Page 1

TOI{O

trLECTRONICS

INC.

Thank

Please

This

you

go

Instruction

r\:

T}is chapter

Controller

B:

This chapter B

'lhis

C:

NOTICBNVARNING

O

'

Conftrnt

For confinrration

purchasing

for

through

Manual

chapter

merchandises

tlte

this Instruction

model TtM-1

model

is composed

indicates

explains how

indicates

TTM-I525

Manual carefully

necassary

2 5in

5

the specifications,

BETORB

hand

at

of model nzune,

DIGITAL

CONTROLLBR

TTM-1s2s

INSTRUCTION

Digital

of

the following

NoticeMaming,

proper

operate

to

manner.

the

USAGE

show the

please

refer

Controller.

and use the

parameter

maintenance/inspection

correct

to

the

MANUAL

(3)

three

Installation

for

model

and

following

unit in proper

chapters:-

and

using

this digital controller

optional function.

ORDENNG INFORMATION.

minner.

Wiring method

and example

to

of usage.

use

the Digital

efficiently.

1

)

Ordering

Information

TTM

peratu

Tem

I

-

5VDC

15 ?rf-tr

relHumiditv

Control

Type

fnput

|

2

Output

Option

t2

SSR drive volt

No

Xt:

Communication RS-485

85V

-

setting

264

of

Power

"N''

Supply

at Output

1

Only Input

1-

2

Feedback resistance.

has

Page 2

2) Pacl<irtg Contents:

'

Check,

if all the

'

Instruction Manual(This

attachments are at

'FittingMetals"

Unit seal

'

your

booklet)

hand.

'lset

'I

'

1

booklet

sealpaper

Iu case anv of

'

Please bc

the

noted

above are

that types of

missins or

Input

l-lou,cver, the types of Thermocouple and

' Please

'

Copy or

hand

Reprint

over this

Instruction

of this

Manual

manual,

a

different

Output cannot be

and

R. T. D. input

to the

wholly or

partially,

' T'he contents of this manual may change without

'

Plcasc bc

3)

noted

that rve

Notice/Warning before usage:

' The

following symbol marks

not be responsible to all of the

shall

In case of

WARNINC

A

operator such as death, electrocution

In case of mishandling, it may

CAUTION

A

unit

or

are used

mishandling,

to the operator

included,

operator of unit and

is

prior

notice

in

serious danger may

slight

please

altered after receiving the

can be changed.

permitted.

not

in future.

defaults resulted

this Instruction

and

cause some damage

injury.

contact our business department.

unit.

keep it

with care.

by using of the

Manual for handling

occur to

a skin bum.

the

to the

unit.

this model

safely.

CAUTION

'

Do not

push

\l/ARNING

Makc

sure the

Mis rviring

Nevcr remodel

(i.

the keys

conect wiring connection before

may

by sharp

cause malfttnction

the

unit for

inq

connection

points

of the unit

prevention

FG

of

of malfunction

terminal.

e. Ball-point-pen,

turning

and may cause

on electricity.

unit

of

metals)

fire.

a

and fire.

prevention

for

of its malfunction.

-2

Page 3

on

I

t, roduc

rr

O

NO'TiCE/WARNING

o

Ordering Information'

1)

Packins

2)

3)

Notice/Warning

INSTALLATION

A.

1.

Panel

l.

l

1.

2 External

l)

t.

l.

4

l.

5

Wiring Method

2.

I 1'ernrinal Iayout

2.

t i

contents'

Installation

Parrel cut

and

of

external

Chart

Installation

Locat.ion

2.2 Notice/Warning

ll

lixarnples

2.

l) ltrput. l'2

0utput I

2)

Output 2

3)

z!)

OPDRATIC)N

B.

Event

Output l'2'

BEFORE

AND

dimensions

USAGE

'

before

lryIRING

Method

usage' '

-----'4

dimensions 4

Panel

cut dimensions

dimensions

--

Method 5

unit installation

of

wiring

for

wiring

at

of eaclt

-

wiring

---'---

IIETHOD

---

3. 0peration Flow and

3.1 Display

3.2

1

2

2

Each

l)BasicMode-

2)Set-up

3)Contro1 ConstanL

4)0ption

5)Feedback

6)Function Key

0ther displays

3.3

4. Definitions

4.1 Auto-tuning

PID Control

4

5

5

6

6

6

7

7

4.2

4.3 Event

4. 4 Additional

l)Event

2)Stand-by sequence

3)Process

4.5 Input

C.

SPECIFICATIONS

1 . General

2, Specification

3 .

Maintenance

conditions

Parameter Information

-

Mode

Setting

resistance Adjustment

Functions

Output

Functions

0utput Hold

Value(PV

display range & Setting

Specifications

Performance'

a.nd Inspect ion

Parameter

Setting

Mode

Setting

&

0N/0FF Control

Abnormal)

Mode

Mode

'

Standard and

--

' '

---'

-

Mode

-' 28

--'--'

range

''

-

-"'

.

1

15

17

20

24

27

27

28

28

29

29

29

4

29

30

31

31

33

I)oscript.ion

1.

0peration

1. I

Information

l.2

Change

I.3

Precaution

2.

Preparation

2. I

Preltaration

2.2

0ther Preparation

2.3

0ption

l)

2) Event.

llvent Input(SV

i

Event

i

Dvent

i

Function

3)

4) Blind

5)

Auto-tuning

of each

and Functions'

Key Information

of

Method

part

Display

of each Display

of Control'

of Set-up Mode

of Remote

Control

Sltting

Input/0utput

Input(RLN/READY)

Mode

Change)

0utput

Setting

Key

Setting

Mode

Setting

part

unit

Mode

--

------'

-----

---

-

-----"'11

-------'

-------'

--'

------

4. Example

7

B

B

B

9

9

12

13

1 3

3

1

3

1

3

1

4

1

Remote

Control

unit

-

33

-3:

Page 4

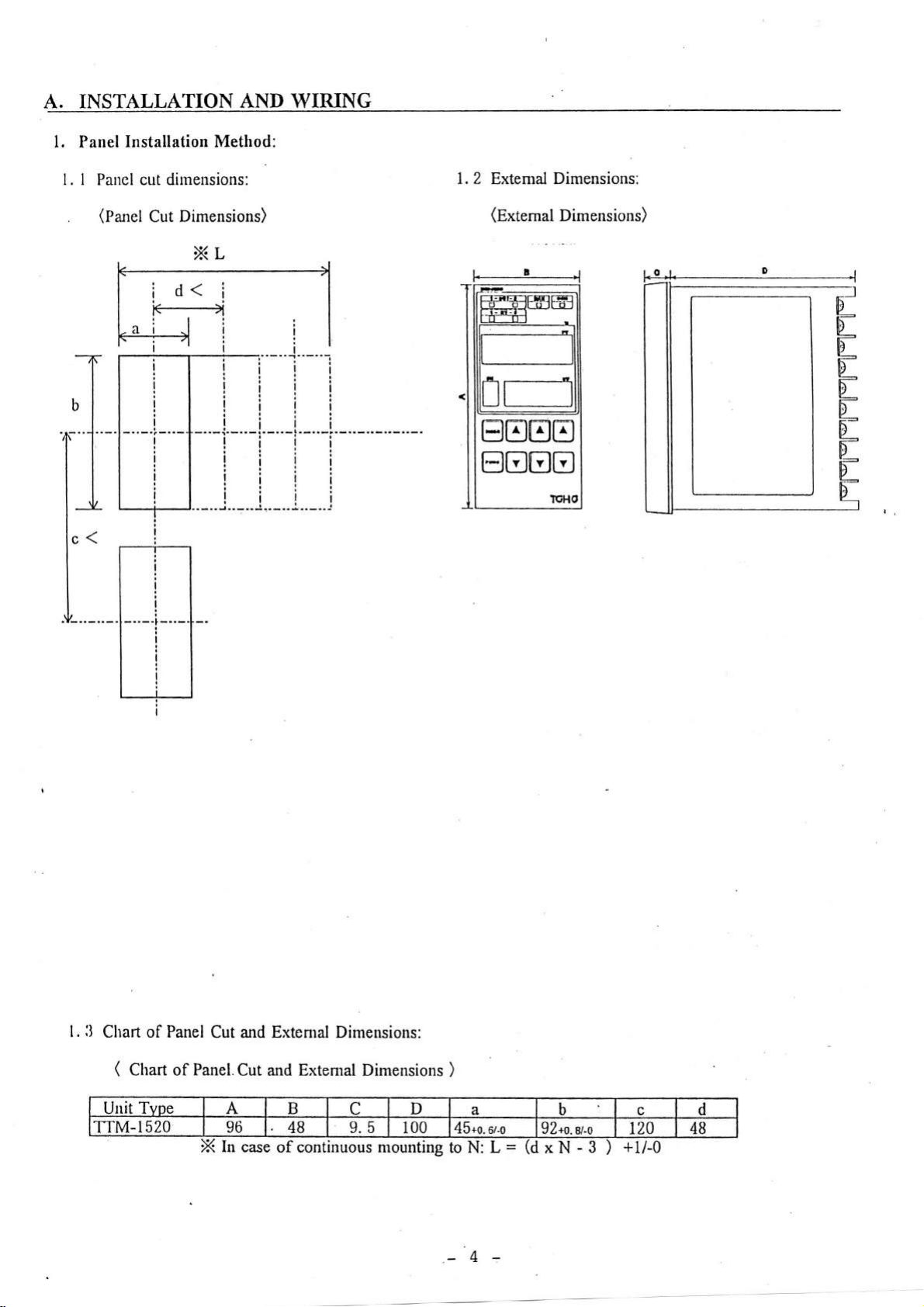

A. INSTALLATION

AND

WIRING

l. Panel

Installation Method:

l. I Paucl cut dirneusions:

(Panel

.

Cut Dimensions)

1. 2

Extenral

(Extemal

Dimensrons:

Dimensions)

ll

l.

Chart of Panel

(

Ctrurt

Unit Tvoe A B

TTM-1520 96

Cut and Extental Dimensions:

Panel.Cut

of

and Extemal Dimensions

48 9.5

In case

of continuous

C

D

100 45*0.

mounting

rg

)

a

sr.o

to N: L

-4

=

b

92+0. el-o

xN-3

)

120

+l/-0

c d

4B

Page 5

1. 4 Installation Method:

5

1.

Location of Unit Installation:

For

installation,

Tcnrperature and Flurnidity are within the linrit of operation environment.

'

.

Arvny from tlre

.

Alvay from electric

.

Less mechanical vibration

.

Arvay frorn

.

Away from tlre

please

gas

direct sunshine and not to be exposed by vvind and rain.

the

direct

make sure the following points

of sulfide and corrosion,

and the int'lttcnce of electromagnetic

noise

and shock.

darnplless

or the flood with watcr.

dust and oil.

and install thc unit at

field.

