Page 1

TURN TABLE

MODEL TTT-710

No. TTT-LB16403E

Please keep this instruction manual close at hand of the persons who are in charge of

the operation of this product.

Before operating this product, please read this instruction manual carefully for its

correct handling.

Page 2

Model: TTT-710 Introduction

Introduction

(a) Thank you for your purchase of our product. The Model TTT-710 TURN TABLE (hereinafter

called the instrument or the product) is the product used in combination with our desktop analytical

instruments to perform continuous automatic multi-specimen measurements.

(b) This product can be used by combining it with the following DKK-TOA analytical instruments:

• pH meter ························ Model HM-30R, Model HM-50G, Model HM-60G, Model HM-42X

• Conductivity meter ············ Model CM-30R, Model CM-40G, Model CM-60G, Model CM-42X

• Multi water quality meter ···· Model MM-60R, Model MM-43X

• Automatic titrator ············· Model AUT-701, Model AUT-501

• Acidity titrator ················· Model TA-70

• Salt titrator ····················· Model TS-70

• Potentiometric titrator ········ Model TP-70

• Automatic burette ············· Model ABT-511

(c) Since important items are described in “Safety Information”, read the contents carefully. In

addition, this instruction manual will be needed in case of trouble or if users have questions in the

future. After reading this manual, store it carefully.

-

1 -

Page 3

Model: TTT-710 Safety Information

Safety Information

(1) Meaning of markings

The signal terminology and symbols related to warnings in the instruction manual are defined

below. The alert symbol mark (

damage and also means “Refer to the instruction manual.”

:

Indicates the degree of hazard which can lead to death or serious injury if you fail to operate the

product properly.

Serious injury means an injury such as loss of sight, burns (high temperature or low temperature),

electric shock, bone fracture and poisoning, and the aftereffects of the injury remains or the injury

requires hospitalization or long periods of outpatient treatment.

:

Indicates the degree of hazard/loss which can result in injury or property damage if you fail to operate

the product properly.

Injury means an injury not requiring hospitalization or long periods of outpatient treatment and refers

to burns or electric shock. Property damage refers to widespread damage to the home, household

goods and livestock, pets, equipment, materials, etc. (damage to other than the product itself).

: General caution mark) indicates the possibility of hazard or

【IMPORTANT】

〔NOTE〕

>> Indicates reference items.

①, ②, ③ Indicates item numbers such as the ones used in operations.

Indicates important matters other than

matters such as preventing damage to the product main body, preventing data

destruction, preventing wasting time, maintaining performance, and observing

regulations.

Indicates comments, reasons, background information, a case example and other

items to help the reader understand the meaning.

(2) Safety compliance items

Explosion and fire

Do not install, use, or store the product in an area where explosive gas or flammable

gas exists or where it may be exposed to water and chemicals. They may enter the

product and cause an explosion or fire.

Do not place the product in a fire or burn it. Doing so may cause an explosion or fire

inside the product.

Do not place containers containing fluid in the empty space for installation. The fluid

may enter the product and cause an explosion or fire.

and . They are the

-

2 -

Page 4

Model: TTT-710 Safety Information

Electric Shock

Always verify that the power is off before connecting or disconnecting the power cord

plug and external connection connectors. In addition, do not connect or disconnect

them with wet hands. Water or reagent entering the product may short the circuits

and cause electric shock or fire.

Do not operate the product with wet hands. It may cause electric shock or fire.

The product main body must be grounded. If a problem occurs in the power supply

system, an electric shock may result.

Hazardous substances

When using the liquid chemical pump to clean the electrodes by chemical, procure

the Safety Data Sheet (SDS) for the reagent to be handled from the vendor and

handle the reagents safely in accordance with the description.

Injury

Do not touch the arm section during measurement. During the cleaning operation,

the arm moves and there is the danger of pinching your fingers or getting injured.

Disassembly and Modification

Do not disassemble or modify the sections of the product that are not described in

the instruction manual. The product can be damaged.

Caution Label Lost

If any caution label affixed to this product becomes too difficult to read or lost, please

order a new one through your local sales agent or our sales office and affix it to its

original position.

(3) Notes on use of the instruction manual

Important items such as “Safety compliance items” are described in this manual. Handle the manual

as follows:

(a) The instruction manual is required not only at the start of operation but also required when

maintenance is performed or in case a failure occurs. Please keep the manual at hand all the time so

that the operator who actually operates the product can read the manual at any time.

(b) If the manual is lost or too smeared to read, please order a new copy through your local sales agent

or directly from our sales office.

(c) Some of the diagrams used in the manual or on product labels may be modified with part of their

shapes or displays omitted or they may be described in abstract form. In addition, numbers etc.

shown on the screen example are just examples for such cases.

(d) The contents of the manual may be changed without prior notice for reasons such as to improve

performance.

(e) Intellectual property right of the manual belongs to DKK-TOA. All or part of the manual must not

be reproduced without permission.

-

3 -

Page 5

Model: TTT-710 Warranty

Warranty

(1) Warranty Coverage

DKK-TOA Corporation (DKK-TOA) warrants its products against defective material or workmanship for the

warranty period.

(a) The warranty period is one year from the date of delivery to the original user.

(b) Specific written agreements with DKK-TOA, if any, shall take precedence over this warranty.

(c) The limitation of warranty described herein may not apply where applicable laws do not allow such limitation.

(2) Limited Warranty

This warranty does not cover the cases listed below.

(a) Direct or indirect failure or damage caused by the use of the product for a purpose or in a manner not prescribed by

the specifications or the instruction manual for the product.

(b) Direct or indirect failure or damage caused by force majeure, including but not limited to an act of God, natural

disaster such as earthquake, storm and flood damage, and lightning, fire, accident, abnormal voltage, salt damage,

gas damage, labor unrest, acts of war (declared or undeclared), terrorism, .civil strife, or acts of any governmental

jurisdiction.

(c) Failure or damage caused by any repair or modification not authorized by DKK-TOA.

(d) Failure or damage caused by the transport, moving, or dropping of the product after the purchase that is not

attributable to DKK-TOA.

(e) Electrodes and consumables (The warranty period for each part has priority when the period is shorter than that for

the main unit of the product. If the customer requires any part after more than six months from the date of

manufacture, consult DKK-TOA or its distributor.)

(f) Failure or damage caused by the use of consumables, parts, or software not supplied by DKK-TOA.

(g) Malfunctions or damage caused by the use of connecting equipment not supplied by DKK-TOA.

(h) Loss of data, settings, programs, or software stored on the product not attributable to DKK-TOA.

(i) Any product other than DKK-TOA’s, if specified by the purchaser or user, that incorporates, or is incorporated into

or combined with DKK-TOA’s products (*1). In such cases, this warranty covers DKK-TOA’s products only.

(j) Any product not under proper maintenance in accordance with the instruction manual furnished by DKK-TOA.

(k) Products without a nameplate (excluding products proved to have been delivered by DKK-TOA).

EXCEPT AS EXPRESSLY SET FORTH IN THE PRECEDING SENTENCES, DKK-TOA MAKES NO

WARRANTY OF ANY KIND WHATSOEVER WITH RESPECT TO ANY PRODUCT. DKK-TOA EXPRESSLY

DISCLAIMS ANY WARANTY IMPLIED BY LAW, INCLUDING BUT NOT LIMITED TO ANY WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

LIMITATION OF REMEDIES: In the event that a defect is discovered within the warranty period, DKK-TOA or its

authorized distributor will, at its option, repair or replace the defective product or its part, or will refund the purchase

price of the product. THIS IS THE EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY.

LIMITATION OF DAMAGES: IN NO EVENT SHALL DKK-TOA BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY KIND FOR BREACH OF ANY WARRANTY, NEGLIGENCE, ON

THE BASIS OF STRICT LIABILITY, OR OTHERWISE.

(3) Others

(a) Product parts for maintenance (*2) will normally be supplied for five years (*3) from the date manufacturing and

sales are discontinued.

(b) The cause of any malfunction or damage shall be determined by a DKK-TOA technician.

(c) For repairs, contact a local distributor in your country or state.

*1: Warranties for products from other companies must be maintained by the user.

*2: Maintenance parts refers to parts that are required to maintain operation of the product.

*3: This five-year period is subject to availability of parts or their replacement.

P30 <1>

-

4 -

Page 6

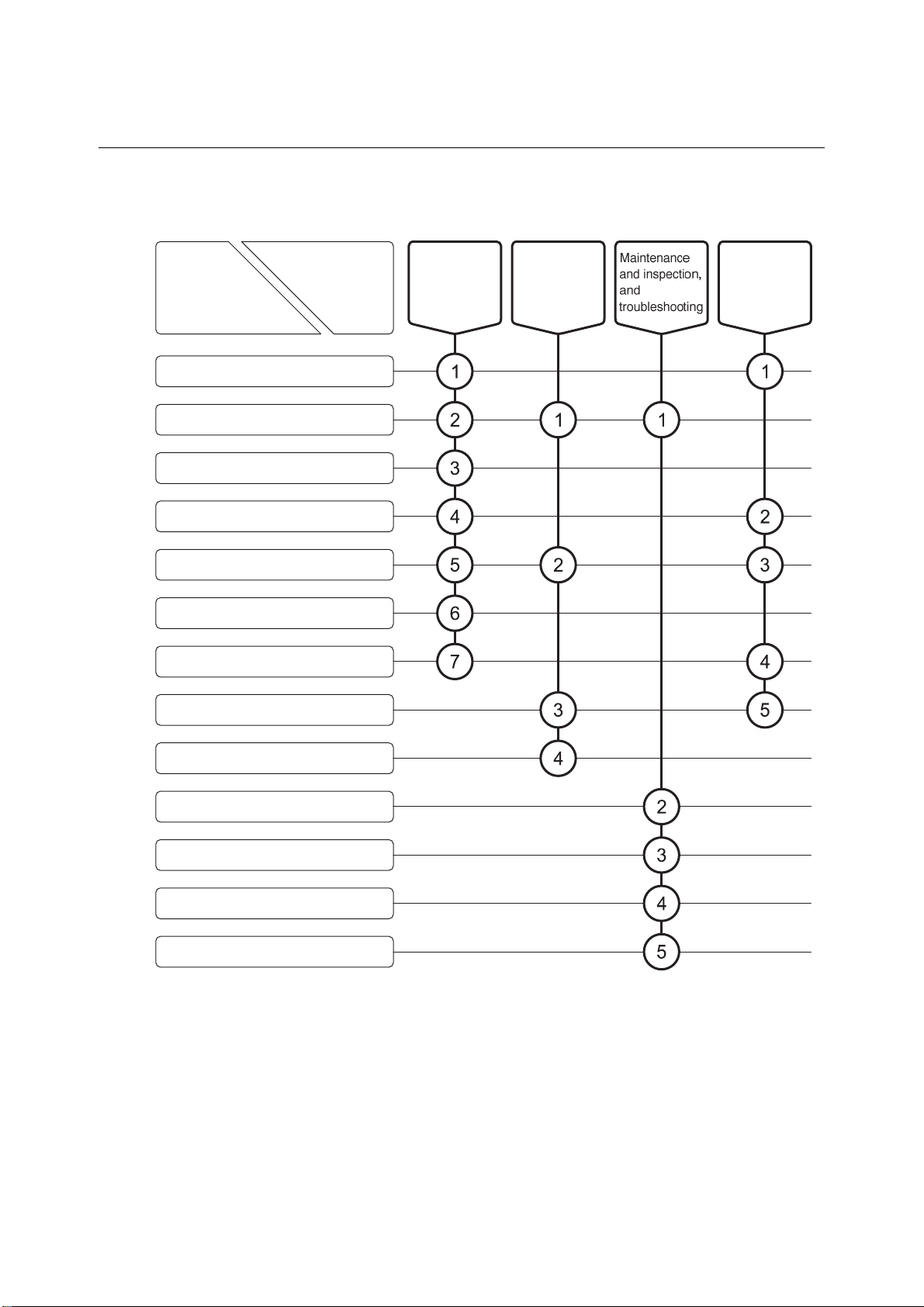

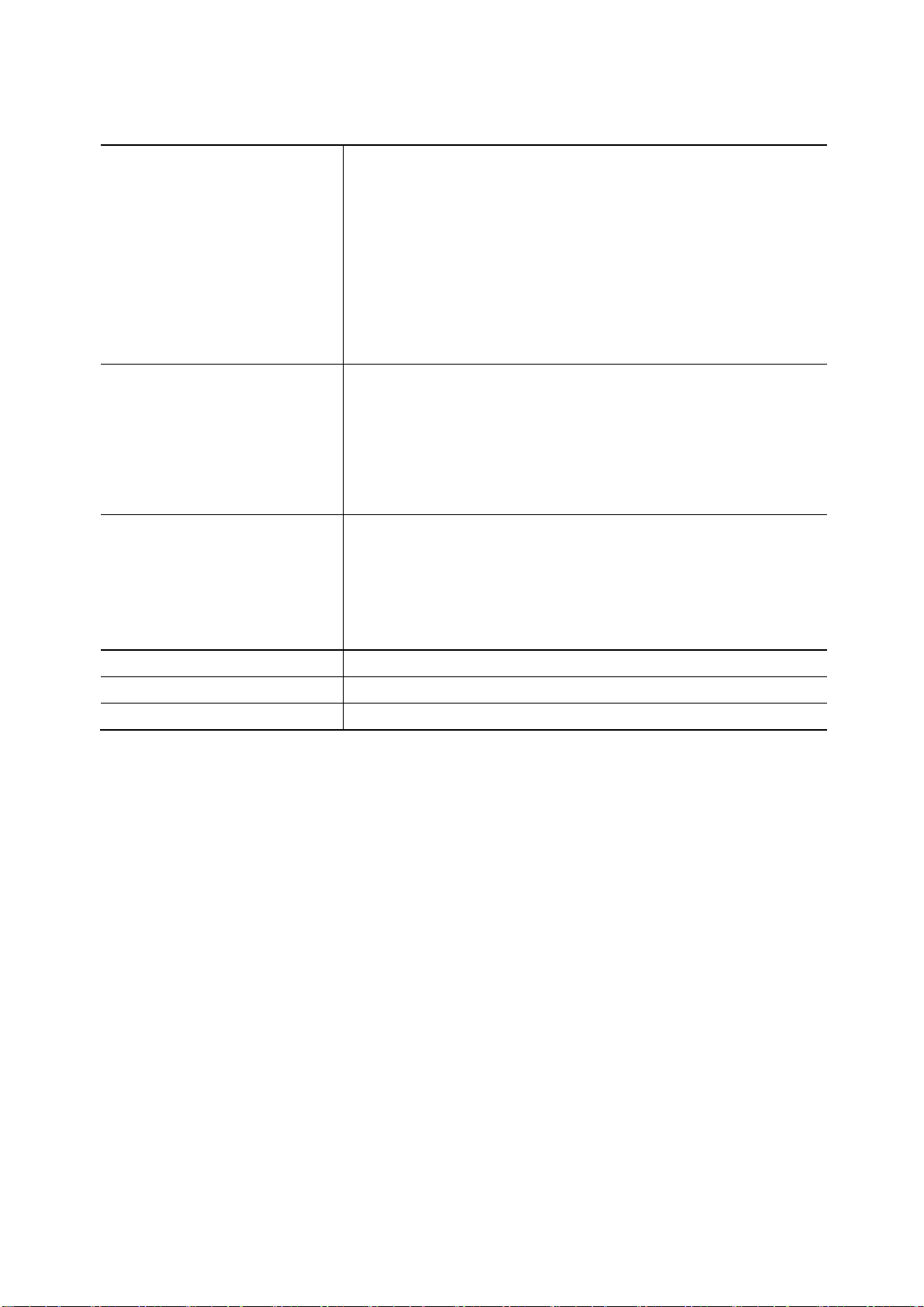

Model: TTT-710 Reading Guide

Reading Guide

Refer to the necessary sections of this instruction manual depending on your purposes such as

understanding the outline of this product or starting the product as shown below. The numbers in

circles indicate sections to be referred to in sequential order.

