Page 1

Toledo • P.O. Box 134 • 8280 AC Genemuiden • NL • www.toledo.nl 0303-25

UK Subject to change

D Änderungen vorbehalten

NL Wijzigingen voorbehouden

F Sous réserve de modifications

S Ändringar förbehålles

SF Pidätämme oikeuden muutoksiin

N Rett till endringer forbeholdes

DK Ret til ændringer forbeholdes

E Reservado el derecho de modificaciones

technicas

P Reservado o direito a modificações

I Con reserva di modifiche

H Változtatás jogát fenntartjuk

CZ Změny vyhrazeny

R дУПО‡МЛfl Toledo ФУТЪУflММУ

ТУ‚В¯ВМТЪ‚Ы ВЪ ‚˚ФЫТН‡ВПЫ ˛ В˛

ФУВ‰ЫНˆЛ˛. иУБЪУПЫ ‚ ЪВıМЛ˜ВТЛВ

ı‡‡НЪВЛТЪЛНЛ ПУ„ЫЪ ‚МУТЛЪ¸Тfl ·ВБ

ФВ‰‚‡ЛЪВО¸МУ„У Ы‚В‰УПОВМЛfl.

GR

TR Değişiklikler mümkündür

UK

D

NL

F

CZ

USERS MANUAL 03

GEBRAUCHSANWEISUNG 07

GEBRUIKSAANWIJZING 12

MODE D’EMPLOI 17

NÁVOD K POUŽITÍ 23

TKZ-205

Art.nr. 827200

Page 2

2 Toledo

Toledo 27

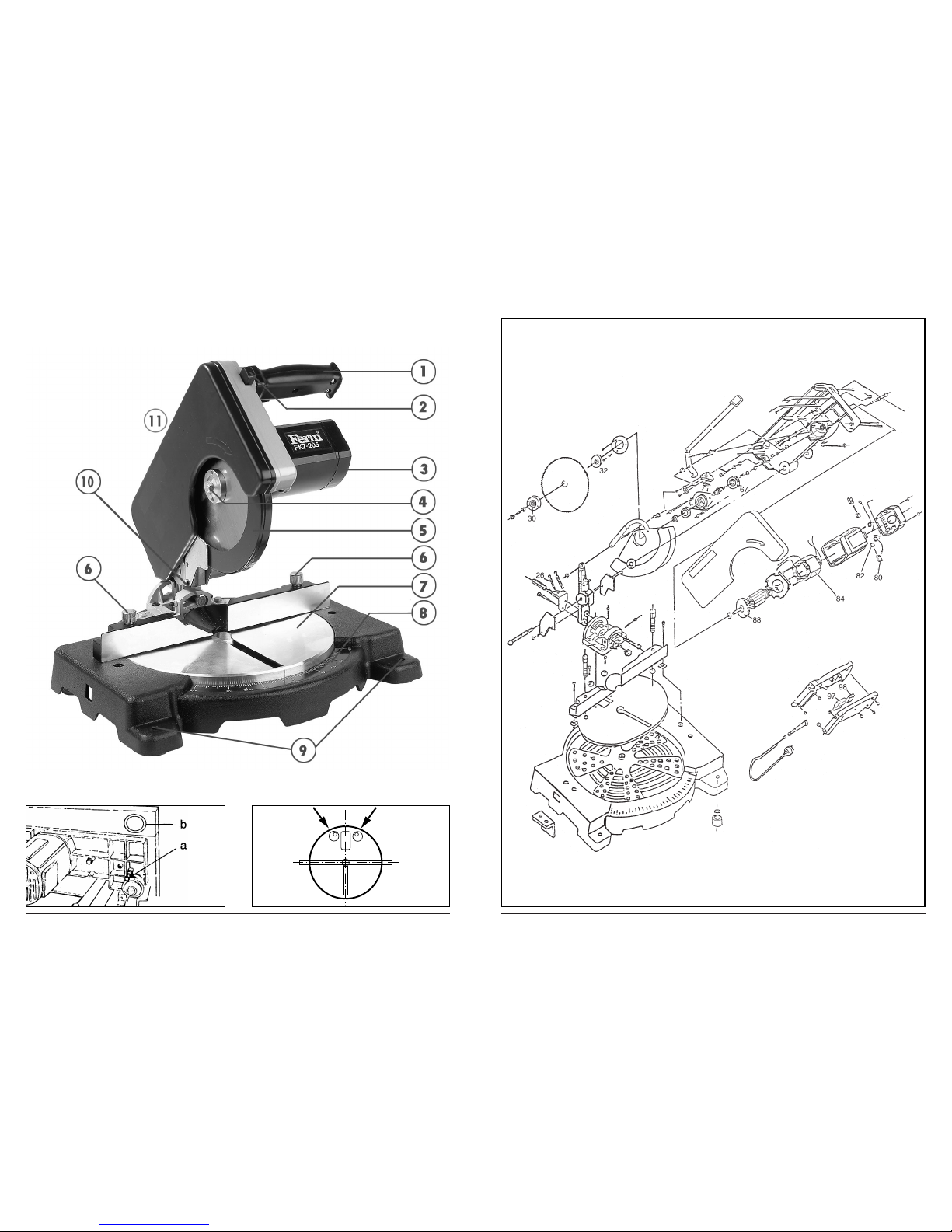

EXPLODED VIEW

Fig. 2

Fig. 3

Fig. 1

Page 3

26 Toledo

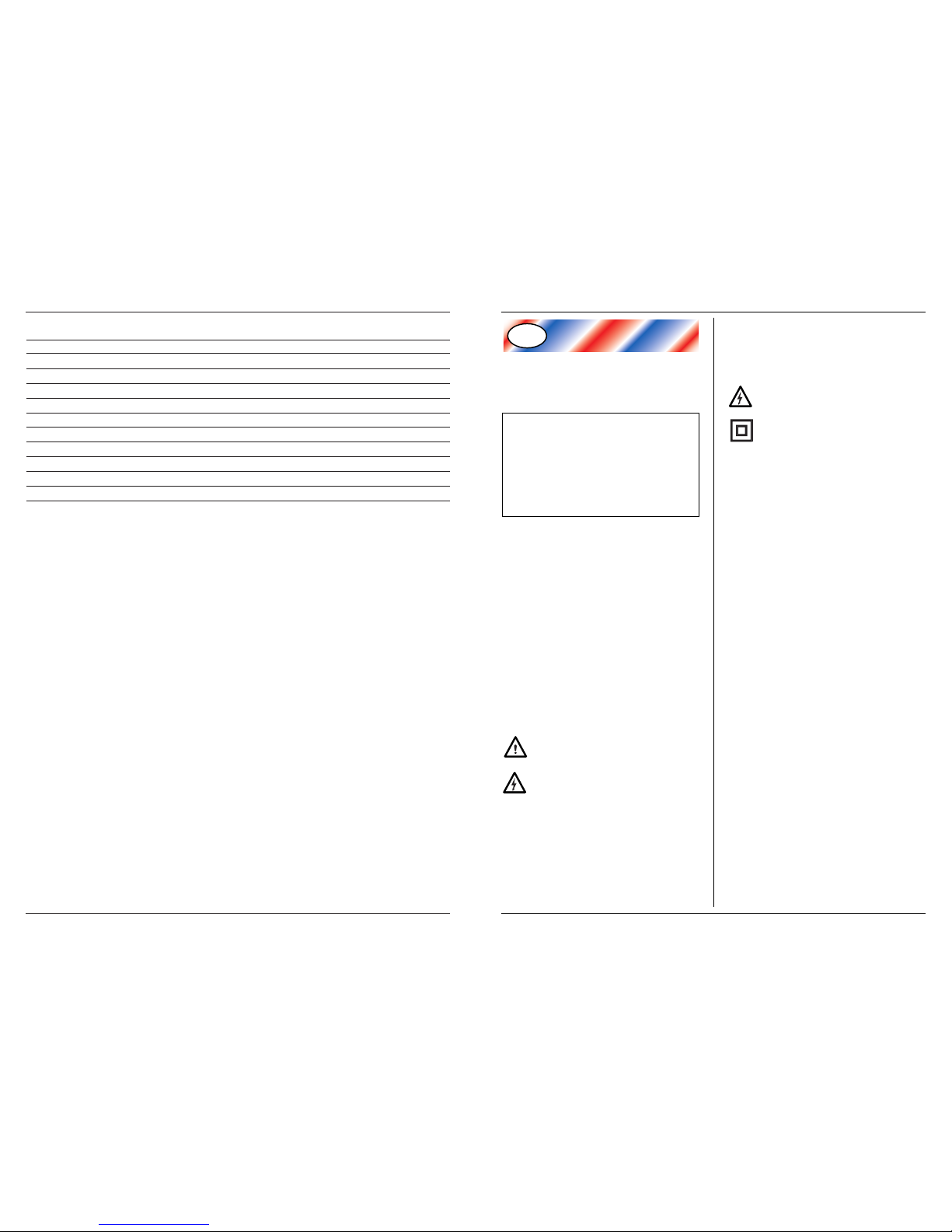

SPARE PARTS LIST

REF. NR. DESCRIPTION TOLEDO NR.

26 SPRING 407630

67 GEAR WHEEL 407631

32 POSITIONING RING 407632

30 CLAMP RING 407633

88 ROTOR-ASSEMBLEY 407634

84 STATOR ASSEMBLY 407635

82 CARBON BRUSH WITH SPRING 407636

80 BRUSH HOLDER 407637

98 CAPACITOR 407638

97 SWITCH 407639

Cutting-off machine

TECHNICAL SPECIFICATIONS

PACKAGE CONTENTS

1 Cutting-off machine

1 Saw blade

1 Instruction manual

1 Safety instructions

1 Guarantee card

Check the machine, loose parts and accessories for

transport damage.

DESCRIPTION (PAGE 2)

SAFETY INSTRUCTIONS

The following symbols are used throughout this manual:

Denotes risk of personal injury, loss of life or

damage to the tool in case of non-observance of the

instructions in this manual.

Denotes risk of electric shock.

Carefully read this manual before using the machine.

Make sure that you know how the machine functions and

how to operate it. Maintain the machine in accordance

with the instructions to make sure it functions properly.

When using electric machines always observe

the safety regulations applicable in your country

to reduce the risk of fire, electric shock and personal injury.

Read the following safety instructions. Keep

these instructions in a safe place.

Electrical safety

When using electric machines always observe

the safety regulations applicable in your country

to reduce the risk of fire, electric shock and personal injury. Read the following safety instructions and also the enclosed safety instructions.

Keep these instructions in a safe place!

Always check that the power supply corresponds to

the voltage on the rating plate.

The machine is double insulated in accordance

with EN50144; therefore no earth wire is

required.

Replacing cables or plugs

Immediately throw away old cables or plugs when they

have been replaced by new ones. It is dangerous to insert

the plug of a loose cable in the wall outlet.

