Page 1

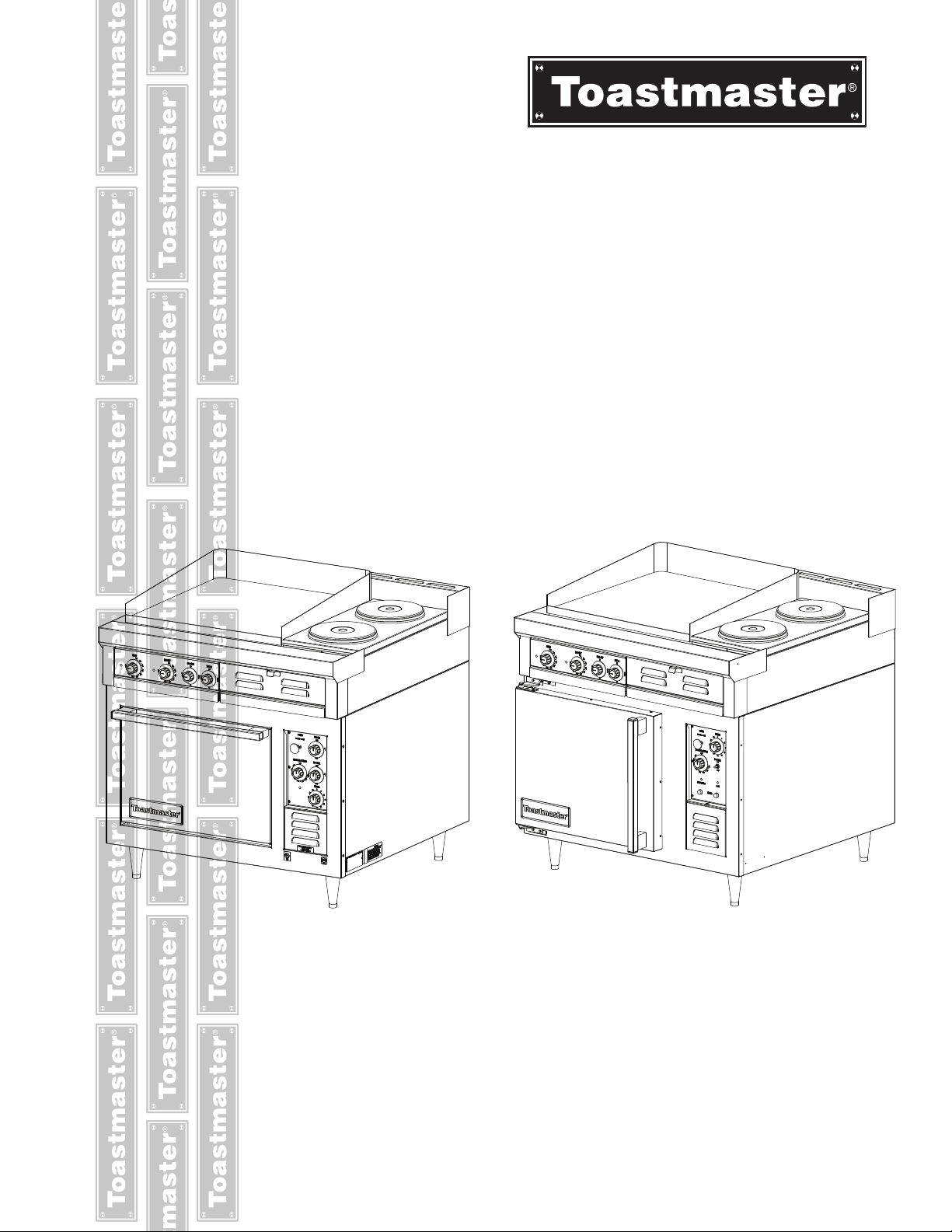

ELECTRIC RANGE

IL2021

TRE36D5 TRE36C5

MODEL

TRE36C & TRE36D

Commerical & Marine Applications

Installation and

Operation

Instructions

2M-W1624 Rev. - June. 11, 2010

Page 2

2

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

UsinganypartotherthangenuineToastmasterfactorysuppliedpartsrelievesthe

manufacturer of all liability.

Toastmaster reserves the right to change specications and product design

withoutnotice. Suchrevisionsdonotentitlethebuyerto correspondingchanges,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Toastmaster exercises good faith efforts to provide

information that is accurate, we are not responsible for errors or omissions

in information provided or conclusions reached as a result of using the

specications. By using the information provided, the user assumes all risks in

connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it

ready when you call to ensure a faster service.

SAFETY SYMBOLS

Model No.

Serial No.

Voltage

Purchase Date

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (314) 678-6347

Fax: (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

The Service Help Desk

Authorized Service Agent Listing

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.toastmastercorp.com

E-mail Service@star-mfg.com

Telephone: (314) 678-6347

Mailing Address: Toastmaster

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

CAUTION

WARNING

2

Page 3

Consult One of Our Many Local Qualified Service Agents Before you call

the Toastmaster Technical Service & Parts Department at 1-800-807-9054.

TABLE OF CONTENTS

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION

Range Top Congurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Equipment Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Recieving the Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Un-crating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Making the Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

CONVECTION OVEN

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Initial Preheat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Typical Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

DECK OVEN

Initial Preheat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Normal Operation, Preheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Oven Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3-Heat Swtiches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Pan Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Vent Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

EXPLODED VIEW

Range Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 - 17

Deck Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 - 19

Convection Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 - 23

WIRING DIAGRAM

Convection Oven w/Range Top 208/240V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Convection Oven w/Range Top 480V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Deck Oven w/Range Top 208/240v . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Deck Oven w/Range Top 480V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

NOTICE Serviceonthisoranyofourotherunitsmustbeperformedbyaqualiedpersonnel

only. Consult your Service Agent Directory. You can call our toll free number 1-800807-9054 or visit our website WWW.STAR-MFG.COM for the service agent nearest you.

3

Page 4

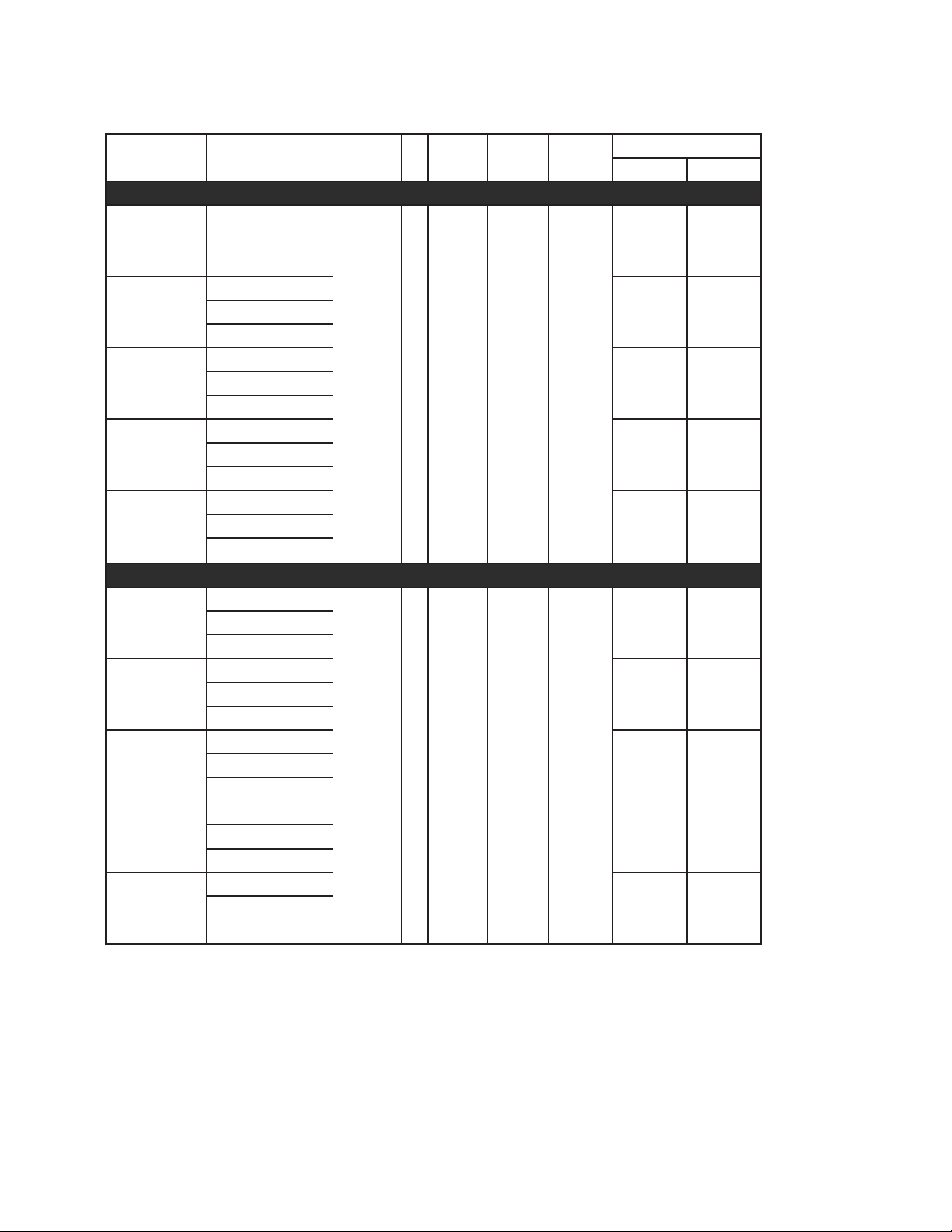

SPECIFICATIONS

Model Voltage Total kW Ph Width Height Depth

Range Convection Oven

TRE36C1 /

TRE36C1M

TRE36C2 /

TRE36C2M

TRE36C3 /

TRE36C3M

TRE36C4 /

TRE36C4M

TRE36C5 /

TRE36C5M

TRE36D1 /

TRE36D1M

TRE36D2 /

TRE36D2M

TRE36D3 /

TRE36D3M

TRE36D4 /

TRE36D4M

TRE36D5 /

TRE36D5M

208V/60Hz

480V/60Hz

208V/60Hz

480V/60Hz

208V/60Hz

21.0 3 36” 37 1/4” 37”

