Page 1

Digital Controller

TTM-200 series

User’s Manual

TOHO ELECTRONICS INC.

Page 2

User’s manual for digital controller TTM-200 series

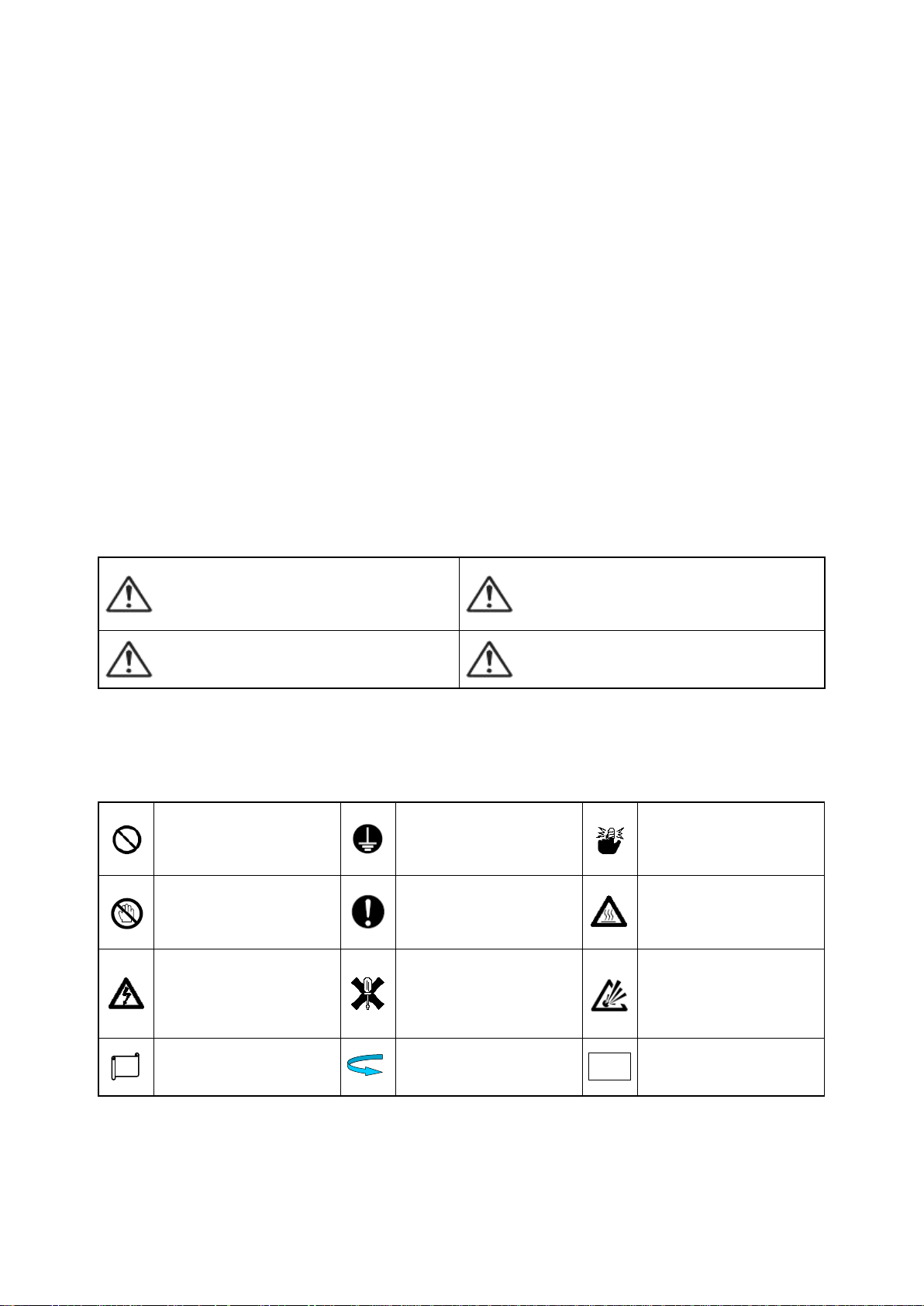

Danger

Improper handling of the

equipment may cause fatality or

serious injury for an impending

reality.

Caution

Improper handling of the

equipment may cause injury or

physical damage on it.

Warning

Improper handling of the

equipment may cause fatality or

serious injury.

Reminder

Care should be taken for

ensuring safety.

General caution, warning or

prohibition without

particularity

Instruction on ground

connection for the

equipment with safety

grounding terminals

Hazard of pinched fingers

on a particular portion of the

equipment

Possible injury caused by

touching a particular portion

of the equipment under

specific conditions

Unspecific behaviors of

general users

Hazard of injury due to high

temperature under specific

conditions

Hazard of an electric shock

under specific conditions

Hazard of injury such as an

electric shock due to

disassembling or

modification of the

equipment

Hazard of burst under

particular conditions

Supplementary explanation

Designation of reference for

explanation

Care for use or operation

Note

Introduction

Thank you for purchasing Toho Electronics’ TTM-200 series.

Before using the products, thoroughly read this manual for a better understanding of them.

Ensure to store this manual and use it whenever needed.

Precautions on the use of the products

Ensure to read this manual before using the equipment.

Take care to understand the following for the safe use of the equipment.

Ensure this manual to be in hands of a person using the equipment.

★ Precautions on safety

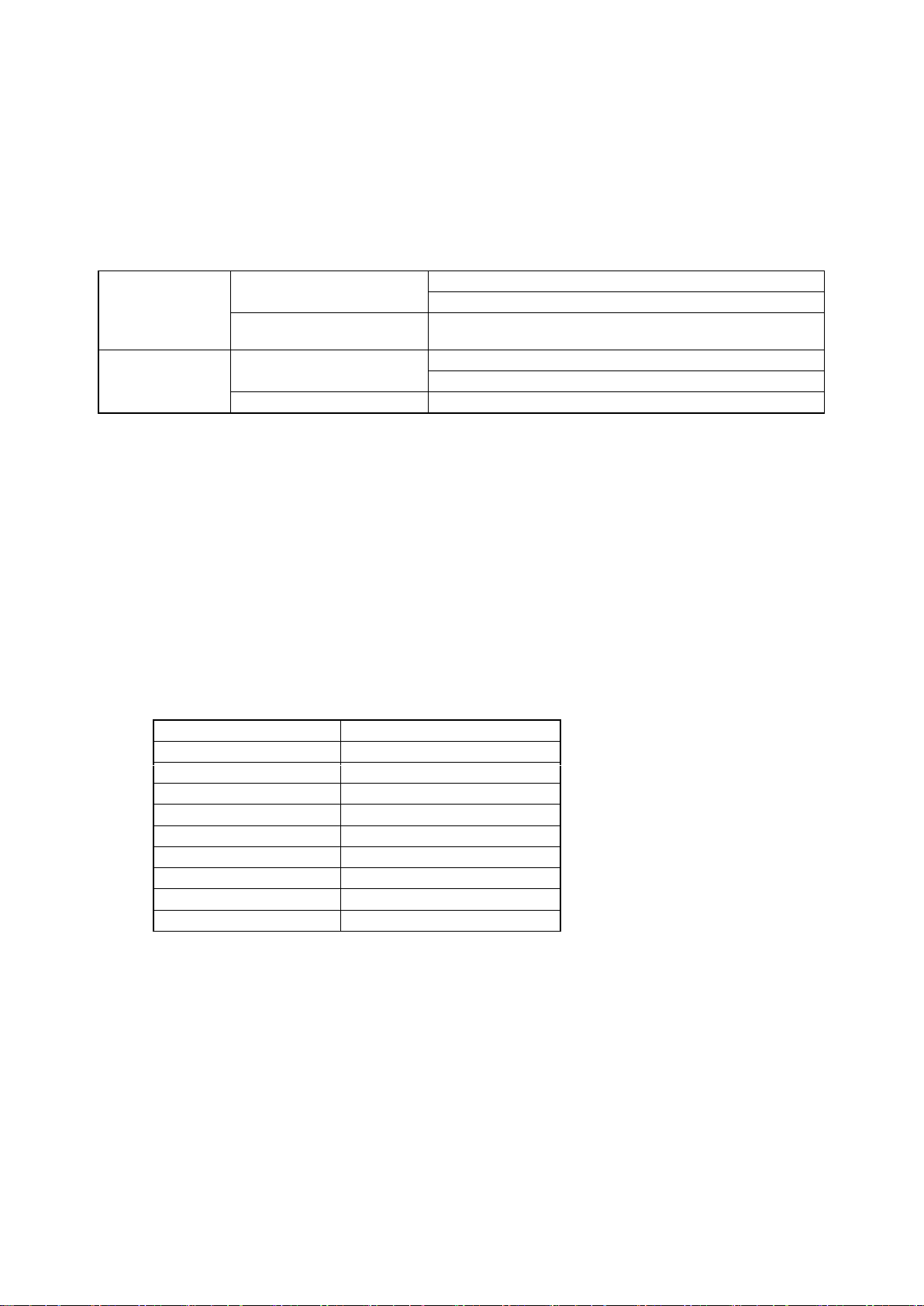

Alarms are defined and categorized into either one of four groups in this manual, depending on degrees of

importance or risk in terms of the safe use of the equipment or prevention of accident or damage on the

equipment. For each alarm, symbol is assigned as shown below.

★ Alarm symbols

An alarm categorized in the group of Caution may still yield to serious result, depending on circumstances.

Any symbol for the four groups intends to raise user’s attention for important description. Carefully observe

it.

★ Other symbols

48-7009-E i

Page 3

Warnings

Improper wiring to the equipment may cause a failure, such as fire. Upon completion of wiring,

ensure to verify the proper wiring before turning on electricity.

Do not turn on electricity until all wiring is complete. Do not touch portions of high voltages such as

power supply terminals, as an electric shock may be resultant.

Install appropriate protective circuits externally if a failure or abnormality of the equipment may

seriously affect related systems.

Do not use the equipment out of the specified range, as it may fail or catch fire.

Do not under any circumstance to modify or disassemble the equipment, as a failure may be caused,

resulting fire or an electric shock.

Do not use the equipment in ambience of flammable or explosive gases.

Do not use the vacant terminals for wiring.

Do not use a pointed object to operate keys.

Do not turn on the power supply until wiring is fully complete in order to prevent an electric shock,

failure or malfunctioning. For replacing a component connected on the equipment, ensure to turn off

the power supply. For turning back on the power supply, do so after all wiring is complete.

Ensure not to trap heat in the space surrounding the equipment in order to provide sufficient heat

release.

Do not put a metal piece or similar inside the equipment. A fire, an electric shock or failure may be

caused.

The equipment is designed for instrumentation. For its use in environments of high voltages or

intense noises, take appropriate measures on the side of user’s equipment.

The equipment is designed for controlling physical values, such as temperatures, on general industrial

facilities. Do not use it for subjects of control that may seriously affect human life.

Turn off the power supply before cleaning the equipment, and wipe it with a soft dry cloth. Do not use

thinners, as they may cause deformation or discoloration of the equipment.

The equipment may cause radio disturbances in domestic settings. User is required to take

appropriate measure.

Ensure to tighten terminal screws at specified torque. Insufficient tightening the screws may cause

an electric shock or fire.

Ensure to observe precautions listed in this manual for the use of the equipment.

Reprinting or duplicating this manual is prohibited.

This manual may be revised without prior notice.

Cautions

Precaution regarding Export Trade Control Ordinance

Investigation on client or application by an appropriate party is required so that the equipment is not used for

mass destruction weapons and such (military application, military facilities, etc.).

48-7009-E ii

Page 4

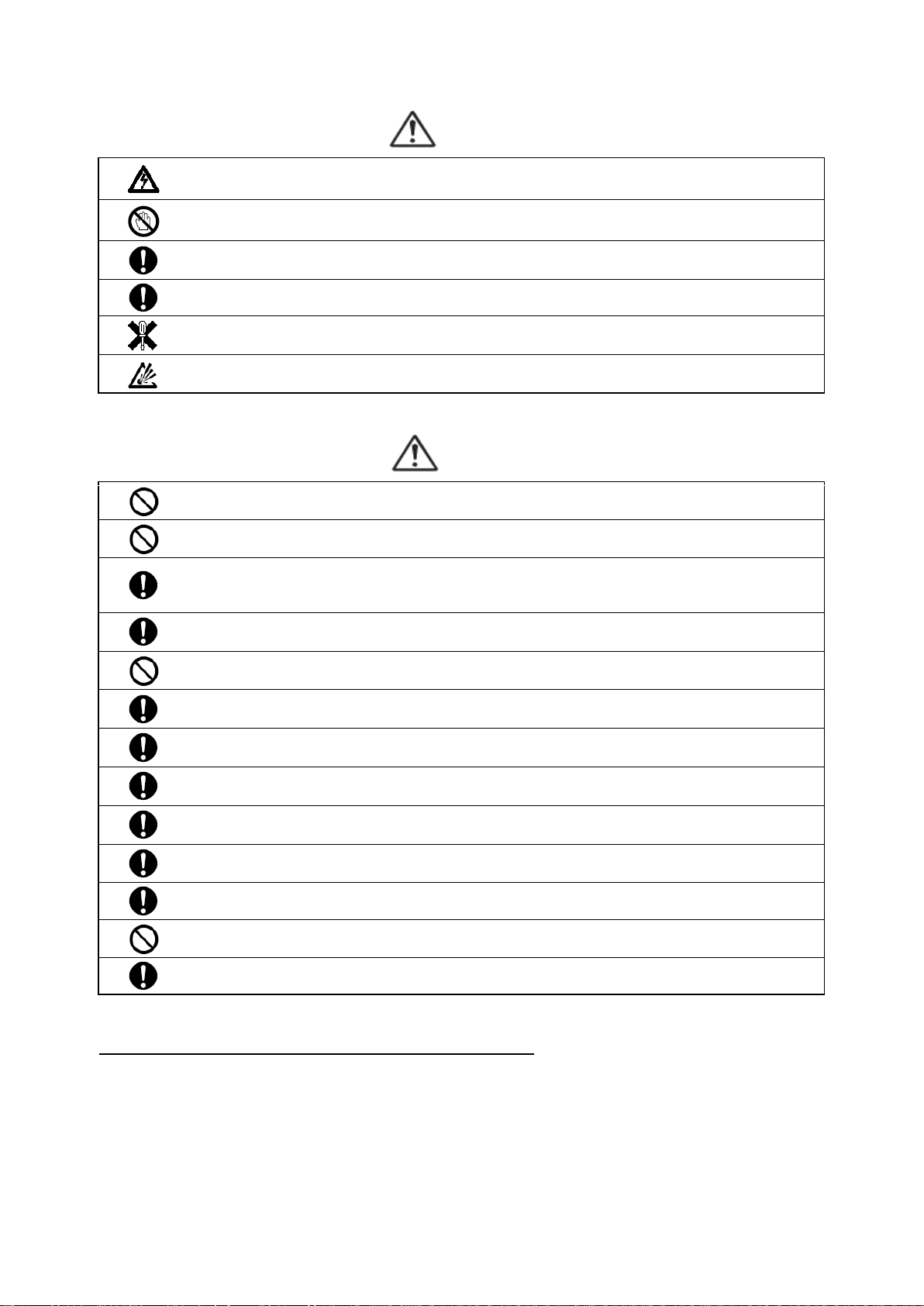

Notation convention in this manual

Abbreviation

Term

PV

Present value

SV

Setting value

AT

Auto-tuning

ENT

Determined

MV1

Primary operating amount

MV2

Secondary operating amount

CT

Current transformer

AI

Remote SV input

0 1 2 3 4 5 6

7 8 9

Minus

Period

Slash

A B C D E F G

H I J K L M N

O P Q R S

T(t)