Using extension cables

Only use an approved extension cable suitable for the

power input of the machine. The minimum conductor

size is 1.5 mm

2

. When using a cable reel always unwind

the reel completely.

SPECIAL SAFETY INSTRUCTIONS

BEFORE EACH USE

- Check the cutting-off machine. If any part of the cutting-off machine is missing, bent or unusable in another way, or if electrical faults occur, switch off the

machine and remove the plug from the socket.

Replace all missing, damaged or faulty parts, before

using the machine again.

- Make sure that hands, eyes, face and ears are well

protected.

- Use of safety goggles without the CE quality mark can

lead to serious injury if the glass breaks.

- In order to prevent the saw blade from becoming

jammed in the saw cut and workpieces being flung

away, the instructions below must be followed:

- Choose a suitable saw blade for the work.

Only use the cutting-off machine to saw wood

and derived products, or light metals such as aluminium. Other materials can be flung away, get

caught in the saw blade or cause other dangers.

- The arrow on the saw blade, which indicates the

direction of rotation, must point in the same

direction as the arrow placed on the machine.

The saw blade teeth must point downwards on

the front of the saw.

- Check whether the saw blade is sharp, undama-

ged and well aligned. Press the saw head downwards after removing the plug.

Turn the saw blade by hand and see whether it

turns freely. Put the machine in the 45 position

and repeat the test. If the saw blade touches anywhere, it must be adjusted again.

- Keep the saw blade and the tensioning surfaces of

the clamps clean.

- The saw blade flange must always be mounted

with the tightened recess towards the saw blade.

1. Grip with switch

2. Unlocking button

3. Motor housing + cover

graphite brushes

4. Saw blade attachment

5. Moveable safety guard

6.

Table adjustment screws

7. Rotary table

8. Degree scale

9. Fastening holes

10. Bevel adjustment bolt

11. Protective cover

Voltage | 230 V~

Frequency | 50 Hz

Power input | 800 W

No-load speed | 4500/min

Disc diameter | 205 x 18 mm

Max. cutting depth 90° | 120x50 mm

Max. cutting depth 45° | 70x55 mm

Weight | 7.0 kg

Lpa (sound pressure) | 88.9 dB(A)

Lwa (sound power level) | 101.9 dB(A)

Vibration value | 2.5 m/s

2

UK

English

Toledo 3

Page 4

ÚDRŽBA

Při provádní údržby motoru dbejte vždy na to, aby

přistroj nebyl pod naptím.

Přístroje značky Toledo jsou konstruovány pro dlouhodobé používání při minimální údržbě. Budou fungovat

bez problémů, pokud se jim bude věnovat náležitá péče a

pokud budou pravidelně čištěny.

Iatní

Kryt přístroje pravidelně čistěte měkkým hadříkem

(nejlépe po každém použití). Odstraňujte prach a špínu z

otvorů ventilace.

Pokud se apínu nepodaří odstranit, použijte měkký

hadřík namočený v mýdlové vodě. Zásadně nepoužívejte

rozpouaštděla, jako jsou benzin, alkohol, čpavek apod.

Tato rozpouštědla by mohla poškodit umlěohmotné

součásti přístroje.

Mazání

Přístroj nevyžaduje žádné dodatečné mazání.

Poruchy

Jestliže dojde k poruše, např. v důsledku opotřebování

některé součásti, obraťte se na zástupce firmy Toledo.

Na konci této příručky se nachází nákres přístroje

rozloženého na jednotlivé díly, které je možné objednat.

ŽIVOTNÍ PROSTŘEDÍ

Přístroj je dodáván v odolném balení, které zabraňuje

jeho poškození během přepravy. Většinu z materiálů,

které jsou na balení použity, lze recyklovat. Zbavujte se

jich proto pouze na místech určených pro odpad

příslušných látek.

Přístroje, které nepotřebujete, odneste k nejbližšímu

zástupci firmy Toledo ve vašem okolí. Zde dojde k jejich

likvidaci v souladu se zásadami ochrany životního

prostředí.

ZÁRUKA

Záruka je poskytována za podmínek, jež najdete na

samostatném záručním listu, který je přiložen k výrobku.

Prohlašujeme na vlastní odpovědnost,

že tento výrobek odpovídá následujícím

normám a standardizovaným dokumentům:

EN61029-1, prEN61029-2-9, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3

v souladu se směrnicemi:

98/37/EEC

73/23/EEC

89/336/EEC

od 10-12-2002

GENEMUIDEN NL

W. Kamphof

Oddělení kvality

CE

ı

PROHLÁŠENÍ O SPLNĚNÍ NOREM

(CZ)

Toledo 25

- The flange screw must be tightened with a 13 mm

open-end wrench.

- Check whether all the tensioning devices and

interlocks are secure and that no single part

shows too great a clearance.

- Never use just your hands for sawing.

- Always secure the workpiece against the check,

so that it cannot topple or turn during sawing. No

impurities may be allowed to gather under the

workpiece.

- Make sure that the workpiece cannot move after

being sawn through, for example, because it is not

supported by the full surface.

- For sawing workpieces which are not being supported by the full surface, use fillings or another

machine.

- Check whether the sawn off pieces can be removed

laterally from the saw blade. Otherwise they can be

caught by the saw blade and flung away.

- Never saw several workpieces at the same time.

- Be especially careful when sawing large, very small or

awkwardly shaped workpieces.

- Use additional supports (tables, trestle or other)

for long workpieces, which will otherwise topple

from the machine table if they are not held.

- Do not use the machine to saw workpieces which

are so small that they can no longer be held safely.

- When sawing profile sections, work must be car-

ried out so that the workpiece cannot slide away

and the saw blade cannot become jammed. A profiled workpiece must lie flat or be held by an auxiliary tool, as a result of which toppling or sliding

during work is prevented.

- Round workpieces such as pipes must be secu-

red, otherwise they will turn and there is a danger

that the saw blade will become jammed. Always

secure the workpiece against the check and on

the table, using a suitable auxiliary tool.

- There may be no nails or foreign objects in the workpiece to be treated.

- In order to prevent damage to the ears, ear mufflers

must be used.

- In order to prevent accidents in case the machine is

switched on by mistake, the mains plug must be

removed from the power point before adjustments

are made to the check or saw head. The same applies

to changing the saw blad or accessories and during

maintenance of the machine.

- In order to prevent electric shocks, when connecting

the plug to the power point, the metal pins may not

be touched in any way whatsoever.

- Do not use the cable to remove the plug from the

power point. Protect the cable from oil, heat and

sharp edges.

- Never apply a detergent or lubricant to a saw

blade which is still rotating.

- In order to prevent fire, the machine may never

be used near inflammable liquids, vapours or

gases.

- Prevent injuries which can occur by not using the

original accessories. Only use the recommended

saw blades.

WHEN THE MACHINE IS IN OPERATION

Do not allow routine, which occurs when using the

machine frequently, to lead to mistakes. Remember that a slight lack of concentration can result in serious injuries in a split second.

1. Before the first saw cut is made, allow the machine to

rotate for a while. Should unusual noises or strong

vibrations be observed, then switch off the machine

and remove the plug from the power point in order

to then determine the cause. Do not switch the

machine on before the cause has been established

and the fault has been remedied.

2. Make sure that the sawn off workpiece does not

become jammed, do not hold it, do not clamp it and

do not secure it against the check. It must be allowed

to move freely along the side of the saw blade. If these

conditions cannot be met, the sawn off workpiece

can be caught by the saw blade and flung away.

3. Avoid placing your hands in an unfavourable place,

whereby one or both hands may come into contact

with the saw blade as a result of a sudden displacement.

4. Before you begin sawing, allow the saw blade to reach

its full revolutions.

5. Press the saw head downwards in such a way that the

motor is not overloaded and the saw blade is not jammed.

6. If you are going to remove jammed material, first

allow the saw blade to come to a standstill. Switch off

the saw and remove the plug from the power point.

7. After finishing the sawing process, hold the saw head

downwards, release the switch and wait until all the

moving parts have come to a halt, before you move

your hands away from the machine.

8. Use only saw blades recommended by the manufac-

turer.

9. Connect the maschine to a dust-collecting device

when sawing.

10. Ensure that the saw blade protective cap is in the cor-

rect position before you start sawing.

MOTOR

In order to prevent damage to the motor, chips and

dust must regularly be removed from it, in order to

ensure an ideal cooling.

1. Connect the machine to a 230V~ circuit.

2. If the motor does not start, the switch must be rele-

ased immediately. Remove the plug from the power

point. Check whether the saw blade can move freely.

If the saw blade moves freely, start the machine again.

3. If the motor suddenly stops during sawing, the switch

must be released immediately. Release the saw blade

from the workpiece, after which sawing can be continued.

4. When using long cables with too small a diameter, a

loss of voltage occurs, which gives problems with the

motor.

4 Toledo

Page 5

PREPARATION

Position the cutting-off machine on a smooth, stable surface. The cutting-off machine may also be fastened to a

working bench. Make sure that the work area is clean and

tidy.

UNLOCKING THE MACHINE

Press the saw head downwards with your left hand and

pull the unlocking button out (a, illustration 2). The

unlocking button is situated on the back right hand side of

the saw head. As soon as the unlocking button has been

pulled out, allow the saw head to come up. Afterwards,

the saw head can be moved downwards, by pressing in

the unlocking button (2, figure 1).

The cutting-off machine has been calibrated in the factory to exactly 45° (right and left). After the first sawing,

check whether the saw blade is at right angles with regard

to the bottom of the machine and the table. In order to

carry out a correction, if necessary, the guiding adjusting

screws, which are situated on both sides of the adjusting

piece, must be turned. In this way, the swivel handle is set

diagonally in order to obtain a saw cut of 45°.

USE OF THE MACHINE

- The cutting-off machine is put into operation by

means of the switch button on the inside of the

handle.

- Before sawing is started, the saw blade must rotate at

its full revolutions.

- Press the saw head with the handle downwards,

slowly and evenly.

- Put pressure on the saw blade, in accordance with

the nature and measurement of the workpiece.

- During sawing, the workpiece must be pressed firmly

on the table.

- In order to saw longer workpieces, use must be made

of supports in order to support the workpiece to be

sawn.

- After finishing sawing, the head must be brought into

the starting position again.

- The saw blade must be sharpened regularly and, if

necessary, changed.

Before each operation, the condition of the saw

blade must be checked.

SAWING DIAGONALLY

- For sawing diagonally at 45°, the nut on the back of

the machine must be loosened using an open-end

wrench.

- Adjust the saw head from the left to the desired setting or to 45°.

- Fasten the nut screw again before you start sawing.

HORIZONTAL SAW CUT

- The head can be turned to 45° both to the left and to

the right.

- Intermediate angles are easy to set, whereby the

desired angle can be read on the degree scale.