480V/60Hz

208V/60Hz

480V/60Hz

208V/60Hz

240V/60Hz

480V/60Hz

Range Deck Oven

208V/60Hz

480V/60Hz

208V/60Hz

480V/60Hz

208V/60Hz

21.6 3 36” 37 1/4” 37”

480V/60Hz

208V/60Hz

480V/60Hz

208V/60Hz

480V/60Hz

Weight

Shipping Installed

525 lbs 417 lbs240V/60Hz

485 lbs 377 lbs240V/60Hz

525 lbs 417 lbs240V/60Hz

430 lbs 322 lbs240V/60Hz

495 lbs 387 lbs

525 lbs 417 lbs240V/60Hz

485 lbs 377 lbs240V/60Hz

525 lbs 417 lbs240V/60Hz

430 lbs 322 lbs240V/60Hz

495 lbs 387 lbs240V/60Hz

2M-W1624 TM 36” RANGE OP MANUAL

4

Page 5

GENERAL INFORMATION

CAUTION

WARNING

WARNING

This equipment is designed and sold for commercial use only by personnel trained and

experienced in its operation and is not sold for consumer use in and around the home nor for

use directly by the general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels associated with

the unit prior to putting it into operation. Make sure all people associated with its use understand the

units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both visible and concealed. This unit

has been tested and carefully packaged to insure delivery of your unit in perfect condition.

If equipment is received in damaged condition, either apparent or concealed, a claim must be made

with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked, a

request for inspection of concealed damage must be made with carrier within 15 days. Be certain to

retain all contents plus external and internal packaging materials for inspection. The carrier will make

an inspection and will supply necessary claim forms.

INSTALLATION

This unit is equipped for the voltage indicated on the nameplates mounted on the right side of the

range. They will operate on alternating current (AC) only.

DO NOT CONNECT TO DIRECT CURRENT (DC).

The installation of the electric range should conform to the:

NATIONAL ELECTRIC CODE AND ALL LOCAL ELECTRIC CODES AND

ORDINANCES AND THE LOCAL ELECTRIC COMPANY RULES AND

REGULATIONS

For your protection we recommend that a qualied electrician install this range. They should be

familiar with electrical installations and all electric codes. Proper connections and power supply are

essential for efcient performance. The external wiring should be in conduit or an approved type

of exible cable suitable for operation at the temperature indicated on the wiring diagram, and of a

proper size to carry the load. The supply circuit should be properly fused and equipped with a means

of disconnecting, as required by local electrical code. THE BODY OF THE RANGE SHOULD BE

GROUNDED (DO NOT GROUND TO A GAS SUPPLY LINE).

GENERAL OPERATING PROCEDURES

The Toastmaster series electric range is wired for operation for 3-phase power supplies by making

line connections at the terminal block, located on the bottom panel, behind the right side panel. All

connections should be made by a qualied service agent. Refer the the Electrical Connection section

& wiring diagram sections of this manual for more information.

Before operating the unit, any rust preventative material needs to be removed from the surface using

a nonammable grease solvent. Once completed, wash the surface with warm water and a mild

detergent, rinse with a damp cloth and dry wipe dry. Griddle surface must be seasoned immediately,

refer to your company guidelines or the seasoning section of this manual.

THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL PROVIDED.

DANGER:

FAILURE TO GROUND THE APPLIANCE COULD RESULT IN ELECTROCUTION

AND DEATH.

2M-W1624 TM 36” RANGE OP MANUAL

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL QUALIFIED

TO WORK WITH ELECTRICITY. IMPROPER INSTALLATION CAN CAUSE

INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT. UNIT MUST BE

INSTALLED IN ACCORDANCE WITH ALL APPLICABLE CODES.

5

Page 6

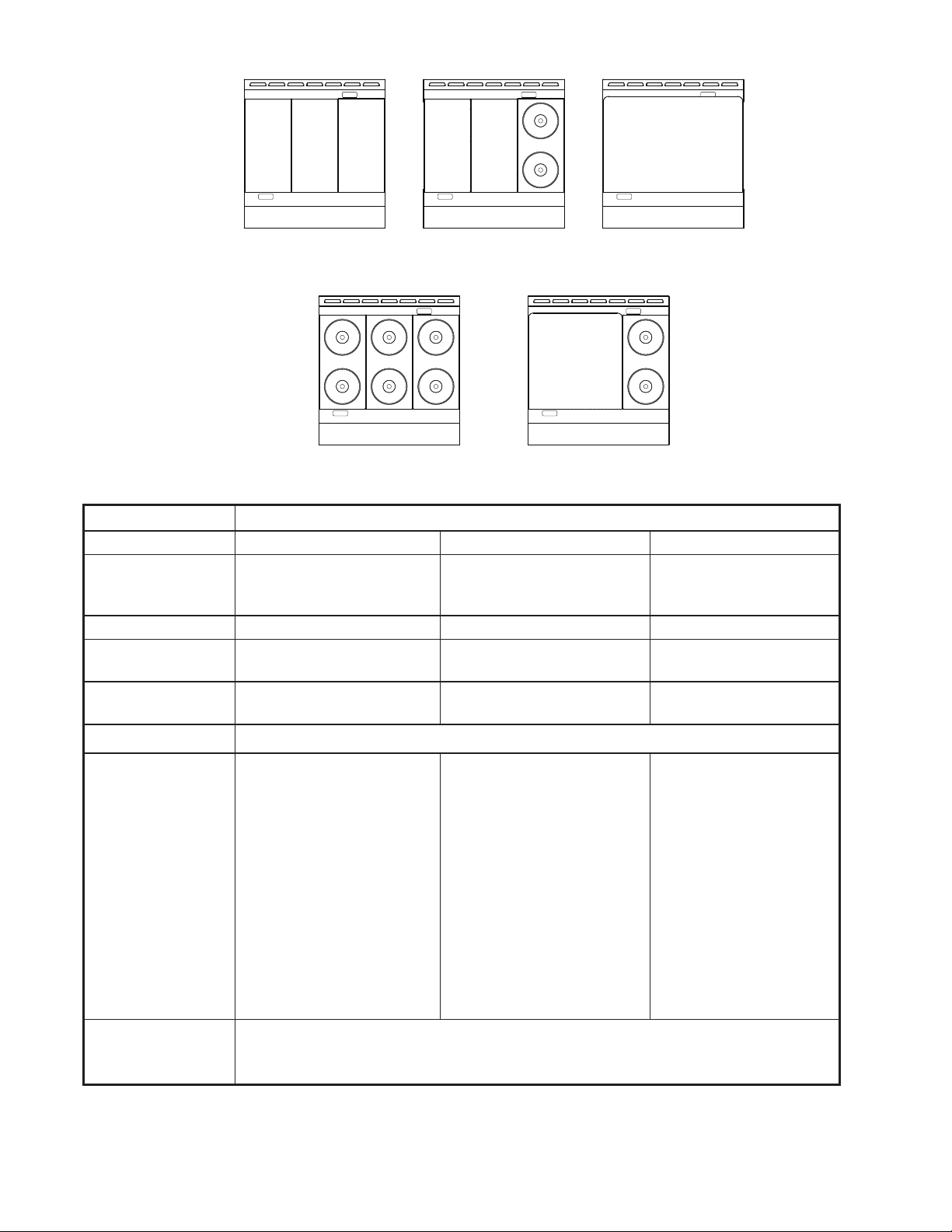

TRE36C1/D1

Three 12” x 24” hot tops

TRE36C2/D2

Two 12” x 24” hot tops

Two round hotplates

TRE36C3/D3

One 36” x 24” griddle plate

TRE36C4/D4

Six round hotplates

TRE36C5/D5

One 24” x 24” griddle plate

Two round hotplates

IL2020

RANGE TOP CONFIGURATION

RangeTopCongurations

Hot Plates Round French Plates Griddle Plates

12” x 24” Hot Plates controlled by

high temperature thermostats.

Round French Plates controlled by

3 heat switch.

Temp Range 0°F to 850°F 0°F to 750°F 0°F to 450°F

Recommended: Stock Pots & Heavy Kettle

Not-Recommended Frying of any kind

Light duty sauce pans and small

stockpots.

Heavy Stock Pots or Heavy Urns or

Kettles

The below procedure is to be followed in situations when the circuit trips when unit is turned on.

36” x 24” or 24” x 24”

grill plates, controlled by

thermostats.

All heavy and light frying.

Element “DRY OUT”

to be done with a

non-GFCI circuit

To “dry out” the hot plate, set the

thermostat dial at 250°F and turn

on the power switch. Allow unit to

cycle at least 15 minutes at this

heat level. Reset the thermostat

to 350°F allowing the same time.