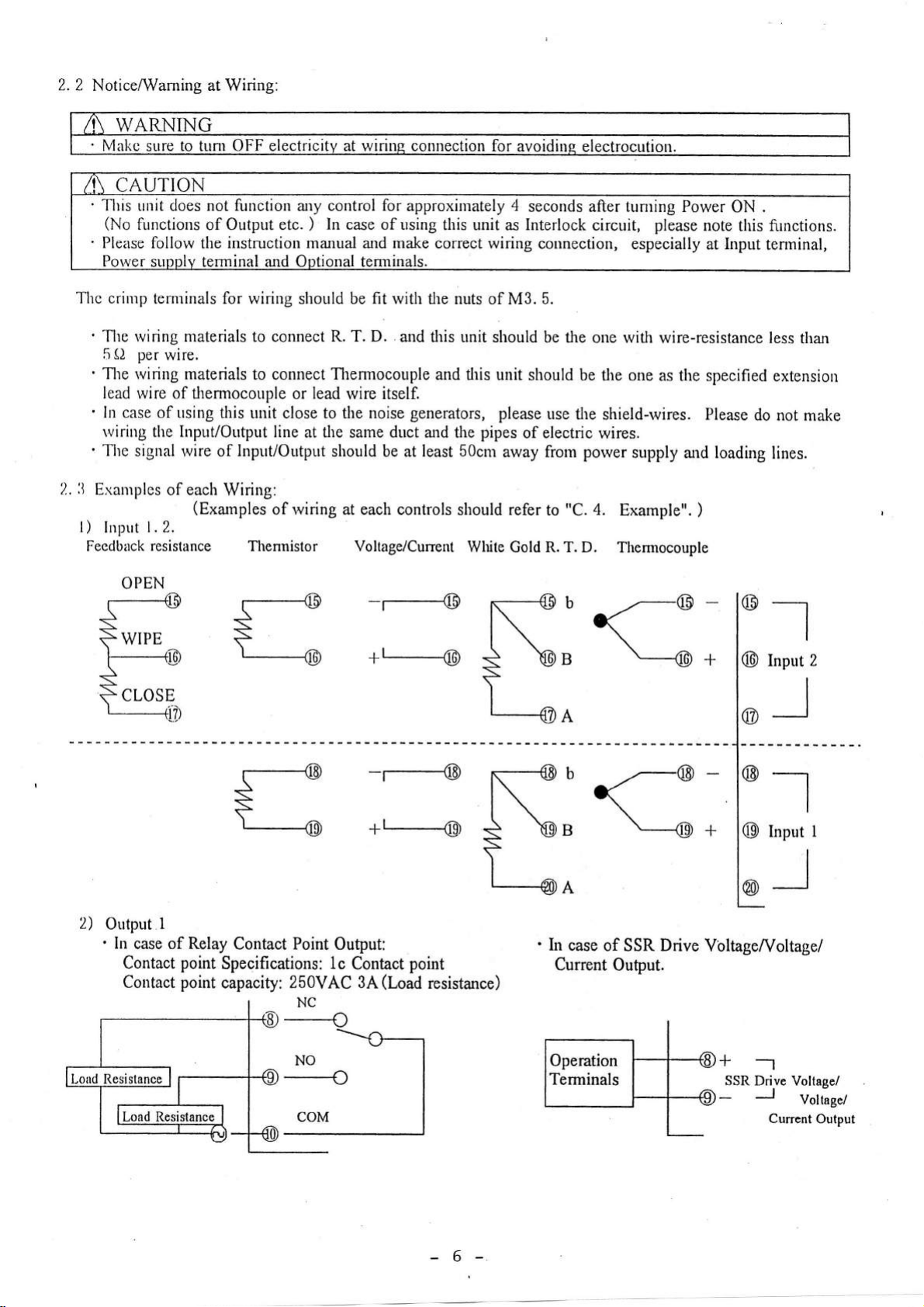

2. WIRING METHOD

Z. 1 Terminal Layout for

r/R(A)

r/R(B)

t

-------{O

OUTPUT2

'(D

+

--'--<o

*AA:

--r---tq

-

*BB

:

+CC

+DD

Wiring:

rc---c

----------f)

AC/DC

24V:.

-HU

----{D

----€)

NO

.-,._€

C

Nc

------{A

No

---{o

c

----<D

Y

TTM-

1s2s

ftD----------,-

TVENT TNPUT/OUTPUT1

I

(D-

63a)______]_

] TVeTTINPUT/OUTPUT2

(q+

(rs)----

x>/

(Xt

6d-\-

:

(H*

f

c

INPUT2

T

'D/

c

INPUTl

--

',

--'+

r-

,

--r+

C

/

V

9

/

V

the proper

----r

T

Jn

----Lr

tH

---:

locations:-

FEEDBACK

RESISTANCE

R

T

D

R

T

D

@--..

(6H

/,')

It I

Y

{

5

>F

AA

*

I]B

*CC

*DD

drive

SSR

current /

Relay contact

Relay contact

voltage

voltage

(outputl)

(output2)

(outputl

)

-5

Page 6

2. 2

NoticeAVaming at Wiring:

CAUTION

flris

uuit does

(No

functions

Please

Porver supply terminal

follow tlie

F

not

filnction any

Output etc.

of

instruction

electricity at

control for

In

)

manual and

Optional

and

wiring connection for

approxirnately

case of using

make

temrinals.

this unit

correct wiring

avoidinc electrocution.

4

seconds after tunring Power

Interlock

as

connection,

circuit,

please

especially

ON

note

this firnctions.

Input

at

.

tenninal,

Thc crirlp terminals

'

The rviring materials

5 O per

'

The rvinng materials

lead

'

ln case

rviring the

'

TIre signal

li

2.

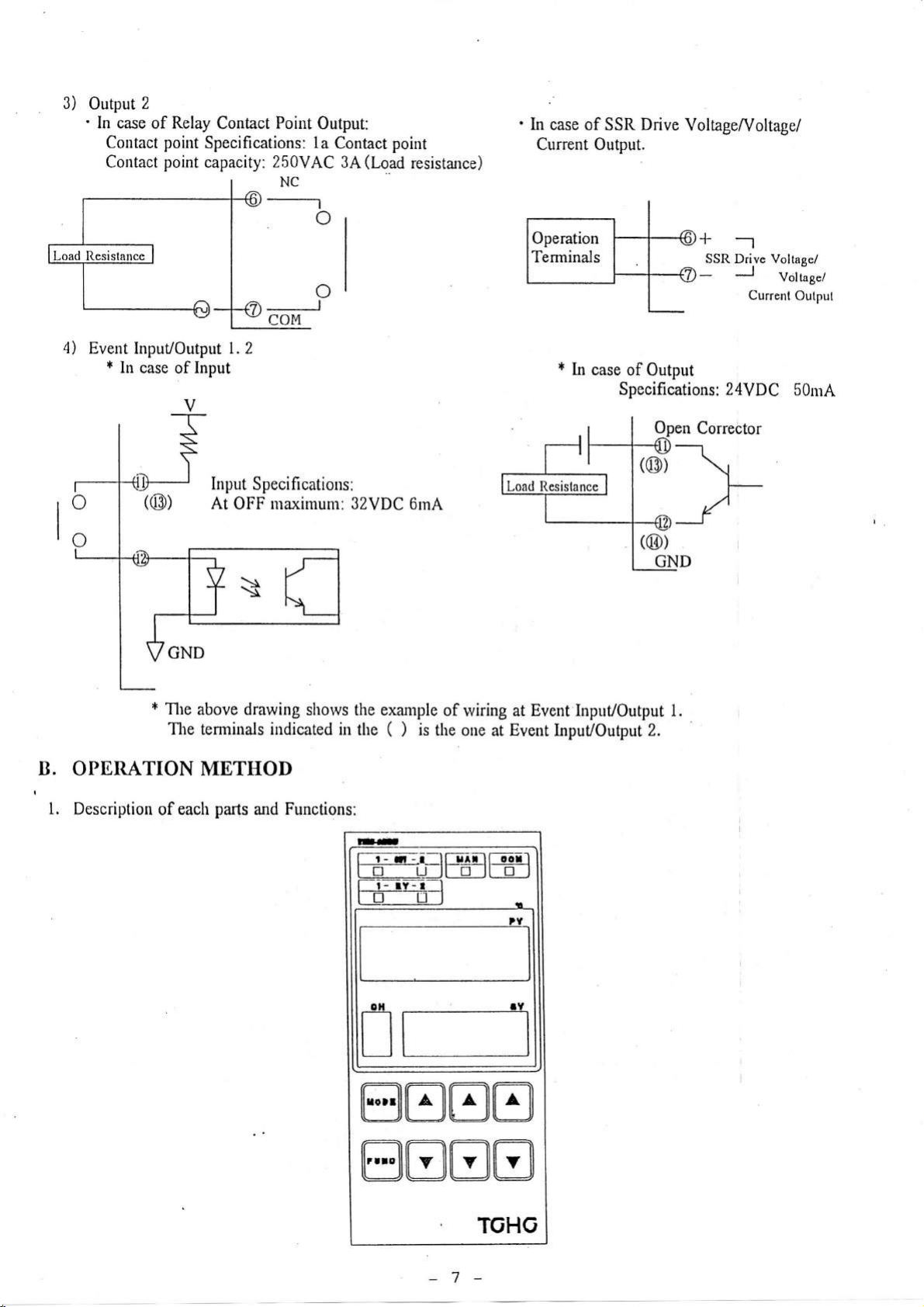

Exanrples

l)

Input

Feedback resistance Thennistor

wire,

wire of thermocouple

of

of

1.2.

OPEN

for wiring should be fit with

connect R. T. D.

to

to connect Thermocouple

using

this

unit close

Input/Output

tvire of

each

Wiring:

(Exarnples

line

Input/Output

of

the nuts of M3.5.

and

this

and flris

lead

or

rviring at each controls

rvire itself.

noise

generators,

least SOcm

to

the

at the same duct ald

should be at

Voltage/Cunent

-r------@

+L@

unit

should

unit

pipes

the

should refer

White Gold R. T. D.

N'<-@-

S

be the

should be

please

use

flre shield-rvires. Please

of electric wires.

away from

to

"C.

s

'@

one with wire-resistance less

one

the

porver

supply

4.

Exampte".

Thermocouple

\---@

L_*^

as the specified

do not

and loading

)

@r

+

@l

than

extensiorr

make

lines.

2

Input

2)

Output

' In

case of Relay

Contact

Contact

I

point

Specifications:

point

capacity:

Contact

Point Output:

1c

Contact

250VAC 3A

NC

_c

-rc-l

Nol

----o

coM

point

(Load

resistance)

I

I

I

N*o

\,

s

L-*^

In

Current Ouput.

