted and Radiated Emissions ......................................................................................................... 5

3.1.3. Radio Frequency Interference ................................................................................................................... 5

3.2. ENVIRONMENTAL.............................................................................................................................................. 6

3.2.1. Temperature Specification......................................................................................................................... 6

3.2.2. Hazardous Areas ....................................................................................................................................... 6

3.3. PHYSICAL SPECIFICATIONS ........................................................................................................................... 6

3.3.1. Appearance and Dimensions..................................................................................................................... 6

3.3.2. Internal Scale Platter.................................................................................................................................. 6

3.3.3. Shipping Information.................................................................................................................................. 6

3.4. DATA INTERFACE............................................................................................................................................... 7

3.4.1. Data Output................................................................................................................................................ 7

3.4.2. Data Input................................................................................................................................................... 7

3.5. CONFIGURATION GUIDE.................................................................................................................................. 7

.................................................................................................................................................. 5

................................................................................................................................. 1

.................................................................................................................................... 3

4. INSTALLA TION INSTRUCTIONS

4.1. UNPACKING AND SETUP.................................................................................................................................. 9

4.1.1. Unpacking Instructions for Low Capacity Scale (for 8572-0002, 1002 versions only) ............................. 9

4.1.2. Level the Scale Base ................................................................................................................................ 10

4.1.3. Install All Optional KOPs........................................................................................................................... 10

4.1.4. Initial Power Up Sequence........................................................................................................................ 10

4.2. PROGRAMMING PROCEDURE....................................................................................................................... 11

4.3. SETUP QUICK REFERENCE............................................................................................................................ 12

4.4. CALIBRATION GROUP PROGRAMMING........................................................................................................ 14

4.4.1. Internal Scale Setup and Calibration ........................................................................................................ 15

4.4.2. Remote Scale Shift Adjust ........................................................................................................................ 18

4.4.3. Remote Scale Setup and Calibration ....................................................................................................... 18

4.5. ZERO, MOTION, AND FILTERING GROUP PROGRAMMING....................................................................... 21

4.6. TARE GROUP PROGRAMMING ...................................................................................................................... 23

4.7. ACCUMULATOR GROUP PROGRAMMING.................................................................................................... 24

4.8. SAMPLE GROUP PROGRAMMING ................................................................................................................. 25

4.9. DISPLAY GROUP PROGRAMMING................................................................................................................. 27

4.10. SERIAL I/O GROUP PROGRAMMING........................................................................................................... 30

4.10. INTERNATIONAL GROUP PROGRAMMING ................................................................................................ 32

................................................................................................................... 9

Page 7

Table of Contents

5. OPERATING INSTRUCTIONS

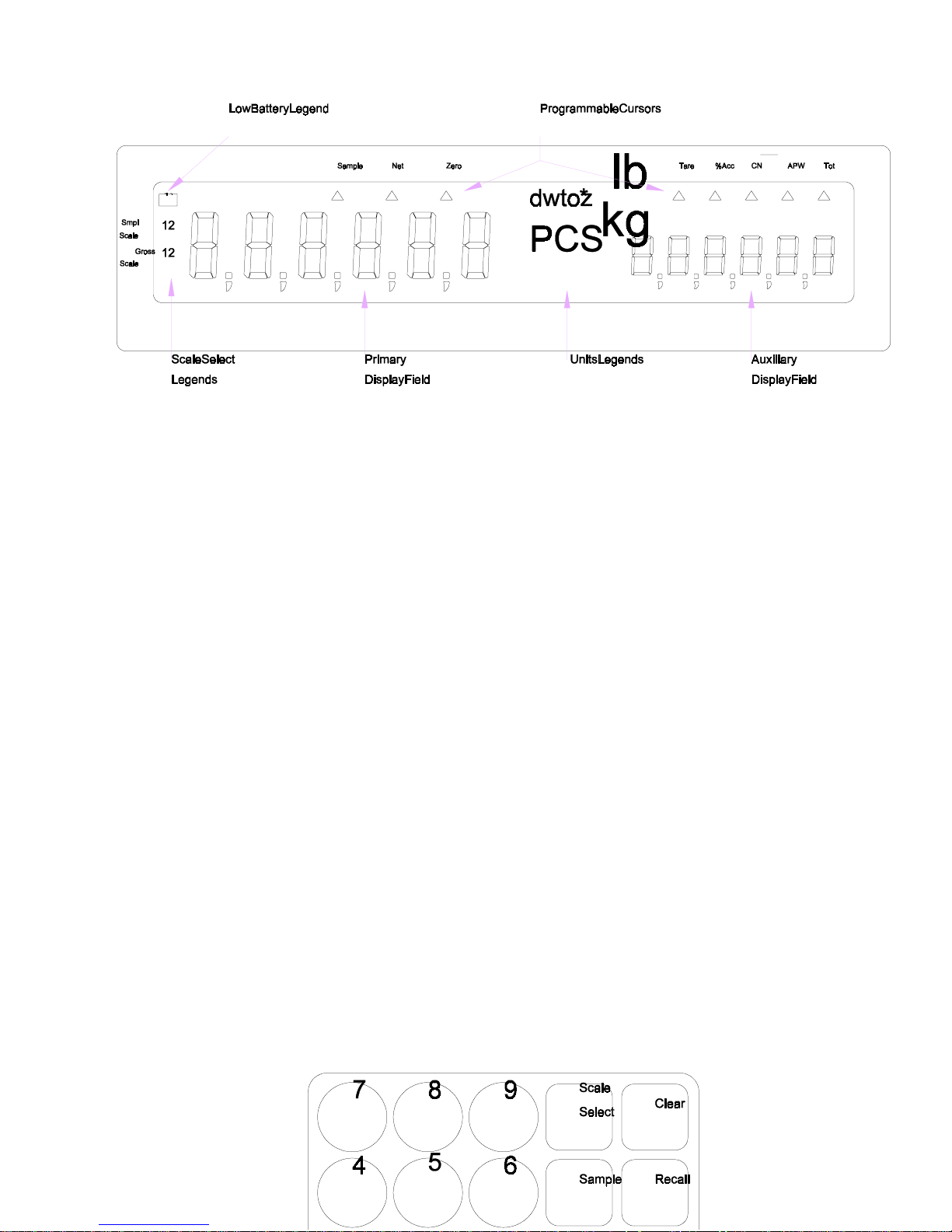

5.1. DISPLAY FORMAT AND LEGENDS ................................................................................................................. 35

5.2. KEYBOARD OPERATION.................................................................................................................................. 36

5.2.1. Order Independent Mode Key Definitions................................................................................................. 37

5.2.2. Order Dependent Mode Key Definitions................................................................................................... 37

5.3. PUSHBUTTON ZERO........................................................................................................................................ 38

5.3.1. Zeroing the Gross Scale............................................................................................................................ 38

5.3.2. Zeroing the Sample Scale......................................................................................................................... 38

5.4. COUNTING OPERATION .................................................................................................................................. 39

5.4.1. Order Dependent Counting Modes........................................................................................................... 39

5.4.2. Order Independent Counting Mode .......................................................................................................... 43

5.5. SAMPLE ENHANCEMENT AND COUNTING WEIGHT RANGE PARAMETERS.......................................... 44

6. INPUT AND OUTPUT CONNECTORS AND INTERFACING

6.1. PRINTER INTERFACE SPECIFICATIONS....................................................................................................... 47

6.1.1. Data Format............................................................................................................................................... 47

6.1.2. Printer Interconnect................................................................................................................................... 49

6.1.3. ASCII Remote Input .................................................................................................................................. 49

6.2. REMOTE SCALE BASE INTERFACING........................................................................................................... 49

6.2.1. Remote DigiTOL® Scale Base Connection............................................................................................. 50

6.2.2. Remote Analog Scale Base Connection................................................................................................... 51

7. PREVENTIVE MAINTEN ANCE

7.1. TROUBLESHOOTING........................................................................................................................................ 53

7.2. ERROR CODES ................................................................................................................................................. 54

7.3. POWER SUPPLY VOLTAGE CHECKS ............................................................................................................ 55

7.3.1. External Power Supply.............................................................................................................................. 55

7.3.2. +12 VDC Logic Supply.............................................................................................................................. 55

7.3.3. +20 VDC Supply........................................................................................................................................ 56

7.3.4. +5 VDC Logic Supply................................................................................................................................ 56

7.3.5. +12.5 VDC Analog Load Cell Excitation ................................................................................................... 56

7.4. LOAD CELL REPLACEMENT............................................................................................................................ 57

7.5. OVERLOAD STOP ADJUSTMENT ................................................................................................................... 58

7.5.1. Low Capacity Overload Adjustment (8572-0002, 0003, 1002, 1003) ...................................................... 59

7.5.2. Higher Capacity Overload Adjustment (8572-0004, 0005, 0006, 1004, 1005, and 1006)....................... 59

7.6. KEYBOARD REPLACEMENT............................................................................................................................ 60

7.7. LOGIC PCB REPLACEMENT............................................................................................................................ 62

7.8. RECOMMENDED SPARE PARTS .................................................................................................................... 62

7.9. OPTIONAL KITS................................................................................................................................................. 63

......................................................................................................................... 35

.............................................................. 47

....................................................................................................................... 53

8. PARTS CATALOG

8.1. EXTERIOR VIEW LOW CAPACITY VERSIONS (Factory Numbers 8572-0002, 1002).................................. 65

8.2. EXTERIOR VIEW HIGHER CAPACITY VERSIONS

(Factory Numbers 8572-0003, 0004, 0005, 0006, 1003, 1004, 1005, and 1006) ............................................. 66

8.3. BOTTOM VIEW .................................................................................................................................................. 67

8.4. PCBs AND TOP COVER.................................................................................................................................... 68

8.5. INTERIOR OF BASE .......................................................................................................................................... 69

................................................................................................................................................ 65

9. INTERCONNECT DRAWING

........................................................................................................................... 70

Page 8

1. GENERAL DESCRIPTION

The Toledo Scale DigiTOL® Model 8572 Parts Counting Scale is a high resolution scale designed f or use in m ost

industrial environments. The 8572 can be used with one analog or DigiTOL® remote scale base, offer ing f lexibility

and consistently accurate parts counting perfor mance.

HAZARDOUS by the National Electric Code (NEC) because of combustible or explosive atmospheres, or in

areas that contain extreme dust, moisture, or corrosive materials.

1.1. STANDARD FEATURES

6

Internal Toledo® DigiTOL® load cell in 5, 10, 25, 50, and 100 lb capacities with one part in 500,000 internal

resolution.

6

Low power LCD (Liquid Crystal Display) with programmable cursors and two, six digit displays for weight data

and counting information.

6

20 position sealed polycarbonate keyboard with embossed edges and tactile feedback.

6

Bidirectional RS-232 serial port for printer or com puter interfac ing with single character ASCII input f or rem ote

print, tare, clear, zero, and accumulator functions.

6

Low power CMOS circuitry to maximize optional battery life.

6

12 VDC 0.6 A wall transformer to power the standard 8572.

The 8572 MUST NOT be used in areas classified as

6

Automatic Average Piece W eight (APW ) enhancement. If select ed, the 8572 automatically recalculates the

APW continuously up to 4% of scale capacity.

6

Selectabl e sample si ze.

6

Pushbutton zeroing (±2% or ±20% of scale capacity) with automatic zero maintenance.

6

Independent or dependent modes of counting operation.

6

A 16 digit ID for transaction identification.

6

A single register accumulator for weight or count data.

6

A resetable consecutive number register that increments every time an accumulation is performed.

6

All setup parameters and scale operating features including calibration are easily configured through the

standard keyboard.

1.2 OPTIONAL FEATURES

6

12.5 VDC 1.5 A wall mount transformer is required to power the 8572 if any optional equipment is installed in

the 8572.

6

Input for one DigiTOL® or analog scale base, with 1 part in 500,000 internal resolution.

6

Bar code input by means of a hand held wand or scanning gun.

6

Internal and/or external batteries for applications requiring operation without AC power.

Page 9

1.3. STATEMENT OF PERFORMANCE

The performance of any count-by-weighing scale is dependent on uniformity of piece weight, the number of

pieces in the sample, the weight of an individual piece and the per cent of rated load plac ed on the scale for a

sample. Count accuracy is also dependant upon correct operation of the scale.

The 8572 high resolution parts counting scale significantly reduces count errors caused by the operator. In

most applications, it provides better practical accuracy than either hand counting or other mechanical

techniques. W ith the proper scale selection, c ount accuracy of ± one piece is attainable. However the most

significant variable is non-uniformity in the weight of the parts to be counted; this variable is beyond the contr ol

of the scale.

1.4. ACCURA CY CONSIDERATIONS

Counting accuracy is determined prim arily by two factors: Sample size as a percentage of full sc ale capacity

and variation in weight from piece to piece of the parts to be counted.

The first factor is the most f requent cause of counting inac curacy because of the user's des ire to hand count

the minimum possible num ber of sample pieces. Using too s mall a sample size results in limited accuracy.

For example, with a sample weight equal to 0.05% of full scale c apacity, the internal sample weight resolution

is ±1 part in 250, therefore counting acc uracy will be limited to ±0.4% in this example. Use of a sample size

that is a higher percentage of full scale capacity will result in improved counting accuracy.

The overall count accuracy can be severely affected if the pieces used for the sample are not truly

representative of the average piece weight. The sec ond factor is not under the control of the par ts counting

scale, but this factor can be m inimized by using the largest practical sam ple size possible and resampling

when counting different lots of the same material.

2

Page 10

2. SYSTEM DESCRIPTION

The 8572 Logic PCB provides a DC voltage to the digital load cell which responds with numeric values proportional

to the weight applied to the platter. This weight information is then used to determine the average piece weight and

corresponding piece count. Setup parameters and calibration are ac ces sible via the fr ont k eyboard, so no internal

access is required to configure the 8572. Setup and calibration data is stored in non-volatile m emory to prevent

memory loss from occurring during a power outage.

2.1. INTERNAL FUNCTIONS

The basic 8572 consists of four major components. These are:

DigiTOL® Load Cell

6666

the Logic PCB.

Logic PCB -

6666

the keyboard, communic ates with the DigiTOL® load cell, dr ives the display PCB, pr ovides a bidir ectional

RS-232 serial printer port, and supplies connections for optional accessories.