Continue doing this until you

reach 850°F then allow the unit

to maintain this temperature for a

minimum of 4 hours. More time

may be required if the unit has to

operate in a moist enviroment

To “dry out” the frenchplate, set

the three-heat switch to the “LO”

setting and turn on the power

switch. Allow unit to run at least

15 minutes at this heat level.

Reset the three-heat switch to

“MED” and allow the same time.

Reset to the “HI” position. When

you reach position 3, allow the unit

to maintain this temperature for a

minimum of 4 hours. More time

may be required if the unit has to

operate in a moist enviorment

To “dry out” the griddle, set the

thermostat to 250°F and turn

on the power switch. Allow

the unit to cycle at least 15

minutes at this setting. Reset

the thermostat to 350°F

allow the same time. Reset

the thermostat to 450°F and

allow the unit to maintain the

temperature for a minimum

of 4 hours. More time may

be required if the unit has to

operate in a moist enviroment.

If unit is out of use for three or more days, a one-hour preheat schedule should be used, especially when

exposed to high humidity and/or cool temperatures.

NOTICE: During the rst few hours of operation you may notice a small amount of smoke & odor coming from the range.

This is normal for a new range and will disappear after the rst few hours of use.

6

2M-W1624 TM 36” RANGE OP MANUAL

Page 7

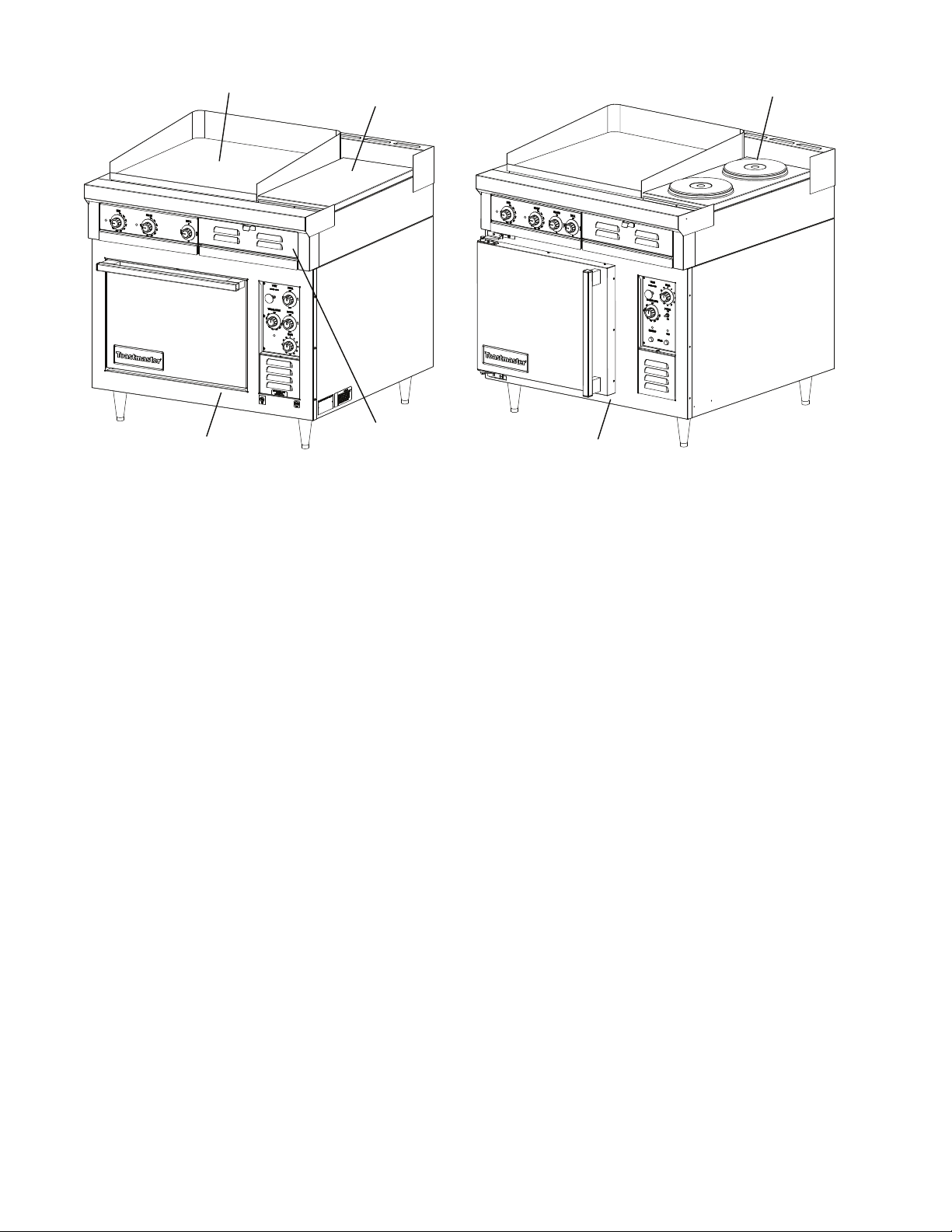

IL2022

Griddle

Hot Plate

Convection Oven

Deck Oven

French Plates

Circuit Breakers

2M-W1624 TM 36” RANGE OP MANUAL

EQUIPMENT DESCRIPTION

Toastmaster Model TRE36 electric oven range are rated heavy duty for commercial use. The oven

range consists of a range top fastened to an oven base. There are marine units available which would

qualify it for shipboard use. These models are indicated with a “M” in the model number The marine

features are on oven door latch, grease tray latch, bolt-down legs, range top adjustable sea rails and a

grab bar across the front.

OVEN BASE: The oven base can be either a deck oven or convection oven.

a. Deck Oven

The deck

vent with damper and landing shelf type aluminized steel lined door. The oven is insulated

on all sides and is equipped with one slide-in rack. Heating is accomplished with top and

bottom formed tubular heating elements which are each controlled by a 3-heat (low, medium,

high) switch. The deck oven has a thermostatic control with a temperature range of 200°F

to 550°F (93°C to 287°C).

b. Convection Oven (“C” in Model #, example

The convection

lined door. The oven is insulated on all sides. Removable rack supports can accommodate

three racks. The heating element is enclosed in the side of the oven cavity and encircles the

oven blower fan. The convection oven has a thermostatic control with a temperature range

of 100°F to 450°F (38°C to 232°C).

RANGE: The range top can consist of up to 3 different components and the components can be

congured in ve ways. Troughs with a drip chute are located in the front and rear for draining into two

wide drawer type receptacles

a. Griddle:

sections are thermostatically controlled.

b. 12”

x 24” Hot Plate: for stock pot cooking (Not recommended for griddling). The hot plates

are thermostatically controlled and have a temperature range of 250°F to 850°F (121°C to

454°C).

c. Round Hot Plate (French Plates): for stock pot cooking.

diameter and are controlled by 3-heat (low, medium, high) switches.

(“D in Model #, example TRE36D1)

oven base has a aluminized steel inner lining, removable deck of rigidized steel,

TRE36C1)

oven has aluminized steel oven liners, vent damper and aluminized steel

for grilling. The griddle can be either 24” x 24” or 24” x 36”. Each of the 12” griddle

The twin hot plates have 9”