Operation

Terminals

^--@

\-*.

case

of SSR

-

Drive

VtlltageA/oltage/

@r

@

+-1

SSR Drive

J

Input

__l

Voltage/

Currcnt

I

Voltagc/

Output

-6

Page 7

3)

Output

'

4)

Event InpuVoutput l.2

2

In case of Relay

In case

(@)

point

point

of

Contact

Contact

*

Contact Point

Specifications:

capacity:

Output:

la

250VAC

NC

Contact point

3A

o

Input

Input

Specifications:

At OFF maximum: 32VDC

(Load

resistarce)

6rnA

ln

case of SSR Drive

*

In

case of

Output.

Specifications:

Current

Voltagef/oltage/

+--1

SSR

Output

Corrector

Drive Voltagci

Voltage/

Current

24VDC

Output

50mA

GND

*

Tlte

above drawing

The

tenninals

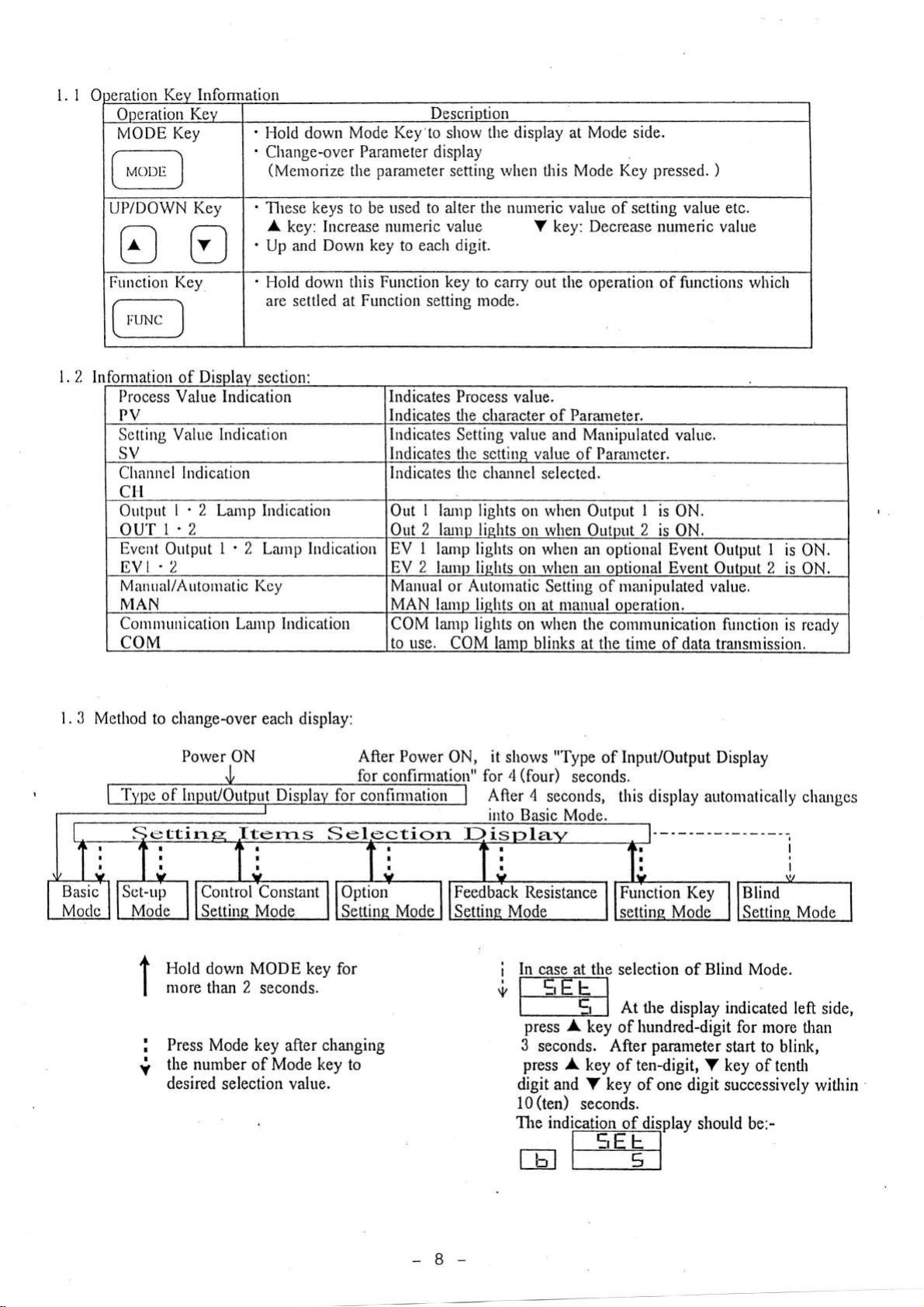

OPBRATION METHOD

B.

l.

Description

of each

parts

indicated

Functions:

and

shotvs

in

the example

(

the

fr- rl

l--E--u-

T-i- rY-r-l

is

)

-i-ll-

of lviring

the one

u^--ll-

lfE_l[

at

tE_:El

o,l

nn

Event Input/Output

at

Event

Input/Output

oorl

-.l

p

i

.Y

1.

2.

@tr8tr

@BtrB

7-

Page 8

1.10

Ooeration

MODE

Key

In

Kev

' IJold

'

down

Change-over

(Menrorize

Description

Mode Key to show the

Parameter display

parameter

the

setting

display

rvhen

at Mode

Mode Key

this

side.

pressed.

)

1.2 ln

'

UP/DOWN Key

EO

Function Key

fonnation

Process Value Indication

PV

Setting Value Indication

SV

Chanrtel Indication

of

Di

These keys to

A

key: Lrcrease numeric value

and

Up

'

Hold down this

are settled

secilon

ctr

Output

I' 2

La.nrp Indication

ou'[1.2

Everrt

Outptfi

.2

EVt

Manual/Automatic

IVIAN

Corrrntuuication Lanrp Iudication

COM

|' 2

Larnp

I(cy

Indication

Down

at

to

used

be

key to

Futrction key to

Function

Indicates Process

Indicates the

Indicates

Indicates the

Indicates

Out

Out

EV

EV 2 liunp

Mauual

alter the

each digit.

setting

I

lunp lights

2 lamu

I

larnp lights

MAN lanru lishts

COM lanrp lights

to use.

nuureric

Y key:

carry

out the operation of frrnctions which

mode.

value.

character of

Setting

tlie channel selected.

or

COM

value

settins

on

lishts

on rvhen Outout

on when an

lights

on rvhen

Autontatic

on at nranual ooeratiou.

on when the communication

lamp

and

value

rvhen

Setting of ma-uipulated value.

blinks at the time

value of setting value etc.

Decrease numeric value

Pararneter.

Manipulated

Paraueter.

of

Output I is ON.

optional

an

optional Event Output 2

2

value.

is

ON.

Event

of

Output

function

data

trarsmission.

I

is

is ON.

is ready

ON.

l. 3

Method

Sr:ttire

to change-over each display:

Porver

ON After Power

terns

Control

Hold

down MODE key for

nrore

t

I

I

I

V

than

Press Mode key

the

number of Mode

desired

'Constant

2

seconds.

selection

after

value.

Sel

changing

key

to

it

ON,

iotr" for 4

Feedback

shows

After 4

i

i l--trE-tr]

"Type

(four)

secouds, this

Resistance

Il case at

of

seconds.

Function Key

the selection of

f--51

A

press

3

seconds. After

press A

digit and Y key

10(ten)

The indication

key of hundred-digit

key

of ten-digit,

seconds.

rtrtril

tE

l---E-l

InpuUoutput

display automatically

At ilre

parameter

of one digit

of

display

Display

Blind

display indicated

start to

key

V

successively

should be:-

I

I

Blind

ine Mode

Mode.

for more

blink,

of tenth

chzurges

left

side,

than

within

-B

Page 9

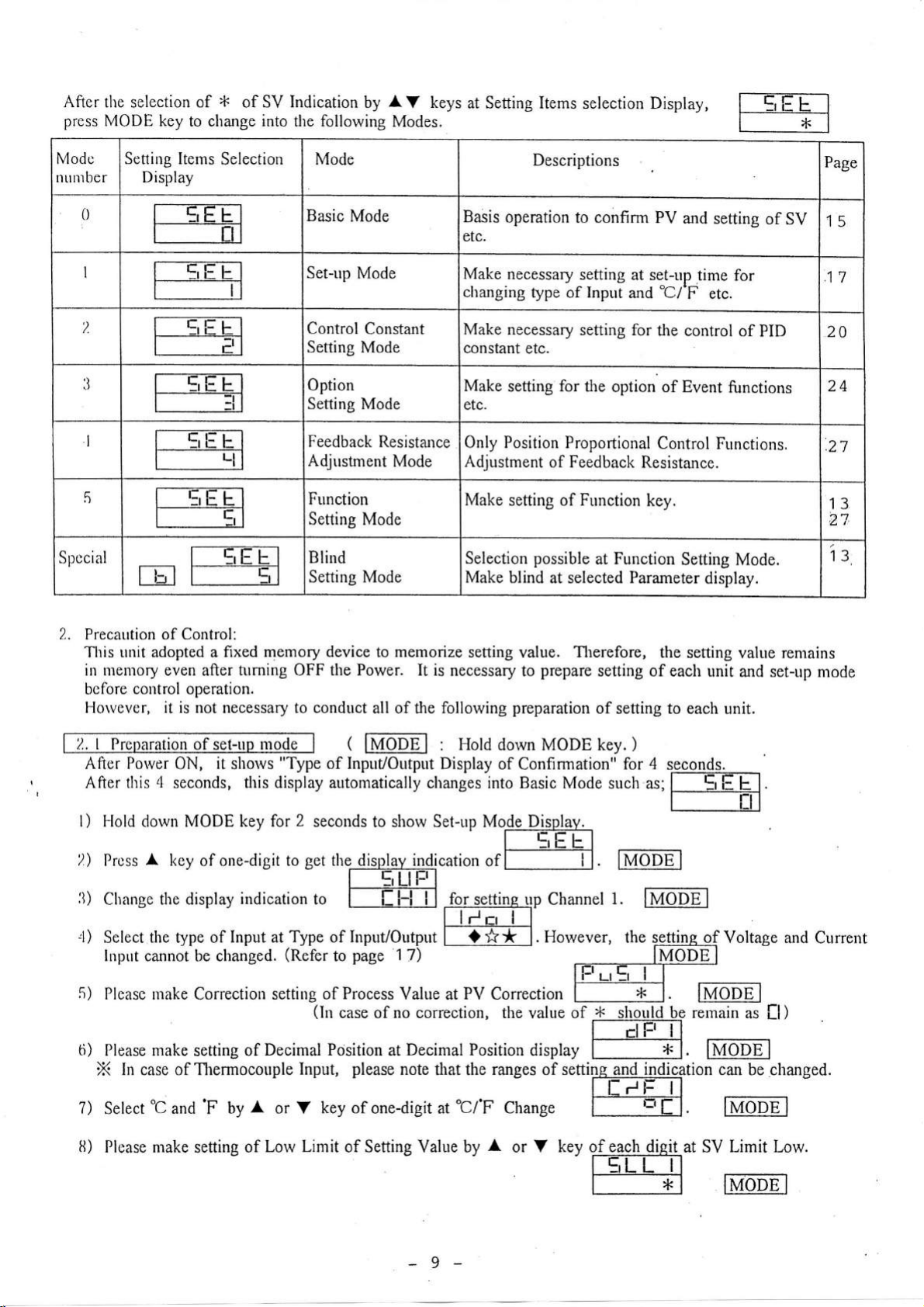

After

the selection of

press

MODE key

*

change into

to

of SV Indication

following

the

by

A

V keys

Modes.

at Setting Items

selection Display,

Modc

ntrnrber

0

I

?.

