Tmi S-CFD Installation Manual

READ THIS FIRST

Carefully examine the crate(s) for damage before opening. If the carton is damaged, immediately

notify shipping company. If the unit(s) were shipped on wooden skids, remove protective wood

and banding straps securing the carton(s) to the skid. Open the carton(s) and remove all protective

packaging. Immediately verify that the electrical rating nameplate located on the cover matches

electrical power supply available. Retain the shipping carton(s) until the unit(s) is installed and

properly operating. TMI, LLC is not responsible for delayed or late claims.

Read and Save These Instructions

AIR CURTAINS

INSTALLATION INSTRUCTIONS

S-CFD, S-IBD, S-LI, S-MI, S-HD SERIES

TMI, LLC

Managing Environments™

Serial No: ________________ Model #: _______________ Date Purchased: ___________

Warning

To Reduce the Risk of Fire, Electrical Shock, or Injury, Observe the Following:

• Use this unit only in the manner intended by the manufacturer. If you have any questions, contact the manufacturer.

• Before servicing or cleaning unit, switch power off at the service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag, to the service panel.

• Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction. Units must be field wired in accordance with all local National

1

Electric Codes, including wire size and materials. Units can accept

or either side of unit. Wires from conduit are to be run to junction box inside of unit.

• Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning

equipment to prevent back drafting. Follow the heating equipment manufacturer’s guideline and safety standards

such as those published by the National Fire Protection Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and local code authorities.

• When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities. Do not operate

this fan with any solid state speed control device.

