Page 1

TMHP2

TMHP4

GAS HOT PLATES

Models

TMHP2, TMHP4, TMHP6

Installation and

Operation

Instructions

2M-Z12969 Rev. - March 13, 2013

is a registerd trademark of Toastmaster, A Middleby Company. All rights reserved.

1

Page 2

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

UsinganypartotherthangenuineToastmasterfactorysuppliedpartsrelievesthe

manufacturer of all liability.

Toastmaster reserves the right to change specications and product design

withoutnotice. Suchrevisionsdonotentitlethebuyertocorrespondingchanges,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Toastmaster exercises good faith efforts to provide

information that is accurate, we are not responsible for errors or omissions

in information provided or conclusions reached as a result of using the

specications. By using the information provided, the user assumes all risks in

connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it

ready when you call to ensure a faster service.

SAFETY SYMBOLS

Model No.

Serial No.

Voltage

Purchase Date

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (800) 264-7827 Local (314) 678-6347

Fax: (800) 396-2677 Local (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

The Service Help Desk

Authorized Service Agent Listing

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Telephone: (800) 264-7827 Local (314) 678-6347

Mailing Address: Toastmaster

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

CAUTION

WARNING

2

Page 3

GENERAL INSTALLATION DATA

CAUTION

CAUTION

This equipment is designed and sold for commercial use only by personnel trained and experienced

in its operation and is not sold for consumer use in and around the home nor for use directly by the

general public in food service locations. For equipment to be used by the general public, please

contact the factory.

This gas appliance is equipped for the types of gas indicated on the nameplate mounted on the front

panel. It is shipped adjusted for use on natural gas.

The installation of the Appliance should conform to the NATIONAL FUEL GAS CODE "ANSI

Z223.1 - LATEST EDITION" AND ALL LOCAL GAS COMPANY RULES AND REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE CURRENT

CAN/CGA-B149.1 NATURAL GAS INSTALLATION CODE OR CAN/CGA-B149.2

PROPANE INSTALLATION CODE AND LOCAL CODES WHERE APPLICABLE.

WARNING: Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing or servicing the equipment.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINITY OF THIS OR ANY OTHER APPLIANCE. KEEP THE APPLIANCE AREA CLEAR

AND FREE FROM COMBUSTIBLES.

This appliance, its pressure regulator and its individual shutoff valve must be disconnected from the

gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2

PSIG. This appliance and its pressure regulator must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 PSIG. For your protection, we recommend a qualied

installing agency install this appliance. They should be familiar with gas installations and your local

gas requirements. In any case, your gas company should be called to approve the nal installation.

In addition, there should be posted, in a prominent location, detailed instructions to be followed in the

event the operator smells gas. Obtain the instructions from the local gas supplier.

LEVELING UNIT

Units are shipped with feet detached. To attach feet, remove the grates, lay unit on it's side and screw

feet into sockets on bottom. Level unit by adjusting the (4) feet which have an adjustment of 1-3/4" for

accurate and perfect line-up with other Star-Max series units.

DO NOT REMOVE FEET.

GAS PIPING

Gas piping shall be new, clean and of such size and so installed as to provide a supply of gas sufcient

to meet the full gas input of the appliance. If the appliance is to be connected to existing piping, it

shall be checked to determine if it has adequate capacity. Joint compound (pipe dope) shall be used

sparingly and only on the male threads of the pipe joints. Such compounds shall be resistant to the

action of L.P. gases. WARNING: Any loose dirt or metal particles which are allowed to enter the gas

lines on the appliance will damage the automatic valve and affect its operation. When installing this

appliance, all pipe and ttings must be free from all internal loose dirt.

3

Page 4

CLEARANCE

Minimum wall clearances for the sides and back of the models contained in this manual shall be as

follows:

Combustible Non-Combustible

Wall Wall

Hotplates 9" 0"

PRESSURE REGULATOR

A convertible pressure regulator set at 6" water column for use on natural gas is furnished. (For LP

models the regulator is set for 10" water column pressure.) Attach the regulator to the supply pipe,

located at the back of the unit, make sure gas ow arrow on regulator is pointing towards manifold.

The gas supply is then connected to the regulator. A 1/8" tap is furnished on the manifold for checking

pressure. The manifold is accessible by removing the front panel.

MANUAL SHUT OFF VALVE

A manual shut off valve should be installed upstream from the unit and within six feet of the appliance,

and is not provided.

CONNECTING GAS SUPPLY LINE

The gas inlet on this appliance is sealed at the factory to prevent entry of dirt. Do not remove this seal

until the actual connection is made to the gas supply line.

CHECKING FOR GAS LEAKS

Soap and water solution or other material acceptable for the purpose, shall be used in locating gas

leakage. Matches, candle ame or other sources of ignition shall not be used for this purpose.

AIR SUPPLY

Provisions for adequate air supply must be furnished.

AIR INTAKES IN BOTTOM

Make certain the air intake openings in the bottom of the appliance are not obstructed. They are

essential for proper combustion and operation of the appliance.