,)

.)

I

5

Special

Setting Items

Display

E

Selection

Mode

Basic

Mode

Set-up

Control

Setting Mode

Option

Setting Mode

Feedback

Adjustment

Function

Setting

Blind

Setting Mode

Mode

Constant

Resistance

Mode

Mode

Descriptions

Basis

operation

etc.

Make necessary

changing

Make necessary

constant

Make

etc.

Only Position

Adjustment

Make

Selection

Make blind

type of Input

etc.

setting

for

Proportional

of

setting

of Function

possible

at selected Parameter

to confirm PV

setting at set-up

'CI'F

and

setting

Feedback

for

the

the

option of Event

Control

Resistance.

key.

at Function

and setting

of

time for

etc.

control of

Setting Mode.

display.

PID

functions

Functions.

SV

Page

15

17

20

24

.21

13

2l

iz

2.. Precaution of Control:

This unit adopted a

in menrory even

bcfore control operation.

Horvever, it is not

2.rP

ion of

fixed memory device

turning

after

necessary to condnct

set-up

After Porver ON, it shorvs "Type

After this

l) I-lold

))

Pre

3)

Change the display

,l)

Select tlre rype of

Input

5)

ri)

zl

seconds, this display

MODE key for

dorvn

I

key of one-digit to

ss

Input

cannot be changed.

indication

the

OFF

mode

2

set

Type of Input/Output

at

(Refer

Power. It is

(

lMotE I

of

Input/Output Display

automatically

seconds

thediq+#f;Ecation

to

fTFl-l-l

page

to

memorize

to

of the follorving

all

shovv Set-up MolglDjfpley-

to

1

7)

setting

necessary

Hold

:

changes into Basic Mode

value.

to

preparation

dorvn MODE key.

of

Confinnation" for

_EEEI

of

I

for

settinq up Channel

i-l'

tr,

fi7

I

<)**

I.

Therefore,

prepare

I

I

Holever,

the

setting

setting of each

of

setting

such as;

)

to

4

seconds.

each unit.

f!--EEEI

l---Til

.

I

.

lMopE I

value remains

unit and set-up mode

Voltage

remain

as

il )

and Current

lMopEl

can be

changed.

7)

Select

r.t

Please make

)

"C

and

'F

by

setting

A

or V key

Lorv Limit

of

of

one-digit at'CfF

of Setting Value by

9-

Change

A

or V kev

lNropEl

of

'rErrTl

each

diqit

at SV

Limit

f---l lmpEl

Low.

Page 10

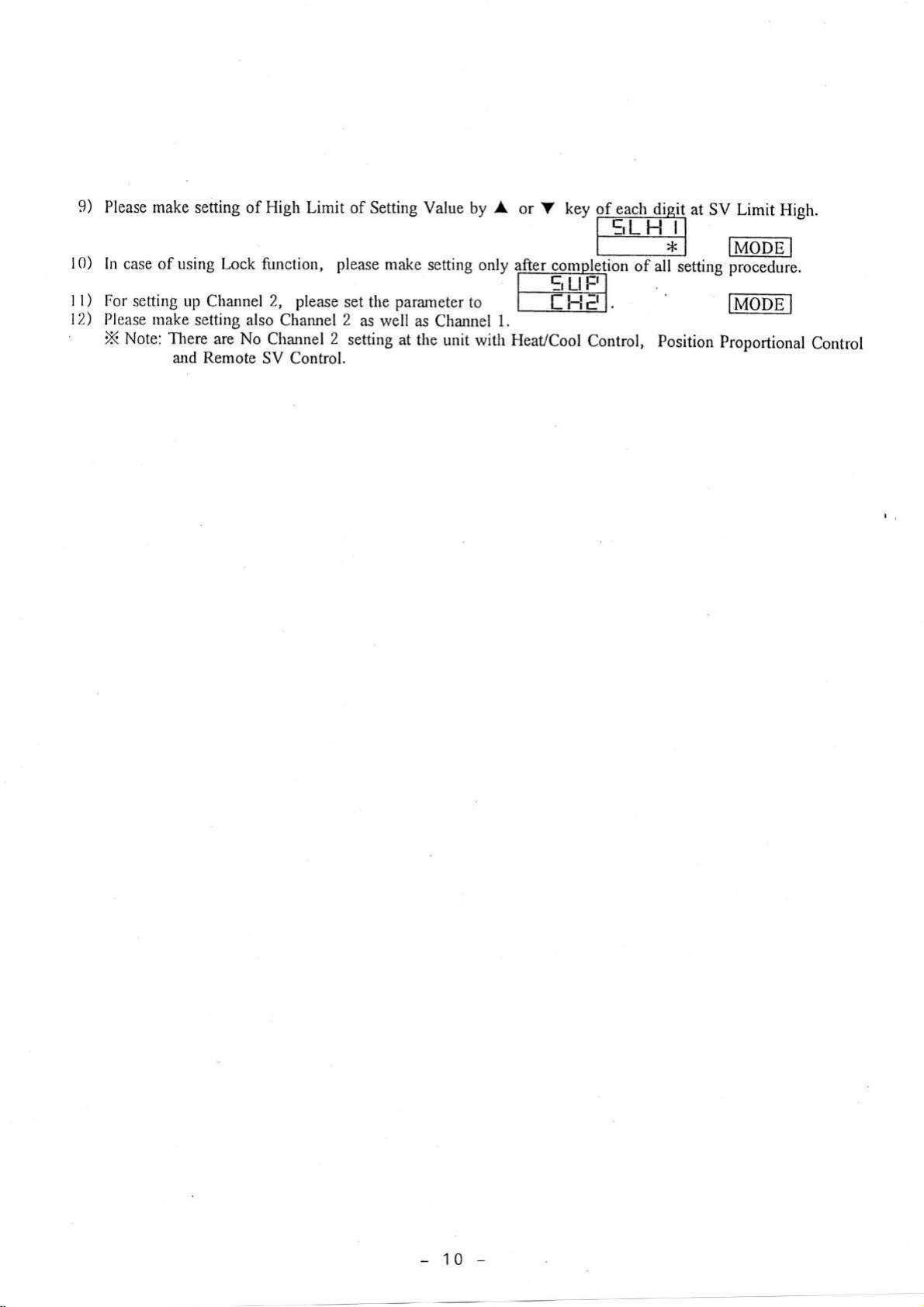

9)

Please make

setting of High Limit

of Setting Value

by

A

or V

key

of each

-rtrtFi-i-l

dieit

at SV Limit

High.

l0)

I

12)

t)

In case

For

Please

X

of using Lock

setting up

make setting

Note: There

and Remote

Channel

also

are No

function,

2, please

Channel

Channel

SV Control.

please

set the

2

2

setting

as

well

make

setting

parameter

as

Channel

at the

only

to

1.

unit

with HeaVCool

f--ak I

rmpletion

Ii-F-t

E

Control,

of all

setting procedure.

Position

lMOpEl

mpEl

Proportional

Control

10

Page 11

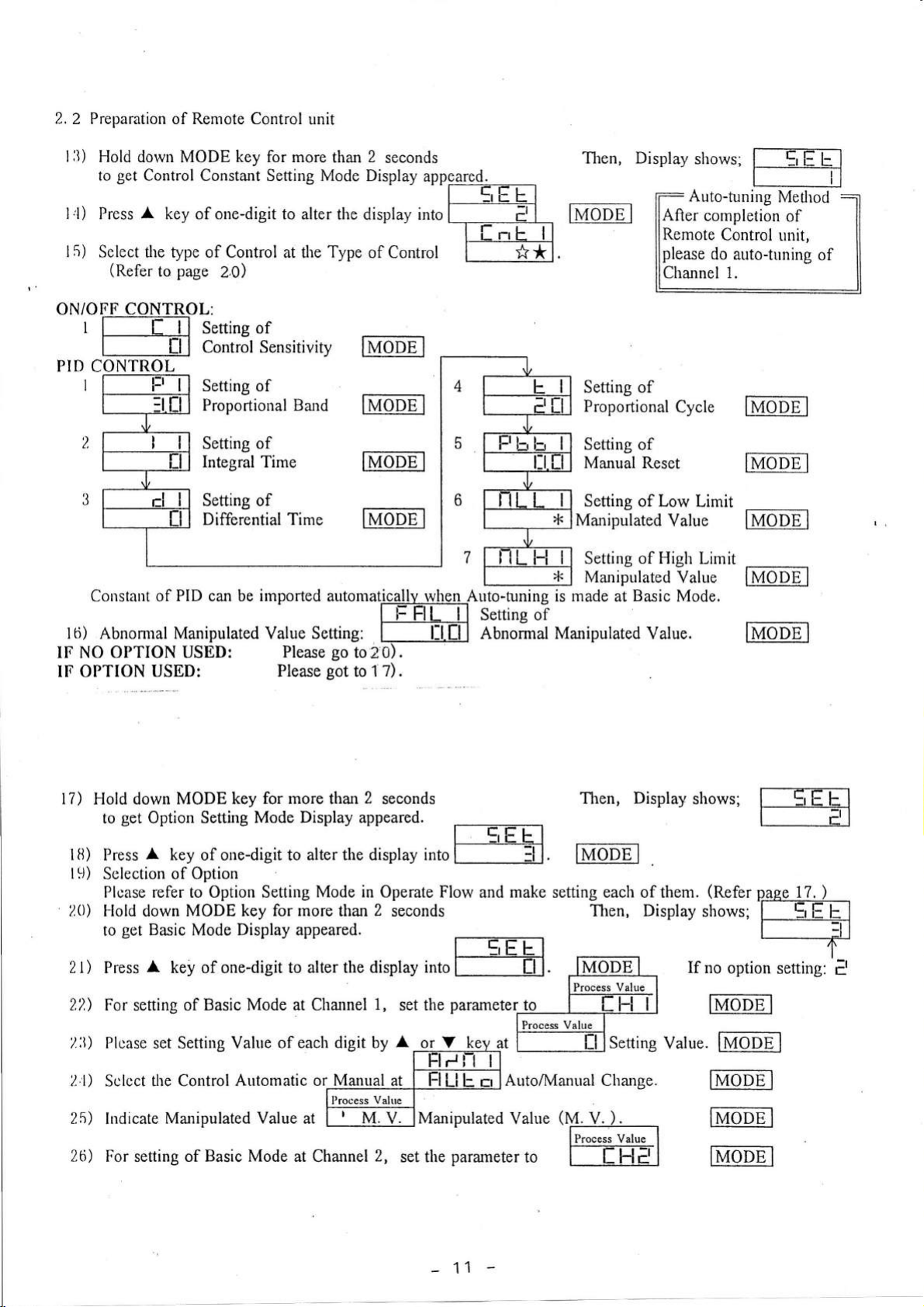

2.2

Preparation of Remote Control

l3)