- In order to fasten or release the machine head at a

desired angle, both guiding adjusting screws are

adjusted.

- The check at 45° is eccentric for a correct adjustment.

COMBINED SAW CUT

A combination of a horizontal diagonal saw cut and a vertical diagonally saw cut.

CHANGING THE SAW BLADE

First allow the saw blade to come to a complete

standstill and remove the plug from the power

point.

- Remove the protective cover (Fig. 1.11). Then clamp

the outward flange with the accompanying wrench

and turn clockwise using an open-end wrench.

- Remove the saw blade and replace it, whereby the

teeth point in the direction of the arrow.

- Before the saw blade is mounted, first clean the flanges.

- Put the outward flange back in position and fasten.

- Before the machine is connected to the mains, the

saw blade safety device must be placed in the starting

position.

- If necessary, do a test cut, by lifting the saw head and

pressing it down.

DUST EXTRACTION

The machine is provided with a connection for dust

extraction (B, illustration 2). For this purpose a dust

extractor with the normal connection can be used.

Toledo 5

- Řezná hlavice musí být po skončení řezání navrácena

do své počáteční polohy.

POZOR! Stav kotouče musí být zkontrolován před

každým použitím přístroje.

Vždy se řiďte bezpečnostími předpisy a platnými

nařízeními.

DIAGONÁLNÍ ŘEZÁNÍ

- Pro diagonální řezání pod úhlem 45° je třeba uvolnit

matici na zadní straně přístroje otevřeným klíčem.

- Nastavte hlavici pily zleva pod požadovaným úhlem

nebo pod úhlem 45°.

- Dříve než budete opět řezat, matici znovu pevně

zašroubujte.

HORIZONTÁLNÍ ŘEZÁNÍ

- Hlavice přístroje může být natočena pod úhlem až

45° doleva i doprava.

- Mezilehlé úhly mohou být snadno nastaveny, přičemž

velikost úhlu lze odečíst na úhlové stupnici.

- Pro upevnění hlavice přístroje pod požadovaným

úhlem nebo pro její uvolnění slouží oba vodicí šrouby

pro přesné nastavení.

- Při správném nastavení na 45° by měly být zarážky na

pracovním stolku umístěny excentricky.

KOMBINOVANÝ ŘEZ PILOU.

Zvolte správné úhly vertikálního a horizontálního

pokosu.

VÝMŰNA ŘEZNÉHO KOTOUŚE.

Dříve než začnete, nechte řezný kotouč úplně zastavit a vytáhněte zástrčku ze zásuvky.

- Odstraňte ochranný kryt (Obr. 1.11). Poté

připevněte svěrkou vnější přírubu dodaným klíčem a

otočte jí ve směru hodinových ručiček otevřeným

klíčem.

- Vyndejte řezný kotouč a vložte místo něj nový. Zuby

řezného kotouče listu musí být orientovány stejným

směrem jako šipka na ochranném krytu.

- Dříve než se nasadí řezný kotouč, příruby musí být

očištěny.

- Nasaďte vnější přírubu na své místo a utáhněte matici

s použitím klíče na přírubu a trubkového nástrčkového klíče.

- Připevněte zpět plastický ochranný kryt pomocí

dvou šroubů (13).

ODSTRAŇOVÁNÍ PRACHU

Přístroj je dodáván s vývodem na odstraňování prachu

(B, obrázek 2). Pro tento účel může být nasazen i odsávač

prachu s běžným propojením.

PORUCHY

Pro případ, kdy přístroj nefunguje dobře, popíšeme v

následujícím několik příčin možných problémů a jejich

řešení:

1. Nadměrné přehřívání motoru.

Větrací otvory jsou ucpány prachem:

- Vyčistěte větrací otvory;

Motor je porouchán:

- Odneste přístroj k opravě k vašemu prodejci přístrojů

Toledo.

2. Zapnutý přístroj nepracuje.

Přerušení přívodu proudu:

- Zkontrolujte, zdali je zásuvka (kontakt zásuvky) pod

napětím. Zkuste například zapojit jiný elektrický

přístroj.

- Odneste přístroj k opravě k vašemu prodejci přístrojů

Toledo.

Poškození síťového vypínače:

- Odneste přístroj k opravě k vašemu prodejci přístrojů

Toledo.

3. Prach není odsáván.

Toto může nastat, je-li prachový pytlík plný:

- Vyprázdněte prachový pytlík.

To také může nastat, je-li ucpán vstup odsávacího

systému:

- Vyčistěte otvor odsávacího systému.

24 Toledo

Page 6

- Aby se zabránilo úrazu v případě náhodného či neúmyslného zapnutí přístroje, před každým nastavováním řezné hlavice nebo úpravou zarážek pracovního stolu přístroj vždy vytáhněte z elektrické

sítě. Stejné pravidlo platí i v případě výměny řezného

kotouče nebo příslušenství, nebo i během údržby

přístroje.

- Abyste při zapojení přístroje do elektrické sítě zabránili úrazu elektrickým proudem, nedotýkejte se v

žádném případě kovových kolíků zástrčky.

- Přístroj nevypínejte zatáhnutím za jeho elektrickou

šňůru. Elektrickou šňůru nevystavujte teplu, mastnotám a kontaktu s ostrými hranami.

- Řezný kotouč nikdy nečistěte nebo nepromazávejte,

jestliže se ještě otáčí.

- Abyste zabránili požáru, přístroj nikdy nepoužívejte v

blízkosti hořlavých tekutin, výparů nebo plynů.

- Vyvarujte se možných zranění, která mohou být

způsobena použitím nevhodného či neznačkového

příslušenství. Používejte pouze řezné kotouče doporučované výrobcem.

- Typ řezného kotouče zvolte vždy v závislosti na

řezaném materiálu.

PŘI POUŽÍVÁNÍ PŘÍSTROJE

Nezpoléhejte se na svoji rutinu, získanou během

častého používání přístroje. I rutinní používání

může vést k chybám. Nezapomeňte, že i krátká ztráta koncentrace může vést k vážnému zranění během zlomku

vteřiny.

1. Přístroj nepoužívejte bez ochranných prvků ve

správné poloze.

2. Dříve než začnete materiál řezat, nechejte řezný

kotouč se chvíli otáčet. V případě neobvyklého zvuku

nebo silných vibrací, přístroj vypněte a vytáhněte

šňůru z elekrické sítě a pokuste se zjistit možnou

příčinu. Přístroj znovu nezapínejte, dokud nebyla

zjištěna příčina a chyba odstraněna.

3. Přesvědčete se, že se odřezaná část materiálu neza-

sekne, nedržte ji rukou a neupínejte a nezajišťujte ji k

zarážám stolku přístroje. Musí se volně pohybovat

podél strany řezného kotouče. V případě, že nejsou

tyto podmínky zajištěny, může dojít ke kontaktu

odřezaného materiálu s kotoučem a k jeho následnému zachycení a odmrštění.

4. Vyvarujte se umístění vašich rukou na takové místo,

kde by mohlo důsledkem náhlého posunutí materiálu

dojít ke kontaktu jedné nebo obou rukou s řezným

kotoučem.

5. Dříve než začnete řezat, vyčkejte, dokud řezný

kotouč nedosáhne plných otáček.

6. Posouvejte kotoučem pily směrem dolů tak, aby

nedošlo k nadměrnému přetížení motoru nebo i k

zadření řezného kotouče.

7. V případě, že chcete odstranit zaseknutý kus mate-

riálu, vyčkejte až do té doby, kdy se řezný kotouč už

nepohybuje. Přístroj vypněte a vytáhněte šňůru z

elektrické sítě.

8. Používejte pouze řezné kotouče, které jsou dopo-

ručené výrobcem.

9. Před řezáním přístroj propojte se zařízením na sběr

prachu.

10. Po ukončení řezání, držte kotouč dole, uvolněte

vypínač a vyčkejte, až se všechny pohybující části

přístroje zastaví. Pouze pak můžete přístroj opustit.

MOTOR

1. Přístroj připojte do elektrické sítě s napětím

220/230V.

2. V případě, že se motor nerozběhl, okamžitě jej

vypněte. Vytáhněte šňůru z elektrické sítě. Zkontrolujte, zdali se řezný kotouč volně otáčí. Jestliže se

řezný kotouč volně otáčí, přístroj znovu uveďte do

chodu.

Aby se zabránilo poškození motoru, pravidelně z

něj odstraňujte piliny a prach a tím dosáhnete jeho

správné chlazení.

3. V případě, že se motor během řezání náhle zastaví,

přístroj okamžitě vypněte. Uvolněte řezný kotouč z

materiálu a pak pokračujte v řezání.

4. Nepoužívejte dlouhé elektrické kabely s příliš malým

průřezem. Ztráta napětí by mohla způsobit problémy

motoru.

PŘÍPRAVA PŘÍSTROJE K PRÁCI

Odřezávací přístroj položte na hladkou a pevnou plochu.

Odřezávací přístroj může být také upevněn na pracovní

stůl. Ubezpečte se, že pracovní plocha je čistá a upravená.

ODEMKNUTÍ PŘÍSTROJE

Levou rukou stlačte hlavici pily směrem dolů a uvolněte

tlačítko pojistky (a, obrázek 2). Pojistka je umístěna

vzadu na pravé straně hlavice pily. Jakmile byla pojistka

vytažena, nechejte hlavici pily zaujmout původní polohu.

Hlavice pily může být poté posunuta dolů stlačením

tlačítka pojistky (2, obrázek 1).

Odřezávací pila byla výrobcem kalibrována přesně na

úhel 45° (doprava a doleva). Po prvním řezání zkontrolujte, zdali řezný kotouč svírá přesně pravý úhel se spodní

částí přístroje a s pracovním stolem. Případnou korekci,

je-li jí zapotřebí, provedeme otočením vodicích šroubů

pro přesné nastavení, které jsou umístěny na obou

stranách nastavovacího dílu. Otočná rukojeť je tímto

natočena diagonálně pro dosažení řezu pily pod úhlem

45°.

PRÁCE S PŘÍSTROJEM

- Dříve než začnete řezat, přesvědčete se, že ochranný

kryt řezného kotouče je ve správné poloze.

- Odřezávací pila se zapne pomocí knoflíku, který je

umístěn na vnitřní straně rukojeti (1).

- Řezný kotouč musí nejprve dosáhnout maximálních

otáček a pak teprve můžete začít řezat.

- Posuňte odemykací knoflík (2) do strany a pomocí

rukojeti tlačte řeznou hlavici pomalu a plynule směrem dolů.

- Na řezný kotouč tlačte podle okolností a rozměrů

řezaného předmětu.

- Materiál musí být během řezání pevně přitisknut k

pracovnímu stolu.

- Pro řezání dlouhých předmětů je třeba použít podpěr pro zajištění materiálu.

