Page 1

Commander

Automatic Wrapper

User’s Guide

Model 0648

64058950 (R04)

Page 2

©Mettler-Toledo, Inc. 2010

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, for any purpose without the express written

permission of Mettler-Toledo, Inc.

U.S. Government Restricted Rights: This documentation is furnished with Restricted Rights.

Page 3

®

METTLER TOLEDO

Customer Feedback

Attention: Retail Quality Manager - MTWR

If you have a problem with one of our products or publications, or just a

suggestion on how we can serve you better, please fill out this form and

send it to the address on the opposite side of this page (U.S. postage paid),

or fax it to us at (614) 438-4355. Your feedback will help us to improve

product performance, quality, and service.

Part / Product Name:

Part / Model Number: Date:

Provided By:

Customer Name:

Address:

Phone Number: Fax Number:

Your comments on product performance, quality, or service:

Do not write in space below. For METTLER TOLEDO use only.

Response (where appropriate). Include root cause analysis and corrective action taken.

METTLER TOLEDO 64058950

METTLER TOLEDO

1900 Polaris Parkway

Columbus, Ohio 43240

METTLER TOLEDO® is a registered trademark of Mettler-Toledo, Inc.

©2010 Mettler-Toledo, Inc.

Printed in USA

Page 4

Page 5

INTRODUCTION

This publication is provided solely as a guide for individuals who have received Technical Training in

servicing the METTLER TOLEDO product.

Information regarding METTLER TOLEDO Technical Training may be obtained by writing to:

Mettler-Toledo, Inc.

1900 Polaris Parkway

Columbus, Ohio 43240

(614) 438-4511

FCC Notice

This device complies with Part 15 of the FCC Rules and the Radio Interference Requirements of the

Canadian Department of Communications. Operation is subject to the following conditions: (1) this device

may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to correct

the interference at their own expense.

METTLER TOLEDO RESERVES THE RIGHT TO MAKE REFINEMENTS OR

CHANGES WITHOUT NOTICE.

Page 6

A

PRECAUTIONS

READ this manual BEFORE

operating or servicing this

equipment.

FOLLOW these instructions

carefully.

SAVE this manual for future

reference.

DO NOT allow untrained

personnel to operate, clean,

inspect, maintain, service, or

tamper with this equipment.

LWAYS DISCONNECT this

equipment from the power

source before cleaning or

performing maintenance.

CALL METTLER TOLEDO for parts,

information, and service.

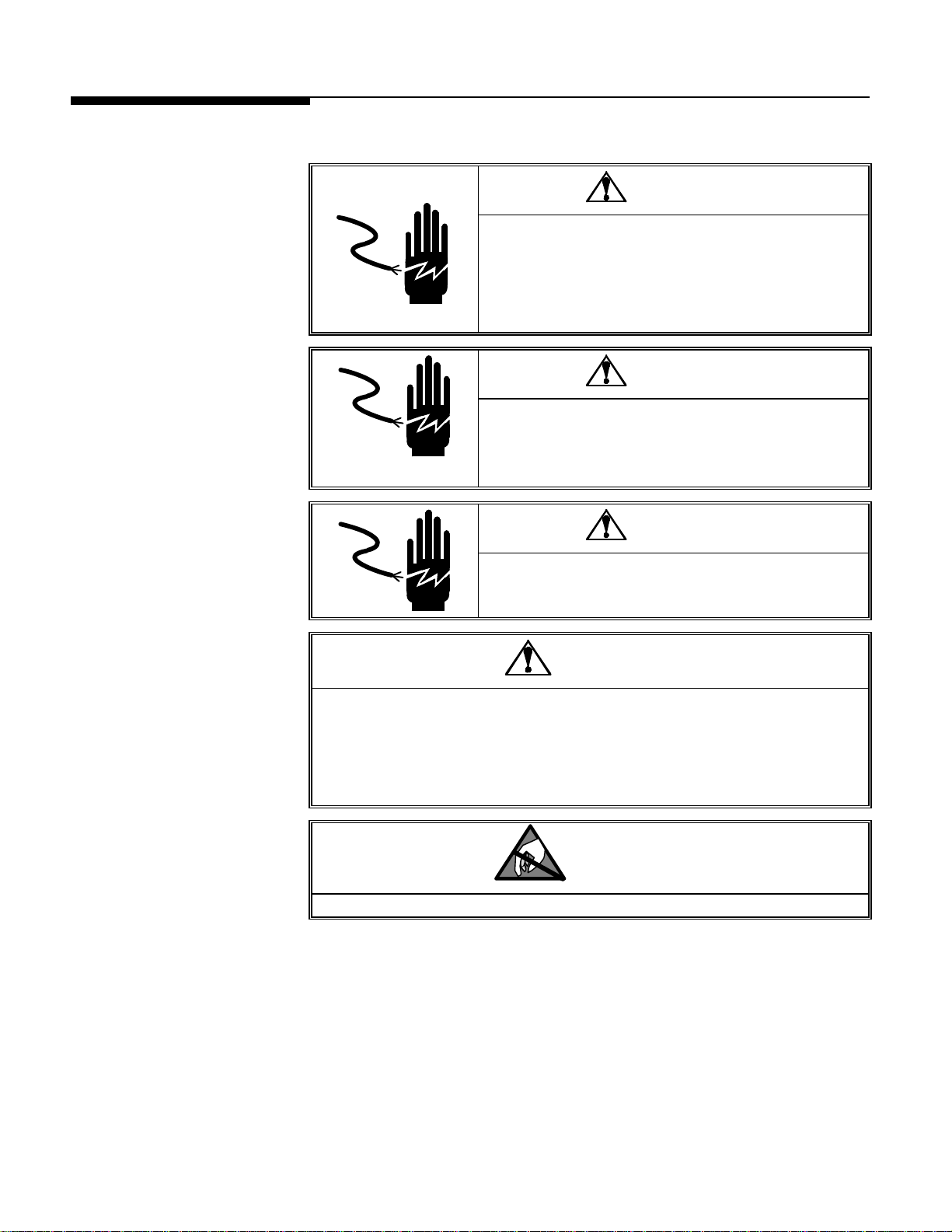

WARNING

ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THIS

EQUIPMENT. EXERCISE CARE WHEN MAKING CHECKS,

TESTS AND ADJUSTMENTS THAT MUST BE MADE WITH

POWER ON. FAILING TO OBSERVE THESE PRECAUTIONS

CAN RESULT IN BODILY HARM AND/OR PROPERTY

DAMAGE.

WARNING

FOR CONTINUED PROTECTION AGAINST SHOCK

HAZARD CONNECT TO PROPERLY GROUNDED OUTLET

ONLY.

DO NOT REMOVE THE GROUND PRONG.

WARNING

DISCONNECT ALL POWER TO THIS UNIT BEFORE

REMOVING THE FUSE OR SERVICING.

CAUTION

BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC

COMPONENTS OR INTERCONNECTING WIRING BETWEEN ELECTRONIC

EQUIPMENT ALWAYS REMOVE POWER AND WAIT AT LEAST THIRTY (30)

SECONDS BEFORE ANY CONNECTIONS OR DISCONNECTIONS ARE MADE.

FAILURE TO OBSERVE THESE PRECAUTIONS COULD RESULT IN DAMAGE TO OR

DESTRUCTION OF THE EQUIPMENT OR BODILY HARM.

CAUTION

OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE DEVICES.