Hold dorvn MODE key for more

get

to

Control Constant Setting Mode Display

I l)

l5)

ON/OFF CONTROL:

I

PID

CONTROL

I

A

Press

Select

(Refer

f-Tll

l--T1l

key of one-digit to alterthe

the type of Control at the Type

page

to

2,0)

Seftins of

contrSl Sensitivity

Setting of

Proportional Band

unit

2

than

seconds

display intol

of Control

tltloDE I

mopE I

appeared.

rE-TtrI

_LGE-N

I

E

**

I

Then,

lMopEl

I

Setting of

Proportional

Display

shows;

Auto-tuning

After completion

Remote

please

Channel

do

Cycle

f=EE

r--_]-l

Control

auto-tr"rning

1.

tMopEl

Method

of

unit,

of

Setting of

Integral Time

Setting

Differential Time

Coustant of

lti)

Abnomal

PID

can

Manipulated

IF NO OPTION USED:

IF

OPTION

17)

fi)

I

t .L))

20)

I-lold down

to

Press

Sclection

Plcase refer to Option Setting

USED:

MODE key

get

Option Setting

A

key

of Option

of one-digit to

llv(oDE

of

lMopE I

be irnported

Value

Please

for

Mode Display appeared.

autonratically

Setting:

Please

go

to

got

to 1

more than

alter

the

Mode in Operate

Z

2

display into

I

rvhen

ft:J-fif-n

I

0).

7).

seconds

l:l.tl

f{-.ffLl

I

l---Tl. mopE

Flow and

Auto-funing is made at

Sering

Abnormal

I

oI

-tl-l_t

make

Setting

Manual Reset

Setting of Low

Manipulated

Setting of High

Manipulated

Manipulated Value.

Then, Display

setting each of them.

of

Basic

I

Value

Value

Mode.

shows;

Limit

Limit

(Refer

ij"j1,tx?,Y,??IJil'$ru::'.lr2iecondsrE-Tilt1,.n,Displayslrows;ry

IMoDE I

lMopE-]

mopE

lMopEl

page

I

17.

)

2l)

2,?,)

2:i)

21)

25)

26)

A

Press

For setting of

Plcase set Setting Value

Plcase set Setting Value

Sclcct the Control

Indicate

For setting of Basic Mode at

key

of one-digit

Basic Mode at Channel

Manipulated Value ut

to alter the

display into

1,

of each digit by A or V

of each digit by

Automatic or Maqu4[

lrtu.lrlManipulated

Channel

2,

set

the

A

or V

|-FIFN_I

ut_.ff-f

set the

-

l------Ti-|. llvIODE I

parameteUlo

key

at

[-----EIl

crlAuto/I4anual

Lll=

Value

l--EFiJl

Setting

Change.

(V.V:)-,--

[p,*;*,r*l

parameter

11

to

I

t

He

If

Value.

I

no

option

TMODE I

IMODEI

ffiODE I

ffiODE

mopEl

setting:

I

f,

Page 12

2.3

l)

In

:!

tl

5

ri

7

Option

Setting Mode:

Option

OP

:l

Event I

PV Event I

PV Event I

LOW

PV Event I

HIGH

PV

Event

sensitivity

I

DI

(Refer

selection

Number

Function

setting

setting

1

function

to

Select Option function

MODE

B

In

)

Key.

case

4

2

page

F':E

Event

PV

PV

LOW

PV

HIGH

PV

sensitivity

DI

A

by

2

Event 2

Event 2

setting

Event 2

setting

Event 2

2

function

or

V key nnd next

Inc

t4

16

t7

1B

Retunr

go

to next

:El

Communication

Paraneter

Communication

Speed

Communication

Address

Response

Time

Communication/

Local

I

to

Display

Delay

Clrange

by

I

Return

to

I

Retum

to

1

-

12

Page 13

2)

Event Input(SV Change):

I

Event

Input/Output

(At

Event

1)

T-E;;I I

'

Displays only when Event

I

is Digital

Inprrt

and

DI

I

Function

r-ilEt

Plcase nrake setting

'

Displays only

Plcase make

Ptcase make setting

Event Input

?

setting

(RUN/READY)

.PlcasesetDIlfrrnctiontoffiRI.JN/READYwhenEvent1is

i In case

.

Displays when

of using

of SV2

Event 2

when

SV3

of

of SV4

Event Output:

1

Event

[-[[lsvz.

t--T;E]

T-tr;TI

[---TllSvs.

ffi

:

T-E;I

is

I

e

I

is Digital

run.

Digital

llt4ODEl

Input and DI

nutopEl

mopE

Output.

2 Function

I

E-TF-I

|

l_-.t;-=Fl

I

|

SV Ctrange.

lis

I

SV

lis

Change.

.Sclect

'

Please

3) Function

ff--=i-tT:-l

f-T-*Tl

complete each setting.

Key

Plcase set the

r-Fln

I

4) Blind

I At the display of

2 Displays

:]

Blind Mode Selection

tl I

Setting

[]

PV EventOutput

Setting Mode.

parameter

Make setting at

Mode:

to

_

rEEI

I

blinking

V

ald

rEil

f---El

Ih]

I

tunction.

Function Key Setting Mode.

down

A

in

tum within

hold

E

L

parameter. Then,

key

of one-digit

.

n\4oDEl

TEEEEI

f--*l

IMODEI

key of

press quickly

*

:

After setting

one-digit,

parameter.

hundred

A

l0

seconds.

(Refertopage

(Refer

digit

key of ten digit,

press

to

for

of desired Blind mode

MODE key

29)

page

27

more thar

to

Y

)

3

seconds to

key of

A

by

get

appear selected

start

digit

ten

Y key of

4

f----Xl Btind

l--c,l-trI

Tl

After setting of

shut

down the

Settins

Blind,

electric

power.

-

X

trr

c,l:

13

:

Selected Parameter

:

Blind the selected

rr

:

No blind

l:

parameter.

the selected

parameter.

Page 14

5)

Auto-tuning Setting:

No Auto-tuning is

possible when the

control is set at ON/OFF

Control.

I Starting

l)

2.) Fix

3)

nrethod

each

Set

the setting

Shift the

parameter

display to

one-digit

It

takes some time to execute

Auto-tLrning:

of

of

value at

Auto-tuning Starting Display of

for more than

"Control

"Basic

2

Notc: ' Auto-hrning operation should

(lnput/Output

intermediate termination

of

operation.

indication

"E. - il"

of Cancellatiorr

FLOW AND

at l{eating/Cooling

only

Opening

only at

only when Cooling

only at Cascade Control unit.

Charge" is

only when Event Option exists and also more

at Current/Voltage Input

only

only

only when Event

only when Event

only when Event

only when

only when Event 1 is

only rvhen Event

only lvhen Event 2 is set at

only

only when Event 2 is

only when Event 2 is

only when Communication

only at

PARAMETER:

Disulav

SV rvhile

at Remote

Position

at

Heating/Cooling Control unit.

Cooling

Event Option exists and

when

selected.

Current/Voltage Output unit.

at ON/OFF Control.

when Option exists.

Event

when Event 2 is

Feedback Resistance Input.

'

'

' The method

3.

OPERATION

:1,

I Display

Di I

Svnrbol

,<l

>l<

2

>l<

lJ

>l<

4

,F5

>l<

fi

>F7

>l<

ll

>l<

!)

,<lo

*l

I

>l<12

.)

)kl

r)

,<14

*r5

,<lri

>FL7

>1.18

,l<19

4<20

7:21

>l<'2

2

,l-

L t)

>l<24

>F25

d<26

>l<27

*28

d<29

connection

In case

Ar"rto-tun ing

lu case of the snapping of a wire or

error

Auto-tuning operation takes too

Condition

No

display

Displays Process Humidity

Displays Remote

Displays

Displays

No

display at ON/OFF Control.

Displays

No

display when Cooling Output

No display when

Displays

Displays

Displays only

"SV

Displays

"SV Change" are selected.

No display

No

display at

Displays

Displays

Displays

Displays

Displays

Displays

Displays

Displavs

Displays

Displays

Displays

Displays

Displays

Displavs

Constant Setting Mode" and

Mode".

seconds

Auto-tuning.

etc.

to start Auto-tuning.

be

)

only after completion

nrade

of Auto-tuning, PID

disconnection

to be appeared. The same

much times.

is sarne as the one of

Condition

Control unit,

zurd Setting

remote

Control

Proportional

Output

Output is

1

exists.

I

is

set

I

is

set

I

is set at

set

2

exists.

set at

set at

set at

Hurnidity

control on Remote

unit.

Control

is

at

set

ON/OFF Control.

is set at Current/Voltage

at ON/OFF

set

unit.

at

at

"PV

"Low

Event".

Limit"

"High

at

"DI".

Event".

"PV

Limit"

"Low

"High Limit"

"DI".

function exists.

"Basic

of Output while

starting

Position

Temperature/Humidity

at

unit.

also more

of

Limit"

of

of

of

"Option

Mode"

Constant

error

Proportional

and hold down

parameter

of

indication to be

method.

Control unit.

Output unit.

Control.

(one)

I

than

(two)

2

than

Event".

"PV

Event".

"PV

Event".

"PV

Event".

"PV

Setting

remains sanle

Mode".

setting

Auto-tuning

appeared

Control

and Remote

Control unit.

function

of "DI Event"

function of

A

and wiring

as the one set before

or V

key

of

operation, Auto-tuning

when

Control unit.

and

"DI

Event"

and

14

Page 15

3.

2 Each Parameter

l) Basic

No.

I

?,

l

4

Mode

ndications

Parameter

Process Value

Channel

I

Process

Cl{

Setting ValLre(SV)

CHI ,A.Lrto/Manual

C!rq!gq

I

Local/Remote

CIJ

Change

Selection

Value

Information

Descriptions

Select

digit.

f

f

Displays

Setting Value

Settingrange:

Setting unil Thermocouple

Change of Automatic

Channel

Select

digit.

"f l{

I selection: It is

I-l

Process

selection: It

F!E

Process

"Fl

Flur

E rr

I" or

Value at

value at Channel 2

Process

(SV).

5LL

R. T.

D. /Thermistor Input

Current/Voltage

1.

urE

Er"

selection: Automatic

l-lFlr, selection: Manual

Change of

Select

digit.

