Page 1

2/07

D

A Middleby Company

10 Sunnen Drive • St. Louis, MO 63143

•

Hot Food Server

Models HFS09, HFS72

OWNER'S OPERATING AND

INSTALLATION MANUAL

is a registered trademark of Toastmaster, A Middleby Company. All rights reserved.

I. DESCRIPTION AND SPECIFICATIONS

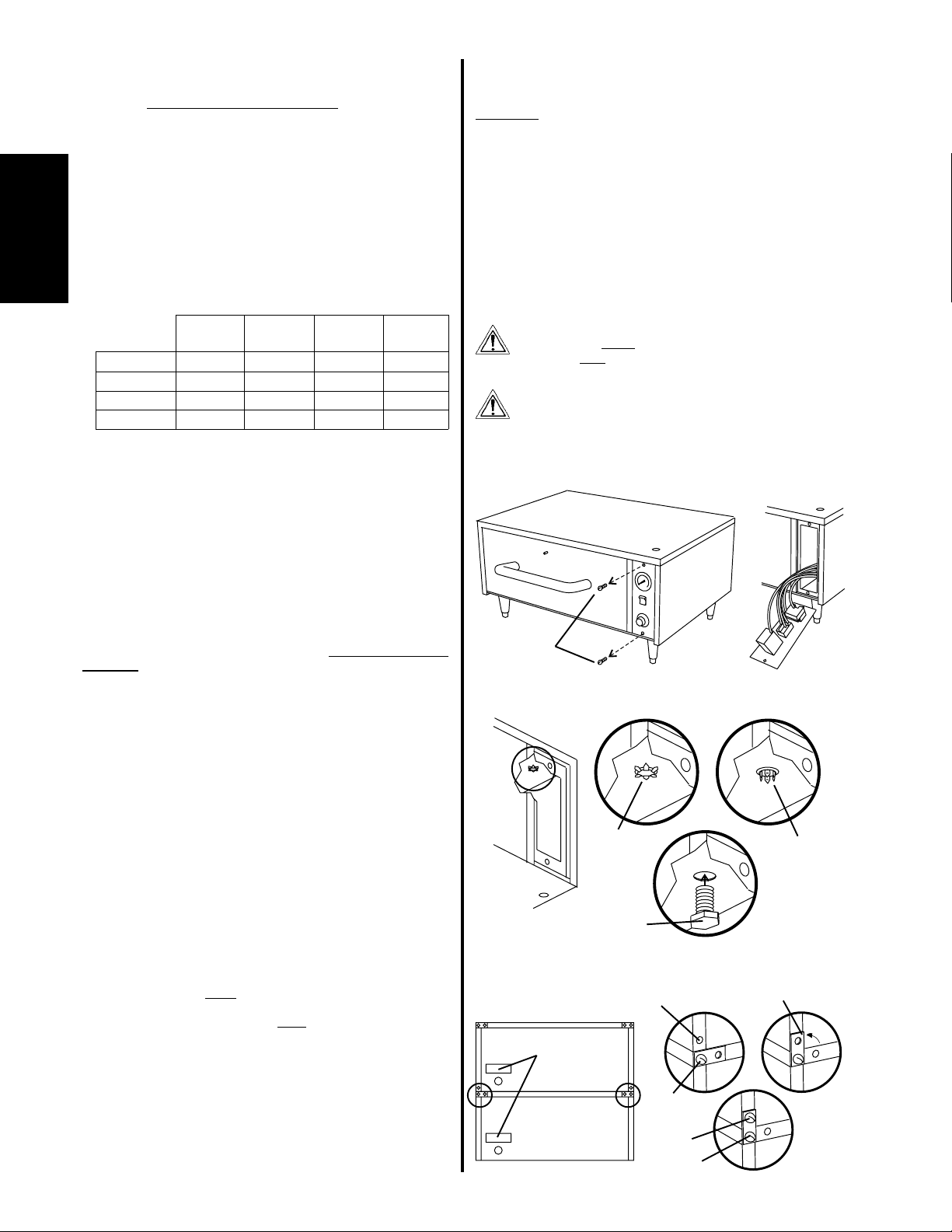

A. Component Location

The major components of the hot food server are shown in Figure 1 below.

Figure 1

4. Removable

food pan

3. Thermometer

800.807.9054 • FAX 314.781.2714

•

page 1

ENGLISH

page 5

FRANÇAIS

5. Moisture

control slider

6. Heating element

(on floor of cabinet)

B. Component Function (see Figure 1)

1. Temperature adjustment knob - see Section III, Operation.

2. Power On/Off (I/O) Switch - see Section III, Operation.

3. Thermometer - see Section III, Operation.

4. Removable food pan - holds the food product. The pan

can be removed for cleaning.

5. Moisture control slider - Opens and closes the moisture

vents in the front panel of the drawer.

6. Heating element - Provides heat to maintain the proper

temperature of the food product.

C. Operating and Electrical Specifications

Pre-Heat Time: 20 minutes

Temperature range: 100-200°F (38-93°C)

Electrical Specifications/HFS09:

120V, 50/60Hz, 1 Ph, 0.5kW, 4.2A

Plug type: NEMA 5-15P

Electrical Specifications/HFS72:

208V, 50/60Hz, 1 Ph, 0.4kW, 1.9A, OR

240V, 50/60Hz, 1 Ph, 0.55kW, 2.3A

Plug type: NEMA 6-15P

NOTE

An electrical wiring diagram is provided on the back cover of this

Manual.

1. Temperature

adjustment knob

2. Power On/Off

(I/O) Switch

CAUTION

Using any parts other than genuine Toastmaster factory parts relieves the manufacturer of all liability.

IMPORTANT

Contact your authorized service agent to perform maintenance and

repairs. A service agency directory is supplied with your hot food

server.

IMPORTANT

Toastmaster (manufacturer) reserves the right to change specifications and product design without notice. Such revisions do not entitle

the buyer to corresponding changes, improvements, additions or

replacements for previously purchased equipment.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

This manual provides detailed information for the installation and

operation of your hot food server. It also contains information to assist

the operator in diagnosing problems in the event of a malfunction.

This manual is an important tool for the operator and should be kept

readily available.

1

página 9

ESPAÑOL

Page 2

II. INSTALLATION

IMPORTANT

IT IS THE

CONCEALED OR NON-CONCEALED DAMAGE TO THE FREIGHT

COMPANY.

A. Installation Options and Kit Availability

ENGLISH

Your hot food server is shipped from the factory with 4 NSF-listed

plastic legs, which may be used on single-unit or two-stack installations. The following kits are available from Toastmaster for additional

installation options:

P/N ACCHFSC Casters kit (for 1-4 units)

P/N ACCHFS6 6 legs kit (for 1-4 units)

P/N ACCHFS9 9 legs kit (for 1-4 units)

All hot food server installations REQUIRE the unit(s) to be mounted

on legs or casters prior to operation. The allowed installation configurations are:

CAUTION

STACKING MORE THAN FOUR SERVERS IS NOT PERMITTED.

B. Legs/Casters Assembly

1. To install the supplied 4/102mm legs (1-2 units only), thread the

2. To install an optional Legs Kit or Casters Kit, refer to the instruc-

C. Stacking the Hot Food Servers (2-4 units only)

CAUTION

If you have installed the optional Casters Kit,

are locked before stacking the hot food servers.