7

Page 8

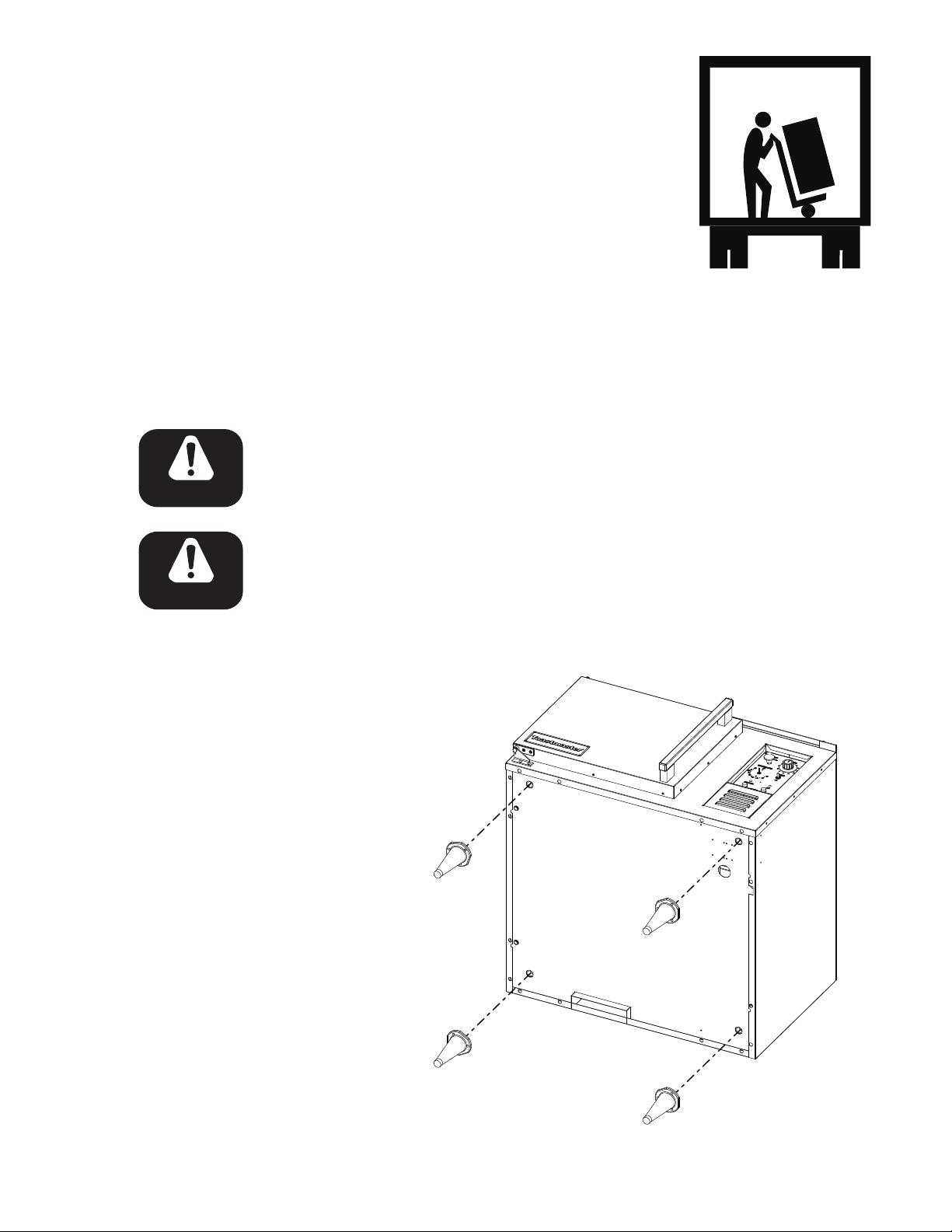

Receiving the Range

IL2023

CAUTION

CAUTION

Upon receipt, check for freight damage, both visible and concealed. Note

visible damage on the freight bill at the time of delivery and require the

carrier’s agent to sign the freight bill. Concealed loss or damage means loss

or damage, which does not become apparent until the merchandise has

been unpacked. If concealed loss or damage is discovered upon unpacking,

make a written request for inspection by the carrier’s agent within 15 days

of delivery. Keep all packing material for inspection. Do not return damaged

merchandise to Toastmaster. File your claim with the carrier.

Location

Prior to un-crating, move the range as near its intended location as practical.

The crating will help protect the unit from the physical damage normally associated with moving it

through hallways and doorways.

The clearances to combustable surfaces must be maintained: 3 inches from the back & sides.

Un-crating

The unit will arrive unassembled inside a wood frame covered by cardboard box and strapped to a

skid. Remove the cardboard cover, cut the straps and remove the wood frame.

RANGE IS VERY HEAVY AND FOR SAFE HANDLING, INSTALLER SHOULD

OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE MATERIALS

HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR PALLET JACK)

TO REMOVE THE UNIT FROM THE SKID AND MOVE IT TO THE PLACE OF

INSTALLATION.

ANY STAND, COUNTER OR OTHER DEVICE ON WHICH RANGE WILL BE

LOCATED MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE OVEN.

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

Remove range from skid and place in intended location.

Installing the Legs

Legs ship standard with all ranges.

To install the 6-inch legs, remove

the legs from the packing, place

some cardboard on the oor and

gently tip the oven onto its back.

Fasten the legs into the threaded

holes provided and then gently ip

the oven onto its legs.

2M-W1624 TM 36” RANGE OP MANUAL

8

Page 9

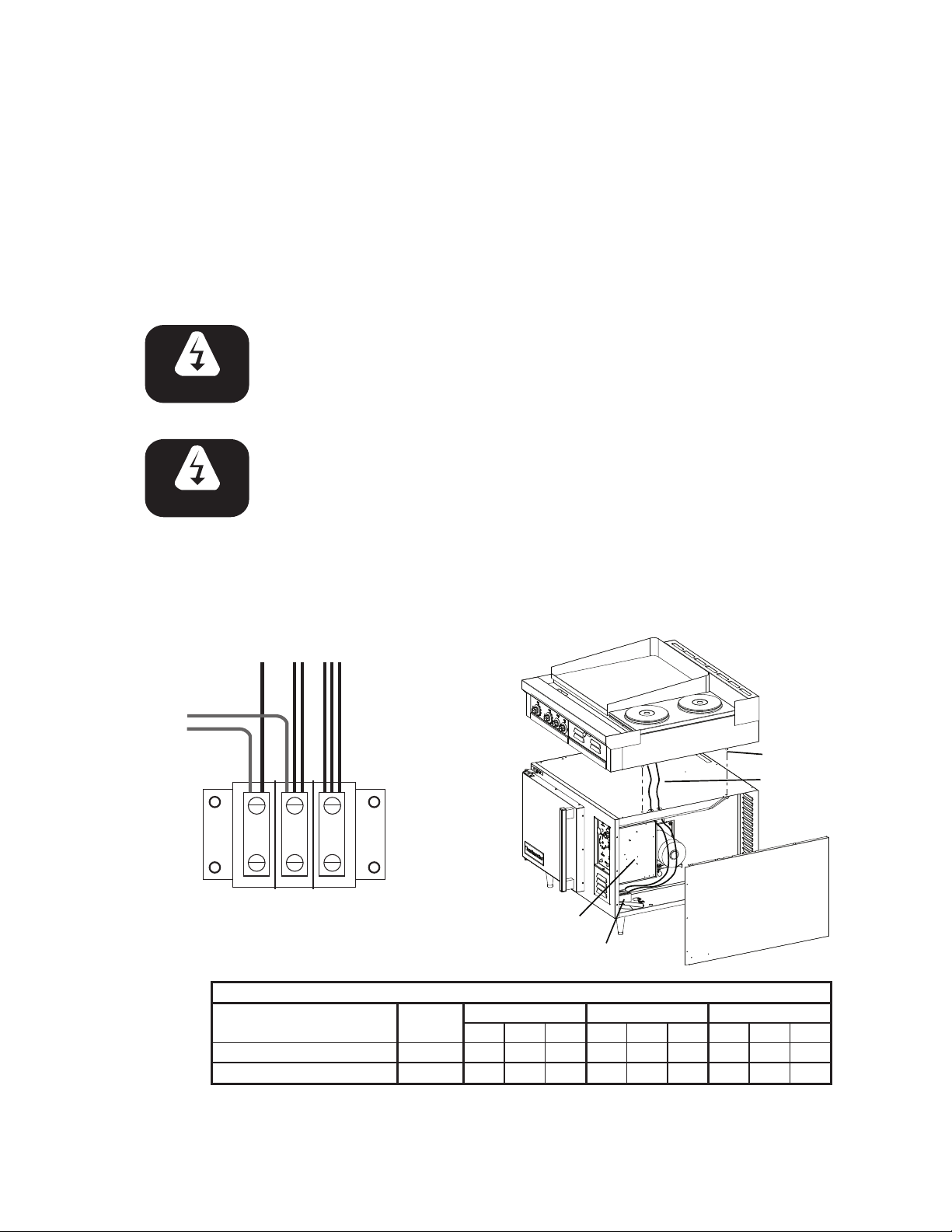

Electrical Connection

WARNING

WARNING

3

IL2024

1,5 2,4,6

TO OVEN

TERMINAL BLOCK

IN OVEN BASE

TO RANGE

TOP

Three Phase

NOTE: 480V UNITS GET WIRED DIRECTLY INTO

THE CIRCUIT BREAKER IN THE OVEN, REFER TO WIRING DIAGRAM.

Terminal Block

Locating Pins (4)

Supply Wires (6)

IL2025

480V

Circuit Breaker

Make all electrical connections in accordance with local codes or in the absence of local codes with

NFPA No. 70 latest edition (in Canada use: CSA STD. C22.1).

The electrical service entrance is provided by a 1 1/4” knockout on the oven bottom. A three pole

terminal block is provided for connection.

Place spacers, (i.e. 2x4 wood block not supplied) at the front and rear of the oven top.

Place the range top on the spacers that are located on top of the oven.

The six wire leads that supply electricity to the cook top are bundled under the front of the top. Route

the six wires through the bushing provided in the oven top.

Align the four locating pins in the bottom corner of the top with the four holes in each corner of the

oven top.

Remove the spacers and lower the top onto the oven.

MAKE SURE THE SIX WIRE LEADS TO SUPPLY ELECTRICITY TO THE RANGE

TOP ARE NOT CRIMPED BETWEEN THE OVEN AND RANGE TOP. FAILURE TO

COMPLY WILL RESULT IN DAMAGE TO EQUIPMENT.

The range can now be connected to power.

BE SURE THE POWER SUPPLY VOLTAGE MATCHES THE VOLTAGE

SPECIFIED ON THE NAMEPLATE LOCATED ON THE RIGHT SIDE OF THE

RANGE. FAILURE TO COMPLY MAY RESULT IN PERSONAL INJURY AND/OR

DAMAGE TO EQUIPMENT

Use the wiring diagram provided in this manual for determining the connections of the cook top wires

to the oven terminal block or circuit breakers on the 480V units.

2M-W1624 TM 36” RANGE OP MANUAL

Making the Electrical Connection

The following table and illustrations provide the voltage and kilowatts necessary to operate the range

and oven.

Range Style

w/ CONVECTION OVEN 21.6 48.3 69.2 62.5 41.9 59.9 54.1 20.5 29.5 27.1

w/ DECK OVEN 21.0 45.8 66.7 62.5 39.7 57.8 54.1 19.9 28.9 27.1

ELECTRICAL SPECIFICATIONS

Total

k.W.

208 Volt 240 Volt 480 Volt

L1 L2 L3 L1 L2 L3 L1 L2 L3

9

Page 10

CLEANING

WARNING

CAUTION

CAUTION

KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY OR HOSE CONTROL

CONSOLE, ELECTRICAL CONNECTIONS, ETC.

MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS MEMBRANES AND

CLOTHING. WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND PROTECTIVE

CLOTHING. CAREFULLY READ THE WARNING AND FOLLOW THE DIRECTIONS ON THE

LABEL OF THE CLEANER TO BE USED.

The range should be thoroughly cleaned at least once a week in addition to the normal daily cleaning to insure

against the accumulation of foreign material.

Any oven cleaner used should be marked “Safe On Aluminum”.

Always start with a cold oven / range

The stainless exterior can easily be cleaned using stainless steel cleaner, always follow the manufacture’s

instructions when using any cleaner

Keep-drip pans under the range top plates clean.

Keep the hotplate and griddle surfaces clean.

Outside of the range and top should be kept clean.

Care should be taken to prevent caustic cleaning compounds from coming in contact with the blower wheel.

The oven interior should be cleaned using a mild soap and a non metal scouring pad. DO NOT use caustic

cleaners. Always apply these cleaners when the oven is cold and rub in the direction of the metal’s grain.

Electric equipment is inherently clean and sanitary, but may become unsanitary if dirt is allowed to accumulate on it.

Take advantage of the clean, sanitary features of electric equipment, give it the regular attention that it deserves the

same as any other highly perfected machinery, to insure best results and continued high operating efciency.

.

CALIBRATION

Calibration Check

Place thermometer in the center of oven cavity.

Set thermostat to 350°F and place both 3-heat switches in the “HIGH” position.

Allow the oven to Preheat for at least half an hour.

NOTE

Cycle on temperatures and cycle off temperatures for 3 cycles. (Red indicator light indicates when oven is calling for

heat)

After 3 cycles average the temperature. (Add all six temperatures and divide by 6)

Calibration Adjustment

A 1/16” at blade screwdriver with a 2” shaft is required to make adjustments to the thermostat.

Maintain the oven temperature at 350°F. Without turning the thermostat, remove the knob.

Locate the adjustment screw at the base of the shaft and insert the screwdriver.

Hold the shaft and turn the screwdriver counter clockwise to increase the temperature and clockwise to decrease

the temperature. (1/8 of a turn will move the temperature 5-7 °F in either direction). Reinstall the oven knob and

recheck the oven temperature.

2M-W1624 TM 36” RANGE OP MANUAL

10

Page 11

TROUBLESHOOTING

CAUTION

WARNING

Troubleshooting is not an exact science, several factors may play a part in why your unit is not operating correctly.

The following symptoms are a general idea of what may be causing the malfunction and should not be considered the

complete answer to the situation that you have with your machine. Here are some of the possible problems you may

encounter and possible solutions to those problems.

TESTS

Serviceonthisoranyotherappliancemustbeperformedbyqualiedpersonnelonly.

NOTICE:

If an item on the list is followed by an asterisk (*), the work should be done by a factory authorized service

representative.

Consult your Toastmaster Authorized Service Agent Directory. You can call our toll free

number 1-800-264-7827 or visit our website WWW.STAR-MFG.COM for the service agent

nearest you.

BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE THIS APPLIANCE WHEN THE

UNIT IS PLUGGED/WIRED INTO A LIVE RECEPTACLE. BEFORE REPLACING ANY PARTS,

DISCONNECT THE UNIT FROM THE ELECTRIC POWER SUPPLY.

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY TOASTMASTER

OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE BODILY INJURY TO THE OPERATOR

AND DAMAGE TO THE EQUIPMENT AND WILL VOID ALL WARRANTIES

RANGE TOP TROUBLESHOOTING

Symptom Possible Causes

No power to unit

Hotplate will not heat

French Plate will not heat

Griddle plate will not heat

Defective thermostat

Failed element

No power to unit

Failed 3-heat switch

Failed element

No power to unit

Failed thermostat

Failed element

Possible Causes Test

Failed Thermostat Verify calibration

Failed element Remove the wires and check for continuity across the element*

Failed 3-heat switch Call factory or consult service manual for proper test

2M-W1624 TM 36” RANGE OP MANUAL

11

Page 12

FEATURES

VENT TIMER

POWER

ON

ONHEATING

FUSES

OFF

TEMPERATURE

Circuit Breaker Panel

Vent Knob

Temperature

Timer

Power

Switch

IL2028

Exterior Construction

The oven exterior dimensions are 36” (91.44cm) Wide, 22” (55.88cm) High, 34” (86.36cm) Deep.

The Front, Back, and Sides are constructed of stainless steel with an aluminized top and bottom

The oven cavity is insulated with high temperature insulation for efciency and reduced heat loss.

Interior Construction

The oven cavity dimensions are 20” (50.8cm) Wide, 17” (43.18cm) High, 29” (73.66cm) Deep.

The oven is designed for three shelves and comes with three Chrome Plated Racks.

The interior of the oven is constructed of aluminized steel.

CONVECTION OVEN

The oven is a forced air convection oven with a vented oven cavity.

The air is driven by a 1/3 HP fan motor.

Controls

Operation

Easy to use manual control knobs.

Mechanical temperature sensing and controls.

Technical

Oven operates as shipped on 208, 240, or 480-Volt Three Phase.

Floor space required is 42” (106.68cm) Wide, 37” (94cm) Deep.

The oven weighs 275 lb.

.

12

2M-W1624 TM 36” RANGE OP MANUAL

Page 13

Initial Preheat

Prior to putting any oven into full time operation at normal cooking temperatures, it must be thoroughly dried

out. Moisture absorption in the closed spaces, in the insulation, and even inside the heating elements can

cause future trouble if not properly treated.

To “dry out” the oven, set the thermostat to 250°F and turn on the power switch. Allow the unit to cycle at

least 15 minutes at this heat level. Reset the thermostat to 350°F allow the same time. Reset the thermostat

to 450°F and allow the unit to maintain the temperature for a minimum of 4 hours. More time may be

required if the unit has to operate in moist environment.

If the unit is out of use for three or more days, a one-hour preheat schedule should be used, especially

when exposed to high humidity and/or cool temperatures.

NOTICE:Duringtherstfewhoursofoperationyoumaynoticeasmallamountof

smoke coming from the oven, and a faint odor from the smoke. This is normal for

anewrangeandwilldisappearaftertherstfewhoursofuse.

CAUTION: ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

CAUTION: KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF SPILLS

OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER OF SLIPS OR FALLS.

General Operation

The convection oven roasts and bakes in shorter time and at lower temperatures with less shrinkage than

conventional commercial ovens.

A blower in the convection oven circulates air within the chamber to heat the entire space evenly and

transfer heat efciently to the product, even with stacked loading.

The airow continuously removes the thick layer of moist, cool air that otherwise would surround the

product. When properly loaded and operated, it maintains this airow throughout the chamber to eliminate

hot spots and roasts or bakes with minimum power consumption at twice the output capacity of a

conventional oven.

The power switch on the lower portion of the control panel energizes the fan motor and activates the

thermostatically controlled circuit for the oven heating elements. When this switch is in the on position, the

red indicator light will illuminate.

Rotating the thermostat control knob from “off” position to selected temperature causes the indicator light

to illuminate and closes the contactor that feeds power to the heating elements. This light will cycle “on

and off” as the thermostat calls for heat in the oven. The blower, however, operates continuously while the

power switch is in the “on” position.

The black knob operates a damper in the oven vent stack. The damper is open when the vent knob is

pulled outward, this will remove moisture from the bake and will provide a dryer bake. Close the vent to

contain the moisture in the bake.

Circuit breakers behind the control panel protect the electrical components from overload. On 208/240V

units the circuit breakers are located in both the range top and oven, 480V units all circuit breakers are in

the oven.

CONVECTION OVEN

2M-W1624 TM 36” RANGE OP MANUAL

CONVECTION OVEN TYPICAL OPERATION

ACTION RESULT

Turn power switch to ON Control Panel heat call light comes on.

Adjust proper temperature, between 140°F - 450°F and allow

preheating for 20 minutes.

Open oven doors and insert product. Set timer for up to 60

minutes.

Timer rings when done. Product should now be done.

13

Oven begins heating

Timer begins counting down

Page 14

INITIAL PREHEAT

OVEN RACK

DECK

IL2033

DOOR REMOVED FOR CLARITY

The preservatives must be cleaned off the oven front before it is heated. Wipe the oven front with a

damp rag and a mild soap solution, rinse with warm water and a damp rag, and then completely dry

the oven front.

Before the initial use of the oven it must be allowed to thoroughly dry the elements out. This is

accomplished by setting the top and bottom oven 3-heat switches to the “Low” position and the

thermostat to 350°F degrees. Allow the oven to heat until all vapor and smoke has been eliminated.

Somewhere along the rising temperature curve between 250°F and 350°F degrees a moderate

amount of smoke will issue from within the oven. Preservative oils and oil accumulated during

manufacture will come off as smoke at these temperatures. Do not be alarmed.

DECK OVEN

NORMAL OPERATION

PREHEATING

The oven will not bake uniformly if not allowed to thoroughly preheat before loading the product. To

compensate for the temperature loss during loading, set the oven thermostat 50° degrees over the

desired cooking temperature, load the oven, then reset the thermostat to the proper temperature

after closing the oven door. The oven can be preheated with the 3-heat switches set on any position,

however, the fastest preheat will be accomplished with both the switches set to the “High” position.

Once the oven is at the set temperature and the product is loaded reset the 3-heat switches to their

proper setting. An indicator light, located below the oven thermostat knob, will go out once the oven

has received the set temperature. Allow the oven indicator lamp to cycle on and off at least two times

during the preheat.