U

V W X Y Z n v

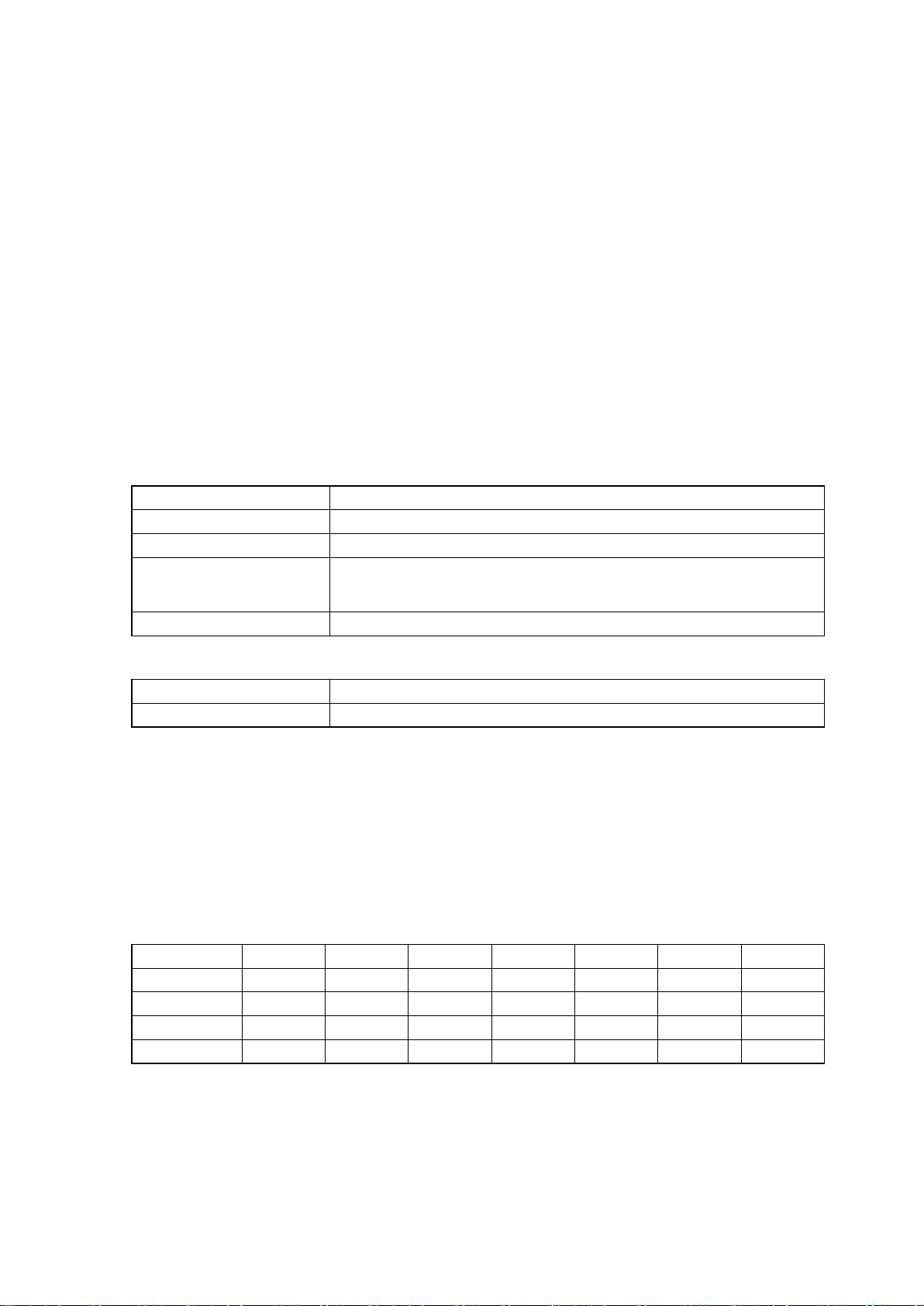

★ Summary notation

Abbreviations in alphabetical characters are used for the diagrams and text in this manual. Some major

examples are as follows.

★ Notation of characters

For parameters and settings, numeric and alphabetic characters are inscribed as follows. (For initial setting, a

character is comprised of eleven segments.)

48-7009-E iii

Page 5

Contents

1. Overview

Outline of TTM-200 series is described, in terms of features, model configuration (codes), names of

components and functions. Thoroughly read this chapter prior to the first use.

This manual is applicable for the product of which main body has a firmware of Ver3.xx or later.

The previous manual must be used if the main body firmware of Ver2.xx or earlier is used.

1.1 Feature ..................................................................................................................................................... 1-2

1.2 Checking the product ............................................................................................................................... 1-3

1.3 Model table .............................................................................................................................................. 1-3

1.4 Names of parts and components .............................................................................................................. 1-4

1.5 Input/output function and essential functions .......................................................................................... 1-7

1.6 Basic flow of setting ...............................................................................................................................1-11

2. Installation

How to install TTM-200 series and precautions on the installation are described.

Read this chapter prior to the installation.

2.1 Precautions on installation ....................................................................................................................... 2-2

2.2 How to install or remove the equipment .................................................................................................. 2-3

2.3 Outside dimensions and panel cutting dimensions .................................................................................. 2-4

3. Wiring

Wiring of TTM-200 series is described.

Read this chapter prior to the wiring.

3.1 Precautions on wiring .............................................................................................................................. 3-2

3.2 Terminal arrangement .............................................................................................................................. 3-3

3.3 Wiring to each terminal ........................................................................................................................... 3-7

3-4 Examples of wiring ................................................................................................................................ 3-15

4. Basic functions

Basic operation (setting method) of TTM-200 series is described.

4.1 Flow of setting mode ............................................................................................................................... 4-2

4.2 Basic operation ........................................................................................................................................ 4-4

4.2.1 Switchover of parameters (flow as a whole) .................................................................................. 4-4

4.2.2 Description of setting item selection screen ................................................................................. 4-19

4.2.3 Setting of input types ................................................................................................................... 4-20

4.2.4 Setting of key functions ............................................................................................................... 4-21

4.2.5 How to set the SV limiter setting ................................................................................................. 4-22

4.2.6 How to set control types ............................................................................................................... 4-23

4.2.7 How to set outputs ........................................................................................................................ 4-25

4.2.8 How to set priority screens ........................................................................................................... 4-26

4.2.9 Switchover to the blind setting mode ........................................................................................... 4-27

4.2.10 Switchover to the ON/OFF control .............................................................................................. 4-29

5. Operation

Operation, often-used setting items, how to set each function and description of the function of TTM-200

series are described.

5.1 Precautions on operating the equipment .................................................................................................. 5-2

5.2 Operating monitor display ....................................................................................................................... 5-3

5.2.1 Operating amount monitor: SET 04 (control setting mode) ........................................................... 5-3

5.2.2 Timer remaining time monitor: Run mode ..................................................................................... 5-3

5.2.3 Temperature measurement monitor: Run mode ............................................................................. 5-3

5.2.4 CT monitor: SET 12 (CT setting mode) ......................................................................................... 5-3

48-7009-E iv

Page 6

5.3 How to set run settings............................................................................................................................. 5-4

5.3.1 Target value (SV) setting ................................................................................................................ 5-4

5.3.2 ON/OFF control setting.................................................................................................................. 5-7

5.3.3 PID control setting ......................................................................................................................... 5-9

5.3.4 Heating/cooling PID control setting ............................................................................................. 5-13

5.3.5 Indicator setting ............................................................................................................................ 5-15

5.3.6 Excessive ascent prevention unit (alarm unit) setting .................................................................. 5-17

5.3.7 Event setting ................................................................................................................................. 5-18

5.3.8 How to set MD/READY .............................................................................................................. 5-20

5.4 How to set each function and description of function ........................................................................... 5-22

5.4.1 Auto-tuning (AT) function ........................................................................................................... 5-22

5.4.2 Self-tuning function ..................................................................................................................... 5-25

5.4.3 Mode/manual function ................................................................................................................. 5-27

5.4.4 Bank function ............................................................................................................................... 5-28

5.4.5 Timer function .............................................................................................................................. 5-31

5.4.6 Loop abnormality function ........................................................................................................... 5-38

5.4.7 Current transformer (CT) abnormality function ........................................................................... 5-40

5.4.8 Position proportional control ........................................................................................................ 5-45

5.4.9 Concurrent temperature ascent function ...................................................................................... 5-46

5.5 Explanation of the program run function ............................................................................................... 5-47

5.5.1 Operation flow of the program run .............................................................................................. 5-48

5.5.2 SET 21 program function setting ................................................................................................. 5-49

5.5.3 SET 21 program function setting screen ...................................................................................... 5-52

5.5.4 SET 22 program setting ............................................................................................................... 5-53

5.5.5 SET 22 program setting screen .................................................................................................... 5-55

5.5.6 Explanation of the screen display and operation of a program run .............................................. 5-56

5.5.7 Complementary explanation of the program run ......................................................................... 5-61

5.6 Explanation of the bank automatic switching function .......................................................................... 5-70

5.6.1 Bank automatic switching setting ................................................................................................ 5-71

5.6.2 SET 23 bank automatic switching function setting mode setting screen ..................................... 5-73

5.6.3 Complementary explanation of the bank automatic switching function ...................................... 5-74

6. Parameters

Various parameters of TTM-200 series are described in terms of their functions.

Read this chapter prior to their settings.

6.1 Input 1 type setting .................................................................................................................................. 6-2

6.2 Remote SV input type setting .................................................................................................................. 6-8

6.3 Function key function setting ................................................................................................................ 6-12

6.4 Control function setting ......................................................................................................................... 6-14

6.5 Output (from OUT 1 to OUT 7) type setting ......................................................................................... 6-49

6.6 Current transformer (CT) setting ........................................................................................................... 6-57

6.7 DI setting ............................................................................................................................................... 6-59

6.8 Timer function setting ............................................................................................................................ 6-62

6.9 Communication function setting ............................................................................................................ 6-65

6.10 Initial setting .......................................................................................................................................... 6-67

6.11 Priority screen setting ............................................................................................................................ 6-71

6.12 Bank function setting ............................................................................................................................. 6-72

6.13 Program function setting ........................................................................................................................ 6-73

6.14 Program setting ...................................................................................................................................... 6-77

6.15 Bank automatic switching function setting ............................................................................................ 6-80

7. Appendix

Product specification, errors (troubles) and parameter setting table of TTM-200 series are described.

7.1 Product specifications .............................................................................................................................. 7-2

7.2 Accessories .............................................................................................................................................. 7-9

7.3 Error (abnormality) display ................................................................................................................... 7-10

7.4 Troubleshooting ......................................................................................................................................7-11

7.5 Setting list .............................................................................................................................................. 7-13

48-7009-E v

Page 7

1. Overview

Features of products, confirmation of products, and model coding and the name of each component or part are

described in this chapter.

1.1 Feature .................................................................................................................................................... 1-2

1.2 Checking the product ............................................................................................................................. 1-3

1.3 Model table............................................................................................................................................. 1-3

1.4 Names of parts and components ............................................................................................................. 1-4

1.5 Input/output function and essential functions ........................................................................................ 1-7

1.6 Basic flow of setting ..............................................................................................................................1-11

48-7009-E 1-1

Page 8

1.1 Feature

★ Improved controllability due to new PID algorithm

(1) Time required to stabilize after start of control has been reduced (compared to Toho’s other models).

(2) Jumpless control function is supported, where post-disturbance overshoots are suppressed.

(3) Selection can be made from three types of PIDs.

(PID auto-tuning with the overshoot suppression function is set as factory default.)

★ Full multi-input

Thermocouples (13 types), resistance temperature detector (2 types), voltage (5 types) and current (one

type) are achieved as input specifications on a single unit. Their changes are possible through setting

changes of parameters. (“K thermocouple” is set as factory default)

★ Compact-sized with dimension of 55 mm (TTM-204) or 65 mm (other than TTM-204) in depth

★ Sampling cycle of 200 ms

★ Loader communication function

Best suited for setting various parameters

Dedicated cable: Option (with charge) (See page 7-9 for specifications.)

Dedicated software: Option (free-of-charge)

★ Blind function and priority screen for a simplified operation

Blind function: Among multiple parameters, only those needed can be displayed.

Priority screen: By transferring the necessary parameter screen to the operating mode screen, indication as

well as the setting would be possible without calling the parameter screens. (max. 20 screens)

★ The valve position proportional control is made possible without feedback resistance.

★ Bank function

Each process value (such as SV, PID constants) which varies in each process can be set at every bank,

enabling the setting changes according to the content of the process. (max. 8 points)

★ Simple timer function

Control of “start or stop of control after predetermined time has elapsed” can be done on a single unit.

The independent use of timer is also allowed. (Independent 3 points)

★ Protective structure In compliance with IP66 or equivalent (TTM-204 only)

★ Applicable to various instrumentation systems, using manual control

★ Password function

★ Modification to the settings at factory default is possible.

★ Display colors of PVs (measurement values) can be changed to green, red or orange.

★ Ramp function enables the setting of gradient.

★ Soft-start function

During PID control, a limit can be applied to an operation volume for a predetermined period of time

when the power switched.

★ Delay timer function

During ON/OFF control, the control output (primary/secondary) can be done with a predetermined lag

time.

★ Program run function

A max. of 8-step program operation is possible.

★ Bank auto-switchover run function

A bank auto-switchover run is possible by using 8 banks at most.