Perform the following steps, starting with the server that has legs/

casters installed:

1. Remove the two screws that hold the control panel in place. Be

2. Gently pull the control panel out from the front of the unit and

3. Remove the cap plug from the top panel of the unit. To remove

4. Place a hot food server atop the unit. Check that all four sides of

5. Attach the two units together by inserting the supplied 3/8 bolt

6. At the rear of the

7. Reposition the stacking clips as shown in Figure 4, and replace

8. Tighten the 3/8 bolt (that you installed in Step 5) to secure the

9. Replace the control panel, and fasten it in place with its screws.

10. Repeat Steps 1-9 until all units are stacked. Note that the cap

CUSTOMERS RESPONSIBILITY TO REPORT ANY

Supplied Casters 6 legs 9 legs

4 legs kit kit kit

Single unit YES YES YES YES

Two-stack YES YES YES YES

Three-stack NO YES YES YES

Four-stack NO YES YES YES

legs into the four holes on the bottom of the hot food server. An

illustration of the server with the supplied legs installed is shown

on the cover of this Manual. For a Two-Stack installation, attach

the legs to the bottom server only.

tions provided with the Kit.

check that the casters

sure to retain the screws. See Figure 2.

allow it to hang by the wiring. DO NOT stretch or disconnect the

wiring! See Figure 2.

the plug, bend the tines on the underside of the plug in towards

the center using a pair of pliers. Then, lift the cap free and discard it. See Figure 3.

the units are aligned.

from inside the control panel opening of the lower server, as shown

in Figure 4. The bolt passes through the hole in the top panel

and into the threaded leg hole in the floor of the upper unit. Tighten

the bolt to a LOOSE fit to allow the position of the units to be

adjusted.

upper server, remove the screws from BOTH

bottom rear corners, as shown in Figure 4. Then, loosen (do not

remove) the two screws on the

lower server that hold the stack-

ing clips in place.

the two screws that you removed in Step 6. Tighten all four

screws.

units together.

plug will remain in place on the top server in the stack.

D. Electrical Connection

IMPORTANT

THE ELECTRICAL CONNECTION TO THE HOT FOOD SERVER

REQUIRES A CIRCUIT BREAKER/FUSED DISCONNECT. ELECTRICAL SPECIFICATIONS ARE LISTED ON THE SERIAL PLATE

(SHOWN IN FIGURE 4), AND IN SECTION I OF THIS MANUAL.

CONSULT ALL APPLICABLE NATIONAL AND LOCAL CODES FOR

FURTHER ELECTRICAL CONNECTION REQUIREMENTS.

1. Before proceeding with the electrical connection, check the following for each hot food server:

a. Check that the electrical supply matches the hot food

servers requirements. Refer to the serial plate (Figure 4)

and to the electrical specifications shown in Section 1 of

this Manual.

b. Check that the appropriate receptacle is available for the

power cord plug.

WARNING

ENSURE THAT

CONNECT

BOTH THE CIRCUIT BREAKER/FUSED DIS-

AND THE POWER ON/OFF (I/O) SWITCH ARE

IN THE OFF (O) POSITION BEFORE PROCEEDING.

WARNING

ENSURE THAT ANY PACKING MATERIAL HAS BEEN REMOVED FROM INSIDE THE CABINET AND FOOD TRAY.

3. Insert (each) power cord plug into its receptacle.

Figure 2

Control panel

mounting screws

Figure 3

1. Cap plug

shown

in place

Underside

of server

3. After stacking,

insert bolt

through cap hole

2. To remove,

bend tines in

towards

center of plug

Figure 4 (left side shown - reposition brackets on BOTH sides)

1. Remove

Data plate

2. Loosen

4. Replace

2

5. Tighten

3. Reposition

Control

panel

opened

Page 3

III. OPERATION

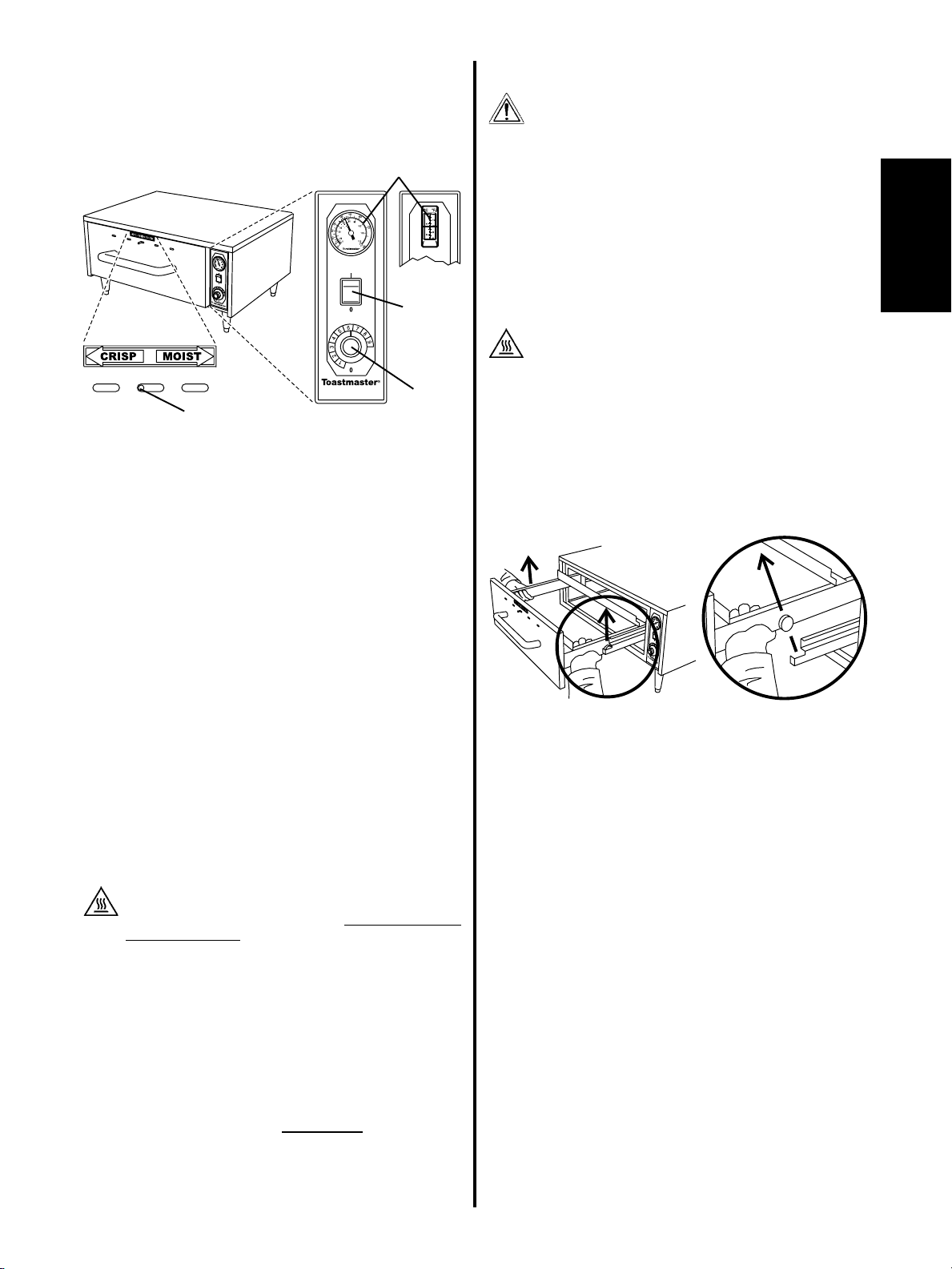

A. Location and Function of Controls

This section provides a basic description of the hot food server controls,

their location, and the functions they perform. The operator MUST be

familiar with the controls. See Figure 5.