Page 7

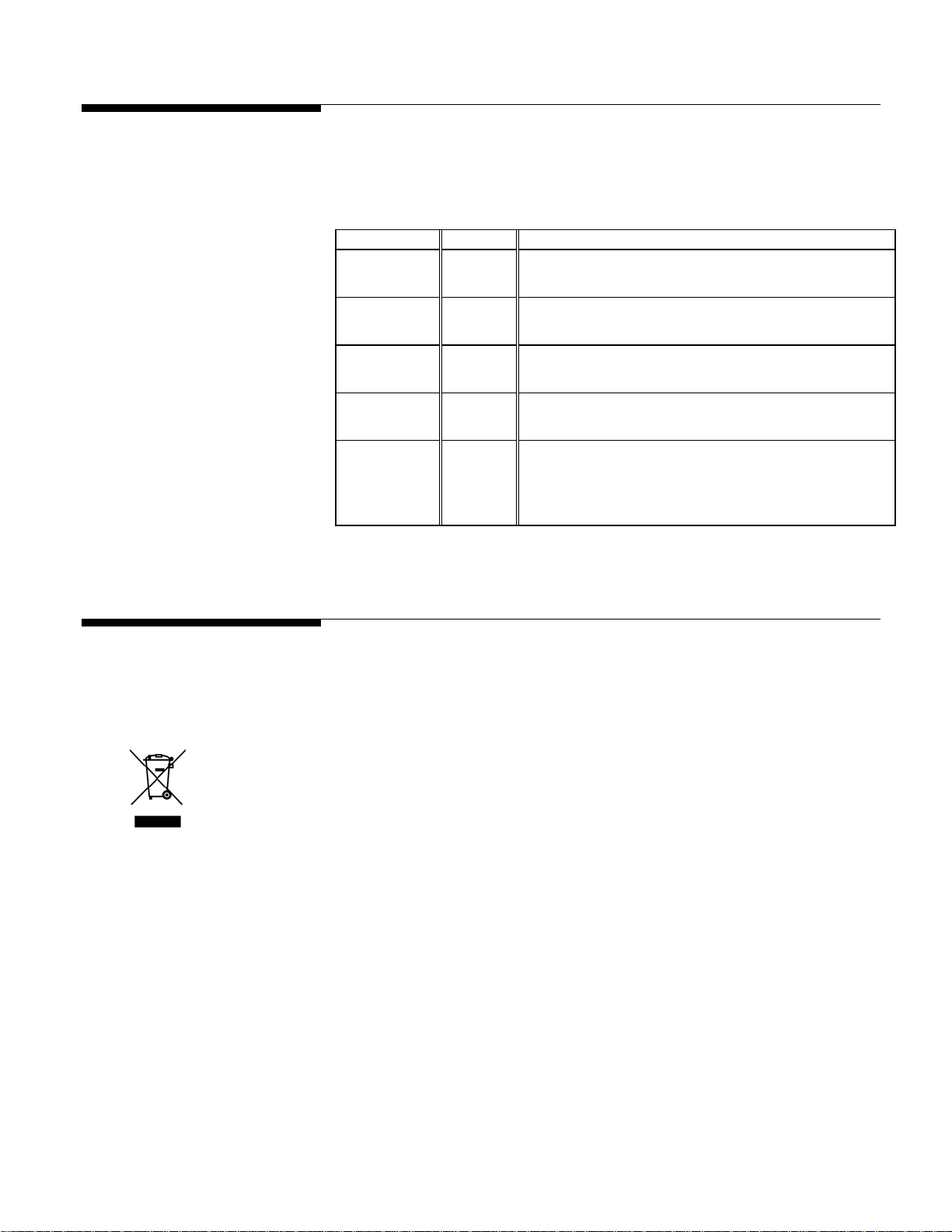

Publication Revision

History

Part Number Date Revisions

64058950

Rev 00

08/07 New manual

Disposal

64058950

Rev 01

64058950

Rev 02

64058950

Rev 03

64058950

Rev 04

In conformance with the European Directive 2002/96/EC on Waste Electrical and

Electronic Equipment (WEEE) this device may not be disposed of in domestic waste.

This also applies to countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting

point specified for electrical and electronic equipment.

04/08 Tray size update (ch4); Fusion GUI update (ch 6)

09/08 Fusion Added; Reports Chapter Added (9)

05/10 Images updated in Chapter 7

Expanded and updated Chapter 1, Chapter 2 Operation,

07/10

Chapter 6 Controller, and 8 Troubleshooting. Added

Fusion 4.2 enhancements. Added Chapter 10 label

requirements.

If you have any questions, please contact the responsible authority or the distributor

from which you purchased this device.

Should this device be passed on to other parties (for private or professional use), the

content of this regulation must also be related.

Thank you for your contribution to environmental protection.

Page 8

CONTENTS

1 Commander System........................................................................................ 1-1

Introduction ........................................................................................................................1-1

Power and Temperature Specifications .................................................................................

2 Operation....................................................................................................... 2-1

System Power Up ................................................................................................................2-1

Wrapper Power Switch ........................................................................................................2-2

Controller Power Switch ......................................................................................................2-3

Controller - Finding Product PLUs.........................................................................................2-4

Calling up PLUs .....................................................................................................................2-4

Tare and Graphical Tare.......................................................................................................2-6

PLU Screen .........................................................................................................................

Controller - Quick Edits......................................................................................................

Film Tension .....................................................................................................................2-13

Printer – Label Printing......................................................................................................2-14

Belt Temperature Controls .................................................................................................2-15

Auto Shut-offs ...................................................................................................................2-16

Stop Switch ......................................................................................................................... 2-17

Normal Shut-down.............................................................................................................2-18

1-2

2-7

2-10

3 Film Loading .................................................................................................. 3-1

Loading Instructions ............................................................................................................3-1

4 Trays.............................................................................................................. 4-1

Loading the Trays ................................................................................................................4-1

Tray Specifications ..............................................................................................................4-2

Tray Reference Chart – 11” Film ..........................................................................................4-3

Tray Reference Chart – 13” Film ..........................................................................................

4-4

5 Printers.......................................................................................................... 5-1

Introduction ........................................................................................................................5-1

Loading Label Stock ............................................................................................................5-2

6 Controller - Operation..................................................................................... 6-1

Introduction ........................................................................................................................6-1

Main Screen Elements.........................................................................................................

PLU Screen .........................................................................................................................

Options Button....................................................................................................................... 6-4

Label Format.............................................................................................................. 6-4

Grade........................................................................................................................ 6-4

Bottom Label Format................................................................................................... 6-4

Satellite Graphic ......................................................................................................... 6-4

Linked Graphic........................................................................................................... 6-4

DayGlo Graphic.......................................................................................................... 6-4

6-2

6-3

Page 9

Accumulator .............................................................................................................. 6-4

Run Total .................................................................................................................. 6-5

Print Inhibits.............................................................................................................. 6-5

Place Label Button ................................................................................................................. 6-6

Edge Offset................................................................................................................ 6-6

PLU Pricing Modes..............................................................................................................6-7

By-Weight PLU ...................................................................................................................... 6-7

By-Count PLU........................................................................................................................ 6-7

Standard Pack PLU ................................................................................................................ 6-7

PLU Search Modes ..............................................................................................................6-8

Country of Origin Labeling (COOL) .....................................................................................6-10

Preconfigured COOL Statements............................................................................................. 6-10

Custom COOL Statements ..................................................................................................... 6-12

Forced COOL ....................................................................................................................... 6-13

COOL PreText ...................................................................................................................... 6-13

Wrapper Control ...............................................................................................................6-14

Mode Buttons...................................................................................................................... 6-15

Done Button........................................................................................................................ 6-15

Film Setting ......................................................................................................................... 6-16

Status................................................................................................................................. 6-17

Convey Package..................................................................................................................6-17

Lower Infeed........................................................................................................................ 6-17

Film Temperature Fields........................................................................................................ 6-18

Ambient Film Temp .................................................................................................. 6-18

Actual Belt Temp ...................................................................................................... 6-18

Set Belt Temp .......................................................................................................... 6-18

Error Logs........................................................................................................................... 6-20

Cut Film Button.................................................................................................................... 6-21

More Data........................................................................................................................... 6-21

Firmware Type ......................................................................................................... 6-21

Firmware Version ..................................................................................................... 6-21

Firmware Date ......................................................................................................... 6-21

Wrapper ID Number ................................................................................................. 6-21

Side Clamp Stretch Distance...................................................................................... 6-21

Center Clamp Run Distance....................................................................................... 6-21

Total Packages Wrapped .......................................................................................... 6-22

Packages Wrapped Since Service .............................................................................. 6-22

Packages Wrapped Since Powerup ............................................................................ 6-22

Package Height ....................................................................................................... 6-22

Package Width ........................................................................................................ 6-22

Package Length ....................................................................................................... 6-22

Refresh ................................................................................................................... 6-22

Return..................................................................................................................... 6-22

Operations Menu...............................................................................................................

Cutting Tests ....................................................................................................................... 6-23

Void Transactions ................................................................................................................ 6-24

Verify Labels........................................................................................................................ 6-24

6-23

Setup Overview.................................................................................................................6-25

Unit Setup ........................................................................................................................6-25

Choose Department.............................................................................................................. 6-26

Scale Mode ......................................................................................................................... 6-26

Page 10

Price Settings....................................................................................................................... 6-26

Manual Mode Keys............................................................................................................... 6-26

Allow Lbs for............................................................................................................ 6-26

Allow By Qtr Pound................................................................................................... 6-26

Allow By Half Pound................................................................................................. 6-27

Tare to Use.......................................................................................................................... 6-27

Proportional Tare...................................................................................................... 6-27

By-Weight Tare ........................................................................................................6-27

Accumulators Setup..............................................................................................................6-27

Void Available...................................................................................................................... 6-28

Scale Settings ......................................................................................................................6-28

Print Mixed Net Weight.............................................................................................. 6-29

Print Horizontal or Vertical Tabular NF......................................................................... 6-29

Calculate Std Pack Unit Price per-lb ............................................................................ 6-30

Hide Keypad ............................................................................................................ 6-30

HTML by PLU ...........................................................................................................6-30

Allow Alternate Language ..........................................................................................6-30

Detail Logs .............................................................................................................. 6-30

Keypress Beep ......................................................................................................... 6-30

Safety Loop.............................................................................................................. 6-30

Alerts ......................................................................................................................6-30

Screen Saver............................................................................................................ 6-30

Frequent Shopper Text............................................................................................... 6-30

Printer & Label Setup ........................................................................................................6-31

Choose Store Logo ...............................................................................................................6-31

Label Printer Setup ............................................................................................................... 6-32

Current Label Stock................................................................................................... 6-32

Eject Length ............................................................................................................. 6-32

Image Offset ............................................................................................................6-32

Run Total Label Format ............................................................................................. 6-33

Label Width ............................................................................................................. 6-33

Stripped Delivery ......................................................................................................6-33

NF Label Format....................................................................................................... 6-33

General Label Formats .............................................................................................. 6-34

Nuval Label Graphic ................................................................................................. 6-34

Dayglo Printer Setup............................................................................................................. 6-35

DayGlo Printer.......................................................................................................... 6-35