48-7009-E 1-2

Page 9

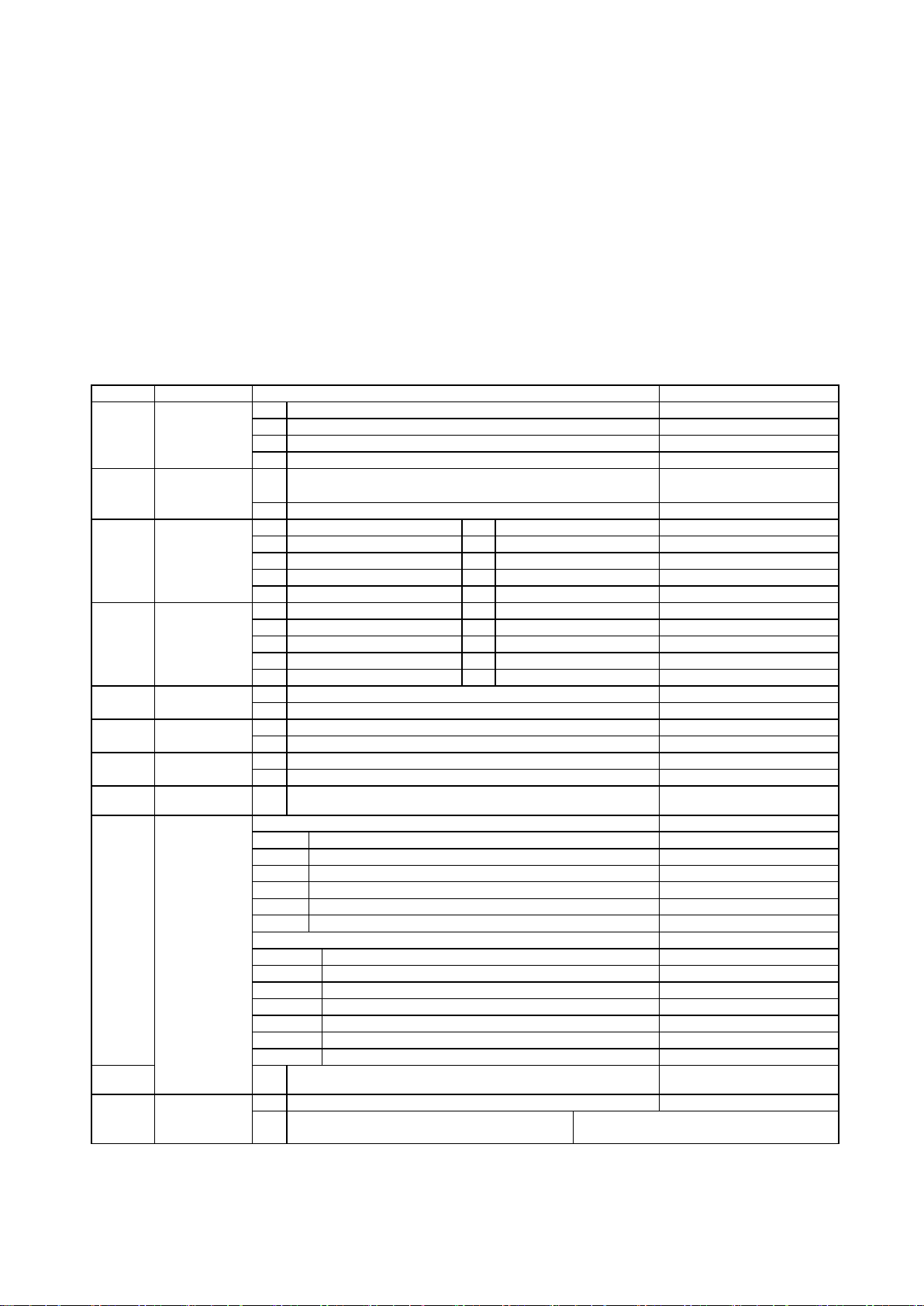

1.2 Checking the product

Symbol

Item

Description

Remarks

①

Size

4

48 x 48

5

96 x 48

7

72 x 72

9 96 x 96

②

Color

Q

Color of case: Black

X

Color of case: Gray

Not available for 205,7,9.

③

Output 1

N

None

J

Voltage 0 - 5 VDC

R

Relay

F

Voltage 1 - 5 VDC

P

SSR drive voltage

G

Voltage 0 - 10 VDC

A

Open collector

I

Current 4 - 20 mADC

K Voltage 0 - 1 VDC

H

Voltage 0 - 10 mVDC

④

Output 2

N

None

J

Voltage 0 - 5 VDC

R

Relay

F

Voltage 1 - 5 VDC

P

SSR drive voltage

G

Voltage 0 - 10 VDC

A

Open collector

I

Current 4 - 20 mADC

K Voltage 0 - 1 VDC

H

Voltage 0 - 10 mVDC

⑤

Outputs 3

and 4

A

Open collector

Common

R

Relay contact

Common

⑥

Outputs 5

and 6

A

Open collector

Not available for 204. *1

R

Relay contact

Not available for 204. *1

⑦

Output 7

A

Open collector

Not available for 204. *3

R

Relay contact (common independent)

Not available for 204. *3

⑧

AI input

Y

Remote SV input: Only voltage and current

Not available for 204.

⑨

Option

Case of TTM-204,207

ST

CT 1,2input

*2

SV

CT 1 input, Event 2 input

*2

UV

Event 1,2 input

STW

CT 1,2input, Event 3 input

Not available for 204.*2,*3

SVW

CT 1 input, Event 2,3 input

Not available for 204.*2,*3

UVW

Event 1,2,3 input

Not available for 204. *3

Case of TTM-205,209

ST

CT 1,2input

*2

SV

CT 1 input, Event 2 input

*2

UV

Event 1,2 input

SVW

CT 1 input, Event 2,3,4 input

*2

UVW

Event 1,2,3,4 input

STUV

CT 1,2 input, Event 1,2 input

*2

STUVW

CT 1,2 input, Event 1,2,3,4 input

*2

⑩

M

Communication (RS-485)

⑪

24 V power

supply

Free power supply

L

24 VAC / 24 VDC

For models 205,207,209 are still under

development.

Prior to the use, check the following.

★ Checking the model

The model number is printed on the box and side of the product. Check that the numbers thereon

matches with the model that had been ordered.

★ Appearance

Check that no scratch or damage is present on the case, front panel or terminal block.

★ Check that accessories are included in the box. (See below for the list of the accessories.)

Mounting tool, brief operation manual and rubber packing (attached to the main frame)

1.3 Model table

TTM20

① ② ③④ ⑤⑥⑦⑧⑨⑩ ⑪

*1 Output6 is not selectable for 207

*2 CT is not selectable, if there are only analogue output.

*3 Either W (only event3) or output7 should be selected for 207.

When the option from ④ is not added, the model code is omitted. Example. TTM-205-Q-RN-M

48-7009-E 1-3

Page 10

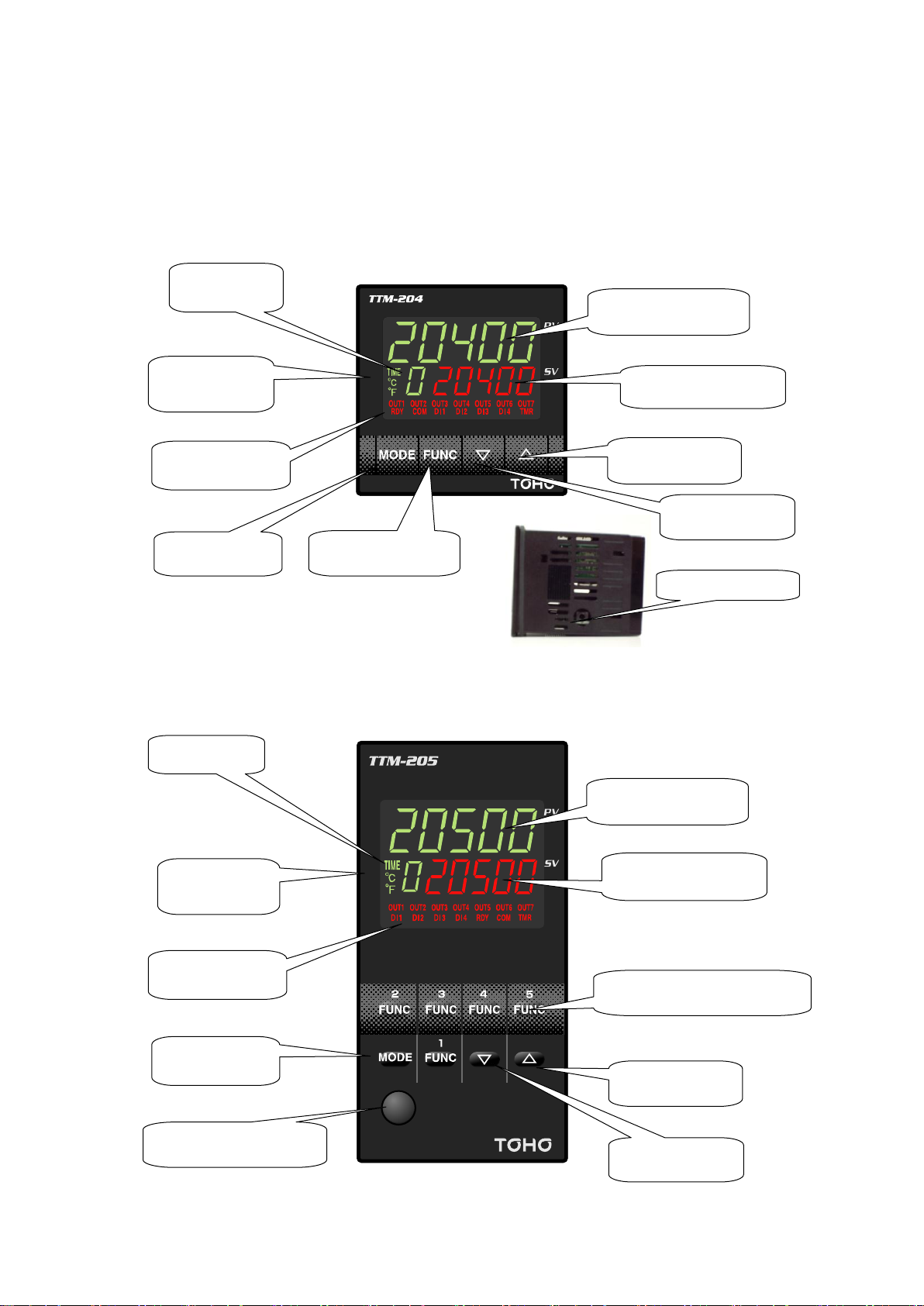

1.4 Names of parts and components

PV display

SV display

Up key

Down key

Function key

Mode key

Bank display

Unit of

temperature and

timer display

Operation display

Loader port

(Located on the bottom wall)

PV display

SV display

Function key (1 to 5)

Up key

Down key

Mode key

Operation display

Unit of

temperature and

timer display

Bank display

Loader port

■ Front panel

★ TTM-204 * The loader port is located in the bottom wall for TTM-204.

★ TTM-205

48-7009-E 1-4

Page 11

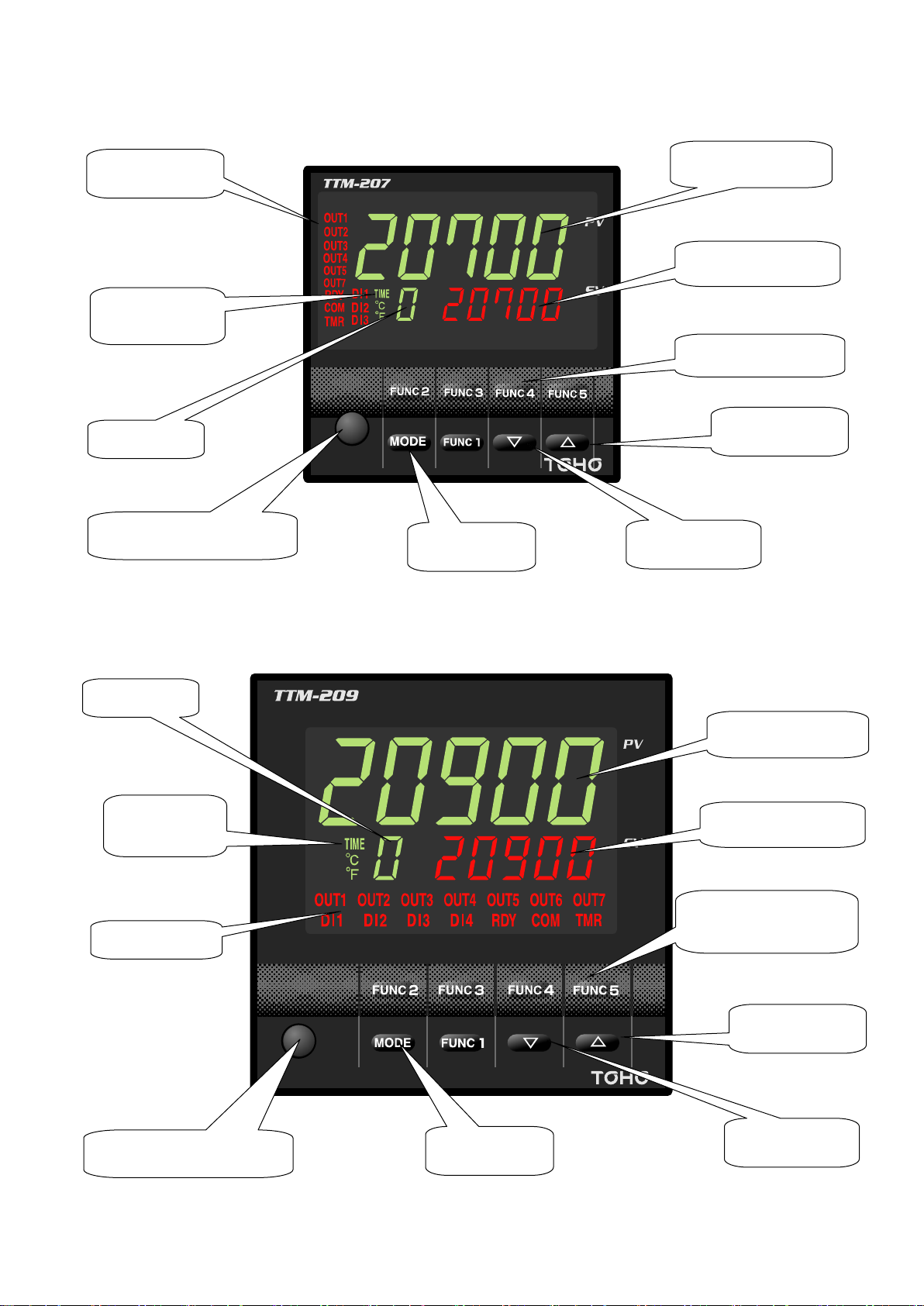

★ TTM-207

Down key

Up key

Function key

(1 to 5)

SV display

PV display

Bank display

Operation display

Unit of

temperature and

timer display

Mode key

Loader port

Bank display

PV display

SV display

Function key

(1 to 5)

Up key

Down key

Mode key

Loader port

Unit of

temperature and

timer display

Operation display

★ TTM-209

48-7009-E 1-5

Page 12

■ What the displays indicate

★ PV display Measurement value (present value) display, each character display and timer setting

time display

★ SV display Setting value (target value) display, output operating amount display, display of

setting value of each character, timer remaining time display and MVI (operating

amount) display

★ Unit of temperature The unit of temperature is displayed when setting data is for temperature. The

display is determined depending on setting for “unit of temperature” in the symbol

“C” or “F.”