Figure 5

4. Moisture

control slider

1. Power On/Off (I/O) Switch

Switches the heating element ON (I) and OFF (O).

2. Temperature adjustment knob

Adjusts the temperature setting of the heating element. This

controls the temperature of the cabinet and pan.

1 is the minimum setting (100°F/38°C after preheating).

9 is the maximum setting (200°F/93°C after preheating).

3. Thermometer

Displays the temperature of the cabinet and pan. A green zone

of 150-175°F (66-79°C) shows the optimum temperature range

for most food products.

4. Moisture control slider

Opens and closes the moisture vents in the front panel of the

drawer.

Moving the slider to the CRISP (left) position opens the

vents, allowing moisture to escape and causing a crisper

food product.

Moving the slider to the MOIST (right) position closes the

vents, trapping moisture inside the cabinet and food product.

B. Operation Procedure

1. Restore electrical power to the hot food server at the circuit

breaker/fused disconnect. Switch the Power On/Off (I/O) switch

to the ON (I) position.

2. Turn the temperature adjustment knob (if necessary) to the

desired setting for the food product.

3. Allow the hot food server to preheat for 20 minutes.

CAUTION - HOT SURFACE

USE CAUTION WHEN LOADING FOOD INTO, AND

REMOVING FOOD FROM, THE PAN.

THE PAN ARE HOT.

4. Open the drawer. Load the food product into the pan, and close

the drawer. Check that the drawer is fully closed to prevent heat

loss into the environment.

5. Move the moisture control slider (if necessary) to open or close

the moisture vents, as required by the food product.

6. The food product will be kept at the temperature shown on the

thermometer. When unloading the product, use caution to avoid

touching the hot surfaces of the pan.

IMPORTANT

It may be necessary to clean the pan after removing some food

products. Refer to Section IV,

Daily Cleaning, in this Manual.

C. Shutdown Procedure

1. Switch the Power On/Off (I/O) switch to the OFF (O) position.

Disconnect electrical power to the hot food server at the circuit

breaker/fused disconnect.

3. Thermometer

1. Power

On/Off (I/O)

Switch

2.

Temperature

adjustment

knob

THE SURFACES OF

IV. DAILY CLEANING

WARNING

WHEN CLEANING THE HOT FOOD SERVER, NEVER

APPLY ENOUGH LIQUID TO STAND IN PLACE ON THE

UNIT. DO NOT SPRAY, RINSE, OR SUBMERGE THE HOT

FOOD SERVER. EXCESSIVE MOISTURE IN THE UNIT

WILL CAUSE A SEVERE ELECTRICAL HAZARD AND MAY

OTHERWISE DAMAGE THE HOT FOOD SERVER.

CAUTION

DO NOT clean your hot food server using abrasive cleaners or pads.

Both will scratch and dull the finish.

1. Switch the Power On/Off (I/O) Switch to the OFF (O) position.

2. Disconnect electrical power to the hot food server at the circuit

breaker/fused disconnect.

3. Allow the hot food server to cool.

CAUTION - HOT SURFACE

DO NOT TOUCH HOT SURFACES ON THE HOT FOOD

SERVER, OR ATTEMPT TO REMOVE THE PAN, UNTIL THE

UNIT HAS COOLED THOROUGHLY.

5. Cleaning the Cabinet Interior and Drawer

a. Remove the drawer from the cabinet as follows:

Open the drawer AND REMOVE THE PAN.

Lift both side rails of the drawer until the rollers are

free, as shown in Figure 6.

Pull the drawer forward, up, and out of the hot food

server.

Figure 6

b. Use a stiff nylon brush to loosen food particles and crumbs

from the following areas:

drawer rails

drawer rollers

cabinet interior

c. Wipe or vacuum the food residue from the interior of the

cabinet.

d. Rinse the drawer rails, drawer rollers, and cabinet interior

with a sponge or cloth soaked in warm detergent water.

e. Wipe the components with a clean, damp cloth, and allow

them to air dry.

5. Cleaning the Pan

a. Empty the contents of the pan.

b. Wash the pan in hot soapy water, and rinse it. Allow the

pan to air dry.

NOTE: If desired, the pan can be pre-rinsed, run through a

dishwater, and then air-dried.

6. Cleaning the Exterior of the Hot Food Server

a. Wipe the exterior of the cabinet with a sponge or cloth

soaked in warm detergent water.

b. Wipe with a clean, damp cloth to remove the excess

detergent, and then wipe again to dry the hot food server.

NOTE: If desired, the exterior surfaces of the cabinet can be

cleaned using a stainless steel cleaner/polish. Be sure to wipe

the polish in the direction of the grain to avoid scratching the

finish.