Keyboard -

6666

covered with an embossed polycarbonate overlay that provides ridges to separate active key areas. The

functions available are tare entry, sample or APW entry, numeric ID entry, clearing of data, printing,

zeroing of the scale, scale selection, recall access and setup selection.

Display PCB

6666

display weight or count information. Six, 0.44" (11 mm) high, seven-segm ent digits display net weight,

percentage of accuracy, consecutive num bering, average piece weight, or total counts. The LCD dis play

also provides low battery and status symbols and eight programmable cursors to indicate display or

operating mode.

Contains the power supply and logic circuitry required to operate the scale. This PCB scans

The sealed membrane, four by five matrix k eyboard with domed keys for tactile feedback , is

- Contains the LCD (liquid crystal display). Six, 0.7" (18 mm ) high, seven- segm ent digits

- A single point loading, high resolution load cell that c ommunic ates weight data to

2.2. OPTIONAL KITS

The standard 0.6 A, 12 VDC power supply (*135156 00A), MUST be replaced with the optional 1.5 A, 12.5

VDC power supply (*135693 00A) when any optional KOP is installed in the Model 8572.

2.2.1. Bar Code

Scanning of bar code data can accomplished by means of the bar code wand kit or the bar c ode s canning

gun kit. The 8572 can read Code 39, Interleaved 2 of 5, or Codabar form at bar code data. Tare, APW ,

and up to 16 digits of alphanumeric ID c an be scanned into the 8572. The 8572, when coupled with the

Model 8860 thermal printer, can print up to six lines of bar code and/or human readable data on an

adhesive label in a variety of formats.

2.2.2. Remote Scale Input

The 8572 remote scale input provides 1 part in 500,000 resolution and approx im ately nine weight updates

per second. The 8572 can accommodate one remote scale base of either the DigiTOL® or analog type.

The remote DigiTOL® scale PCB is com patible with all Toledo Scale DigiT OL® scale bas es including the

Model 2157 floor scale (digital j-box), also referred to as DigiTOL® POWER MODULE. The remote

analog scale PCB can supply excitation voltage for up to four 350 ohm load cells and is com patible with

both 2 mV/V and 3 mV/V analog load cells.

NOTE: The 8572 requires that four load cells be used with the digital j-box. The Model 2157 floor scale (digital

j-box) provides up to 1 part in 280,000 resolution.

2.2.3. Battery Power Operation

3

Page 11

2.2.3.1. Battery Powered Operating Time

The internal battery kit allows operation of the 8572 when AC power is not available. The internal

battery provides up to 8 hours of power. The battery can be removed by means of an access cover

located on the back of the 8572. T he normal rec harge time is approximately 12 hour s with the 8572

turned off. The exter nal battery pack provides up to 32 hours of power and is easily replaced with a

freshly charged external battery pack for applications requiring extended use without AC power. T he

normal battery recharge time is approximately 16 hours with the 8572 turned off.

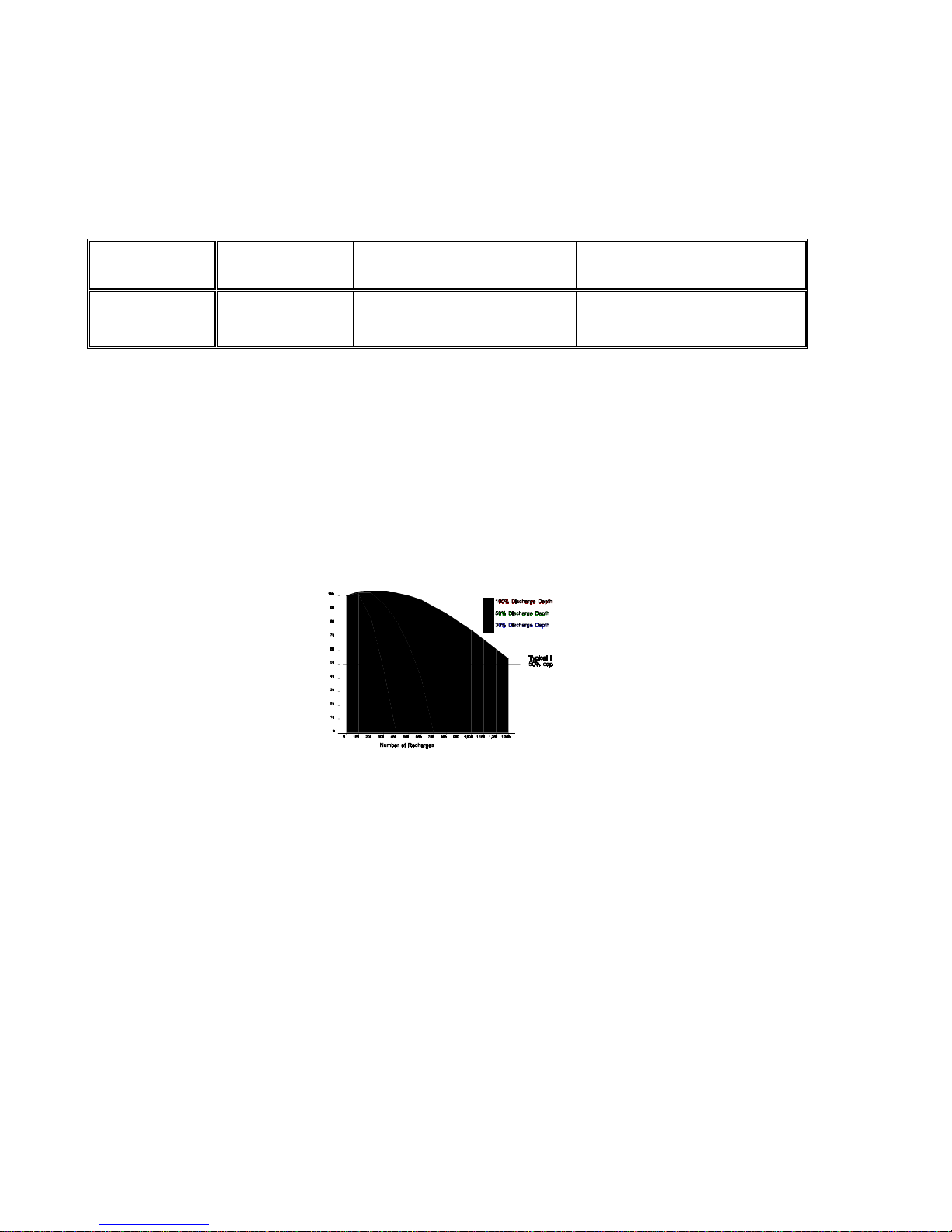

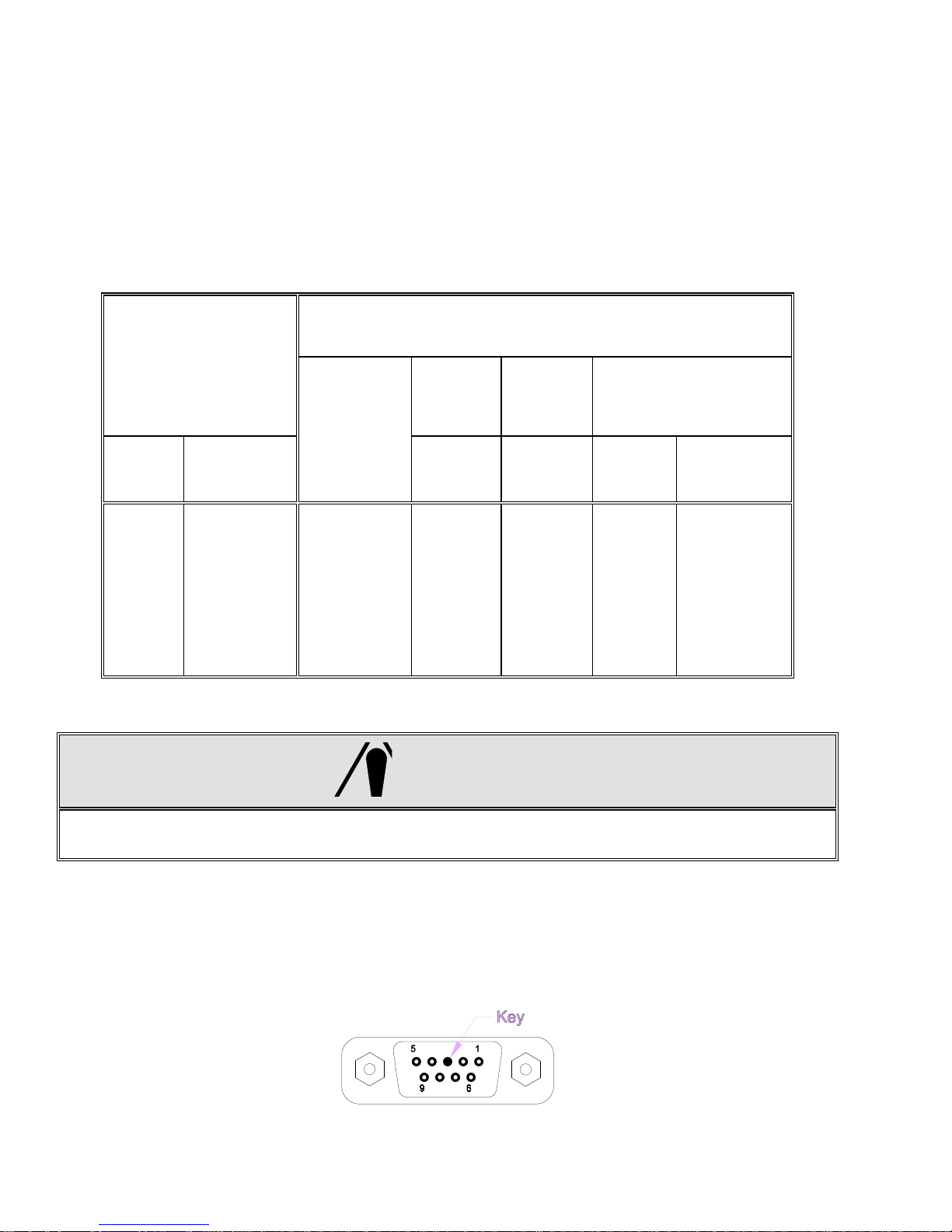

Battery Option

Installed

Internal 8 hours 3 hours (Not recommended) 2 Hours (Not Recommended)

External 32 hours 16 Hours 8 Hours

Table 2-1 Recommended Battery Powered Operating Time With Example Configurations

2.2.3.2. Battery Service Life Considerations

Battery service life is a major f ac tor in es timating the maximum operating tim e of a c harged battery.

The internal and external battery options use a lead/acid "gel" cell type of battery that is similar to

an automobile battery.

completely discharged on a repetitive basis

deeply a battery is routinely discharged and how many times the battery can be recharged. A

battery is considered to have exceeded its working lif e when the fully charged capacity is less than

50% of the original rated capacity. Refer to Table 2-1.

No other

Options Installed

Remote DigiTOL® Scale

Bar Code KOP

Lead/acid batteries lose charge capacity more quickly if they are

. There is an inverse relationship between how

Remote Analog Scale Base

(4-350 Α Load Cells)

To maximize the working life of a

battery, recharge the battery on a the

basis of how many hours the scale has

been in use rather than running until the

8572 powers itself down. If a particular

scale configuration results in a

maximum battery charge life of 24

hours before the battery is exhausted,

then the battery pack should normally

be used for 8 hours and then

recharged. Extra battery packs and an

external battery charger are available to

permit continuous battery powered

operation. Following this procedure will

greatly increase the service life of the

battery and prevent premature battery

failure.

a battery at temperatures above 860 F (300 C) shortens service life considerably.

Figure 2-1 Number of Recharge Cycles Related to Battery Discharge Depth

Always recharge batteries after use. Batteries stored in a discharged state may refuse to take a

charge.

Storing batteries at 500 F (100 C) or below extends shelf life before recharging is necessary.

Batteries should be recharged every six months of s torage (when stored at room temperature) .

3. SPECIFICATIONS

4

Operating and storage conditions also

influence battery service life. Operating

Page 12

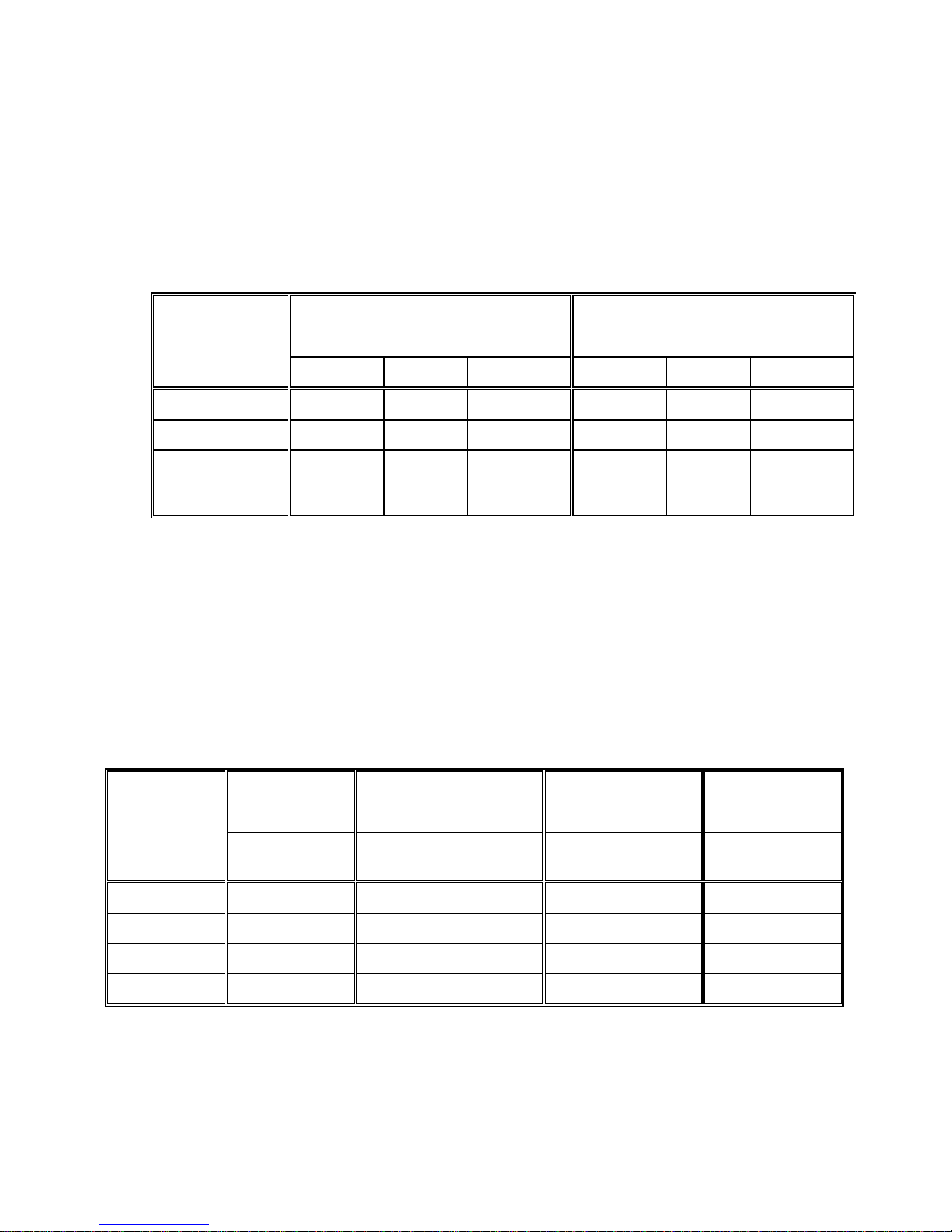

3.1. ELECTRICAL

3.1.1. Power Requirements

The 8572 operates at 120 VAC (+10%, -15%) 60 Hz. Export versions of the 8572 oper ate on 220 VAC,

50 Hz. Power to the 8572 is provided by means of an external 0.6 A / 12 VDC power supply. Power

consumption for the basic 8572 without any options installed is four watts.