Timer display Lights up when timer is set.

★ Bank display The bank selected is displayed.

★ Behaviors of the displays

OUT 1 Output 1 monitor display. Turns on when output is ON.

OUT 2 Output 2 monitor display. Turns on when output is ON.

OUT 3 Output 3 monitor display. Turns on when output is ON.

OUT 4 Output 4 monitor display. Turns on when output is ON.

OUT 5 Output 5 monitor display. Turns on when output is ON.

OUT 6 Output 6 monitor display. Turns on when output is ON.

OUT 7 Output 7 monitor display. Turns on when output is ON.

DI 1 DI 1 monitor display. Turns on when DI 1 is operating.

DI 2 DI 2 monitor display. Turns on when DI 2 is operating.

DI 3 DI 3 monitor display. Turns on when DI 3 is operating.

DI 4 DI 4 monitor display. Turns on when DI 4 is operating.

RDY RDY monitor display. Lights up when operation is in “READY (operation

halted).”

COM Communication monitor display. Blinks on and off when the communication

function is operating (in communication).

TMR Timer monitor display. Lights up when the timer function is operating.

■ Key operations

★ FUNC Function key. Used when a set function is to be executed.

★ MODE Mode key. Used when the screen is to be switched over.

Pressing it for 2 seconds changes the screen to the parameter screen.

Pressing it for 2 seconds changes the screen to the operating mode screen.

★ [△] Up key. Used for increasing setting values.

Used for changing over the input setting mode.

Holding it pressed accelerates the increase speed.

★ [▽] Down key. Used for reducing setting values.

Used for changing over the input setting mode.

Holding it pressed accelerates the reduction speed.

■ Others

★ Loader port Dedicated cables are connected for loader communication.

48-7009-E 1-6

Page 13

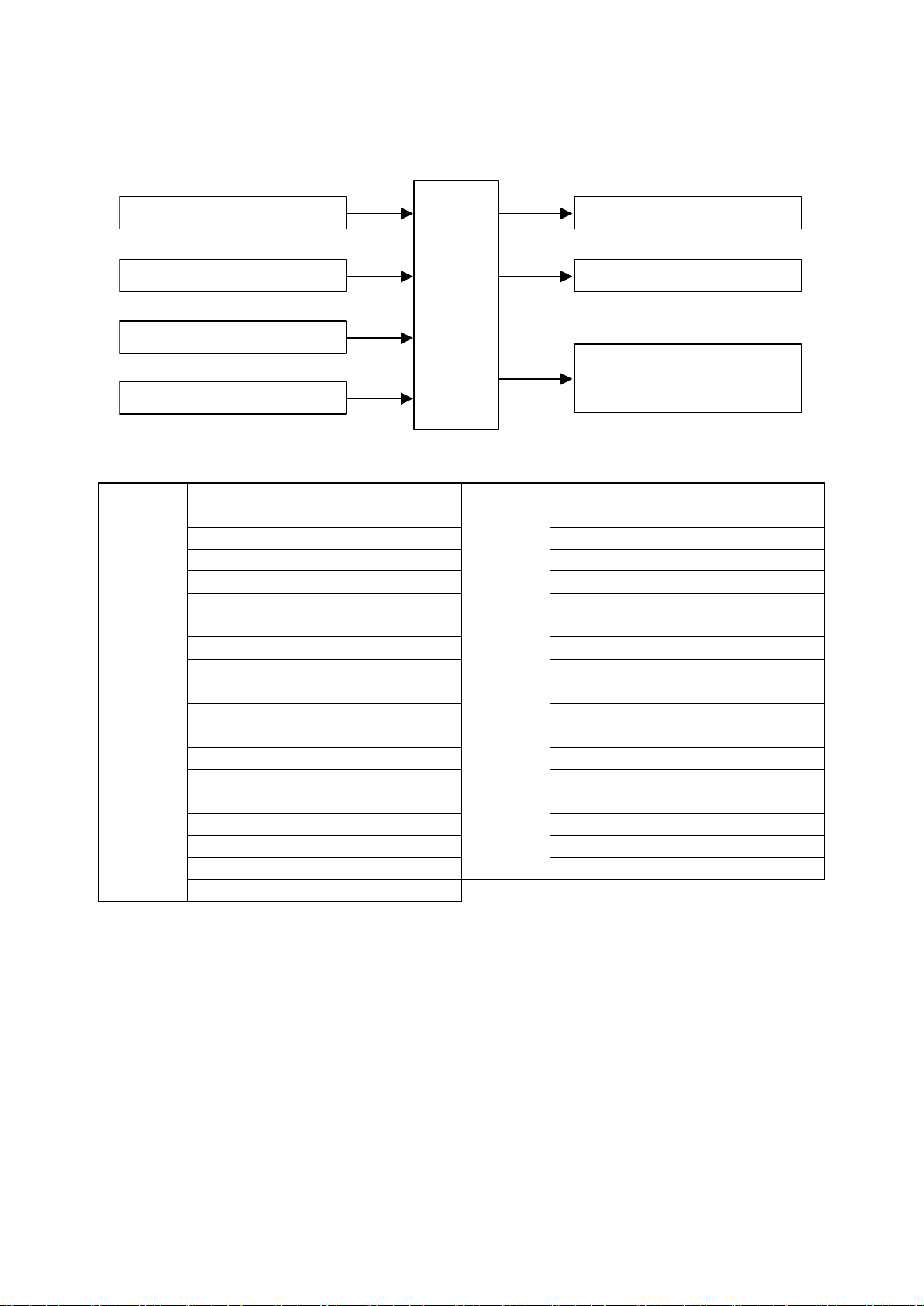

1.5 Input/output function and essential functions

Measurement value (PV) input

CT input (2 points: optional)

DI input (4 points: optional)

AI input (1 point: optional)

Output 1

Outputs 2 to 7 (optional)

Communication output (optional)

TOHO communication

MODBUS communication

Control

section

Outputs

1 and 2

Primary output

Outputs

3 to 7

Primary output

Secondary output

Secondary output

Event output

Event output

RUN output

RUN output

RDY output

RDY output

Timer 1 output

Timer 1 output

Timer 1 ON delay output

Timer 1 ON delay output

Timer 1 OFF delay output

Timer 1 OFF delay output

Timer 1 ON+OFF delay output

Timer 1 ON+OFF delay output

Timer 2 output

Timer 2 output

Timer 2 ON delay output

Timer 2 ON delay output

Timer 2 OFF delay output

Timer 2 OFF delay output

Timer 2 ON+OFF delay output

Timer 2 ON+OFF delay output

Timer 3 output

Timer 3 output

Timer 3 ON delay output

Timer 3 ON delay output

Timer 3 OFF delay output

Timer 3 OFF delay output

Timer 3 ON+OFF delay output

Timer 3 ON+OFF delay output

Transmission output

End output (during program run) *1

End output (during program run)

Input and output functions are described. See corresponding pages for setting each function.

Assignment of outputs

*1: Selectable only for a program run.

48-7009-E 1-7

Page 14

■ Input section

Temperature input

Thermocouple

K, J, T, E, R, S, B, N, U and L

WRe 5-26, PR40-20 and PLII

Resistance temperature

detector

Pt 100 and JPt 100

Analog input

Voltage

0 - 1 VDC, 0 - 5 VDC, 1 - 5 VDC

0 - 10 VDC, 0 - 10 mVDC

Current

4 - 20 mADC

Close

Active

Bank switchover

Bank switchover

MD

READY

AUTO

MANUAL

Reverse operation

Forward operation

AT stop

AT start

Timer stop

Timer start

Step feed *1

Pause *1

Interlock *1

* The following types of inputs can be selected in the input section: measurement value input (1 point),

CT input (2 points), DI input (4 points) and AI input (1 point).

Selectable points depend on models. See the model selection table.

★ Measurement value input

* The input of the controlled objects is selectable with a single unit using parameter setting.

*The K thermocouple is set as factory default.

★ CT input (optional)

* Heater disconnection failure is detected by CT (current detector) when the heater disconnection alarm

is effective.

* Max. 2 points are selectable (to be designated at order placement).

For models TTM-204 and 207, a single point for the CT input is provided when a single point for the

DI input is selected.

* Usable CT is “CTL-6-P-N-(S).” (For product specification, see page 7-9.)

* CT input is not selectable for analog output.

★ DI input (optional)

* The following functions can be executed with DI (digital) input.

The DI Input is an external no-voltage contact signals.

* List of functions due to DI

*1: Selectable only for a program run.

Close: Contact signal OFF

Active: Contact signal ON

* Max. 4 points are selectable (to be designated at order placement).

Up to 2 points are selectable for TTM-204.

DI 3 and DI 4 inputs are not selectable when input 7 is selected for TTM-207.

DI 2 input is to be selected when CT 1 input is selected for TTM-204 and 207.

★ AI input (optional)

* Voltage and current inputs only. (Voltages of 0 - 10 mV are excluded.)

48-7009-E 1-8

Page 15

■ Output section

Relay contact

250 VAC, 3 A (resistance loads) and 1a contact

Voltage for SSR drive

0 - 12 VDC (load resistance: 600 or greater)

Open collector

24 VDC, 100 mA (load current)

Voltage

0 - 5 VDC, 1 - 5 VDC and 0 - 10 VDC

(resistance loads: 1 k or greater)

0 - 1 VDC and 0 - 10 mVDC (load resistance: 500 k or greater)

Current

4 - 20 mADC (load resistance: 600 or less)

Relay contact

250 VAC, 1 A (resistance loads) and 1a contact

Open collector

24 VDC, 100 mA (load current)

Output 1

Output 2

Output 3

Output 4

Output 5

Output 6

Output 7

TTM-204

TTM-205

TTM-207

TTM-209

* The number of outputs is 7 at most, which can be assigned individually for control output, event

output, RUN/RDY output, timer output and transmission output.

(Assignment of outputs is to be designated at order placement.)

★ Output (OUT) 1 and output (OUT) 2

* Target connection of output can be set.

Primary output, secondary output, event output, RUN output, RDY output, timer 1 output, timer 2

output, timer 3 output, transmission output and end output

★ Output (OUT) 3, output (OUT) 4, output (OUT) 5, output (OUT) 6 and output (OUT) 7

* Target connection of output can be set.

Primary output, secondary output, event output, RUN output, RDY output, timer 1 output, timer 2

output, timer 3 output and end output

* Some specifications are not selectable, depending on the model. Check them on the model table.

★ Selection of output types

* Outputs 1 and 2

* Outputs 3, 4, 5, 6 and 7

* Transmission output function selection

PV (measurement value) output

SV (setting value) output

MV 1 (primary operating amount) output

MV 2 (secondary operating amount) output

Control SV (setting value) output

Forward and reverse operations can be switched over for all the outputs above.

★ Selectable outputs for each model

* TTM-204: Outputs 3 and 4 are for common shared.

* TTM-207: Outputs 3 and 4 are for common shared.

When DI 3 is selected, output 7 will not be selectable.

* TTM-205 and 209: Outputs 3 and 4 are for common shared.

48-7009-E 1-9

Page 16

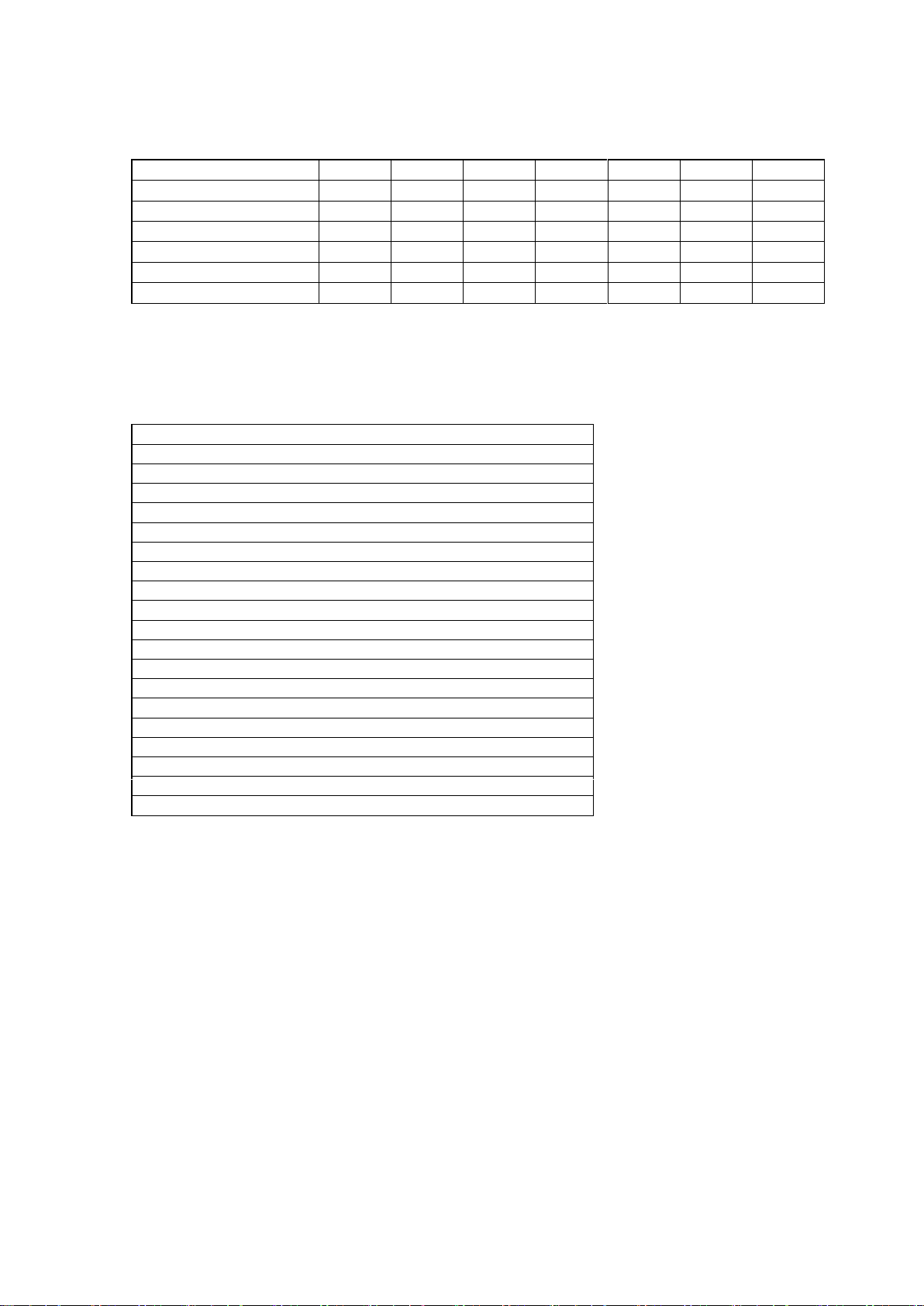

★ Assignment of outputs

Type of output

Output 1

Output 2

Output 3

Output 4

Output 5

Output 6

Output 7

Primary output (heating)

Secondary output (cooling)

Transmission output

Event output

Timer output

End output *1

Output assignment targets

Primary output

Secondary output

Event output

RUN output

RDY output

Timer 1 output

Timer 1 ON delay output

Timer 1 OFF delay output

Timer 1 ON+OFF delay output

Timer 2 output

Timer 2 ON delay output

Timer 2 OFF delay output

Timer 2 ON+OFF delay output

Timer 3 output

Timer 3 ON delay output

Timer 3 OFF delay output

Timer 3 ON+OFF delay output

Transmission output

End output *1

Each output can freely be assigned to output types.