OVEN RACK

The oven is equipment with a removable rack as standard. Baking pies, bread, or for roasting

operations the rack can be placed directly on the metal deck and the pans placed on the rack. For

cakes or pastries the rack can be slid into the rack supports, located about halfway up the oven sides,

and the pans placed on the rack in this raised position.

2M-W1624 TM 36” RANGE OP MANUAL

14

Page 15

VENT

UPPER

LOWER

TIMER

TEMPERATURE

INICATOR LIGHT

IL2032

CONTROL PANEL

DECK OVEN

2M-W1624 TM 36” RANGE OP MANUAL

3-HEAT SWITCHES

While the oven thermostat controls the

temperature, the 3-heat switches control

the amount of power from the upper and

lower elements. Setting the top element

3-heat switch to “High” will burn (or broil)

the tops and setting the bottom 3-heat

switch to “Low” will not cook the bottom of

most products. Set the 3-heat switches

to achieve the best uniformity between

the top and bottom of the product. Best

results for baking will be accomplished with the top 3-heat switch set to the “Low” position and

the bottom 3-heat switch set to either “Medium” or “High”.

The Temperature Switch Setting and Rack Position chart is suggested as a guide in baking

the various classes of product. Be aware this chart is only a suggestion. Correct temperature,

switch settings and rack positions will be arrived at through experience.

Class of

product

Average

Temperature

Switch

Settings

Rack Position

Pie 375-425°F Medium On Deck

Rolls 375-400°F High Rack Support

Cake 350-400°F High Rack Support

Pastries 325-375°F High Rack Support

Bread 425-450°F Medium On Deck

Roast 300-325°F Medium On Deck

PAN PLACEMENT

Place the pan in the center of the oven rack for the best baking results. Keep the oven door

closed as much as possible. Excessively opening the oven door will cool the front section of

the oven and the products placed near the opening will bake slower.

VENT CONTROL

The oven is supplied with an oven vent control located above the thermostat dial. If cooking

products with high moisture content open the vent by pulling the knob out. The moisture will be

vented out the back of the oven as steam. If the products require a moist baking environment

push the vent damper closed.

TIMER

A 60 minute mechanical timer is standard equipment for the TRE36D units. To set, turn the

dial until the indicator line is aligned with the desired time on the control panel. If setting the

timer for less than 10 minutes the dial must rst be turned past the 10 minute mark then reset

to the required time. Once the timer has timed-out it will sound a bell for about 5 seconds then

automatically turn off.

15

Page 16

Toastmaster Electric Range Top TRE36 Series

Fig No. Part Number Description Application

P9-50401-02 SMOOTH RANGE PLATE ASSY 1/2 X 2’

1

P9-50401-03 SMOOTH RANGE PLATE ASSY 1/2 X 3’

2N-11120-12 ELMNT TK 208V 2600W 208V

2

2N-11120-13 ELMNT TK 240V 2600W 240V

2N-11120-14 ELMNT TK 480V 2600W 480V

3 P9-50300-82-1 EGO PLATE FRM ASY PHANT

PS-11010-341 HOTPLATE 208V 5000W CAST 208V

4

PS-11010-351 HOTPLATE 240V 5000W CAST 240V

PS-11010-361 HOTPLATE 480V 5000W CAST 480V

2N-11010-09 ELMNT T/P 208V 2KW O/S 208V

5

2N-11010-21 ELEMT T/P 240V 2KW O/S 240V

2N-11010-23 ELEMT T/P 480V 2KW O/S 480V

2N-11010-10 ELMNT T/P 208V 3KW I/S 208V

6

2N-11010-22 ELMNT T/P 240V 3KW I/S 240V

2N-11010-24 ELEMT T/P 480V 3KW I/S 480V

7 P9-50300-42 ZIG ZAG ASSY W SNOUT

8 P9-50300-41 ELEM PAN ASSY W/SNOUT

P9-50300-22 208-240V 3/16 STAT BULB HLDR 208/240V

9

P9-50300-43 480V 3/16 BULB HLDR 480V

N2-RF21-415-W4 PAN ASSY A/L - TM NON MARINE

10

N2-RF21-414-W3 MARINE PAN ASSY - TM MARINE

Q9-RF21-423-2 SWITCH DOOR ASSY 208V-430 208/240V

11

Q9-RF21-423-21 SWITCH DOOR ASSY 480V-430 480V

12 P9-RF21-228 CIRCUIT BREAKER COVER 208/240V

13 2E-31800-01 CB 250V50A 1 POLE CRLNGSW 208/240V

14 2E-30304-W35 SWITCH - 3 POS ROTARY EGO ROUND PLATES

2T-30402-23 STAT ADJ 850o 48C/T NAK HOTPLATES

15

2T-30402-08 STAT ADJ 450°F GRIDDLES

N2-RF21-305-W3 CONTROL PANEL TM - 1 & 3 TRE36C1, D1, C3, D3

16

N2-RF21-306-W3 CONTROL PANEL TM - 2 & 5 TRE36C2, C5, D2, D5

N2-RF21-304-W3 CONTROL PANEL TM - 4 TRE36C4, D4

2M-60301-W178 LABEL-CNTL PANEL TM RT 1 TRE36C1 / TRE36D1

2M-60301-W179 LABEL-CNTL PANEL TM RT 2 TRE36C2 / TRE36D2

17

2M-60301-W180 LABEL-CNTL PANEL TM RT 3 TRE36C3 / TRE36D3

2M-60301-W181 LABEL-CNTL PANEL TM RT 4 TRE36C4 / TRE36D4

2M-60301-W182 LABEL-CNTL PANEL TM RT 5 TRE36C5 / TRE36D5

2J-31601-01 PILOT LT 250V 6LEAD BLK 208/240V

18

2J-31601-02 PILOT LT 480V 6LEAD BLK 480V

N2-70701-W62 KNOB ASSY-TM RANGE TOP HOTPLATES

N2-70701-W61 KNOB ASSY-TM RANGE TOP GRIDDLES

19

N2-70701-W63 KNOB ASST-TM RANGE TOP ROUND PLATES

20 P9-50300-44-1 GRAB BAR ASSY 36 RANG MARINE

21 P9-60102-93 MARINE LATCH ASSY MARINE

P9-50302-301 SEARAIL ASSY 3’ MARINE

22

P9-50302-303-1 SEARAIL ASSY 1’ MARINE

2M-W1624 TM 36” RANGE OP MANUAL

Page 17

IL2026, Rev. -, 5/27/2010

MODEL: TRE36 RANGE TOP

MARINE APPLICATIONS

1

2

3

4

5

10

20

21

22

11

12

13

17

18

19

14

15

16

6

7

8

9

2M-W1624 TM 36” RANGE OP MANUAL

Page 18

TRE36D 36” BAKE DECK OVEN MAIN ASSEMBLY

Fig No Part No Qty Description Application

1 2C-20103-02 37 SCRW SM PLT 10 X .5 PHLSL

2 N9-LA36-159 1 TOP LA OVEN S/S

2N-11050-25

3

2N-11050-29 ELMNT 36” OVEN 480V O/S 480V

2N-11050-31 ELE 36”OVN 208V O/S 1.8KW 208V

2N-11050-26

4

2N-11050-30 ELMNT 36” OVEN 480V I/S 480V

2N-11050-32 ELE 36”OVN 208V I/S 1.2KW 208V

5 P9-50301-09 12 LONG ELEMENT CLIP S/S

6 P9-50301-10 12 SHORT ELEMENT CLIP

7 2C-20301-15 8 NUT HEX 10-32 PLTD

8 N9-LA36-109-1 1 CAPILLARY SHIELD

9 2P-70901-05 1 PLGBTNBLKPLSTC 3/4DP-750

10 2E-31200-02 1 LUG GROUNDING UL APPROVED

11 2C-20103-01 2 SCRW SM PLT 10X7/8 PHIL

12 2E-30500-07 1 TRM BLOCK 3PLELRGE 125AMP

13 N9-LA36-128 1 SWITCH DOOR ASSY

14 N2-LA36-193-W2 1 DOOR ASSY A/L

16 N9-LA36-184 1 DECK CHANNEL ASSY A/L

NI 2A-72500-06 4 LEG 5 1/2 W/BOLT DOWN ADJ Marine

NI 2B-50200-09 1 RACK 36 OVEN

NI 2B-50200-52 1 RACK 36 OVEN CRUISE LINE Marine

ELE 36OVN 240V O/S 1.8KW 240V

2

ELE 36OVN 240V I/S 1.2KW 240V

2

OVEN DOOR & CONTROL PANEL

Part Number Qty Description Application

2A-50800-07 2 TENSION DISC STD OVEN

2A-LA36-145 2 DOOR RODS LA36

2A-LA36-146 2 DOOR PIPE LA36

2A-3013164 2 SPACER, DOOR & DRAWER HND

2E-30304-W35 2 SWITCH - 3 POS ROTARY (mounted w/2 screws)

2E-31800-01 2 CB 250V50A 1 POLE CRLNGSW 208V(M), 240V (M)

2E-31800-04 1 CB 480V 50A 3-POLE 480V (M)

2H-60106-31 1 INSULATION DOOR

2J-30801-01 1 TIMER MECHANICAL LONG

2J-31601-01 1 PILOT LT 250V 6LEAD BLK 208V (M)

2J-31601-02 1 PILOT LT 480V 6LEAD BLK 480V (M)

2M-60301-W02WL 1 LABEL-W/D TM RANGE

2M-60301-W183 1 LABEL-CNTL PANEL TM DO

2P-51001-01 1 SPRING OVN LH DOOR

2P-51001-02 1 SPRING OVN RH DOOR

2R-50312-79-W2 1 HANDLE-DOOR TM DECK OVEN

2T-30402-07 1 STAT ADJ 550o 48 C/T

N2-50312-33-W2 1 DOOR OUTSIDE PANEL ASSY - TM

N2-70701-W64 1 KNOB ASSY-TM OVEN TIMER

N2-70701-W65 2 KNOB ASSY-TM OVEN 3POS SW

N2-70701-W66 1 KNOB ASSY-TM OVEN TSTAT

N9-LA36-116 1 VENT PIPE ASSY

N2-LA36-130-W1 1 CONTROL SLIDE ASSY-W1

N2-LA36-142-W1 1 DOOR INSIDE PANEL A/L-TM

Q9-50312-81 1 BREAKER HOLDER

2M-W1624 TM 36” RANGE OP MANUAL

18

Page 19

IL2034 Rev. - 6/11/10

Model:

TRE36D Deck Oven

2

1

3

5

6

7

1

9

1

10

11

12

13

14

16

8

4

See Controls

Parts List

See Door

Parts List

2M-W1624 TM 36” RANGE OP MANUAL

19

Page 20

TRE36C 36” CONVECTION OVEN MAIN

ASSY

Item

No.