Toledo 23

MALFUNCTIONS

In the case of the cutting-off machine not working properly, we give a number of possible causes and the

appropriate solutions below.

1. The electric motor becomes excessively hot.

The cool air slots of the motor are blocked with dirt.

- Clean the cool air slots.

The motor is faulty.

- Present the machine to your Toledo dealer for checking and/or repair.

2. The machine does not work when switched

on.

The saw blade is jammed.

- Check the machine for objects which are causing it to

jam and remove them.

Interruption in the mains connection.

- Check the mains connection for breakage.

- Present the machine to your Toledo dealer for chec-

king and/or repair.

3. The motor stops during sawing.

The saw blade is jammed in the workpiece.

- Release the switch, remove the plug from the power

point and loosen the saw.

Interruption in the mains connection

- Check the mains connection for breakage.

- Present the machine to your Toledo dealer for chec-

king and/or repair.

4. The dust is not being vacuumed up.

This is possibly due to a blocked dust extraction.

- Clean the dust extractor opening.

MAINTENANCE

For maintenance work and cleaning, always discon-

nect the machine from the mains voltage. Never

use water or highly inflammable liquids for cleaning the

machine. Clean the machine using a brush.

PERIODICAL MAINTENANCE TO THE MACHINE

PREVENTS UNNECESSARY PROBLEMS!

1. Keep the ventilation slots of the machine clean in

order to prevent overheating of the motor.

2. In order to prevent damage to the motor and to

make an optimal use of an ideal cooling of the motor,

chips and dust must be removed regularly from it.

3. Do not use solvents to clean the plastic parts. Liquids

such as brake fluid, petrol, products on a paraffin

base, pickling oils etc. contain chemical substances

which can damage, corrode or destroy the plastic.

The Toledo machines have been designed to operate

over a long period of time with a minimum of maintenance. Continuous satisfactory operation depends upon

proper machine care and regular cleaning.

Cleaning

Keep the ventilation slots of the machine clean to prevent overheating of the engine.

Regularly clean the machine housing with a soft cloth,

preferably after each use. Keep the ventilation slots free

from dust and dirt.

If the dirt does not come off use a soft cloth moistened

with soapy water. Never use solvents such as petrol,

alcohol, ammonia water, etc. These solvents may

damage the plastic parts.

Lubrication

The machine requires no additional lubrication.

Faults

Should a fault occur, e.g. after wear of a part, please contact your local Toledo dealer.

In the back of this manual you find an exploded view

showing the parts that can be ordered.

ENVIRONMENT

In order to prevent the machine from damage during

transport, it is delivered in a sturdy packaging. Most of

the packaging materials can be recycled. Take these

materials to the appropriate recycling locations.

Take your unwanted machines to your local Toledodealer. Here they will be disposed of in an environmentally safe way.

GUARANTEE

The guarantee conditions can be found on the separately

enclosed guarantee card.

6 Toledo

Page 7

We declare under our sole responsibility that this

product is in conformity with the following

standards or standardized documents

EN61029-1, prEN61029-2-9, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3

in accordance with the regulations:

98/37/EEC

73/23/EEC

89/336EEC

from 10-12-2002

GENEMUIDEN NL

W. Kamphof

Quality department

Trennmaschine

TECHNISCHE DATEN

BESCHREIBUNG (Seite 2)

AUSPACKEN

- Trennmaschine

- Sägeblatt Ø 205 mm.

- Schutzhaube

Überprüfen Sie die Maschine, lose Teile und Zubehör auf

Transportschäden.

SICHERHEITSVORSCHRIFTEN

In dieser Betriebsanleitung erscheinen folgende Piktogramme:

Verweist auf Verletzungs gefahr, Gefahr für Leben

und mögliche Beschädigung der Maschine, falls die

Anweisungen in dieser Betriebsanleitung nicht befolgt werden.

Deutet das Vorhandensein elektrischer Spannung

an.

Lesen Sie diese Betriebsanleitung aufmerksam, bevor Sie

die Maschine in Betrieb nehmen. Machen Sie sich vertraut mit der Funktionsweise und der Bedienung. Warten Sie die Maschine entsprechend den Anweisungen,

damit sie immer einwandfrei funktioniert. Die Betriebsanleitung und die dazugehörende Dokumentation müssen in der Nähe der Maschine aufbewahrt werden.

1. Griff mit Schalter

2. Entriegelungsknopf

3. Motorgehäuse +

Abdeckhaube Kohlebürsten

4. Sägeblattbefestigung

5. Versetzbare

Schutzeinrichtung

6. Tischregulierungsschrauben

7. Drehtisch

8. Gradanzeige

9. Befestigungslöcher

10. Regulierungsschraube

für die Schräglage

11. Schutzhaube

Spannung | 230 V~

Frequenz | 50 Hz

Aufgenommene Leistung | 800 W

Drehzahl unbelastet/min | 4500/min

Abbmessung Sägeblatt | 205x18 mm

Max. Schnittkapazität 90° | 120x50 mm

Max. Schnittkapazität 45° | 70x55 mm

Gewicht | 7.0 kg

Lpa (Schalldruckpegel) | 88.9dB(A)

Lwa ( Schallleistungspegel) | 101.9 dB(A)

Vibrationswert | 2.5 m/s

2

Deutsch

D

CE

ı

DECLARATION OF CONFORMITY

(UK)

Toledo 7

Elektrická bezpečnost

Při používání elektrických přístrojů je vždy třeba

dodržovat bezpečnostní předpisy platné ve

vašem státě. Sníží se tím nebezpečí požáru,

zasažení elektrickým proudem a zranní osob.

Pročtěte zde uvedené bezpečnostní pokyny a

seznamte se i s bezpečnostními pokyny

přiloženými k nástroji. Uložte tyto pokyny na

bezpečném místě.

Vždy se přesvědčete zdali výška elektrického

napětí souhlasí s hodnotou uvedenou na nálepce

přístroje.

Přístroj má dvojnásobnou izolaci v souladu s

normou EN 50144; nepotřebuje tedy uzemňovací drát.

V případě, že vyměnujete elektrickou šňůru nebo

zástrčku.

V případě, že jste vyměnili elektrickou šňůru nebo

zástrčku, nahrazené okamžitě odstraňte. Mohli byste je

omylem znovu zapojit do elektrické sítě.

V případě použití prodlužovacích kabelů

Používejte pouze schválené prodlužovací kabely, které

vyhovují použitému výkonu přístroje. Vodiče kabelů

musí mít v průřezu aspoň 1.5 mm

2

. V případě, že je kabel

ještě smotán, tak jej úplně vytáhněte.

SPECIFICÁ BEZPEČNOSTNÍ

POKYNY

PŘED KAŽDÝM POUŽITÍM PŘÍSTROJE

1. Zkontrolujte přístroj. V případě, že některá část

odřezávací pily chybí, je zdeformovaná nebo

nefunkční, nebo v případě elektrické poruchy,

přístroj vypněte a vytáhněte z elektrické sítě.

Předtím než přístroj znovu použijete, všechny jeho

chybějící, poškozené nebo zdeformované části

vyměňte.

2. Přesvědčete se, že používáte správnou ochranu

rukou, tváře, zraku a sluchu, která zabraňuje jejich

možnému zranění.

- Při použití ochranných brýlí bez označení CE může

dojít v případě rozbití skla k vážnému poškození

zraku.

- Abyste zabránili zadření řezného kotouče v materiálu a jeho následnému odmrštění, důsledně

dodržujte následující pokyny:

- Pro každý typ práce používejte pouze vhodné

řezné kotouče.

Odřezávací pilu používejte pouze k řezání dřeva

či příbuzných materiálů nebo k řezání lehkých

kovů, jako je například hliník. Jiné materiály

mohou způsobit zadření kotouče, odmrštění

výrobku nebo zapříčinit jiné nebezpečné situace.

- Šipka umístěná na řezném kotouči, která naz-

načuje směr jeho rotace, musí mít stejnou orientaci se šipkou naznačenou na přístroji. Ozubení

řezného kotouče musí směřovat dolů na přední

část přístroje.

- Přesvědčete se, že řezný kotouč je ostrý,

nepoškozený a že je správně vyrovnaný. Po vypnutí přístroje posuňte hlavici pily směrem dolů.

Otáčejte řezným kotoučem a přesvědčete se, že

se volně otáčí. Nastavte přístroj pod úhlem 45° a

test zopakujte. V případě, že se ještě někde řezný

kotouč dotýká přístroje, musíte jej nastavit znovu

do správné polohy.

- Řezný kotouč a upínací plochy svěrek musí zůstat

čisté.

- Řezný kotouč se připevňuje k přístroji pomocí

přitáhnutí příruby směrem ke kotouči.

- Šroub příruby se utahuje otevřeným klíčem o

velikosti 13 mm.

- Přesvědčte se, že jsou všechny dotýkající se části a

propojení přístroje v pořádku a že každá z nich

správně doléhá a není příliš vzdálena od přístroje.

- Nikdy neřežte materiál tak, že ho držíte

pouze ve vašich rukách.

- Materiál vždy zajistěte tak, aby se během řezání

nekymácel a nemohl se otáčet. Pod materiálem se

nesmí shromažďovat žádné nečistoty.

- Přesvědčete se, že materiál po jeho přeříznutí

zůstane zajištěn a jednotlivé odřezané části, které

ztratily podporu v nějakém místě, se nebudou

volně pohybovat.

- Při řezání materiálu, který není podepřen po celé

své ploše, používejte podložky nebo další

pomůcky.

- Používejte pouze řezné kotouče doporučované výrobcem a takové, které odpovídají normě EN-847-1.

- Během práce s přístrojem používejte systém na

odstraňování prachu.

- Zkontrolujte, zda je možné odřezané části odebrat

od řezného kotouče na stranu tak, aby při jejich

odebírání nedošlo ke kontaktu. Jinak by mohlo dojít k

jejich zachycení a odmrštění.

- Nikdy neřežte více kusů materiálu najednou.

- Buďte zvlášťe opatrní při řezání velkých, velmi

malých částí nebo kusů se zvláštním tvarem.

- Buďte opatrní během řezání s horizontálním i vertikálním pokosem.

- Při řezání velkých kusů, které by se mohly

nezajištěné převrhnout, používejte další

podložky a pomůcky (stoly, podstavce a jiné).

- Přístroj nepoužívejte k řezání kusů materiálu,

které jsou tak malé, že je nelze dostatečně upevnit a zajistit.

-V případě, že je vyřezáván nějaký profil nebo tvar,

musí být zajištěno, že materiál nemůže sklouznout a že nedojde k zadření řezného kotouče.

Aby se zabránilo jeho převrhnutí nebo sklouznutí, materiál s profilem musí horizontálně přiléhat nebo musí být uchycen pomocí dalšího

zařízení.