The 8572 meets the NIST H-44, Canadian Gazette Part 1, and OIML-SP7/SP2 line voltage variation

specifications.

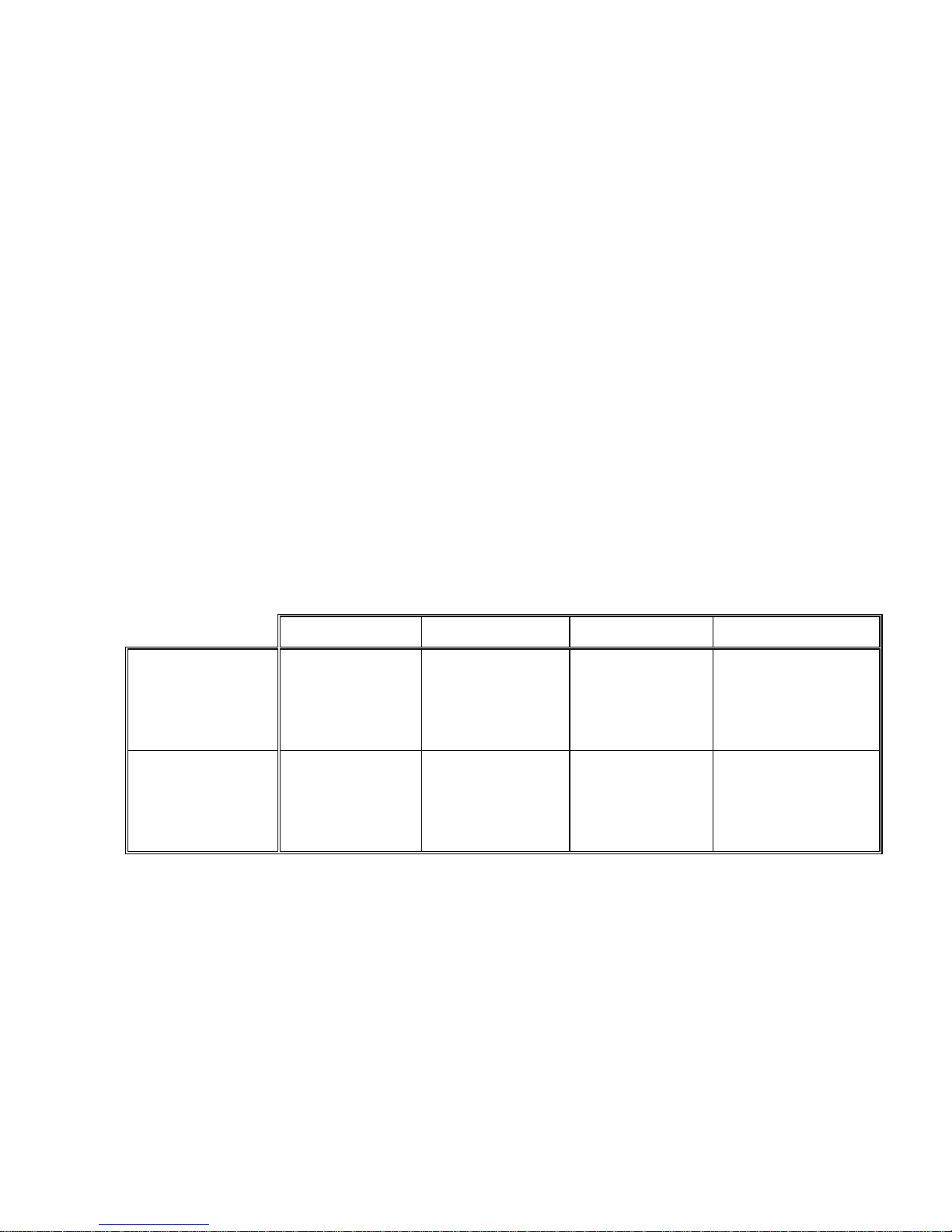

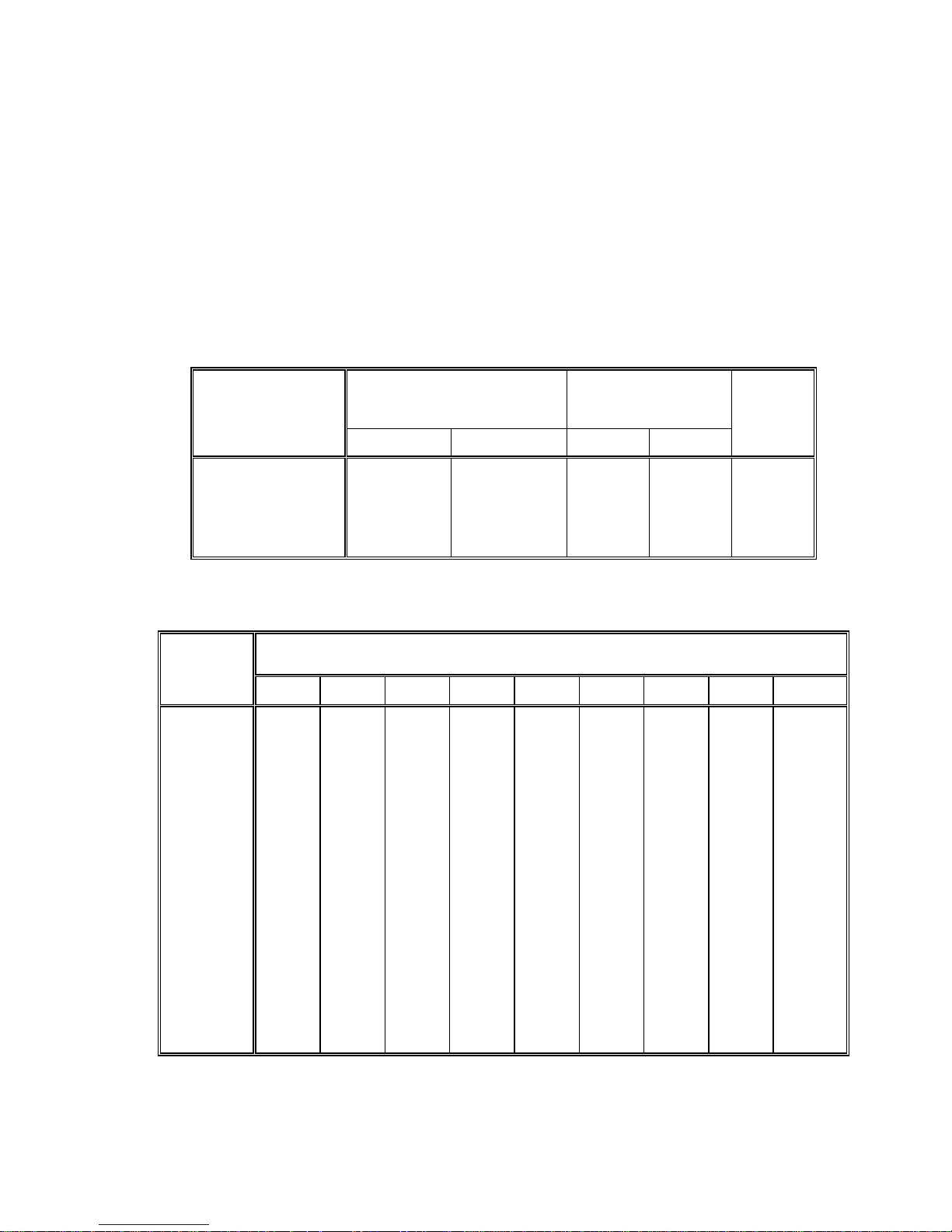

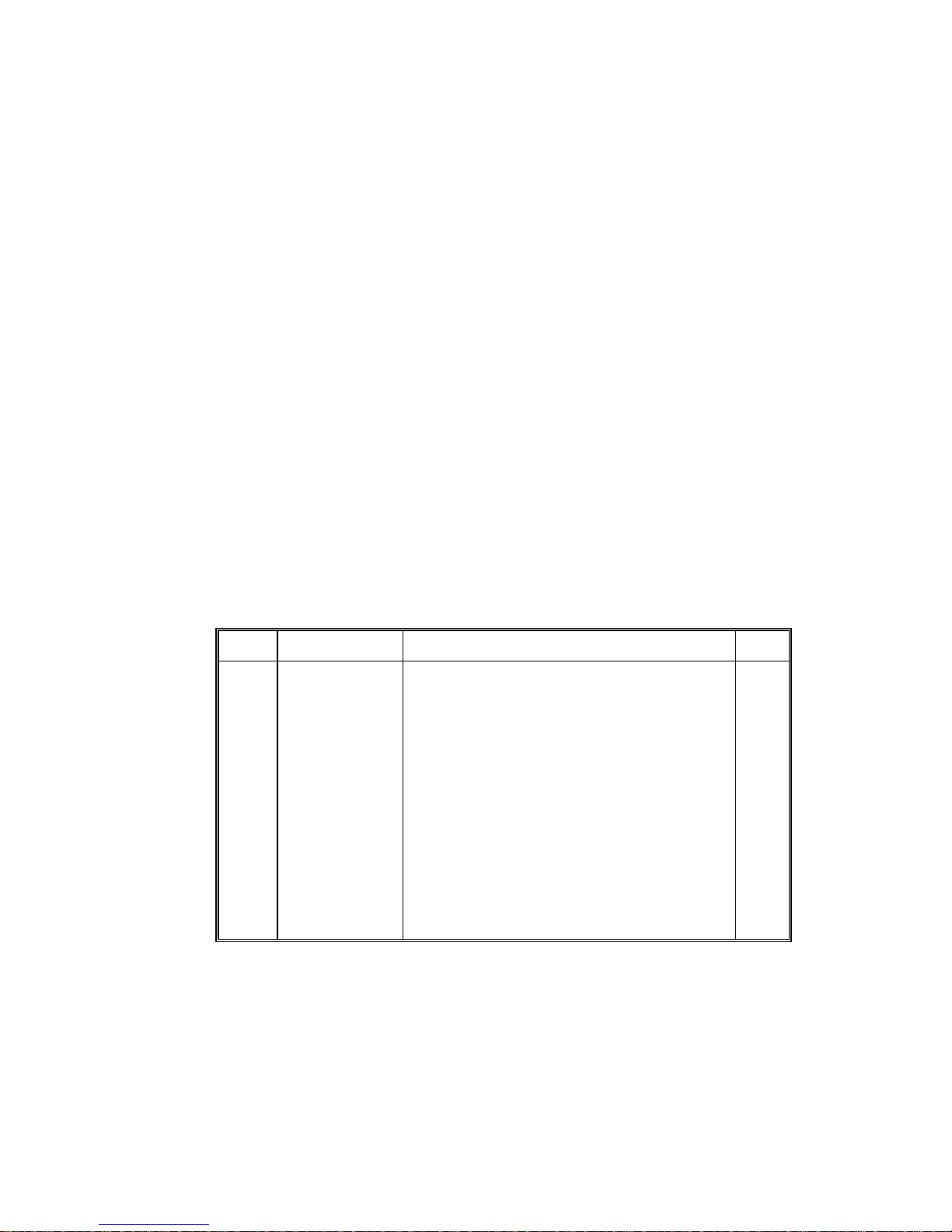

Line Voltage

AC Line Voltage Line Frequency in Hz

Variation

Specification

Minimum Nominal Maximum Minimum Nominal Maximum

NIST H-44 100 120 130 59.5 60 60.5

Canadian 108 120 132 58.8 60 61.2

OIML-SP7/SP2

102

187

204

120

220

240

132

242

264

58.8

49.0

49.0

60

50

50

61.2

51

51

Table 3-1 AC Line Power Voltage Specifications

3.1.2. Conducted and Radiated Emissions

The 8572 meets or exceeds FCC docket 80-284 for conducted and radiated emissions requirements.

The 8572 meets or exceeds the VDE 0871 class B specification for conducted and radiated emissions.

3.1.3. Radio Frequency Interference

The 8572 meets U.S.A., Canadian, VDE 0871 class B, and U.K. requirements f or RFI susceptibility as

listed below with a maximum of one display increment of change.