Purpose

Section

●Introduction

●Safety information

1. Content of Package

2. Specifications and Functions

3. Name and Function of Each Part

4. Preparations

5. Basic Operation

Start

(start-up)

Perform

respective

operations

Understand

the outline of

this product

6. How to Use the Various Functions

7. RS-232C Interface

8. Maintenance and Inspection

9. Troubleshooting

10. Transport, Storage, Disposal

11. Parts and Option List

-

5 -

Page 7

Model: TTT-710 Table of Contents

Table of Contents

●Introduction

●Safety Information

(1) Meaning of markings ⋅⋅⋅⋅ 2

(2) Safety compliance items ⋅⋅⋅⋅ 2

(3) Notes on use of the instruction manual ⋅⋅⋅⋅ 3

●Warranty

●Reading Guide

1. Content of Package

2. Specifications and Functions

······················································································· 1

········································································· 2

···························································································· 4

················································································ 5

··································································· 9

················································ 11

(1) Specifications ⋅⋅⋅⋅ 11

(2) Functions ⋅⋅⋅⋅ 13

3. Name and Function of Each Part

(1) Name of main parts ⋅⋅⋅⋅ 14

(2) Key types and functions of operation panel ⋅⋅⋅⋅ 15

4. Preparations

4.1 Installation Preparations ····································································· 16

4.2 Wiring ···························································································· 18

(1) Power cable and ground connections ⋅⋅⋅⋅ 18

(2) Connection to analytical instruments ⋅⋅⋅⋅ 19

4.3 Piping ···························································································· 25

(1) Piping diagram ⋅⋅⋅⋅ 25

(2) Pure water tank connection ⋅⋅⋅⋅ 26

(3) Waste solution tank connection ⋅⋅⋅⋅ 27

4.4 Table Plate Mounting ········································································· 30

4.5 Mounting the electrode cartridge, electrode, and titration nozzle ·················· 31

4.6 Optional Parts Connection ·································································· 35

(1) Air pump box connection ⋅⋅⋅⋅ 35

(2) Waste water valve connection ⋅⋅⋅⋅ 37

(3) Propeller stirring unit connection ⋅⋅⋅⋅ 39

(4) Reagent washing kit connection ⋅⋅⋅⋅ 40

5. Basic Operation

················································································· 16

·········································································· 46

········································ 14

5.1 Operation Screens Map ····································································· 46

5.2 Basic Operation ··············································································· 49

-

6 -

Page 8

Model: TTT-710 Table of Contents

(1) Use by connecting an automatic titrator or X Series or R Series analytical

instruments (RS-232C) ⋅⋅⋅⋅ 49

(2) Use by connecting R Series analytical instruments (OPTION2) ⋅⋅⋅⋅ 51

(3) Use by connecting acidity titrator (TA-70), salt titrator (TS-70),

or potentiometric titrator (TP-70) ⋅⋅⋅⋅ 52

(4) Use by connecting automatic burette (ABT-511) ⋅⋅⋅⋅ 54

(5) Power off ⋅⋅⋅⋅ 55

6. How to Use the Various Functions

6.1 Manual Operation ············································································· 56

(1) Arm movement and stirring operation ⋅⋅⋅⋅ 56

(2) Table plate rotation and stirring operation ⋅⋅⋅⋅ 57

(3) Stirring operation and speed adjustment ⋅⋅⋅⋅ 59

(4) Pumps and waste water valve operation and tank liquid level judgment ⋅⋅⋅⋅ 60

(5) Electrode manual washing ⋅⋅⋅⋅ 63

6.2 Various Conditions Setting ·································································· 65

(1) Number of table specimens setting ⋅⋅⋅⋅ 65

(2) Measurement conditions setting ⋅⋅⋅⋅ 66

(3) RS-232C communication conditions setting ⋅⋅⋅⋅ 67

(4) Liquid level sensor alarm setting ⋅⋅⋅⋅ 68

(5) Display contrast setting ⋅⋅⋅⋅ 69

(6) Next specimen preparatory stirring function setting ⋅⋅⋅⋅ 69

(7) Electrode washing conditions setting ⋅⋅⋅⋅ 70

7. RS-232C Interface

···································································· 74

····································· 56

7.1 Interface Specifications ······································································ 74

(1) Communication conditions ⋅⋅⋅⋅ 74

(2) Connector and pin arrangement ⋅⋅⋅⋅ 74

7.2 Message Format ·············································································· 75

(1) Receive format (PC → Turntable) ⋅⋅⋅⋅ 75

(2) Send format (Turntable → PC) ⋅⋅⋅⋅ 83

8. Maintenance and Inspection

8.1 Product Main Body Maintenance ·························································· 87

8.2 Maintenance List ·············································································· 88

8.3 Washing Water Flow Passage Maintenance and Inspection ························ 90

(1) Washing water flow passage inspection ⋅⋅⋅⋅ 90

(2) Washing water tube replacement ⋅⋅⋅⋅ 91

(3) Pure water pump replacement ⋅⋅⋅⋅ 92

8.4 Waste Solution Flow Passage Maintenance and Inspection ························ 94

(1) Waste solution flow passage inspection ⋅⋅⋅⋅ 94

(2) Waste solution hose replacement ⋅⋅⋅⋅ 95

8.5 Electrode Storage Beaker Water Level Inspection ···································· 96

8.6 Electrode Arm Maintenance and Inspection ············································ 96

(1) Electrode arm up and down operation inspection ⋅⋅⋅⋅ 96

················································· 87

-

7 -

Page 9

Model: TTT-710 Table of Contents

(2) Electrode arm position inspection and adjustment ⋅⋅⋅⋅ 96

8.7 Liquid Level Sensor Replacement ························································ 98

(1) Pure water tank liquid level sensor replacement ⋅⋅⋅⋅ 98

(2) Waste solution tank liquid level sensor replacement ⋅⋅⋅⋅ 99

9. Troubleshooting

9.1 Safety precautions when an abnormality occurred ·································· 101

9.2 Abnormality by Error Display and Countermeasures ······························· 102

9.3 Other Troubles and Countermeasures ················································· 104

9.4 System Reset Method······································································ 107

10. Transport, Storage, Disposal

10.1 Transport ······················································································ 108

10.2 Storage ························································································ 109

10.3 Disposal ······················································································· 110

11. Parts and Option List

········································································ 101

·············································· 108

······························································ 111

(Last page ⋅⋅⋅⋅ 113)

-

8 -

Page 10

Model: TTT-710 1. Content of Package

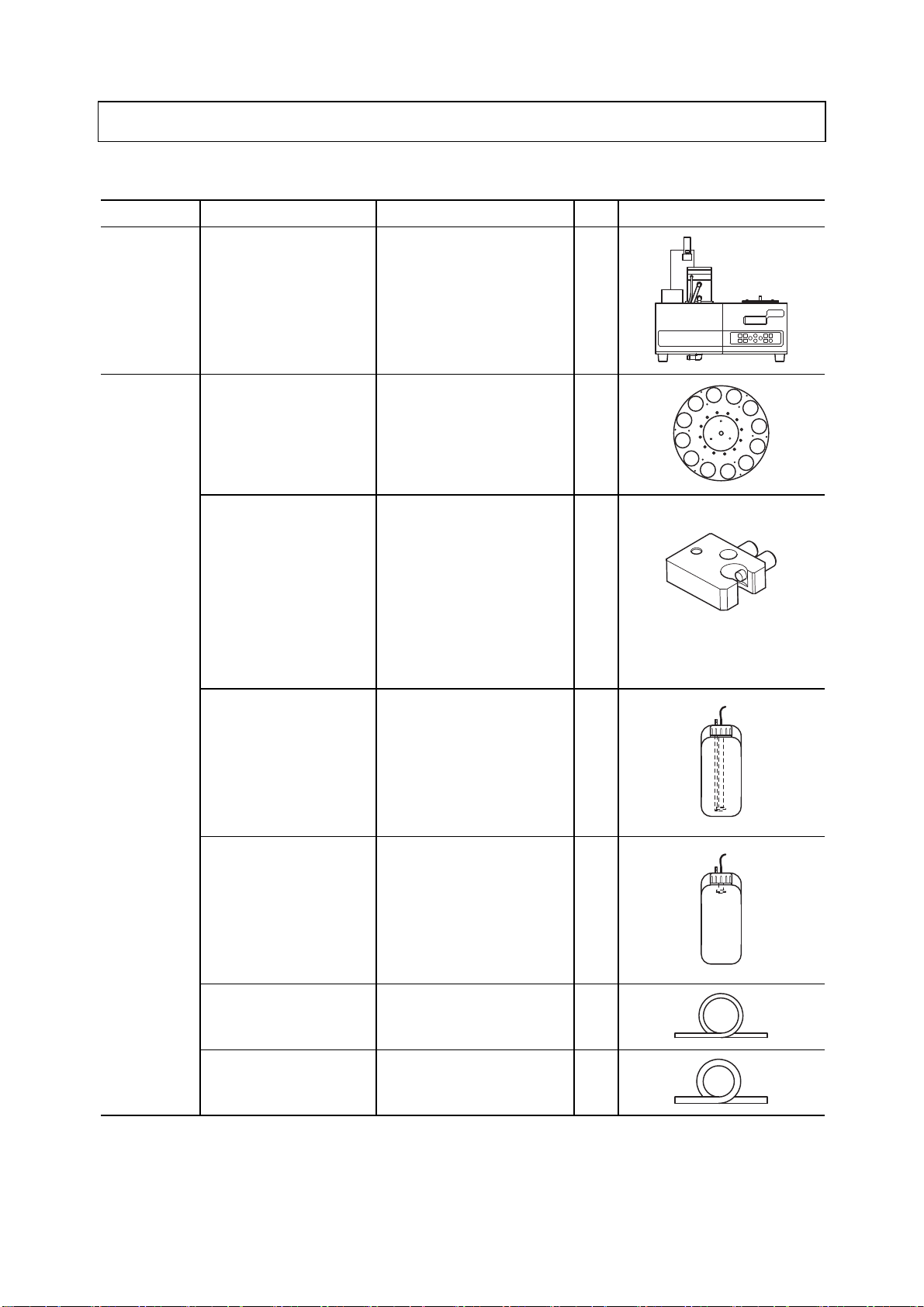

1. Content of Package

Packing List (Standard Accessories)

Classification Description Model Q’ty Appearance

Main Body Turntable TTT-710 1

Accessories Table plate*1 For 12 specimens 7401540U

For 18 specimens 7401550U

For 36 specimens 7401560U

For 60 specimens 7401570U

Electrode cartridge*2

Pure water tank (10L)

(with liquid level sensor)

7505010K(1CH cartridge 1(X))

7505020K(1CH cartridge 2(X))

7506840K(1CH cartridge 3(X))

6597970K (2CH cartridge 1)

7505030K(2CH cartridge 2(X))

6597940K (2CH cartridge 3)

6597980K (Multi cartridge)

6597990K (Sample suction

cartridge)

− 1

1

1

7505010K

(1CH cartridge 1(X))

Waste solution tank (10L)

(with liquid level sensor)

Washing water tube (3m) − 1

Waste solution hose

(1.5m)

− 1

− 1

-

9 -

(To be continued)

Page 11

Model: TTT-710 1. Content of Package

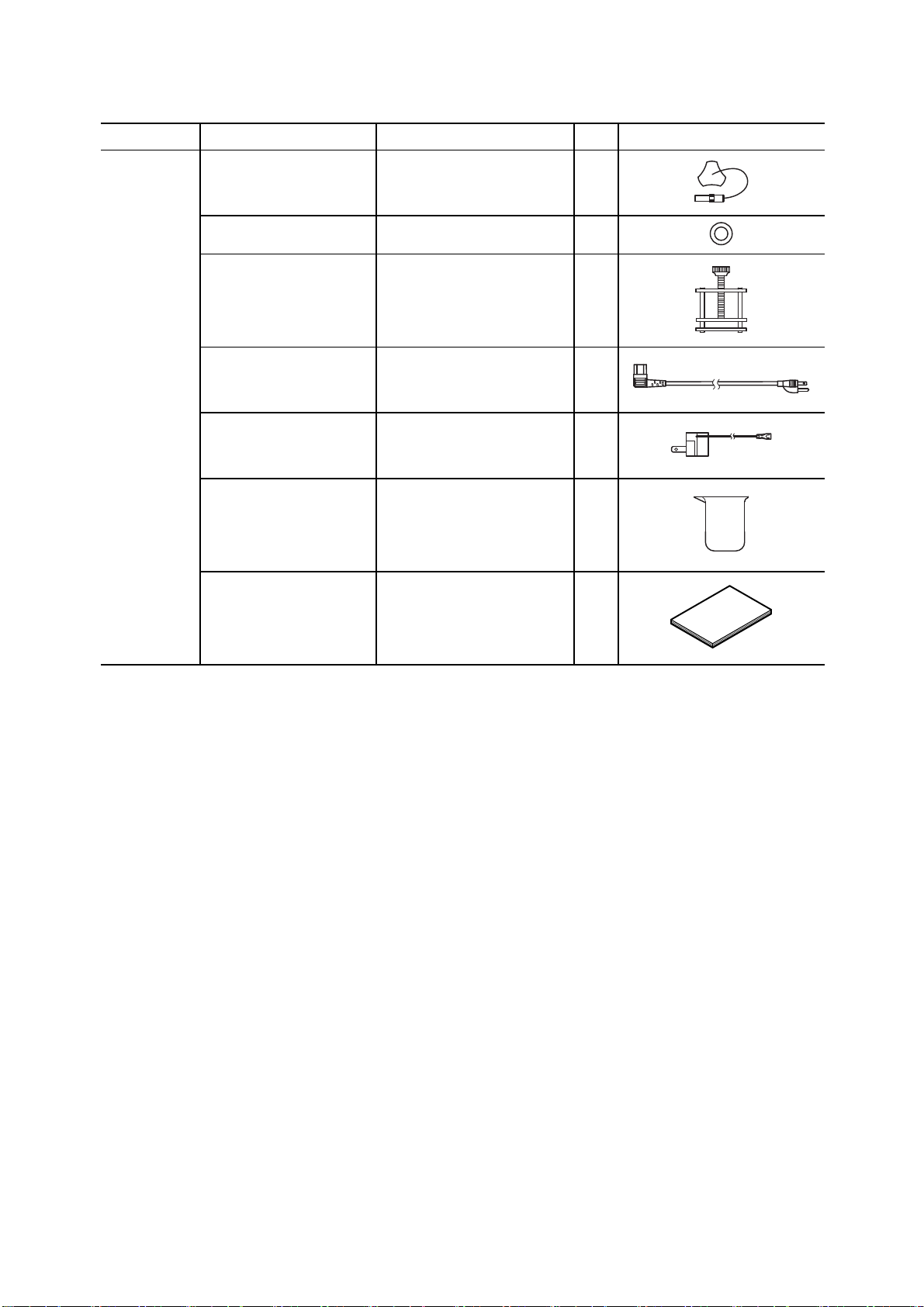

(Continued from previous page)

Classification Description Model Q’ty Appearance

Accessories End detection pin 7401630U 1

O-ring 115A006 1

Small Hoffman pinch cock 126C049 1

Power cable − 1

3P-2P adapter*3 − 1

Disposable beaker

(200mL)

Instruction manual −

136C179 1

〔NOTE〕 *1: When the product is purchased, any one kind of specified number of specimens table is

supplied

*2: When the product is purchased, any one kind of specified electrode cartridge is

supplied

*3: 3P-2P adapter may not be provided depending on the type of power cable.

-

10 -

Page 12

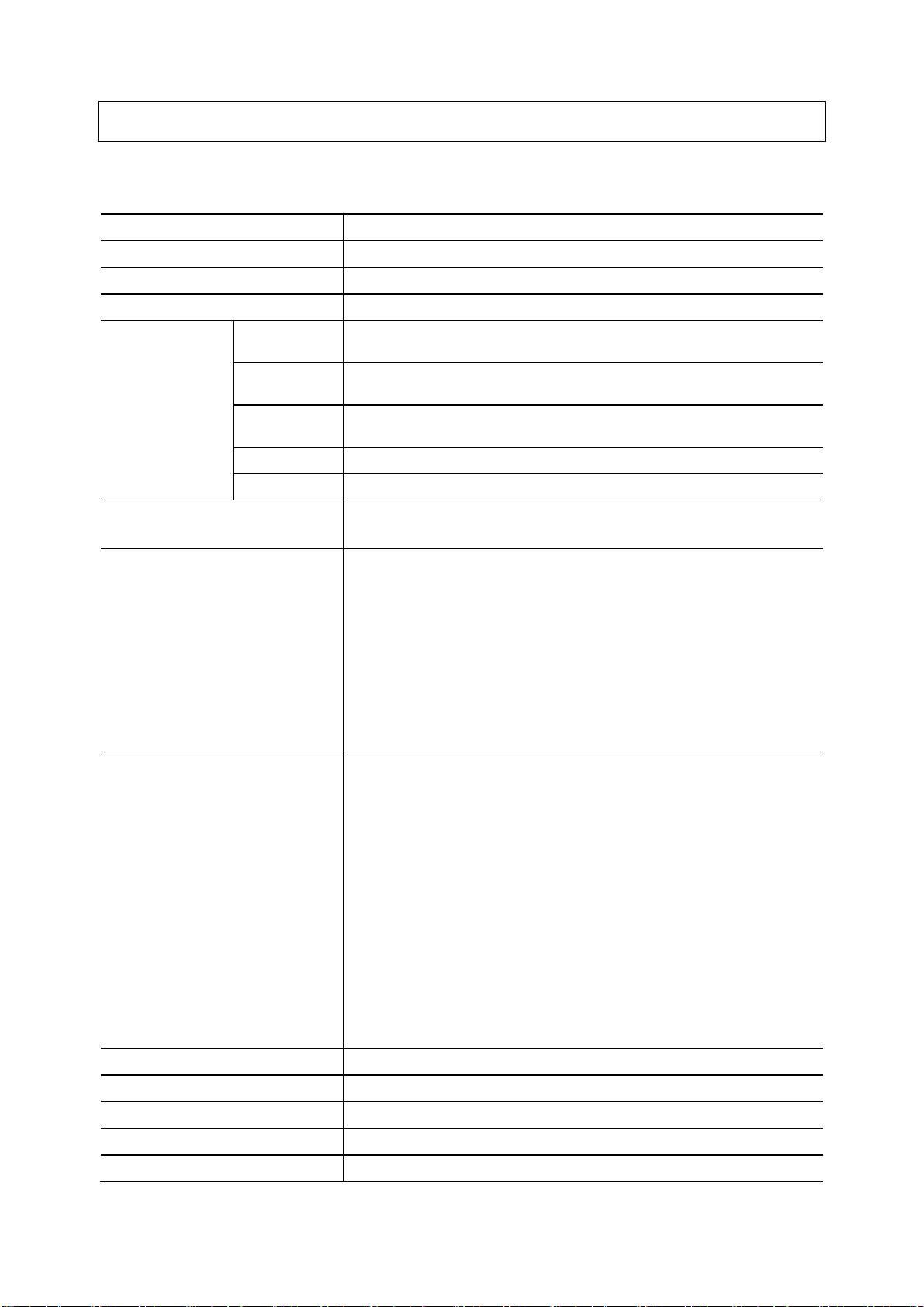

Model: TTT-710 2. Specifications and Functions

2. Specifications and Functions

(1) Specifications

Product name Turntable

Model TTT-710

Display 20 digits x 4 lines, character LCD display

Number of table specimens 12, 18, 36, 60, 100 specimens (100 specimens table is optional)

Usage beaker size 12 specimens 200mL beaker, 300mL tall beaker

18 specimens 100mL tall beaker

36 specimens 30mL beaker, 50mL tall beaker

60 specimens 20mL dedicated beaker (NICHIDENRIKA GLASS Model H-20)

100 specimens 20mL dedicated beaker (NICHIDENRIKA GLASS Model H-20)

Stirring method

External control input/output

Washing method

(Our recommended product: AGC TECHNO GLASS or HARIO glass beaker)

(Our recommended product: AGC TECHNO GLASS or HARIO glass beaker)

(Our recommended product: AGC TECHNO GLASS glass beaker)

Standard: Magnetic stirrer method

When options connected: Propeller stirring method

RS-232C (control for Automatic titrator AUT-701/AUT-501, X Series

HM-42X/CM-42X/MM-43X, R Series HM-30R/CM-30R/MM-60R,

dedicated titrator TA-70/TS-70/TP-70)

OPTION 2 (R Series, G Series) control input/output

Automatic burette (ABT-511) / Flow analysis reference unit (FAR-201A)

control input/output

External control box control input/output

Air pump box control output

Liquid level sensor signal input (washing water 1, waste solution)

Power output for propeller stirring unit

Standard: Pure water shower washing

When options attached: Pure water bubbling washing (air pump box (with

bubbling) when waste water valve attached)

Liquid chemical shower washing (when external

signal box, reagent pump, reagent washing reservoir

attached)