/2” conduit by punching out the knockouts on top

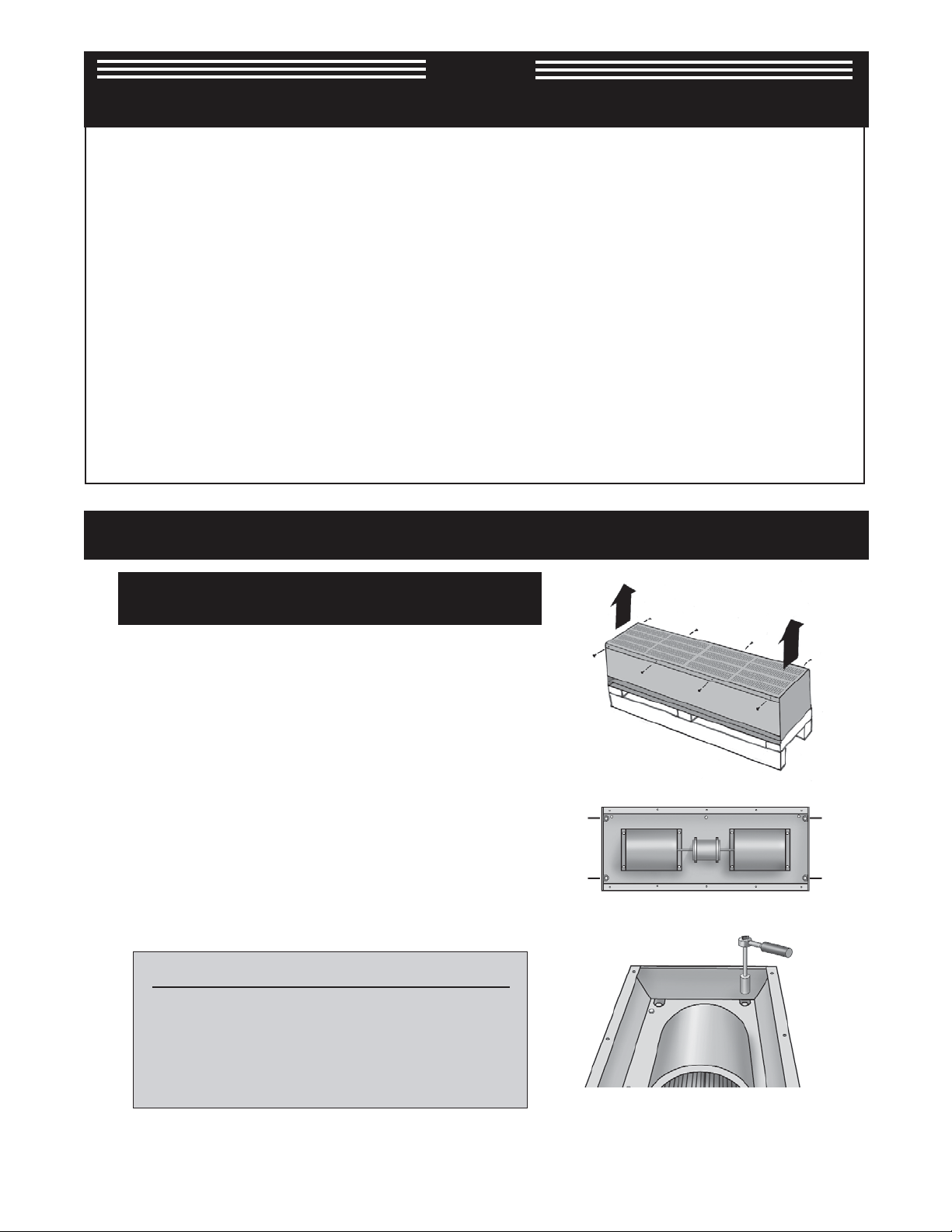

Uncrating and Unpacking

Please read the “READ THIS FIRST” note on the

front cover of this manual before proceeding.

Carefully remove as much of the crate as possible so the inlet screws

are exposed. Use a Phillips head screwdriver to remove the screws that

hold the intake screen in place. Remove the screen and applicable filter(s). Place the screws in a safe place. (See Fig. 1)

Use a 3/8” socket and extension to remove four lag bolts that hold

the unit to the skid. The air curtain is now ready for installation. The

air curtain can be lifted by the blower housing inlets. Use caution.

Do not grasp the unit by the blower wheels. They will bend, pulling

the unit out of balance and alignment. (See Fig. 1 & Fig. 2)

The air curtain is now ready for installation.