○: Output assignment possible

×: Output assignment not possible

* At factory shipment, the output 1 is assigned to the primary output, and the outputs 2 to 7 to the secondary outputs.

*1: Selectable only for a program run.

★ Details on output assignment targets

Each output can individually be assigned to the following item.

*1: Selectable only for a program run.

■ Communication function

★ Communication

* This function is for communication with a host computer. (The communication function option is

required.)

* Communication protocol TOHO protocol

MODBUS protocol (RTU mode)

MODBUS protocol (ASCII mode)

* Interface RS485

* For detailed specifications, see pages 6-65 and 66.

★ Loader communication

* This communication function is for setting all data of TTM-200 series in a lump.

* In order to use the loader communication, the dedicated software for the communication must be

installed on the personal computer (PC) being used.

* To connect TTM-200 series to your PC, TOHO’s dedicated connection cable “TTM-LOADER” (sold

separately) is required.

(For the product specifications, see page 7-9.)

* When normal communication (or communication in option) is used (or active), the loader

communication cannot be used.

48-7009-E 1-10

Page 17

1.6 Basic flow of setting

Power-on

The mode changes to either “constant value run mode” or “program run mode” when four seconds are

elapsed after the power is turned-on.

Initial screen

4 sec

* Constant run value mode is established with the SET 21 operating type setting (C/P 0).

In addition, the SET 21 and 22 parameters are not displayed.

* With SET 23 bAF 1, the auto bank switchover function is selectable.

With bAF 0, the SET 23 parameters are not displayed.

Constant value run mode

* All setting item selection screens can move to the

constant value run mode screen.

MODE key for 2 seconds

The screen SET 01 appears when the run mode

screen moves to each setting item selection screen.

Each setting item selection screen

SET 01 - SET 23

* Using the ▲ /▼ key, the setting item selection

screens SET 01 to SET 23 are displayed in

sequence.

(In case of no function registered, the

corresponding screen is not displayed.)

(For bank auto-switchover, see page 6-15.)

Blind setting

screen

Parameter setting

screen in each

SET

* Each parameter setting

screen is displayed in

sequence when the MODE

key is pressed on the

parameter setting screen,

which is displayed when the

MODE key is pressed in each

setting item selection screen

(SET**). Holding the MODE

key pressed for at least 2

seconds moves each

parameter setting screen back

to the run mode screen.

Program run mode

* Program run mode is established

with the SET 21 operating type

setting (C/P 0).

* With SET 23 bAF 1,

the auto bank

switchover function

is selectable.

With bAF 0, the

SET 23 parameters

are not displayed.

MODE key for 2 seconds

Each setting item selection

screen SET 01 - SET 23

* Using the ▲ /▼ key, the setting item selection

screens SET 01 to SET 23 open in sequence.

(In case of no function registered, the

corresponding screen is not displayed.)

(For program run, see page 6-13.)

(For bank auto-switchover, see page 6-15.)

Blind setting

screen

Parameter setting

screen in each

SET

* All setting item selection screens can move

to the run mode screen.

* Each parameter setting screen

is displayed in sequence when

the MODE key is pressed on the

parameter setting screen, which

is displayed when the MODE

key is pressed in each setting

item selection screen (SET**).

Holding the MODE key pressed

for at least 2 seconds moves

each parameter setting screen

back to the run mode screen.

* A shortcut to SET 22 can be

made if FU* d is set for the

SET 3 function key function

setting.

(For details, see pages 6-12 and

13.)

* The screen moves back to the run mode screen in case of no key operation in each setting item

selection screen or parameter setting screen in each SET for about 2 minutes.

* For how to set the blind setting, see pages 4-27 and 28, the section 4-2-9 “Ba sic operation.”

48-7009-E 1-11

Page 18

2. Installation

Precautions on installation, installation method and outside dimensions are described in this chapter.

2.1 Precautions on installation ..................................................................................................................... 2-2

2.2 How to install or remove the equipment ................................................................................................ 2-3

2.3 Outside dimensions and panel cutting dimensions ................................................................................. 2-4

48-7009-E 2-1

Page 19

2.1 Precautions on installation

Warning

Ensure to turn the power supply off before beginning removal or reinstallation of the equipment in order to prevent

an electric shock or equipment failure.

★ Ambient temperature and humidity (the equipment to be used in the specified range as listed below)

(1) Temperature range: 0 - 50 °C

(2) Humidity range: 20 - 90% PH (no dew condensation allowed)

(3) Installation gradient: Base plane ± 10 degrees

★ Do not install the equipment in the following places.

(1) Where temperature abruptly changes to generate dew

(2) Where corrosive or flammable gases are generated

(3) Where water, oil, steam or chemicals are received

(4) Where vibration or noise is directly applied

(5) Where dusty or salty ambience, or many iron scraps is present

(6) Where direct sunlight is received

(7) Where circuits may negatively be affected by static electricity, noise or magnetism

(8) Where direct warm or cool air is received from an air-conditioner

★ Precautions on installation

(1) Provide sufficient space for ventilation so that the ambient temperature does not rise to 50 °C or

higher. In case that the temperature of 50 °C or higher is suspected, use a fan or air-conditioner to

cool the ambience.

Take care that no cold air flows directly on the equipment.

(2) Do not install the equipment on a device that may generate large heat, such as heater and

transformer.

(3) Install the equipment away as much distant as possible from high-voltage devices, power lines or

power equipment.

(4) Do not block off the ventilation opening on the equipment. Ensure a sufficient gap between

stacked units of equipment.

48-7009-E 2-2

Page 20

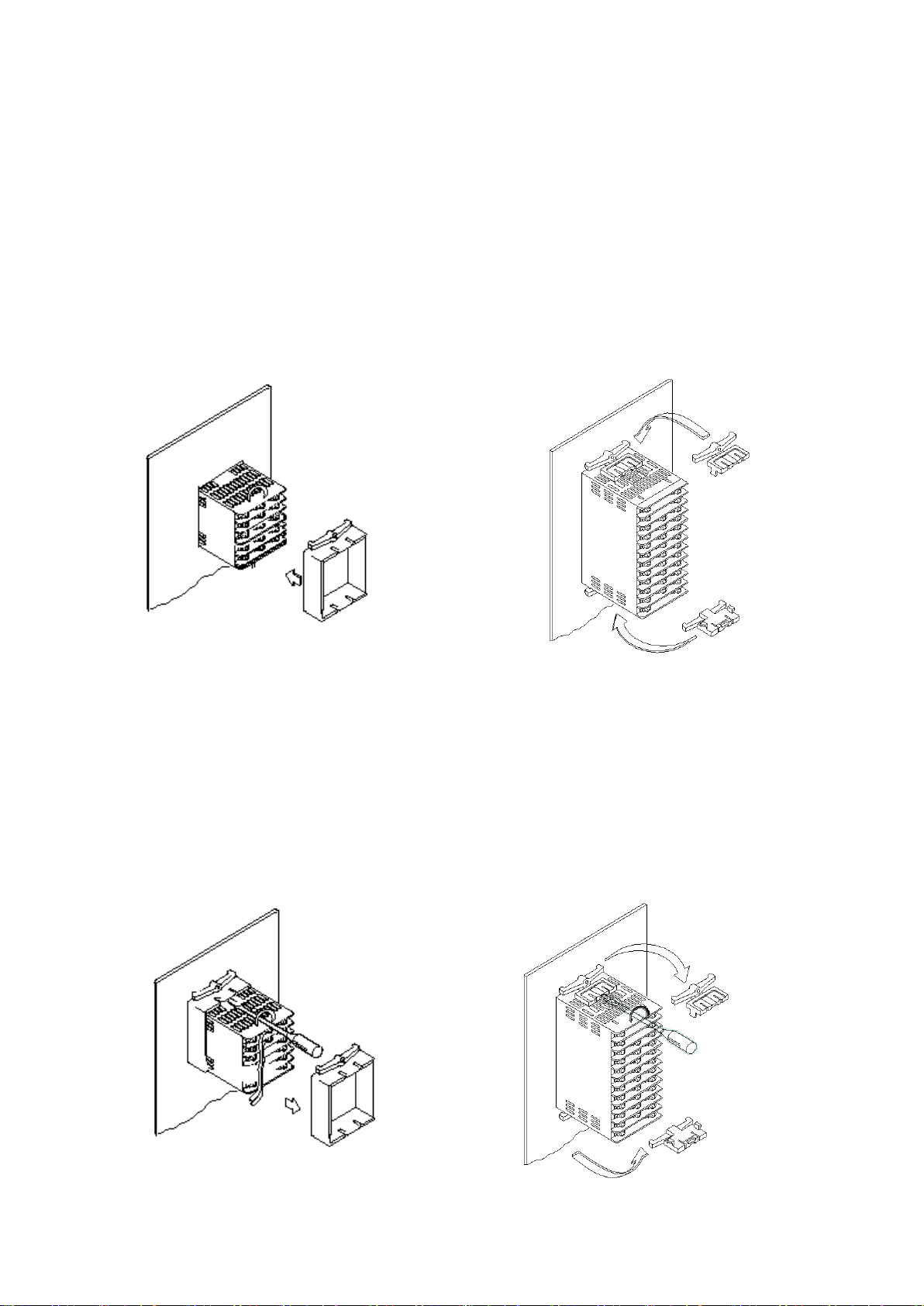

2.2 How to install or remove the equipment

★ Installation on a panel

(1) Make an opening on the panel.

(2) Insert the equipment into the opening.

(3) Install the mounting attachment from behind the panel. Ensure that the equipment is securely

fixed.

* Conduct wiring after the equipment is installed.

* Turn on the power after the wiring.

TTM-204 TTM-205/207/209

★ Removal from the panel

(1) Turn off the power.

(2) Disconnect the wiring.

(3) Insert a flat-head screw driver into the clearance formed between gabs on the equipment and

attachment. Turn the screw driver clockwise or counterclockwise to dislocate the gabs to remove

the attachment from the equipment.

(4) Remove the equipment from the panel.

* Ensure to conduct removal work after turning off the power.

TTM-204 TTM-205/207/209

48-7009-E 2-3

Page 21

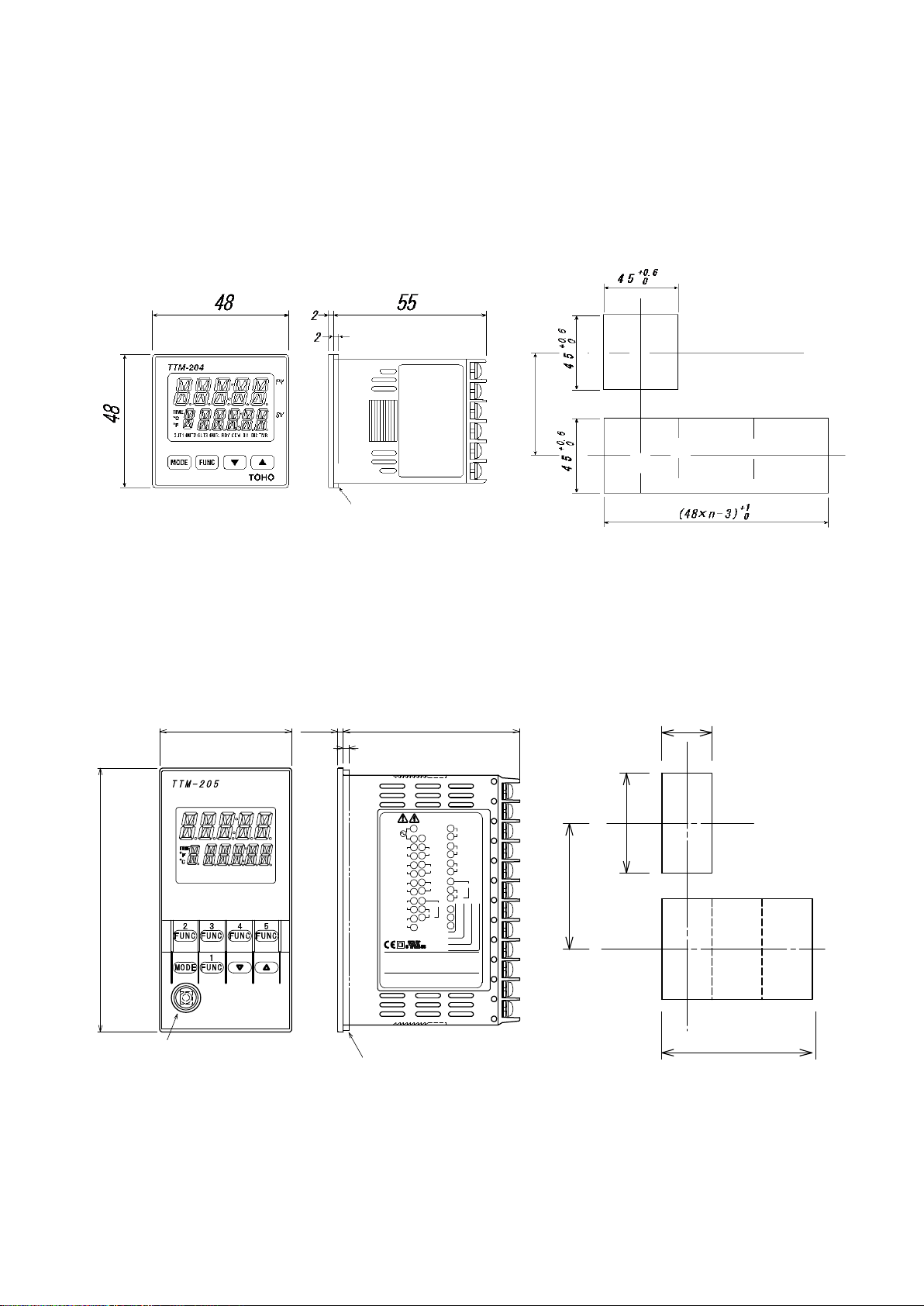

2.3 Outside dimensions and panel cutting dimensions

2

6 52

1

2

3

4

C-

NO+

OUT1

C-

NO+

C-

NO+

C-

NO+

C-

NO+

5

6

7

8

9

10

11

12

MADE INJAPAN

TOHO EL ECTRONICS INC.