EXHAUST CANOPY

It is essential that facilities be provided to carry off fumes and gases.

GAS INPUT OF OPEN TOP RANGES

For Natural Gas: Regulator output pressure set at 6" water column.

For Propane Gas: Regulator output pressure set at 10" water column.

Note: The appliance is equipped with natural gas orice hoods. A separate set of hoods will be

provided for use on propane gas. The propane hoods are located on the front panel.

Factory set LP models do not include the natural gas hoods.

4

Page 5

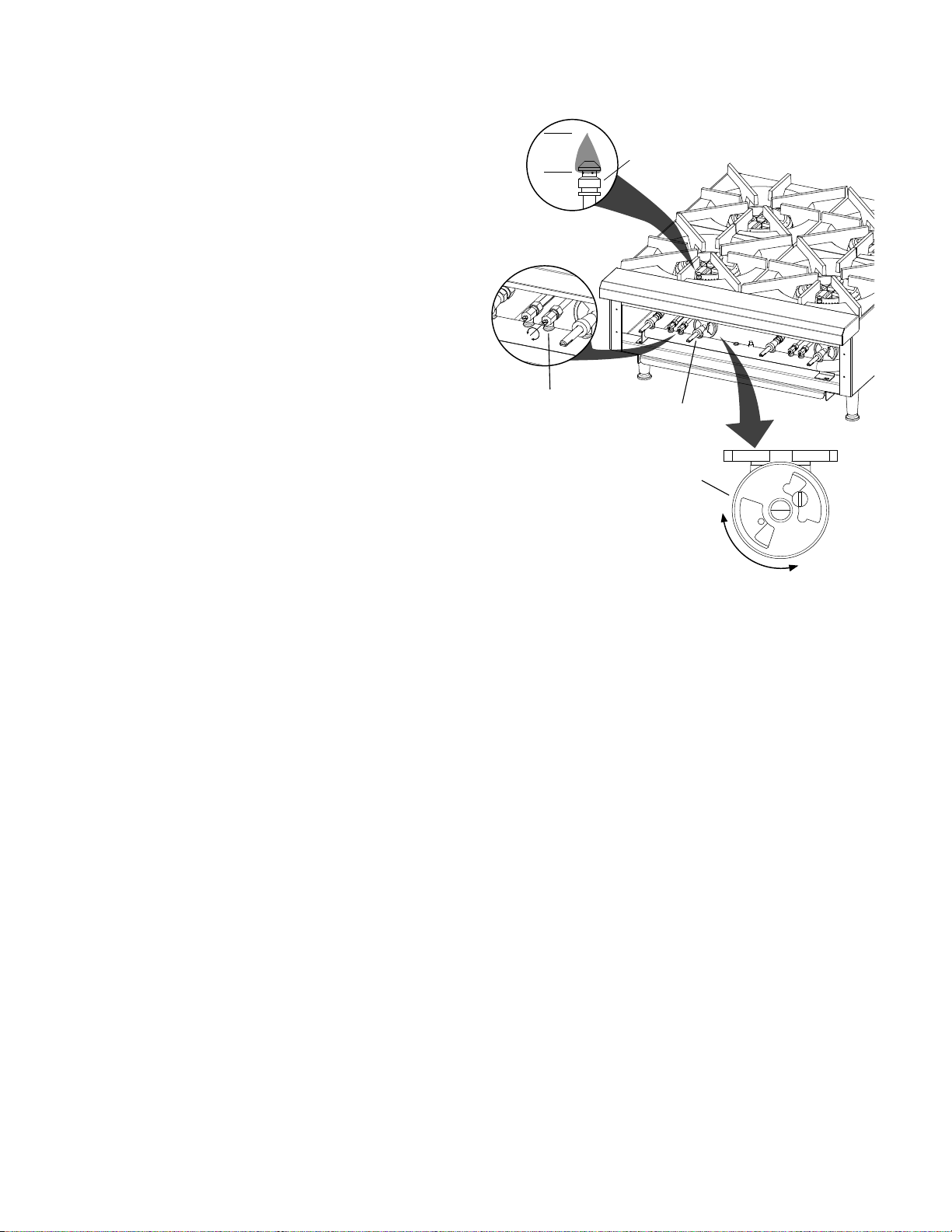

LIGHTING INSTRUCTIONS

1/4”

Flame

Pilot Valve

Air Shutter

Control

Valve

Pilot

IL2426

The appliance is equipped with standing pilots; each pilot is located in front of the burner on Models TMHP2,

TMHP6. Pilots should be lighted immediately after the gas is turned on by the manual shutoff valve.

1. Turn control knobs to "OFF" position.

2. Light pilot with a lighted taper.

3 The pilot valves are located on the manifold installed

at the front of the unit behind the front panel. For

access to the valves

4. Loosen the set screws securing the knobs in

position, and remove the knobs. Remove the front

panel, which is attached to the frame with 4 sheet

metal screws.