Eject Length ............................................................................................................. 6-35

Current Label Stock................................................................................................... 6-35

Image Offset ............................................................................................................6-35

Label Format............................................................................................................ 6-35

Stripped Delivery ......................................................................................................6-35

Calibrate Printer Gap Sensor.................................................................................................. 6-36

Bottom Label Printer Setup and Calibrate Bottom Printer ........................................................... 6-36

Barcode Setup...................................................................................................................6

-37

Barcode Type.......................................................................................................................6-37

GS1 Databar Barcodes.............................................................................................. 6-38

Presets Setup....................................................................................................................6-40

Pages................................................................................................................................. 6-40

Add Page ................................................................................................................6-41

Adding Preset Pages By Department ...........................................................................6-42

Page 11

Adding Pages using Custom ..................................................................................... 6-43

Edit Page ................................................................................................................ 6-45

Graphical Tare Presets.............................................................................................. 6-46

Keys................................................................................................................................... 6-47

Edit Preset Keys ....................................................................................................... 6-47

Backroom Setup................................................................................................................6-55

Cycle Lifter .............................................................................................................. 6-55

Cycle Xfer................................................................................................................ 6-55

Cycle Convey........................................................................................................... 6-55

Hardware Version Information.................................................................................... 6-55

Choose Indexer.................................................................................................................... 6-56

Date Forward Hour...............................................................................................................6-56

Select Film Size ................................................................................................................... 6-56

Macros Setup ...................................................................................................................... 6-57

Macro Placement.................................................................................................................6-60

Setup Passwords/Levels ....................................................................................................

6-61

Service Scale Setup ..........................................................................................................6-62

Enable By-Count Auto Clear .................................................................................................. 6-62

Enable Force Count ..............................................................................................................6-62

Enable Forced COOL ............................................................................................................ 6-62

Auto Sense.......................................................................................................................... 6-63

PLU Transaction Timeout ...................................................................................................... 6-63

Search Screen Timeout ......................................................................................................... 6-63

Transaction Screen Overrides ................................................................................................ 6-63

Quick Edits .......................................................................................................................6-64

View Version Information...................................................................................................6-64

View Logs.........................................................................................................................6-64

Minimize Application ........................................................................................................6-64

Serial Devices Setup .........................................................................................................6-64

Load Cell Setup ................................................................................................................6-64

Launch External Program...................................................................................................6-65

Report Generator...............................................................................................................6-65

Quit To Desktop.................................................................................................................6-66

Shutdown System..............................................................................................................6-66

7 Cleaning and Maintenance.............................................................................. 7-1

Wrapper - Daily Cleaning ....................................................................................................7-1

Cleaning Precautions............................................................................................................ 7-1

Daily Cleaning...................................................................................................................... 7-2

Infeed / Riser Cleaning........................................................................................................7-5

To Clean................................................................................................................... 7-5

To re-insert............................................................................................................... 7-5

Controller Screen – Daily Cleaning ......................................................................................7-6

Printer - Cleaning .............................................................................................................

External Cleaning ................................................................................................................. 7-7

Mechanism Cleaning ............................................................................................................ 7-8

..7-7

8 Troubleshooting.............................................................................................. 8-1

Printer - Troubleshooting Guide............................................................................................

8-1

Page 12

No Label is Printed or Issued ................................................................................................. 8-1

Applicator Won’t Pick or Apply Labels..................................................................................... 8-1

Label Placement Varies on Package .......................................................................................8-2

Label Applicator Won’t Turn Labels......................................................................................... 8-2

Light Print or mottled print on Labels..................................................................................... 8-2

Extra Labels Are Printed ........................................................................................................ 8-3

Labels Not Indexing Correctly ................................................................................................ 8-3

Printer Status LED .................................................................................................................8-4

Wrapper - Troubleshooting Guide .........................................................................................8-4

Film Tearing or Film Tracking Poorly ......................................................................................8-4

Trays left open, poor overwrap, or no overwrap....................................................................... 8-5

Not picking film ....................................................................................................................8-5

Error Logs ...........................................................................................................................8-6

Controller Error Log............................................................................................................... 8-6

Wrapper System Error Log ..................................................................................................... 8-7

Error Display Screens ..........................................................................................................8-8

Commander Error Codes........................................................................................................ 8-8

Commander Help ................................................................................................................ 8-14

Remote Access Assistance................................................................................................... 8-14

9 Extra Programs............................................................................................... 9-1

Commander Task Manager...................................................................................................9-1

Overview: .............................................................................................................................. 9-1

Requirements and Installation.................................................................................................. 9-2

Environment .......................................................................................................................... 9-2

Application Flow ....................................................................................................................9-2

Production Reports ............................................................................................................9-14

Main Screen ........................................................................................................................ 9-14

Custom Production Report..................................................................................................... 9-15

Daily Production Report ........................................................................................................ 9-18

Price Override Report ............................................................................................................ 9-19

Detailed PLU Report.............................................................................................................. 9-20

Department Summary........................................................................................................... 9-21

Setup: Configuring Reports .................................................................................................... 9-22

Additional Controls ...............................................................................................................9-26

10 Label Requirements...................................................................................... 10-1

General Requirements .......................................................................................................

Label Paper......................................................................................................................... 10-1

Adhesive ............................................................................................................................. 10-2

Release Liner ....................................................................................................................... 10-2

Total Thickness Label + Adhesive + Liner................................................................................ 10-2

Light Transmission For Gap Sensor Operation.......................................................................... 10-2

Label Stripping..................................................................................................................... 10-2

Finished Label Roll Requirements.......................................................................................10-3

Core and Method of Label Attachment..................................................................................... 10-3

Die Cutting .......................................................................................................................... 10-3

Slitting ................................................................................................................................ 10-3

Winding.............................................................................................................................. 10-4

10-1

Page 13

Label Curl ........................................................................................................................... 10-4

Splicing .............................................................................................................................. 10-5

Finished Label and Roll Dimensional Requirements.............................................................

10-5

Preprinted Labels..............................................................................................................10-7

Special Shaped Labels ......................................................................................................10-9

Definition Of Transmission Optical Density .........................................................................10-9

Label and Liner Optical Density........................................................................................

Black Stripe Optical Density.............................................................................................

10-10

10-10

Page 14

For your notes

Page 15

1 Commander System

Introduction

The METTLER TOLEDO Commander is an integrated prepack wrapper and labeling

system. The Commander consists of three components: Model 648 Automatic

Wrapper, Commander Controller Module, and Printer(s). Your system could have

one or two printers for Data labels and DayGlo labels.

By having all three components in one built-in system the Commander will:

• Reduce Overall Footprint of Wrapping System

• Reduce the Number of System Components

• New and Improved Electronics and Reporting Capability

• Combine Functions of Wrapper and Controller

Chapter 1: Commander System

Introduction

The Commander is designed to wrap items pre-placed into foam or paper trays.

This User’s Guide discusses the operation and minor maintenance/troubleshooting of

the Commander Wrapper, Controller, and Printer. This manual will cover operation for

software versions up to Revision 4.2. For details on setup and maintenance please refer

to the Printer Service Manual (P/N C82784900A rev. 2 or higher), UC Software

Technical Manual (B16588100A rev 4 or higher) or the Commander Wrapper Service

Manual (P/N 64058951).