++

-

DI4

-

+

DI2

34

33

32

31

30

-

+

DI1

29

28

27

26

(A)+

RS485

(B)-

+

-

DI3

+

A

I/V

RTD

TC/10mV

+ b

-

- B

24

23

22

C-

21

20

19

18

17

AI(I/V)

CT2

CT1

OUT4

C-

NO+

OUT3

NO+

+

-

16

15

14

13

SERIAL : * ****-* ****

100-240Vac~

50/60Hz

T O H O

PV

SV

DI3

OUT3

DI2

OUT2

DI1

OUT1

RDY

OUT5

COM

OUT6

TMR

OUT7

DI4

OUT4

ローダ通信端子

TTM-205-**-**********

48

9 6

OUT2

OUT5

OUT6

OUT7

25

11VA

パッキン

9 2

+0.6

0

4

5

+0.6

0

1

台取付時

n台取付時

(4 8×n - 3 )

+ 1

0

6

0 以上

When installing a single

unit of the equipment

When installing n

units of the equipment

Packing

60 or more

Packing

Loader communication

terminal

When installing a single

unit of the equipment

When installing n

units of the equipment

60 or more

Outside dimensions Panel cutting dimensions

Outside dimensions Panel cutting dimensions

48-7009-E 2-4

TTM-204

TTM-205

Page 22

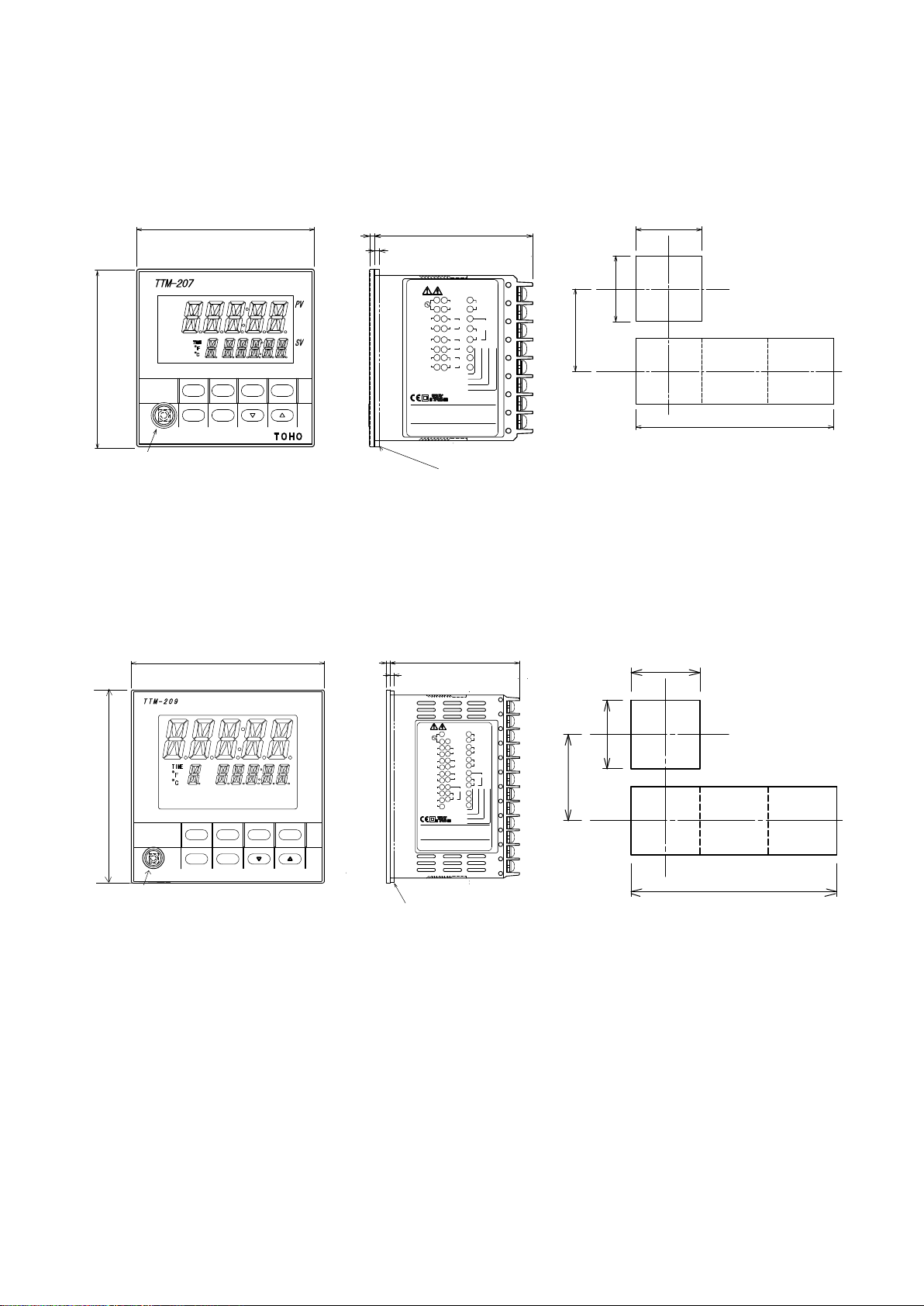

TTM-207

パッキン

2

652

ローダ通信端子

FUNC5FUNC4

MODE

FUNC2 FUNC3

FUNC1

1

2

100-240Vac~

50/60Hz

(A)+

(B)-

3

C-

+

4

NO+

-

C-

5

+

NO+

C-

6

7

-

OUT1

OUT2

DI1CT1

DI2CT2

RS485

AI(I/V)

+

-

NO+

+ b

C-

-

-

B

I/V

RTD

TC/10mV

NO+

8

+

A

NO+

C-

OUT4

OUT3

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

MADE INJAPAN

TOHO ELECTR O NICS INC.

SERIAL : *****-* * ***

TTM-207-**-**********

9

OUT5

OUT7

+

-

NO+

C-

DI3

11VA

DI3

DI2

DI1

TMR

COM

RDY

OUT5

OUT4

OUT3

OUT2

OUT1

OUT7

72

48

7 2

0

( 7 2× n - 3 )

+ 1

68

+

0

.

6

0

68

+

0

.

6

0

9

0 以上

1

台取付時

n台取付時

2

652

FUNC2

MODE

FUNC3 FUNC4 FUNC5

FUNC1

PV

SV

T O H O

OUT1 OUT2 OUT3 OUT4 OUT5 OUT6 OUT7

DI1 DI2 DI3 DI4 RDY COM TMR

ローダ通信端子

1

2

3

4

C-

NO+

OUT1

C-

NO+

C-

NO+

C-

NO+

C-

NO+

5

6

7

8

9

10

11

12

MADEINJAPAN

TOHO EL ECTRONICS INC.

++

-

DI4

-

+

DI2

34

33

32

31

30

-

+

DI1

29

28

27

26

(A)+

RS485

(B)-

+

-

DI3

+

A

I/V

RTD

TC/10mV

+ b

-

- B

24

23

22

C-

21

20

19

18

17

AI(I/V)

CT2

CT1

OUT4

C-

NO+

OUT3

NO+

+

-

16

15

14

13

TTM-209-**-**********

SERIAL : *****-**** *

100-240Vac~

50/60Hz

OUT2

OUT5

OUT6

OUT7

25

11VA

パッキン

96

96

1 2 0 以 上

9 2

+0.6

0

9 2

+0.6

0

1台取付時

n台取付時

(9 6 × n - 3 )

+1

0

Packing

Loader communication

terminal

When installing a single

unit of the equipment

When installing n

units of the equipment

90 or more

Packing

Loader communication

terminal

When installing a single

unit of the equipment

When installing n

units of the equipment

120 or more

Outside dimensions Panel cutting dimensions

TTM-209

Outside dimensions Panel cutting dimensions

48-7009-E 2-5

Page 23

3. Wiring

Precautions on wiring and arrangement of terminals are described in this chapter.

3.1 Precautions on wiring ........................................................................................................................... 3-2

3.2 Terminal arrangement ........................................................................................................................... 3-3

3.3 Wiring to each terminal ......................................................................................................................... 3-7

3-4 Examples of wiring ............................................................................................................................. 3-15

48-7009-E 3-1

Page 24

3.1 Precautions on wiring

Warning

Do not turn on the power until all wirings are complete in order to prevent an electric shock or equipment failure.

3.7

5.8

★ For inputs from a thermocouple, use the specified wires or compensating leads.

★ For inputs from a resistance temperature detector, use lead wires with small resistance and no resistance

difference is present among the 3 wires (3-wire type).

★ Provide input signal lines away from power supply lines, power lines or load lines so as not to affect input

signal lines with noise induction.

★ Wire the power supply for instruments such that they do not receive noises from the power supply for

power devices.

The use of a noise filter is recommended in case that the equipment is vulnerable to noises.

Take note of the following points when using a noise filter.

◎ Install the noise filter as close to a temperature controller as possible.

Wire the instruments in as short a distance as possible to output lines (secondary side) of the noise

filter and power terminals for the temperature controller.

◎ Isolate the noise filter input line (primary side) from its output line (secondary side).

High-frequency elements of noises may be induced, resulting in no provision of much noise

attenuation effect as expected, in case of input and output wires being close one another, such as

being bundled together or installed in a same duct or tube.

◎ Wire the grounding wire of the noise filter in as short a distance as possible.

A long grounding wire is like inserting an inductance, resulting in deteriorated high-frequency

characteristics.

◎ Before installing the noise filter, peel off the paint applied on a mounting plate of the noise filter as

★ For the power supply, use and twist wires that cause less voltage drop.

★ It takes about 4 seconds for the unit to activate after its power is turned on. Use delay relays when using

★ When using the unit with 24 V power supply, supply the power from a SELV circuit (power supply

★ When using the unit with DC24V power source, set ①-terminal to plus (+), ②-terminal to minus (-).

★ The equipment is not attached with power supply switch fuses. Separately install fuses in proximity of

★ Use crimping terminals that match the screw sizes.

★ For the communication ,use a shielded twisted pair cable.

appropriate, in order to reduce the contact resistance between the noise filter and equipment housing.

the equipment for generating signals for interlocking circuits.

secured with safety).

the equipment, as needed.

◎ Recommended fuse rating: Rated voltage of 250 V and rated current of 1 A

◎ Size of crimping terminal: Terminal width of 6 mm or smaller

Crimping terminal recommended

Manufacturer: NICHIFU

Model: ICTV-1.25Y-3N (Y terminal)

ICTV-1.25-3S (round terminal)

◎ Tightening torque recommended: 0.5 Nm (5 kgfm)

◎ Applicable wire

Use wires in sizes suitable for the terminals.

The use of shielded wires is recommended.

For Pt100 (resistance temperature detector), use identical wires of low lead resistance and no

resistance difference among 3 wires.