5. Turn the adjustment screws on the front of the

pilot valves. The pilots should be adjusted to blue

short ame (1/4" high) to have good ignition to the

burners. Repeat for remaining pilots.

6. If the pilot(s) is out turn off gas, wait 5 minutes and

repeat steps (1) through (5).

ADJUSTING BURNERS

7. With control valve for the front burner turned to

full "ON" position, close the air shutters to give a

soft blue ame having luminous tips and open to a

point where the yellow tips disappear, then tighten

the locking screws. Repeat this procedure with the

remaining burners.

8. Install the front panel to the front of the frame & reconnect and secure the knobs back into position.

ADJUSTING UNIT FOR USE ON PROPANE GAS

Units are shipped with orices and pressure regulator for operation with natural gas (6" water column). To

convert unit from natural to propane gas follow these instructions

1. Set regulator outlet pressure to 10" water column. A 1/8" pipe plug on the manifold can be removed for

attaching a pressure gauge. Remove the slotted cover from the pressure regulator and invert the plug.

Replace the cover on the regulator and plug on the manifold. Regulator is now set at 10" W.C.

2. Remove natural gas orifices, #46 for all models, and install propane orifices, painted black,

(#54 for all models except) located in a bag on the outside of the front panel. In order to remove natural

gas orices:

a. Remove grates and burners.

b. Remove orices from the manual valves and from ttings on extended gas pipes, replace with the propane

orices.

c. Install burners and grates.

OPERATING PROCEDURE

Each burner will deliver up to 22,000 BTU/HR of heat on all models and is controlled by a manual On/Off valve.

The right control knob controls the front burner and the left control knob controls the rear burner on all models.

After the pilot is once lit and adjusted, the burners will ignite automatically by turning the control knob to any

position between On and Off.

CLEANING THE EXTERIOR (Stainless Steel Only)

The exterior surface can be kept clean and attractive by regularly wiping it with a clean soft cloth. Any

discoloration can be removed with a non-abrasive cleaner. The burner grates and trough tray can be removed

for cleaning.

MAINTENANCE AND REPAIRS

Contact the factory or one of its representatives or a local service company for service or maintenance if

required.