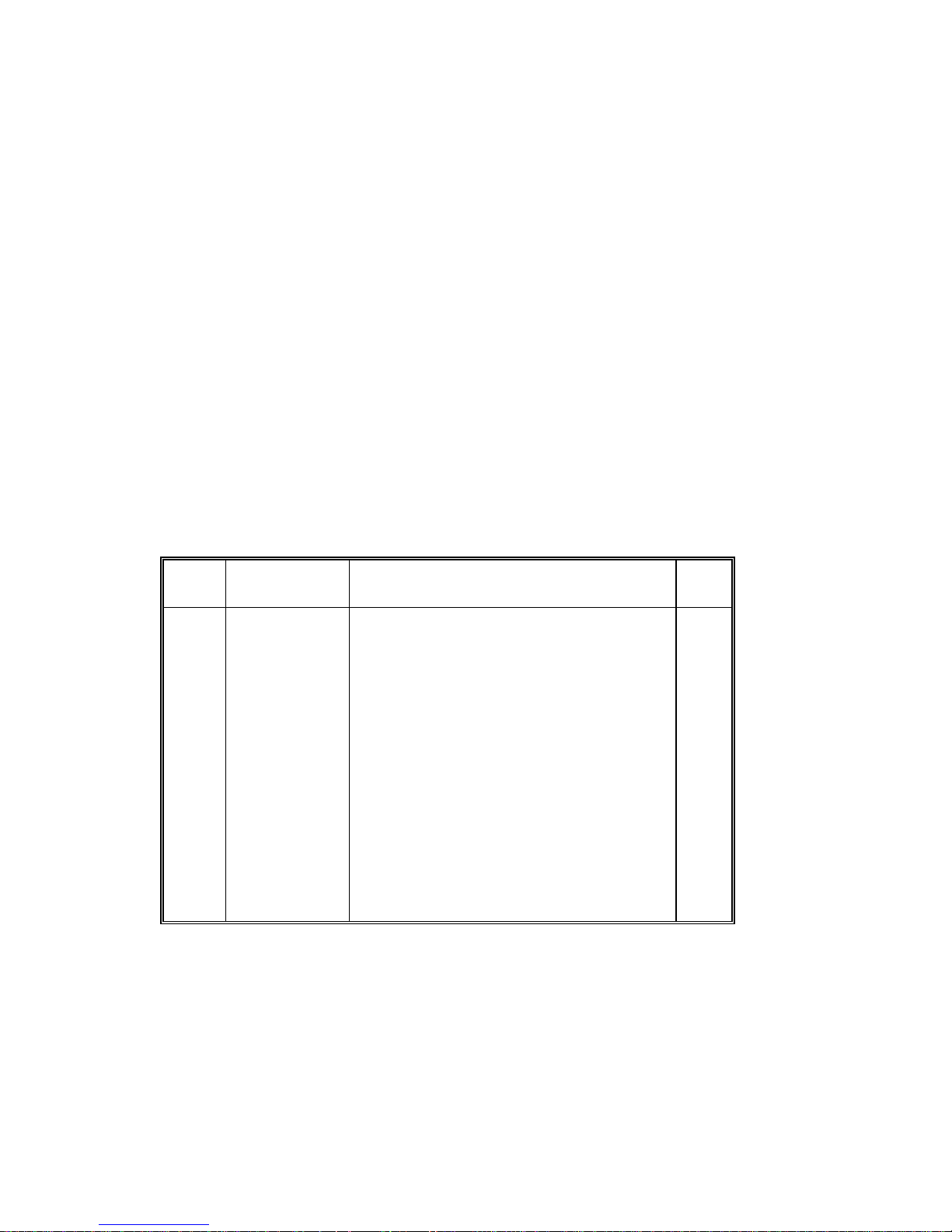

Radio

U.S.A. Canadian VDE 0871 Class B U.K.

Interference

Frequency

Field Strength Transmitted Power at

27 MHz 3 volts/meter 4 watts at 2 meters 3 volts/meter 10 volts/meter

144 MHZ N.A. N.A. 3 volts/meter N.A.

169 MHz 3 volts/meter N.A. 3 volts/meter 10 volts/meter

464 MHZ 3 volts/meter 4 watts at 2 meters 3 volts/meter 10 volts/meter

Field Strength Field Strength

Specified Distance

Table 3-2 Radio Frequency Interference Continued

(N.A.) Not Applicable

5

Page 13

3.2. ENVIRONMENTAL

The 8572 is intended for use in a general purpose atmosphere. It is intended for indoor applications where

dirt, oil or water is not present. The 8572 is not designed for "hose-down" applications. Typical examples of

misapplication of the scale include, but are not limited to: Immersion in liquid, hosedown, corrosive

chemicals.

3.2.1. Temperature Specification

The 8572 has an operating temperatur e range of from 10 0 to 40 0 C, (50 0 to 104 0 F) at 10 to 95%

relative humidity, non-condensing. The 8572 has a storage temperature range of -40 0 to 60 0 C, (-40

to 140 0 F) at 10 to 95% relative humidity, non-condensing.

3.2.1.1. Internal DigiTOL® Load Cell

The 8572 internal scale has a zero temper ature coefficient of 24 PPM/0C and a span temperature

coefficient of 23 PPM/0C.

3.2.1.2. Remote Analog Scale PCB

The optional analog scale PCB has a zero temperature coefficient of 0.1 uV/0C and a span

temperature coefficient of 6 PPM/0C

3.2.2. Hazardous Areas

0

In locations classified as hazardous by the National Electrical code (NEC) because of combustible or

explosive atmospheres or materials, special precautions are required.

DO NOT USE THE 8572 IN THESE LOCATIONS

3.3. PHYSICAL SPECIFICATIONS

3.3.1. Appearance and Dimensions

The 8572 enclosure is fog white with a black platter ass em bly and multi-c olor k eyboard. the unit is 5.3"

(135 mm) high, 14.7" (375 mm) wide and 14.6" (370 mm) deep. The standard 8572 weighs

approximately 20 lb (9.1 kg). The bas e and sub-platter are made from die- cast aluminum . The 8572

uses a single point loading, moment-insensitive load cell. The cover and bezel are made of heavy

structural plastic. A level indicator bubble is mounted in the sub-platter which can be viewed by

removing the platter.

3.3.2. Internal Scale Platter

The 5 lb capacity scale has an 8" X 8" (205 m m) plastic platform . The 10, 25, 50, and 100 lb capacity

scales has a 14.5" wide (370 mm) X 10.8" deep (275 mm) painted steel platter.

3.3.3. Shipping Information

Approximate shipping weight is 22 lb (10 k g). Carton dimensions ar e 9" (230 mm) X 19" (485 mm) X

19" (485 mm).

.

3.4. DATA INTERFACE

6

Page 14

The 8572 supplies a bidirectional RS-232 printer port standard. The baud rate is selectable from 300 to

9600 baud and parity is selectable as even, odd, or parity bit always a "0". All data is in a 10 bit fram e: 1

start bit, 7 ASCII coded data bits, 1 parity bit and 1 stop bit. The 8572 printer port is powered by the

external RS-232 device connected to the 8572. Both the transmit and receive RS-232 data lines of the

8572 printer port must be connec ted to a true RS- 232 exter nal devic e to permit data output. No hands hak e

lines are provided on the printer port.

3.4.1. Data Output

When a print request oc curs (caus ed by pressing the

an ASCII "P" into the printer port), the 8572 will output data unless output is inhibited. Data output will

be inhibited by an unstable weight reading (scale "in motion"), an out of range weight reading (under

zero or over capacity) or if the 8572 is in the expanded weight display mode. If repeat print is disabled

the 8572 will output data only once per weighment after which the load on the scale must be removed

and a new load placed on the scale before data can be output.

A selectable checksum character can be added to the data output to perm it detection of transmission

errors. A selectable ASCII <SO> (shif t out) charac ter can be added to the data output to request lar ge

print size in the Model 8806 and 8860 printers.

3.4.2. Data Input

The 8572 printer port can be configured to permit an external device to control the 8572. Upper case,

ASCII characters ("C", "P","T" and "Z") received into the printer port are equivalent pressing to the

CLEAR, PRINT, TARE

transmitted and or cleared by ASCII characters.

3.5. CONFIGURATION GUIDE

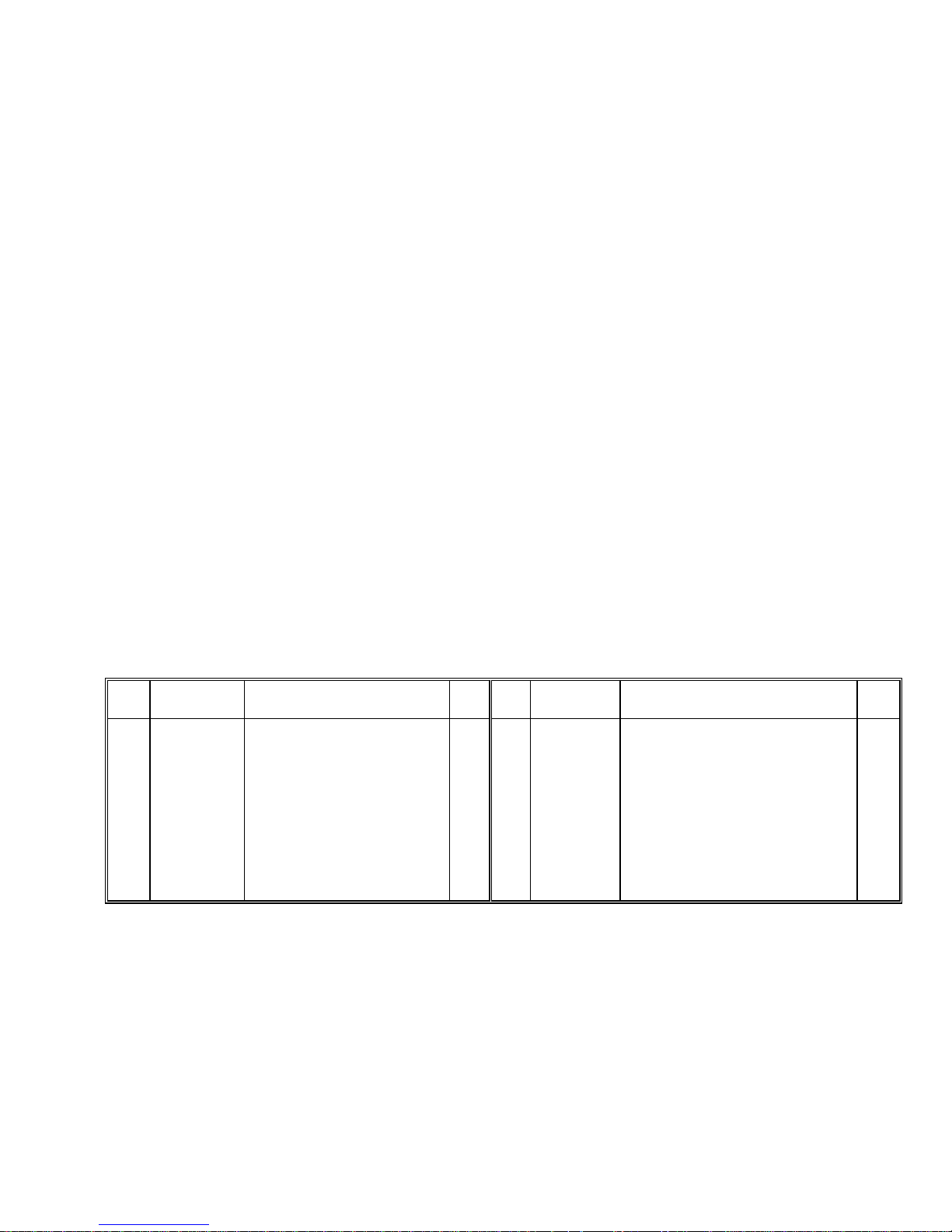

Factory Number Pounds Capacity Metric Capacity Load Cell Capacity

120 VAC, 60 Hz

U.S.A. and

Canadian

Versions

8572-0002

8572-0003

8572-0004

8572-0005

8572-0006

and

PRINT

key, an autoprint operation or by receiving

ZERO

keys on the 8572 keyboard. The accumulator total can be

5 X 0.001 lb

10 X 0.002 lb

25 X 0.005 lb

50 X 0.01 lb

100 X 0.02 lb

2.5 X 0.0005 kg

5 X 0.001 kg

10 X 0.002 kg

25 X 0.005 kg

50 X 0.01 kg

3.75 kg

7.5 kg

15 kg

30 kg

60 kg

220 VAC, 50 Hz

Europe and

General Export

Versions

8572-1002

8572-1003

8572-1004

8572-1005

8572-1006

5 X 0.001 lb

10 X 0.002 lb

25 X 0.005 lb

50 X 0.01 lb

100 X 0.02 lb

2.5 X 0.0005 kg

5 X 0.001 kg

10 X 0.002 kg

25 X 0.005 kg

50 X 0.01 kg

Table 3-3 Factory Number Configuration

7

3.75 kg

7.5 kg

15 kg

30 kg

60 kg

Page 15

- For Your Notes -

8

Page 16

4. INSTALLATION INSTRUCTIONS

Examine the shipping box for damage.

Open the box, remove the scale, and plac e the scale on a f lat, level, stable surf ace. Save the shipping box f or

future use.

IMMEDIATELY make a claim with the carrier if damage is found.

2 CAUTION!

Do not lift the scale by the platter or sub-platter. Grasp the scale by the base

to lift. Do not stress or bump the sides of the platter as this will place a side

torque on the platter and may damage the load cell.