1-1

Page 16

METTLER TOLEDO® Commander User's Guide

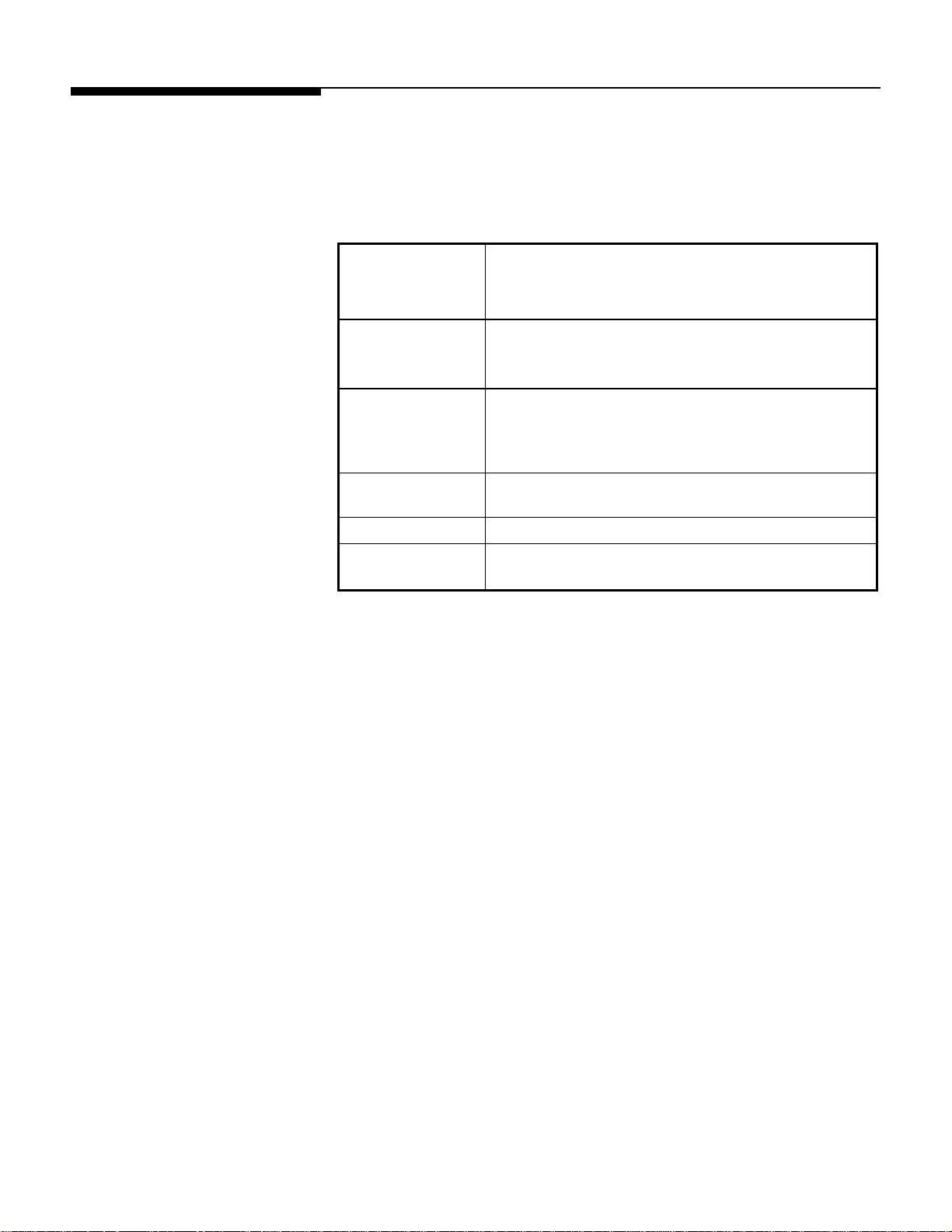

Power and Temperature Specifications

The Commander wrapper is not designed to wrap loose and/or liquid products. This unit

is not intended for washdown or hazardous area operation, or for operation in

environments of extreme dust, heat, cold, or humidity.

Electrical and

Certification

Voltage/Amperes

Recommended

Operating

Temperature

Range

Humidity

Wrapper Weight

Shipping Weight

with 2 printers

208/230 VAC, 14.1 Amps, 50/60 Hz.

ETL #2002405

Conforms to UL Standard 763 and CSA C22.2 195

208 VAC/50-60 Hz

(can be configured for 240 VAC)

20A Supply/2350 VA (default)

40°F to 70°F (5°C to 20°C)

5% to 95%

Non-condensing

600 lbs

900 lbs

1-2

Page 17

p

2 Operation

System Power Up

There are two main power switches on the Commander wrapper. The wrapper power

switch controls power to the wrapper electrical components and the printers. The

controller power switch is independent of the wrapper power switch and controls power

only to the controller. Shown below are the power switch locations. When powering a

system up, the wrapper should be powered up first (2) and then the controller (4). Refer

to the power up sequence 1-5 below.

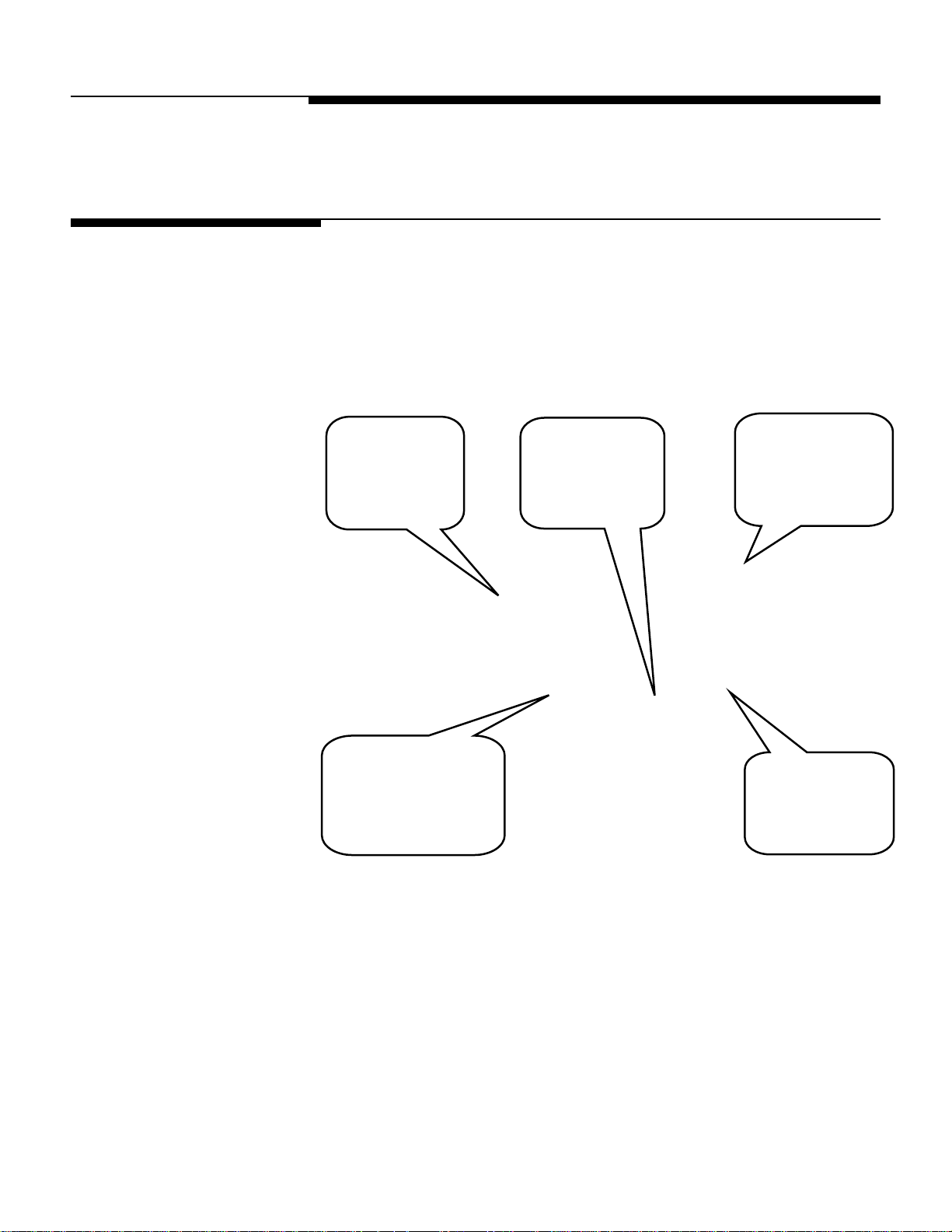

Chapter 2: Operation

System Power Up

4

Lift cover, press 1

on the Controller

power switch to

turn

ower on.

5

Allow sealing belt to reach

operating temperature.

Select Wrapper Control to

view or change.

1

Remove any items

from the belts, then

keep hands clear.

3

Printer LED displays

green for Ready. If

not, check power

switch inside cover.

2

Turn the wrapper

power switch lever

to 1 (on).

Keep hands clear of the machine infeed and discharge areas. A message will appear on

the Controller indicating that the machine is powering up. Press the START button, in the

message box, to begin the Startup Self Test.

Note: the machine will not initiate the Self Test until the START button has been pressed.

During the test, the conveyors are in motion. Make sure the belts are clear of any items

before pressing the button.

Wait for the Sealing Belt to reach the programmed temperature before starting to wrap

packages (usually 20-30 minutes). To view the current temperature, press the Wrapper

button. Adjust the temperature if needed. The temperature will display highlighted in Blue

if the belt is too cold and in Red if the belt is too hot. When the belt reaches the

assigned temperature the field will have no highlighted color.