5

Page 6

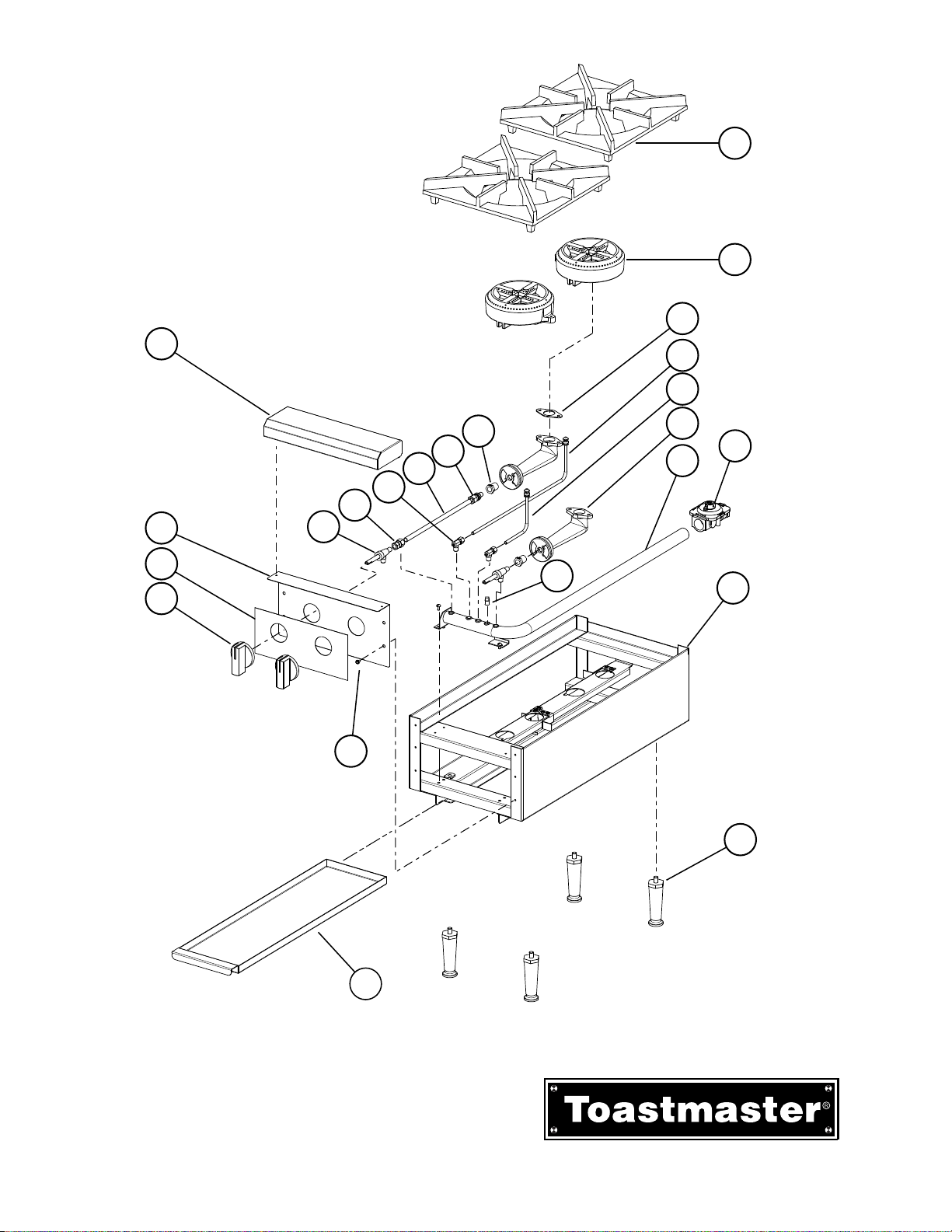

MODEL: TMHP2, TMHP4, TMHP6

Gas Hotplates

SK2431 REV - 8/26/09

1

2

3

4

5

6

8

9

10

11

14

15

16

23

17

18

19

20

21

22

12

13

7

6

Page 7

PARTS LIST October 1, 2008, Rev -

MODEL: TMHP2, TMHP4, TMHP6, Gas Hotplates

FIG No. Part No Qty Description Application

2

1 2F-Z0637

2 2F-Z0615

3 2I-Z0752

4 I4-602014

5 I4-602013

6 2F-Z0747

7 2P-1453 1 PLUG-PIPE 1/8NPT SQ HD ALL

2J-602012

8

9 2J-Z0792 1 REGULATOR TMHP2

10

11 2A-Z0314 4 FOOT, 4 IN DIE CAST TMHP2

12

13 2C-8833 AR SCREW 8-18X1/2 HEX STL NP TMHP2

14 2R-Z13014

15

16

2J-604002 TMHP4

2J-606002 TMHP6

I8-TC0010

I8-TC0012 BASIC ASSY HOTPLATE 24” TMHP4

I8-TC0014 BASIC ASSY HOTPLATE 36” TMHP6

I4-Z6024

I4-Z6025 PAN-24 TMHP4

I4-Z6026 PAN-36 TMHP6

2M-Z12936

2M-Z12937 GRAPHIC PANEL, 24” HTPLT TMHP4

2M-Z12938 GRAPHIC PANEL, 36” HTPLT TMHP6

I4-Z6012

I4-Z6013 FRONT PANEL-24 TMHP4

I4-Z6014 FRONT PANEL-36 TMHP6

CASTING

4 TMHP4

6 TMHP6

2

BURNER 7” ROUND

4 TMHP4

6 TMHP6

2

GASKET-BURNER

4 TMHP4

6 TMHP6

1

PILOT TUBE ASSY LONG

2 TMHP4

3 TMHP6

1

PILOT TUBE ASSY SHORT

2 TMHP4

3 TMHP6

2

VENTURI SHORT CASTING

4 TMHP4

6 TMHP6

1 MANIFOLD ASSEMBLY

BASIC ASSY HOTPLATE 12” TMHP2

1

PAN-12 TMHP2

1

2

KNOB, MANUAL GAS

4 TMHP4

6 TMHP6

GRAPHIC PANEL, 12” HTPLT TMHP2

1

FRONT PANEL-12

1

TMHP2

TMHP2

TMHP2

TMHP2

TMHP2

TMHP2

TMHP2

TMHP2

TMHP2

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE 1

INCLUDE MODEL AND SERIAL NUMBER OF 2

Some items are included for illustrative purposes only and in certain instances may not be available.

is a registerd trademark of Toastmaster, A Middleby Company. All rights reserved.

7

Page 8

PARTS LIST October 1, 2008, Rev -

MODEL: TMHP2, TMHP4, TMHP6, Gas Hotplates

Fig No. Part No Qty Description Application

17 2V-Y8832

18 2A-Z0790

19 2V-6671

20 2V-Z0869

21 2A-Y3961

22

23

2A-Y3297 2,4,6 ORIFICE #46 NAT ALL

2A-Z1455 2,4,6 ORIFICE #54 LP ALL

I8-TC0011

I8-TC0013 FRONT BULLNOSE ASSY 24” TMHP4

I8-TC0015 FRONT BULLNOSE ASSY 36” TMHP6

2

VALVE-MANUAL GAS

4 TMHP4

6 TMHP6

1

FITTING-STRAIGHT

2 TMHP4

3 TMHP6

2

VALVE-LINCOLN BRASS#3817

4 TMHP4

6 TMHP6

1

TUBE 3/8 DIA

2 TMHP4

3 TMHP6

1

ORIFICE FITTING

2 TMHP4

3 TMHP6

FRONT BULLNOSE ASSY 12” TMHP2

1

TMHP2

TMHP2

TMHP2

TMHP2

TMHP2

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE 2

INCLUDE MODEL AND SERIAL NUMBER OF 2

Some items are included for illustrative purposes only and in certain instances may not be available.

is a registerd trademark of Toastmaster, A Middleby Company. All rights reserved.