4.1. UNPACKING AND SETUP

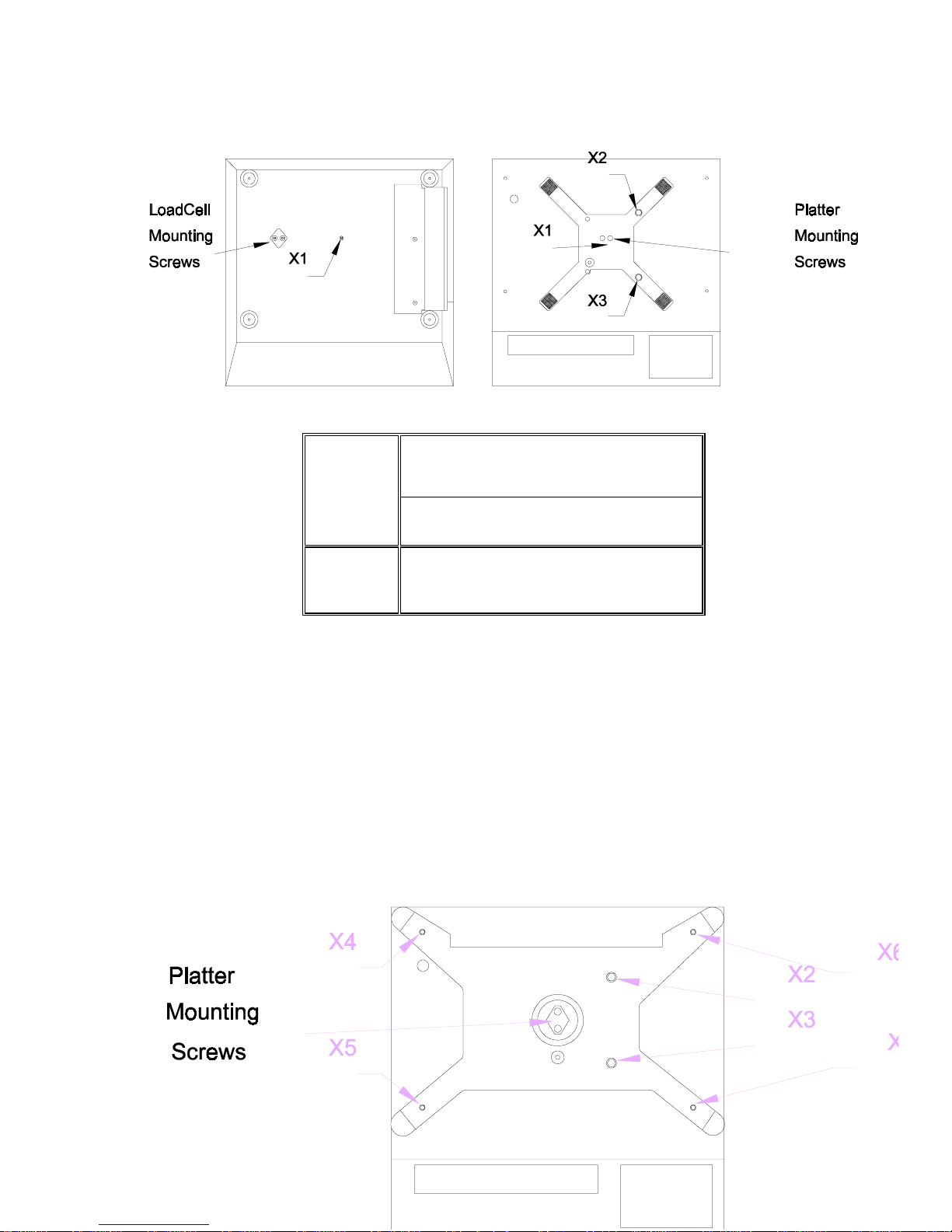

For the 5 lb capacity scale (8572-0002, 1002), follow the procedure lis ted in Section 4.1.1. For all other

versions, lift the platter upward to remove, find the level bubble indicator located in the center of the

subplatter and proceed to Section 4.1.2.

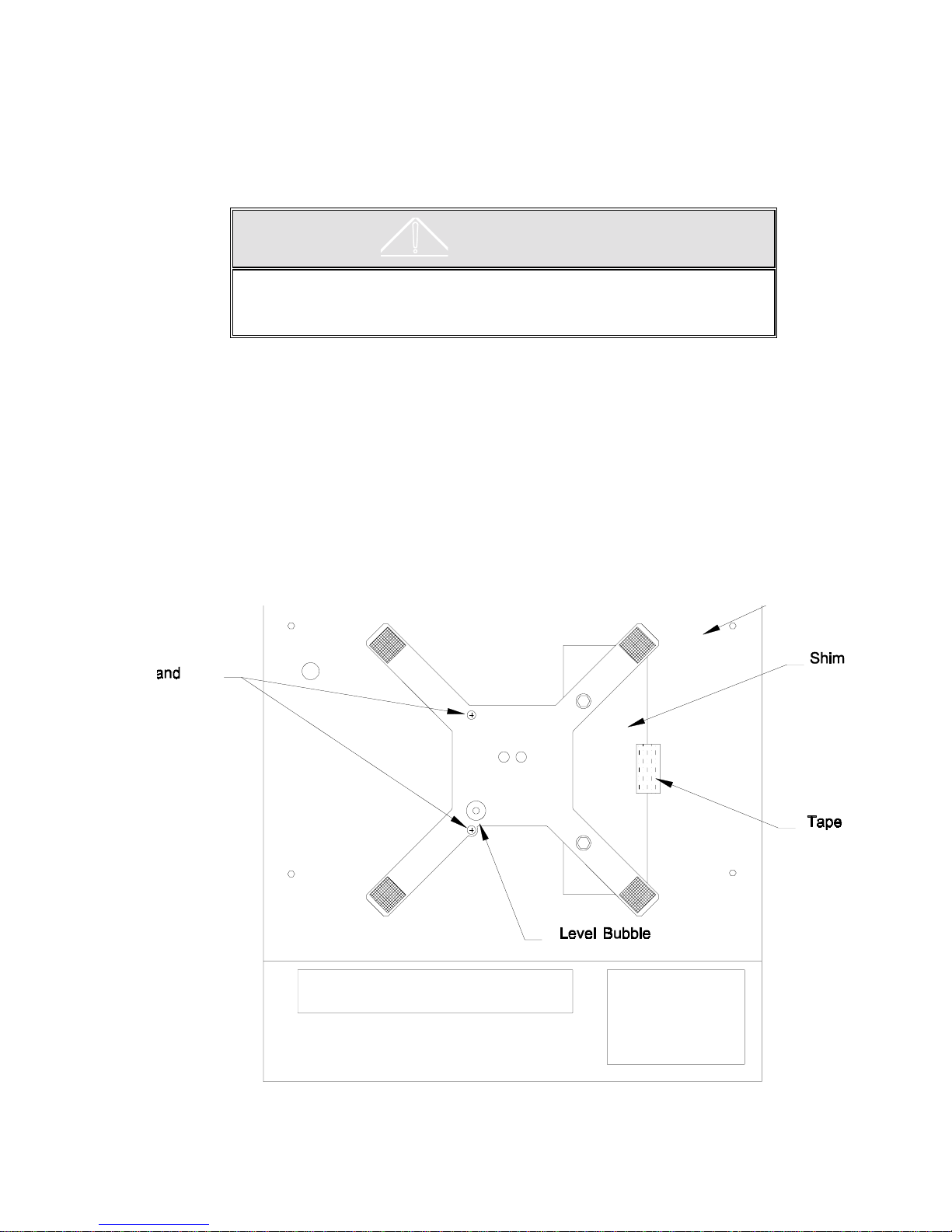

4.1.1. Unpacking Instructions for Low Capacity Scale (for 8572-0002, 1002 versions only)

Remove the rubber band securing the 8" X 8" plastic platter to the s ub-platter. G rasp the plas tic platter

by the edges and lift straight up to remove it. The platter is held by hook and loop fasteners in the

corners. Remove the two #8-32 screws and rubber O rings from the top of the sub-platter. Remove the

tape and shim from the top of the right side of the dead- deck . Locate the level bubble indicator located

on the left front of the subplatter. Refer to Figure 4-1. Save all shipping hardware for future use.

4.1.2. Level the Scale Base

Figure 4-1 Low Capacity Shipping Hardware

9

Page 17

Level the scale by turning the adjustable feet on the bottom of the scale bas e until the level indicator is

correct. The feet mus t be adjusted so the scale does not roc k. Carefully tighten the lock nut at each

adjustable foot. Refer to Figure 4-2.

Figure 2 - Level Bubble

4.1.3. Install All Optional KOPs

Install any desired options in the 8572. Refer to the installation instructions included with the optional kit

of parts. Adding any option to the 8572 requires substituting the optional 1.5 A / 12.5 VDC power supply

(*135693 00A) for the standard 0.6 A / 12 VDC power supply (*135156 00A).

4.1.4. Initial Power Up Sequence

Connect AC power to the 8572 and turn on the power switch (located on the right side of the base near

the front). The following sequence of events will then occur:

6

All cursors, data fields, and legends light up and the decimal point then scr olls across the dis plays

from the right-most digit to the left-most digit.

6

The software part number and revision level are then displayed for a few seconds.

an example of the L02 revision powerup display. If a

[tESt ]

message is displayed instead of the

[135629 L02]

software part number then the 8572 is in the factory test mode. The test mode is entered by

powering up the 8572 with the setup switch turned on and is for factory setup use only. To exit the

test mode: power down the 8572, slide the setup switch to the rear of the enclosure, and power up

the 8572. Refer to Section 4.2. for setup switch location and description.

6

During power up the Logic PCB tests all memory devices and establishes com munication with the

load cell and any optional PCB's that are enabled in setup. Error m ess ages are displayed if any of

the memory tests are failed or if the load cell or optional PCB does not respond.

[E3]

If an

error is displayed then the setup mem ory is corrupt. Access the setup as descr ibed in

Section 4.2. and verify 8572 programming and calibration.

If any other error messages are displayed during the power up sequence refer to Sec tion 7.1. for

error code explanations and recommendations.

6

The last step of the power up sequence involves capturing zero on the gross scale if auto zero

capture or tare interlocks are enabled in setup. If the weight on the gross scale is within the auto

zero capture range (±2% or ±20% of programm ed scale capacity as selected in s etup), zero will be

automatically captured by the 8572 and sample and gross scale selection will be as selected in

setup step

If the weight reading is outside of the zero capture range, the prim ary display shows

[18]

.

[ E E E]

indicate that the weight indication is greater than the auto zero capture range. The primary display

shows

[-E E E]

to indicate that the weight indication is less than the auto zero capture range.

is

to

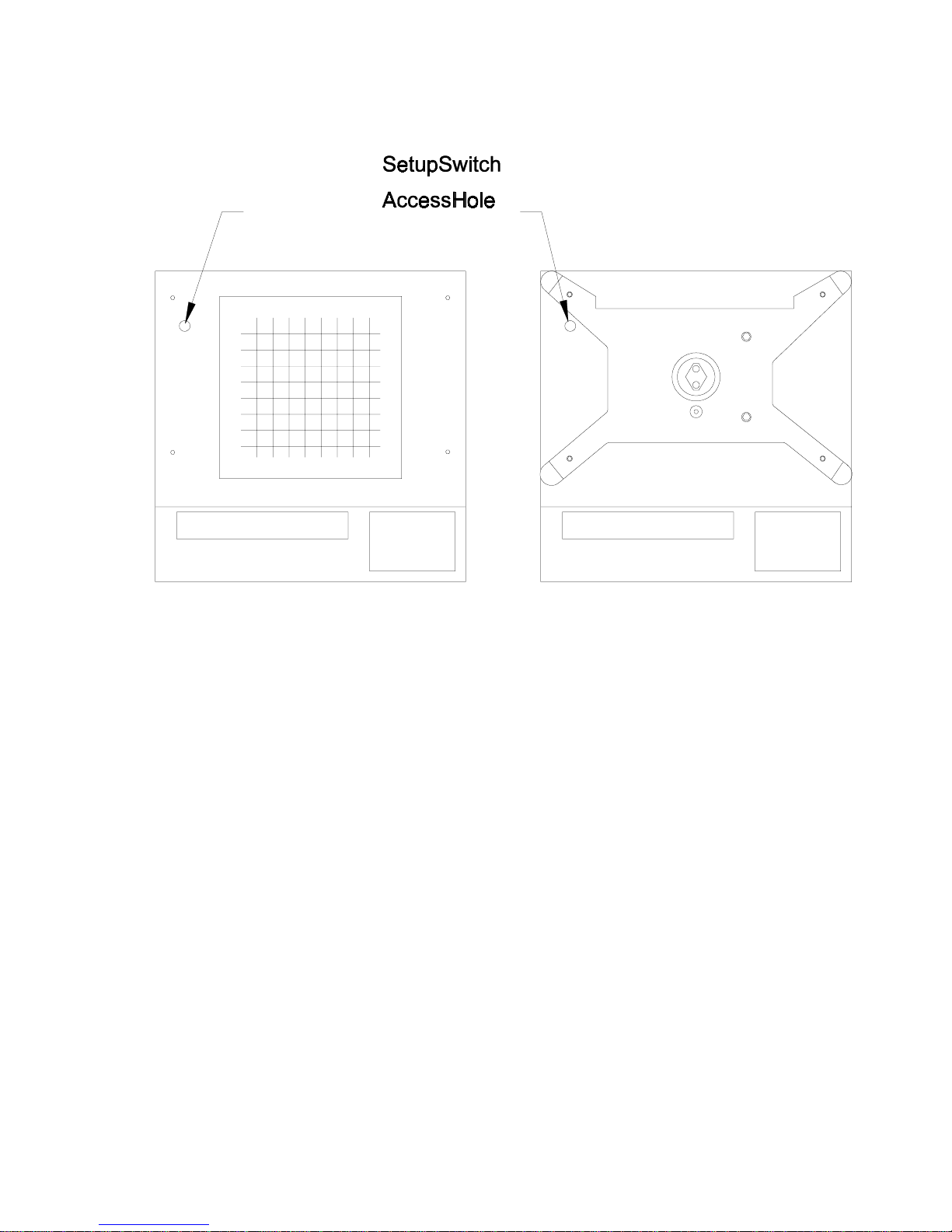

4.2. PROGRAMMING PROCEDURE

The SETUP mode perm its access to the programm ing and calibration parameters. To enter the SETUP

mode on the 8572, remove the platter ( on scales with the 11" by 14" platform) or rem ove the plastic cover

10

Page 18

plug (on scales with the 8" square platter) and locate the setup s witch access hole. Refer to Figure 4-3.

Slide the setup switch toward the front of the scale using a pointed, non-conductive object. Do not us e an

object that could be easily dropped into the unit.

Low Capacity Versions Higher Capacity Versions

Figure 4-3 Setup Switch Access Hole

After the setup switch is actuated, the 8572 displays

[-- ]

. The 8572 is now in the setup mode and ready to be

programmed.

The following keys are redefined to perform the function specified when in the setup mode.

ENTER

- Press this key to terminate a data entry for a specific step or accept the displayed value and

advance to the next setup parameter.

ZERO

CLEAR

- Press this key to back-up to the previous step.

- Press this key to clear the display, when the 8572 is prompting for data entry, and permit a new

value to be entered.