2-1

Page 18

METTLER TOLEDO® Commander User's Guide

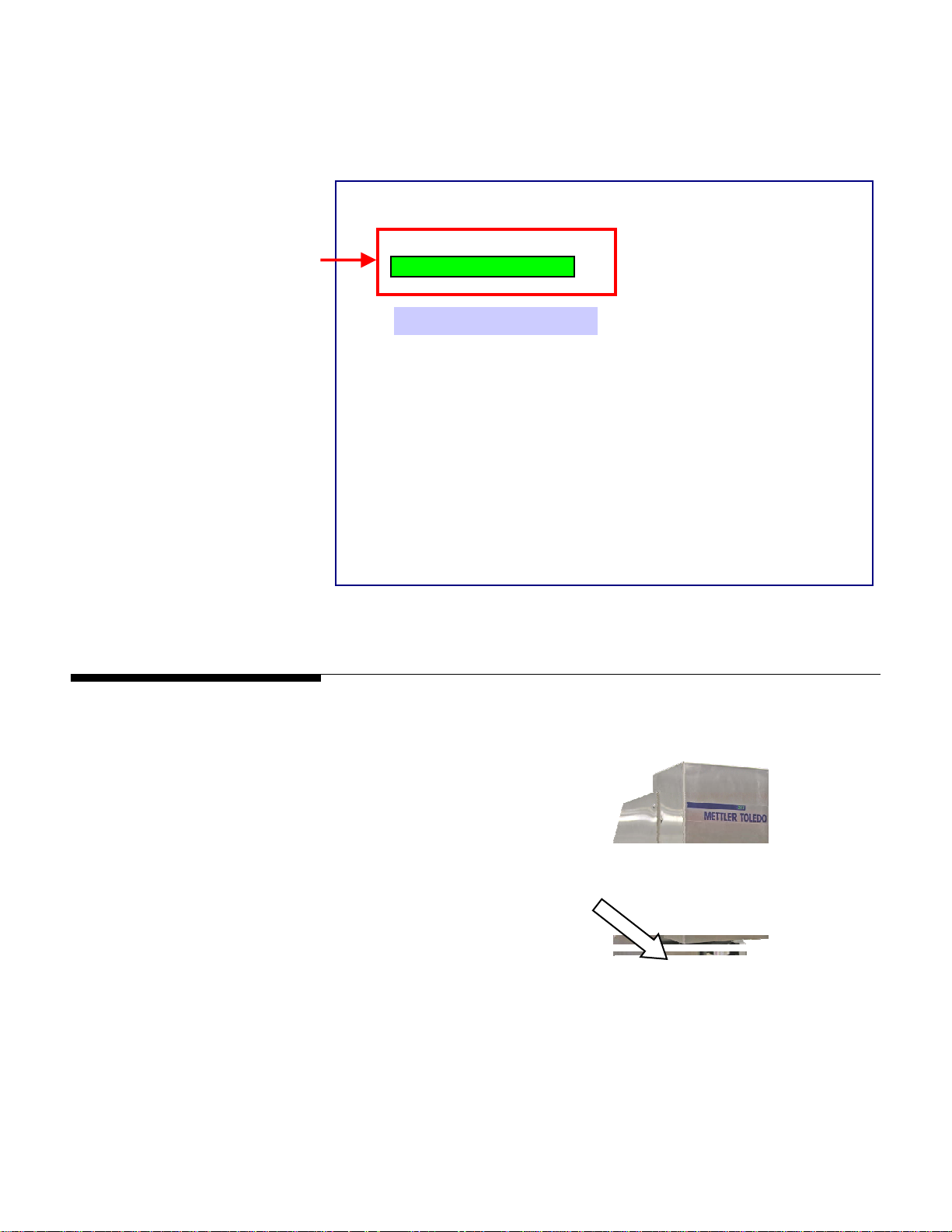

Wrapper Power Switch

There is a main ON/OFF power switch located on the front right of the Wrapper. This

switch removes power to the wrapper electrical components and the printers. Power to

the controller will remain on. If this switch is turned off while the Controller is still on, an

error message will alert the operator that communication to the other machine functions

has failed.

ON

1. Turn Power Switch clockwise from 0 (off) to I (on) to turn on the machine power.

2. Keep hands clear of the machine infeed and discharge areas. An error message will

appear on the Controller indicating that the machine is powering up. Press the

START button, in the message box, to begin the Self Test.

Note: the machine will not initiate the Self Test until the START button has been

pressed. During the test, the conveyors are in motion. Make sure the belts are clear

of any items before pressing the button.

3. Wait for the Sealing Belt to reach the programmed temperature before starting to

wrap packages (usually 20-30 minutes). To view the current temperature, from the

Controller hit the Wrapper button and adjust the temperature if needed. The

temperature will display highlighted in Blue if the belt is too cold and in Red if the

belt is too hot. When the belt reaches the assigned temperature the field will have

no highlighted color.

OFF

2-2

4. When the Belt Temperature reaches its assigned temperature, the machine is ready

to wrap.

Note: The Controller is powered separately and is not controlled by the Wrapper ON/OFF

power switch.

Page 19

Controller Power Switch

Chapter 2: Operation

Controller Power Switch

The controller power is separate from the main wrapper. The controller power can be left

on for day-to-day operation to minimize start up time. The Controller can be turned on

(1) or off (0) by pressing the switch located under the top cover behind the controller.

Pressing the switch to off (0) starts a “soft shutdown” procedure. This procedure must

be performed before disconnecting the power to the wrapper. The same shutdown

procedure may be initiated from the controller screen - “Setup / Shutdown System”. Do

not interrupt the soft shutdown procedure.

OFF

ON

Controller Power Switch

2-3

Page 20

METTLER TOLEDO® Commander User's Guide

Controller - Finding Product PLUs

Calling up PLUs

There are three ways to call PLUs: Preset Buttons, Numeric Entry or by Searching.

These are Preset Buttons.

Simply press them once

to call the PLU.

2-4

Page 21

This is the Numeric Keypad.

You key in the PLU Number,

and then press ENTER.

Chapter 2: Operation

Controller - Finding Product PLUs

This is the Search Button.

By pressing the search

button you can locate the

PLU based on its name or

part of its name.

2-5

Page 22

METTLER TOLEDO® Commander User's Guide

Tare and Graphical Tare

If forced tare is enabled and Graphical Tare is enabled, calling a PLU or pressing the

Tare override (by pressing the Tare box on a By Weight PLU) will bring up a copy of the

Graphical Tare screen. If the forced tare is enabled but not Graphical Tare, the standard

Forced Tare wizard keyboard will display.

Tare can be entered by either selecting the preset key, entering the value, or by placing

the container on the platter then pressing the “Platter Tare” key.

Graphical Tare screen

2-6

Page 23

PLU Screen

There are options on this screen

that can be changed before you

start weighing and labeling.

Chapter 2: Operation

PLU Screen

You can change items such as

the Use By Date if they are not

prohibited in the Unit’s Setup.

2-7

Page 24

METTLER TOLEDO® Commander User's Guide

You can select a Macro

assigned to the PLU and

adjust the Label Placement.

If you wish, you can

change the Extra Text.

2-8

Page 25

The OPTIONS button is used

if you wish to change the

graphics, grade, accumulator

or label format.

Chapter 2: Operation

PLU Screen

NOTE: this PLU screen is in Normal

or Pre-Wrapped Mode; in Wrap

Only or Manual Mode the Place

Label button would be gray and

unavailable.

Wrapper Control takes you to the wrapper control screen where you can modify various

settings of the wrapper itself, such as the tension and temperature of the film.

The Place Label button allows you to graphically select the location and orientation that

the label will be placed on the package.

2-9

Page 26

METTLER TOLEDO® Commander User's Guide

NOTE: back on the PLU screen, the PRINT

button does not need to be pressed for

each package; all the actions will begin

based on the weight change on the scale.

When you are done, press the CLEAR

button to EXIT this PLU.

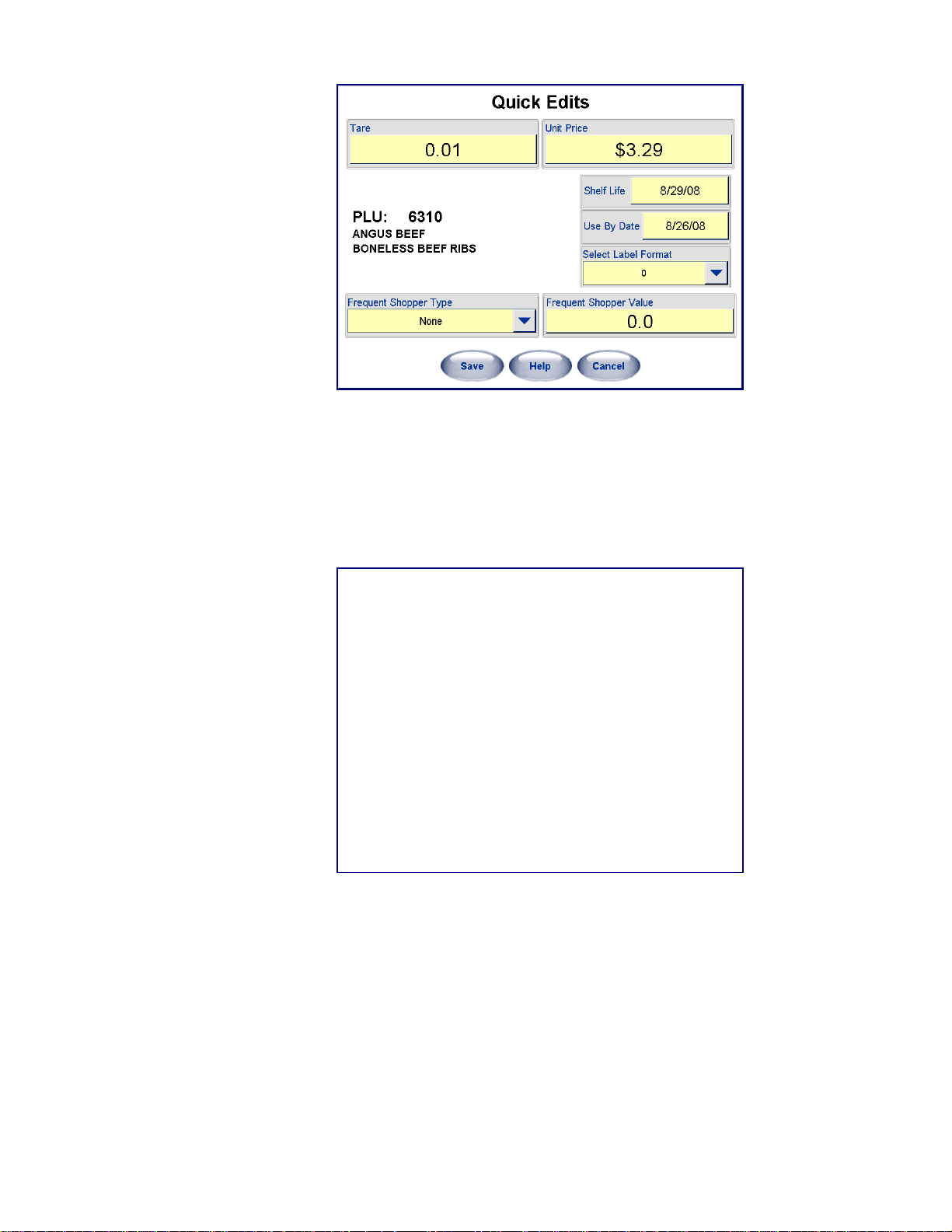

Controller - Quick Edits

- If in NORMAL Mode the machine will weigh and wrap a package and labels will be

printed and applied automatically.