Part No. QTY Description App.

1 Q9-F6-160 1 TOP A/L

2 2H-F6-259 1 INSULATION-TOP REAR

3 2H-F6-260 1 INSULATION-REAR FILLER

4 Q9-F6-113 1 VENT PIPE ASSEMBLY

2N-11090-09

2N-11090-10 ELMNT F6OVEN 240V 6KW 240V

5

2N-11090-11 ELMNT F6OVEN 480V 6KW 480V

6 2H-F6-251 1 INSULATION-SIDE R/H FRONT

7 2H-F6-159-1 1 INSULATION CAN SIDE UPPER

8 2H-F6-252 1 INSULATION-SIDE R/H REAR

9 2H-F6-159 1 INSULATION CAN SIDE LOWER

10 Q9-F6-189 1 MOTOR MOUNT ASSEMBLY NO

11 2H-F6-254 1 INSULATION- BOTTOM REAR

12 2H-F6-253 1 INSULATION-BOTTOM FRONT

13 Q9-F6-131 1 BOTTOM FRONT CHANNEL

14 Q9-F6-137 1 SWITCH DOOR

15 2F-70601-28 1 HINGE BRAKET LOWER LEFT

16 Q9-F6-129 1 FRONT STD

17 2F-70601-27 1 HINGE BRAKET UPPER LEFT

18 Q9-F6-130 1 TOP FRONT CHANNEL ALL

19 Y9-50300-63 1 MARINE PAN LATCH ASSY MARINE

20 Q9-50301-52 1

21 Q9-F6-132 2 HINGE NUT PLATE

22 2H-F6-257 1 INSULATION- LEFT FRONT

23 2H-F6-256 1 INSULATION-LEFT REAR

24 2H-F6-258 1 INSULATION-TOP FRONT

25 2H-F6-255 1 INSULATION-BACK

2H-F6-158 1 CAN SIDE INSULATION

NI

ELMNT F6OVEN 208V 6KW 208V

1

DOOR STOP LH ARM&BRACKET

ASSY

MARINE

TRE36C CONVECTION OVEN

DOOR ASSY

Part No. QTY Description App.

2A-3013164 2 SPACER, DOOR & DRAWER HND

2C-20103-06 AR SCRW SM PLT 6 X 3/8 PHL

2C-20109-13 AR SCRW MS SS 10-32 X .5 PH

2C-20202-17 AR WSHR LOCK FOR 70601-27/28

2F-70601-05 AR PLATE & BUSH HINGE HALF

2F-70601-06 AR HINGE PIN, HALF HINGE

2H-F6-144-1 1 DOOR INSULATION

2M-60301-W185 1 NAMEPLATE LOGO TM

2R-50312-79-W2 1

N2-F6-145-W2 1 OUTSIDE DOOR PANEL ASSY

N2-F6-146-W1 2 STIFFENER - DOOR HANDLE

PS-50301-50-1 1 DOOR STOP ASSY L/H MARINE

Q9-F6-144 1 INSIDE DOOR PANEL A/L

HANDLE, DOOR TM CONVE

OVEN

TRE36C CONVECTION OVEN

CONTROLS ASSY

Part No. QTY Description App.

2E-30303-06 1 SWT TOG ON-ON DPDT BLK

2E-30700-03 1 CONTC 3POLE 40A208-240VAC

2E-30701-03 1 CONTC2POL35A208-240V50/60

2E-308010-01 2 CB 250V 50A

2E-30901-02 2 FUS HLDR FOR 15AMP FUSE

2E-31400-04 1 XFRMR 480/240VAC 100VA 480V

2E-31800-04 1 CB 480V 50A 3 POLE 480V

2J-30801-01 1 TIMER MECHANICAL LONG

2J-31601-01 2 PILOT LT 250V 6LEAD BLK

2R-70701-25 1 KNOB DAMPER BLACK PLAIN

2T-30402-27 1 STAT ADJ 450 DEG 48 PILOT

N2-70701-W64 1 KNOB ASSY-TM OVEN TIMER

N2-70701-W67 1 KNOB 450o D PHANTOM

N2-F6-138-W2 1 CONTROL SLIDE SPOTWELD

208V,

240V

20

2M-W1624 TM 36” RANGE OP MANUAL

Page 21

IL2035 Rev. - 6/11/10

Model:

TRE36C CONVECTION OVEN

MAIN ASSEMBLY

1

7

6

8

9

10

11

5

4

15

17

19

16

18

20

21

24

25

22

23

14

12

13

2

SEE

CONTROLS

PARTS LIST

SEE DOOR

PARTS LIST

3

2M-W1624 TM 36” RANGE OP MANUAL

21

Page 22

CONVECTION OVEN MOTOR FAN ASSEMBLY

Item No. Part No. QTY Description Application

1 2C-20104-18 4 SCRW HXHDCP 5/16-18X1-1/4 ALL MODELS

2 2C-20201-09 AR WSHR PLT 5/16 FLAT SAE ALL MODELS

3 2A-20503-01 4 5/16IDX27/640DX5/16LG STL ALL MODELS

4 2I-70801-06 4 RUBBER GROMMET 7/16 I.D. ALL MODELS

5 2U-30200-03 1 MTR 1/3HP 480V 3PH 60HZ 480V

5 2U-30200-12 1 MTR 1/3HP 115/208-240 1PH 208/240V

6 Q9-F6-180 1 MOTOR MOUNT WELDMENT ALL MODELS

7 2H-F6-184 1 MOTOR INSULATION ALL MODELS

8 Q9-F6-186 1 MOTOR INSULATION RETAINER ALL MODELS

9 2C-20301-13 AR NUT HEX 1/4-20 PLTD ALL MODELS

10 2C-20301-06 4 NUT HEX 5/16-18 PLTD ALL MODELS

11 2C-20202-08 4 WSHR PLT 5/16 LOCK SPLIT ALL MODELS

12 2C-20306-02 4 AVK CAD 1/4-20 1ST GRP ALL MODELS

13 Q9-F6-185 4 BLOWER SPACER ALL MODELS

14 2C-20201-07 4 WSHR FLT 1/4 SAE PLTD ALL MODELS

15 2C-20104-14 4 SCRW HXHD TAPBOLT ALL MODELS

16 2C-20103-06 4 SCRW SM PLT 6 X 3/8 PHL ALL MODELS

17 Q9-F6-406 1 WELD ORIFICE RING ALL MODELS

18 Q9-F6-181 1 MOTOR MOUNT PLATE ALL MODELS

19

2U-71500-03

1 BLOWER WHEEL F-6 ALL MODELS

22

2M-W1624 TM 36” RANGE OP MANUAL

Page 23

2

3

4

1

5

6

19

18

17

16

7

8

9

10

11

2

12

13

14

15

IL2036 Rev. - 6/07/10

Model:

TRE36C Motor Fan Assembly

2M-W1624 TM 36” RANGE OP MANUAL

23

Page 24

2M-61105-W15, Rev. -

CONVECTION OVEN W/ RANGE TOP 208V / 240V

1

2

3

4

5

8

7

6

10

9

8

8

8

88

2

1

5

1667

1667

1667

4

1

3

2

3

1

2

3

4

3

9

2 3 4 2 3 4

5

2

8

1

8

1

2

5

4

10

4

2

1

6

7

HEAT ELEMENT

THERMOSTAT

3 HEAT SWITCH

MOTOR

PILOT LAMP

CONTACTOR

POWER SWITCH

CIRCUIT BREAKER

SPEED UNIT

FUSE

MODEL DESIGNATION

TOP ARRANGEMENT

SEC-1

A

B

B

A

C

SEC-2

A

B

B

A

C

SEC-3

C

B

C

A

C

TOP SECTION WIRE DIAGRAMS

A

B

C

GRILL

HOT TOP

SPEED UNITS

RT36A-T

RT36B-T

RT36C-T

RT36D-T

RT36E-T

POWER

SUPPLY

THREE

PHASE

BLOCK

TERMINAL

TOP

RANGE

ELECTRICAL CONNECTIONS

OVEN

L1

L2

L3 2-4-6

1-5

3 1

2

-

ELECTRICAL DATA

NUMBER

MODEL

LOADING

KW PER PHASE

TOTAL

KW

RT36-T & FCOFL-T

6.6 10.0 5.0 21.6

L1 L2 L2 L3 L3 L1

THREE PHASE AMPS

208 VOLT 240 VOLT

48.3L169.2L262.5L341.9L159.9L254.2

L3

L1 L2 L3

L2

L1

2000

3000

27

27

28

28

32 32

34

31

38 38

33 33

37

36

35

28 28

30

CONNECT WIRES

FROM RANGE TOP

TO OVEN TERMINAL

BLOCK AS SHOWN

AT RIGHT

1

2

3

4

5

6

DASHED LINES TO BE

CONNECTED TO TERMINAL BLOCK

IN FIELD AT INSTALLATION.