Liquid chemical bubbling washing (when external

signal box, reagent pump, reagent washing reservoir,

air pump box (with bubbling), waste water valve

attached)

Pure water soak washing (when waste water valve

attached)

Liquid chemical soak washing (when external signal

box, reagent pump, reagent washing reservoir, waste

water valve attached)

Air blow (when air pump box attached)

Washing sequences 8 kinds and user washing

Washing time 0 to 9999 seconds for all washing modes

Number of air blows 1 to 9 times

Number of repetitive measurements 1 to 9 times

Measurement end detection

Detected by end detection pin or end table No. setting

-

11 -

Page 13

Model: TTT-710 2. Specifications and Functions

Washing water 1 (pure water) empty

Tank liquid level alarm

Power source 100 to 240VAC 50/60Hz

Fuse F4AH 250V (1 pc)

Waste solution full

Washing water 2 (reagent) empty (when optional liquid level sensor

connected)

Standard

Power

consumption

Main body

dimensions

Main body weight

Performance guaranteed temperature

& humidity range

When options

connected

Dimensions when

table plate not

mounted

Dimensions when

table plate mounted

Max dimensions

when operating

Max Approx. 60VA (when 100VAC used)

Max Approx. 90VA (when 240VAC used)

Max Approx. 100VA (when 100VAC used)

Max Approx. 130VA (when 240VAC used)

Approx. 440 (W) ×409 (H) × 391(D) mm

Approx. 566 (W) ×409 (H) × 507(D) mm

Approx. 566 (W) ×534 (H) × 507(D) mm

Approx. 16kg (when table plate not mounted)

Approx. 18kg (when table plate mounted)

5 to 40 ºC 20 to 85%RH (No condensation)

-

12 -

Page 14

Model: TTT-710 2. Specifications and Functions

(2) Functions

Manual operation • Arm movement (up/down and left/right)

• Table rotation (movement to next specimen No., movement to specified No.

movement to home position)

• Stirring operation (ON/OFF and speed adjustment)

• Pump (pure water pump, air pump, reagent pump) and waste water valve

open/close operation

• Tank liquid level judgment (pure water tank, reagent tank, waste solution

tank)

• Washing sequence (pure water shower, pure water bubbling, reagent shower,

reagent bubbling, pure water soak, reagent soak, air blow)

• Electrode washing by washing mode

Conditions setting • Measurement start table No. (1 to number of specimens of each table plate)

• Measurement end table No. (1 to number of specimens of each table plate

and endless)

• Number of repetitive measurement (1 to 9 times)

• Stirring time before measurement (0 to 9999 seconds)

• Wait time before measurement (0 to 9999 seconds)

• End buzzer time (0 to 9999 seconds)

RS-232C interface Standard equipment

Communication conditions

Baud rate (Selected from among 300, 600, 1200, 2400, 4800, and 9600bps)

Data length (Selected from 7 and 8Bit)

Parity (Selected from NONE, ODD, EVEN)

Stop bit (Selected from 1 and 2Bit)

Liquid level sensor Enable/disable settable

Display Adjustable contrast

Next specimen preparatory stirring Enable/disable settable (Enable for only next specimen stirring specifications)

-

13 -

Page 15

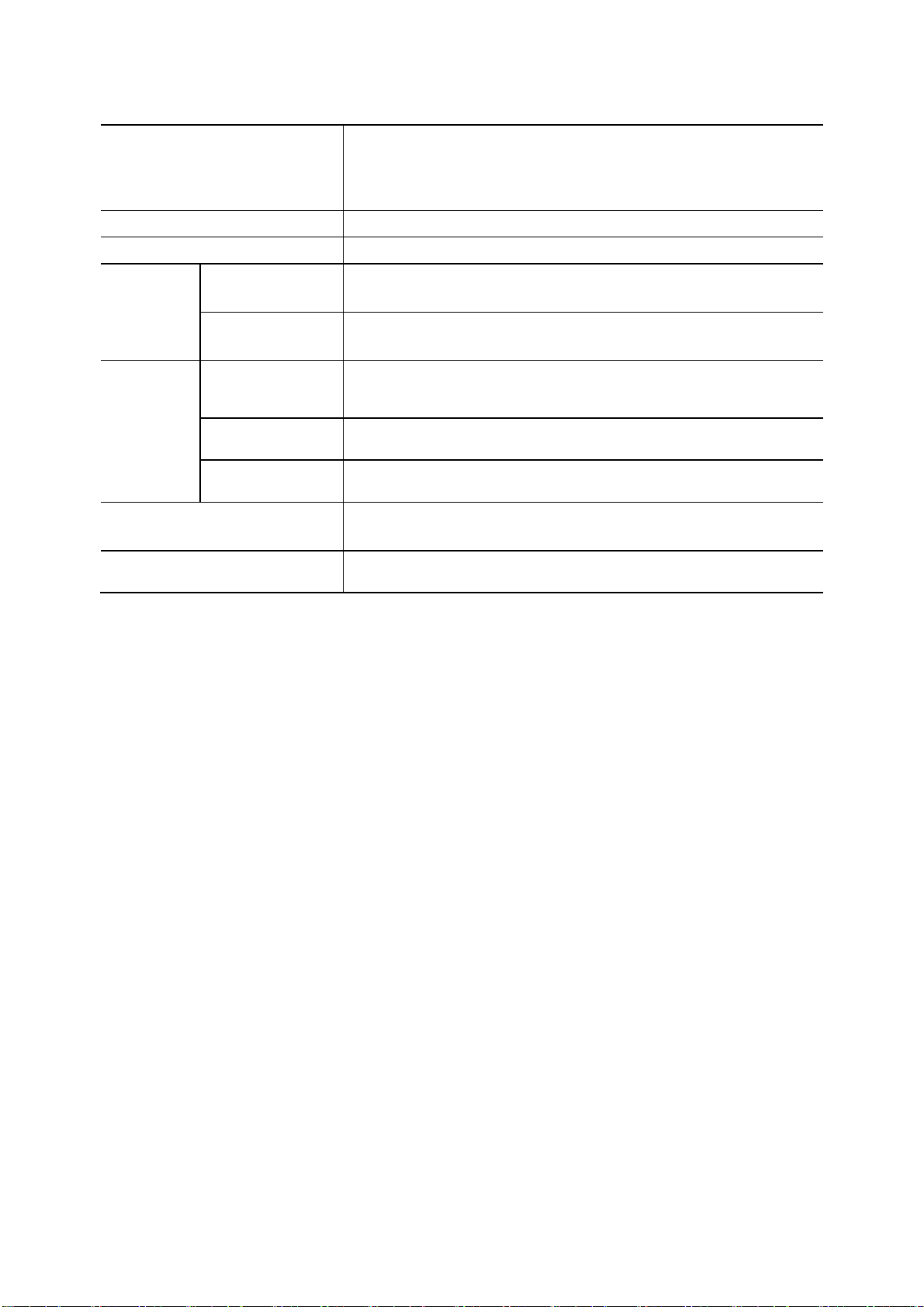

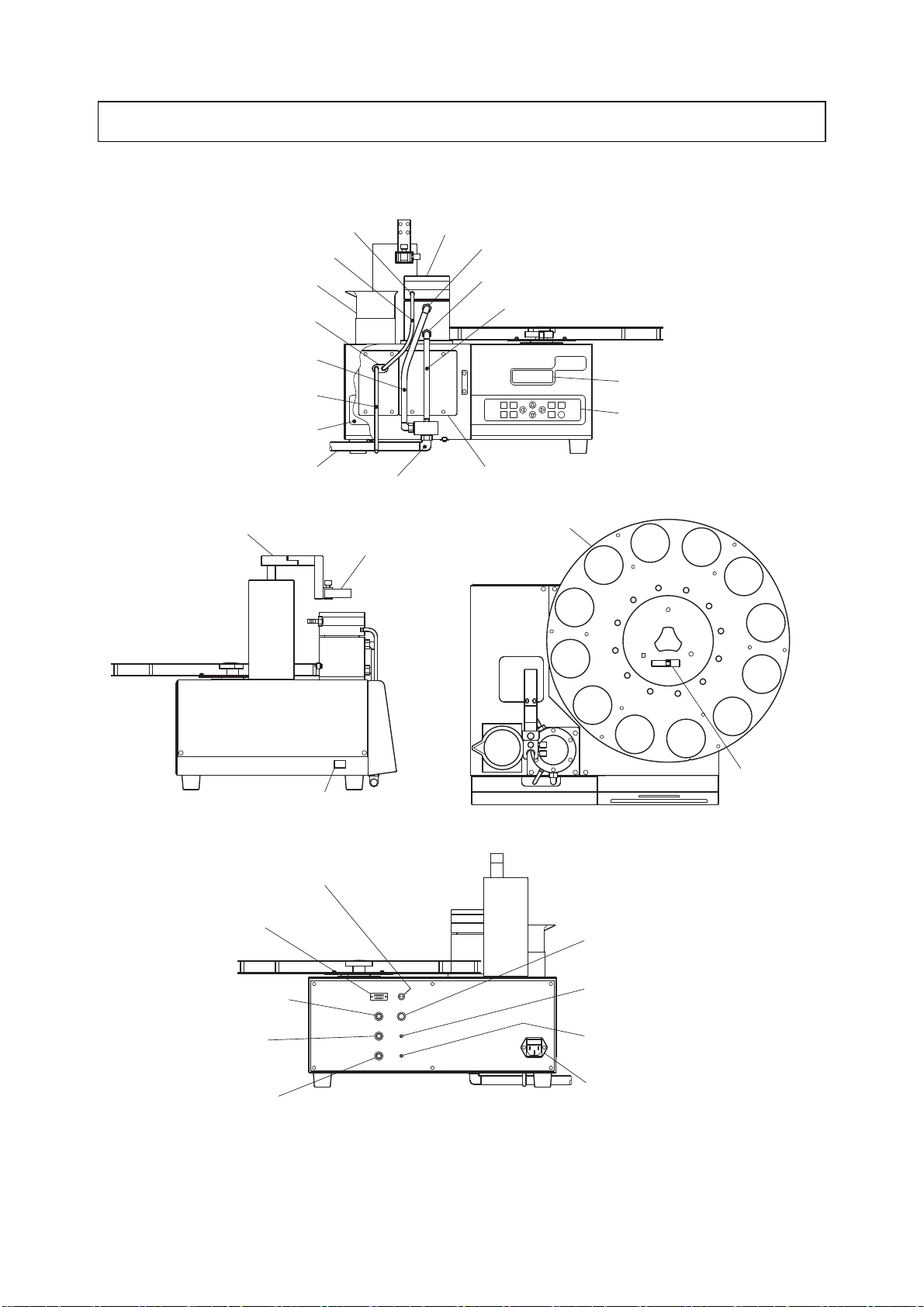

Model: TTT-710 3. Name and Function of Each Part

3. Name and Function of Each Part

(1) Name of main parts

Pure water supply port

Washing water tube

(for washing reservoir)

Electrode storage beaker

Pure water pump

Waste solution hose

(for overflow port)

Washing water tube (for pump)

Piping cover

Waste solution hose

(for outlet 2)

Electrode arm

Waste solution outlet 2

Washing reservoir

Overflow port

Waste solution outlet 1

Waste solution hose (for outlet 1)

Display

Operation panel

Waste water valve attaching port

<Front side>

Table plate

Electrode cartridge

Power switch

(|: power ON ○: power OFF)

<Left side>

Upper stirring unit connection connector

(TO STIRR.)

RS-232C connection connector

(RS-232C)

R/G Series connection connector

(EXT. SIG. OPTION2)

External signal box connection

connector

(EXT. SIG. BOX)

ABT/FAR connection connector

(EXT. SIG. FAR-201A/ABT-511)

<Back side>

Name of Main Parts

End detection pin

<Top side>

Air pump box connection connector

(TO AIR PUMP)

Liquid level sensor connection connector

(for pure water)

(LEVEL ALARM RINSE 1)

Liquid level sensor connection connector

(for waste solution)

(LEVEL ALARM DRAIN)

Power inlet (with fuse)

(~100-240V 130VA FUSE F4AH250V)

-

14 -

Page 16

Model: TTT-710 3. Name and Function of Each Part

(2) Key types and functions of operation panel

Operation Panel

Key Types and Functions of Operation Panel

No.

① START/STOP key

Type of key

(Notation in text)

( START/STOP )

② ARM key

( ARM )

③ TABLE key

( TABLE )

④ WA S H k e y

( WASH )

⑤ SIGNAL key

( SIGNAL )

⑥ STIRRER key

( STIRRER )

⑦ SET key

( SET )

⑧ ENTER key

( ENTER )

Functions

• Performs continuous measurement start or force-quit during

measurement.

(Other than RS-232C communication)

• Switches to the arm manual operation screen.

• Switches to the table manual operation screen.

• Switches to the washing conditions setup and manual washing

operation screen.

• Switches to each operation signal confirmation screen.

• Starts or ends manual stirring operation.

• Switches to the setup screen of each measurement condition.

• Enters each condition set value.

• Performs manual washing or each operation signal confirmation.

⑨ Up and down keys

( )

⑩ Left and right keys

( )

• Changes values (increment/decrement) and switches the setting item

selection.

• Performs arm up/down operation during manual operation.

• Switches the setting item selection.

• Performs arm left and right operation during manual operation, table

rotation operation, and stirring speed adjustment.

-

15 -

Page 17

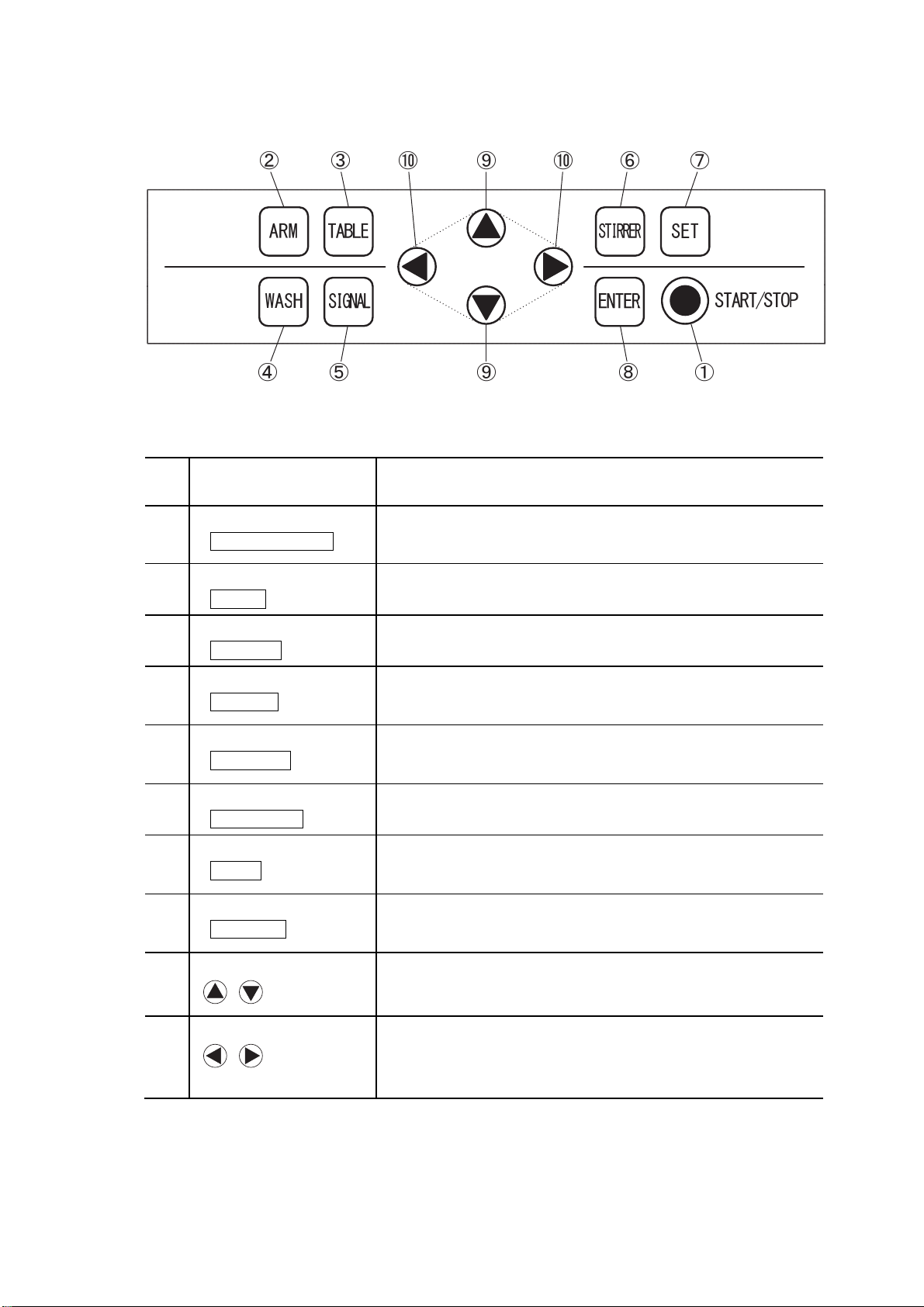

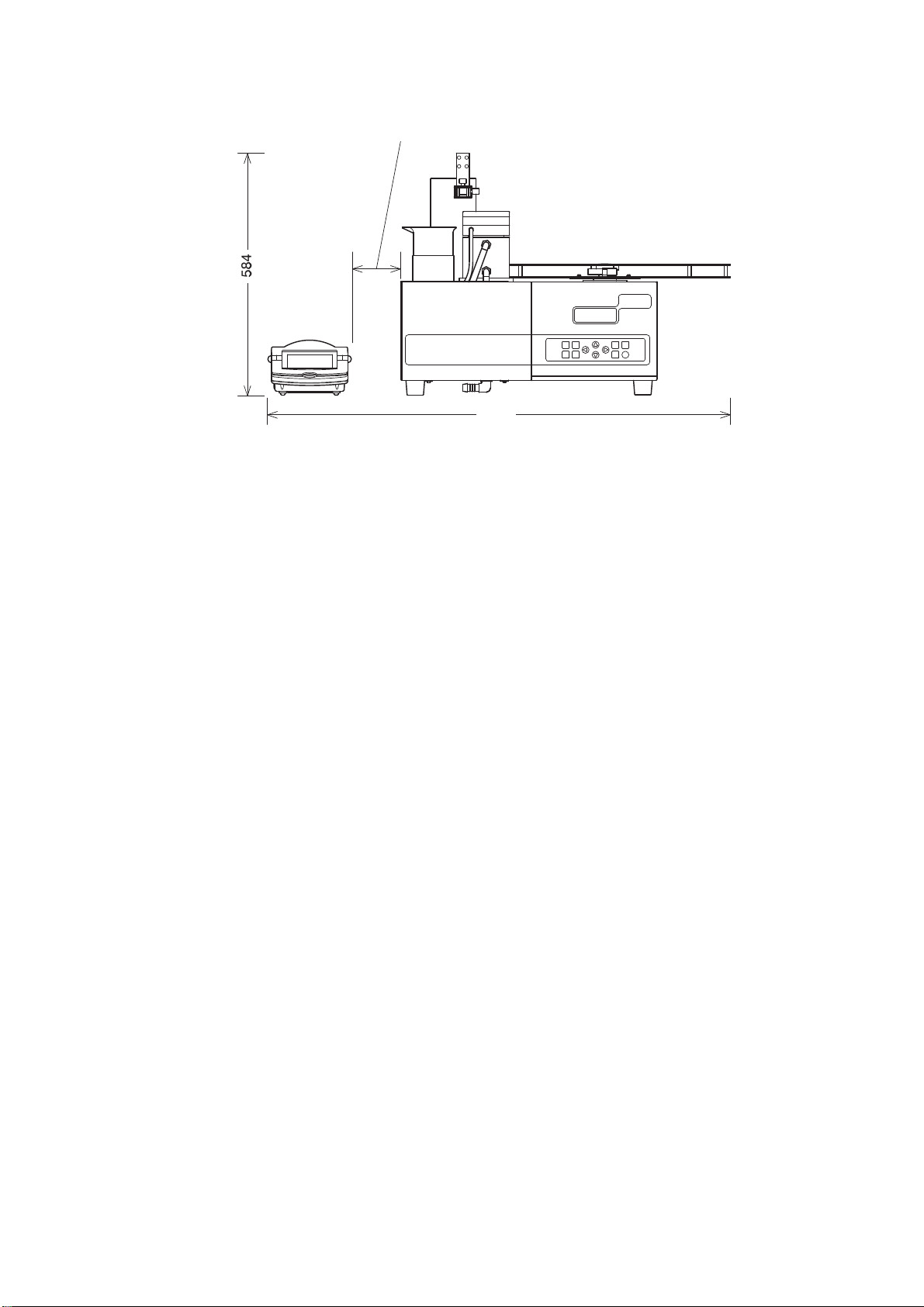

Model: TTT-710 4.1 Installation Preparations

4. Preparations

4.1 Installation Preparations

Install the product main body at a flat place.