- If in PRE-WRAPPED Mode the package will go through the system, be weighed and

labeled but not wrapped.

- If in MANUAL Mode the package will be weighed but not run through the system.

The label will print out and need to be manually removed and applied to the

package.

- If in WRAP ONLY Mode the package will be wrapped but not weighed and no label

will be issued or applied.

The Mode can be changed from the Wrapper Control screen.

By using the Quick Edits selection on the Controller, some of the more common

numeric data in a PLU record can be changed. The Quick Edit function changes the

record in the database immediately. Items that can be changed include the price, tare,

shelf-life, and use-by date.

Quick Edits are accessed by pressing the Setup button on the Main screen. The Setup

screen is shown below.

2-10

Page 27

NOTE: Quick Edits is not for adding

new records or deleting PLUs. See

the UC editor section in the UC

Software Tech Manual for

information on adding and deleting

PLUs.

Chapter 2: Operation

Controller - Quick Edits

To return to the Main screen, press the Return button. Touch the Quick Edits button to

enter the Quick Edits mode and select the department (below). Press Next.

The Quick Edits screen displays the current department. Type in the PLU number and

press the Enter key. The PLU data will be retrieved from the database. To change any of

the displayed fields, touch the box that displays the data.

2-11

Page 28

METTLER TOLEDO® Commander User's Guide

The PLU can also be converted to a Frequent Shopper price by touching the Frequent

Shopper Type and Price boxes.

To change the Shelf Life or Use By dates by touching the appropriate boxes and

selecting a new date from the calendar.

Touch the arrow keys at the top to change the month. You can also enter the date

numerically by touching the “Use Numerical Keypad” key.

Touch the new date, and then press the OK key to make the change.

Repeat this process for any other items that need to be modified.

2-12

Page 29

Film Tension

Chapter 2: Operation

Film Tension

This section explains how film tension is used to achieve the best wrap program for a

particular tray and how the sealing belt temperature is used.

Film Setting controls the tension of the film during the wrapping process. This ensures

a properly wrapped tray with the least amount of wrinkles. The Film Setting is found by

pressing the Wrapper Control button on the PLU screen or the Wrapper Button on the

Main screen.

NOTE: the Commander can use

either 11” or 13” film. This setting is

based on the film size the machine

was set up for at installation. Contact

Mettler Toledo service if you wish to

use a different film size than what the

machine is currently configured for.

From the Wrapper Control screen, select a film setting appropriate to the type of package

being wrapped.

5: Low Tension 13”

OK

C

C

C

3 Medium Tension Normal tension mode for most products

and trays. The default film tension setting

is 3.

5 Low Tension Less tension for larger trays with height

greater than 3 inches, less stable trays,

fragile products, or products with sharp

edges that may tear the film.

The default setting is a film tension of 3 for 13” film.

2-13

Page 30

METTLER TOLEDO® Commander User's Guide

When a change is made to the Film Tension, the field will change color while the

wrapper is adjusting to the new setting. The film tension usually adjusts within a few

seconds. When ready, a white background will be displayed again. DO NOT send

anything through the wrapper until the white background appears.

5: Low Tension 13”

OK

C

C

C

Printer – Label Printing

Check the printer’s status LED (front of unit) to make sure the printer is ready.

Green LED indicates printer is ready.

Red LED indicates an error condition.

Orange LED indicates a blocked sensor.

2-14

Page 31

Belt Temperature Controls

NOTE: The film may not be completely

sealed until the belt temperature has

reached the designated level. In a cold

room, this could take up to fifteen

minutes when first powered up.

NOTE: If the desired temperature is

higher than the actual temperature, the

actual temperature field will appear in

blue until the belt temperature increases

to the desired temperature. If the

desired temperature is lower than

actual temperature, the actual belt

temperature will appear in red until the

belt cools down to the set temperature.

Chapter 2: Operation

Belt Temperature Controls

To set the belt temperature, press the Set Belt Temp box and select the desired

temperature from the drop down list. The temperature is shown in degrees centigrade (C).

The actual and ambient temperature is also show below the selected belt temperature.

5: Low Tension 13”

OK

C

C

C

If after reaching the selected temperature the film does not seal, increase the

temperature. If the film is charring or browning, decrease the temperature.

C

5: Low Tension 13”

OK

C

C

C

C

C

2-15

Page 32

METTLER TOLEDO® Commander User's Guide

Auto Shut-offs

The Commander comes equipped with three (3) Interlock Switches and one (1) Stop

Switch, all of which stop operation of the unit if they are actuated.

One interlock switch is actuated when the safety light curtain (located at the Infeed

Safety Sensors), is broken; two are triggered if the top covers on the Canopy or Transfer

Conveyor are opened; and the Stop Switch (located on the front of the machine) is

actuated by manually pushing down.

Canopy Safety

Switch

Stop Switch

2-16

Transfer

Inside view of Infeed

Safety Switch

with Photoeye detail

Infeed Safety Sensors

Conveyor

Safety

Switch

Page 33

Stop Switch

The Commander will stop all

wrapper movement immediately

when the Stop Switch is pressed

down.

Chapter 2: Operation

Auto Shut-offs

Once depressed, the Stop Switch must be reset

before operation can begin again. Follow the

arrows turning the Stop Switch clockwise.

This will activate the Switch again. Then follow

instructions on the controller screen to re-start the

wrapper.

2-17

Page 34

METTLER TOLEDO® Commander User's Guide

Normal Shut-down

The main power switch on the front of the Commander will turn off power to the wrapper

electronics and the printers. Turn this switch off first to 0 (off).

The controller power is not switched by the wrapper power switch and uses a dedicated

switch for shutting down or powering up. The Controller power switch will perform a soft

shut down of the operating system or it can be shut down using the Setup – Shutdown

System functions on the controller. Do this after switching the wrapper power switch off.

When using the machine daily, or for extended downtime, the following is

recommended.

For daily use:

• Turn the Wrapper Power Switch OFF.

• Leave the Controller Power ON.

Extended Down Time (Two or more days)

• Turn the Wrapper Power Switch to OFF.

• Turn the Controller Power Switch to OFF.

2-18

Page 35

3 Film Loading

Loading Instructions

The Commander is designed to work with either 11 inch or 13 inch food-grade stretch

film from 58 to 80 gauge. For a list of approved film vendors, contact Mettler Toledo.

The film width will be set up at installation time by a qualified technician to work with

your choice of film. Loading film is easy and once familiar with the machine, changing

film will generally take less than a minute. To change or load new film, perform the

following steps. Power to the Commander does not need turned off.

1

Open the top cover.

Open the transfer belt cover.

Lift the transfer belt to the locking

position using the handle until it

locks in the raised position.

Note: if the unit has a DayGlo

printer in place, remove the

printer’s lock pin and rotate the

printer so it is not blocking the

way.

Release the film bobbin using

4

the latch and pivot the bobbin

outwards.

Hold the bobbin and rotate the

handwheel counter-clockwise to

release the tension.

Remove any empty film roll.

Chapter 3: Film Loading

Loading Instructions

2

3 3

5

3-1

Page 36

METTLER TOLEDO® Commander User's Guide

6

8

10

12

Position the new film roll so

the film unrolls from the top

and away from the machine.

Slide the new roll of film on

the bobbin until the roll

contacts the stop disk.

Note: if using 11” film the roll

will not contact the stop disk

and must be centered by the

distributor.

Tighten the handwheel (clockwise)

to secure the film to the bobbin.

Re-latching the film bobbin.

Pull the film and thread it first

under the dancer roller.

Continue pulling the film up over

the curved rollers and into and

through the film folders.

Lower the transfer belt by first

lifting by the handle and using

the tab on the locking lever to lift

the lever up.

Make sure you have a firm

hold on the handle to safely

lower the belt.

Close the transfer belt cover.

7

9

11

13

3-2

Page 37

Chapter 3: Film Loading

Loading Instructions

From the front of the machine,

14

grab the film and pull it up.

While continuing to hold the

film, close the top cover.

15

On the Controller, press the CUT

16

FILM button.

The Controller screen will then

return to the previous function

17

and the machine is then ready

to use.

3-3

Page 38

METTLER TOLEDO® Commander User's Guide

For your notes

3-4

Page 39

4 Trays

Loading the Trays

The Commander wrapper is designed to wrap product contained in standard food trays,

designed for automatic wrapping.

If the dimensions of the tray exceed the maximum allowed by the machine, the machine

will stop and reject the tray.

1. Trays must be sufficiently rigid and the item must be contained completely within

the dimensions of the tray.