48-7009-E 3-2

Page 25

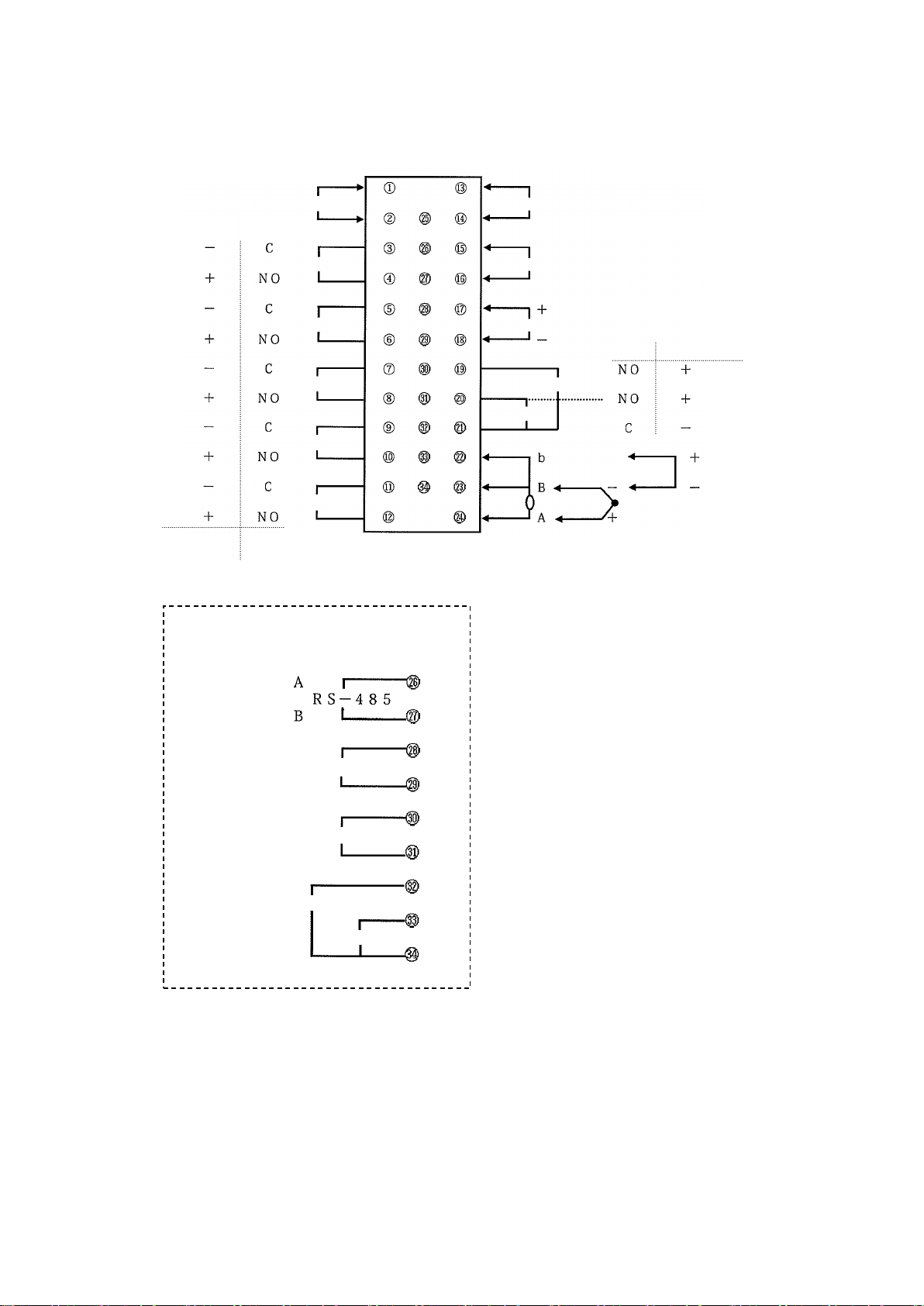

3.2 Terminal arrangement

* Outputs 3 and 4 are for common (C) shared

Relay Open collector

① ⑬ ⑦ NO +

Input power supply

② ⑭ ⑧

NO

+

Output 4

- C ③ ⑮ ⑨ C -

Output 1

+ NO ④ ⑯ ⑩ b +

- C ⑤ ⑰ ⑪ B - -

Output 2

+ NO ⑥ ⑱ ⑫ A +

Relay RTD input TC input Analog input

0 - 10 mV input

Output 3

Other than

relay output

A ⑬ A ⑬ A ⑬

RS-485 RS-485 RS-485

B ⑭ B ⑭ B ⑭

⑮ ⑮ ⑮

CT 1 input DI 1 input CT 1 input

⑯ ⑯ ⑯

⑰ ⑰ ⑰

CT 2 input DI 2 input DI 2 input

⑱ ⑱ ⑱

* Only the above can be selected

for the model with CT and DI.

Specifications for communication

and 2 points of CT

Specifications for communication

and 2 points of DI

Specifications for communication,

1 point of CT and 1 point of DI

Main body rear surface terminals

+ + + - -

-

Notation for terminal arrangement is as follows.

C: Common

NO: Normal open

+, -: There is polarity for wiring.

A, B, b: There is designation for wiring.

CT: Current transformer input (no polarity)

DI: Digital input

RTD: Resistance temperature detector input

TC: Thermocouple input

I: Current input

V: Voltage input (excluding 0 - 10 mV)

* Parameters can be used for changing input types. (Multi-input)

* “NO” and “C” for outputs are for the equipment model with relay contact output. “+” and “-” for

other than the equipment model with relay contact output.

* Terminal block is not provided in case the model selection is not made at the product model.

★ TTM-204

48-7009-E 3-3

Page 26

★ TTM-207

Input power supply

Output 1

Output 2

Output 5

Other than

relay output

Relay

(The output 5 is only for an open collector.)

AI input (models in voltage and current)

Output 3

Output 4

Relay

Open collector

* Outputs 3 and 4

are for common

(C) shared

RTD input

TC input

0 - 10 mV input

Analog input

Main body rear surface terminals

48-7009-E 3-4

Page 27

CT 1 input

CT 2 input

Output 7

Open collector

Relay

NO

DI 1 input

DI 2 input

DI 3 input

CT 1 input

DI 2 input

Output 7

Open collector

Relay

NO

CT 1 input

DI 2 input

DI 3 input

RS-485

RS-485

+ + + + + + - - - - -

-

+

-

NO

C

+

-

NO

C

Communication + 2 points of CT + Output 7 Communication + 3 points of DI

Communication + 1 point of CT + 1 point of Communication + 1 point of CT +

DI + Output 7 2 points of DI

48-7009-E 3-5

Page 28

★ TTM-205/209

Other than

relay output

Relay

Input power supply

Output 1

Output 2

Output 5

Output 6

Output 7

AI input (models in voltage and current)

Relay

Open collector

* Outputs 3 and 4 are for common (C) shared

Output 3

Output 4

RTD input

TC input

0 - 10 mV input

Analog input

CT 2 input

CT 1 input

DI 1 input

DI 2 input

DI 3 input

DI 4 input

Main body rear surface terminals

+ + +

+ - -

-

Communication + DI

48-7009-E 3-6

Page 29

3.3 Wiring to each terminal

TTM-204

Terminal Nos. ① and ②

TTM-205

TTM-207

TTM-209

Type of power supply

Fluctuation range

Frequency

Power consumption

100 to 240 VAC

85 to 264 VAC

50/60 Hz

10 VA or less

24 VAC

21.6 to 26.4 VAC

50/60 Hz

4 W or less

24 VDC

21.6 to 26.4 VDC

4 W or less

Type of power supply

Fluctuation range

Frequency

Power consumption

100 to 240 VAC

85 to 264 VAC

50/60 Hz

11 VA or less

24 VAC

21.6 to 26.4 VAC

50/60 Hz

6 W or less

24 VDC

21.6 to 26.4 VDC

6 W or less

* Isolation diagram

Where relays and open collectors are included in

outputs

Where outputs are SSRs, current outputs or voltage

outputs

Power supply circuit

Power supply circuit

PV input

CPU circuit

Output 1

PV input

CPU circuit

Output 1

AI input

Output 2

AI input

Output 2

CT input

Outputs 3 to 7

CT input

Outputs 3 to 7

DI

Communication

DI

Communication

In connection diagrams, left side of the terminal number represents inside the equipment while right side

shows the external side of the equipment.

★ Power supply

TTM-204

TTM-205/207/209

* Wire the power supply for instruments in such a way that they don’t receive noise from the power supply of the

power devices.

The use of a noise filter is recommended in case that the equipment is vulnerable to noises.

Take care the following when a noise filter is used.

◎ Install the noise filter as close to a temperature controller as possible.

Wire the instruments in as short a distance as possible to output lines (secondary side) of the noise filter and

power terminals for the temperature controller.

◎ Isolate the noise filter input line (primary side) from its output line (secondary side).

High-frequency elements of noises may be induced, resulting in no provision of much noise attenuation effect as

expected, in case of input and output wires being close one another, such as being bundled together or installed in

a same duct or tube.

◎ Wire the grounding wire of the noise filter in as short a distance as possible.

A long grounding wire is equivalent to insert of an inductance, resulting in deteriorated high-frequency

characteristics.

◎ Before installing the noise filter, peel off the paint applied on a mounting plate of the noise filter as appropriate, in

* For the power supply, use and twist wires that has lesser voltage drop.

* It takes about 4 seconds for the unit to activate after its power is turned on. Use delay relays when

* In case of using the equipment with a 24 V power supply, supply the power from a SELV circuit

* The equipment is not supplied with power supply switch fuses. Separately install fuses in proximity

* The input power supply and the input/output are isolated one anther on the equipment.

order to reduce the contact resistance between the noise filter and equipment housing.

using the equipment for generating signals for interlocking circuits.

(power supply secured with safety).

of the equipment, as needed.

◎ Recommended fuse rating: Rated voltage of 250 V and rated current of 1A

* No. of outputs depends on specifications and models. Isolated

* Outputs 3 to 7 are isolated. ------ Non-isolated

48-7009-E 3-7

Page 30

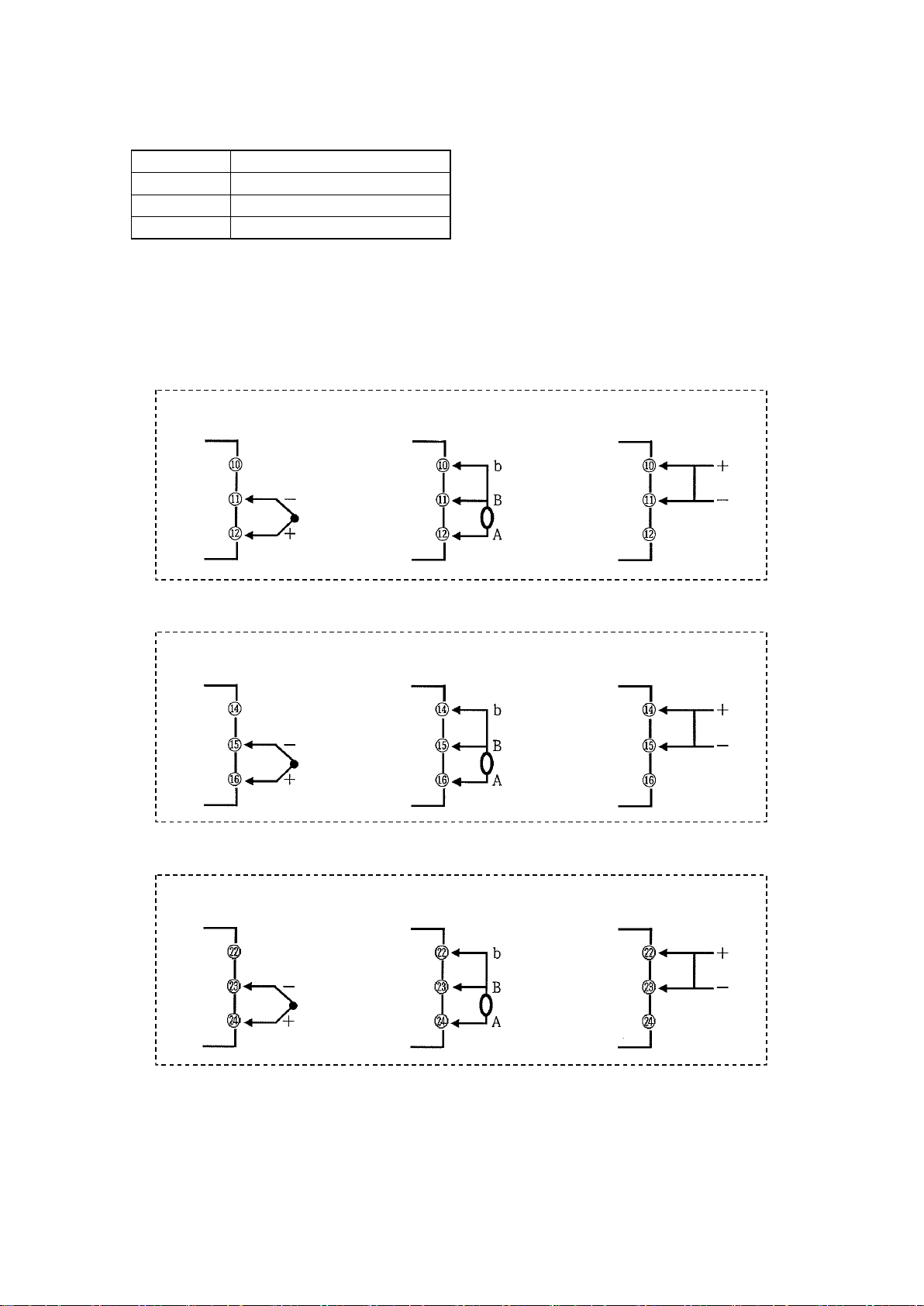

★ Input

TTM-204

Terminal Nos. ⑩, ⑪ and ⑫

* Use sensors that match the types of inputs.

(“K thermocouple” is set as factory default.)

* For thermocouple input, use wires or compensated

leads.

* For input from resistance temperature detector, use

wires that the wire resistance of leads is small and no

resistance difference is present among 3 wires (3-wire

type).

* Provide input signal lines distant from power supply

lines, power lines or load lines so as not to affect input

signal lines with noise induction.

TTM-205

Terminal Nos. ○22, ○23 and ○24

TTM-207

Terminal Nos. ⑭, ⑮ and ⑯

TTM-209

Terminal Nos. ○22, ○23 and ○24

Thermocouple 0 - 10 mV

Resistance temperature

detector

Analog input

TTM-204

Thermocouple 0 - 10 mV

Resistance temperature

detector

Analog input

TTM-205/209

Thermocouple 0 - 10 mV

Resistance temperature

detector

Analog input

TTM-207

48-7009-E 3-8

Page 31

★ AI input (current and voltage only)

TTM-205

Terminal Nos. ⑰ and ⑱

TTM-207

Terminal Nos. ⑨ and ⑩

TTM-209

Terminal Nos. ⑰ and ⑱

TTM-204

Terminal Nos. ⑮, ⑯, ⑰ and ⑱

TTM-205

Terminal Nos. ⑬, ⑭, ⑮ and ⑯

TTM-207

Terminal Nos. ⑲, ⑳, ○21 and ○22

TTM-209

Terminal Nos. ⑬, ⑭, ⑮ and ⑯

* When the event input (DI 1 or

DI 2) is selected, CT 1 or CT 2

are not selectable.

* When the event input (DI 2) is

selected, CT 2 is not selectable.

* When the event input (DI 1 or

DI 2) is selected, CT 1 or CT 2

are not selectable.

* When the event input (DI 2) is

selected, CT 2 is not selectable.

TTM-204

TTM-207

TTM-205/209

TTM-207 TTM-205/209

* AI input is optional.

(TTM-204 is not equipped with AI input.)

* Provide input signal lines distant from power supply lines, power lines or load lines so as not to affect

input signal lines with noise induction.

★ CT (current detector) input

* CT input is optional.

* Heater disconnection failure is detected by CT (current detector) when the heater disconnection alarm

is effective.

* CT possible to be used is “CTL-6-P-N”

* Max. 2 points are selectable (to be designated at order placement).

* CT input is not selectable for analog output.