8

Page 9

Warranty Statement

This warranty is effective on all Toastmaster equipment sold on or after July 1, 2006, and supersedes all

previous warranties.

Toastmaster warrants equipment that it manufactures to be free from defects in material and

workmanship. Toastmaster’s obligation is limited to repairing or replacing, at Toastmaster’s option, without

cost to the customer, any part found to be defective, as well as any labor or material expense required to

replace the part.

Length of Warranty

This warranty is effective for a period of 18 months from the date of shipment from Toastmaster,

or 12 months from the date of purchase by the end user, whichever is earlier.

Exceptions

• This warranty is valid only for the original end user owner/operator of the equipment.

• This warranty does not apply to normal maintenance functions, including (but not limited to)

improper operation, installation or the use of an improper utility supply.

• This warranty is valid only if the equipment is used in a commercial setting. The equipment

is designed and constructed for commercial use by trained professionals only. Any use of the

equipment in private or domestic applications immediately voids this warranty.

• This warranty does not apply to any parts, labor and material expenses for service that is not

pre-approved and performed by a Toastmaster authorized service agent. Any such service

immediately voids this warranty.

• This warranty does not apply to any parts, labor and material expenses associated with the

installation of parts that are not factory-approved for use in the equipment. Any use of such

parts immediately voids this warranty.

• This warranty is not valid if terms of payment have not been met.

• For warranty service on Pop-up toasters and light countertop equipment, an exchange program

would supersede a service call. Please nd Warranty Exchange Program’ authorization to

follow. (http://www.toastmastercorp.com/lespdfcat/warranty_exchange_2008.pdf)

Toastmaster reserves the right to change the design and specications of this equipment or any related

documentation at any time. The end user is not entitled to upgrades resulting from these changes.

This warranty is exclusive and supersedes all other warranties for the equipment, both expressed and

implied. There are no implied warranties of merchantability or of tness for a particular purpose.

The foregoing is Toastmaster’s sole and exclusive obligation and the end user sole and exclusive remedy

for any action including breach of contract or negligence. In no event shall Toastmaster be liable for a sum

in excess of the purchase price of the equipment, or for any prospective or lost prots of the end user.

is a registerd trademark of Toastmaster, A Middleby Company. All rights reserved.

9

Page 10

Page 11

Page 12

5

10

maintenance et les réparations nécessaires.

Contactez l’usine ou l’un de ses représentants, ou bien encore une société de services locale pour la

MAINTENANCE ET RÉPARATIONS

être retirés pour être nettoyés.

être nettoyées à l’aide d’un agent nettoyant non abrasif. Les grilles des brûleurs et l’égouttoir peuvent

La surface externe peut être nettoyée en utilisant un linge propre et doux. Les décolorations peuvent

NETTOYAGE DE L’EXTÉRIEUR (Acier inoxydable seulement)

commande vers n'importe quelle position entre On et Off.

fois allumé et réglé, les brûleurs seront automatiquement s'enammer en tournant la molette de

de contrôle de gauche contrôle le brûleur arrière sur tous les modèles. Après que le pilote est une

manuel On / Off valve. Le bouton de commande de droite commande le brûleur avant et le bouton

Chaque brûleur se livrer à 22,000 BTU / HR de la chaleur sur tous les modèles et est contrôlé par un

PROCÉDURE DE FONCTIONNEMENT

c. Réinstallez les brûleurs et les grilles.

avec les orices à propane.

b. Retirez les orices des robinets manuels et des raccords sur les tuyaux à gaz et remplacez-les

a. Retirez les grilles et les brûleurs.

de supprimer les orices de gaz naturel:

en noir, (# 54 pour tous les modèles excepté), situé dans un sac à l'extérieur de la face avant. An

2. Retirer orices de gaz naturel, # 46 pour tous les modèles, et d'installer orices propane, peinte

d’eau (10 pouces).

régulateur et branchez sur le conduit. Le régulateur est maintenant réglé à .254 mm de colonne

le couvercle rainuré du régulateur de pression et insérez-y la prise. Replacez le couvercle sur le

de 1/8 de pouce sur le conduit peut être retiré pour y connecter une jauge de pression. Retirez

1. Réglez la pression de sortie du régulateur à 254 mm de colonne d’eau (10 pouces). Un tuyau

instructions ci-dessous:

gaz naturel (à 152 mm de colonne d’eau - 6 pouces). Pour convertir l’unité au propane, suivez les

Les unités sont envoyées avec les couvercles d’orices et le régulateur pour une utilisation au

RÉGLAGE DE L’UNITÉ POUR L’UTILISATION AU PROPANE

Serrez ensuite les vis de serrage. Reprenez cette procédure pour le brûleur arrière.

amme bleue dont les extrémités sont lumineuses et de façon à ce que la amme ne soit pas jaune.

de contrôle du brûleur frontal est en position “ON”, fermez les obturateurs d’air an d’obtenir une

Retirez le panneau frontal an de pouvoir accéder aux obturateurs d’air principaux. Lorsque le robinet

RÉGLAGE DES BRÛLEURS

5. Installez le panneau frontal sur l’avant du cadre.

(1) à (3).