Provide an empty space of the following dimensions as installation space for the product main body

and the analytical instruments to be connected.

• When using with X Series analytical instruments ⋅⋅⋅⋅ 896 (W) × 584 (H) × 557 (D) mm

• When using with R Series analytical instruments ⋅⋅⋅⋅ 918 (W) × 584 (H) × 557 (D) mm

• When using with G Series analytical instruments ⋅⋅⋅⋅ 948 (W) × 584 (H) × 557 (D) mm

• When using with Automatic Titrator AUT-701 (including Titration Burette ABT-7 1 unit)

⋅⋅⋅⋅ 1076 (W) × 584 (H) × 557 (D) mm

• When using with Automatic Titrator AUT-501 (including Titration Burette ABT-511 1 unit)

⋅⋅⋅⋅ 1126 (W) × 584 (H) × 557 (D) mm

• When using with dedicated Titrator TA-70, TS-70, or TP-70

⋅⋅⋅⋅ 876 (W) × 584 (H) × 557 (D) mm

• When using with Automatic Burette ABT-511 ⋅⋅⋅⋅ 886 (W) × 584 (H) × 557 (D) mm

Also provide an empty space of 100mm (10cm) or more between the product main body left side and

the analytical instrument or a wall to turn on or off the power easily.

-

16 -

Page 18

Model: TTT-710 4.1 Installation Preparations

Provide an empty space of 100mm or more.

918

Example of Installation Combined with R Series Analytical Instruments

-

17 -

Page 19

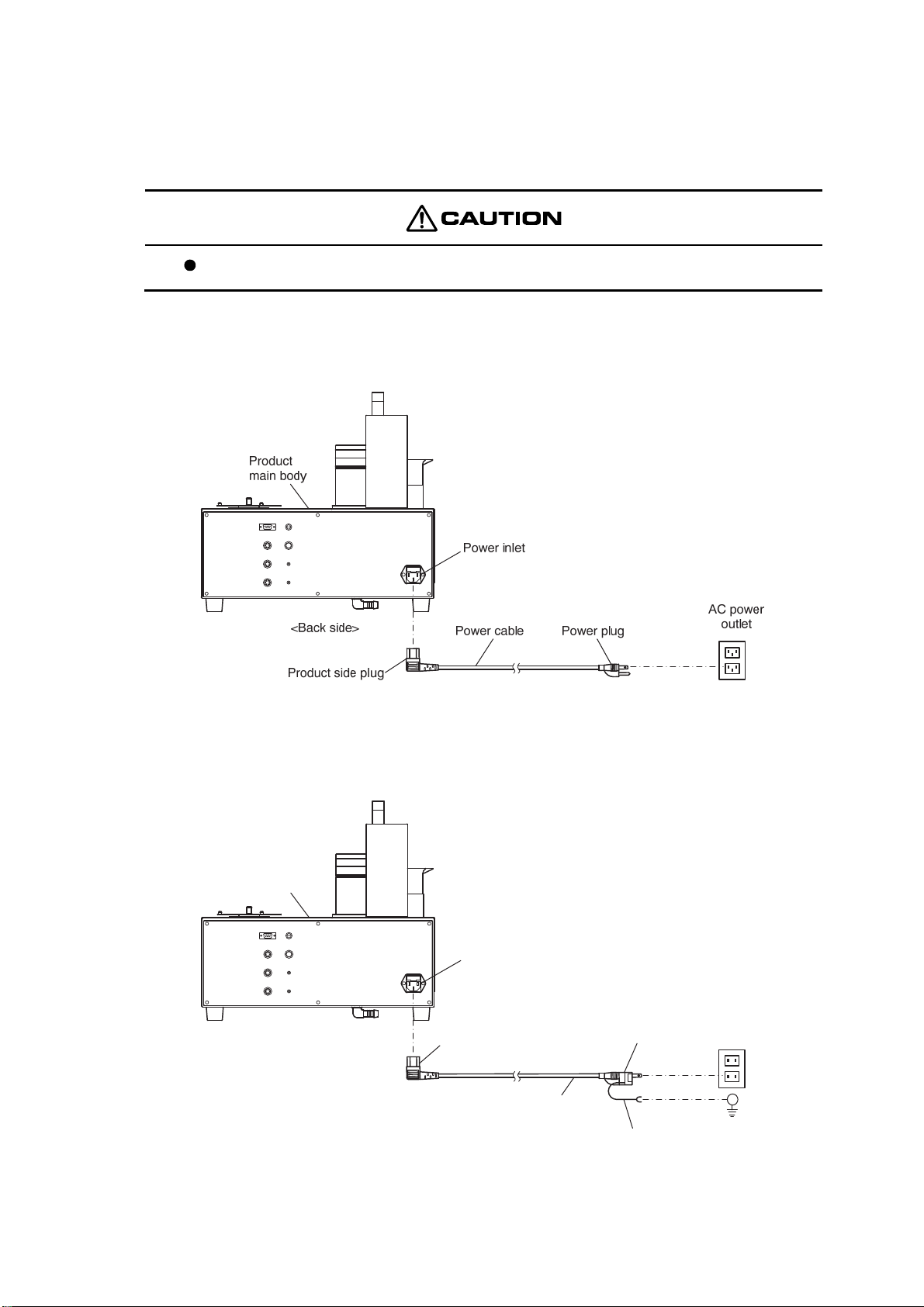

Model: TTT-710 4.2 Wiring

4.2 Wiring

(1) Power cable and ground connections

Never use a power cable and 3P-2P adapter other than the accessories.

(a) Confirm that the power switch on the left-hand side of the product main body is off (OFF) and

connect the product side plug of the accessory power cable to the power inlet on the back side of

the main body. Connect the plug at the other end of the power cable to an AC power outlet.

Power Cable and Ground Connections

(b) When the power plug cannot be connected to 3-pin outlet, connect the accessory 3P-2P adapter to

the power cable and connect it to an AC power outlet. Also connect the 3P-2P adapter ground wire

to a ground line. (When accessory 3P-2P adapter is provided)

Product

main body

Power inlet

AC power

<Back side>

Product side plug

3P-2P adapter

Power cable

outlet

Ground wire

Power Cable and Ground Connections

(When power plug cannot be connected to 3-pin outlet)

-

18 -

Ground line

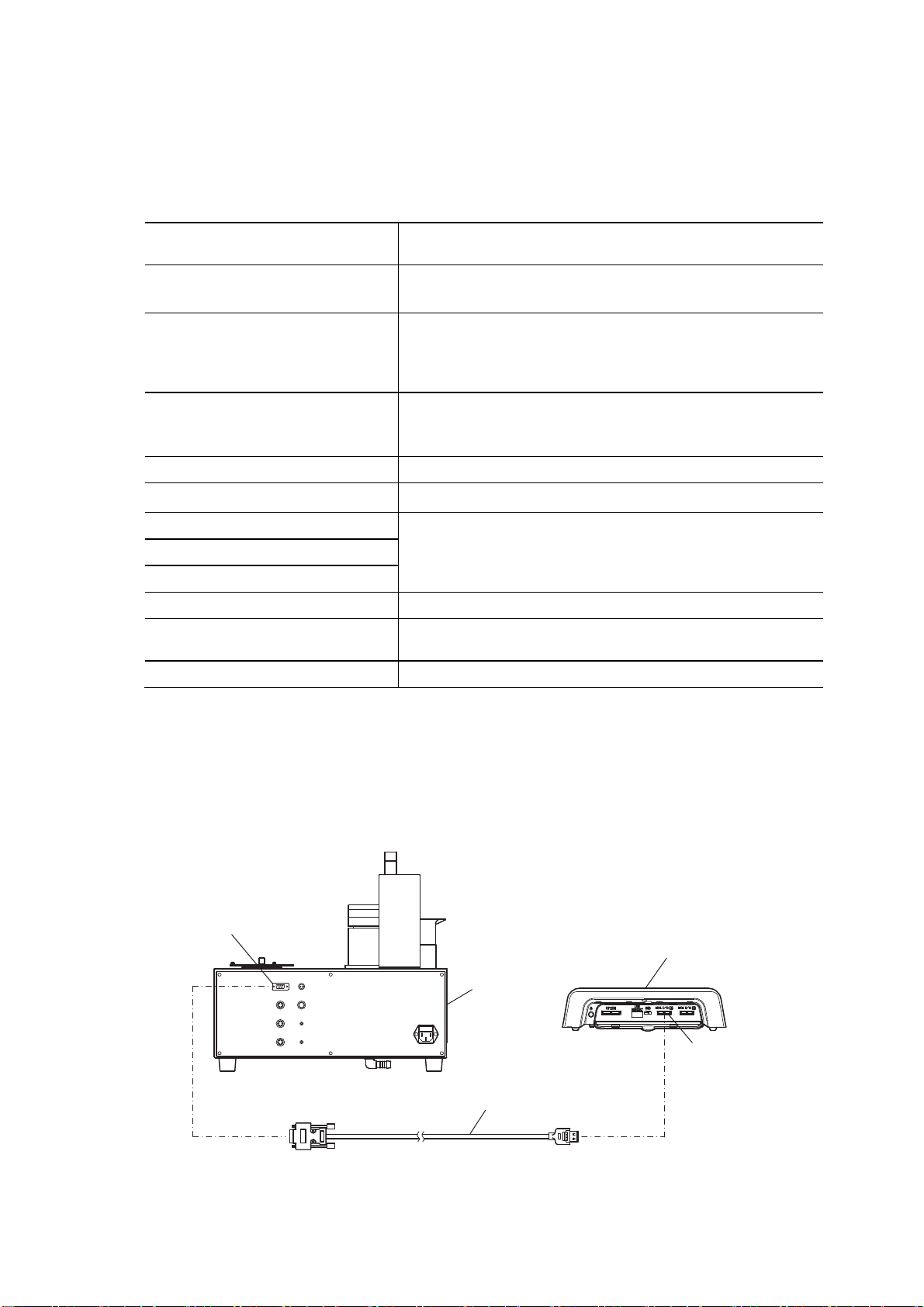

Page 20

Model: TTT-710 4.2 Wiring

(2) Connection to analytical instruments

The analytical instruments that can be used with the product main body are listed in the table below.

Refer to (a) to (i) and connect the cable corresponding to the analytical instruments to be used.

Connectable Analytical Instruments and Cable Connection Method

Connectable analytical instruments,

etc.

X Series analytical instruments

(HM-42X, CM-42X, MM-43X)

R Series analytical instruments

(HM-30R, CM-30R, MM-60R)

G Series analytical instruments

(HM-50G, HM-60G, CM-40G, CM-60G,

IM-55G, WM-50EG)

Automatic titrator (AUT-701) >> 4.2(2) (e) “Connection to automatic titrator (AUT-701)”

Automatic titrator (AUT-501) >> 4.2(2) (f) “Connection to automatic titrator (AUT-501)”

Acidity titrator (TA-70) >> 4.2(2) (g) “Connection to dedicated titrator (TA-70, others)”

Salt titrator (TS-70)

Potentiometric titrator (TP-70)

Automatic burette (ABT-511) >> 4.2(2) (h) “Connection to automatic burette (ABT-511)”

Flow analysis reference unit

(FAR-201A)

Personal computer (PC) >> 4.2(2) (j) “Connection to personal computer (PC)”

Cable connection method (reference item)

>> 4.2(2) (a) “Connection to X Series analytical instruments

(HM-42X, others)”

>> 4.2(2) (b) “Connection to R Series analytical instruments

(HM-30R, others) (RS-232C connection)”

>> 4.2(2) (c) “Connection to R Series analytical instruments

(HM-30R, others) (OPTION2 connection)”

>> 4.2(2) (d) “Connection to G Series analytical instruments

(HM-50G, others)”

>> 4.2(2) (i) “Connection to flow analysis reference unit

(FAR-201A)”

(a) Connection to X Series analytical instruments (HM-42X, others)

Connect the RS-232C connection connector of product main body and the RS-232C connection

connector of X Series analytical instruments (HM-42X, others) using the turntable connection

RS-232C cable (optional).

RS-232C connection connector

(RS-232C)

<Back side>

Product main body

Turntable connection RS232C cable

(Part code No.: 7433040K)

X Series analytical instruments

(HM-42X, CM-42X, MM-43X)

<Left side>

RS-232C connection

connector

(EXT.I/O)

Connecting to X Series Analytical Instruments (HM-42X, others)

-

19 -

Page 21

Model: TTT-710 4.2 Wiring

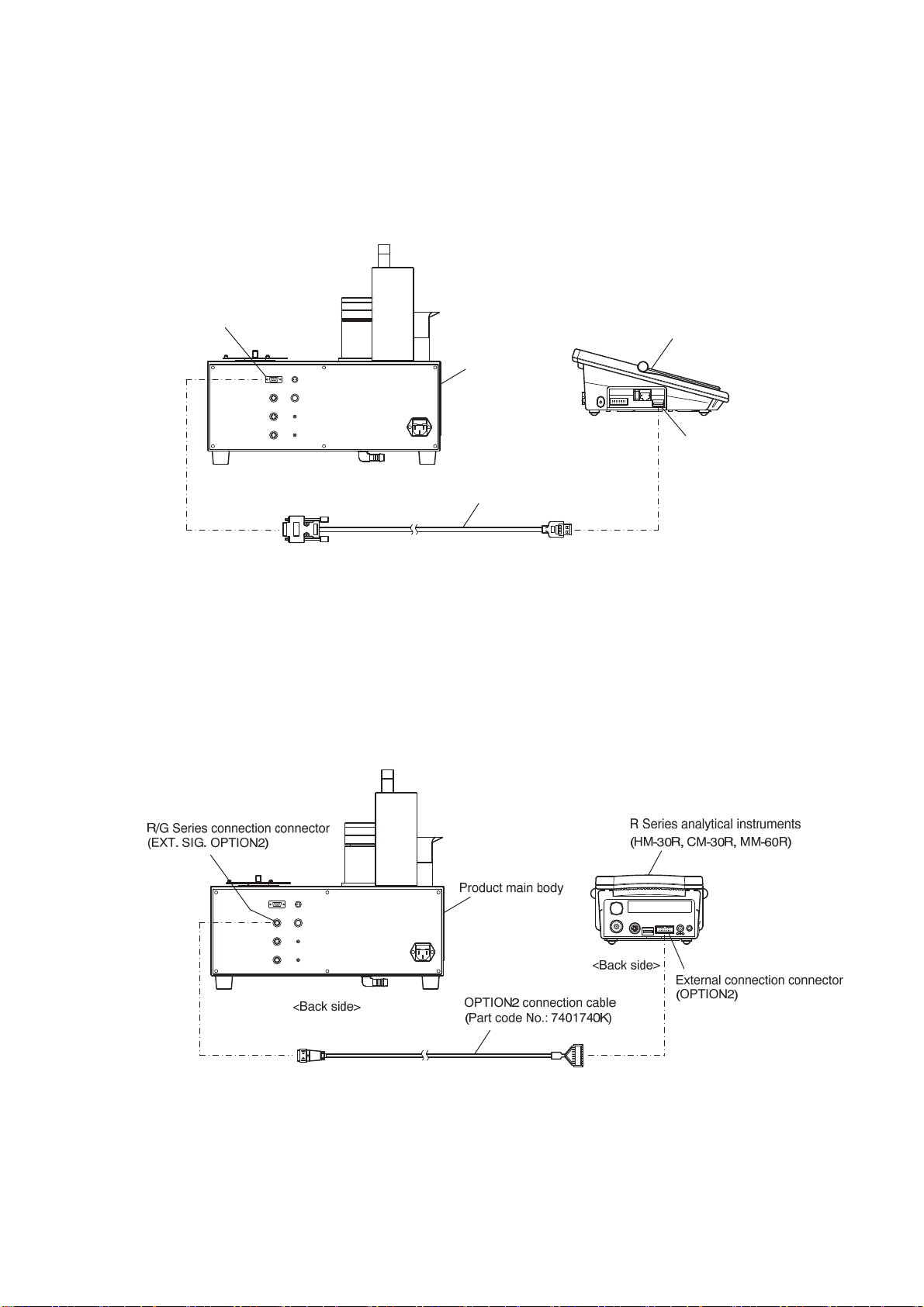

(b) Connection to R Series analytical instruments (HM-30R, others) (RS-232C

connection)

Connect the RS-232C connection connector of product main body and the RS-232C connection

connector of R Series analytical instruments (HM-30R, others) using the TTT connection 232C cable

(optional).