7. Replace all components into the hot food server.

3

ENGLISH

Page 4

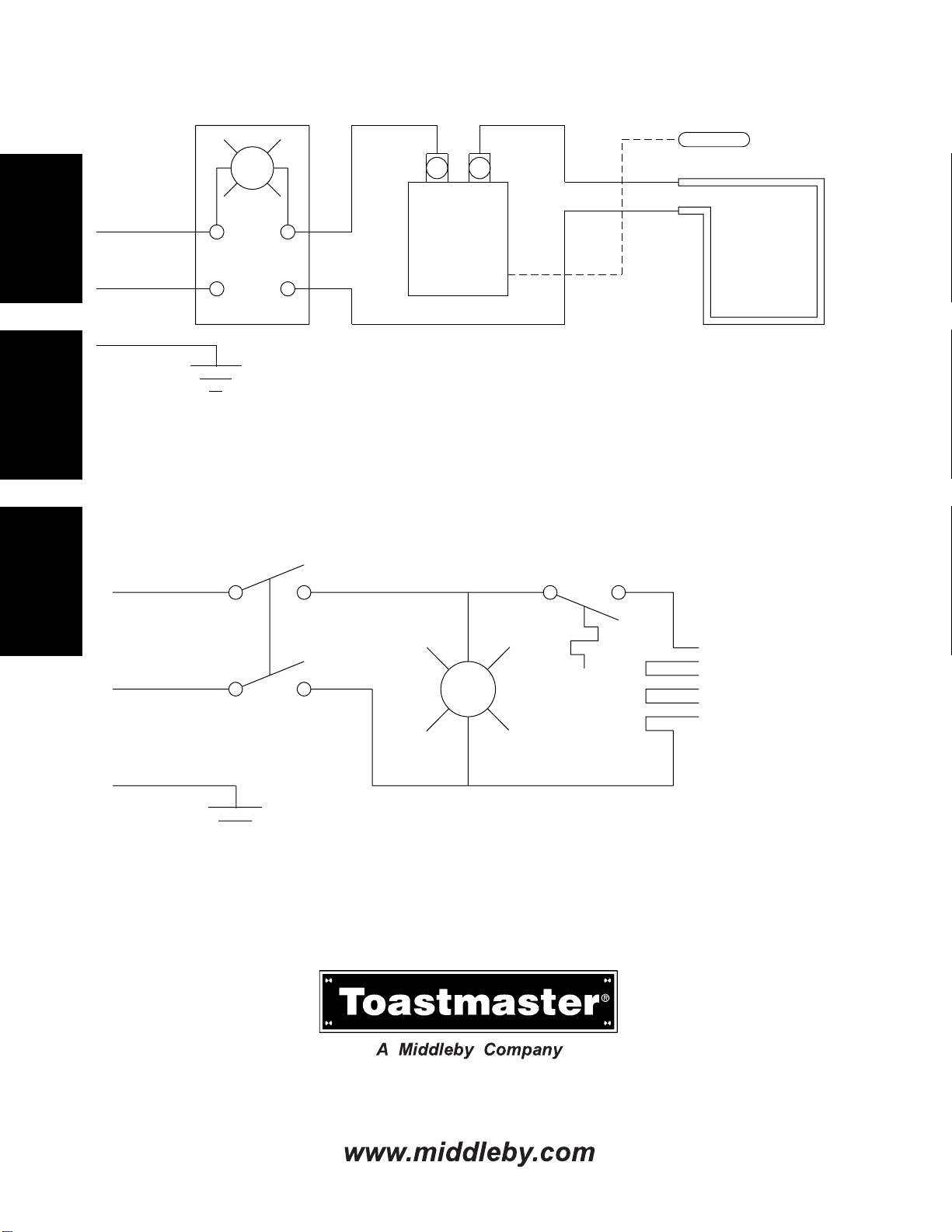

Wiring Diagram

THERMOSTAT BULB

ENGLISH

page 1

BLACK

L1

WHITE

NEUTRAL

FRANÇAIS

page 5

ESPAÑOL

página 9

BLACK

L1

LAMP

POWER ON/OFF

(I/O) SWITCH

GND

THERMOSTAT

Electrical Schematic

THERMOSTAT

HEATING

ELEMENT

HFS09:

120V/500W

HFS72:

230V/500W

WHITE

NEUTRAL

POWER ON/OFF

(I/O) SWITCH

GND

LAMP

A Middleby Company • 10 Sunnen Drive • St. Louis, MO 63143

HEATING

ELEMENT

HFS09: 120V/500W

HFS72: 230V/500W

800.807.9054 • FAX 314.781.2714

•

4

Page 5

2/07

D

A Middleby Company

10 Sunnen Drive • St. Louis, MO 63143

•

CHAUFFE-PLATS

Modèles HFS09, HFS72

MANUEL DINSTALLATION

ET DE FONCTIONNEMENT

est une marque déposée de Toastmaster, une société Middleby. Tous droits réservés.

I. DESCRIPTION ET SPÉCIFICATIONS

A. Emplacement des composants

Les composants principaux du chauffe-plats sont illustrés à la

Figure 1, ci-dessous.

Figure 1

4. Plateau

amovible

3. Thermomètre

800.807.9054 • Télécopieur 314.781.2714

•

page 1

ENGLISH

page 5

FRANÇAIS

5. Curseur

de contrôle

dhumidité

6. Élément chauffant

(sur la plate-forme de la

chambre)

B. Fonction des composants (voir Figure 1)

1. Bouton de réglage de température voir Section III,

Fonctionnement.

2. Interrupteur On/Off (I/O) voir Section III,

Fonctionnement.

3. Thermomètre voir Section III, Fonctionnement.

4. Plateau amovible contient laliment. Il peut être retiré

afin de le nettoyer.

5. Curseur de contrôle dhumidité Ouvre et ferme les sorties

dair situées sur le panneau avant du tiroir.

6. Élément chauffant Génère de la chaleur pour pouvoir

garder laliment à la température désirée.

C. Spécifications électriques et de fonctionnement

Préchauffage : 20 minutes

Plage de température dutilisation : 38-93°C (100-200°F)

Spécifications électriques/HFS09 :

120 V, 50/60 Hz, 1 Ph, 0,5 kW, 4,2 A

Type de fiche : NEMA 5-15P

Spécifications électriques/HFS72 :

208 V, 50/60 Hz, 1 Ph, 0,4 kW, 1,9 A,OU

240 V, 50/60 Hz, 1 Ph, 0,55 kW, 2,3 A

Type de fiche : NEMA 6-15P

REMARQUE

Vous trouverez un schéma de câblage au verso de ce manuel.

1. Bouton de réglage de

température

2. Interrupteur

On/Off (I/O)

página 9

ESPAÑOL

ATTENTION

Lutilisation de pièces autres que les pièces Toastmaster dorigine

décharge le fabricant de toute responsabilité.

IMPORTANT

Contactez votre réparateur agréé pour effectuer la maintenance et

les réparations. Un répertoire de centres de service est fourni avec

votre chauffe-plats.

IMPORTANT

Toastmaster (fabricant) se réserve le droit de modifier les

spécifications et la conception du produit sans préavis. Ces révisions

nimpliquent pas, pour lacheteur, lobtention de modifications,

améliorations, ajouts ou remplacements correspondants pour les

appareils achetés préalablement.

CONSERVEZ CE MANUEL POUR RÉFÉRENCE

ULTÉRIEURE

Ce manuel fournit des informations détaillées relatives à linstallation

et au fonctionnement de votre chauffe-plats. Il contient également des

informations permettant daider lopérateur à diagnostiquer les

problèmes en cas de défaut de fonctionnement. Ce manuel est un outil

important quil convient davoir sous la main.

5

Page 6

II. INSTALLATION

IMPORTANT

IL EST DE LA

SOCIÉTÉ DE TRANSPORT TOUT DOMMAGE APPARENT OU

NON APPARENT.

A. Options dinstallation et disponibilité des lots

Votre chauffe-plats est accompagné de pieds en plastic de 4 po et

listés NSF, il peuvent être utilisés pour les chauffe-plats simples ou

doubles. Pour plus doptions dinstallation, les lots suivants sont

disponibles auprès de Toastmaster :

N/P ACCHFSC lot de roulettes (pour 1 à 4 éléments)

N/P ACCHFS6 lot de pieds de 6 po (pour 1 à 4 éléments)

N/P ACCHFS9 lot de pieds de 9 po (pour 1 à 4 éléments)

Toute installation de chauffe-plats NÉCESSITE le montage de pieds ou

de roulettes sous l(es) appareil(s) avant utilisation. Les configurations dinstallation permises sont les suivantes :

FRANÇAIS

1 élément OUI OUI OUI OUI

2 éléments OUI OUI OUI OUI

3 éléments NON OUI OUI OUI

4 éléments NON OUI OUI OUI

MISE EN GARDE

IL NEST PAS PERMIS DE SUPERPOSER PLUS DE QUATRE

ÉLÉMENTS.

B. Assemblage des pieds/roulettes

1. Pour installer les pieds de 4"/102 mm fournis uniquement avec

les chauffe-plats simples ou doubles, faites passer les pieds

dans les quatre trous situés au bas du chauffe-plats. Le chauffeplats et les quatre pieds installés qui laccompagnent sont illustrés

sur la page de couverture de ce manuel. Pour une superposition de deux éléments, nattachez les pieds que sous lappareil

du bas.

2. Pour installer un lot de pieds ou de roulettes optionnel, reportezvous aux directives fournies avec ce lot.

C. Superposition de chauffe-plats (2 à 4 éléments

seulement)

ATTENTION

Si vous avez installé le lot de roulettes optionnel,

roulettes sont bloquées avant de superposer les appareils.