48-7009-E 3-9

Page 32

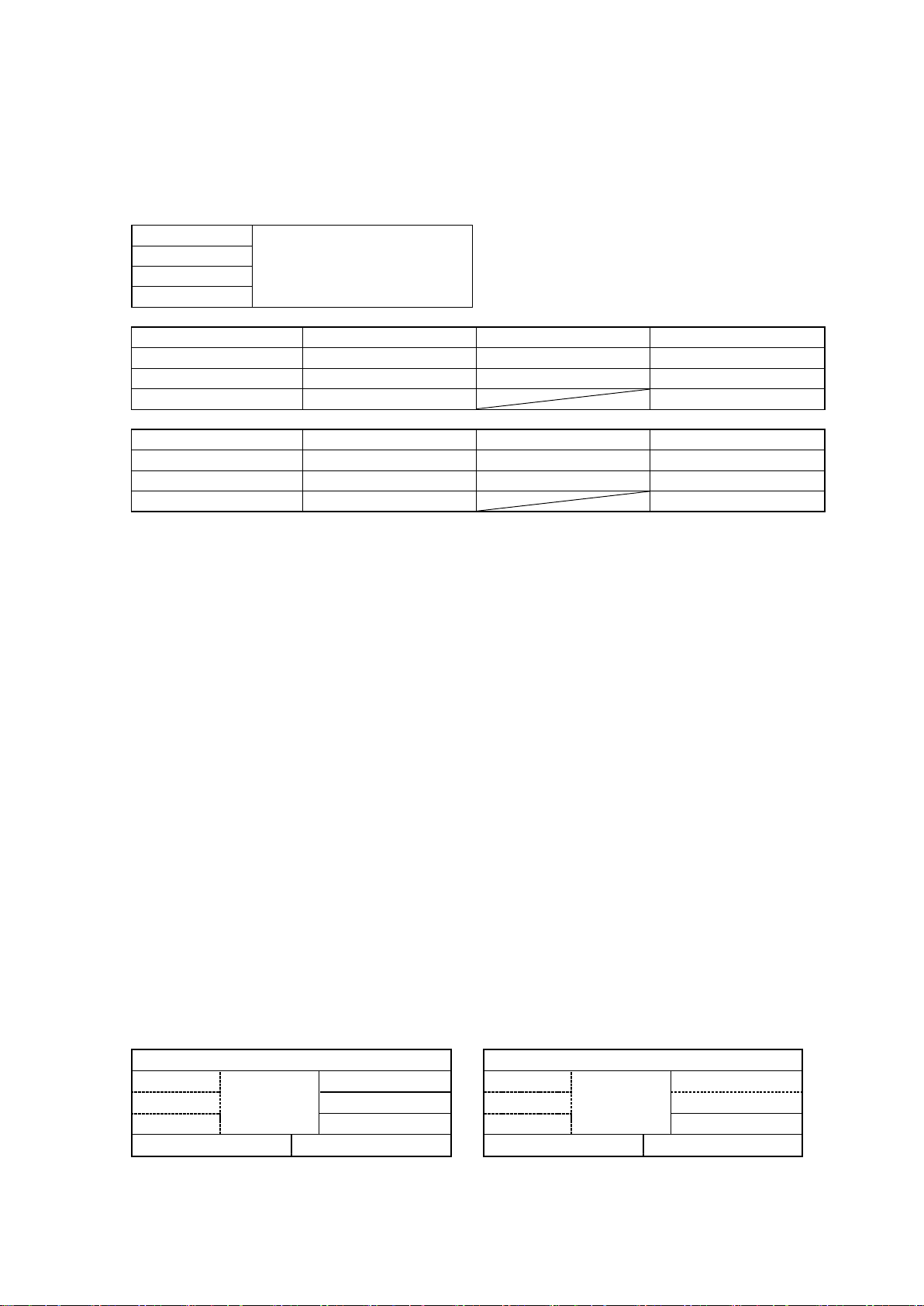

★ Event (DI) input

TTM-204

Terminal Nos. ⑮, ⑯, ⑰ and ⑱

TTM-205

Terminal Nos. ○28, ○29, ○30, ○31, ○32, ○33 and ○34

TTM-207

Terminal Nos. ⑲, ⑳, ○21, ○22, ○23 and ○24

TTM-209

Terminal Nos. ○28, ○29, ○30, ○31, ○32, ○33 and ○34

* When CT 1 or CT 2 is

selected, DI 1 or DI 2 are not

selectable.

* When CT 1 is selected, DT 1

is not selectable.

* When CT 1 or CT 2 is

selected, DI 1 or DI 2 is not

selectable.

* When CT 1 is selected, DI 1 is

not selectable.

* When the output 7 is selected,

DI 3 is not selectable.

TTM-204

TTM-207

TTM-205/209

* For TTM-205/209, the common for

DI 3/DI 4 is shared.

Close

Active

Bank switchover

Bank switchover

During constant value run

MD

READY

During program run

Start

Stop

MD

MANUAL

Reverse operation

Forward operation

AT stop

AT start

Timer Stop

Timer Stop

Constant value run

Program run

Step feed (during program run) *1

Pause (during program run) *1

Interlock *1

- - - - - - - - + + + + +

+ + +

+

* DI input is optional.

* Max. 4 points are selectable (to be designated at order placement).

* The following functions can be executed through the DI (digital) inputs.

The DI inputs are external no-voltage contact signals.

* List of functions due to DI

48-7009-E 3-10

*1: Selectable only for a program run.

Close: Contact signal OFF

Active: Contact signal ON

Page 33

★ Communication function

TTM-204

Terminal Nos. ⑬ and ⑭

TTM-205

Terminal Nos. ○26 and ○27

TTM-207

Terminal Nos. ⑰ and ⑱

TTM-209

Terminal Nos. ○26 and ○27

Communication

TTM-204

TTM-207

TTM-205/209

Communication

Communication

* There are two types of communication functions, the “communication” and “loader communication”.

The “Communication” is optional.

★ Communication

* This function is for communication with a host computer. (The communication function option is

required.)

* Communication protocol

TOHO protocol

MODBUS protocol (RTU mode)

MODBUS protocol (ASCII mode)

* Interface

RS485

★ Loader communication

* This communication function is for setting all data of TTM-200 series in a lump.

* In order to use the loader communication, the dedicated software for the communication must be

installed on the personal computer (PC) being used.

* To connect TTM-200 series to your PC, TOHO’s dedicated connection cable “TTM-LOADER” (sold

separately) is required.

48-7009-E 3-11

Page 34

★ Output

Model

Terminal No.

Output 1

Output 2

Output 3

Output 4

Output 5

Output 6

Output 7

TTM-204

③ and ④

⑤ and ⑥

⑦ and ⑨

⑧ and ⑨

TTM-205

③ and ④

⑤ and ⑥

⑲ and ○21

⑳ and ○21

⑦ and ⑧

⑨ and ⑩

⑪ and ⑫

TTM-207

③ and ④

⑤ and ⑥

⑪ and ⑬

⑫ and ⑬

⑦ and ⑧

○

23

and ○24

TTM-209

③ and ④

⑤ and ⑥

⑲ and ○21

⑳ and ○21

⑦ and ⑧

⑨ and ⑩

⑪ and ⑫

Type of output

Output 1

Output 2

Output 3

Output 4

Output 5

Output 6

Output 7

Primary output

(heating)

Secondary output

(cooling)

Transmission

output

Event output

Timer output

End output

Relay contact

250 VAC, 3 A (resistance loads) and 1a contact

Voltage for SSR drive

0 - 12 VDC (load resistance: 600 or greater)

Open collector

24 VDC, 100 mA (load current)

Voltage

0 - 5 VDC, 1 - 5 VDC and 0 - 10 VDC

(resistance loads: 1 k or greater)

0 - 1 VDC and 0 - 10 mVDC (load resistance: 500 k or greater)

Current

4 - 20 mADC (load resistance: 600 or less)

Relay contact

250 VAC, 1 A (resistance loads) and 1a contact

Open collector

24 VDC, 100 mA (load current)

Output 1

Output 2

Outputs 3 and 4

Relay

SSR/current/voltage/

open collector

Relay

SSR/current/voltage/

open collector

* Outputs 3 and 4 are for common shared

Relay

Open collector

Assignment of outputs

: Output assignment possible

: Output assignment not possible

Type of output and specification

* Outputs 1 and 2

* Outputs 3, 4, 5, 6 and 7

TTM-204

48-7009-E 3-12

Page 35

TTM-207

Output 1

Output 2

Outputs 3 and 4

Output 5

Relay

Output 7

SSR/current/voltage/

open collector

Relay

SSR/current/voltage/

open collector

Relay

Open collector

Relay

Open collector

* Outputs 3 and 4 are for common shared

Relay

Open collector

48-7009-E 3-13

Page 36

TTM-205/209

Output 1

Output 2

Outputs 3 and 4

Output 5

Relay

Output 6

SSR/current/voltage/

open collector

Relay

SSR/current/voltage/

open collector

Relay

Open collector

Relay

Open collector

* Outputs 3 and 4 are for common shared

Relay

Open collector

Output 7

Relay

Open collector

○

19

○

20

○

21

* Max. 7 points of outputs are provided. They are usable for control output, event output, RUN/RDY

output, transmission output, and timer outputs (3 points).

They should be designated at order placement. See the model table on page 1-3.

* No. of outputs selectable depends on models. In the table “★ Output” on page 3-12, cells filled

with diagonal lines indicate that none is selectable. Selection can also be checked on the model table

on page 1-3.

* “NO” and “C” for outputs are for the equipment model of relay contact output. “+” and “-” for

outputs are for other than the equipment model of relay contact output. Properly wire outputs to

target connections, as target connections are designated.

(Take sufficient care the polarity “+” and “-” when wiring.)

48-7009-E 3-14

Page 37

3-4 Examples of wiring

Temperature sensor

(K thermocouple)

External

relay

Heater

★ Connection configuration

★ Configuration example

TTM-204

Heater

External

relay

K thermocouple

* Take care when wiring, as thermocouple

has polarity of “+” and “-.”

Power

supply

(Example) TTM-204

Power

supply

Terminal No.

Description

①

Power supply

②

③

Output 1

Common

④

Normal open

⑤

Output 2

Not used in this case.

⑥

⑦

Output 3

Output 4

Not used in this case.

⑧

⑨

⑩

Input

Not used in this case.

⑪

“-” side

⑫

“+” side

⑬

Communication

Not used in this case.

⑭

⑮

CT or DI input

Not used in this case.

⑯ ⑰ ⑱

1) Input: K thermocouple, output 1: relay contact output and single phase 100 V

Terminal description for the above wiring example

48-7009-E 3-15

Page 38

2) Input: resistance temperature detector, output 1: SSR drive voltage and single phase 100 V

★ Configuration example

Temperature sensor

(resistance

temperature detector)

(Example) TTM-209

TTM-209

Heater

★ Connection configuration

Power

supply

Heater

Resistance

temperature

detector

* Take care wiring, as “A,” “B” and “b” are

designated on a resistance temperature detector.

TRS1245

SSR

Power

supply

Terminal

No.

Description

Terminal

No.

Description

①

Power supply

⑲

Output 3

Output 4

Not used in this case.

② ⑳ ③

Output 1

“-” side

○

21

④

“+” side

○

22

Input

b

⑤

Output 2

Not used in this case.

○

23

B ⑥

○

24

A

⑦

Output 5

Not used in this case.

○

25

This terminal is not used.

⑧

○

26

Communication

Not used in this case.

⑨

Output 6

Not used in this case.

○

27

⑩

○

28

DI input

Not used in this case.

⑪

Output 7

Not used in this case.

○

29

⑫

○

30

⑬

CT input

Not used in this case.

○

31

⑭

○

32

⑮

○

33

⑯

○

34

⑰

AI input

Not used in this case.

⑱

Terminal description for the above wiring example

48-7009-E 3-16

Page 39

3) Input: resistance temperature detector, output 1: SSR drive voltage and 3-phase 200 V

Temperature sensor

(resistance temperature

detector)

(Example) TTM-204

* Usable SSR in 3-pahse 200 V is a product

with the input current of 10 mA or less.

Heater

★ Connection configuration

★ Configuration example

Heater

* Take care when wiring,

as SSR has polarity of

“+” and “-.”

* Take care wiring, as “A,” “B”

and “b” are designated on a

resistance temperature detector.

Power

supply

Resistance

temperature

detector

-

SSR

+

-

SSR

+

Power

supply

Terminal No.

Description

①

Power supply

②

③

Output 1

“-” side

④

“+” side

⑤

Output 2

Not used in this case.

⑥

⑦

Output 3

Output 4

Not used in this case.

⑧

⑨

⑩

Input

b

⑪

B

⑫ A ⑬

Communication

Not used in this case.

⑭

⑮

CT or DI input

Not used in this case.

⑯

⑰

⑱

* SSR may be shorted out

due to its internal failure.

The use of “temperature

fuses” or an

“over-temperature

prevention device” is

recommended to cut off the

output circuit of SSR.

Terminal description for the above wiring example

48-7009-E 3-17

Page 40

4) Input: K thermocouple, output 1: SSR drive voltage, output 2: relay contact output and single phase 100

Temperature sensor

(K thermocouple)

★ Configuration example

(Example) TTM-205

External

relay

Refriger-

ator

Heater

Power

supply

★ Connection configuration

* SSR may be shorted out due to its internal failure. The use of temperature

fuses or an over-temperature prevention device is recommended to cut off

the output circuit of SSR.

K

thermocouple

* Take care when wiring,

as thermocouple has

polarity of “+” and “-.”

Refriger-

ator

External

relay

Heater

TRS1245

Power

supply

Terminal

No.

Description

Terminal

No.

Description

①

Power supply

⑲

Output 3

Output 4

Not used in this case.

②

⑳

③

Output 1

“-” side

○

21

④ “+” side

○

22

Input

Not used in this case.

⑤

Output 2

Common

○

23

“-” side

⑥

Normal open

○

24

“+” side

⑦

Output 5

Not used in this case.

○

25

This terminal is not used.

⑧

○

26

Communication

Not used in this case.

⑨

Output 6

Not used in this case.

○

27

⑩

○

28

DI input

Not used in this case.

⑪

Output 7

Not used in this case.

○

29

⑫

○

30

⑬

CT input

Not used in this case.

○

31

⑭

○

32

⑮

○

33

⑯

○

34

⑰

AI input

Not used in this case.

⑱

V (heating/cooling control)

Terminal description for the above wiring example

48-7009-E 3-18

Page 41

5) Input: K thermocouple, output 1: relay contact output, output 2: transmission output and single phase

★ Configuration example

(Example) TTM-204

TTM-204

Temperature sensor

(K thermocouple)

External

relay

Heater

Recorder

★ Connection configuration

External

relay

Heater

K

thermocouple

* Take care when wiring, as

thermocouple has polarity of “+”

and “-.”

Power

supply

Power

supply

Terminal No.

Description