1

- Press this key to indicate a

0

- Press this key to indicate a NO response and advances to the next setup selection.

YES

response and advances to the next setup selection.

11

Page 19

4.3. SETUP QUICK REFERENCE

NOTE: The following chart pertains to the

(135629 LO2)

prompt displayed after powerup. Recommended default selections are shown in

[10] ACCESS CALIBRATION GROUP

[11] Weight Units 0 = lb units, no display legend

legend

[12] Linearity Compensation

[13] Remote Scale Selec tion

[15A] Internal Scale Capacity

[16A] Internal Scale Increment Size

[17A] Access Internal Scale Calibration

[14] DigiTOL J-box Shift Adjust

[15B] Remote Scale Capacity

[16B] Remote Scale Increment Size

[17B] Calibrate Remote Scale

[18] Power up Scale Select

1 = lb units and display

2 = kg

3 = g

4 = oz

5 = toz

6 = t

7 = dwt

0 = Disabled

1 = Enabled

0 = Disabled

1 = Single DLC

2 = DigiTOL® J-Box

3 = Analog Input

0 = Sample 1, Gross 1

1 = Sample 1, Gross 2

2 = Sample 2, Gross 1

3 = Sample 2, Gross 2

[20] ACCESS ZERO, MOTION, FILTERING GROUP

[21] Internal Scale AZM 0 = Disabled

[22] Remote Scale AZM 0 = Disabled

[23] Powerup Zero Capture 0 = Disabled

[24] Pushbutton Zero 0 = Disabled

[25] Motion Detect W i ndow 0 = Motion Detect Disabled

[26] Scale 1 Display Filter 0 = Disabled

[27] Scale 2 Display Filter 0 = Disabled

1 = Enabled

1 = Enabled

1 = 2% Scale Capacity

2 = 20% Scale Capacity

1 = Enabled

1 = 0.5 Increment

2 = 1 Increment

1 = Light

2 = Medium

3 = Heavy

1 = Light

2 = Medium

3 = Heavy

revision software. The so f tware r evision is the s ec ond

Italics

.

[28] Enhanced APW Repeat.

0 = Disabled

1 = Enabled

[30] ACCESS TARE GROUP

[31] Gross Scale Tare 0 = Tare Disabled

Tare

[32] Sample Scale Tare 0 = Tare Disabled

[33] Tare Interlock

[34] Auto Clear Tare

1 = Pushbutton Tare

2 = Pushbutton/Keyboard

1 = Pushbutton Tare

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

[40] ACCESS ACCUMULATOR GROUP

[41] Transaction Accum ul ator 0 = Acc umulation Disabled

[42] Auto Clear Accum ul ator

1 = Accumulate Piece Count

2 = Accumulate Gross Weight

3 = Accumulate Net Weight

0 = Disable

1 = Autoclear After Print

[50] ACCESS COUNTING GROUP

[51] APW or Piec e/Unit Weight 0 = Pieces per Unit Weight

[52] Include Sample

[53] Sample Mode and Size

[54] Sample Enhancement 0 = Disabled

[55] Minimum Sampl e Range

[56] Auto Sample Acceptance 0 = Manual Sample Accept

[57] Order Mode Select

[58] Auto Clear APW

[59] Piece Count Auto Ranging

1 = Average Piece Weight

0 = Disabled

1 = Enabled

0 = Variable Sample (10)

1 = Fixed Sample

1 = Enabled

0.02%

1 = Auto Sample Accept

0 = Independent

1 = ID, Tare, APW

2 = ID, Tare, Sample

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

Note: Recommended def aul t selections are shown in

4.3. SETUP QUICK REFERENCE CONTINUED

12

Italics

.

Page 20

[60] DISPLAY CONFIGURATION GROUP

[61] Recall Percent of Ac curacy 0 = Disabled

[62] Power Up Auxiliary Display 0 = Blank

[63] Count Descriptor 0 = None

[64] Cursor Assignment

[65] Decimal Point

[66] ID Enable 0 = Disabled

[67] ID Auto Clear

[68] Consecutive Numbering 0 = Disabled

[69] Test Mode

1 = Enabled

1 = APW

2 = CN

3 = % Acc

1 = "PCS"

2 = "*"

0 = Period Decimal Point

1 = Comma Decimal Point

1 = Enabled

0 = Disabled

1 = Enabled

1 = Enabled

[70] SERIAL I/O GROUP

[77] Print Net Wei ght Expanded

[78] Print Count Expanded

[79] Repeat Print

[81] Auto Print

[82] Option I/O Port Mode

[83] Option I/O Port Parity

[84] Option I/O Port Checksum

[85] Option I/O Port Baud Rate

[86] Option I/O Port Stop Bit

[90] INTERNATIONAL GROUP

[91] Analog Verify

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Bar Code Input

2 = Not Used

0 = Space

1 = Odd

2 = Even

0 = Disabled

1 = Enabled

9600

1

0 = Disabled

1 = Enabled

[71] Printer Port Parity 0 = Space

[72] Printer Port Checksum

[73] Printer Port Baud Rate

[74] Print Format 0 = Single Line

[75] Print Fields

[76] Print ID Expanded

1 = Odd

2 = Even

0 = Disabled

1 = Enabled

9600

1 = Multiple Line

02145

0 = Gross Weight

1 = Tare Weight

2 = Net Weight

3 = Displayed Weight

4 = APW or PCS/WGT

5 = Count

6 = Sample Size

7 = ID

8 = Acc Total

9 = Blank Field/New Line

0 = Disabled

1 = Enabled

Note: Recommended def aul t selections are shown in

[92] Bracketed W ei ght Printing

[93] Hand Entered Tare Symbol

[94] ASCII Remote Input

[95] Scale # Display Mode

[96] Order Dependant Prompts 0 = Cursors

[97] Printed Count Legend 0 = None

[98] Examine Individual Load Cell Weights

[99] Reset Default Parameters

Italics

.

0 = Disabled

1 = Enabled

0 = "TRH"

1 = "PT"

0 = Disabled

1 = Enabled

0 = Gross/Sample Selection

1 = Indicates Acti ve S cale

1 = Text

1 = "PCS"

2 = "*"

3 = "STUECK"

0 = Retain Current Setup

1 = US Default Setup

2 = Export Default Setup

13

Page 21

4.4. CALIBRATION GROUP PROGRAMMING

FROM THIS POINT FORWARD

[X.X ]

WILL SHOW THE DISPLAYED PROMPT AND

THE INDENTED PARAGRAPHS WILL EXPLAIN THE SETUP STEPS FUNCTION AND

SELECTIONS. TO EXIT THE SETUP MODE, SLIDE THE SETUP SWITCH TO THE

REAR OF THE SCALE ANY TIME THE DISPLAY IS SHOWING

[--]

.

[10] CALIBRATION GROUP

With

[--]

on the display press the 1 key and then the 0 key. The display will then show

[11 X]

.

[11 1] CALIBRATION UNITS

Select the units to be used for the primar y display and the test weight type used during span adjust and

calibration. Enter selection using the numeric keys on the keyboard.

Number Display Weight Legend Calibration Weights

0

1

2

3

4

5

6

7

None

lb

kg

g

oz

toz

t

dwt

lb

lb

kg

g

oz

troy oz

metric tons

penny-weight

[12 0] LINEARITY COMPENSATION

The 8572 provides a calibration procedure to allow compensation of nonlinearities in the weighing

performance of the scale base. T his procedure is not nor mally required and is provided for use only when

the normal calibration procedure does not result in a linear response from the scale.

0

- Linearity compensation is disabled.

1

- Two step linearity compensation is enabled.

NOTE:

When us ing linearity compensation, test weights of one half scale capacity and full sc ale capacity mus t

be used. If less than full capacity is used, linearity compensation is not performed.

[13 0] REMOTE SCALE SELECTION

Selects type of remote scale base in use. Enter selection using the numeric keys on the keyboard.

Number Scale 2 Selection

0

1

2

3

Note:

If a remote scale bas e is not selec ted

Model 2157 (digital j-box) is not selected

None

Single DigiTOL® Load Cell

Model 2157 Floor Scale (digital j-box)

Analog Load Cell

[13 0]

[13 2]

, then steps

, then step

[14], [15b], [16b]

[14]

is skipped.

, and

[17b]

are skipped. If

14

Page 22

4.4.1. Internal Scale Setup and Calibration

[15A] [100] INTERNAL SCALE CAPACITY

Enter a valid capacity for the internal scale using the numeric keys on the keyboard followed by the

ENTER

NOTE

key. Refer to step

: The scale capacity entered must be large enough to use at least 35% of full load c ell capacity. If a

capacity selection is entered that is too sm all for the load cell, the 8572 will display an

[11]

and Tables 4-1 and 4-2 for valid capacity selections.

[E36]

error during

calibration. Refer to Table 4-1 for minimum valid scale capacities for a specific load cell capacity.

[16A] [0.02] INTERNAL SCALE INCREMENT SIZE

Press the 0 key to display the next selection. Press the

ENTER

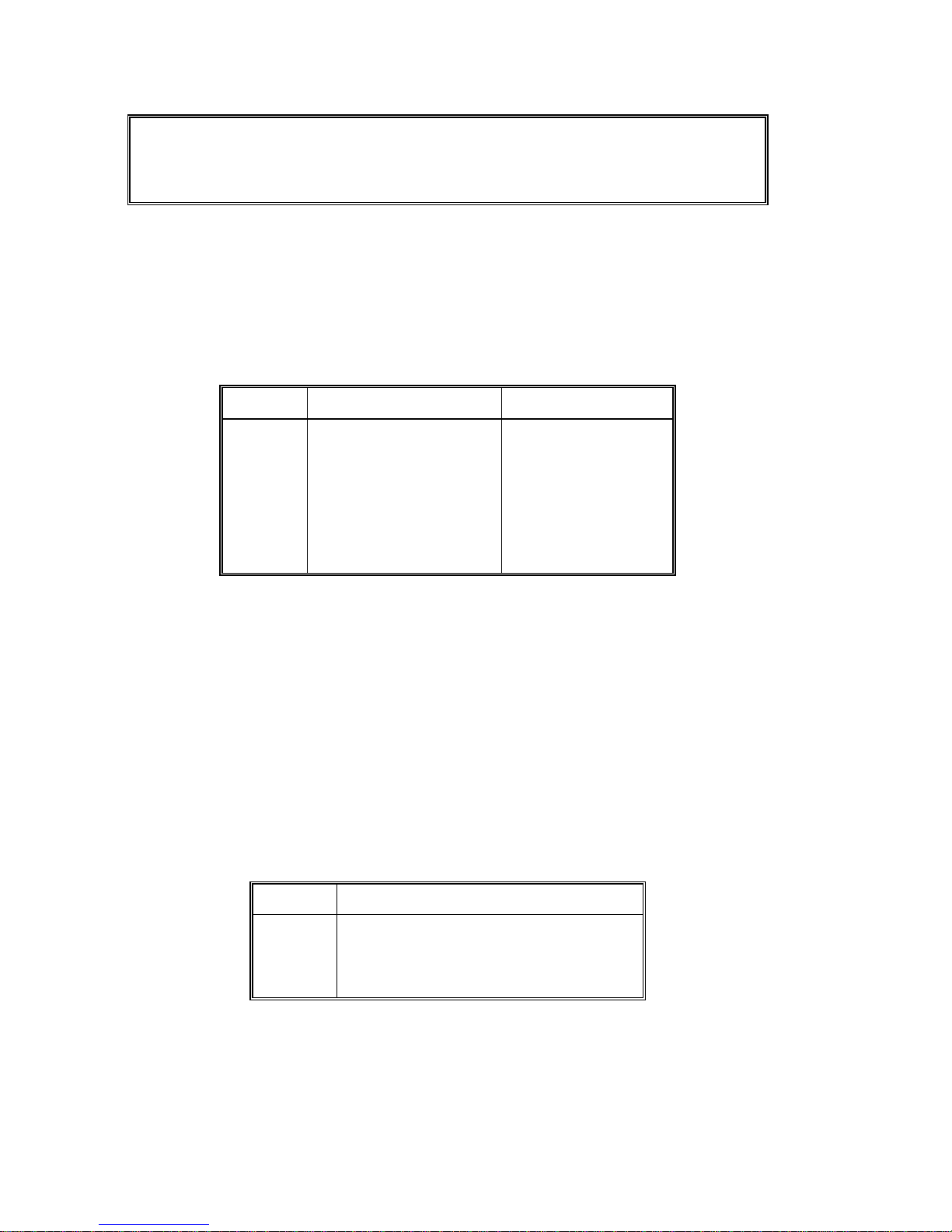

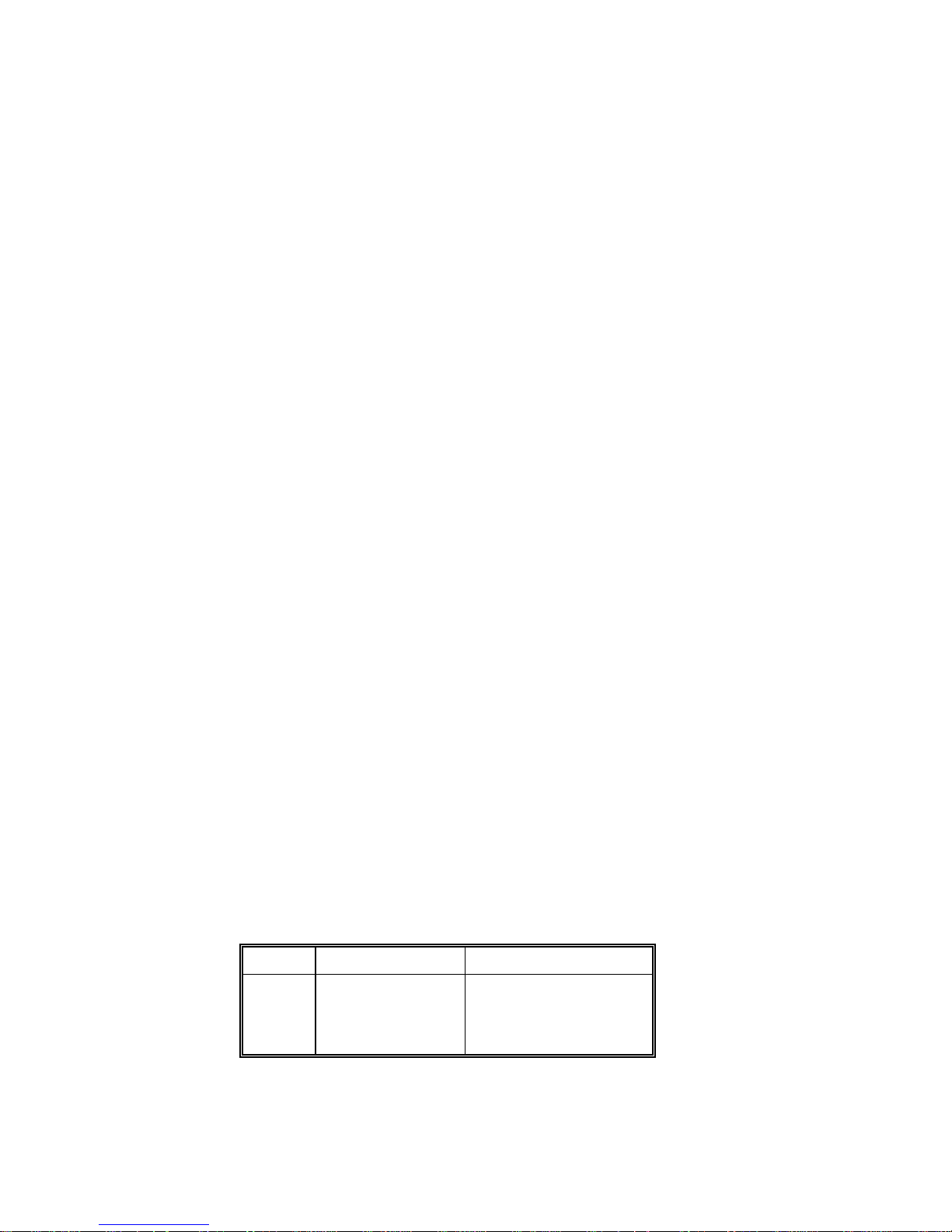

increment size. Refer to Tables 4-1 and 4-2 for valid increment selection.