TERMINAL BLOCK

2M-61105-W16, Rev. -

CONVECTION OVEN W/ RANGE TOP 480V

A: GRILL B: HOT TOP C: SPEED UNIT

MODEL DESIGNATION

TOP ARRANGEMENT

SEC-1

A

B

B

A

C

SEC-2

A

B

B

A

C

SEC-3

C

B

C

A

C

RT36A-T

RT36B-T

RT36C-T

RT36D-T

RT36E-T

POWER

SUPPLY

THREE

PHASE

RANGE TOP

CONNECT TO

OVEN CIRCUIT

BREAKER

ELECTRICAL CONNECTIONS

OVEN

TERMINAL

BLOCK

L1

L2

L3 2-4-6

1-5

3 1

2

3

L1-L2 L2-L3 L1-L3 TO TAL L1 L2 L3

RT36-T & FCOFL-T 6.2 10.2 5.2 21.8 20.6 29.9 28.3

480 VOLT

AMPS THREE PHASE

CONVECTION OVEN / RANGE ELECTRICAL DATA

kW PER PHASE

LOADING

MODEL NUMBER

2

L3

480

L1T1L3

240

L1

11

T3

L2

4

3

MOTOR

L2

T2

H1

WIRE

7

OVEN WIRING

5

X1

H2

NUT

10

6

1

6

X2

PHASE

5

162 3

54

DASHED LINES TO

BE CONNECTED TO

CIRCUIT BREAKER

IN FIELD AT

INSTALLATION

TERMINAL BLOCK

12

12

1

2

3

4

5

6

7

9

10

11

HEAT ELEMENT

THERMOSTAT

3

HEAT SWITCH

MOTOR

PILOT LAMP

CONTACTOR

POWER SWITCH

SPEED UNIT

FUSE

TRANSFORMER

CIRCUIT BREAKER

CONNECT WIRE FROM

RANGE TOP TO OVEN

CIRCUIT BREAKER

AS SHOWN AT RIGHT

CAUTION: CHECK OVEN FOR PROPER DIRECTION

OF FAN ROTATION

CHANGE PHASING OF POWER IF NECESSARY TO

CORRECT.

2

5

1

2000

3000

TO BREAKER

1667

1667

1667

4

1

3

2

TO BREAKER

2

5

1

4

1

2

3

4

1

2

4

3

2 3 4

2 3

TO BREAKER

3

9

24

Page 25

1

2

3

4

5

6

5 5

2

1

4

1667

1667

1667

4

1

3

2

3

1

2

3

4

3

6

2 3 4 2 3 4

4

2

5

1

4

3

3

2

C

2

1 L1

L2

12L1

C L2

5

1

4

2

1

P1

P2

P1

P2

HEAT ELEMENT

THERMOSTAT

3 HEAT SWITCH

PILOT LAMP

CIRCUIT BREAKER

SPEED UNIT

TOP ARRANGEMENT

SEC-1

A

B

B

A

C

SEC-2

A

B

B

A

C

SEC-3

C

B

C

A

C

TOP SECTION WIRE DIAGRAMS

2M-61106-W02, Rev. -

DECK OVEN W/ RANGE TOP 208V / 240V

A B C

GRILL HOT TOP SPEED UNITS

POWER

SUPPLY

PHASE

THREE

BLOCK

TERMINAL

TOP

RANGE

ELECTRICAL CONNECTIONS

OVEN

L1

L2

L3 2-4-6

1-5

3 1

2

-

ELECTRICAL DATA

LOADING

KW PER PHASE

TOTAL

KW

6.0 10.0 5.0 21.0

L1 L2 L2 L3 L3 L1

THREE PHASE AMPS

208 VOLT 240 VOLT

45.8L166.7L262.5L339.7L157.8L254.2

L3

L1

1

2

OVEN WIRING

2000

3000

MODEL DESIGNATION

RT36A-T

RT36B-T

RT36C-T

RT36D-T

RT36E-T

STAR

NUMBER

MODEL

RT36-T & DO36-T

1 2 3 4 5 6

L2

L3

DASHED LINES TO BE

CONNECTED TO TERMINAL BLOCK

IN FIELD AT INSTALLATION

TERMINAL BLOCK

CONNECT WIRES FROM RANGE

TOP TO LOWER OVEN

TERMINAL BLOCK AS SHOWN

AT RIGHT

2M-61106-W11, Rev. -

DECK OVEN W/ RANGE TOP 480V

1

2

3

4

5

6

2

1

4

1667

1667

1667

4

1

3

2

3

1

2

3

4

1

2

4

3

6

2 3 4 2 3 4

4

2

1

4

3

3

2

C

2

1 L1

L2

12L1

C

L2

5

1

1C

1B

1A

2

7

3

8A

8B

8C

4A

8A

8B

8C

4A

5B 5A

66

CONNECT WIRES FROM RANGE

TOP TO OVEN CIRCUIT

BREAKER AS SHOWN AT RIGHT

TERMINAL BLOCK

OVEN

TERMINAL

BLOCK

POWER

SUPPLY

DASHED LINES TO BE

CONNECTED TO CIRCUIT

BREAKER

IN FIELD AT INSTALLATION

HEAT ELEMENT

THERMOSTAT

3 HEAT SWITCH

PILOT LAMP

CIRCUIT BREAKER

SPEED UNITS

MODEL DESIGNATION

TOP ARRANGEMENT

SEC-1

A

B

B

A

C

SEC-2

A

B

B

A

C

SEC-3

C

B

C

A

C

TOP SECTION WIRE DIAGRAMS

A

B C

GRILL HOT TOP SPEED UNITS

PHASE

THREE

CONNECT TO

RANGE TOP

ELECTRICAL CONNECTIONS

L1

L2

L3 2-4-6

1-5

3 1

2

-

ELECTRICAL DATA

LOADING

KW PER PHASE

TOTAL

KW

6.0 10.0 5.0 21.0

L1 L2 L2 L3 L3 L1

AMPS

480 VOLT

19.9L128.9L227.1

L3

L1 L2 L3

L2

L3

OVEN WIRING

2000

3000

L1

1 2 3 4 5 6

TO BREAKER TO BREAKER TO BREAKER

BREAKER

OVEN CIRCUIT

NUMBER

MODEL

RT36-T + DO36-T

RT36A-T

RT36B-T

RT36C-T

RT36D-T

RT36E-T

B C C

RT36F-T

25

Page 26

26

Page 27

Warranty Statement

Toastmaster warrants equipment that it manufactures to be free from defects in material and

workmanship. Toastmaster’s obligation is limited to repairing or replacing, at Toastmaster’s option, without

cost to the customer, any part found to be defective, as well as any labor or material expense required to

replace the part.

Length of Warranty

This warranty is effective for a period of 12 months from the date the equipment is placed in service.

Exceptions

• This warranty is valid only for the original end user owner/operator of the equipment.

• This warranty does not apply to normal maintenance functions, including (but not limited to)

improper operation, installation or the use of an improper utility supply.

• This warranty is valid only if the equipment is used in a commercial setting. The equipment

is designed and constructed for commercial use by trained professionals only. Any use of the

equipment in private or domestic applications immediately voids this warranty.

• This warranty does not apply to any parts, labor and material expenses for service that is not

pre-approved and performed by a Toastmaster authorized service agent. Any such service

immediately voids this warranty.

• This warranty does not apply to any parts, labor and material expenses associated with the

installation of parts that are not factory-approved for use in the equipment. Any use of such

parts immediately voids this warranty.

• This warranty is not valid if terms of payment have not been met.

Parts Warranty

Parts that are sold to repair our of warranty equipment are warranted for ninety (90) days. The part

only is warranted, the labor to replace the parts is NOT warranted.

Portable Equipment

Toastmaster will not honor service bills that include travel time and mileage charges for servicing any

products considered “Portable”. These products should be taken to the Service Agency for repair.

A portable unit is a unit thats designed to sit on a countertop, has a powercord & is less than 50lbs

installed.

Toastmaster reserves the right to change the design and specications of this equipment or any related

documentation at any time. The end user is not entitled to upgrades resulting from these changes.

This warranty is exclusive and supersedes all other warranties for the equipment, both expressed and

implied. There are no implied warranties of merchantability or of tness for a particular purpose.

The foregoing is Toastmaster’s sole and exclusive obligation and the end user sole and exclusive remedy

for any action including breach of contract or negligence. In no event shall Toastmaster be liable for a sum

in excess of the purchase price of the equipment, or for any prospective or lost prots of the end user.

is a registerd trademark of Toastmaster, A Middleby Company. All rights reserved.

27

Page 28

STAR INTERNATIONAL HOLDINGS INC. COMPANY

Star - Holman - Lang - Wells - Bloomeld - Toastmaster

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(314) 678-6303

www.star-mfg.com

28

Loading...

Loading...