IMPORTANT NOTE

Fig. 01

1

2

3

4

Fig. 2

If the air curtain(s) was ordered with optional electrical

components and accessories (door switch, control panels,

mounting brackets, etc), the accessories may be found in

the crate containing the air curtain or in an additional crate

or box. Check all of the crates and boxes before disposing

2

Fig. 3

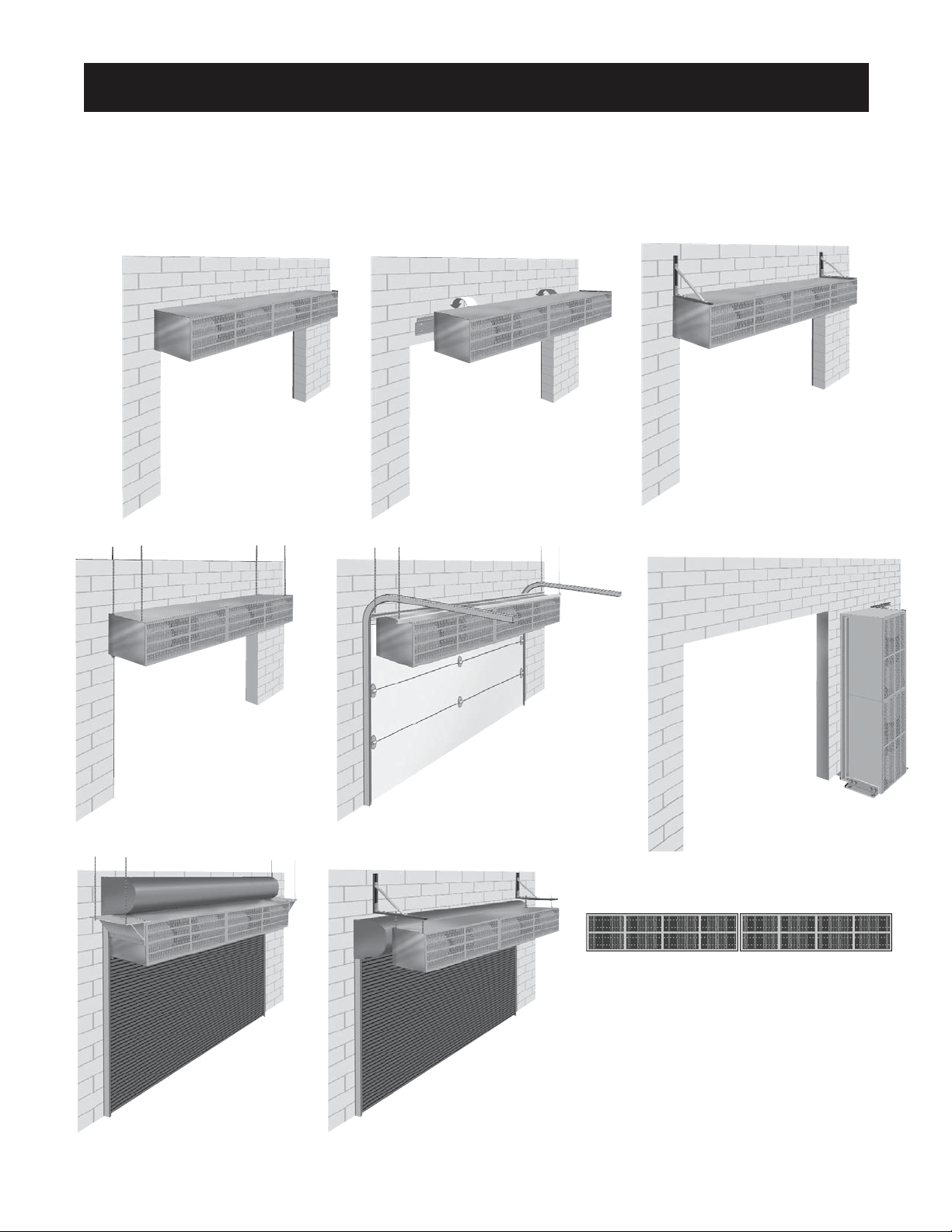

Mounting Methods

How your Air Curtain is mounted depends on your doorway opening and what equipment or obstructions are in the way.

Below are the standard methods of mounting. All mounting methods will require additional hardware. to complete the

mounting operation. Lag screws, hex bolts, washers, nuts and threaded rods can be supplied by others, but wall brackets, extension bars and extension plates will have to be ordered from TMI, LLC. Check with a sales representative at 1800-888-9750

Wall

Standard Wall

Mount

Mounting Plate

Mounting

Brackets

Ceiling Mount

with

Threaded Rods

Extension

Plates with

Threaded Rods

Extension Bars

with

Threaded Rods

Wall Mounting

Brackets with

Threaded Rods

Vertical

Mounting

for

Low Ceilings

or

No Space

Above Header

Tandem Mounting

If your installation requires tandem mounting,

there should be no space between units. Wall

mounting brackets cannot be used. Also keep in

mind that the wiring must go from the master unit

to the slave unit by using jumper wires.