8572

Default Capacities Minimum Capacities Load

Factory

Number

lb kg lb kg

8572-0002, 1002

8572-0003, 1003

8572-0004, 1004

8572-0005, 1005

8572-0006, 1006

5 X 0.001

10 X 0.002

25 X 0.005

50 X 0.01

100 X 0.02

2.5 X 0.0005

5 X 0.001

10 X 0.002

25 X 0.005

50 X 0.01

3

6

12

25

50

Table 4-1 Default and Minimum Internal Scale Builds

Increment

Scale Capacity (Total Number of Displayed Increments)

Size

3000 4000 5000 6000 10000 20000 25000 40000 50000

0.0001

0.0002

0.0005

0.001

0.002

0.005

N.A.

N.A.

1.5

3

6

15

N.A.

N.A.

2

4

8

20

N.A.

1

N.A.

5

10

25

N.A.

N.A.

3

6

12

30

1

2

5

10

20

50

2

4

10

20

40

100

or 1 key to accept the displayed

Cell

Capacity

1.5

3

6

12

25

N.A.

5

N.A.

25

50

125

N.A.

N.A.

20

N.A.

N.A.

N.A.

3.75 kg

7.5 kg

15 kg

30 kg

60 kg

5

10

25

50

N.A.

N.A.

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

10

20

30

60

150

300

600

1500

3000

6000

15000

30000

60000

40

80

200

400

800

2000

4000

8000

20000

40000

N.A.

50

100

250

500

1000

2500

5000

10000

25000

50000

N.A.

60

120

300

600

1200

3000

6000

12000

30000

60000

N.A.

100

200

500

1000

2000

5000

10000

20000

50000

N.A.

N.A.

Table 4-2 Valid Scale Builds

(N.A.) Not Applicable

15

200

400

1000

2000

4000

10000

20000

40000

N.A.

N.A.

N.A.

250

500

1250

2500

5000

12500

25000

50000

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

1000

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

Page 23

[17A] CALIBRATE SCALE 1

Press the 1 key to calibrate scale 1, or press the 0 key to advance to skip calibrate the next

programming step.

[E SCL] EMPTY SCALE

Empty the scale platter then press the

[CAL 01]

as a zero reading is recorded. The display then shows

ENTER key.

The display then counts down from

[Av]

while the analog verify reading is

[CAL 16]

to

recorded.

The span calibration sequence is next. Scale calibration will follow one of two following procedures

depending on how linearity compensation is programmed.

If linearity compensation is disabled, setup step

If linearity compensation is enabled, setup step

[12 0]

, then Section 4.4.1.2. will be skipped.

[12 1]

, then Section 4.4.1.1. will be skipped.

4.4.1.1. Internal Scale Span Calibration (With Linearity Compensation Off)

[Add Ld] ADD LOAD

Place test weights as close to 50% of full scale capacity as possible on the center of the scale

platter and press the

disabled, setup step

Enter the value of the test weights using the numeric keys followed by the

NOTE:

The test weight value used should be as close to the programm ed scale capacity as pos sible,

ENTER

[12 0]

key. This prompt will only occur if linear ity compensation has been

.

ENTER

key.

but in any case no less than 50% of scale capacity. In no case may the test weight used be larger than

the scale capacity programmed in setup step

[15A]

.

The display then counts down from

[CAL 16]

[CAL 09]

to

. The 8572 compares the programmed

scale capacity with the number of raw counts output by the load cell. If the load cell is not sending

sufficient counts for the scale capacity entered, the 8572 sends the load cell new T1 calibration

parameters and attempts to increase the number of counts from the load cell.

If the load cell cannot output enough counts for the pr ogramm ed scale capacity an

be displayed. This error means the s cale capacity entered in setup step

[15A]

[E36]

is too small for the

load cell and must be increased, or that the load cell is not operating properly.

If the 8572 receives enough counts from the load cell the count down will continue from

[CAL 01].

Increasing the number of counts out of the load c ell will require an additional

[CAL 09]

step to complete the calibration.

[E SCL] EMPTY SCALE (Occurs only if new calibration data is sent to load cell)

Empty the scale platter then press the

[CAL 01]

to

as a zero reading is recorded. The display then shows

ENTER key.

The display then counts down from

[Av]

while the analog verify

reading is recorded. If linearity compensation is disabled the 8572 then skips to section 4.3.1.4.

error will

to

[E SCL]

[CAL 16]

16

Page 24

4.4.1.2. Internal Scale Span Calibration (With Linearity Compensation On)

[Add FL] ADD FULL CAPACITY LOAD

Place test weights as close to 100% of f ull scale capacity as possible on the center of the scale

platter and press the

enabled, setup step

ENTER

[12 1]

key. This prompt will only occur if linear ity compensation has been

.

Enter the value of the test weights using the numeric keys followed by the

NOTE

: Linearity compensation calibration requires test weights as close to 100% and 50% of scale

capacity as possible. Calibration with test weights other than 100% of capacity at

capacity at

The display counts down from

[Add L0]

can result in weighing errors.

[CAL 16]

[CAL 09]

to

. The 8572 compares the pr ogrammed s cale

ENTER

[Add FL]

key.

or 50% of

capacity with the number of raw counts output by the load cell. If the load cell is not sending

sufficient counts for the scale capacity entered, the 8572 sends the load cell new T1 calibration

parameters and attempts to increase the number of counts from the load cell.

If the load cell cannot output enough counts for the pr ogramm ed scale capacity an

[E36]

be displayed. This error means the s cale capacity entered in setup step 15A is too small for the

load cell and must be increased, or that the load cell is not operating properly.

If the 8572 receives enough counts from the load cell the count down will continue from

[CAL 01].

Increasing the number of counts out of the load c ell will require an additional

[CAL 09]

step to complete the calibration.

[Add LO] ADD HALF CAPACITY LOAD

Place test weights as close to 50% of full scale capacity as possible on the center of the scale

platter and press the

Enter the value of the test weights using the numeric keys followed by the

ENTER

key.

ENTER

key.

error will

to

[E SCL]

The 8572 then counts down from

[CAL16]

[CAL 01]

to

.

[E SCL] EMPTY SCALE (Occurs only if new calibration data is sent to load cell)

Empty the scale platter then press the

[CAL 01]

as a zero reading is recorded.

ENTER

key. The display then counts down from

[Av]

is displayed as analog verify reading is recorded.

4.4.1.3. Internal Scale Calibration Complete

[CAL1 d] SCALE 1 CALIBRATION DONE

The display shows

[CAL1 d]

for two seconds and then will advance to one of three poss ible steps

depending on how setup step 13 is programmed:

NOTE

: If remote scale bas e is disabled (step

group and advance to the

[13 3]

or

) the 8572 will skip setup step

[--]

display. If a Single DLC or analog remote base is selected, (step

[14]

[13 0]

), the 8572 will skip all further steps in the 10's

and advance to step

[15b]

.

[CAL 16]

[13 1]

to

17

Page 25

4.4.2. Remote Scale Shift Adjust

[14] SHIFT ADJUST (Model 2157 Floor Scale (digital j-box), setup step [13 2])

This step accesses shif t er r or c ompensation for the Model 2157 or the DigiTO L® Power Module. Pres s

the 1 key to enter the shift adjust step or press the 0 key to skip this step and advance to step

NOTE

: The digital j-box must be connected to four load cells when used with the 8572.

[E SCL] EMPTY SCALE

[15b]

.

Empty the scale platter then press the

[SHF 01]

as a zero reading is recorded.

ENTER

key. The display then counts down from

[SHF 16]

[CELL 01] CELL TO BE ADJUSTED?

The display will then show

directly over cell 01 and press the

The display will then show

[CELL 01]

ENTER

[CELL 02]

where 01 is the first cell to be shif t adjusted. Place a weight

key. The display will count down from

[SHF 16]

to

.

Repeat this procedure for cells 2, 3 and 4. Place the weight directly over each load cell in turn and

press the print key. Press the

ZERO

key to back up to the previous load cell if necessary.

24

1J-Box 3

Figure 4-4 Model 2157 Load Cell Location

4.4.3. Remote Scale Setup and Calibration

to

[SHF 01]

.

[15b] [XXX] REMOTE SCALE CAPACITY

Enter a valid capacity for the remote scale using the numeric keys followed by the

[11]

step

, the remote scale base data plate and technical manual, and Table 4-2 for valid capacity

ENTER

key. Refer to

selection.

NOTE

: The scale capacity entered must be large enough to use at least 35% of full load c ell capacity. If a

capacity selection is entered that is too small, the scale will display an

[E36]

error during calibration.

[16b] [0.01] REMOTE SCALE INCREMENT SIZE

Press the 0 key to display the next selection. Press the

ENTER

or 1 key to accept the displayed

increment size. Refer to Table 4-2 for valid increment size selection.

[17b] CALIBRATE SCALE 2

Press the 1 key to calibrate the remote scale, or pres s the 0 key to advance to the next programm ing

step.

[E SCL] EMPTY SCALE

18

Page 26

Empty the scale platter then press the

[CAL 01]

as a zero reading is recorded. The display then shows

ENTER

key. The display then counts down from

[Av]

while the analog verify reading is

[CAL 16]

to

recorded.

The span calibration sequence is next. Scale calibration will follow one of two following procedures

depending on how linearity compensation is programmed.

If linearity compensation is disabled, setup step

If linearity compensation is enabled, setup step

[12 0]

, then Section 4.4.3.2. will be skipped.

[12 1]

, then Section 4.4.3.1. will be skipped.

4.4.3.1. Remote Scale Span Calibration (Linearity Compensation Off)

[Add Ld] ADD LOAD

Place test weights as close to full sc ale capacity as possible on the center of the scale platter and

press the

setup step

Enter the value of the test weights using the numeric keys followed by the

NOTE

: The test weight value used should be as close to the programmed sc ale capacity as possible,

ENTER

[12 0]

key. This prompt will only occur if linearity compensation has been disabled,

.

ENTER

key.

but in any case no less than 10% of scale capacity. In no case may the test weight used be larger than

the scale capacity programmed in setup step

The display then counts down from

[15b]

[CAL 16]

.

[CAL 09]

to

. The 8572 compares the programmed

scale capacity with the number of raw counts output by the load cell. If the load cell is not sending

sufficient counts for the scale capacity entered, the 8572 sends the load cell new T1 calibration

parameters and attempts to increase the number of counts from the load cell.

If the load cell cannot output enough counts for the pr ogramm ed scale capacity an

[E36]

error will

be displayed. This error means the s cale capacity entered in setup step 15A is too small for the

load cell and must be increased, or that the load cell is not operating properly.

If sufficient counts are received fr om the load cell the c ount down continues fr om

01].

Increasing the number of counts out of the load c ell will require an additional

[CAL 09]

[E SCL]

complete the calibration.

[E SCL] EMPTY SCALE (Occurs only if new calibration data is sent to load cell)

Empty the scale platter then press the

[CAL 01]

to

as a zero reading is recorded.

linearity compensation is disabled the 8572 will skip to section 4.3.2.4.

ENTER key.

[Av]

is displayed as analog verify reading is recorded. If

The display then counts down from

[CAL2 d]

.

4.4.3.2. Remote Scale Span Calibration (Linearity Compensation On)

[Add FL] ADD FULL CAPACITY LOAD

Place test weights as close to 100% of f ull scale capacity as possible on the center of the scale

platter and press the

enabled, setup step

Enter the value of the test weights using the numeric keys followed by the

ENTER

[12 1]

key. This prompt will only occur if linear ity compensation has been

.

ENTER

key.

[CAL

to

step to

[CAL 16]

19

Page 27

NOTE

: Linearity compensation calibration requires test weights as close to 100% and 50% of scale

capacity as possible. Calibration with test weights other than 100% of capacity at

capacity at

[Add L0]

can result in weighing errors.

[Add FL]

or 50% of

The display counts down from

[CAL 16]

[CAL 09]

to

. The 8572 compares the pr ogrammed s cale

capacity with the number of raw counts output by the load cell. If the load cell is not sending

sufficient counts for the scale capacity entered, the 8572 sends the load cell new T1 calibration

parameters and attempts to increase the number of counts from the load cell.

If the load cell cannot output enough counts for the pr ogramm ed scale capacity an

[E36]

be displayed. This error means the s cale capacity entered in setup step 15A is too small for the

load cell and must be increased, or that the load cell is not operating properly.