- Válcové materiály jako jsou například trubky musí

být zajištěny proti prokluzu. Jinak by mohlo dojít k

jejich nekontrolovanému protáčení nebo i

zadření řezného kotouče. Materiál vždy zajistěte

a upevněte k stolku přístroje a pracovnímu stolu

pomocí nějakého dalšího zařízení.

-V řezané části materiálu nesmí být žádný spojovací

materiál nebo jiné předměty.

- Aby se zabránilo možnému poškození sluchu,

používejte ochranu uší.

22 Toledo

Page 8

Nous declarons sous notre propre responsabilité

que ce produit est en conformité avec les normes

ou documents normalisés suivants

EN61029-1, prEN61029-2-9, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3

conforme aux réglementations:

98/37/CEE

73/23/CEE

89/336/CEE

dès 10-12-2002

GENEMUIDEN NL

W. Kamphof

Quality department

Kotoučová odřezávací pila

TECHNICKÉ ÚDAJE

INFORMACE O VÝROBKU

Obr. A. (Strana 2)

1. Rukojeť s vypínačem

2. Tlačítko pojistky

3. Kryt motoru + kryt uhlíkových kartáčů

4. Připojení řezného kotouče

5. Pohyblivý bezpečnostní chránič

6. Šrouby pro nastavení stolu

7. Otočný stůl

8. Úhlová stupnice

9. Otvory pro připevnění

10. Nastavovací šroub úkosu

11. Ochranný kryt

OBSAH BALENÍ

- Kotoučová odřezávací pila

- Řezný kotouč Į 160 mm

- Uživatelská příručka

- Záruční list

- Bezpečnostní pokyny

Nejdříve zkontrolujte zdali není balení přístroje

poškozeno a nic v něm nechybí.

BEZPEČNOSTNĺ POKYNY

V příručce budou používány následující symboly:

Označuje nebezpečí (smrtelného) zranéní nebo

poškození nástroje, k nimž může dojít, pokud se

nebude dbát pokynů obsaženżých v této příručce

Označuje nebezpečí zasažení elektrickým proudem

Než začnete nástroj používat, pečlivě pročtěte tuto př

íručku. Seznamte se s tím, jak nástroj funguje a jaká je jeho

obsluha. K tomu, aby nástroj náležitě fungoval, je třeba

provádět jeho údržbu v souladu s pokyny obsaženými v

této příručce. Příručku i další dokumentaci mějte

uloženy v blízkosti nástroje.

Napětí | 230 V~

Frekvence napětí | 50 Hz

Příkon | 800 W

Počet otáček

při nezatíženém přístroji | 4500/min.

Rozměry řezného kotouče | 205x18 mm

Tloušťka dřeva 90° | 120x50 mm

Tloušťka dřeva 45° | 70x55 mm

Hmotnost přístroje | 7.0 kg

Lpa (úroveň hlasitosti) | 88.9 dB(A)

Lwa (emise hluku při zatížení) | 101.9 dB(A)

Vibrační hodnota | 2,5 m/s

2

C

esky

CZ

ˇ

CE

ı

DÉCLARATION DE CONFORMITÉ

(F)

Toledo 21

Elektrische Sicherheit

Beachten beim Benutzen von Elektromaschinen

immer die örtlichen Sicherheitsvorschriften

bezüglich Feuerrisiko, Elektroschock und Verletzung. Lesen Sie außer den folgenden Hinweisen ebenfalls die Sicherheitsvorschriften im einschlägigen Sonderteil.

Die Hinweise müssen sicher aufbewahrt werden!

Überprüfen Sie immer, ob Ihre Netzspannung der

des Typenschilds entspricht.

Die Maschine ist nach EN 50144 doppelisoliert; daher ist Erdung nicht erforderlich.

Austauschen von Kabeln oder Steckern

Entsorgen Sie alte Kabel oder Stecker, unmittelbar nachdem Sie durch neue ersetzt sind. Das Anschließen eines

Steckers eines losen Kabels an eine Steckdose ist gefährlich.

Verwendung von Verlängerungskabeln

Benutzen Sie nur ein genehmigtes Verlängerungskabel,

das der Maschinenleistung entspricht. Die Ader müssen

einen Mindestquerschnitt von 1,5 mm2haben. Befindet

das Kabel sich auf einem Haspel. muß es völlig abgerollt

werden.

SPEZIELLE SICHERHEITSVORSCHRIFTEN

VOR JEDER INBETRIEBNAHME

- Kontrollieren Sie die Trennmaschine. Sollte irgendein Teil der Trennmaschine fehlen, verbogen oder

auf eine andere Art unbrauchbar sein, oder sollten

elektrische Fehler auftreten, schalten Sie die

Maschine ab und ziehen Sie den Stecker aus der

Steckdose. Ersetzen Sie alle fehlenden, beschädigten

oder fehlerhaften Teile, bevor Sie die Maschine wieder in Betrieb nehmen.

- Sorgen sie dafür, daß Ihre Hände, Augen, Ohren und

Ihr Gesicht ausreichend geschützt sind.

- Die Verwendung von Sicherheitsbrillen ohne CEPrüfzeichen, kann durch Glasbruch zu schweren Verletzungen führen.

- Um zu verhindern, daß das Sägeblatt in der Sägeschneide eingeklemmt wird und Werkstücke herausgeschleudert werden, müssen folgende Anweisungen

befolgt werden:

- Wählen Sie ein für die Arbeit geeignetes Säge-

blatt. Sägen Sie mit der Trennmaschine nur Holz

und davon abgeleitete Produkte oder Leichtmetall wie Aluminium. Andere Materialien könnten

abspringen, sich in dem Sägeblatt verhaken oder

ander gefährliche Situationen verursachen.

- Der Pfeil auf dem Sägeblatt, der die Drehrichtung

angibt, muß in die gleiche Richtung weisen wie der

auf der Maschine angebrachte Pfeil. Die Sägeblattzähne müssen an der Vorderseite der Säge nach

unten weisen.

- Kontrollieren Sie, ob das Sägeblatt scharf, unbeschädigt und gut ausgerichtet ist. Drücken Sie,

nachdem Sie den Stecker aus der Steckdose gezogen haben, den Sägekopf nach unten.

- Drehen Sie mit der Hand das Sägeblatt und prüfen

Sie ob dieses frei läuft. Bringen Sie die Maschine in

eine 45° Position und wiederholen Sie den Test.

Sollte das Sägeblatt an irgendeiner Stelle anlaufen,

muß dieses erneut ausgerichtet werden.

- Halten Sie das Sägeblatt und die Spannflächen der

Klemmen sauber.

- Die Sägeblattflansch muß immer mit der angedrehten Aussparung zum Sägeblatt hin montiert

werden.

- Die Flanschschraube muß mit einem 13-mm

Steckschlüssel angezogen werden.

- Kontrollieren Sie, ob die Spannvorrichtungen

und Verriegelungen fest sind und kein einziges

Teil einen zu großen Spielraum hat.

- Sägen Sie niemals aus der freien Hand.

- Drücken Sie das Werkstück immer fest gegen

den Anschlag, damit dieses während des Sägens

nicht kippt oder sich verdreht. Unter dem

Werkstück dürfen sich keine Verunreinigungen

ansammeln.

- Sorgen sie dafür, daß das Werkstück sich nach

dem Durchsägen nicht bewegen kann, z.B. weil es

nicht auf der gesamten Oberfläche tragend ist.

- Verwenden Sie beim Sägen von Werkstücken,

die nicht auf der gesamten Oberfläche tragend

sind, Füllungen oder eine andere Maschine.

- Kontrollieren Sie ob abgesägte Stücke seitlich vom

Sägeblatt entfernt werden können, da diese sonst

vom Sägeblatt ergriffen und weggeschleudert werden könnten.

- Sägen Sie niemals mehrere Werkstücke in einem

Arbeitsgang.

- Seien Sie besonders vorsichtig beim Sägen von

großen, sehr kleinen oder unhandlichen Werkstücken.

- Verwenden Sie zusätzliche Stützen (Tische,

Blöcke u.ä.) für lange Werkstücke, die, wenn sie

nicht unterstützt werden vom Maschinentisch

fallen.

- Sägen Sie mit der Maschine keine Werkstücke,

die so klein sind, daß sie nicht mehr sicher festgehalten werden können.

- Sorgen Sie beim Sägen von Profilen dafür, daß das

Werkstück sich nicht verschieben kann und das

Sägeblatt nicht eingeklemmt werden kann. Ein

Werkstück mit Profil muß flach liegen oder von

einem Hilfsstück gehalten werden, wodurch ein

Kippen oder Verschieben während des Sägens

vermieden wird.

- Runde Werkstücke, wie beispielsweise Rohre

müssen festgehalten werden, da dies sich sonst

drehen könnten und die Gefahr besteht, daß das

Sägeblatt eingeklemmt wird. Halten Sie mit einem

geeigneten Hilfsstück das Werkstück immer

gegen den Anschlag und auf dem Tisch.

- Nägel oder andere Fremdkörper dürfen nicht in

dem zu bearbeitenden Werkstück vorhanden

sein.

- Um Gehörbeschädigungen zu vermeiden, müs-

sen Sie einen Ohrenschutz tragen.

8 Toledo

Page 9

- Um Unfälle durch versehentliches Einschalten

der Maschine zu vermeiden, muß bevor Einstellungen am Anschlag oder dem Sägekopf vorgenommen werden der Netzstecker aus der Steckdose gezogen werden. Dies gilt auch für das Auswechseln von Sägeblättern, Zubehör oder bei

der Wartung der Maschine.

- Um einen Elektroschock zu vermeiden, dürfen

beim Anschließen des Steckers an die Steckdose

die Metallstifte unter keinen Umständen berührt

werden.

- Ziehen Sie den Stecker nicht an der Schnur aus

der Steckdose. Schützen sie die Schnur gegen Öl,

Wärme und scharfkantige Gegenstände.

- Bringen Sie niemals Reinigungsmittel oder Gleitmittel auf einem sich noch drehenden Sägeblatt

an.

- Um einen Brand zu vermeiden, darf die Maschine

niemals in der Nähe von leichtentzündlichen Flüssigkeiten, Dämpfen oder Gasen verwendet werden.

- Vermeiden Sie Verletzungen die durch den

Gebrauch von nicht originalem Zubehör entstehen können. Verwenden Sie ausschließlich die

empfohlenen Sägeblätter.

DIE INBETRIEBNAHME DER MASCHINE

Lassen Sie sich durch die Routine, zu der Sie bei

vielfältigem Gebrauch der Maschine gelangen,

nicht zu fehlerhaften Arbeiten verleiten. Denken Sie daran,

daß die kleinste Unbedachtsamkeit in Bruchteilen einer

Sekunde zu schweren Verletzungen führen kann.