-

Local

l-lEr"

"r

E

L f L

E

selection: Local

l-ltrr selection: Remote

"f

is

Value

Setting

or

Mode

or'L

HE"

possible

Channel

possible

(PV)

by each

l-ELH

Input

Input I

Control

"ilFlrr"

Remote

and

f

L

AV

by

change

to

1

and Basic Mode.

to change

and Basic Mode.

at Channel

A

I

-'------'----

".'

Manual

and

AV

by

Control

Control

Mode

AV

by

"

operation

operation

key of

the

the

I

and Change

V keys.

0. 1"C

Control

key

ofone-

Channel

at

key

of one-

one-

display of

display of

('F)

1"C

('F)

disit

at

Initial

Value

TC

'rr

R,i.D.rri

-----t]-tl

I.V

Flurtcr

I

[H

L IL

Display

Conditions

Remarks

*1

I

*2

>F3

LI

rt

tl

*4

and

5

ti

7

u

Process

CHI

MrUUp,Ll atgd _V_qlqe_

Manipulated Value

CHI Process Value

Q_ogl_ile _O_uJptlt_ _ _ _

I

CH

Auto-tuning

start.

SV2

CI-II

Value

Displays

Value

Manipulated

percentage.

Displays Process

Value of Cooling

Start Auto-tuning at Channel

of one-digit for more

If

Process

of Output

rr selection: Start Auto-tuning at Channel

trr

of

any

1.

Value of Output

display selected

at Channel

Value

I

to

Value at Channel

Output.

1.

Hold

2

than

to start Auto-tuning.

while Auto-tuning, it

be displayed

r----Frtrl

In

case of cancellation, Cancellation

made same manner as Start of Auto-tunine.

Change

Settingftmse:

Setting unit:

of SV2 Setting Value.

ELL

Thermocouple Input

R. T. D.

Current/Voltage

Settine bv each

l-ELFI I

/Thermistor

AV

kevs.

"""--""'

Input

Input

1

and Manipulated

I

and Manipulated

AY

down

(rr

!: !:

)

1"C

""-"

0.

l"C

I

in

key

L

shows

can be

('F)

('F)

digit

c,l=

TC

R.T.D.TFI

_____t;t-[-

LV

*5

*7

*6

l:

*12

I

n

15

Page 16

I

CIJI SV3

l0

ll

t?.

,)

l

l.)

lrl Auto-huring

SV4CHI

Proccss Value

CI-ll

(SV)

Sclting

CI-I2

ChanAe

Value

Auto/lManual

Process Value

CI-12

pt! qtg{

\4r11r1

f,'r*----

r---i_

hl r rr i nr rl rteA\/r lr re

CH2

start.

""1*

_V_4!'le-

I

r

Change

Settingrange:

Setting unit:

Churge

Settingrange:

Setting unit:

Displays Process

Setting

Change

Channel

Select " Fl

digit.

of SV3

Settine

of SV4 Setting

Settins bv

Value

Settingrange:

Selting unit:

of

2.

Flur

E cr

Setting

ELL

Thennocouple

R. T. D. /Themtistor

Cunentfy'oltage

bv each

5LL

Thermocouple Input

R. T. D. firennistor

Current/Voltage

each

(SV).

l-5LFl

AY

l-EL!-l

AV

Value

Setting by each

5LL

Thennocouple

T. D.

R.

Current/Voltaqe

Automatic Control and

ur t. Er

selection:

firermistor

or " l-l Fl rr

"

ll Flr, selection:

Displays Process Value of

Value

_

Manipulated Value

percentage.

of

at Output

Start Auto-tuning at Channel

one-digit

Auto-tuning.

1.

Output

of

for more than

Value at Channel

""""""'

Input

Input

1.

I

l"C

"""' 0.

Input

keys.

Value at Channel

I

l.

"'-" l"C

"""'

Input

0.

Input

kevs,

(PV)

of Chamel

A

V keys.

2

and

l-ErLl-l I

""""""'

Input

Input

-"""

Iunut

Manual

A

by

"

Automatic Control

Manual Control

Channel 2 and Manipulated

I

to be

2.

Hold dorvn

2

to

start

Control at

Y

key of one-

displayed in

A

(cr

r')

('F)

l"C

1

digit

('F)

l"C

1

digit

Change

l"C

0. l.C

I

disit

Y key

('F)

('F)

('F

('F)

IC

R.T.D.TtI

_-_-_l=1.[-

l.v

1'C

_____--tr.

R.T.D.TI.I

---__l=l.E-

I.V

'lc

R.T.D.TII

)

_____[rE

I.V

Flurtcr

tr.

tl

rr

tt

il

n

crFF

813

,k13

*l

*3

*1

x1

*t

*6

t5

cr-t2 svz Change of

Setting

l6

t7

SV3

CI.Iz

CI12 SV4 Change

In case of cancellation,

made sune

Setting unit:

Settinq bv

Change of

Setting range:

Setting unit:

Settinc bv

Setting Value

Setting

Setting unit:

.

mauner

SV2

range:

Themocouple Input

R. T. D. /Themristor

Current/Voltage

each

SV3 Setting Value at Channel

Themrocouple Input

R. T. D.

Current/Voltage

each

of SVrl Setting Value at

(SV)

range:

R. T.

Current/Voltase

as

Setting

L L E-5L

E

AV

L E

EL

/Thermistor

A

V kevs.

.

Setting by each

5L L E-EL

Thennocouple

D.

firenrristor

Czurcellation

Start of Auto-tunins.

Value

at

(c,

Channel 2.

He

""""""'

"""'

Input

Input I

keys.

-5L

l-lE

Input

Input

Channel 2.

l-!E]

Input

Input

"""-'-""

"""'

"""'-""

A

V keys.

""""""'

"""'

Input 1

F F

0.

2.

0. I'C

)

l,C

l'C

l'C

1

1"C

0.

can be

('F)

('F)

digit

('F)

('F)

digit

('F

l'C

dieit

)

('F)

TC

R. T. D

I.V

TC

R.T.D.TI{

.'ilt

_____l=l.u

_-___l=1.[-

I.V

'tc

.

R.T.D.1'I'I

_____[tn

I.V

*1

*12

fl

fl

>F1

*13

I

rr

*1

)F13

I

n

-

16

Page 17

2.)

Set-up

,-u

ndications

Mode

No.

I

Set-up Mode

C.ha!,r

1.

CHI Type of

lrp_qtlQgtp-u_t

g

lnput

l_e-c!

l_

$ 9

type of

<)

'l

-t

:r :r

_lL!

-r5

:rE

:l '-l

In

I

I JPtl

Select

i-op_

f

f

Displays

Tltermocouple

Input

type

1}enrrocouple

K

"[!-!

digit.

! selection: It is

i-l

Process

selection: It

!*ie

Process

the type of

:

i

Symbol of Input

J Themrocour:le

Thermocouple

E

Thermocouple

T

R Thermocouple

S Themrocouple

Thermocouple

N

WSREAMz6RE

Pr100

00

Descriptions

I

or

"

"f !+I"

possible

Value

of Channel

possible

is

value of Chzurnel

Input/Output.

type

R. T. D. Input

'

AV

by

change

to

I

to change

2

and Basic Mode.

type of

) [nnrrt fvne

I

-5VDC

4-20mADC

O-

O-IOVDC

0-10mVDC

0-5VDC

E

E

,-l

Ll

I.nitial

Value

key

of one-

the display

ald Basic

the display of

of

Mode.

Unit

Type

InpuU

Output

Voltage ' Cunent Input

IVDC

Display

Conditions

Remarks

*1

I

[!-l

used.

of

EE

EI

Select

Mode

(Displays

4

seconds

Power

type of Thermistor

Inout

i

A

fvue

B

I

tvoe

C tvpe

D

I{

tvoe

type

LI

Set-up

tvne

only

after

input.

and

)

r)

CHI

PV

I CHI

P_e_c!rfr+!.

Conection

!99

i_ti_o_n_

:

Symbol of Ouput

*'

each

or

2

tvpe

contact

Output

Vah.re at Channel

100- 100

-

('F)

1"C

1

digit

A

kevs.

V

l:l.fl' by

"

* Output

None

]- Relav

SSR Drive Voltase Outout

i:r

Voltase Output

LI

t

I

Current

Conection

Setting range:

Sening unit:

Settins bv

Display selection of decimal

Select

_

of Process

" fl"

2

type

Output

or

A

100.

or

-

0. 1"C

point

of one-digit.

Y key of

*

1.

0- 100.

('F)

one-digit.

:

Symbol of

*

Relav contact

r

!:l SSR

Voltace Output

LI

I

I

Current

0

Output

Output

Drive

TC

R.T.D.TH

_____l=1.[-

I,V

I.V

R.T.D.TH

type

1

tvpe

Outuut

Voltase Output

Output

-El

n

fl

rtn

-

17

:

Page 18

5

CHl

'Q/'F

ri

CHI

SV Lirnit Low

I

CHI

$!

8

cl-l

Sqt-turg

Change

Lirnit High

I

qf

Lock

Selection of

Select

Setting

Setting

rrEr

l

rrruLUuPtE

Setting range:

range High.

more

be

)'rn f--,,1

r\ r u rrrPul

Setting range:

range High.

more

be

l/^l+^

-^//a..--^,.]

b

Setting

rarge High.

be more

'I'|

r rrLr

^-*:.+^-

trrrJtut rrrPut

Setting range:

range High.

nrore

be

Setting of High Lirnit

Setting

1-t. I

rrrr

l

rrruLUuPrc rrIPu

Setting rzmge:

range High.

be more than

r\ r L,

Setting range:

range High,

more

be

\/^lr^

-^//-.,--^,.+

5L'

Setting range:

range

nrore

be

Tl"^--:.+^- r-^..G

t rrLr

rrllDtur

Setting range:

range

be more

Select the

Select

Symbol

"C

f

Low

by

display

,

or

Limit

AV

rtrlJu

"E

keys.

I'

of

L-r

SV Setting range

But

the

('F).

50'C

than

SV

Setting

But

the difference

5. 0"C

than

range:

than

than

by

rrrpul

than

f

-^,,+

rPu

SV Setting range

But

the difference

50

digits.

I--..+

SV Setting range

But

the difference

5. 0"C

AV

keys.

SV Setting range

But

the difference

('F).

50"C

SV

Setting range

But

the difference

5. 0"C

r-^,.+

SV Setting range

High.

than

But

the difference

50

digits.

rlrPul

SV Setting range

High. But

than

type of

the

5. 0C

Lock function

"fl-E" by

Tvpe

OFF

I

I All

E

Ll

=l

tr,

E, AII Lock

Lock

Basic

Mode

Set-up Mode

Control Constant

Option

'F

and

l=

A

by

"

of Setting

difference

range

('F).

('F).

of

Setting Value

('F).

Pu

difference

('F).