Effectuez les étapes suivantes, en commençant par le chauffe-plats

possédant des pieds/roulettes :

1. Retirez les deux vis de fixation qui maintiennent le tableau de

commande. Placez les vis dans un endroit sûr. Voir Figure 2.

2. Retirez avec précaution le tableau de commande de la face

avant du chauffe-plats et laissez-le pendre par le câblage.

Nétirez PAS ou NE débranchez PAS le câblage ! Voir Figure 2.

3. Enlevez le capuchon protecteur du panneau supérieur de

lappareil. Pour enlever le capuchon, pliez les dents situées sur

la sous-face du bouchon vers lintérieur et vers le centre à laide

dune pince. Soulevez ensuite le capuchon pour le libérer et

mettez-le au rebut. Voir Figure 3.

4. Placez un chauffe-plats au-dessus du premier. Assurez-vous

que les quatre côtés des chauffe-plats sont alignés.

5. Attachez les deux chambres ensemble en insérant le boulon de

3/8" à partir de lintérieur de louverture du tableau de commande

de lappareil du bas, comme illustré à la Figure 4. Le boulon

passe à travers le trou du panneau supérieur et dans le trou

fileté, destiné au pied, de la plate-forme de lappareil du haut. NE

Serrez PAS TROP le boulon pour permettre un ajustement de la

position des appareils.

6. A larrière de la chambre

coins inférieurs, comme illustré à la Figure 4. Desserrez ensuite

(ne déposez pas) les deux vis de la chambre

maintiennent les fixations de superposition en place.

7. Repositionnez les fixations de superposition comme le montre la

Figure 4, et reposez les deux vis qui avaient été déposées à

létape 6. Serrez les quatre vis.

8. Serrez le boulon de 3/8" (qui avait été installé à létape 5) afin de

maintenir les appareils ensemble.

9. Reposez le tableau de commande et fixez-le à laide des vis.

10. Recommencez les étapes 1à 9 jusquà ce que les appareils

soient superposés. Notez que le capuchon protecteur restera

en position sur le chauffe-plats situé en haut de la pile.

RESPONSABILITÉ DU CLIENT DE SIGNALER À LA

Pieds de 4" Lot de Lot de Lot de

fournis roulettes pieds de 6 pieds de 9

du haut, déposez les vis des DEUX

Vérifiez que les

du bas qui

D. Raccordement électrique

IMPORTANT

LE RACCORDEMENT ÉLECTRIQUE AU CHAUFFE-PLATS

NÉCESSITE UN DISJONCTEUR/SECTIONNEUR À FUSIBLES. LES

SPÉCIFICATIONS ÉLECTRIQUES SE TROUVENT SUR LA PLAQUE

DE SÉRIE (VOIR FIGURE 4) ET À LA SECTION I DE CE MANUEL.

CONSULTEZ TOUTES LES RÉGLEMENTATIONS NATIONALES

ET LOCALES APPLICABLES POUR EN SAVOIR PLUS SUR LES

EXIGENCES EN MATIÈRE DE RACCORDEMENT ÉLECTRIQUE.

1. Avant dentreprendre les raccordements électriques, vérifiez

ce qui suit pour chaque chauffe-plats :

a. Vérifiez si lalimentation en électricité est adaptée aux

exigences du chauffe-plats. Consultez la plaque de série

(Figure 4) et les spécifications électriques (section 1 de ce

manuel).

b. Vérifiez que la prise de courant appropriée est disponible

pour le cordon dalimentation.

AVERTISSEMENT

AVANT DE CONTINUER, ASSUREZ-VOUS QUE LE

DISJONCTEUR/SECTIONNEUR

ET LINTERRUPTEUR ON/

OFF (I/O) SONT POSITIONNÉS SUR « O » (OFF).

AVERTISSEMENT

VERIFIEZ QUIL NE RESTE PLUS DEMBALLAGE A

LINTÉRIEUR DE LAPPAREIL ET DU PLATEAU.

2. Insérez tous les cordons dalimentation dans leur prise

respective.

Figure 2

Vis de montage

du tableau de

commande

Tableau de

commande

Figure 3

Sous-face

du

chauffe-

plats

1. Capuchon

protecteur en

place

3. Après

superposition,

insérez le boulon

à travers le trou

destiné au

capuchon

protecteur

2. Pour

enlever, pliez

les dents vers

lintérieur et

vers le centre

du capuchon

Figure 4 (côté gauche illustré supports de

repositionnement de CHAQUE côté)

1. Déposez

Plaque

didentification

2. Desserrez

4. Reposez

6

5. Serrez

3. Repositionnez

Page 7

III. FONCTIONNEMENT

A. Emplacement et fonction des commandes

Cette section offre un aperçu des commandes du chauffe-plats, de

leur emplacement et de leurs fonctions. Lopérateur DOIT se familiariser

avec ces commandes. Voir Figure 5.

Figure 5

4. Curseur de

contrôle dhumidité

1. Interrupteur On/Off (I/O)

Permet de mettre lélément chauffant sous tension « ON » (« I »)

et hors tension « OFF » (« O »).

2. Bouton de réglage de température

Permet de régler la température de lélément chauffant. Il contrôle

la température de la chambre et du plateau.

« 1 » est le réglage minimum (100°C/38°F après

préchauffage).

« 9 » est le réglage maximum (93°C/200°F après

préchauffage).

3. Thermomètre

Affiche la température de la chambre et du plateau. Une « zone

verte » de 66 à 79°C (150 à 175°F) indique la plage de température

optimum pour la plupart des aliments.

4. Curseur de contrôle dhumidité

Ouvre et ferme les sorties dair situées sur le panneau avant du

tiroir.

Le déplacement du curseur vers la gauche, en position

« CRISP » (croustillant) ouvre les sorties dair, permettant

ainsi à lhumidité de séchapper et produisant un produit

plus croustillant.

Le déplacement du curseur vers la droite, en position

« MOIST » (humide) ferme les sorties dair, piégeant ainsi

lhumidité dans la chambre et laliment.

B. Procédure dutilisation

1. Remettez le chauffe-plats sous tension au niveau du disjoncteur/

sectionneur à fusibles. Positionnez linterrupteur On/Off (I/O)

sur ON (« I »).

2. Tournez le bouton de réglage de température (si nécessaire) au

réglage désiré pour laliment.

3. Laissez préchauffer le chauffe-plats pendant 20 minutes.

ATTENTION TEMPÉRATURE ÉLEVÉE

PROCÉDEZ AVEC PRÉCAUTION LORS DU CHARGEMENT

ET DU RETRAIT DES ALIMENTS DANS/DU PLATEAU.

SURFACES DU PLATEAU SONT CHAUDES.

4. Ouvrez le tiroir. Chargez laliment sur le plateau et fermez le tiroir.

Vérifiez que le tiroir est correctement fermé pour éviter toute

perte de chaleur.

5. Déplacez le curseur de contrôle dhumidité (si nécessaire) de

façon à ouvrir ou fermer les sorties dair, selon les exigences de

laliment.

6. Laliment sera maintenu à la température affichée sur le

thermomètre. Lors du retrait du produit, procédez avec précaution

afin de ne pas toucher les surfaces chaudes du plateau.

IMPORTANT

Il sera peut-être nécessaire de nettoyer le plateau après le

retrait des aliments. Reportez-vous à la section IV,

quotidien, de ce manuel.