1. Lassen Sie die Maschine eine Zeit lang laufen, bevor

Sie den ersten Sägeschnitt durchführen. Sollten Sie

dabei ungewöhnliche Geräusche oder starke Schwingungen wahrnehmen, schalten Sie die Maschine

aus und ziehen Sie den Stecker aus der Steckdose, um

anschließend die mögliche Ursache zu untersuchen.

Schalten Sie die Maschine erst wieder ein, nachdem

die mögliche Ursache festgestellt und das Problem

gelöst wurde.

2. Achten Sie darauf, daß das abgesägte Werkstück

nicht eingeklemmt wird und halten Sie dieses nicht

fest. Klemmen und verriegeln Sie dieses nicht gegen

den Anschlag. Das Werkstück muß sich frei entlang

der Seite des Sägeblatts bewegen können. Ist dies

nicht der Fall, besteht die Gefahr, daß das abgesägte

Werkstück vom Sägeblatt gegriffen und weggeschleudert wird.

3. Vermeiden Sie eine ungünstige Plazierung Ihrer

Hände, bei der diese durch eine plötzliche Verschiebung in das Sägeblatt geraten könnten.

4. Lassen Sie das Sägeblatt erst im höchsten Drehzahl-

bereich laufen, bevor Sie mit dem Sägen beginnen.

5. Drücken Sie den Sägekopf so nach unten, daß der

Motor nicht überbelastet wird und das Sägeblatt

nicht festläuft.

6. Bei der Entfernung von Klemm-Material, muß das

Sägeblatt erst still stehen. Schalten Sie die Säge aus

und ziehen Sie den Stecker aus der Steckdose.

7. Halten Sie den Sägekopf nach Beendigung des Sägeprozesses nach unten, lassen Sie den Schalter los und

warten Sie bis alle sich bewegenden Teile zum Stillstand gekommen sind, bevor Sie Ihre Hände von der

Maschine entfernen.

8. Verwenden Sie nur vom Hersteller empfohlene

Sägeblätter.

9. Schließen Sie die Maschine während des Betriebs an

eine Staubsammelanlage an.

10. Überzeugen Sie sich vor Arbeitsbeginn davon, daß

die Sägeblattschutzhaube ordnungsgemäß angebracht ist.

MOTOR

Um Beschädigungen am Motor zu vermeiden,

muß dieser regelmäßig von Sägespäne und Staub

befreit werden, um eine optimale Kühlung garantieren zu

können.

1. Schließen Sie die Maschine an einen 230 V. Strom-

kreis an.

2. Sollte der Motor nicht starten, muß der Schalter

sofort losgelassen werden. Ziehen Sie den Stecker

aus der Steckdose. Kontrollieren Sie ob das Sägeblatt

sich frei bewegen kann. Sollte das Sägeblatt sich frei

bewegen können, starten Sie die Maschine erneut.

3. Sollte der Motor während des Sägens plötzlich stil-

lstehen, muß der Schalter sofort losgelassen werden.

Lösen Sie das Sägeblatt vom Werkstück, anschließend kann das Sägen fortgesetzt werden.

4. Bei der Verwendung von langen Kabeln mit einem

kleinen Durchmesser entsteht ein Spannungsverlust,

der zu Motorproblemen führen kann.

Toledo 9

- Faire éventuellement un sciage d'essai libre en soulevant et rabaissant la tête de scie.

ASPIRATION DE POUSSIERE

La machine est pourvue d'un raccord pour l'aspiration de

la poussière (b, schéma 2). Pour cela on peut utiliser un

aspirateur à connexion habituelle.

PANNES

Dans le cas où la machine à tronçonner ne fonctionnerait

pas convenablement, nous vous présentons ci-dessous

un nombre de causes possibles et les solutions correspondantes.

1. L'électromoteur surchauffe.

Les fentes d'air de refroidissement du moteur sont

bouchées par des saletés.

- Nettoyer les fentes d'air de refroidissement

Le moteur est défectueux.

- Présenter la machine à votre concessionnaire Toledo

pour contrôle et/ou réparation.

2. La machine est mise en marche, mais ne fonctionne pas.

La lame de scie est coincée.

- Vérifier s'il y a des objets dans la machine pouvant

coincer et les retirer.

Interruption du circuit électrique.

- Vérifier s'il n'y a pas de rupture dans la connexion sur

le circuit.

- Présenter la machine à votre concessionnaire

Toledo pour contrôle et/ou réparation.

3. Le moteur s'arrête pendant le sciage.

La lame de scie est coincée dans la pièce à travailler.

- Lâcher l'interrupteur, retirer la fiche de la prise

électrique et dégager la scie.

Interruption dans le circuit électrique.

- Vérifier s'il n'y a pas de rupture dans la connexion sur

le circuit.

- Présenter la machine à votre concessionnaire Toledo

pour contrôle et/ou réparation.

4. La poussière n'est pas aspirée.

Cela peut être imputée à une aspiration bouchée de

la poussière.

- Nettoyer l'ouverture de l'aspiration de poussière.

ENTRETIEN

Retirer toujours le courant de la machine lors de

l'entretien et des travaux de nettoyage. Ne jamais

utiliser de liquides inflammables pour le nettoyage de la

machine. Nettoyer la machine à l'aide d'une brosse.

L'ENTRETIEN PERIODIQUE DE LA MACHINE

EVITE DES PROBLEMES INUTILES !

1. Garder propres les fentes de ventilation de la

machine pour éviter le surchauffement du moteur.

2. Pour éviter des endommagements du moteur et faire

un usage optimal d'un refroidissement idéal du

moteur, celui-ci devra être libéré régulièrement des

copeaux et poussières qui l'encombrent.

3. Ne pas utiliser de solvants pour nettoyer les parties

en plastique. Les liquides tels que les liquides de

freins, l'essence, les produits à base de pétrole, les

huiles décapantes etc. contiennent des produits chimiques pouvant détériorer, entamer, ou détruire le

plastique.

Les machines de Toledo ont été conçues pour fonctionner longtemps sans problème avec un minimum d’entretien. En nettoyant régulièrement et correctement la

machine, vous contribuerez à une longue durée de vie de

votre machine.

Nettoyage

Nettoyez régulièrement le carter au moyen d’un chiffon

doux, de préférence à l’issue de chaque utilisation. Veillez à ce que les fentes d’aération soient indemnes de

poussière et de saletés.

En présence de saleté tenace, employez un chiffon doux

humecté d’eau savonneuse. Proscrivez l’emploi de solvants comme l’essence, l’alcool, l’ammoniaque etc. car

ces substances attaquent les pièces en plastique.

Graissage

Cette machine ne nécessite pas de graissage supplémentaire.

Pannes

En cas de panne survenue par exemple à la suite de l’usure d’une pièce, contactez votre distributeur Toledo

local.

Au dos de ce mode d’emploi, vous trouverez un dessin

des pièces avec les pièces dont vous pouvez renouveler

la commande.

ENVIRONNEMENT

Pour éviter les dommages liés au transport, la machine

est livré dans un emballage robuste. L’emballage est

autant que possible constitué de matériau recyclable.

Veuillez par conséquent destiner cet emballage au recyclage.

Si vous allez changer de machines, apportez les machines

usagées à votre distributeur Toledo local qui se chargera

de les traiter de la manière la plus écologique possible.

GARANTIE

Pour les conditions de garantie, lisez le certificat de

garantie joint à part.

20 Toledo

Page 10

6. Avant de dégager le matériel fixant la pièce à travailler, attendre d'abord l'immobilité de la lame scie.

Mettre la scie en arrêt et retirer la fiche de la prise

électrique.

7. Tenir la tête de scie dirigée vers le bas, après la fin du

processus de sciage, lâcher le commutateur et

attendre que touts les parties mouvantes soient au

repos, avant de dégager les mains de la machine.

8. N’utilisez pas de lames de scie endommagées ou

déformées.

9. Utilisez uniquement les lames de scie recommandées

par le fabricant.

10. Avant de commencer à scier, contrôlez que le capot

protecteur de la lame de scie se trouve dans la position correcte.

MOTEUR

Pour éviter des endommagements du moteur,

celui-ci doit être régulièrement libéré de copeaux et

de poussières et cela afin d'assurer un refroidissement idéal.

1. Connecter la machine sur un circuit de courant électrique de 230V~.

2. Lorsque le moteur ne démarre pas, lâcher immédiatement l'interrupteur. Retirer la fiche de la prise

électrique. Contrôler la marche libre de la lame de

scie. Lorsque la lame tourne librement, redémarrer

le moteur.

3. Lorsque le moteur s'arrête subitement pendant le

sciage, lâcher immédiatement l'interrupteur. Libérer

la lame de scie de la pièce à travailler après quoi on

pourra continuer le sciage.

4. Lors de l'utilisation de câbles longs et de diamètres

trop petits, il se produira une perte de tension, ce qui

peut provoquer des problèmes du moteur.

PREPARATIF

Placer la machine à tronçonner sur une surface lisse et

stable. La machine à tronçonner peut aussi être fixée sur

un établi. Veiller à ce que le lieu de travail soit ordonné et

propre.

DEVERROUILLAGE DE LA MACHINE

De la main gauche, appuyer vers le bas la tête de scie et

tirer vers l'extérieur le bouton de verrouillage (a, schéma

2). Le bouton de verrouillage se trouve à droite, à l'ar-

rière de la tête de scie. Dès que le bouton de verrouillage

est tiré vers l'extérieur faire remonter la tête de scie.

Ensuite la tête de scie pourra être placée vers le bas en

appuyant sur le bouton de déverrouillage (2, schéma 1).

La machine à tronçonner a été réglée à l'usine sur exactement 45° (à droite et à gauche). Vérifier, au premier travail de sciage, si la lame de scie se trouve bien en angle

droit vis à vis du dessous de la machine et de la table. Pour

effectuer éventuellement une correction, on devra tourner les vis de réglage du guidage qui se trouvent de chaque côté de la pièce d'adaptation. De cette manière, le

levier de virement est réglé de façon oblique afin d'obtenir un trait de sciage de 45°.

UTILISATION DE LA MACHINE

- La machine à tronçonner est mise en service par le

bouton interrupteur à l'intérieur de la poignée.

- Avant de commencer à scier la lame de scie doit tourner à plein régime.

- Pousser lentement et régulièrement la tête de scie

vers le bas par la poignée.

- Exercer une pression sur la lame de scie, conformément à la qualité et aux mesures de la pièce à travailler.

- Pendant le sciage, la pièce à travailler doit être tenue

fixée et pressée sur la table.

- Pour scier des pièces plus longues, il faut utiliser des

appuis pour soutenir la pièce à scier.

- Lorsque le sciage est terminé, la tête de scie doit être

replacée dans la position de départ.

- La lame de scie doit être régulièrement affûtée et

remplacée si nécessaire.

Avant chaque service contrôler l'état de la lame de

scie.