AV

key

of

Loc\

Lock

Lock

Mode Lock

Settinq Lock

except

Settins

display

V

Value

Low

witn

Low

with

Low

rvith

Low

with

Low

with

Low

rvith

Low

with

Low

rvith

at Channel

key

of one-digit.

at

SV

-

5 L F!

SV

-

E

L

SV

-

ErL

SV

-

5 L l-!

at Channel 1.

SV

-

5

L L

SV

-

E L

SV Setting

-

5

L L

SV

-

E

L L

at Channel 1

of one-digit.

Value

Channel

Setting

I

should

Setting

I should

ll

Setting

I

l-l

should

Setting

I

should

Setting

I strould

Setting

I

should

L

I should

Setting

I

should

(SV)

1.

*14

Ef

1.

tl

-tI

l-t.t!

-rI

t:t.[

-tI

t:I.tl

tetlil

t-t.fl

5 il

Ertlfltl

rfl

r:r.il

I

-

1B

Page 19

9

CHZ

lqp-q(Qutp-u-t-

l0

CI.I2

PV

Correction

il

CtI2

Decinral Position

t2

CHz

ll{'n

Type

of

- - -

-Qhqnge----

Same

as the

Same

as CHI PV

Setting

Sarne Decimal

Same as CHI

by each

Select by

Select by

A

A

type

of Input/Output

Correction.

AY

keys.

as the

one of

V key

Y key

"C/'F

of one-digit.

Change

of one-digit.

CH1.

at CHl.

Type

of

Input/

Qutput

used

TC

-______tr.

R.T.D.TH

_____t=LEl-

I.V

TC

R.T.D.TH

_____l=t.E.

I.V

L:If

*1

*1

fl

*1

n

I-l

*1

*14

l3

l4

15

CH2

SV Limit

CH2

SY-

I-j,r,jt_Hjgb_

CI-I2

Setting of

Lorv

Lock

Same

as

CHI

Setting by

Same

as CHl SV

Setting by

Same

as CHI

Select by

SV

AY

AV

Lock

A

V key of

Limit Low.

keys.

Limit

keys.

Setting.

High.

one-digit.

TC

R.T.D.TH

_____l=l.E-

I.V

TC

--l-E'-tltl-

R,T.D

- - -ErE-tl.

I.V

_EJ[!EI

TH

tnnn

*1

tl

fl

)F1

*1

n

-

19

:

Page 20

:t)

Control

lndications

Constant Setti

Mode

No.

t

Set-rrp Mode

Channel Selection

?.

,)

I

CL{

I_vp!r_qleq!!r_ol

CHI

Prqp_q(r_otrgl F_ry_d_

Select

digit.

f

f

Select the

-

"I

selection:

I

Fl

Constalt

selection:

l{

e

Constalt

Select

Select * by

*

* Type of Control

2

noints control

I

Temperature difference

T

Control

*Renrark

Setting

Setting

Setting unit:

Setting

range:0.

of

by

Descriptions

or

I"

l-l

type

by

l:

Proportional Band

A

Percentage

"f Fle"

possible

It is

Mode

at Channel

possible

It is

Mode at Channel 2.

of Control at Channel

A

V key

A

V

Temperature

temperature difference

Cliannel

key

V

1-200.

of one-digit.

key

of ten-digit.

difference

2

SV such as:

of each digit .

0

(%)

AV

by

to change the

L

to cltange

* Tvpe

I

;,

l! ON/OFF

Ll

control: It

between

CHI SV

at Channel

against

EL

Initial

Value

key

of one-

Control

the Control

1.

of Control

PID

Control Nonnal

PID Control Reverse

(Nomral

(Reverse

I

PV

CH2 SV.

ON/OFF

Control

Control

controls the

Channel

-

l.

L

-EL

l-l

Display

Conditions and

Remarks

!

f H

*Remark

IE

operation)

operation)

operation)

operation)

actual value

and

:l.tl

*1

1

of

*6

.l

CFII

!r1t_eg1ql_frpe_ _

;)

6

7

il

I

cll

Differential Time

CHl

1o_po_(

!

CHl

Control Sensitivity

I

CFI

Manual

i_op3r!

Reset

_Cy_cl e

Setting of

Setting by

Setting

Setting

Setting

Setting by

Setting range:

Setting unit: seconds

Setting of

Setting by

Setting range:

Setting

Setting of Control

Setting by

Setting rarlge:

Setting

Setting to add manipulated

value at Channel

Setting by

Seuing

Setting unit:

lntegral Time

A

key

V

range:

unit:

0-3600

seconds

Differential Tirne

of

A

V key of each digit

of each digit

0-3600

Proportional

A

Y key

of each digit

1- 120

unit:

seconds

Sensitivity at Channel 1.

A

key

Y

0-100

unit: Thermocouple Input

R. T. D.

Current/Voltage

A

V key

ftmge:

0.

%

of each digit

or

/Thennistor

1.

of

0-100.0

(percentage)

Channel

at

at Chalnel

Cycle

at Channel

0. 0-100. 0

Input

Input

value to

each digit

I

.

I

.

I

.

.

"""""'-'

'------

0. l"C

the manipulated

.

1"C

I

('F)

dieit

('F)

Relay

Contact

Point

e I

SSR

Drive

Voltagc

TC

-------tt'

R.T.D.TH

___-_l=1.[-

E

I.V

|J.I

*6

I

*6

I

*6

*15

*16

rr

lt

>k6

-20

Page 21

I

CIII

MV Limit Low

I0

ll

I

cl{

Xz! !_ !r11r 1t_llrglr _ _

Cl-ll

Abnonlal

Manipulated

Setting

Setting

Channel

Relay

Sening range: 0. 0

Setting unit:

Setting

Settinc unit:

Setting of Fligh

Charnel

Relay Contact

Setting

Sefting unit:

Setting range:

Setting unit: 7o

Setting of Abnonnal

of

Setting by

value

Setting

Setting unit:

of Low Limit

1.

Contact '

%

b

range:

range:

EE'

range:

-

7o

l.

'

MVLimit Lorv

%

MV Limit

A

0. 0-100.0

%

Manipulated

of

Setting

SSR

(percentage)

10

(nercentase)

Limit

Setting

SSR

(percentage)

(Dercentase)

V key of

(percentage)

by

Drive

MVLimit

-

P

MV Limit

-

of Manipulated

by

Drive

I

-

Manipulated value

each digit

Value

at

A

keys.

Y

Voltage Output

High

High

Value at

A

V keys.

Voltage Output

-100.0

1t0. 0

at Channel

.

*6

l:1.fl

-tn.fl

*6

- - - -

Ifll].tl

I ll:|.tl

I

t:t.I

1?.

I

CFI

Cooling Output

Prouortional Bald

r:-lrn

f---*

l:]

Cooling

llppg,tt-qlglcycle

l.'l

p_o_ol

ilg_

Egrqljetqtiviry

t5 CHI

Dcad Band

t(i

CI-II

9_o_oli1g_Qy1pr4_

MV Linrit Low

1

Output

Q1rlprlt- _ _

Setting of

Channel

Setting range:

Setting unit: Times

Setting of Cooling Output Proportional

Channel

Relay

Setting range:

Setting unit:

YoltaB,c,LurIclll rIrP

Setting range:

Settins unit:

Setting of Cooling

Channel

Sqtturc" range,:

Setting

Setting

Setting by

Settinc

S;ti,[ iu,,t:

Setting

Channel

-

Relay

Setting

Setting

voltage/uurrent

Setting

Settins

Cooling Output Proportional

1.

l.

Contact

l.

unit:

Setting by

0.

l-10.0

Setting

'

SSR

I

-120

seconds

I

-120

seconds

Output Control Sensitiviry at

Setting

(0,

0

0)

flle-ry1o_cp_up.lq

T.-n.

n.

Current/Voltace Input

rni.":'iii6 r-ti,

of Dead Band

A

V key of each digit

ranse:

100(- tCtO. 0)

-

AY

A

by

Drive

Yoltage

A

by

V

100 ( 100. 0)

-

_lnpUt_ _':

at Channel

Tlie;,i-.i-;l,ie- ilrpul

T. D. /Themristor

R.

Current/Voltase

Lorv

of

l.

Contact

raxge:

unit:

range:

unit: %

0.

%

-

Limit of

Setting by

'

SSR

0

-

(percentage)

rnput

10

-

(percentace)

Input

Manipulated Value at

Drive Voltage

MVLimit

MV Limit

key

A

Bzurd

at

key

of each digit.

Cycle at

Y

keys.

Output

each

of

pul

1.

-100(100.0)

j:'jrj:'j:'j

Input

Y

keys.

High

High

digit

-:'_: -::'_t-EG)_

--

r--- :---

0.

.

"""'

0. 1'C

Output

.

-t-.c('

p')

I

dieit

l:"p-(f)-

('F.)

I

dicit

*7

*B

:l.tl

*7

*8

*9

efl

e

x<7

x10

rI

_L:Lt!.

i1.n

l:t.I

LI

rr

ll

ri

*7

t-l

tt

*7

>l:

[J

_

-

-

)1

Page 22

t7

C_o-olipg-Qy!p-ut-

M-Y-Lul!-Ujsh

l8

CI{2

Type of Cqntrql

Setting

Channel

-

-

Relny Contact

Setting

Setting

Y

Setting range:

Settins unit: 7o

Same

of Low

range: Cooling

unit: %

Ortilge/uur[eltI

as

Limit of Mzuripulated

1.

Setting

' SSR Drive Voltage Output

(percentage)

rnput

Cooling

(nercentase)

Type

CHI

of Control.

A

V keys.

by

outllut MV

output MV

Value at

Limit Low

Limit

-110.

-100.0

0

*7

XB

I

t:t.[

I

*1

te

l9

CI{2

Proportional Band

20

cll2

'21

CH?

fle 1e_rltiql JU!e_ _

-D_i

,),)

CII2

po_r1

tq

P

totrg[ _Cy_c]

Same as CHI

Setting

as CHI

Same

Setting by

as

Same

Same

e_

CHI

Setting

as

Setting by

Proportional

A

Y

by

by

CHI

key of each digit

Integral

A

V key of each digit

Differential Time.

A

V key

Proportional Cycle.

A

V

key of each digit

Band

Tirne.

each digit

of

:t1

*6

:l.tl

*1

.

*6

n

*1

.

*6

I

Rclay Contact

.

Point

e n

SSR

Drivc

Voltagc

*1

*6

*15

e

o.)

1, \t

CI{2

Control

L

I

L

I

24

CH2

\,!4r11a.! _(qs_e!

Sensitivity

Same as CHI Control Sensitivity.

A

V

key

Manual Reset.

A

Y key of each digit

-

_ _ _

Setting by

Same

as CHI

Setting by

each digit

of

'tc

R.T.D.TH

____-t;10.

I.V

n

*1

*16

n

*1

*6

n.tl

'25

CI-I2

MV

Lirnit Low

Sarne as CHI

Setting by

MV Limit Low.