2. Place the tray on the Infeed Belt against the black guide on the right side to start the

machine.

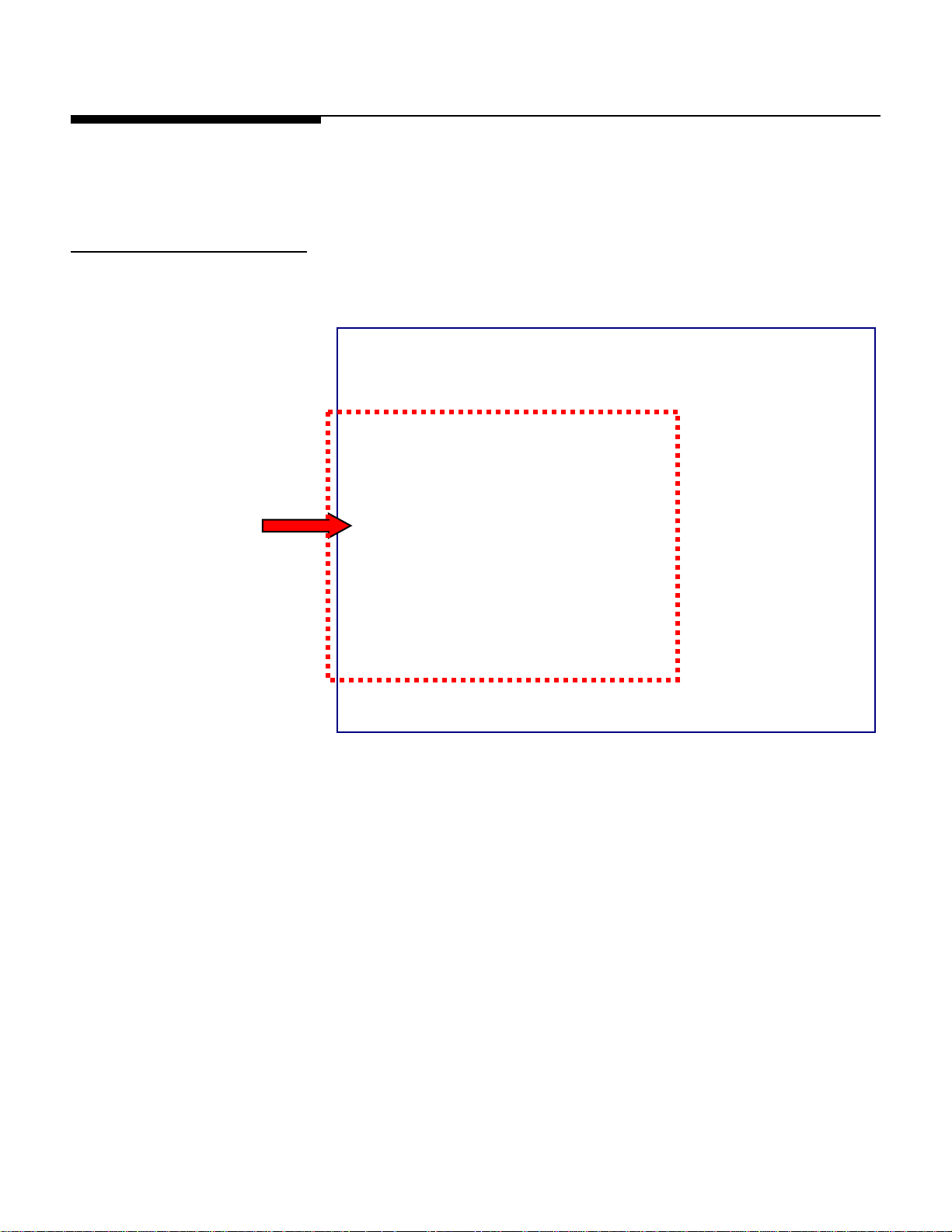

3. Proper placement is when the red sensor light (A) shines on the upper right hand

corner of the tray. Simultaneously, a short beep will sound when placement is

correct.

Chapter 4: Trays

Loading the Trays

4. A tray must pass through the photoeyes before the next package can be placed and

weighed. Allow belts to stop before placing the next tray.

A

4-1

Page 40

METTLER TOLEDO® Commander User's Guide

Tray Specifications

All products must be completely contained in the trays. If a product overhangs the tray

damage can occur and the machine will not be able to properly wrap the product.

The trays must also be stiff enough to support the product properly.

No water or liquid can be in the tray.

The tray dimensions used by the Commander must fall within the following limits

(shown using 13” film). When the Commander is set up for 11 inch film, 9S and

10x14 trays are too large for the film and cannot be used.

13”

Film

Minimum

(mm)

Minimum

(in)

Maximum

(mm)

Maximum

(in)

L 180 7.1 400 15.8

W 130 5.1 260 10.3

H 20 0.8 133 5.25

Maximum allowable dimensions will be less when using the machine with 11 inch film.

Some trays will require loading a certain way, landscape or portrait. Refer to the tray

loading reference tables for 11 inch and 13 inch machines on the following pages.

4-2

Page 41

Tray Reference Chart – 11” Film

Chapter 4: Trays

Tray Reference Chart – 11” Film

If tray height is

less than 3”

If tray height is

less than 3”

If tray height is

greater than 3”

If tray height is

greater than 3”

If tray height is

greater than 3”

4-3

Page 42

METTLER TOLEDO® Commander User's Guide

Tray Reference Chart – 13” Film

If tray height is

less than 3”

If tray height is

less than 3”

If tray height is

less than 3”

If tray height is

greater than 3”

If tray height is

greater than 3”

If tray height is

greater than 3”

4-4

Page 43

5 Printers

Introduction

Thermal label printers on the Commander have a large label capacity and are designed

to print labels containing human-readable information, UPC/EAN bar code symbols, and

graphics. Your system may have one or two printers installed, a Price Label

Printer/Applicator or DayGlo Label Printer/Applicator.

When used in an automatic system such as the Commander System, the price label

applicator can apply 2.63 in. (67mm) wide labels with lengths of 2.1 in. (53mm) to

4.2 in. (106mm).

The DayGlo label applicator can apply 1.56 in. (40mm) wide labels with lengths from

0.9 in. (23mm) to 1.5 in. (38mm).

The label print width range is 1.57 in. (40mm) to 3.14 in. (80mm).

All information and settings to the printer are set by the Controller.

Chapter 5: Printers

Introduction

For additional information on the printer and label specifications, refer to the 317

Service Manual (P/N C82784900A rev. 2 or higher).

Ope

5-1

Page 44

METTLER TOLEDO® Commander User's Guide

Loading Label Stock

The power can be left ON when changing labels on the 317 printer.

Some systems have two printers installed. If your system has two printers, the process

of changing labels is the same on both printers.

Note: Mettler-Toledo recommends cleaning the printer mechanism with every label

change.

For reference, you can always refer to the loading instructions located below or on the

inside of each printer door.

The following step-by-step instructions follow along with this diagram.

Before you begin installing the new labels, place the new roll of

labels on the Ticket Wheel with the labels unwinding from the

top to the front of the printer.

5-2

Page 45

Chapter 5: Printers

Loading Label Stock

Begin installation of the labels

by raising the ski bracket.

1

Route the labels around the rear

guide and into the printer

engine.

2

Manually feed about 2 1/2" of

3

labels into the printer or until it

stops when it reaches the rubber

platen roller. Make sure the

labels go through the Gap

Sensor.

Press and release the Label

Feed button until labels are fed

approximately 16 inches

straight down from the stripper

bar.

4

Remove the labels from the liner.

5

Route the labels around the

rear guide and into the printer

6

engine.

5-3

Page 46

METTLER TOLEDO® Commander User's Guide

7

Note: if using perforated or black preprinted stock, a Service Technician may need to

adjust the printer for proper indexing of the labels.

Remove the liner take-up clip

from the take-up spool. Wind

the liner around the take-up

spool and secure with the liner

clip.

Lower the Ski Bracket.

Once the new labels are in

place, close the side cover and

secure the knob.

Your printer is now ready to go.

Check the Status LED on the

front of the printer.

• GREEN indicates the printer

is Ready.

• ORANGE indicates a

blocked label taken sensor.

Recheck that you have

threaded the labels

correctly.

8

5-4

Page 47

6 Controller - Operation

Introduction

PrePack Controller software is designed for use in a PrePack Food Environment. The

PrePack Controller is a part of a programmable wrapper system that offers very flexible

programming and formatting with an easy-to-use user interface.

Chapter 6: Controller - Operation

Introduction

Classic Interface

Fusion Interface

The Commander controller can display in either a Classic or Fusion interface. All

functions and options are available in both interfaces; it is simply a matter of operator

viewing preference.

For further details on changing the controller interface, see the UC Software Technical

Manual (B16588100A) or contact your system administrator.

6-1

Page 48

METTLER TOLEDO® Commander User's Guide

Main Screen Elements

1

14

13

2

3

4

5

6

7

9

12 11 10 8

Weight Display. Touch to zero the scale.

1

Current Department, date, time, and network ID.

2

Price Look Up (PLU) number display.

3

CLEAR button clears values from the display.

4

ENTER accepts the displayed value.

5

BACKSPACE erases the last entry. When pressed again it erases digits to the left.