4. Si une ou des veilleuses sont éteintes, fermez le gaz, attendez 5 minutes et reprenez les étapes

pouce de haut) pour obtenir un bon allumage les brûleurs.

Les veilleuses devront être réglées de façon à ce que la amme soit bleue et courte (un quart de

vis le retenant au cadre. Tournez les vis de réglage situées à l’avant des robinets des veilleuses.

panneau frontal. Pour accéder aux robinets, retirez le panneau frontal en dévissant les quatre (4)

3. Les robinets des veilleuses sont situés sur le conduit installé à l’avant de l’unité, derrière le

2. Allumez les veilleuses à l’aide d’un briquet.

1. Placez les boutons en position “OFF”.

que le gaz est ouvert au moyen du robinet d’arrêt manuel.

devant chaque brûleur sur les Modèles TMHP2, TMHP6. Les veilleuses devraient être allumées dès

L’appareil est équipé de veilleuses d’allumage qui brûlent en permanence . Ces veilleuses sont situées

INSTRUCTIONS POUR L’ALLUMAGE

Page 13

4

11

naturel.

situés sur le panneau frontal. Les usine réglés modèles de LP n'incluent pas les capots de gaz

couvercles est fourni pour utiliser l’appareil avec du propane. Les couvercles pour le propane sont

Remarque : L’appareil est équipé de couvercles d’orices pour le gaz naturel. Un autre ensemble de

Pour le propane: La pression de sortie du régulateur est à 254 mm de colonne d’eau (10 pouces).

Pour le gaz naturel: La pression de sortie du régulateur est à 152 mm de colonne d’eau (6 pouces).

ENTRÉE DE GAZ DES CUISINIÈRES À GAZ À PLAQUE OUVERTE

Il est primordial que des installations soient prévues pour l’évacuation des gaz et fumées.

HOTTE ASPIRANTE

sont primordiales pour une combustion adéquate et un bon fonctionnement de l’appareil.

Assurez-vous que les ouvertures situées en dessous de l’unité ne sont pas obstruées. Elles

OUVERTURES EN DESSOUS DE L’UNITÉ

Vous devrez prévoir une alimentation en air adéquate.

ALIMENTATION D’AIR

aucun cas être utilisées dans ce but.

localiser les fuites de gaz. Des allumettes, des bougies ou autres sources d’ignition ne devraient en

Il est possible d’utiliser une solution à base d’eau et de savon ou tout autre matériau acceptable pour

RECHERCHE DE FUITES DE GAZ

canalisation d’alimentation de gaz.

l’unité. Gardez la protection en place jusqu’à ce que vous soyez prêt à effectuer la connexion à la

L’entrée de gaz pour cet appareil est scellée à l’usine pour éviter que des saletés ne pénètrent dans

CONNEXION DE LA CANALISATION D’ALIMENTATION DE GAZ

l’appareil. Ce robinet n’est pas fourni.

Un robinet d’arrêt manuel devrait être installé en amont de l’unité, à environ 183 cm (6 pieds) de

ROBINET D’ARRÊT MANUEL

distribution en retirant le panneau frontal.

installé sur le conduit de distribution pour vérier la pression. Il est possible d’accéder au conduit de

L’alimentation de gaz doit ensuite être connectée au régulateur. Un robinet de 1/8 de pouce est

assurez-vous que la èche du ux de gaz sur le régulateur pointe vers le conduit de distribution.

pression de eau colonne.) Reliez le régulateur au tuyau d’alimentation situé à l’arrière de l’unité et

avec du gaz naturel est fourni avec l’appareil. (Pour le LP modèle le régulateur est placé pour 10"

Un régulateur de pression convertible réglé à 152 mm de colonne d’eau (6 pouces) pour être utilisé

RÉGULATEUR DE PRESSION

Plaques Chauffantes 9" 0"

Combustible Non-Combustible

Mur Mur

comme suit:

Minimum distances aux mur pour les côtés et le dos des modèles contenus en ce manuel seront

DÉGAGEMENT

saleté à l’intérieur.

installez cet appareil, ainsi que les tuyaux et raccords, assurez-vous qu’ils sont exempts de toute

l’appareil endommageront le robinet automatique et affecteront son fonctionnement. Lorsque vous

AVERTISSEMENT : Toutes les saletés ou particules de métal dans les canalisations de gaz de

extérieur des tuyaux. Les pâtes utilisées devraient être résistantes à l’action des gaz basse pression.

adéquate. La pâte lubriante ne devrait être utilisée qu’avec parcimonie et seulement sur le letage

canalisations déjà existantes, elles devraient être vériées pour déterminer si leur capacité est

à fournir une alimentation en gaz sufsante pour l’appareil. Si l’appareil doit être connecté à des

Les canalisations de gaz devraient être neuves, propres, de taille adéquate et être installées de façon

CANALISATIONS DE GAZ

Page 14

3

CAUTION

CAUTION

12

NE PAS RETIRER LES PIEDS.