A

V key of

each

digit.

.

Rclay

SSR

_____[rI

I.V

-l

[[

x1

*6

-22.-

Page 23

26

CYT?

MV

I,ur:il

Hrglr

Sarne

as CHI MV Limit

Setting by

AV

High.

keys.

.

Relay

SSR

__tIL:rtl

*1

x6

t)1

LI

CHZ Seuing of

Abnonnal

Manipulated

,)o

Ll,

CH2 Cascade

Scaling

?..1)

CI-{2 Cascade

Sqalj,tg_H,gl,_____

:]0

CIl2 SV Setting

for

Cascade

AuJq:tltUUrA

Lorv

value

Same as CHI Abnormal

Setting by

Setting range:

Setting unit:

Setting

at Channel

r

rrcr llruLuul"rrt rulrut

Setting range:

rarge

High. But

be more

y

r\

r

rrrPut

Setting range:

range High. But

be more

\/^l+^-^//r.,....^-l f ......+

b

Setting range:

range High. But the

be more

rrtr

I

lrrrstur

Setting range: SV

range High. But

be more than

Setting of Cascade

at Channel

l uEr ilruGUulJrts

Setting rarlge: SV Setting

range High. But

more

be

|.,

t( r

rlllJul.

Setting range:

range High. But

be more

Y Urrag,c,\-urrtsIlI rup

Setting

range High. But

more

be

r tlErrlrlst.uf rtrput

Setting

range High.

more

be

Setting of Auto-tuning

at Channel

Settinsranse:

Setting unit:

A

key

V

0.

o/o

(percentage)

of Cascade

2.

SV Setting

50"C

than

SV

5. 0'C

than

SV Setting

50

than

rtrlrut

0'C

5.

2.

rulJul,

50"C

than

SV Setting range Low

5. 0'C

than

range:

range:

SV Setting range Low

50

than

SV Setting range Low

But

5. 0.C

than

2.

f

flle-ry1o-c_o_uplq

R.

-1.-D,.

Current/Voltage Input

of each digit

0-100.

Scaling Low

Sening

the

difference

('

F).

Setting range

the difference

('

Pur

differenbe

digits.

Setting range Lorv

the difference

('

Scaling

Setting

the difference

("

the

difference with

('

the difference

digits.

the

difference

("

Setting

FlSL-f

[lte-rygi5t-o-r-IppU!

Manipulated

0

AV

by

range Lorv

rvith

Lorv

with

F).

range Low

with

with

F).

High

A

by

V key of

range Lorv

with

F).

F).

with f FIE

F).

setting

by

value

AV

FlEl-!

hpUt_ _':'j:'_

Value

.

of Manipulated

key

-

I

-

f

-

f

-

f

of Manipulated

,'

f

-

I

-

Setting.

of each digit.

SV Setting

Fl

5 !-l

SV Setting

FlS

l-!

SV

Setting

FIE

!-!

SV Setting

FI5l-i should

each digit,

SV Setting

Fl5

L

SV Setting

FIE

L

SV Setting

L

SV Setting

-

with

Fl5

I

on Cascade

key of each digit

-'

L

_ : _ _l_ECF)_

:

:':

:':

-0-.-i-'g-Cf') -

I

Value

should

should

should

Value

should

should

should

should

Control

.

dieit

_

r il:tn

t:t.I

il

-rI

t:t.il

-!iltlI

r:t.I

IJnt_l

Etll.tl

Ertriltl

l:t.tl

r

il

___H.fl

*1

*1

*11

.J-

I

.t-

I

*t

1

)tl

*11

rr

LI

rr

tt

Page 24

se Mod

No.

I

Option

2

Event I Function

PV Event

Output

Selection Select

E:

El

Setting

setting by

E

Setting the frrnction

i

function

:

i

Svmbol

E]

:l

Descriptions

by

function

l:

"

l,

E, El"

Eventl

Event2 fi.rnction

:

Cornmunication

Input

of

:

Digital

I

:

Digital Output

A

and

V

Output

key

Input

of

Channel Selection

Type

of selection Channels

I

1CH

2CH

I

CFV

2CH

A

V key

Event I

of

of one-digit.

PV

Event

(Set

by

Conrrnon

of

one-digit.

Output

AV

key

Initial

Value

Display

Conditions and

Remarks

*t7

I

*18

I

I

100

of

digit)

:l tl tl

*18

x<19

* Selection of

(Set

Symbol Tvpe

rr

LI

I

E

:l

Ll

E

!l

,l

EI

*

Selection of Additional

(Set

Svmbol Type

l l

I

E

=l

Ll

!'

lI,

,l

A

by

None

Deviation

Deviation

Deviation

Deviation

hieh

Absolute

Absolute

Absolute

Range

hish and low limit'

by

None

Event

Stand-bv sequence

Process

Event

Event

Stand-bv seouence

Event

*

PV

PV

Event

function

V key

of

AV

of ten-digit)

PV Event

h sh/lorv lirnit

h

lor.v limit

range

lorv limit

and

value hiqh/low

value hiqh lirnit

value

ofabsolute value

key

Functiorrs

limit

sh

for

low limit

Functions

of one-digit)

of additional Functions

outout

output hold

output hold

output hold

abnomral

Value

lrold

(PV)

abnomral

+

Stand-by

+

PV

*

PV

+

Stand-by

lirnit

seouence

abnomral

abnomral

sequence

24

Page 25

.,1

5

Event

PV

I

ip1 11

!_o1v_ |

PV Eveut

I

gl1

!-lj

_l 1ry

Output

_S_e_tt_r

Output

it_

$ etlipe_

Setting

Setting by

Setting range:

I

e _

Sefting unit:

Setting of High

Setting by

Setting

Setting

Low

of

R. T. D.

limit

A

V key

Without R. T.

"C

limit of PV

A

V

key of each

ftmge;

R. T. D.

Without R.

unit:

T. D

of PV Event

of each digit.

199.

-

D

1999-9999?

-

Event

digit.

199.

-

1999-9999"C

-

Output l.

9-999.

Output

9"C

('F

1.

9-999. 9"C

('F

("F)

)

('F)

)

*18

*20

I

or

l-l.il

*18

*2r

tl

or

l:1.I

6

7

B

I

PV Event

Sensitivity

I

DI

Function

2

Event

PV Event

Function

I

Function

2

Setting

Setting range:

Setting of Event I

of Sensitivity

Setting

Setting by

Symbol

by

A

A

il

e

function

Same

A

Setting

Sanle function

Setting

by

by

A

V

0-9999"C

0. 0-999.

V key

Type of

No function

SV

RI-JN

as

V key

as

V key

of PV Event

key

of

each digit.

('F)

9"C

Input function.

of one-digit.

DI

functions

chanse

READY

/

Event 1.

of one-digit.

PV Event 1.

of each digit.

('F)

Output 1

or

:l

*18

*20

tr

or

r_t.il

*18

4<22

tr

*23

I

*23

*24

tl tl

r0

PV Event

L-oy_ I irq i1

il PV Event

Hielr lirit

t2

PV Event

gelsili_v!ty_

2

_S_eg_i 1

2

Setting

2

_ _

Same Low limit

g

Setting by

_

Sarne

Setting by

Sarne

Setting

setting as PV

A

V key

High limit

Sensitivity as

by

setting as PV Event

A

V key

A

V key of each digit.

of each digit.

of each

PV Event

-25

Event

digit.

1.

*23

*25

I

or

t:t.I

1

or

l:l.I

or

t:t.fl

*23

*26

n

*23

*24

fl

Page 26

l:l

l.l

2

DI

Comrnunication

Parameter

Function

function as

Same

Setting

Setting

:

O

:

I

:

*

A

V key of each

by

of Communication Parameter.

Selection

Selection of Data length:

Selection of Parity:

DI 1

of

with

BBC

function.

Check

BB

digit.

x23

*27

*28

EElr,I

l5

Cornmunication

Spqqd

lf)

Courmunication

Address

t7

Response

Tinte

Delay

:

>k

Selection of Stop Bit:

Setting

of Communication

Setting

by

Svnrbol

A

te

ELI

Li

E!

EIE;

Setting

Setting range:

Setting

Setting

Setting

of Communication

Setting by

of Response

Setting

by

range:

unit: mSEC

A

A

V key

V

of each digit.

Communication

I2OO

24OO

4BOO

9600

key

of each digit.

1-99

Delay

Y key

of each digit.

0-250

Speed.

BPS

BPS

BPS

BPS

address.

tirne.

Speed

Settins

*28

LtE!Etfl

*28

I

*28

I

-26

Page 27

l8

Comurunication

Local Change

/

Setting

Setting

of Communication

A

by

V key

of one-digit.

Local

/

change.

*28

5

ndications

No.

I

Close down

Feedback

2,

Full

Feedback Resistance Adiustment

t-.----Ftrm

[-;;;l

ed

Open

time:

Resist-

time:

Symbol

L f L

fc'll

At

close down

When all valve closed completely, press

one-digit.

At

close down

When

one-digit.

all valve opened completely, press

Communication/Local

Local

Communication

Descriptions

time, Adjust Feedback

(Memory)

time, Adjust Feedback

(Memory)

Setti ns

resistance.

resistarce.

A

A

key

key

of

of

r rr

t- r.- L-

Initial

Value

Display

Conditions and

Remarks

*29

*29

6)F

No.

I

Ind ir:atinrrs

Function Key

Setting

Setting of

Setting by

Symbol

1-l

tl

I

I Sendine back Settinc Mode

E

:l

Ll

*

Caution:

When

or

on stay.

Lock

Function Key

Descriptions Initial

Function

A

Function

Key.

V key

one-digit.

of

setting

of Function

Key

No ftlnction

UNDO: Retunr the setting to the one

alreadv memorized.

Lock

RTJN/READY

RUN

READY

CHI and

ftinction selected either at Set-up

Parameter

all

*

: Control start.

susDend Control

:

Sirnultaneously

CH2

Setting, Lock condition will

effect.

Mode

keep

Value

Display

Conditions

Remarks

rr

LI

and

-27

Page 28

3. 3

Other

Displays:

l_r-Tl

Displays whenever

Also

displays when

Feedback

Displays rvhenever

the wire

Displays at

please

Displays

please

Displays at Auto-tuning error, such as Over display or

the case rvhen too

For cancellation

In

case this Error display shows after

service.

Displays

resistance input and

is

snapped at Input

Memory

contact

A/D converter error. In case

at

contact us for repairing service.

when the

Input value

the

wire

Input

error.

for repairing service.

us

much

of this

display,

operator tries to change

exceeds the High limit of Display

is snapped

ABb

temtinal at

exceeds the Low limit of Display ralrge.

value

line of

In case this

is

time

spent

press

themrocouple,

at

R. T. D.

l-5V,

for

the

4-20mA, 0-IV, 0-10V

Error

display

this Error display

auto-tuning ard also at

keys for resetting

any

re-input

Parameter

of