RS-232C connection connector

(RS-232C)

<Back side>

Product main body

<Left side>

TTT connection 232C cable

(Part code No.: 118C087)

R Series analytical instruments

(HM-30R, CM-30R, MM-60R)

RS-232C connection

connector

Connecting to R Series Analytical Instruments (HM-30R, others) (RS-232C connection)

(c) Connection to R Series analytical instruments (HM-30R, others) (OPTION2

connection)

Connect the R/G Series connection connector of product main body and the external connection

connector (OPTION 2) of R Series analytical instruments (HM-30R, others) using the OPTION 2

connection cable (optional).

Connecting to R Series Analytical Instruments (HM-30R, others) (OPTION2 connection)

-

20 -

Page 22

Model: TTT-710 4.2 Wiring

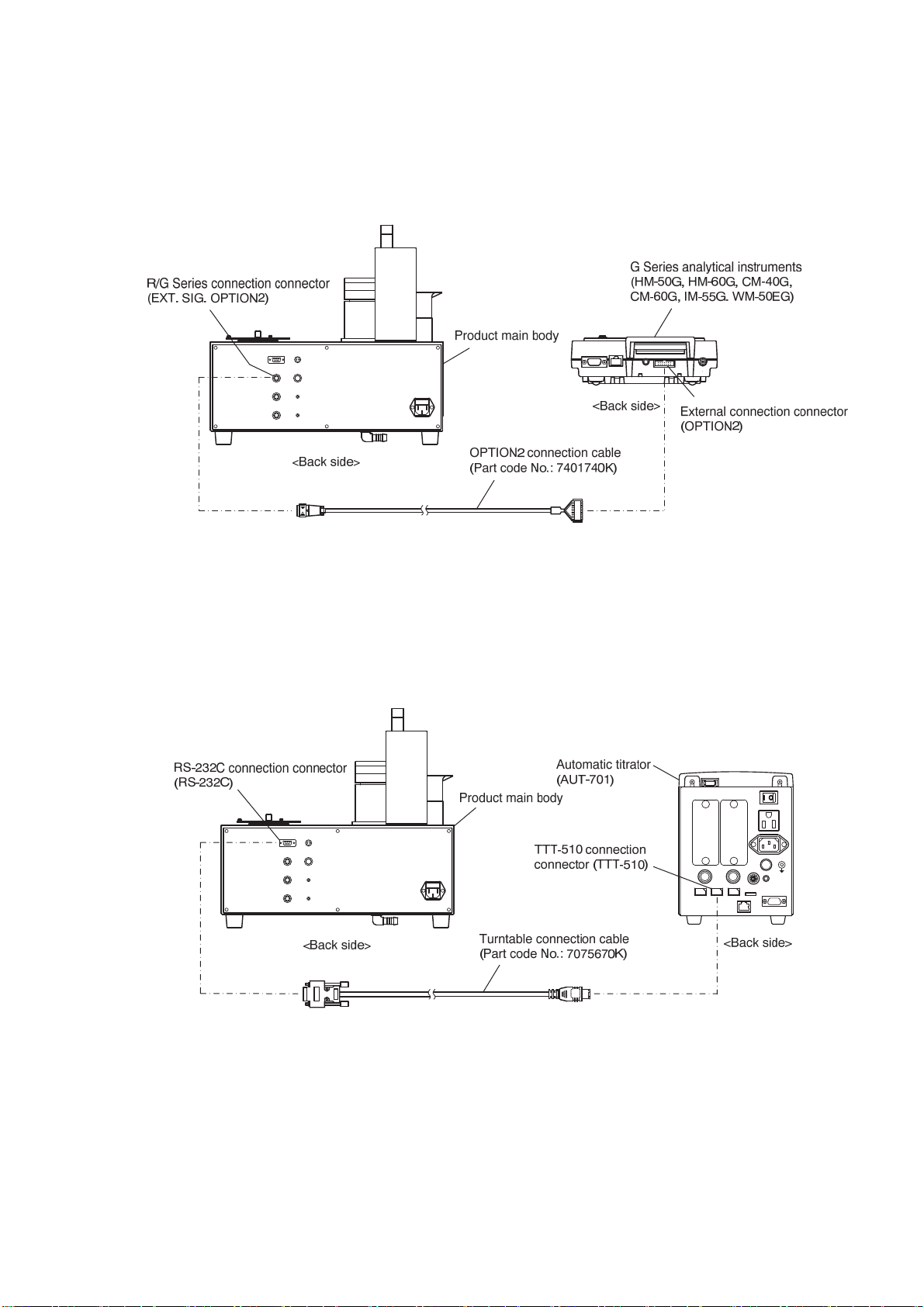

(d) Connection to G Series analytical instruments (HM-50G, others)

Connect the R/G Series connection connector of product main body (EXT. SIG. OPTION2) and the

external connection connector (OPTION 2) of G Series analytical instruments (HM-50G, others) using

the OPTION 2 connection cable (optional).

Connecting to G Series Analytical Instruments (HM-50G, others)

(e) Connection to automatic titrator (AUT-701)

Connect the RS-232C connection connector of product main body and the TTT-510 connection

connector of automatic titrator (AUT-701) using the turntable connection cable (optional).

Connecting to Automatic Titrator (AUT-701)

-

21 -

Page 23

Model: TTT-710 4.2 Wiring

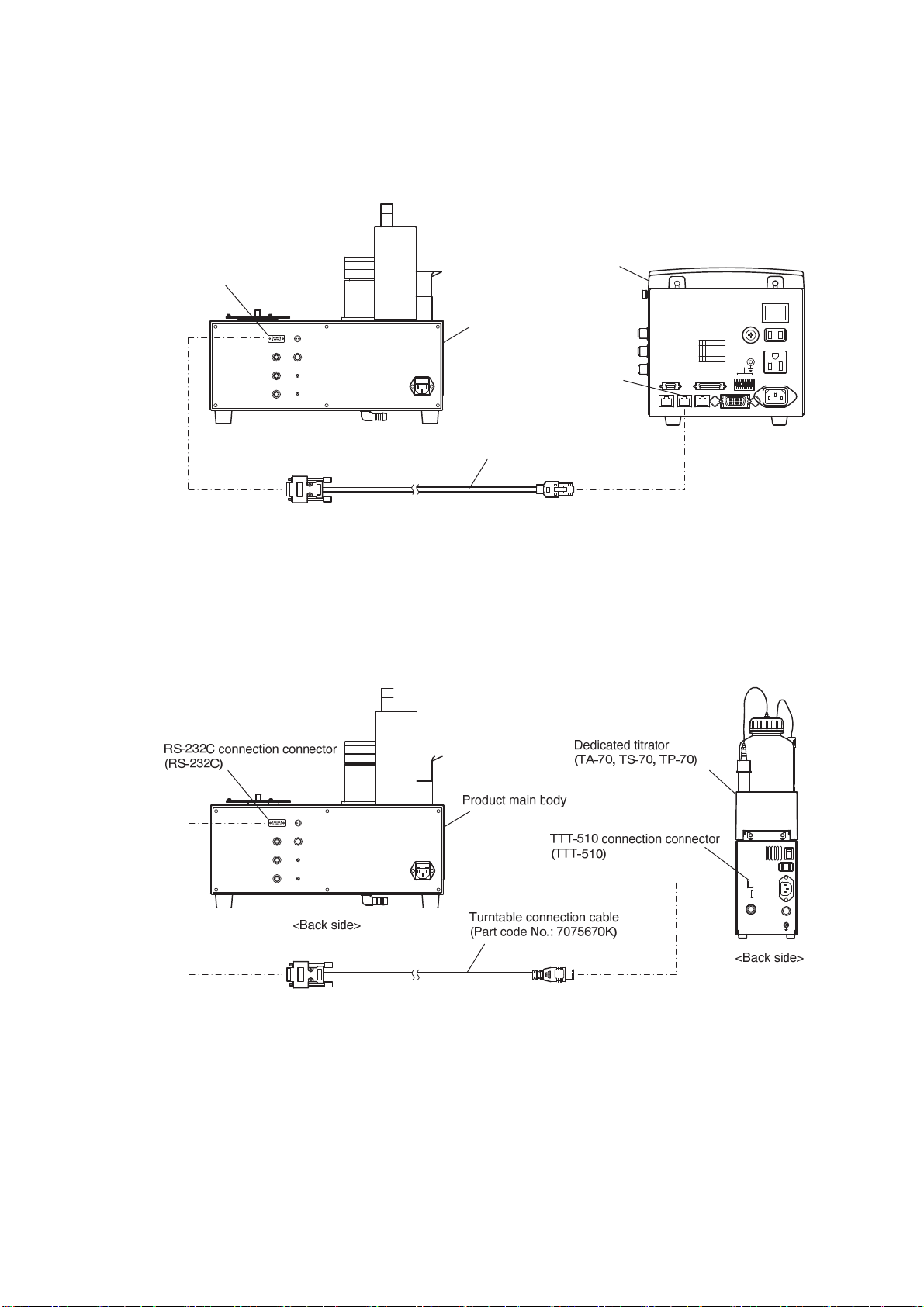

(f) Connection to automatic titrator (AUT-501)

Connect the RS-232C connection connector of product main body and the TTT-3100 connection

connector of automatic titrator (AUT-501) using the RS-232C cable (optional).

RS-232C connection connector

(RS-232C)

<Back side>

Product main body

RS-232C cable

(Part code No.: 0GC00006)

Automatic titrator

(AUT-501)

TTT-3100 connection

connector (TTT-3100)

Connecting to Automatic Titrator (AUT-501)

(g) Connection to dedicated titrator (TA-70, others)

Connect the RS-232C connection connector of product main body and the TTT-510 connection

connector of dedicated titrator (TA-70, others) using the turntable connection cable (optional).

<Back side>

Connecting to Dedicated Titrator (TA-70, others)

-

22 -

Page 24

Model: TTT-710 4.2 Wiring

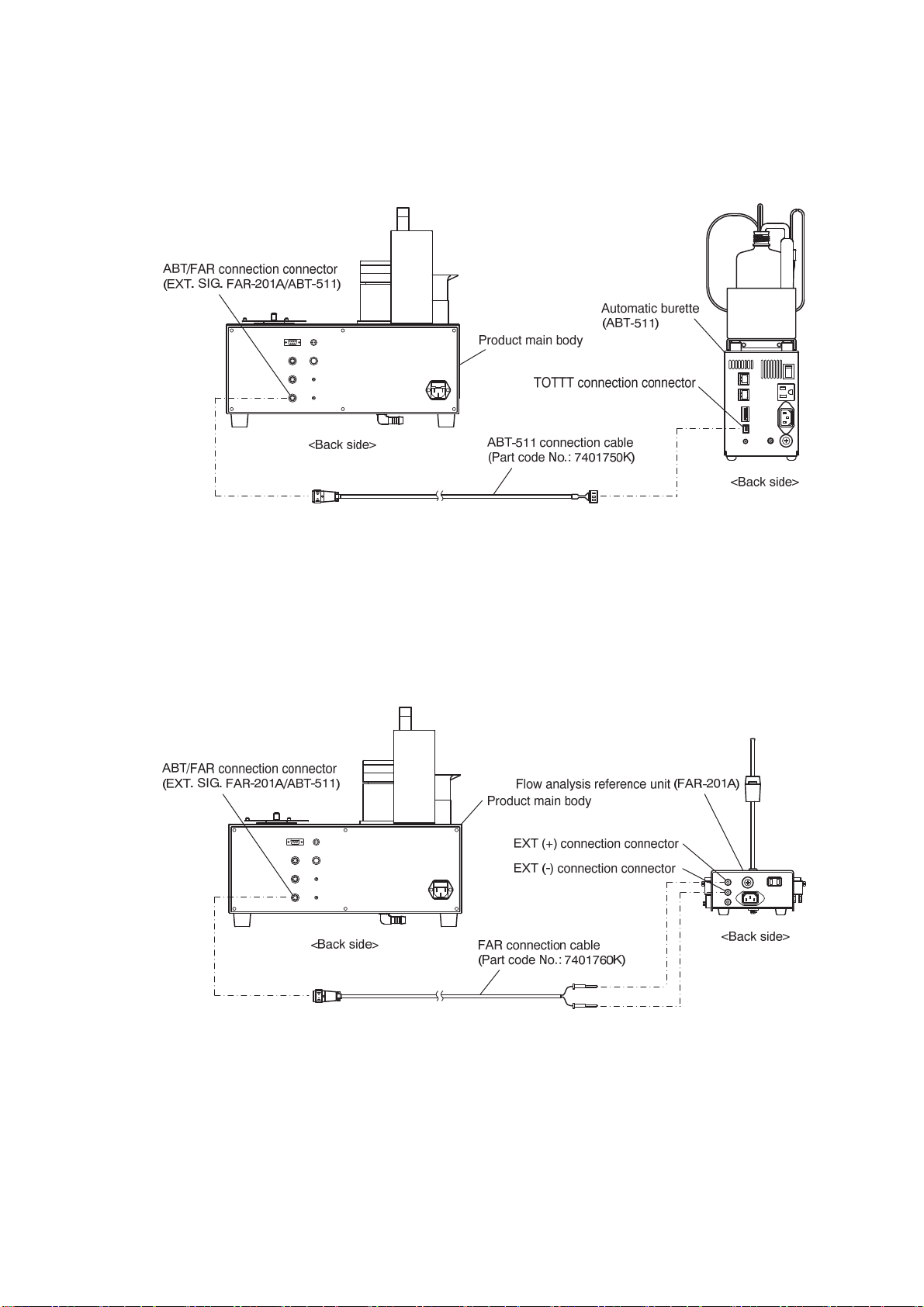

(h) Connection to automatic burette (ABT-511)

Connect the ABT/FAR connection connector of product main body and the TOTTT connection

connector of automatic burette (ABT-511) using the ABT-511connection cable (optional).

Connection to Automatic Burette (ABT-511)

(i) Connection to flow analysis reference unit (FAR-201A)

Connect the ABT/FAR connection connector of product main body and the EXT (+) and EXT (-)

connection connector of flow analysis reference unit (FAR-201A) using the FAR connection cable

(optional).

Connecting to Flow Analysis Reference Unit (FAR-201A)

-

23 -

Page 25

Model: TTT-710 4.2 Wiring

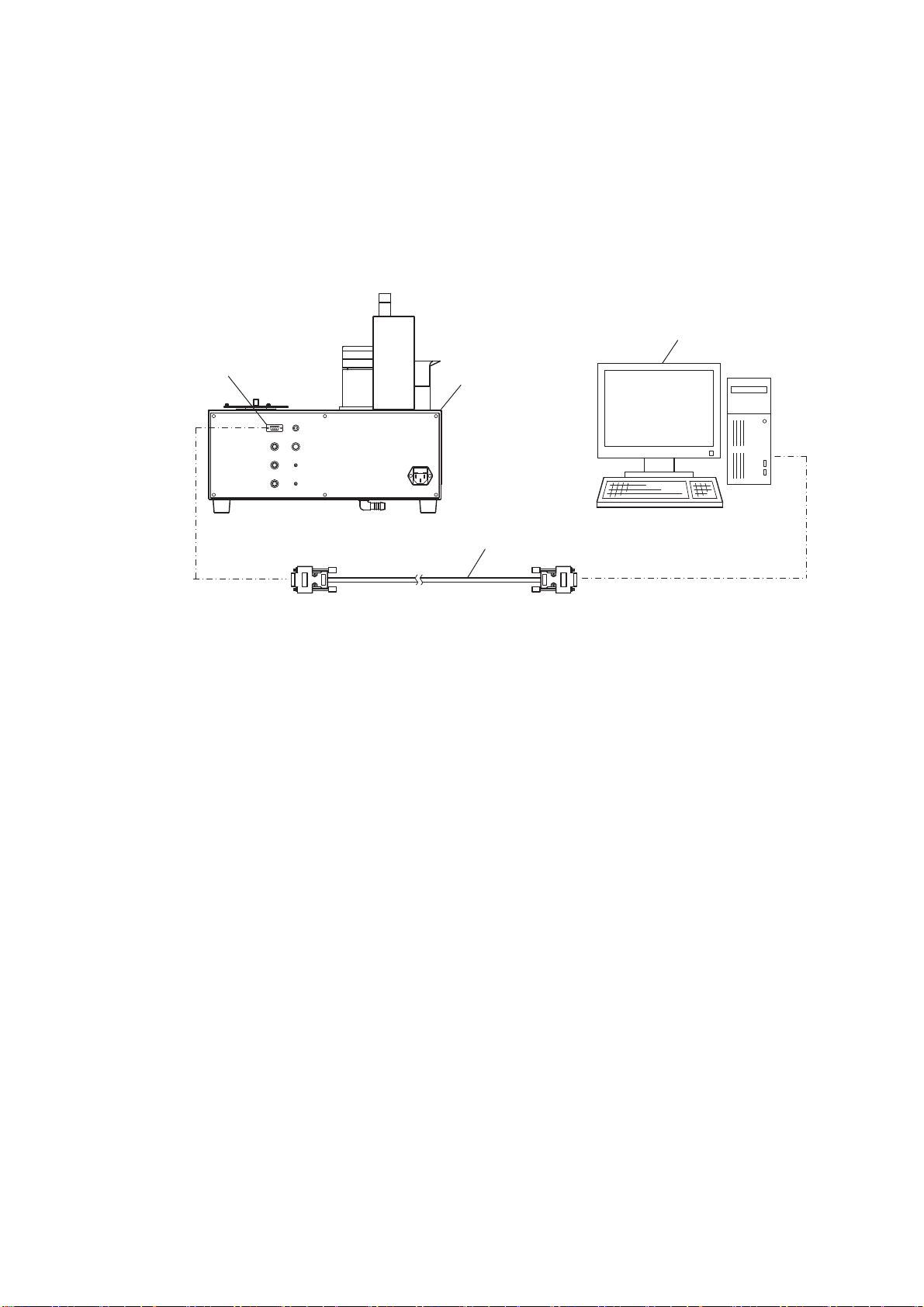

(j) Connection to personal computer (PC)

(a) The connection cable is different depending on the connector of the PC to be used. Refer to the PC

instruction manual and connect the RS-232C connection connector of product main body and the

PC connector using a suitable cable (straight type).