C. Procédure de mise en arrêt

1. Positionnez linterrupteur On/Off (I/O) sur OFF (« O »). Mettez le

chauffe-plats hors tension au niveau du disjoncteur/sectionneur

à fusibles.

3. Thermomètre

1.

Interrupteur

On/Off (I/O)

2.

Bouton de

réglage de

température

LES

Nettoyage

IV. NETTOYAGE QUOTIDIEN

AVERTISSEMENT

PENDANT LE NETTOYAGE DU CHAUFFE-PLATS, NE

LAISSEZ JAMAIS UNE TROP GRANDE QUANTITÉ DE

LIQUIDE EN CONTACT AVEC LAPPAREIL. NASPERGEZ

PAS, NE RINCEZ PAS ET NIMMERGEZ PAS LE CHAUFFEPLATS. UNE HUMIDITE EXCESSIVE ENTRAÎNERAIT

DIMPORTANTS RISQUES DÉLECTROCUTION ET

POURRAIT ÉGALEMENT ENDOMMAGER LE CHAUFFEPLATS.

MISE EN GARDE

NE PAS utiliser de substances ou de produits abrasifs pour lentretien

du chauffe-plats. Ceux-ci peuvent rayer et ternir la surface.

1. Positionnez linterrupteur On/Off (I/O) sur OFF (« O »).

2. Mettez le chauffe-plats hors tension au niveau du disjoncteur/

sectionneur à fusibles.

3. Attendez que lappareil refroidisse.

ATTENTION TEMPÉRATURE ÉLEVÉE

NE TOUCHEZ PAS LES SURFACES CHAUDES DU

CHAUFFE-PLATS, OU NESSAYEZ PAS DENLEVER LE

PLATEAU AVANT LE REFROIDISSEMENT COMPLÈT DE

LAPPAREIL.

4. Nettoyage de lintérieur de la chambre et du tiroir

a. Enlevez le tiroir de la chambre de la façon suivante :

Ouvrez le tiroir ET ENLEVEZ LE PLATEAU.

Soulevez les glissières de chaque côté du tiroir jusquà

ce que les deux roulettes soient libérées, comme

lillustre la Figure 6.

Tirez le tiroir vers lavant, vers le haut et en dehors du

chauffe-plats.

Figure 6

b. Utilisez une brosse de nylon rigide pour libérer les morceaux

de nourriture et les miettes des endroits suivants :

glissières de tiroir

roulettes de tiroir

intérieur de la chambre

c. Essuyez ou aspirez les restes de nourriture de lintérieur

de la chambre.

d. Rincez les glissières et les roulettes du tiroir, ainsi que

lintérieur de la chambre à laide dune éponge ou dun chiffon

trempé dans de leau savonneuse chaude.

e. Essuyez les différents composants à laide dun chiffon

humide et propre et laissez-les sécher à lair libre.

5. Nettoyage du plateau

a. Videz le contenu du plateau.

b. Lavez le plateau dans de leau savonneuse chaude et

rincez-le ensuite. Laissez-le sécher à lair libre.

REMARQUE : Si vous le désirez, vous pouvez préalablement

rincer le plateau, le passer dans le lave-vaisselle et ensuite le

sécher à lair libre.

6. Nettoyage de lextérieur du chauffe-plats

a. Essuyez lextérieur de lappareil à laide dune éponge humide

ou dun chiffon trempé dans de leau savonneuse chaude.

b. Frottez avec un chiffon humide et propre afin denlever tout

excès de détergent et essuyez ensuite pour sécher le

chauffe-plats.

REMARQUE : Si vous le désirez, les surfaces extérieures du

chauffe-plats peuvent être nettoyées à laide dun nettoyant

pour inox. Assurez-vous de bien utiliser le produit à polir dans

le sens de linox pour éviter de rayer la surface.

7. Remettez tous les composants dans le chauffe-plats.

7

FRANÇAIS

Page 8

Schéma de câblage

LAMPE DE THERMOSTAT

ENGLISH

page 1

NOIR

BLANC

NEUTRE

FRANÇAIS

page 5

ESPAÑOL

página 9

NOIR

L1

L1

TÉMOIN

INTERRUPTEUR

ON/OFF (I/O)

MASSE

THERMOSTAT

Schéma de raccordement électrique

THERMOSTAT

ÉLÉMENT

CHAUFFANT

HFS09 :

120 V/500 W

HFS72 :

230 V/500 W

BLANC

NEUTRE

INTERRUPTEUR

ON/OFF (I/O)

MASSE

TÉMOIN

A Middleby Company • 10 Sunnen Drive • St. Louis, MO 63143

ÉLÉMENT

CHAUFFANT

HFS09 : 120 V/500 W

HFS72 : 230 V/500 W

800.807.9054 • Télécopieur 314.781.2714

•

8

Page 9

D 2/07

A Middleby Company

10 Sunnen Drive • St. Louis, MO 63143 EE. UU

•

Servidor de alimentos calientes

Modelos HFS09, HFS72

MANUAL DE INSTALACIÓN Y

OPERACIÓN DEL

PROPIETARIO

es una marca registrada de Toastmaster, Una compañía Middleby. Reservados todos los derechos.

I. DESCRIPCIÓN Y ESPECIFICACIONES

A. Localización de componentes

En la Figura 1 se muestran los componentes principales del

servidor de alimentos calientes.

4. Bandeja de

alimentos

desmontable

Figura 1

3. Termómetro

800.807.9054 • FAX 314.781.2714

•

page 1

ENGLISH

page 5

FRANÇAIS

5. Palanca

de control de

la humedad

6. Elemento térmico

(en la base de la cámara)

B. Función de los componentes (vea la Figura 1)

1. Perilla de ajuste de la temperatura - vea la Sección III,

Operación

2. Interruptor de potencia (I/O) - vea la Sección III, Operación

3. Termómetro - vea la Sección III, Operación

4. Bandeja de alimentos desmontable - Es donde se colocan

los alimentos. Se puede retirar para limpiarla.

5. Palanca de control de la humedad - Abre y cierra los

orificios de control de la humedad en el panel delantero

del cajón.

6. Elemento térmico - Proporciona calor para mantener la

temperatura apropiada de los alimentos.

C. Especificaciones de operación y eléctricas

Tiempo de precalentamiento: 20 minutos

Límites de temperatura: 100-200°F (38-93°C)

Especificaciones eléctricas/HFS09:

120V, 50/60Hz, 1 fase, 0.5kW, 4.2A

Tipo de enchufe: NEMA 5-15P

Especificaciones eléctricas/HFS72:

208V, 50/60Hz, 1 fase, 0.4kW, 1.9A, O

240V, 50/60Hz, 1 fase, 0.55kW, 2.3A

Tipo de enchufe: NEMA 6-15P

NOTA

En la tapa posterior de este manual encontrará un diagrama de

cableado eléctrico.

1. Perilla de ajuste de la

temperatura

2. Interruptor de

potencia (I/O)

página 9

ESPAÑOL

PRECAUCIÓN

Si se utilizan piezas distintas de las originales suministradas en

fábrica por Toastmaster, el fabricante queda libre de toda

responsabilidad.

IMPORTANTE

Antes de realizar tareas de mantenimiento y reparación, póngase en

contacto con el técnico de servicio autorizado. Con el servidor de

alimentos calientes se incluye una lista de agencias de servicio.