MISE EN GARDE

soit parfaitement alignée et de niveau avec les autres unités séries Star-Max.

niveau en réglant les quatre (4) pieds qui doivent être réglés à 4.45 cm (1.75 pouce) pour que l’unité

l’appareil sur le côté et vissez les pieds dans les logements situés sous l’appareil. Mettez l’unité à

Les unités sont envoyées avec les pieds détachés. Pour installer les pieds, retirez les grilles, couchez

MISE À NIVEAU DE L’APPAREIL

obtenir ces ins-tructions auprès de votre fournisseur local de gaz.

détecterait une odeur de gaz devraient être afchées bien en vue à proximité de l’unité. Vous pouvez

nale. De plus, des instructions détaillées indiquant la marche à suivre dans le cas où l’opérateur

gaz. Dans tous les cas de gure, la compagnie locale de gaz devrait venir approuver l’installation

cette agence devrait connaître les installations à gaz ainsi que les exigences locales concernant le

protection, nous recommandons qu’une agence spécialisée installe votre appareil. Le personnel de

d’alimentation de gaz lorsque les pressions d’essai sont égales ou inférieures à 0.5 PSIG. Pour votre

l’alimentation de gaz en fermant le robinet d’arrêt manuel pendant les essais de pression du système

d’essai sont supérieures à 0.5 PSIG. Cet appareil et le régulateur de pression doivent être coupés de

système d’alimentation de gaz pendant les essais de pression du système lorsque les pressions

Cet appareil, le régulateur de pression et le robinet d’arrêt individuel doivent être déconnectés du

HORS DU VOISINAGE DE L’APPAREIL.

TENIR TOUT COMBUSTIBLE

INFLAMMABLES À PROXIMTÉ DE CET APPAREIL OU DE TOUT AUTRE APPAREIL.

NE PAS ENTREPOSER NI UTILISER DE’ESSENCE NI AUTRES VAPEURS OU LIQUIDES

ESURE DE SÉCURITÉ

de procéder à son installation ou entretien.

Lire attentivement les instructions d'installation, de fonctionnement et d'entretien avant

incorrect de cet appareil peut causer des dommages matérials, des blessures ou la mort.

AVERTISSEMENT: L'installation, le réglage, la modication, la réparation ou l'entretien

B149.2, AINSI QU’AUX CODES LOCAUX, LE CAS ÉCHÉANT.

NATUREL ACTUEL CAN/CGA-B149.1 OU AU CODE D’INSTALLATION AU PROPANE CAN/CGAL’INSTALLATION AU CANADA DEVRAIT ÊTRE CONFORME AU CODE D’INSTALLATION AU GAZ

COMPAGNIE DE GAZ LOCALE.

Z223.1 - DERNIÈRE ÉDITION”, AINSI QU’À TOUTES LES RÈGLES ET RÉGLEMENTATIONS DE LA

L’installation de l’appareil devrait être conforme au CODE NATIONAL DU GAZ COMBUSTIBLE “ANSI

l’appareil. Il est envoyé réglé pour une utilisation au gaz naturel.

Cet appareil à gaz est équipé pour les types de gaz indiqués sur la plaque signalétique à l’avant de

pouvant être utilisé par le public général, prière de contacter l’usine.

être utilisé à la maison ou par le public général dans les lieux de restauration. Pour tout équipement

par un personnel formé et expérimenté à son fonctionnement. Cet équipement n’est pas vendu pour

Cet équipement est conçu et vendu pour une utilisation commerciale seulement, et pour être utilisé

MISE EN GARDE

DONNÉES GÉNÉRALES D’INSTALLATION

Page 15

2

2

Ces symboles sont utilisés pour souligner à l’utilisateur les

instructions d’utilisation ou d’entretien importantes contenues

dans le manuel qui accompagne l’appareil.

CONSERVEZ CE MANUEL POUR RÉFÉRENCE FUTURE

AVIS

L’utilisationdetoutepièceautrequelespiècesd’origineSTARdégagelefabricant

de toute responsabilité.

Toastmaster se réserve le droit de changer les spécications et la conception

du produit sans préavis. Ces changements ne donnent pas le droit à

l’acheteur d’obtenir les changements, améliorations, ajouts ou remplacements

correspondants pour l’équipement acheté préalablement.

Dû aux modications périodiques de dessins, méthodes, procédures, règles

et régulations, les spécications contenues dans ce manuel sont susceptibles

de changer sans préavis. Quoique Toastmaster exerce la bonne foi de fournir

le renseignement correct, Toastmaster n’est pas responsable pour les erreurs

ou les omissions dans le renseignement pourvu ou les conclusions tirées à la

suite de l’utilisation des spécications. En utilisant le renseignement pourvu,

l’utilisateur assume tous les risques en relation avec telle utilisation.