If the 8572 receives enough counts from the load cell the count down will continue from

[CAL 01].

Increasing the number of counts out of the load c ell will require an additional

[CAL 09]

step to complete the calibration.

[Add LO] ADD HALF CAPACITY LOAD

Place test weights as close to 50% of full scale capacity as possible on the center of the scale

platter and press the

enabled, setup step

Enter the value of the test weights using the numeric keys followed by the

NOTE

: The test weight value used must be as close to the 50% programmed scale capacity as

ENTER

[12 1]

key. This prompt will only occur if linear ity compensation has been

.

ENTER

key.

possible.

The 8572 then counts down from

[CAL16]

[CAL 01]

to

.

error will

to

[E SCL]

[E SCL] EMPTY SCALE (Occurs only if new calibration data is sent to load cell)

Empty the scale platter then press the

[CAL 01]

to

as a zero reading is recorded.

ENTER

[Av]

key. The display then counts down from

is displayed as analog verify reading is recorded.

4.4.3.3. Remote Scale calibration Done

[CAL2 d] REMOTE SCALE CALIBRATION DONE

The display shows

[CAL2 d]

for two seconds and then the 8572 will display

[-- ]

.

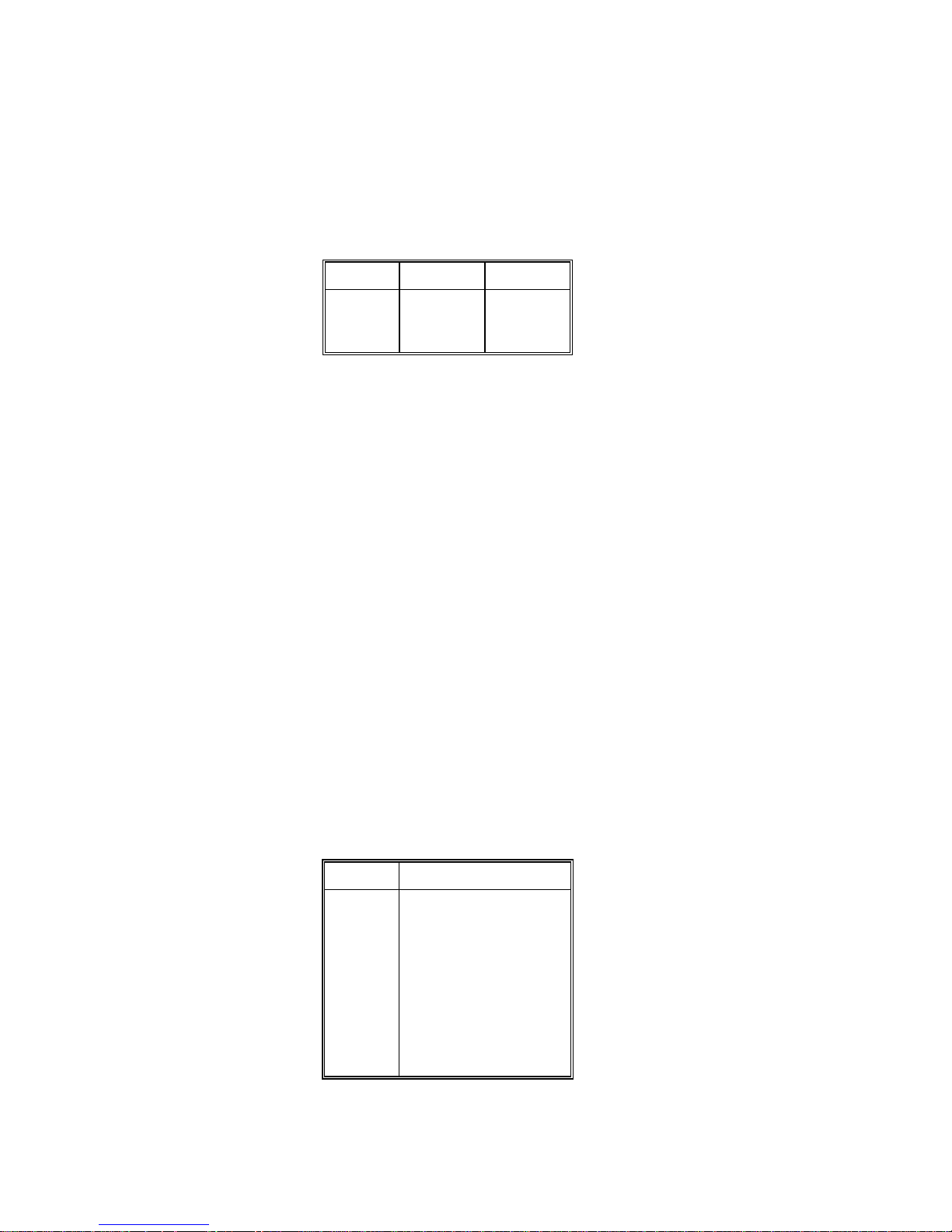

[18 0] POWER UP SCALE SELECT MODE

This step selects the def ault power up scale select ion for which base is us ed for sampling and which base

is used for counting (gross).

Enter selection using the numeric keys on the keyboard.

Number Sample Scale Counting (Gross) Scale

0

1

2

3

Internal (Scale 1)

Internal (Scale 1)

External (Scale 2)

External (Scale 2)

Internal (Scale 1)

External (Scale 2)

Internal (Scale 1)

External (Scale 2)

[CAL 16]

4.5. ZERO, MOTION, AND FILTERING GROUP PROGRAMMING

20

Page 28

[20] ZERO, MOTION, AND FILTERING GROUP

With

[--]

on the display press the 2 key then the 0 key. The display will then show

[21 X]

.

[21 1] INTERNAL SCALE AUTO ZERO MAINTENANCE (AZM)

This selection controls AZM for the internal scale. Auto zero maintenance is a f eature that maintains the

displayed zero in the center of the zero increment. It will correct for zero drift up to a 0.1 increm ent per

second, over a range of ± 2% of s c ale capac ity if the tare interloc k is enabled, s etup s tep

of ± 20% of scale capacity if the tare interlock is disabled, setup step

0 -

Internal scale AZM is disabled.

1 -

Internal scale AZM is enabled, as controlled by tare interlock.

[33 0]

.

[33 1]

, or a range

[22 1] REMOTE SCALE AUTO ZERO MAINTENANCE (AZM)

This selection controls AZM for the remote scale, otherwise this step is identical to setup step 21.

0 -

Remote Scale AZM disabled.

1 -

Remote Scale AZM enabled.

[23 1] POWERUP ZERO CAPTURE

This s tep programs the range for autom atic zero capture when power is applied to the 8572. If powerup

zero capture is enabled, and the scale is outside of the zero capture range, the display will show

weights above the zero capture range), or

[-E E E]

(for weights below the zero capture range), on the

[E E E]

(for

display until zero is manually captured.

Enter selection using the numeric keys on the keyboard.

Number Powerup Zero Capture Range

0

1

2

Disabled

±2% of Scale Capacity

±20% of Scale Capacity

[24 1] PUSHBUTTON ZERO RANGE

A zero key is provided to rezero the scale over a range of ± 2% of scale capacity if the tare interlock is

enabled, setup step

[33 0]

. The scale must be in the gross mode and in a no motion condition to allow zeroing.

0 -

Pushbutton zero is disabled.

1 -

Pushbutton zero is enabled, as controlled by tare interlock.

[33 1]

, or a range of ± 20% of scale c apac ity if the tare interlock is disabled, setup step

[25 1] MOTION DETECTION

21

Page 29

The 8572 includes a weight in motion detector which requires three suc cessive weight readings within the

selected range of ± 0.5 increm ent or ± 1 increment for a "no motion" signal. The motion detector signal

inhibits AZM, ZERO, TARE, PRINT and SAMPLE functions. If the tare interlock is disabled, motion will

blank the lb/kg cursors.

Enter selection using the numeric keys on the keyboard.

Number Motion Detect Window

0

1

2

Disabled

±0.5 Increment

±1 Increment

[26 1] SCALE 1 DISPLAY FILTER

The 8572 has a low pass multi-pole digital f ilter that is s electable f or various environm ental conditions . T he

display rate is slowed slightly as heavier filtering is selected.

Enter selection using the numeric keys on the keyboard.

Number Display Filter

0

1

2

3

Disabled

Light

Medium

Heavy

[27 1] REMOTE SCALE DISPLAY FILTER

This step controls the filter for scale 2, otherwise this step is identical to the scale 1 filter.

Enter selection using the numeric keys on the keyboard.

Number Display Filter

0

1

2

3

Disabled

Light

Medium

Heavy

[28 0] ENHANCED APW REPEATABILITY

Enabling this function helps to ensure m axim um APW accu racy and repeatability and helps to m inim ize the

effects of vibration. When sampling, the APW calculation will take approximately two seconds.

0

- Enhanced APW Repeatability Disabled

1

- Enhanced APW Repeatability Enabled

4.6. TARE GROUP PROGRAMMING

22

Page 30

[30] TARE GROUP

With

[--]

on the display press the 3 key then the 0 key. The display will then show

[31 X]

.

[31 2] GROSS SCALE TARE ENABLE

The 8572 allows pushbutton tare, manual keyboard tare, or both with the gross s c ale. T he s c ale must be in

a "no motion" condition before a tare can be taken, subject to tare interlock restrictions.

Enter selection using the numeric keys on the keyboard.

Number Tare Mode

0

1

2

Pushbutton & Keyboard Tare

Tare Disabled

Pushbutton Tare Only

[32 1] SAMPLE SCALE TARE ENABLE

The 8572 allows pushbutton tare only with the sample scale. The s cale m ust be in a "no m otion" condition

before a tare can be taken, subject to tare interlock restrictions.

0 -

Sample Scale Pushbutton Tare Disabled

1 -

Sample Scale Pushbutton Tare Enabled

[33 0] TARE INTERLOCK

Tare interlocks include the following functions: Tare weights can be c leared only at gross zero. Tare can

only be entered in the gross mode. Keyboard tare can only be entered in the gross mode. Previous tare

values must be cleared bef ore a new tare value can be entered. Multiple tares ar e not possible. T he lb/kg

cursors will not blank with motion. Tare interlock also limits the range over which pushbutton zero and AZM

will operate to ± 2% of scale capacity. Pushbutton zero and AZM will operate over a range of ± 20% of

scale capacity if tare interlock is disabled.

0 -

Tare Interlock Disabled

1 -

Tare Interlock Enabled

[34 0] AUTO CLEAR TA RE

The 8572 can automatically clear tare when the scale returns to zero after settling to a no m otion condition

at least ten increments above net zero. The scale must r eturn to within one positive increment of zero or

any negative gross weight to be considered to have to returned to zero. The scale must be in the count

mode for auto clear tare to occur.

0 -

Auto Clear Tare Disabled

1 -

Auto Clear Tare Enabled

4.7. ACCUMULATOR GROUP PROGRAMMING

[40] ACCUMULATOR GROUP

23

Page 31

With

[--]

on the display press the 4 key then the 0 key. The display will then show

[41 X]

.

[41 1] TRANSACTION ACCUMULATOR

A single register accumulator is provided to accum ulate piec e count, gros s weight or net weight as selec ted

below. Accumulation is perfor med by pressing the

PRINT

key while in the count mode, by use of the host

port command, or indirectly by the auto print function. When an accumulation is performed the auxiliary

display will blank, the TOTAL cursor will flash and then return to the previous recalled display. The

accumulation register can store up to seven digits of total piece count or nine digits of total weight.

The accumulated total c an be displayed by pressing the

RECALL

key. The TOTAL curs or will turn when

the auxiliary display is showing accumulated total to indicate this is the accumulator total.

Enter selection using the numeric keys on the keyboard.

Number Accumulator Mode

0

1

2

3

Disabled

Count

Gross Weight

Net Weight

[42 0] AUTO CLEAR ACCUMULATOR AFTER TOTAL PRINT

The 8572 accumulator c an be programmed to autom atically clear after the

PRINT

key is pressed with the

total count in the auxiliary display. If this function is disabled the accumulator must be m anually cleared by

pressing the 0 key followed by the

ENTER

key, while the accumulated total is displayed by means of the

recall function.

0 -

Disable Auto Clear Accumulator After Total Print

1 -

Enable Auto Clear Accumulator After Total Print

24

Page 32

4.8. SAMPLE GROUP PROGRAMMING

[50] SAMPLE GROUP

With

[--]

on the display press the 5 key then the 0 key. The display will then show

[51 X]

.

[51 1] APW OR PIECES PER UNIT WEIGHT

0 -

If the piece weight is to be entered as pieces per unit of weight.

1 -

If the piece weight is to be entered as a decimal average piece weight.

[52 0] INCLUDE SAMPLE

Include sample is provided to autom atically add the sam ple size to the total count and s am ple weight to the

gross and net weight of a transaction. If include sample is enabled the s ample pieces must not be added to

the gross scale or the total count and weight will be off by the amount of the sample.

0 -

Include Sample is Disabled

1 -

Include Sample is Enabled

[53 0] [53 10] FIXED SAMPLE, SAMPLE SIZE SELECTION

The 8572 operates with fixed or variable sam ple sizes. Press the 0 key to select variable sample size or

press the 1 key to select fixed sam ple s ize mode. Af ter the s ampling mode is s elec ted the 8572 will dis play

the fixed or the default variable sam ple s ize. Press the 0 key for the next default sample s ize or press the

key to accept the default sample size. Options for sample size are 5, 10, 20, 50 or 100.

0 -

Variable Sample Size

1 -

Fixed Sample Size

1

[54 1] SAMPLE ENHANCEMENT

Sample enhancement is provided to allow the 8572 to recalc ulate the APW on the basis of a larger s ample

size each time more pieces are added to the scale.

NOTE

: This function is disabled when the 8572 is in the dual scale counting mode or if a

minimum sample percentage of 0.00% is selected in setup step

0 -

Sample Enhancement is disabled

1 -

Sample Enhancement is Enabled

[55]

.

[55 0.02] MINIMUM SAMPLE RANGE

Selects the percentage of scale capacity that must be reached before an average piece weight can be

calculated and a count sequence initiated. The available percentages are 0.00%, 0.02%, 0.05% and