IMPORTANTE

Toastmaster (fabricante) se reserva el derecho de modificar las

especificaciones y diseño del producto sin previo aviso Estas

modificaciones no dan derecho al comprador a los cambios, mejoras,

adiciones o reemplazos por equipo comprado con anterioridad.

CONSERVE ESTE MANUAL PARA USARLO COMO

REFERENCIA EN EL FUTURO

Este manual proporciona información detallada sobre la instalación

y operación del servidor de alimentos calientes. También contiene

información para ayudar al operador a solucionar problemas en el

caso de una avería. Este manual es una herramienta importante para

el operador y debe conservarse en un lugar de fácil acceso.

9

Page 10

II. INSTALACIÓN

IMPORTANTE

ES

RESPONSABILIDAD DEL CLIENTE INFORMAR A LA EMPRESA

DE TRANSPORTE SOBRE CUALQUIER DAÑO VISIBLE U OCULTO.

A. Opciones de instalación y disponibilidad del kit de

instalación

El servidor de alimentos calientes se envía de fábrica con patas de

plástico de 4 pulg., clasificadas según el formato nacional estándar o

NSF, que se pueden usar en instalaciones de una o dos unidades.

Toastmaster tiene disponibles los juegos siguientes para opciones

de instalación adicionales:

N/P ACCHFSC Juego de ruedas (para 1-4 unidades)

N/P ACCHFS6 Juego de patas de 6 pulg. (para 1-4 unidades)

N/P ACCHFS9 Juego de patas de 9 pulg. (para 1-4 unidades)

Antes de poner en funcionamiento las instalaciones de servidores

de alimentos calientes, éstas REQUIEREN que la(s) unidad(es) se

instalen con las patas o ruedas. Las configuraciones de instalación

permitidas son las siguientes:

Una unidad SÍ SÍ SÍ SÍ

Torre de dos

unidades SÍ SÍ SÍ SÍ

Torre de tres

unidades NO SÍ SÍ SÍ

Torre de cuatro

unidades NO SÍ SÍ SÍ

PRECAUCIÓN

NO ESTÁ PERMITIDO APILAR MÁS DE CUATRO SERVIDORES.

B. Ensamblado de las patas/ruedas

ESPAÑOL

1. Para instalar las patas de 4 pulg./102 mm suministradas (1-2

unidades solamente), enrosque las patas en los cuatro orificios

de la parte inferior del servidor de alimentos calientes. En la

cubierta de este manual aparece una ilustración del servidor

con las patas suministradas instaladas. Para una torre de dos

unidades, instale las patas en el servidor inferior solamente.

2. Para instalar un juego de patas o de ruedas opcional, consulte

las instrucciones proporcionads con el juego.

C. Torre de servidores de alimentos calientes (2-4

unidades solamente)

PRECAUCIÓN

Si ha instalado el juego de ruedas opcional,

están aseguradas antes de apilar los servidores de alimentos

calientes.

Realice los pasos siguientes, comenzando con el servidor que tiene

las patas/ruedas instaladas:

1. Retire los dos tornillos que sujetan el panel de control en posición.

Asegúrese de conservar los tornillos Vea la Figura 2.

2. Tire con cuidado del panel de control para retirarlo de la parte

delantera de la unidad y deje que cuelgue de los cables. NO

estire ni desconecte los cables. Vea la Figura 2.

3. Retire el tapón del panel superior de la unidad. Para retirar el

tapón, doble los dientes de la parte inferior del mismo hacia

adentro y hacia al centro, usando unos alicates. Después retire

el tapón y deséchelo. Vea la Figura 3.

4. Coloque un servidor de alimentos calientes encima de la unidad.

Compruebe si los cuatro lados de las unidades están alineados.

5. Una las dos unidades insertando el perno de 3/8 pulg.

suministrado desde el interior de la abertura del panel de control

del servidor inferior, como se muestra en la Figura 4. El perno

pasa a través del orificio en el panel superior y dentro del orificio

roscado de la pata en la base de la unidad superior. Enrosque el

perno SIN APRETARLO para poder ajustar la posición de las

unidades.

6. En la parte

AMBAS esquinas inferiores posteriores, como se muestra en la

Figura 4. Después afloje (sin retirar) los dos tornillos en el servidor

inferior que sujetan los clips de apilado en posición.

7. Vuelva a colocar los clips de apilado como se muestra en la

Figura 4 y sustituya los dos tornillos que retiró en el paso 6.

Apriete los cuatro tornillos.

8. Apriete el perno de 3/8 pulg. (que instaló en el paso 5) para

asegurar las unidades.

9. Vuelva a instalar el panel de control y sujételo en posición con

sus tornillos.

10. Repita los pasos 1 al 9 hasta que haya apilado todas las

unidades. Observe que el tapón permanecerá en posición en el

servidor superior de la pila.

Patas de Juego de Juego de Juego de

4 pulg. ruedas patas de patas de

suministradas 6 pulg. 9 pulg.

verifique si las ruedas

posterior del servidor superior, retire los tornillos de

D. Conexión eléctrica

IMPORTANTE

LA CONEXIÓN ELÉCTRICA CON EL SERVIDOR DE ALIMENTOS

CALIENTES

REQUIERE UN DISYUNTOR O DESCONEXIÓN POR

FUSIBLE. LAS ESPECIFICACIONES ELÉCTRICAS SE INDICAN

EN LA PLACA DE INFORMACIÓN (MOSTRADA EN LA FIGURA 4)

Y EN LA SECCIÓN I DE ESTE MANUAL.

CONSULTE TODOS LOS CÓDIGOS NACIONALES Y LOCALES

APLICABLES PARA OTROS REQUISITOS DE CONEXIÓN

ELÉCTRICA.

1. Antes de proseguir con la conexión eléctrica, compruebe lo

siguiente para cada servidor de alimentos calientes:

a. Compruebe que la fuente de energía eléctrica concuerde

con los requisitos del servidor de alimentos. Consulte la

placa de información (Figura 4) y las especificaciones

eléctricas mostradas en la Sección 1 de este manual.

b. Compruebe que el enchufe del cable de potencia cuente

con el receptáculo apropiado.

AVISO

ASEGÚRESE DE QUE

DESCONEXIÓN POR FUSIBLE

TANTO EL DISYUNTOR O

COMO EL INTERRUPTOR

(I/O) ESTÉN DESCONECTADOS (POSICIÓN "O") ANTES

DE CONTINUAR.

AVISO

ASEGÚRESE DE QUE LOS MATERIALES DE EMBALAJE

SE HAYAN RETIRADO DEL INTERIOR DE LA CÁMARA Y

BANDEJA DE ALIMENTOS.

2. Inserte cada enchufe del cable de potencia en su receptáculo.

Figura 2

Tornillos de

montaje del panel

de control

Figura 3

Lado

inferior del

servidor

1. Tapón

mostrado en

posición

3. Después de

apilar las

unidades, inserte

el perno a través

del tapón

2. Para

retirarlo, doble

los dientes

hacia adentro

y hacia el

centro del

Figura 4 (lado izquierdo mostrado - vuelva a colocar las

abrazaderas en AMBOS lados)

1. Retirar

Placa de

información

2. Aflojar

4. Volver a

instalar

10

5. Apretar

3. Volver a colocar

Panel de

control

abierto

tapón

Page 11

III. OPERACIÓN

A. Ubicación y función de los controles

Esta sección proporciona una descripción básica de los controles

del servidor de alimentos calientes, su localización y sus funciones.