SCIAGE OBLIQUE

- Pour le sciage oblique sur 45°, la vis femelle sur le dos

de la machine devra être dévissée à l'aide d'une clé à

tube.

- Régler la tête de scie de la gauche jusqu'à la position

désirée ou jusqu'à 45°.

- Revisser la vis femelle avant de commencer à scier.

LIGNE DE SCIAGE HORIZONTALE

- La tête peut être tournée jusqu'à 45°, aussi bien vers

la gauche que vers la droite.

- Des angles intermédiaires sont facilement réglables,

et l'angle désiré peut être lu sur l'échelle graduée.

- Pour fixer la tête de scie dans un angle désiré ou pour

le défaire, procéder à un nouveau réglage par les deux

vis de réglage du guidage.

- Le buttoir sur 45° est excentrique pour un réglage

juste.

LIGNE DE SCIE COMBINEE

Une combinaison d'une ligne de scie oblique et d'une

ligne de scie réglable obliquement.

CHANGEMENT DE LA LAME DE SCIE

Laisser d'abord venir au repos complet la lame de

scie et retirer la fiche de la prise électrique.

- Retirer le capot de protection (Schéma 1.11). Ensuite

coincer la bride extérieure à l'aide de la clé correspondante et tourner dans le sens des aiguilles d'une

montre avec une clé à tube.

- Retirer la lame de scie et la remplacer, en veillant à

placer les dents de scie dans la direction de la flèche.

- Avant de monter la lame de scie, nettoyer d'abord les

brides.

- Replacer la bride extérieure dans la position et revisser.

- Avant de reconnecter la machine sur le courant

électrique, replacer la protection de la lame de scie

dans la position de départ.

Toledo 19

VORBEREITUNG

Stellen Sie die Trennmaschine auf einen glatten, stabilen

Untergrund. Die Trennmaschine kann auch auf einer

Werkbank befestigt werden. Sorgen Sie für einen aufgeräumten und sauberen Arbeitsplatz.

ENTRIEGELN DER MASCHINE

Drücken Sie den Sägekopf mit der linken Hand nach

unten und ziehen Sie den Verriegelungsknopf (a, Abb. 2)

heraus. Der Entriegelungsknopf befindet sich auf der

rechten Rückseite des Sägekopfes. Lassen Sie, sobald der

Verriegelungsknopf herausgezogen ist, den Sägekopf

nach oben kommen. Anschließend kann der Sägekopf

nach unten bewegt werden, indem der Entriegelungsknopf (2, Abb. 1) eingedrückt wird.

Die Trennmaschine wurde fabriksmäßig auf 45° (rechts

und links) eingestellt. Prüfen Sie bei der ersten Sägearbeit

ob das Sägeblatt rechtwinklig zu der Unterseite der

Maschine und des Tisches ausgerichtet ist. Um eventuell

eine Korrektur durchzuführen, müssen die Gleitstellschrauben, die sich auf beiden Seiten des Anpassungsstück befinden, gedreht werden. Um einen Sägeschnitt

von 45° zu erhalten, wird auf diese Art und Weise der

Schwenkgriff schräg eingestellt.

VERWENDUNG DER MASCHINE

Vor jeder Bearbeitung, muß der Zustand des Sägeblatts kontrolliert werden.

- Die Trennmaschine wird über einen Schalterknopf

auf der Innenseite der Handgriffes in Betrieb gesetzt.

- Bevor Sie mit dem Sägen beginnen, muß das Sägeblatt

die höchste Drehzahl erreichen.

- Drücken Sie den Sägekopf mit dem Handgriff langsam

und gleichmäßig nach unten.

- Üben Sie einen Druck auf das Sägeblatt aus, der der

Bearbeitungsart und den Abmessungen des

Werkstücks entspricht.

- Während des Sägens muß das Werkstück fest auf

den Tisch gedrückt werden.

- Um längere Werkstücke sägen zu können, müssen

Sie Stützen zur Unterstützung des zu sägenden

Werkstücks verwenden.

- Nach Fertigstellung des Werkstücks muß der Kopf

wieder in die Ausgangsposition gebracht werden.

- Das Sägeblatt muß regelmäßig geschliffen und falls

notwendig auch ausgetauscht werden.

DIAGONALSÄGEN

- Für das Diagonalsägen in einem Winkel von 45°, muß

die Mutter auf der Rückseite der Maschine mit einem

Steckschlüssel gelöst werden.

- Bringen Sie den Sägekopf von der linken Seite aus in

die gewünschte oder 45°-Einstellung.

- Drehen Sie die Mutterschraube wieder fest, bevor

Sie mit dem Sägen beginnen.

HORIZONTALER SÄGESCHNITT

- Der Kopf kann bis zu einem Winkel von 45° nach

links und nach rechts gedreht werden.

- Dazwischen liegende Winkeleinstellungen können

problemlos eingestellt werden, wobei die

gewünschte Einstellung auf der Gradanzeige abgelesen werden kann.

- Um den Maschinenkopf in dem gewünschten Winkel

fest einzustellen oder zu lösen, werden die beiden

Gleitstellschrauben verstellt.

- Der Anschlag auf 45° ist exzentrisch für eine genaue

Einstellung.

KOMBINIERTER SÄGESCHNITT

Eine Kombination des diagonalen Sägeschnitts und des

Vertikalen diagonalen Sägeschnitts.

AUSWECHSELN DES SÄGEBLATTS

Lassen Sie das Sägeblatts erst vollständig zum Stillstand kommen und ziehen Sie den Stecker aus der

Steckdose.

- Entfernen Sie die Schutzhaube (Abb. 1.11). Anschließend klemmen sie die Außenflansch mit dem

beiliegenden Schlüssel ein und drehen diese mit Hilfe

eines Steckschlüssel im Uhrzeigersinn.

- Entnehmen Sie das Sägeblatt und tauschen Sie dies

aus, wobei die Zähne in Richtung des Pfeils zeigen

müssen.

- Bevor Sie das Sägeblatt montieren können, müssen

Sie erst die Flanschen reinigen.

- Bringen Sie die Außenflansch wieder in Position und

schrauben Sie diese fest.

- Bevor die Maschine wieder an das Stromnetz angeschlossen werden kann, muß der Sägeblattschutz in

die Ausgangsposition gebracht werden.

- Führen Sie eventuell einen freien Probeschnitt aus,

indem Sie den Sägeknopf heben und nach unten drücken.

STAUBABSAUGUNG

Die Maschine ist mit einem Anschluß für Staubabsaugung

ausgestattet (b, Abb. 2). Hierdurch kann ein Staubsauger

mit einem gängigen Anschluß verwendet werden.

10 Toledo

Page 11

STÖRUNGEN

Sollte die Trennmaschine nicht einwandfrei funktionieren, werden nachstehend einige mögliche Ursachen und

die passenden Lösungen beschrieben.

1. Der Elektromotor ist überhitzt.

Die Lüftungsschlitze des Motor sind durch Verschmutzungen verstopft.

- Reinigen Sie die Lüftungsschlitze

Der Motor ist defekt

- Lassen Sie die Maschine von Ihrem Toledo-Fachändler kontrollieren und/oder reparieren.

2. Die eingeschaltete Maschine arbeitet nicht.

Das Sägeblatt ist eingeklemmt.

- Kontrollieren Sie ob irgendwelche Gegenstände die

Ursache hierfür sind und entfernen Sie diese.

Unterbrechung des Netzanschlusses.

- Kontrollieren sie den Netzanschluß auf eventuelle

Bruchstellen.

- Lassen Sie die Maschine von Ihrem Toledo-Fachhandler kontrollieren und/oder reparieren.

3. Der Motor hält während des Sägens an.

Das Sägeblatt sitzt fest im Werkstück.

- Lassen Sie den Schalter los, ziehen Sie den Stecker

aus der Steckdose und lösen Sie die Säge.

Unterbrechung des Netzanschlusses.

- Kontrollieren Sie den Netzanschluß auf eventuelle

Bruchstellen.

- Lassen Sie die Maschine von Ihrem Toledo-Fachhändler kontrollieren und/oder reparieren.

4. Staub wird nicht aufgesogen.

Die Ursache ist möglicherweise eine verstopfte Staubabsaugung.

- Reinigen Sie die Staubabsaugung.

WARTUNG

Nehmen Sie bei Wartungs- und Reinigungsarbei-

ten die Maschine immer von der Netzspannung.

Verwenden sie niemals Wasser oder leichtentzündliche Flüssigkeiten zur Reinigung der Maschine. Bürsten sie die

Maschine mit Hilfe einer Bürste sauber.

DURCH REGELMÄSSIGE WARTUNG DER

MASCHINE VERMEIDEN SIE UNNÖTIGE PROBLEME!

1. Sorgen Sie dafür, daß die Lüftungsschlitze der

Maschine frei sind, um Überhitzung des Motor zu

vermeiden.

2. Um Beschädigungen am Motor zu vermeiden und

optimal Gebrauch von einer idealen Kühlung des

Motors machen zu können, muß dieser regelmäßig

von Sägespäne und Staub gereinigt werden.

3. Verwenden Sie keine Lösungsmittel um die Teile aus

Plastik zu reinigen. Flüssigkeiten wie Bremsflüssigkeit, Benzin, Produkte mit Bestandteilen aus Petroleum, Beizöl usw. beinhalten chemische Stoffe, die

das Plastik beschädigen, angreifen oder vernichten

können.

Die Maschinen von Toledo sind entworfen, um während

einer langen Zeit problemlos und mit minimaler Wartung zu funktionieren. Sie Verlängern die Lebensdauer,

indem Sie die Maschine regelmäßig reinigen und fachgerecht behandeln.

Reinigen

Reinigen Sie das Maschinengehäuse regelmäßig mit

einem weichen Tuch, vorzugsweise nach jedem Einsatz.

Halten Sie die Lüfterschlitze frei von Staub und Schmutz.

Entfernen Sie hartnäckigen Schmutz mit einem weichen

Tuch, angefeuchtet mit Seifenwasser. Verwenden Sie

keine Lösungsmittel wie Benzin, Alkohol, Ammonia,

usw. Derartige Stoffe beschädigen die Kunststoffteile.

Schmieren

Die Maschine braucht keine zusätzliche Schmierung.

Störungen

Wenden Sie sich in Störungsfällen, z.B. durch Verschleiß

eines Teils, an Ihren örtlichen Toledo-Vertragshändler.

Am Ende dieser Betriebsanleitung finden Sie eine Zeichnung der erhältlichen Ersatzteile.

UMWELT

Um Transportschäden zu verhinderen, wird die

Maschine in einer soliden Verpackung geliefert. Die Verpackung besteht weitgehend aus verwertbarem Material. Benutzen Sie also die Möglichkeit zum Recyclen der

Verpackung.