ENTRETIEN ET RÉPARATIONS

Contactez votre détaillent local pour les réparations ou l’entretien requis. Assurez-vous d’avoir le numéro de

modèle, le numéro de série, le voltage et la date d’achat pour un service plus rapide. Entrez l’information

requise ci-dessous pour référence rapide.

SYMBOLE DE SÉCURITÉ

N° de modèle

N° de série

Voltage

Date d’achat

Agent de service autorisé

Voir la liste pourvue avec l’appareil

Ou

Pour une liste mise à jour voir :

Site web : www.star-mfg.com

Courriel : Service@star-mfg.com

13

Page 16

14

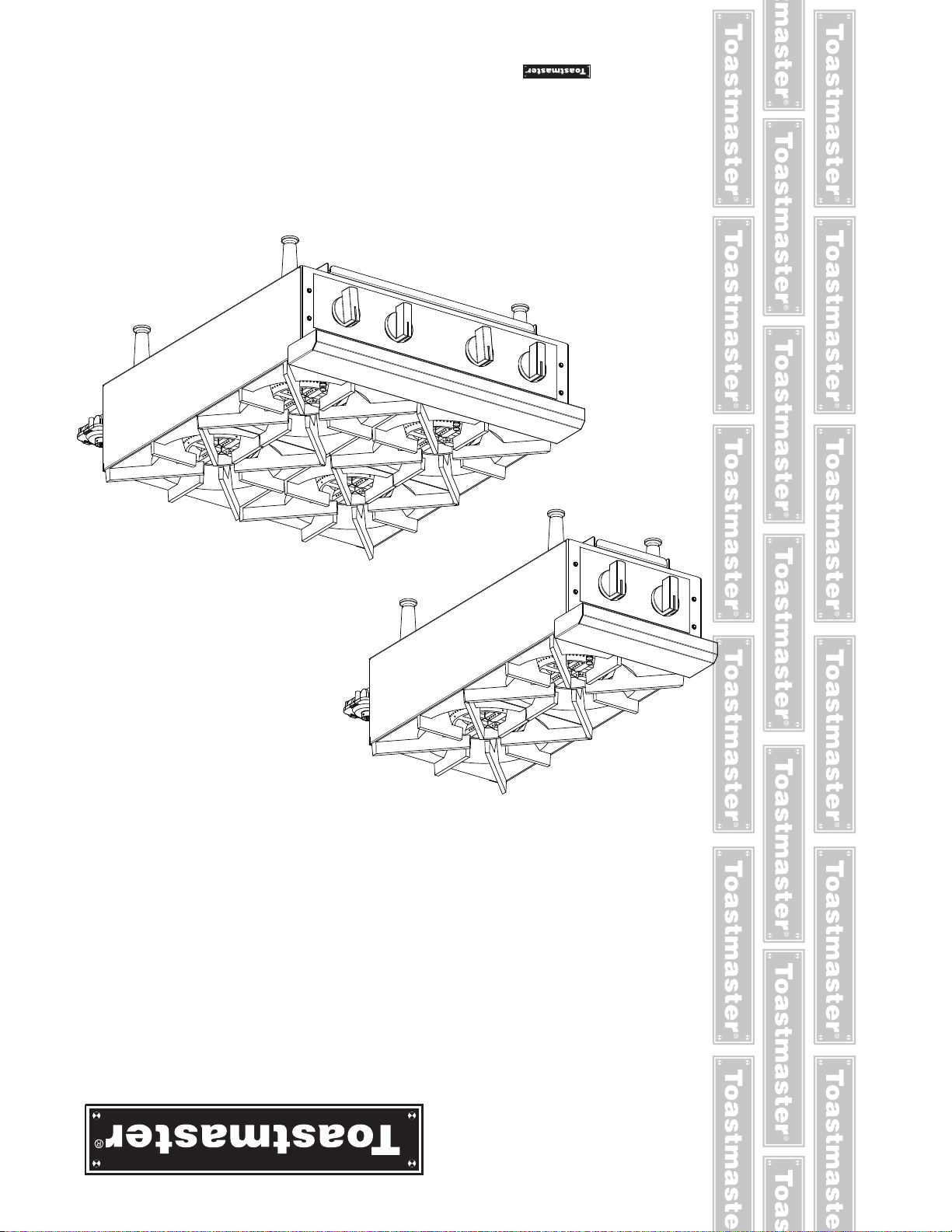

TMHP2

TMHP4

est une marque de Registerd Toastmaster, la Compagnie A Middleby. Tous droits réservés.

Modèles

2M-Z12969 Rev. - Oct. 1, 2009

et d’opération

d’installation

Instructions

TMHP2, TMHP4, TMHP6

AU GAZ

PLAQUES CHAUFFANTES

Loading...

Loading...