El operador DEBE estar familiarizado con los controles. Vea la Figura

5.

4. Palanca de

control de la

humedad

1. Interruptor de potencia (I/O)

Enciende ("I") y apaga ("O") el elemento térmico.

2. Perilla de ajuste de la temperatura

Controla el ajuste de la temperatura del elemento térmico. Esto

controla la temperatura de la cámara y de la bandeja.

"1" es el ajuste mínimo (100°F/38°C después del

precalentamiento)

"9" es el ajuse máximo (200°F/93°C después del

precalentamiento).

3. Termómetro

Muestra la temperatua de la cámara y de la bandeja. Una "zona

verde" de 150-175°F (66-79°C) muestra los límites óptimos de

temperatura para la mayoría de alimentos.

4. Palanca de control de la humedad

Abre y cierra los orificios de control de la humedad en el panel

delantero del cajón.

Si se coloca la palanca en la posición "CRISP" (Crujiente)

(izquierda) se abrirán los orificios permitiendo que escape

la humedad y produciendo un producto más crujiente.

Si se coloca la palanca en la posición "MOIST" (Húmedo)

(derecha) se cerrarán los orificios, atrapando la humedad

en el interior de la cámara y del alimento.

B. Procedimiento de operación

1. Restaure la energía eléctrica al servidor de alimentos calientes

mediante el disyuntor o desconexión por fusible. Coloque el

interruptor de potencia (I/O) en la posición de encendido ("I").

2. Gire la perilla de ajuste de la tempertura (si es necesario) al

ajuse deseado para el alimento.

3. Permita que el servidor de alimentos calientes se caliente durante

20 minutos.

PRECAUCIÓN - SUPERFICIE CALIENTE

VAYA CON CUIDADO AL COLOCAR Y SACAR ALIMENTOS

DE LA BANDEJA.

ESTÁN CALIENTES.

4. Abra el cajón. Coloque el alimento en la bandeja y cierre el cajón.

Compruebe si el cajón está completamente cerrado para evitar

la pérdida de calor en el ambiente.

5. Ajuste la palanca de control de la humedad (si es necesario)

para abrir o cerrar los orificios de control de la humedad, según

sea necesario para el alimento.

6. El alimento se mantendrá a la temperatura mostrada en el

termómetro. Cuando saque el producto, vaya con cuidado para

evitr tocar las superficies calientes de la bandeja.

IMPORTANTE

Después de sacar algunos alimentos de la bandeja puede ser

necesario limpiarla. Consulte la Sección IV,

en este manual.

C. Procedimiento de desconexión

1. Coloque el interruptor de potencia (I/O) en la posición de apagado

("O"). Desconecte el suministro de energía eléctrica del servidor

de alimentos calientes mediante el disyuntor o conexión por

fusible.

Figura 5

3. Termómetro

1.

Interruptor

de potencia

(I/O)

2.

Perilla de

ajuste de la

temperatura

LAS SUPERFICIES DE LA BANDEJA

Limpieza diaria,

IV. LIMPIEZA DIARIA

AVISO

CUANDO LIMPIE EL SERVIDOR DE ALIMENTOS

CALIENTES, NO APLIQUE TANTO LÍQUIDO QUE QUEDE

ESTANCADO EN LA UNIDAD. NO ROCÍE, ENJUAGUE O

SUMERJA EL SERVIDOR DE ALIMENTOS CALIENTES. UN

EXCESO DE HUMEDAD EN LA UNIDAD PRESENTARÁ UN

GRAVE PELIGRO DE DESCARGA ELÉCTRICA Y, EN EL

MENOR DE LOS CASOS, PUEDE DAÑAR EL SERVIDOR

DE ALIMENTOS CALIENTES.

PRECAUCIÓN

No use limpiadores o esponjas abrasivas para limpiar el servidor

de alimentos calientes. Se rayará el acabado y se perderá el brillo.

1. Coloque el interruptor de potencia (I/O) en la posición de apagado

("O").

2. Desconecte el suministro de energía eléctrica del servidor de

alimentos calientes mediante el disyuntor o conexión por fusible.

3. Permita que el servidor de alimentos se enfríe.

PRECAUCIÓN - SUPERFICIE CALIENTE

NO TOQUE LAS SUPERFICIES CALIENTES DEL

SERVIDOR DE ALIMENTOS NI INTENTE RETIRAR LA

BANDEJA HASTA QUE LA UNIDAD SE HAYA ENFRIADO

COMPLETAMENTE.

4. Limpieza del interior de la cámara y cajón

a. Retire el cajón de la cámara siguiendo estos pasos:

Abra el cajón Y RETIRE LA BANDEJA.

Levante los rieles laterales del cajón hasta liberar los

rodillos, como se muestra en la Figura 6.

Tire del cajón hacia adelante, hacia arriba y fuera del

servidor de alimentos calientes.

Figura 6

ESPAÑOL

b. Utilice un cepillo de nilón duro para soltar las partículas y

migas de alimentos de las siguientes áreas:

rieles del cajón

rodillos del cajón

interior de la cámara

c. Limpie o aspire los residuos de alimentos del interior de la

cámara.

d. Enjuague los rieles del cajón, rodillos del cajón e interior de

la cámara con una esponja o paño empapados con agua

templada y detergente.

e. Frote los componentes con un paño húmedo y limpio y

permita que se sequen al aire.

5. Limpieza de la bandeja

a. Vacíe el contenido de la bandeja.

b. Lave la bandeja en agua caliente y jabón, y enjuáguela.

Permita que la bandeja se seque al aire.

NOTA: Si lo desea, podrá enjuagar primero la bandeja, pasarla

por el lavaplatos y secarla al aire.

6. Limpieza del exterior del servidor de alimentos calientes

a. Limpie el exterior de la cámara con una esponja o paño

empapados en agua templada y detergente.

b. Frote con un paño limpio y húmedo para eliminar el exceso

de detergente y vuelva a frotar para secar el servidor de

alimentos calientes.

NOTA: Si lo desea, las superficies exteriores de la cámara se

pueden limpiar empleando un limpiador o abrillantador para

acero inoxidable. Asegúrese de frotar el abrillantador en la

dirección del grano para evitar rayar el acabado.

7. Vuelva a instalar todos los componentes en el servidor de

alimentos calientes.

11

Page 12

Diagrama de cableado

BULBO DEL TERMOSTATO

ENGLISH

page 1

NEGRO

L1

BLANCO

NEUTRO

FRANÇAIS

page 5

ESPAÑOL

página 9

NEGRO

L1

LÁMPARA

INTERRUPTOR DE

ENCENDIDO/

APAGADO (I/O)

TIERRA

TERMOSTATO

Esquema eléctrico

ELEMENTO

TÉRMICO

HFS09:

120V/500W

HFS72:

230V/500W

TERMOSTATO

BLANCO

NEUTRO

INTERRUPTOR DE

ENCENDIDO/

APAGADO (I/O)

TIERRA

LÁMPARA

A Middleby Company • 10 Sunnen Drive • St. Louis, MO 63143 EE. UU.

ELEMENTO

TÉRMICO

HFS09: 120V/500W

HFS72: 230V/500W

800.807.9054 • FAX 314.781.2714

•

12

Loading...

Loading...