Bringen Sie bei Ersatz die alten Maschinen zu Ihren örtlichen Toledo-Vertagshändler. Er wird sich um eine

umweltfreundliche Verarbeitung ïhrer alten Maschine

bemühen.

GARANTIE

Lesen Sie die Garantiebedingungen auf der separat beigefügten Garantiekarte.

Toledo 11

- Choisir la lame de scie adéquate pour le travail à

faire. Avec la machine à tronçonner scier uniquement du bois ou des produits dérivés ou des

métaux légers tels que l'aluminium. Les autres

matériaux peuvent sauter ou s'accrocher dans la

lame de scie, ou provoquer d'autres dangers.

- La flèche sur la lame de scie indiquant la direction

de la rotation, doit être dirigée vers la même

direction que la flèche placée sur la machine. Les

dents de la lame de scie doivent être dirigées vers

le bas sur le devant de la machine.

- Contrôler que la lame de scie soit bien affûtée,

qu'elle ne présente pas de détériorations et

qu'elle soit bien centrée. Après avoir retiré la

fiche de la prise électrique, appuyer la tête de scie

vers le bas.

- Faire tourner la lame de scie à la main et vérifier si

elle tourne librement. Placer la machine en position de 45° et répéter ce test. Lorsque la lame de

scie frotte en un endroit, il faudra la régler à nouveau.

- Tenir propres la lame de scie et les surfaces de

tension des pinces de serrage.

- La bride de la lame de scie doit toujours être

montée avec l'entaille serrée tournée vers la lame

de scie.

- La vis bridée doit être resserrée avec une clé à

tube de 13 mm.

- Contrôler que toutes les directions de tension et

tous les verrouillages soient serrés et qu'aucune

partie ne présente un jeu trop grand.

- Ne jamais scier dans la main libre.

- Presser toujours fortement la pièce à travailler

contre le buttoir, de sorte qu'elle ne puisse pas se

renverser, ou se tourner. Il ne doit pas être possible aux saletés de s'accumuler sous la pièce à travailler.

- Veiller à ce que la pièce à travailler ne puisse pas

bouger après la coupure, par ex. parce qu'elle ne

porte pas sur la surface entière.

- Pour des pièces ne portant pas sur la surface

toute entière, utiliser des remplissages ou une

autre machine.

- Contrôler si des morceaux sciés peuvent être retirés

le long de la lame de scie. Car ils pourraient être

accrochés par la lame de scie et projetés.

- Ne jamais scier plusieurs pièces en même temps.

- Etre particulièrement attentif lors du sciage de grandes pièces, de très petites pièces et de pièces difficiles

à manier.

- Utiliser des appuis auxiliaires (tables, tréteaux et

autres) pour des pièces longues qui se déversent

de la table de la machine lorsqu'elles ne sont pas

soutenues.

- Ne pas scier avec cette machine, des pièces si

petites qu'elles ne peuvent plus être tenues en

toute sécurité.

- Pour le sciage de profilés, travailler de telle façon

que la pièce à travailler ne puisse s'échapperet ne

coince pas la lame de scie. Une pièce profilée doit

être posée bien à plat, ou alors être tenue à l'aide

d'une pièce auxiliaire empêchant ainsi le renversement ou le glissement durant le travail.

- Les pièces à travailler rondes, telles que des

tubes, doivent être tenues sinon elles se

tordraient et la lame de scie risquerait de s'accrocher. Tenir, toujours à l'aide d'une pièce auxiliaire

appropriée, la pièce à travailler contre le buttoir

et sur la table.

- Il ne doit pas y avoir de clous ou autre objets étrangers dans la pièce à travailler.

- Pour éviter des endommagements de l'ouïe, il convient de porter des protège-oreilles.

- Pour éviter des accidents par la mise en marche par

erreur de la machine, retirer la fiche de la prise électrique, avant de procéder au réglage du buttoir ou de

la tête de scie. La même chose compte pour le remplacement de la lame de scie ou des accessoires et

lors de l'entretien de la machine.

- Pour éviter des chocs électriques, il est défendu de

toucher de quelle manière que ce soit, les tiges en

métal lors de la connexion de la fiche sur la prise

électrique.

- Ne pas se servir du câble électrique pour retirer la

fiche de la prise. Protéger le câble contre l'huile, la

chaleur, et des arrêtes tranchantes.

- Ne jamais appliquer un produit de nettoyage ou un

produit de glissement sur la lame de scie tournant

encore.

- Pour éviter un incendie, la machine ne doit jamais

être utilisée à proximité de liquides, de vapeurs

ou de gaz inflammables.

- On évitera des blessures pouvant se produire par

l'utilisation de pièces qui ne sont pas d'origine.

Utiliser uniquement les lames de scie conseillées.

LORSQUE LA MACHINE EST EN SERVICE

Veiller à ce qu'une routine qui se produit souvent

lors d'utilisations répétées de la machine, n'engendre pas de fautes graves. Réalisez qu'une légère inattention peut entraîner de graves blessures en une fraction de

seconde.

1. Faire ourner la machine pendant quelque temps

avant de procéder au premier sciage. S'il se produisait

des bruits anormaux ou de fortes vibrations, débrancher alors la machine et retirer la fiche de la prise

électrique afin d'en déterminer la cause. Ne pas

remettre la machine en fonction avant d'avoir trouvé

la cause des dérangements et d'y avoir remédié.

2. Veiller à ce que la pièce sciée ne se trouve pas

coincée, ne pas la tenir, ne pas la coincer et ne pas la

coincer contre une butée. Elle doit pouvoir se mouvoir librement le long de la lame de scie. Lorsque cela

n'est pas possible, le morceau scié peut être accroché

par la lame de scie et être projeté en l'air.

3. Eviter le placement désavantageux des mains, car lors

d'un glissement soudain une ou les deux mains peuvent se trouver prises par la lame de scie.

4. Faire tourner la lame de scie à plein régime, avant de

commencer à scier.

5. Abaisser la tête de scie de telle façon que le moteur

n'en soit pas surchargé et que la lame de scie ne se

coince pas.

18 Toledo

Page 12

Machine à tronçonner

SPECIFICATIONS TECHNIQUES

PRODUCT INFORMATION

Fig. A. (PAGE 2)

1. Poignée avec interrupteur

2. Bouton de déverrouillage

3. Logement du moteur + capot de couverture balai à

bloc de charbons.

4. Fixation de lame de scie

5. Appareil protecteur mobile

6. Vis pour ajuster la table

7. Table de rotation

8. Echelle graduée

9. Trous de fixation

10. Boulon d'ajustement en oblique

11. Capot de protection

CONTENU DE BOITE

- Machine a tronçonner

- Lame de scie Ø 205 mm

- Consignes de sécurité

- Mode d’emploi

- Certificat de garantie

Vérifiez que l’appareil et les accessoires n’ont pas été

endommagés pendant leur transport.

CONSIGNES DE SÉCURITÉ

Dans ce mode d’emploi, il est fait usage des pictogrammes suivants :

Indique un éventuel risque de lésion corporelle, un

danger de mort ou un risque d’endommagement

de la machine si les instructions de ce mode d’emploi ne sont

pas respectées.

Indique la présence de tension électrique.

Lisez attentivement ce mode d’emploi avant d’utiliser la

machine. Assurez-vous d’avoir bien pris connaissance du

fonctionnement de la machine et de son utilisation.

Entretenez la machine conformément aux instructions

afin qu’elle fonctionne toujours correctement. Conservez ce mode d’emploi et la documentation jointe à proximité de la machine.

Sécurité électrique

Lors d’utilisation de machines électriques,

observez les consignes de sécurité locales en

vigueur en matière de risque d’incendie, de chocs

électriques et de lésion corporelle. En plus des

instructions ci-dessous, lisez entièrement les

consignes de sécurité contenues dans le cahier de

sécurité fourni à part.

Conservez soigneusement ces instructions!

Vérifiez toujours si la tension de votre réseau correspond à la valeur mentionnée sur la plaque signalé-

tique.

La machine est doublement isolée conformément à la norme EN50144; un fil de mise à la

terre n’est pas donc pas nécessaire.

En cas de changement de câbles ou de fiches

Jetez immédiatement les câbles ou fiches usagés dès

qu’ils sont remplacés par de nouveaux exemplaires. Il est

dangereux de brancher la fiche d’un câble défait dans une

prise de courant.

En cas d’emploi de câbles prolongateurs

Employez exclusivement un câble pro longateur homologué, dont l’usage est approprié pour la puissance de la

machine. Les fils conducteurs doivent avoir une section

minimale de 1,5 mm

2

. Si le câble prolongateur se trouve

dans un dévidoir, déroulez entièrement le câble.

PRESCRIPTIONS SPECIALES DE

SECURITE

AVANT CHAQUE UTILISATION

- Contrôler la machine à tronçonner. Lorsqu'il manque une pièce quelconque de la machine à tronçonner, ou qu'une pièce est tordue ou inutilisable de

quelque autre manière que ce soit, ou lorsqu'il se

produit des défectuosités électriques, éteindre alors

la machine et retirer la fiche de la prise électrique.

Remplacer toutes les pièces manquantes, endommagées ou détériorées, avant de remettre la machine

en service.

- Veiller à ce que les mains, les yeux, la figure et les

oreilles soient bien protégés.

- L'utilisation de lunettes de protection sans marque

de qualité CE, peut, dans le cas de bris du verre, entraîner de graves endommagements.

- Pour éviter le coincement de la lame de scie dans le

trait de scie et la projection de pièces à travailler, il

convient de bien suivre les instructions suivantes :

Tension | 230 V~

Fréquence | 50 Hz

Puissance consommée | 800 W

Vitesse à vide | 4000/min

Dimension du scie | 205x18 mm

Épaisseur de bois 90° | 120x50 mm

Épaisseur de bois 45° | 70x55 mm

Poids | 7.0 kg

Lpa (niv. de pression acoustique)| 88.9 dB(A)

Lwa (niv. puissance acoustique) | 101.9 dB(A)

Vibrations | 2.5 m/s

2

F

Français

Toledo 17

Wir erklären in alleiniger Verantwortung, daß

dieses Produkt mit den folgenden Normen oder

normativen Dokumenten übereinstimmt:

EN61029-1, prEN61029-2-9, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3

gemäß den Bestimmungen der Richtlinien:

98/37/EWG

73/23/EWG

89/336/EWG

ab 10-12-2002

GENEMUIDEN NL

W. Kamphof

Quality department

Afkortmachine.

TECHNISCHE SPECIFICATIES

PRODUKT INFORMATIE

Fig. A. (Pag. 2).

INHOUD VAN DE VERPAKKING

- Afkortmachine

- TCT Zaagblad Ø 205 mm

- Veiligheidsinstructies

- Gebruiksaanwijzing

- Garantiekaart

Kontroleer voor het gebruik of de inhoud van de verpakking niet beschadigd is door transport en of alle onderdelen aanwezig zijn.