(b) When the PC uses a D-sub 9 pin connector, RS-232C cable (part No.:0GC00002) is available as a

DKK-TOA option. If the PC does not have RS-232C port, purchase and use USB-RS232C adapter

(manufacturer: MOXA, Part code: UPort 1150I) as a recommended part.

PC

RS-232C connection connector

(RS-232C)

Product main body

<Back side>

RS-232C straight cable, etc.

To PC side connector

Connecting to Personal Computer (PC)

-

24 -

Page 26

Model: TTT-710 4.3 Piping

4.3 Piping

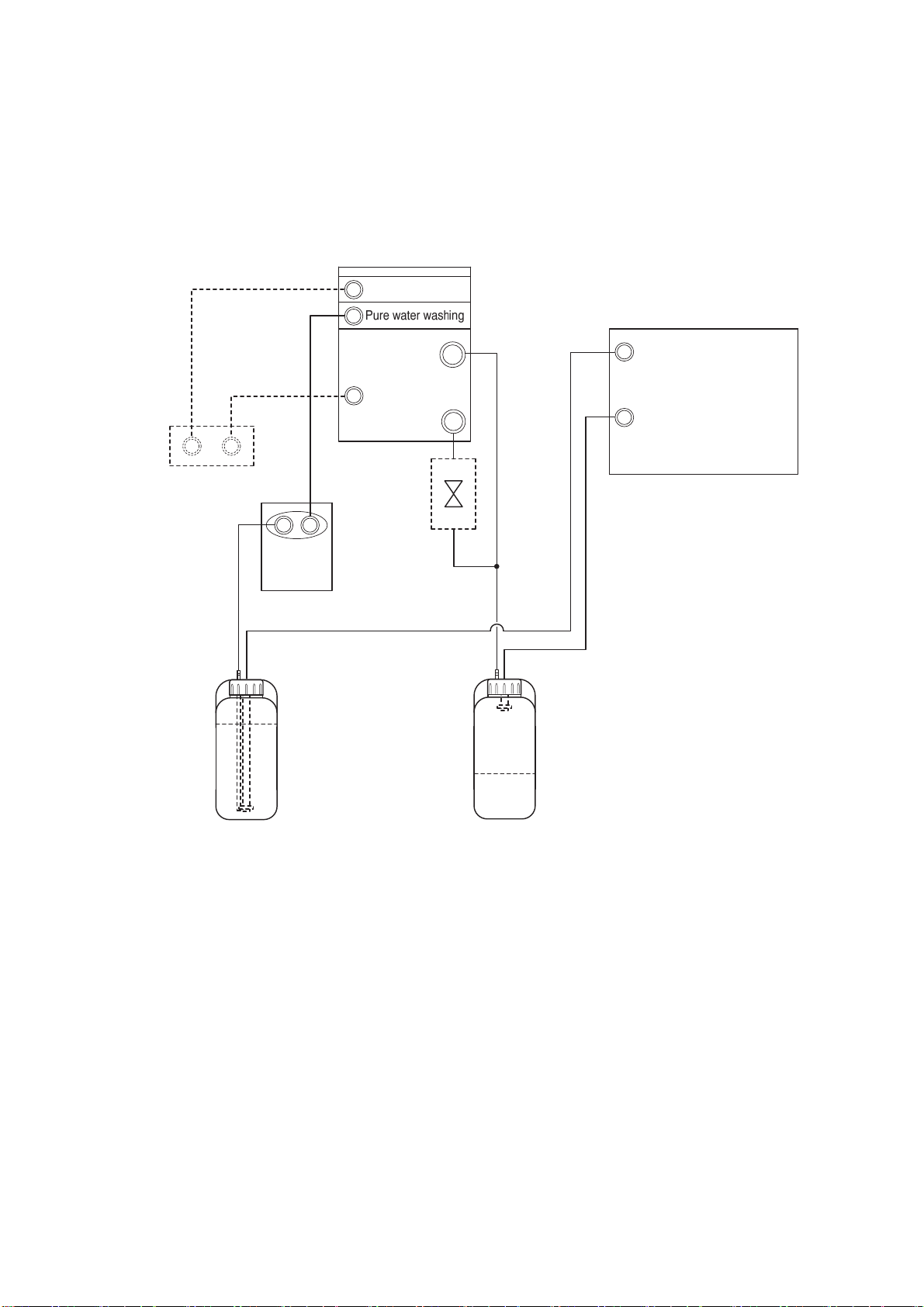

(1) Piping diagram

The pure water tank and waste solution tank piping diagram is shown below. The areas of dotted

lines are optional specifications.

Washing reservoir

Air blow

Product back side

Air pump

box

Overflow

Air bubbling

Drain

Waste water

valve

Pure water pump

Liquid level sensor

connection connector

(for pure water)

(LEVEL ALARM RINSE1)

Liquid level sensor

connection connector

(for waste solution)

(LEVEL ALARM DRAIN)

Pure water

tank

Waste

solution tank

Piping Diagram

-

25 -

Page 27

Model: TTT-710 4.3 Piping

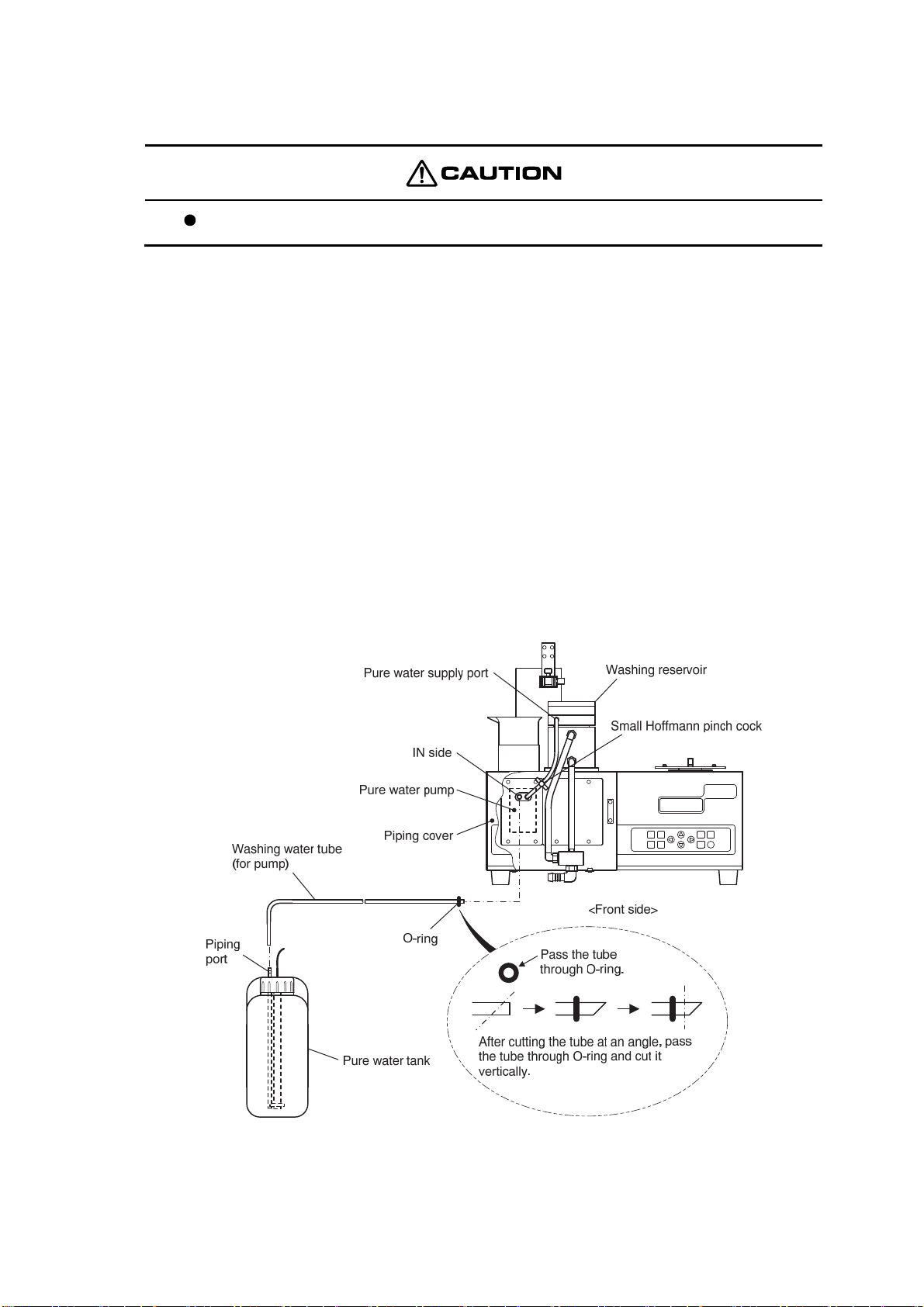

(2) Pure water tank connection

Be sure that liquid chemical is not sucked into the pure water pump.

① Install the pinch cock. ⋅⋅⋅⋅⋅⋅ Install the accessory small Hoffmann pinch cock to the pipe between

② Fill the tank with pure water ⋅⋅⋅⋅⋅⋅ Prepare the accessory 10L tank as the pure water tank by

③ Cut the tube. ⋅⋅⋅⋅⋅⋅ Use cutters, etc. to cut the accessory washing water tube (part code: 116E049)

④ Pass the tube through O-ring. ⋅⋅⋅⋅⋅⋅ Pass one end of the washing water tube (for pump)

the pure water pump and the washing reservoir pure water supply port. The amount of pure water

supplied to the washing reservoir can be adjusted by how this pinch coke is tightened.

filling at least half full of pure water.

to a suitable length matching the distance between the IN side of the pure water pump at the front

of the main body and the pure water tank to be installed and use the tube as the washing water tube

(for pump).

prepared at step ③ through the accessory O-ring.

⑤ Connect the tube. ⋅⋅⋅⋅⋅⋅ Remove the product main body piping cover forward and connect one

end (O-ring side) of the washing water tube (for pump) to the IN side of the pure water pump and

fix it with the O-ring. Connect the other end of the washing water tube to the pure water tank

piping port.

Connecting the Washing Water Tube to the Pure Water Punp

-

26 -

Page 28

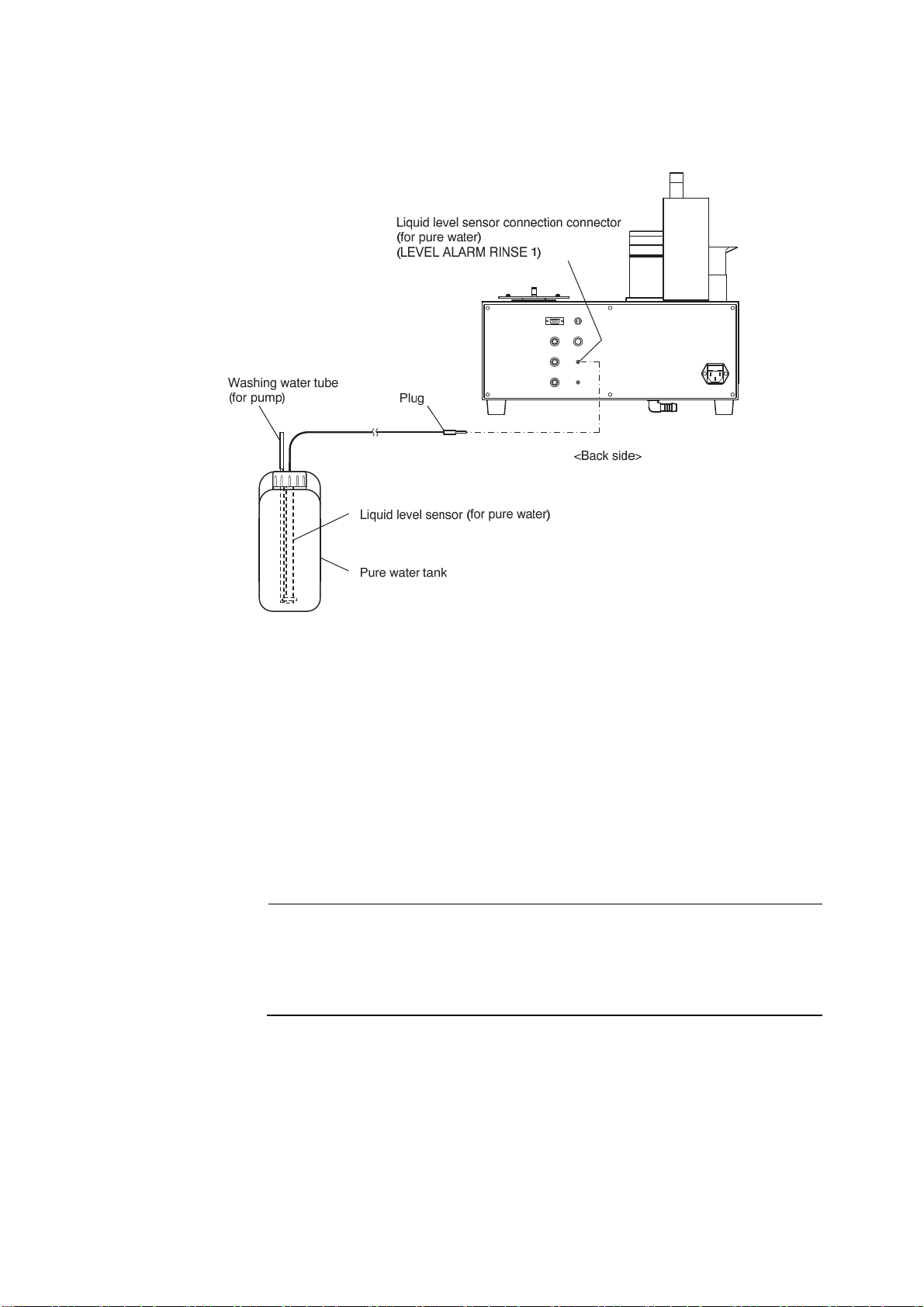

Model: TTT-710 4.3 Piping

⑥ Insert the plug. ⋅⋅⋅⋅⋅⋅ Insert the plug of liquid level sensor into the liquid level sensor connection

connector (for pure water) (LEVEL ALARM RINSE 1) of the product main body.

Inserting the Plug of Liquid Level Sensor (for pure water)

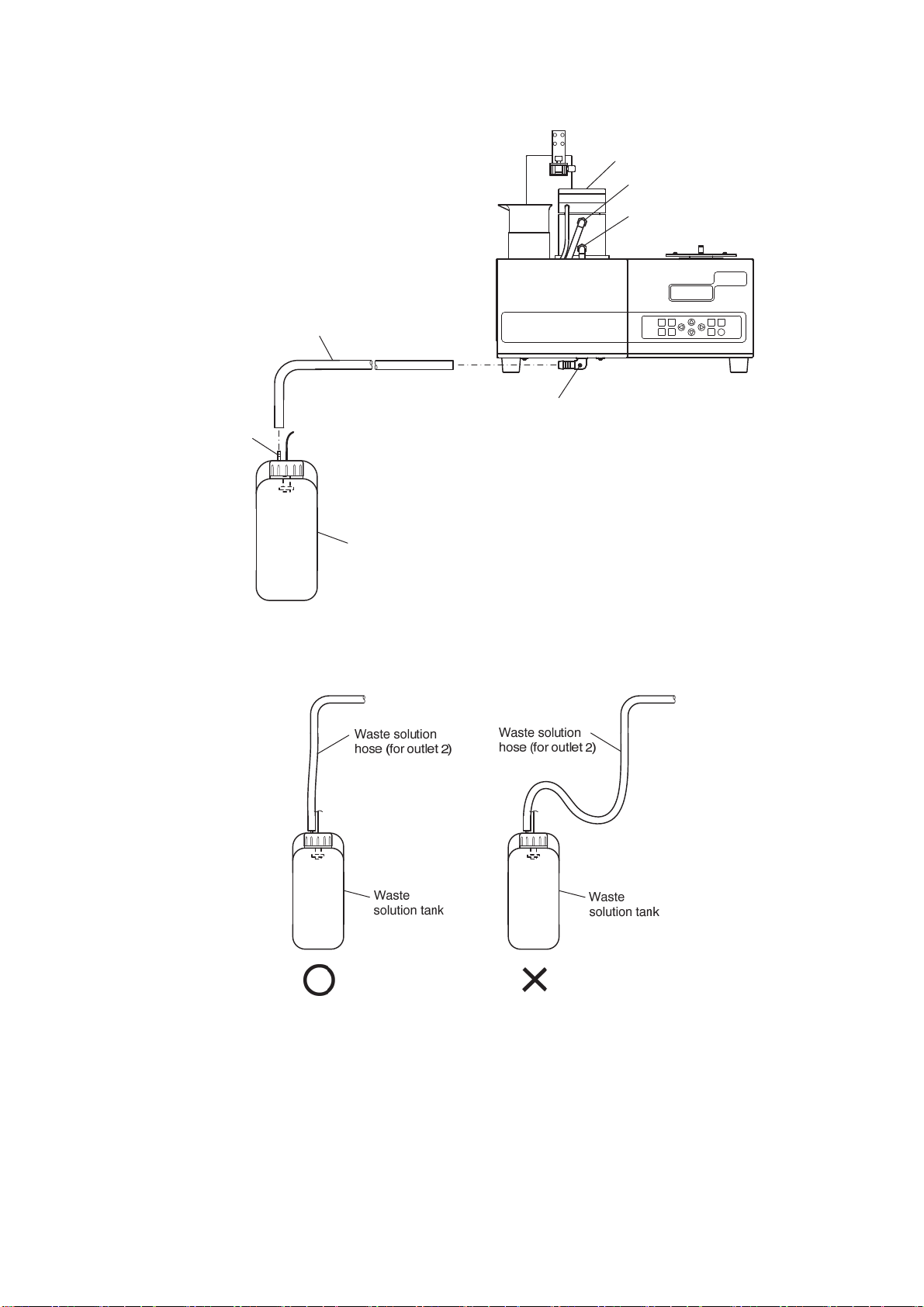

(3) Waste solution tank connection

① Cut the waste solution hose. ⋅⋅⋅⋅⋅⋅ Use a hose cuter, etc. to cut the accessory waste solution

hose (part code: XD701500) to a suitable length matching to the distance between waste solution

outlet 2 of product main body and the waste solution tank to be used and use the hose as the waste

solution hose (for outlet 2).

② Connect the waste solution hose. ⋅⋅⋅⋅⋅⋅ Connect one end of the waste solution hose (for outlet

2) prepared at step ① to waste solution outlet 2 of product main body and the other end to the

waste solution tank piping port.

【IMPORTANT】 • Install the waste solution tank at a place sufficiently lower than the

product main body. Also be sure that the waste solution hose (for outlet 2)

is straight from top to bottom. If the hose is installed at a high place or is

bent midway between top and bottom, the waste solution will collect in the

hose and will not flow into the waste solution tank.

-

27 -

Page 29

Model: TTT-710 4.3 Piping

Washing reservoir

Overflow port

Waste solution outlet 1

Waste solution hose (for outlet 2)

Waste solution outlet 2

Piping

port

Waste solution tank

<Front side>

Connecting the Waste Solution Hose (for outlet 2)

Correct Method of Piping the Waste Solution Hose

③ Insert the plug. ⋅⋅⋅⋅⋅⋅ Insert the plug of the liquid level sensor into the liquid level sensor

connection connector (for waste solution) of the product main body.

-

28 -

Page 30

Model: TTT-710 4.3 Piping

Liquid level sensor connection connector

(for waste solution)

(LEVEL ALARM DRAIN)

Waste solution hose

(for outlet 2)

Liquid level sensor (for waste solution)

Plug

<Back side>

Waste solution tank

Inserting the Plug of the Liquid Level Sensor (for waste solution)

-

29 -

Page 31

Model: TTT-710 4.4 Table Plate Mounting

4.4 Table Plate Mounting

① Set the table plate on the holder. ⋅⋅⋅⋅⋅⋅ Place the table plate on the table holder plate so that the

holes (3 places) in the accessory table plate match the pins (3 places) of the product main body

table holder plate.

Product main body

Table holder plate

<Top side>

Setting the Table Plate on the Table Holder Plate

② Fix the table plate. ⋅⋅⋅⋅⋅⋅ Fix the table plate by tightening the table plate fixing cap nut connected

to the end detection pin from the top of the table plate.

③ Fix the end detection pin. ⋅⋅⋅⋅⋅⋅ Fix the end detection pin to the end detection pin holder of the

table plate.

Pins (3 places)

Table plate

Holes (3 places)

Fixing the Table Plate

-

30 -

Page 32

Model: TTT-710 4.5 Mounting the electrode cartridge, electrode, and titration nozzle

4.5 Mounting the electrode cartridge, electrode, and titration

nozzle

The electrode cartridge is different depending on the number of table plate specimens, kind of

electrode used, and the number of titration nozzles used. Use the electrode corresponding to the

application. >> “Types of Electrode Cartridge Table”

Mounting the Electrode Cartridge, Electrode, and Titration Nozzle

① Mount the electrode cartridge. ⋅⋅⋅⋅⋅⋅ After loosening the knurled knob at the end of the

electrode arm of the product main body, hold the electrode cartridge with the dent facing upward

and insert the cartridge into the end of the electrode arm and fix it by tightening the knurled knob.

② Mount the electrode and titration nozzle. ⋅⋅⋅⋅⋅⋅ Loosen the electrode fixing bolt of the

electrode cartridge, insert the electrode and titration nozzle to be used, and fix the electrode by

tightening the electrode fixing bolt. (The electrode cartridge accessory adapter may be necessary

depending on the electrode to be used. Refer to the “Types of Electrode Cartridge table” and

“Usable Electrode Type Classification Table” for the adaptors corresponding to the electrodes

used.)

③ Clamp the cable, etc. ⋅⋅⋅⋅⋅⋅ Clamp the electrode cable and the tube from the titration nozzle with

the clamp at the top of the electrode arm.

-

31 -

Page 33

Model: TTT-710 4.5 Mounting the electrode cartridge, electrode, and titration nozzle

Types of Electrode Cartridges Table

Name

(Number of mountable

electrodes and nozzles)

1CH cartridge 1(X)

(Electrode:1 Nozzle: 1)

1CH cartridge 2(X)

(Electrode:1 Nozzle: 2)

1CH cartridge 3(X)

(Electrode:1)

2CH cartridge 1

(Electrode:2 Nozzle: 1)

*

1

*

3

Model

7505010K

7505020K

7506840K

6597970K

Number of

usable table

specimens

All number of

specimens

12 specimens

18 specimens

36 specimens

All number of

specimens

12 specimens

18 specimens

36 specimens

Usable electrode type

X

R

J (white adapter use)

X

R

J (white adapter use)

X

R

J (White adapter use)

J

ION (silver adapter

use)

*

2

Appearance

X

2CH cartridge 2(X)

(Electrode:2)

7505030K

12 specimens

18 specimens

36 specimens

R

J (white adapter use)

ION (silver adapter

use)

X

2CH cartridge 3

(Electrode:2 Nozzle: 2)

6597940K

12 specimens

18 specimens

R

J (white adapter use)

ION (silver adapter

use)

J (max. 2)

Multi cartridge

(Electrode: 4 Nozzle: 4)

6597980K 12 specimens

ION (2)

(Up to 4 can be

mounted by using the

silver adapter)

Sample suction cartridge

(Nozzle: 1)

6597990K

All number of

specimens

−

Nozzle

*1: A temperature sensor can be installed by using the accessory blue adapter at the nozzle mounting hole.

However, with 1CH cartridge 1(X), it can be used only when the 12, 18, or 36 specimens tables are used.

*2: Electrode types “X, R, J, or ION” described in the table indicate the usable electrode type classification. For details,

refer to the Usable Electrode Type Classification Table.

*3: When 60 or 100 specimens table is used, only the micro titration nozzle (AST-P008) can be mounted.

-

32 -

Page 34

Model: TTT-710 4.5 Mounting the electrode cartridge, electrode, and titration nozzle

Usable Electrode Type Classification Table

Electrode type (X) Electrode type (R)

Name Model Name Model Name Model

GST-5841C

GST-5841S ELP-031 CT-58101C

GST-5842S ELP-032 ELC-007

GST-5823S ELP-035 ELC-008

pH composite

electrode

ORP composite

electrode

Conductivity cell

GST-5824C ELP-036

GST-5825C ELP-039

GST-5846C GST-5721C

GST-5847C GST-5721S

GST-5851C GST-5722S

PST-5821C GST-5723S

CT-58101B GST-5724C

CT-58101C GST-5725C

ELC-009 GST-5726S

ELC-010

Electrode type (J) Electrode type (ION)

pH composite

electrode

ORP composite

electrode

GST-5741C

Conductivity cell

PST-5721C

CT-57101B

Name Model Name Model Name Model

GST-5731C

pH composite

electrode

ORP composite

electrode

Please inquire separately regarding use of other electrodes.

GST-5711C

ELP-062 HS-305DS ORP electrode HP-105

GST-5311C

GS-5011C C-50101C

PS-5011C CG-511B

ELM-016 CG-511C

PTS-5011C

Silver composite

electrode

Comparison electrode

Conductivity cell

ELX-006 Chloride ion electrode CL-125B

HS-305D pH glass electrode HGS-2005

C-50101B Silver electrode HA-101

-

33 -

Page 35

Model: TTT-710 4.5 Mounting the electrode cartridge, electrode, and titration nozzle

Usable Nozzles and Temperature Sensors Table

Nozzle Temperature sensor

Name Model Name Model

Degassing nozzle (1 to 20mL) P000070 Temperature sensor (general purpose, SUS) ELT-001

Degassing nozzle (50mL) P000071

Titration nozzle (micro volume) AST-P008 Temperature sensor TH-1005B

Suction nozzle P000035

Temperature sensor (general purpose,

glass)

ELT-002

-

34 -

Page 36

Model: TTT-710 4.6 Optional Parts Connection

4.6 Optional Parts Connection

(1) Air pump box connection

(a) Air pump box (air blowing only) (part code: 7400560U) is used only when blowing off water drops

clinging to the electrode by air blow after electrode washing.

(b) Adding air box bubbling (with bubbling) (part code: 7401640U) can perform the electrode

bubbling washing and the air blowing after electrode washing.

(c) To perform bubbling washing, a waste water valve (optional) sold separately must be installed.

(i) When using the air pump box (air blowing only)

① Cut the tube. ⋅⋅⋅⋅⋅⋅ Cut the tube from the air pump box to a suitable length using cutters, etc.

② Connect the tube. ⋅⋅⋅⋅⋅⋅ Connect the end of the tube from the air pump box to the washing

reservoir air connection port of the product main body.

Connecting the Tube to the Air Pump Box

③ Connect the cable. ⋅⋅⋅⋅⋅⋅ Connect the air pump connection connector of the product main body

and the air pump box using the air pump box accessory connection cable.

Air pump connection connector

(TO AIR PUMP)

<Back side>

Product main body

Air pump box

connection cable

Air pump box

<Back side>

Connecting the Cable to the Air Pump Box

-

35 -

Page 37

Model: TTT-710 4.6 Optional Parts Connection

(ii) When using the air pump box (with bubbling)

① Cut the tube. ⋅⋅⋅⋅⋅⋅ Cut the tube from the AIR BLOWING side of the air pump box to a suitable

length using cutters, etc.

② Connect the tube. ⋅⋅⋅⋅⋅⋅ Connect the end of the tube from the air pump box to the air connection

port of the product main body.

Connecting the Tube to the Air Pump Box

③ Remove the blank tube. ⋅⋅⋅⋅⋅⋅ After turning the set screw and removing the blank tube from the

washing reservoir, remove the set screw and ferrule from the blank tube.

Connect the Bubbling Washing Tube to Air Pump Box

④ Connect the bubbling washing tube. ⋅⋅⋅⋅⋅⋅ Pass the end of the bubbling washing tube through

the set screw and ferrule removed at step ③ and connect the tube to the washing reservoir.

【IMPORTANT】 • Be sure that all or part of the piping of the bubbling washing tube to the

washing reservoir is a higher position than the washing reservoir piping

port.

-

36 -

Page 38

Model: TTT-710 4.6 Optional Parts Connection

○

Bubbling Washing Tube Piping Examples

⑤ Connect the cable. ⋅⋅⋅⋅⋅⋅ Connect the air pump connection connector of the product main body

and the air pump box using the air pump box accessory connection cable.

Air pump connection connector

(TO AIR PUMP)

<Back side>

○

Product main body

×

Air pump box

<Back side>

Air pump box

connection cable

Connecting the Cable to the Air Pump Box

(2) Waste water valve connection

(a) When performing electrode bubbling washing, use the waste water valve (optional) to collect the

washing water at the washing reservoir.

(b) When performing bubbling washing with pure water or when the waste solution contains sludge,

use a pinch cock type waste solution valve (7401650U).

(c) When performing bubbling washing with liquid chemical, use the solenoid type waste water valve

(7401660U).

① Remove the drain pipe. ⋅⋅⋅⋅⋅⋅ Remove the product main body piping cover by pulling it forward

and disconnect the drain pipe from the washing reservoir waste solution outlet.

-

37 -

Page 39

Model: TTT-710 4.6 Optional Parts Connection

Washing reservoir

Waste solution outlet 1

Blank panel

(Remove)

Screw (4 places)

Magnet catch

(2 places)

Power switch

Cover hook (2 places)

Drain piping

(Remove)

Magnet (2 places)

Removing the Drain Pipe and Blank Panel

② Remove the blank panel. ⋅⋅⋅⋅⋅⋅ Loosen the 4 screws and remove the blank panel.

Piping cover

(Front side)

③ Insert the connector plug. ⋅⋅⋅⋅⋅⋅ Pass the waste water valve connector plug into the product main

body through the hole left by removing the blank panel and insert the plug into the internal

connector receiver (CN9).

Inserting the Waste Water Valve Connector Plug

-

38 -

Page 40

Model: TTT-710 4.6 Optional Parts Connection

④ Assemble the waste water valve mounting plate. ⋅⋅⋅⋅⋅⋅ Using the 4 screws that removed the

blank panel at step ②, assemble the waste water valve mounting plate.

⑤ Pipe the waste water valve. ⋅⋅⋅⋅⋅⋅ When using the pinch cock type waste water valve, install the

drain pipe removed at step ①. When using the solenoid valve type waste water valve, pipe it with

the tube supplied with the waste water valve. (For details, refer to the “Installation instructions”

supplied with the waste water valve.)

Assembling and Piping the Waste Water Valve

(3) Propeller stirring unit connection

Use the propeller stirring unit (optional) when stirrer stirring by stirring bar is impossible because

the viscosity of the measured solution is high or some other reason.

① Install the propeller stirring unit. ⋅⋅⋅⋅⋅⋅ After loosening the knurled knob at the end of the

electrode arm of the product main body, insert the propeller stirring unit at the end of the electrode

arm and fix it by tightening the knurled knob.

Install the Propeller Stirring Unit

② Fix the electrode and titration nozzle. ⋅⋅⋅⋅⋅⋅ Loosen the electrode fixing bolt at electrode

mounting section and insert the electrode and titration nozzle to be used and fix the electrode by

tightening the electrode fixing bolt.

-

39 -

Page 41

Model: TTT-710 4.6 Optional Parts Connection

③ Connect the cable plug. ⋅⋅⋅⋅⋅⋅ Connect the cable plug of the propeller stirring unit to the upper

stirring unit connection connector (TO STIRR.) of the product main body.

Connecting the Cable Plug

④ Clamp the cable, etc. ⋅⋅⋅⋅⋅⋅ Clamp the propeller stirring unit cable, electrode cable, and the tube

from the titration nozzle with the clamp at the top of the electrode arm.

(4) Reagent washing kit connection

When electrode washing is performed with a liquid other than pure water, the optional reagent

washing kit must be used.

When handling the liquid chemical, procure the Safety Data Sheet (SDS) for the

reagent to be handled from the vendor and wear suitable protective gear and handle

the chemical safely in accordance with the description.

The liquid chemical washing kit consists of the following:

• Reagent washing reservoir (The product main body must be modified.)

• External control box

• Reagent pump

• Washing water tank (with liquid chemical level sensor)

• Waste solution tank (with liquid chemical level sensor)

• Connection piping (PTFE tube, pulse suppressor 2 sets)

-

40 -

Page 42

Model: TTT-710 4.6 Optional Parts Connection

(i) Connection system diagram when reagent washing kit used

Reagent washing reservoir

Air blow

Reagent washing

Air pump

box

External signal

box

Reagent

pump

Pure water washing

Overflow

Air bubbling

Drain

Pure

water

pump

TTT back side

EXT.SIG.BOX

TO AIR PUNP

Waste water

valve

Reagent tank

Pure water tank

Note) The dotted lines are optional.

(ii) External signal box connection

Never place articles on top of the external signal box.

Install the external signal box as far away from water as possible.

-

41 -

Waste solution

tank

Page 43

Model: TTT-710 4.6 Optional Parts Connection

① Connect the “TO TTT” connector of external signal box and the “EXT.SIG.BOX” connector of the

turntable main body using the accessory external control box connection cable.

External Signal Box Connection Cable

② Connect the accessory power cable to the power inlet on the back side.

External signal box

<Back side>

External signal box

<Back side>

Power inlet

Power inlet

Product side plug

Power cable

<For 3P outlet>

Product side plug

Power cable

<For 2P outlet>

Power plug

3P-2P adapter

Ground wire

AC power

outlet

AC power

outlet

Ground line

(iii) Reagent pump and reagent tank connection

① Fill the reagent tank at least half full of the washing water to be used.

② Cut the washing water tube (PTFE tube) supplied to the following lengths using cutters, etc.:

Between reagent pump and pulse suppressor: Approx. 10cm × 2 pcs

Between reagent washing reservoir and pulse suppressor: Approx. 30 to 50cm ×1 pc

Between reagent tank and pulse suppressor: Cut to a suitable length.

-

42 -

Page 44

Model: TTT-710 4.6 Optional Parts Connection

③ Pipe the reagent pump, reagent washing reservoir, and reagent tank as shown in the figure below.

Reagent washing

reservoir

Washing water tube

(PTFE tube)

Pulse suppressor

Reagent

pump

Washing water tube

(PTFE tube)

Liquid level sensor

Reagent tank

④ Connect the power connector of reagent pump to “TO RINSE PUMP” of the external signal box

and insert the liquid level sensor plug of the reagent tank into “LEVEL ALARM RINSE 2” of the

external signal box.

-

43 -

Page 45

Model: TTT-710 4.6 Optional Parts Connection

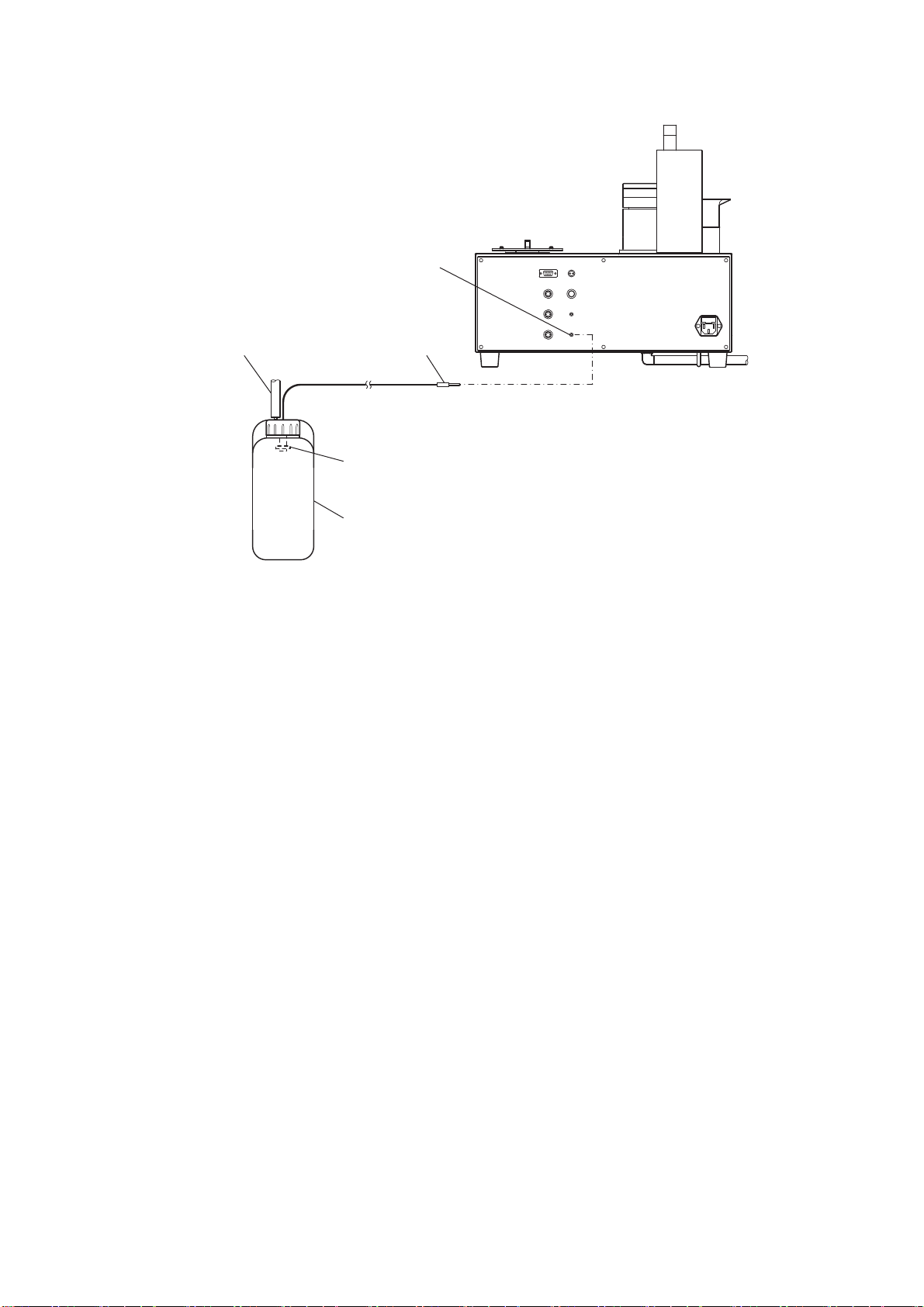

(iv) Waste solution tank connection

① Cut the waste solution hose supplied to a suitable length using a hose cutter, etc. Cut the hose to

match the distance between the waste solution outlet on the front side of main body and the waste

solution tank to be installed.

② Connect one end of the waste solution hose to the waste solution outlet on the front side of main

body.

Waste solution hose

<Front side>

③ Connect the other end of the waste solution hose to the piping port of the waste solution tank.

Install the waste solution tank at a position sufficiently lower than the turntable main body. Also be

sure that the waste solution hose is straight from top to bottom. If the hose is bend midway between

top and bottom, the waste solution will collect in the hose and will not flow into the waste solution

tank.

Waste solution

hose

Piping port

<Front side>

Waste solution tank

Waste solution

hose

Waste solution tank

Waste solution tank

○

-

44 -

×

Page 46

Model: TTT-710 4.6 Optional Parts Connection

④ Insert the plug of the liquid level sensor into “LEVEL ALARM DRAIN” on the back side of the

main body.

Liquid level sensor connection connector

(for waste solution)

(LEVEL ALARM DRAIN)

Waste solution hose

(for outlet 2)

Plug

<Back side>

Liquid level sensor (for waste solution)

Waste solution tank

-

45 -

Page 47

Model: TTT-710 5.1 Operation Screens Map

5. Basic Operation

5.1 Operation Screens Map

(Set the power switch to ON.)

ARM STIRRER

ARM

Arm movement:

STIRRER

ENTER

SET

TABLE

TABLE

Table plate rotation:

Arm movement:

STIRRER

STIRRER

WASH

Item selection:

WASH

ENTER

ENTER

Washing end

Arm movement:

Stirring speed adjustment:

ARM

No. setting:

Arm movement:

Stirring speed adjustment:

TABLE

ENTER

Arm movement:

Table plate rotation:

(Continued to 2/3)

STIRRER

STIRRER

Stirring speed adjustment:

START/STOP

All measurements end

Measurement starts by analytical instrument

All measurements end

Operation Screens Map (1/3)

ENTER

ENTER

(based on the product side operations)

(based on the analytical instrument side operations)

-

46 -

No. setting:

Sequence selection:

Value setting:

Page 48

Model: TTT-710 5.1 Operation Screens Map

SIGNAL

SIGNAL

Item selection:

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

(Continued to 3/3)

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

-

47 -

Page 49

Model: TTT-710 5.1 Operation Screens Map

SET

Item selection:

SET

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

Operation Screens Map (3/3)

-

48 -

Page 50

Model: TTT-710 5.2 Basic Operation

5.2 Basic Operation

Continuous measurement operation is different depending on the analytical instruments used as

follows:

(1) Use by connecting an automatic titrator, X Series or R Series

analytical instruments (RS-232C)

When this product is used by connecting it to an automatic titrator (AUT-701 and AUT-501), X

Series analytical instruments (HM-42X, CM-42X, MM-43X) or R Series analytical instruments

(HM-30R, CM-30R, MM-60R) by RS-232C connection, continuous measurements are performed

based on analytical instrument side operations such as setup, measurement start/stop. Then

“REMOTE” is displayed on the Measuring screen.

(a) Measurement preparations

① Set the power switch to ON. ⋅⋅⋅⋅⋅⋅ Set the power switch of this product and the analytical

instrument to ON as follows:

• The order in which the power switch of the product main body and the analytical instrument is

set to ON is not specified. However, when this product is used together with X Series or R Series

analytical instruments and automatic burette (ABT-511) or flow analysis reference unit

(FAR-201A), turn on the power switch of automatic burette and flow analysis reference unit to

ON last of all.

ⓐ Turn on this product. ⋅⋅⋅⋅⋅⋅ Set the power switch at the left-hand side of the product main body

to ON.

• After the Opening screen is displayed for 1 second and initial operations of electrode arm and

table plate rotation are performed, the Measurement Waiting screen is displayed.

Opening screen Measurement Waiting screen

ⓑ Turn on the analytical instrument. ⋅⋅⋅⋅⋅⋅Set the power switch of the analytical instruments, etc.

to be used to ON.

② Set the measurement conditions. ⋅⋅⋅⋅⋅⋅Set the measurement conditions in accordance with the

following items:

ⓐ Set the number of table specimens. ⋅⋅⋅⋅⋅⋅ >> 6.2 “Various Conditions Setting” (1)“Number of

table specimens setting”

ⓑ Set the RS-232C communication conditions. ⋅⋅⋅⋅⋅⋅ >> 6.2 “Various Conditions Setting” (3)

“RS-232C communication conditions setting”

ⓒ Set the electrode washing conditions. ⋅⋅⋅⋅⋅⋅ The conditions set at the analytical instruments are

effective.

>> Instruction manual of analytical instrument to be used.

ⓓ Set the sample measurement conditions.⋅⋅⋅⋅⋅⋅ For the measurement start/stop table No. stirring

time, waiting time before measurement, number of repetitive measurements, and end buzzer

time, sample measurement conditions set at the analytical instruments are effective.

>> Instruction manual of analytical instrument to be used.

-

49 -

Page 51

Model: TTT-710 5.2 Basic Operation

③ Set the measurement specimens.⋅⋅⋅⋅⋅⋅ Set the beakers containing the measurement samples

and stirring bar sequentially, starting from the set measurement start table No.

④ Prepare the end detection pin.⋅⋅⋅⋅⋅⋅ Insert the end detection pin at the table No. of the last

measurement specimen.

• To end measurement at the table No. set last at the analytical instrument side; fix the end

detection pin to the end pin fixing part of the table plate.

(b) Continuous measurement from start to end

Operation Procedure

Operation Screen example

① Display the Measurement Waiting screen. ⋅⋅⋅ Confirm

that the Measurement Waiting screen is displayed in the

product main body screen.

• If another screen is displayed, switch to the Measurement

Waiting screen by switch operation.

Measurement Waiting screen

② Start measurement. ⋅⋅⋅ Press the start key of the

connected analytical instrument.

• The display changes to “REMOTE” and the Measuring

screen is displayed. The continuous measurement begins

based on the analytical instrument side operations.

• During continuous measurement, the sequence operation

currently being performed is displayed.

• During continuous measurement, product main body key

operations other than stirring speed adjustment during

stirring are ineffective.

③ Effective operations during measurement ⋅⋅⋅ The

following operations can be performed during continuous

measurement:

• When the

operation, the stirring speed can be adjusted.

• Continuous measurement can be stopped. >> ④ (3)

④ Measurement end ⋅⋅⋅ Continuous measurement ends in

any of the cases (1) to (3) below.

(1) When measurement of table No. with end detection pin

inserted is ended

(2) When measurement of the end specimen No. set at the

analytical instrument is ended

(3) When the stop key of the analytical instrument side is

pressed

• When continuous measurement ends, the electrode arm

moves to the washing reservoir and after the electrode

washing operation is performed, the electrode arm moves to

the electrode storage beaker and operation ends.

• The display returns to the Measurement Waiting screen.

or key is pressed during stirring

Measuring screen

(arm moving)

Measuring screen

(stirring operating)

-

50 -

Page 52

Model: TTT-710 5.2 Basic Operation

(2) Use by connecting R Series analytical instruments (OPTION2)

When this product is used by connecting it to R Series analytical instruments (HM-30R, CM-30M,

MM-60R) by “OPTION2” connection, setup, measurement start/stop, and other operations are

performed based on the product side operations.

(a) Measurement preparations

① Set the power switch to ON.⋅⋅⋅⋅⋅⋅ >> 5.2(1)(a) “Measurement preparations” ①

② Set the measurement conditions. ⋅⋅⋅⋅⋅⋅ Set the measurement conditions in accordance with the

following items:

ⓐ Set the number of table specimens. ⋅⋅⋅⋅⋅⋅ >> 6.2 “Various Conditions Setting” (1)“Number of

table specimens setting”

ⓑ Set the electrode washing conditions. ⋅⋅⋅⋅⋅⋅ >> 6.2 “Various Conditions Setting” (7)

“Electrode washing conditions setting”

ⓒ Set the sample measurement conditions. ⋅⋅⋅⋅⋅⋅ >> 6.2 “Various Conditions Setting” (2)

“Measurement conditions setting”

(Sample measurement conditions: Measurement start/stop table No., stirring time, waiting time

before measurement, number of repetitive measurements, and end buzzer time)

ⓓ Set the analytical instrument side conditions. ⋅⋅⋅⋅⋅⋅ Set the connection mode to “OPTION2” and

turntable measurement to “ON”. >> Instruction manual of analytical instrument to be used

③ Set the measurement specimens. ⋅⋅⋅⋅⋅⋅ >> 5.2(1)(a) “Measurement preparations” ③

④ Prepare the end detection pin.⋅⋅⋅⋅⋅⋅ Insert the end detection pin at the table No. of the last

measurement specimen.

• When the end detection pin is not used, fix it to the end pin holder of the table plate. (Continuous

measurement is performed up to the end table No. set at this product.)

(b) Continuous measurement from start to end

Operation Procedure

Operation Screen example

① Display the Measurement Waiting screen. ⋅⋅⋅ Confirm

that the Measurement Waiting screen is displayed in the

product main body screen.

• If another screen is displayed, switch to the Measurement

Waiting screen by key operation.

Measurement Waiting screen

(To be continued)

-

51 -

Page 53

Model: TTT-710 5.2 Basic Operation

(Continued from previous page)

Operation Screen example

② Start measurement. ⋅⋅⋅ Press the start key of the

connected analytical instrument and then press

START/STOP of the product main body.

• The display remains “AUTO” and the Measuring screen is

displayed. Continuous measurement by the product main

body starts.

• During continuous measurement, the sequence operation

currently being performed is displayed.

• During continuous measurement, product main body key

operations other than START/STOP and stirring speed

adjustment during stirring are ineffective.

③ Effective operations during measurement ⋅⋅⋅ The

following operations can be performed during continuous

measurement:

• When the

operation, the stirring speed can be adjusted.

• Continuous measurement can be stopped. >> ④ (3)

or key is pressed during stirring

Measuring screen

(arm moving)

Measuring screen

(stirring operating)

④ Measurement end ⋅⋅⋅ Continuous measurement ends in

any of the cases (1) to (3) below and Measurement Cancel

screen is displayed.

(1) When measurement of table No. with end detection pin

inserted is ended

(2) When measurement of the end table No. set at the

product is ended

(3) When START/STOP of the product main body is

pressed

• When continuous measurement ends, the electrode arm

moves to the washing reservoir and after the electrode

washing operation is performed, the electrode arm moves to

the electrode storage beaker and operation ends.

• The display returns to the Measurement Waiting screen.

Measurement Cancel screen

“END” is blinking

during end

processing.

(3) Use by connecting acidity titrator (TA-70), salt titrator (TS-70), or

potentiometric titrator (TP-70)

When using this product by connecting it to an acidity titrator (TA-70), salt titrator (TS-70), or

potentiometric titrator (TP-70), setup, measurement start/stop, and other operations are performed

based on the product side operations.

(a) Measurement preparations

① Set the power switch to ON.⋅⋅⋅⋅⋅⋅ Turn on the power switches in the following order:

ⓐ Turn on the analytical instruments. ⋅⋅⋅⋅⋅⋅ Set the power switch of the analytical instruments, etc.

used to ON.

ⓑ Turn on this product. ⋅⋅⋅⋅⋅⋅ Set the power switch on the left-hand side of the product main body

to ON.

-

52 -

Page 54

Model: TTT-710 5.2 Basic Operation

• After the Opening screen is displayed for 1 second and initial operations of electrode arm and

table plate rotation are performed, the Measurement Waiting screen is displayed.

Opening screen Measurement Waiting screen

② Set the measurement conditions. ⋅⋅⋅⋅⋅⋅ Set the measurement conditions in accordance with the

following items:

ⓐ Set the number of table specimens. ⋅⋅⋅⋅⋅⋅ >> 6.2 “Various Conditions Setting” (1)“Number of

table specimens setting”

ⓑ Set the electrode washing conditions. ⋅⋅⋅⋅⋅⋅ >> 6.2 “Various Conditions Setting” (7)

“Electrode washing conditions setting”

ⓒ Set the sample measurement conditions. ⋅⋅⋅⋅⋅⋅ >> 6.2 “Various Conditions Setting” (2)

“Measurement conditions setting”

(Sample measurement conditions: Measurement start/stop table No., stirring time, waiting time

before measurement, number of repetitive measurements, and end buzzer time)

ⓓ Set the RS-232C communication conditions. ⋅⋅⋅⋅⋅⋅ >> 6.2 “Various Conditions Setting” (3)

“RS-232C communication condition setting”

③ Set the measurement specimens. ⋅⋅⋅⋅⋅⋅ >> 5.2(1)(a) “Measurement preparations” ③

④ Prepare the end detection pin. ⋅⋅⋅⋅⋅⋅ >> 5.2(2)(a) “Measurement preparations” ④

(b) Continuous measurement from start to end

Operation Procedure

Operation Screen example

① Display the Measurement Waiting screen. ⋅⋅⋅ Confirm

that the Measurement Waiting screen is displayed in the

product main body screen.

• If another screen is displayed, switch to the Measurement

Waiting screen by key operation.

② Start measurement. ⋅⋅⋅ Press START/STOP of the

product main body.

• The display remains “AUTO” and the Measuring screen is

displayed. Continuous measurement by the product main

body starts.

• During continuous measurement, the sequence operation

currently being performed is displayed.

• During continuous measurement, product main body key

operations other than START/STOP and stirring speed

adjustment during stirring are ineffective.

Measurement Waiting screen

Measuring screen

(arm moving)

-

53 -

(To be continued)

Page 55

Model: TTT-710 5.2 Basic Operation

(Continued from previous page)

Operation Screen example

③ Effective operations during measurement ⋅⋅⋅ The

following operations can be performed during continuous

measurement:

• When the

operation, the stirring speed can be adjusted.

• Continuous measurement can be stopped. >> ④ (3)

or key is pressed during stirring

Measuring screen

(stirring operating)

④ Measurement end ⋅⋅⋅ Continuous measurement ends in

any of the cases (1) to (3) below and Measurement Cancel

screen is displayed.

(1) When measurement of table No. with end detection pin

inserted is ended

(2) When measurement of the set end table No. is ended

(3) When START/STOP of the product main body is

pressed

• When continuous measurement ends, the electrode arm

moves to the washing reservoir and after the electrode

washing operation is performed, the electrode arm moves to

the electrode storage beaker and operation ends.

• The display returns to the Measurement Waiting screen.

Measurement Cancel screen

“END” is blinking

during end

processing.

(4) Use by connecting automatic burette (ABT-511)

When using this product by connecting it to an automatic burette (ABT-511), setup, measurement

start/stop, and other operations are performed based on the product side operations.

(a) Measurement preparations

① Set the power switch to ON. ⋅⋅⋅⋅⋅⋅ >> 5.2(1)(a) “Measurement preparations” ①

• Always turn on the power switches in order of automatic burette, product main body.

② Set the measurement conditions. ⋅⋅⋅⋅⋅ ⋅Set the measurement conditions in accordance with the

following items:

ⓐ Set the number of table specimens. ⋅⋅⋅⋅⋅⋅ >> 6.2 “Various Conditions Setting” (1)“Number of

table specimens setting”

ⓑ Set the electrode washing conditions. ⋅⋅⋅⋅⋅⋅ >> 6.2 “Various Conditions Setting” (7)

“Electrode washing conditions setting”

ⓒ Set the sample measurement conditions. ⋅⋅⋅⋅⋅⋅ >> 6.2 “Various Conditions Setting” (2)

“Measurement conditions setting”

(Sample measurement conditions: Measurement start/stop table No., stirring time, waiting time

before measurement, number of repetitive measurements, and end buzzer time)

③ Set the measurement specimens. ⋅⋅⋅⋅⋅⋅ >> 5.2(1)(a) “Measurement preparations” ③

④ Prepare the end detection pin. ⋅⋅⋅⋅⋅⋅ >> 5.2(2)(a) “Measurement preparations” ④

-

54 -

Page 56

Model: TTT-710 5.2 Basic Operation

(b) Continuous measurement from start to end

Operation Procedure

Operation Screen example

① Display the Measurement Waiting screen. ⋅⋅⋅ Confirm

that the Measurement Waiting screen is displayed in the

product main body screen.

• If another screen is displayed, switch to the Measurement

Waiting screen by key operation.

② Start measurement. ⋅⋅⋅ Press START/STOP of the

product main body.

• The display remains “AUTO” and the Measuring screen is

displayed. Continuous measurement by the product main

body starts.

• During continuous measurement, the sequence operation

currently being performed is displayed.

• During continuous measurement, product main body key

operations other than START/STOP and stirring speed

adjustment during stirring are ineffective.

Measurement Waiting screen

Measuring screen

(arm moving)

③ Effective operations during measurement ⋅⋅⋅ The

following operations can be performed during continuous

measurement:

• When the

operation, the stirring speed can be adjusted.

• Continuous measurement can be stopped. >> ④ (3)