3

Mounting Notes

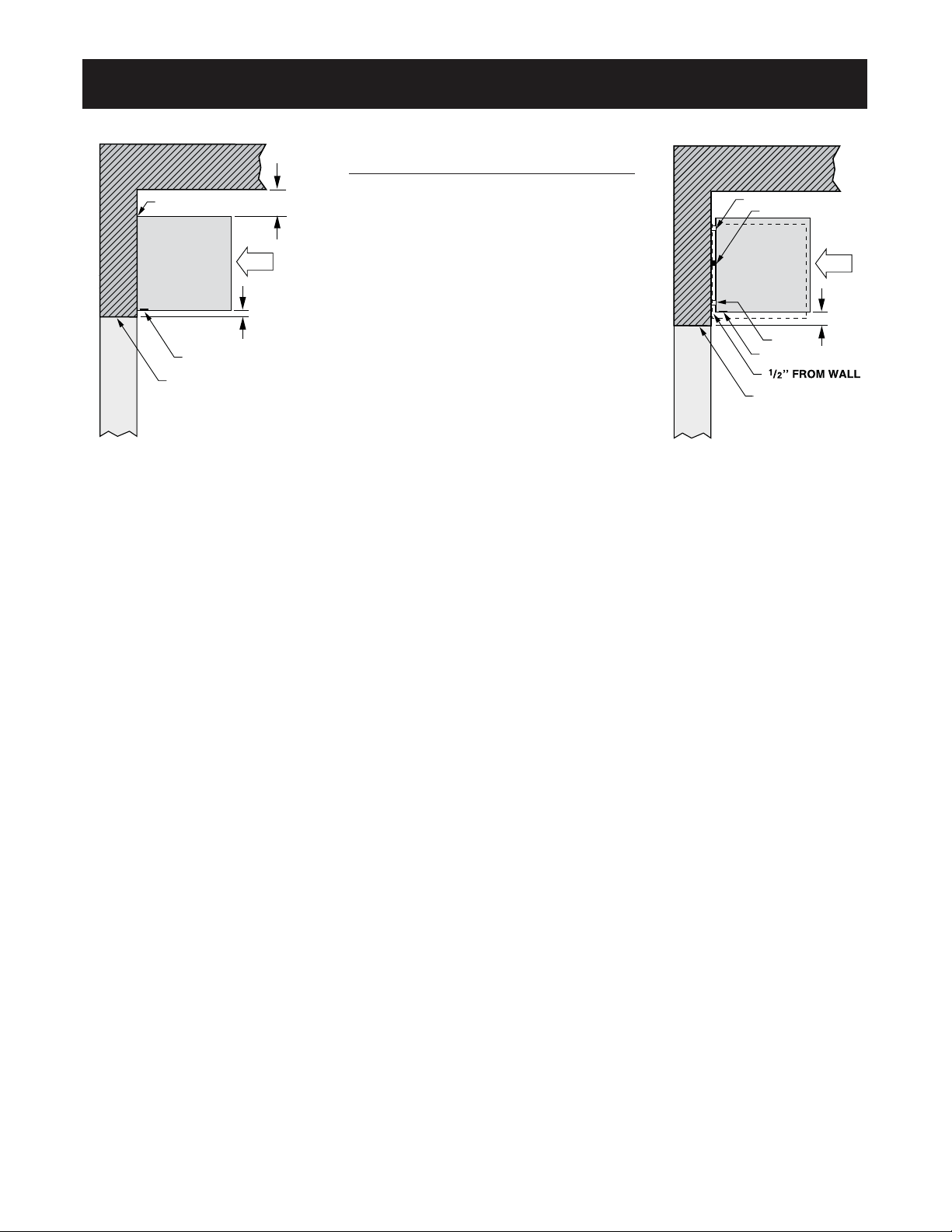

IMPORTANT

FLUSH MOUNT

4’’

Minimum

Space

Required

A minimum of 4'' (8'' preferred) is recommended

above the top of the air curtain for the installation

SPACER

SEAL

and removal of the screen or to gain access to

AIR

CURTAIN

AIR

INTAKE

junction boxes.

AIR

CURTAIN

AIR

INTAKE

For optimal performance, the bottom of the unit

1’’

OUTLET NOZZLE

TOP OF DOORWAY

Fig. 4

Maximum

(discharge nozzle) should be no more than 1''

above the top of the door opening with the unit

mounted flush to the wall. (See Fig. 4)

If the unit must be mounted higher, it must be

spaced out from the wall 1/2'' for every inch the

unit is above the door opening. Also a seal must

be placed between the entire length of the unit

2’’

SPACER

OUTLET NOZZLE

TOP OF DOORWAY

Fig. 5

and the wall. (See Fig. 5)

1. Units may be attached to the wall directly, suspended from overhead, or supported by brackets. The style of door will

determine the best mounting method and as a general rule, use the mounting configuration that positions the air curtain

as close to the top of the doorway as possible without interfering with door operation.

2. To achieve optimal protection, the unit should be mounted on the inside of the building, flush to the wall and as close to

the top of the door opening as possible. NOTE: An S-IBD unit can be mounted on the outside of the doorway opening. If

the unit is exposed to the weather, a drip plate should be placed on the motor(s) to protect it from the elements.

3. To ensure peak performance, keep the air stream free of obstructions. Make sure that nothing interferes with the curtain

of air. If the air curtain cannot be installed flush with the wall, be sure to seal the gap between the wall and the back of

the air curtain along the entire length of the unit to prevent airflow through this void. (See Fig. 5). The discharge vane is

directed from 0° to 20° toward the door opening. If the air stream strikes any obstruction (the top edge of the doorway,

a door opening device, etc.), the effectiveness of the unit will be greatly reduced.

4. The air curtain will not perform properly if negative air pressure exists in the building. Under these conditions, a means

for makeup air to the building must be provided so that the air pressure on both sides of the opening is in balance.

5. Before mounting the air curtain, check the supporting structure to verify that it has sufficient load-carrying capacity to

support the weight of the unit(s). The mounting hardware (may be supplied by others) should be capable of supporting

a minimum of three (3) times the weight of the unit.

4

Standard Wall Mounting

1. Remove the screws that hold the intake screen in place. Remove the screen

and applicable filter(s). The rear side of the air curtain has four mounting

holes that can accept four 3/8” mounting bolts or lag screws with washers.

(See Fig. 6)

2. Place the Air Curtain into position. Using a pencil, mark the 4 mounting

holes. (See Fig. 7) Remove the unit. If using lag screws, pre-drill the

mounting holes. If using mounting anchors, drill the holes and place the

anchors.

3. Again place the Air Curtain into position. Using a ratchet and socket with a

long extension, screw the unit to the wall. (See Fig. 8) The socket exten-

Fig. 6

1

3

sion should allow you to install the unit without having to remove the

motor/blower plate.

NOTE: Mounting bolts or lag screws of sufficient size and strength should be

installed and tightened through the four 7/8” holes in motor/blower

plate.

4. Replace intake grill.

2

4

Fig. 7

If motor/blower plate has to be removed, the junction box inside

the unit must be removed, along with any electrical switches that

might be in the way. The electrical switches have a lever that slides

in one direction to release the switch contacts from the switch

body. All wires will stay intact, making replacing the blower plate

7

/16'' whiz lock nuts holding plate in place and slide

Fig. 8

easy. Remove

the plate out. Rotate the top portion of plate so it comes out first.

Remember when installing the plate to put the bottom of the plate

in first and push and rotate the top of the plate in last.

The unit is now ready to be wired. See page 14. It must be field wired

in accordance with all applicable local, state, provincial, and national

laws, including wire size and materials.

5

Loading...

Loading...