6

The Search button is used to search the Database for a PLU based on alpha-numeric input from

7

the operator.

The Operations button is used to access the Cutting Test and Void Transactions functions

8

The Wrapper button is used to access various settings for the wrapper such as the tension of the

9

film and the temperature of the belt. This button will appear RED if there is an error in the

wrapping unit.

If the Help system is enabled, a Help button will appear on certain screens. When touched, this

10

button will launch the Help system. The arrow describes the area occupied by the button when it

is enabled.

The Setup button is used to enter the controller's Setup Mode.

11

Preset Page Selector Buttons are used to select the preset page you wish to use to perform a

12

transaction. When there are more buttons than can be displayed on the screen, use the arrow left

or arrow right buttons to toggle through all of the pages. The current page will be highlighted.

These buttons are configured in Setup mode in Presets Setup.

Preset Buttons are used for one-touch call up of PLU records. A PLU number can be assigned to a

13

certain key. When this key is pressed, it calls up the record assigned to it.

Gross/Net indicator. When Net displays, this indicates a tare weight.

14

Main Screen Elements

6-2

Page 49

PLU Screen

1

19

18

17

16

15

2 3 4

Chapter 6: Controller - Operation

PLU Screen

5

6

7

8

9

10

11

1 This is the weight of the item (less the tare) if the PLU is sold by weight. Touch to zero the scale.

2

The Tare is programmed into the PLU record. Touch this box to override the tare, if allowed in setup.

3

The Unit Price is programmed into the PLU record. Touch to override (if allowed in setup). This is used to calculate the

Total Price.

4

This value is the Total Price of the item. If the item is sold by weight, this is the unit price multiplied by the weight of the

item. Total Price is never operator accessible.

5

Pack Date uses the current date set in the controller. This will print on the label if it is included in the label format.

6

Shelf Life is programmed into the PLU record. This date is used to show the date when the item should not be sold

anymore. This date will print on the label if it is included in the label format. When the box is white, this date can be

changed.

7

The Use By Date is programmed into the PLU record. This date is calculated based on the current Pack Date. The item

should not be consumed beyond this date. This date will print on the label if it is included in the label format. When the box

is white, this date can be changed.

8

Clear ends the transaction and returns the display to the Main Screen.

9

The Options button is used for temporary overrides to change various settings.

10

A Help button will appear on certain screens. When touched, this button will launch the Help system.

11

Print - prints the item label.

12

Landscape/Turn Label allows the user to modify the label’s orientation.

13

The Place Label button allows you to graphically select the location and orientation that the label will be placed on the

package.

14

Wrapper Control takes you to the Wrapper Control screen where you can modify various settings of the wrapper itself, such

as the tension and temperature of the film.

15

Total Packages, Total Weight, and Run Total show any accumulated totals that apply to the current Run.

16

Family Pack is a macro that is setup to reduce the price when sold in larger quantities.

17

Rewrap flags the transaction as an item that was previously weighed and pulled from the case.

18

The Extra Text number is programmed into the PLU record so when the PLU is called, the associated Extra Text is called.

When the box is white, this can be changed.

19

Gross/Net indicator: when Net displays, this indicates a tare weight.

14 15 16

PLU Screen Elements

6-3

Page 50

METTLER TOLEDO® Commander User's Guide

Options Button

The Options button on the PLU Screen is used for the following temporary overrides.

The Options screen below allows overrides on all of the items. The boxes are white,

indicating overrides are allowed. If the boxes are not white, no overrides are allowed.

The overrides can be enabled or disabled from the Transaction Screen Overrides

screen in the Service Scale Setup, as shown below. In order to allow the overrides, the

boxes must be checked.

Label Format

An alternate label format can be selected for this run using this override.

Grade

You can select another Grade for this run using the drop down menu.

Bottom Label Format

If configured, this is used to apply a bottom label to every package when used in

an automatic system with a bottom label applicator.

Satellite Graphic

If a Satellite Graphic is configured on the label, you can use this to override the

graphic used for this run, or disable it for this run.

Linked Graphic

If a linked graphic is configured on the label and in the PLU record, this can be

used to select another for this run.

DayGlo Graphic

If there is a DayGlo printer used, the programmed graphic can be changed for this

run. Select from a drop down list or using the Keypad enter the graphic’s

corresponding number.

Accumulator

A different accumulator for the totals information can be selected using this

function.

6-4

Page 51

Chapter 6: Controller - Operation

Run Total

Totals from the selected PLU’s current run are gathered based on weight, cost, and

number of packages. These are displayed on the PLU Edit Screen. They can be

printed on a “Run Totals” label if needed.

Note: the Run Totals label format is set up from the Label Printer Setup screen.

Print Inhibits

Select the Print Inhibits button from the Options screen to view what items you can

refrain from printing on a label for this transaction.

PLU Screen

6-5

Page 52

METTLER TOLEDO® Commander User's Guide

Place Label Button

Selecting the Place Label button on the PLU screen will bring up the Label Placement

Note: when the printer is in

Wrap Only or Manual

Mode the Place Label

button on the PLU screen

turns gray and the text is

replaced by the Mode you

are in.

screen.

From this screen you can graphically select where on a package the final label will be

placed as well as the orientation of the label.

1

At this point, the button

cannot be selected because

label placement is not

required when the wrapper

is in Wrap Only or Manual

Mode.

2

The green arrow (1) shows the edge of the package the offset is applied to. The red

letter A (2) indicates the orientation of the label graphics.

You can select a landscape or portrait package orientation. Then click on one of the

squares to assign a quadrant that the label will be applied. Next a label will appear and

by clicking on it you can change rotate the label 90°.

Note: Label Placement must be assigned prior to running packages through the

wrapper system. Depending on which label orientation has been selected, the 317

printer(s) may need to be manually adjusted as well.

Th

6-6

However, once label placement has been designated, if a package is going to be

inserted Landscape rather than Portrait checking the Turn Label button on the PLU

screen will adjust label placement. The label will correct to be in the designated

quadrant regardless of package orientation.

Edge Offset

Edge Offset shows the numeric value of where the label will begin from the edge of the

package. Default is 25.

Page 53

PLU Pricing Modes

By-Weight PLU

Chapter 6: Controller - Operation

PLU Pricing Modes

PLU is an abbreviation for Price Look Up. The PLU is a reference number assigned to

access a product's record that includes fields such as the description, price, tare, etc.

Different PLU's will have different pricing modes. Meat is normally sold "By Weight" by

the pound or kilogram. Many bakery products are sold "By Count". Other products may

be sold in a standard package that all weighs the same (or assumes all weight is the

same or a minimum value). The different pricing modes are as follows:

Examples of products sold by weight are meats, cheese, poultry, and produce. ByWeight items can be priced in three ways:

• Priced "Per Pound" - Typically weighed items are priced per the pound. The weight

multiplied by the unit price equals the total price of the product to the customer.

• Priced "Per Fraction of a Pound" (fractional) - The item may also be priced by the

fraction of the pound (where legal and desired). Pricing per 1/4 pound and per 1/2

pound are available.

• "Pounds for" price - The PLU may be sold with a pounds for price (rather than price

per pound). (2 pounds for $1.00).

By-Count PLU

Standard Pack PLU

Note: if the scale is calibrated for kilograms (kg), the above applies but based off of kg.

Examples of items sold by the count are cookies, donuts, rolls, bread, etc. Example: 4

Apples for $0.69. The By-Count PLU allows the operator to use the wrapper for a

labeling operation. Pricing is entered as a certain quantity of items for a set price. If the

total weight for the items is needed, a weight field can be configured on the label to print

the weight of the items in addition to the By-Count information.

Examples of items sold by Standard Pack include whole chickens, sheet cakes, bread,

etc. The Standard Pack PLU is similar to By-Count and also allows the operator to use

the wrapper for a labeling operation. The labels indicate the net weight of the item and

total price of the item. These types of items all weigh the same (or are assumed to

weigh the same or of a minimum value).

6-7

Page 54

METTLER TOLEDO® Commander User's Guide

PLU Search Modes

The Search Function allows you to search for a PLU by name or partial name. This is

helpful if the PLU number is unknown or if a list of choices is desired.

From the Main Screen, click on the Search button.

From here the Search screen will appear. Select the Department you want via a

dropdown menu (1). Then using the keyboard (2) type in the word, or portion of the

word, you are looking for and hit the Search button (3).

The returned search list is browsed via a scroll bar.

1

2

3

6-8

Page 55

Chapter 6: Controller - Operation

PLU Search Modes

This will return a list of any PLU in the database which contains that word as part of a

keyword or description. Highlight the PLU by touching it.

This will return the PLU in the PLU Screen.

6-9

Page 56

METTLER TOLEDO® Commander User's Guide

Country of Origin Labeling (COOL)

Country of Origin Labeling (COOL) is information assigned to a specific PLU that

designates where a product came from and the processing it went through.

If a COOL is associated with a PLU, you will be prompted to choose a preconfigured

COOL statement or, in some cases, create custom COOL statements prior to going on to

the PLU transition screen.

COOL associations are set up from the UC Editor. For more information on the COOL

setup procedure see the UC Editor Manual or UC Software Technical Manual.

Preconfigured COOL Statements

If a PLU is selected that has a forced COOL statement, the Preconfigured COOL

Declaration screen will appear. Preconfigured COOL Declaration screen consists of: